WO2016042379A1 - Compositions for the delivery of agrochemicals to the roots of a plant - Google Patents

Compositions for the delivery of agrochemicals to the roots of a plant Download PDFInfo

- Publication number

- WO2016042379A1 WO2016042379A1 PCT/IB2015/001591 IB2015001591W WO2016042379A1 WO 2016042379 A1 WO2016042379 A1 WO 2016042379A1 IB 2015001591 W IB2015001591 W IB 2015001591W WO 2016042379 A1 WO2016042379 A1 WO 2016042379A1

- Authority

- WO

- WIPO (PCT)

- Prior art keywords

- unit

- zones

- root development

- agrochemical

- pesticide

- Prior art date

Links

Classifications

-

- A—HUMAN NECESSITIES

- A01—AGRICULTURE; FORESTRY; ANIMAL HUSBANDRY; HUNTING; TRAPPING; FISHING

- A01N—PRESERVATION OF BODIES OF HUMANS OR ANIMALS OR PLANTS OR PARTS THEREOF; BIOCIDES, e.g. AS DISINFECTANTS, AS PESTICIDES OR AS HERBICIDES; PEST REPELLANTS OR ATTRACTANTS; PLANT GROWTH REGULATORS

- A01N25/00—Biocides, pest repellants or attractants, or plant growth regulators, characterised by their forms, or by their non-active ingredients or by their methods of application, e.g. seed treatment or sequential application; Substances for reducing the noxious effect of the active ingredients to organisms other than pests

-

- A—HUMAN NECESSITIES

- A01—AGRICULTURE; FORESTRY; ANIMAL HUSBANDRY; HUNTING; TRAPPING; FISHING

- A01G—HORTICULTURE; CULTIVATION OF VEGETABLES, FLOWERS, RICE, FRUIT, VINES, HOPS OR SEAWEED; FORESTRY; WATERING

- A01G29/00—Root feeders; Injecting fertilisers into the roots

-

- A—HUMAN NECESSITIES

- A01—AGRICULTURE; FORESTRY; ANIMAL HUSBANDRY; HUNTING; TRAPPING; FISHING

- A01N—PRESERVATION OF BODIES OF HUMANS OR ANIMALS OR PLANTS OR PARTS THEREOF; BIOCIDES, e.g. AS DISINFECTANTS, AS PESTICIDES OR AS HERBICIDES; PEST REPELLANTS OR ATTRACTANTS; PLANT GROWTH REGULATORS

- A01N37/00—Biocides, pest repellants or attractants, or plant growth regulators containing organic compounds containing a carbon atom having three bonds to hetero atoms with at the most two bonds to halogen, e.g. carboxylic acids

- A01N37/18—Biocides, pest repellants or attractants, or plant growth regulators containing organic compounds containing a carbon atom having three bonds to hetero atoms with at the most two bonds to halogen, e.g. carboxylic acids containing the group —CO—N<, e.g. carboxylic acid amides or imides; Thio analogues thereof

- A01N37/22—Biocides, pest repellants or attractants, or plant growth regulators containing organic compounds containing a carbon atom having three bonds to hetero atoms with at the most two bonds to halogen, e.g. carboxylic acids containing the group —CO—N<, e.g. carboxylic acid amides or imides; Thio analogues thereof the nitrogen atom being directly attached to an aromatic ring system, e.g. anilides

- A01N37/24—Biocides, pest repellants or attractants, or plant growth regulators containing organic compounds containing a carbon atom having three bonds to hetero atoms with at the most two bonds to halogen, e.g. carboxylic acids containing the group —CO—N<, e.g. carboxylic acid amides or imides; Thio analogues thereof the nitrogen atom being directly attached to an aromatic ring system, e.g. anilides containing at least one oxygen or sulfur atom being directly attached to the same aromatic ring system

-

- A—HUMAN NECESSITIES

- A01—AGRICULTURE; FORESTRY; ANIMAL HUSBANDRY; HUNTING; TRAPPING; FISHING

- A01N—PRESERVATION OF BODIES OF HUMANS OR ANIMALS OR PLANTS OR PARTS THEREOF; BIOCIDES, e.g. AS DISINFECTANTS, AS PESTICIDES OR AS HERBICIDES; PEST REPELLANTS OR ATTRACTANTS; PLANT GROWTH REGULATORS

- A01N43/00—Biocides, pest repellants or attractants, or plant growth regulators containing heterocyclic compounds

- A01N43/48—Biocides, pest repellants or attractants, or plant growth regulators containing heterocyclic compounds having rings with two nitrogen atoms as the only ring hetero atoms

- A01N43/54—1,3-Diazines; Hydrogenated 1,3-diazines

-

- A—HUMAN NECESSITIES

- A01—AGRICULTURE; FORESTRY; ANIMAL HUSBANDRY; HUNTING; TRAPPING; FISHING

- A01N—PRESERVATION OF BODIES OF HUMANS OR ANIMALS OR PLANTS OR PARTS THEREOF; BIOCIDES, e.g. AS DISINFECTANTS, AS PESTICIDES OR AS HERBICIDES; PEST REPELLANTS OR ATTRACTANTS; PLANT GROWTH REGULATORS

- A01N43/00—Biocides, pest repellants or attractants, or plant growth regulators containing heterocyclic compounds

- A01N43/72—Biocides, pest repellants or attractants, or plant growth regulators containing heterocyclic compounds having rings with nitrogen atoms and oxygen or sulfur atoms as ring hetero atoms

- A01N43/74—Biocides, pest repellants or attractants, or plant growth regulators containing heterocyclic compounds having rings with nitrogen atoms and oxygen or sulfur atoms as ring hetero atoms five-membered rings with one nitrogen atom and either one oxygen atom or one sulfur atom in positions 1,3

- A01N43/78—1,3-Thiazoles; Hydrogenated 1,3-thiazoles

-

- A—HUMAN NECESSITIES

- A01—AGRICULTURE; FORESTRY; ANIMAL HUSBANDRY; HUNTING; TRAPPING; FISHING

- A01N—PRESERVATION OF BODIES OF HUMANS OR ANIMALS OR PLANTS OR PARTS THEREOF; BIOCIDES, e.g. AS DISINFECTANTS, AS PESTICIDES OR AS HERBICIDES; PEST REPELLANTS OR ATTRACTANTS; PLANT GROWTH REGULATORS

- A01N47/00—Biocides, pest repellants or attractants, or plant growth regulators containing organic compounds containing a carbon atom not being member of a ring and having no bond to a carbon or hydrogen atom, e.g. derivatives of carbonic acid

- A01N47/08—Biocides, pest repellants or attractants, or plant growth regulators containing organic compounds containing a carbon atom not being member of a ring and having no bond to a carbon or hydrogen atom, e.g. derivatives of carbonic acid the carbon atom having one or more single bonds to nitrogen atoms

- A01N47/10—Carbamic acid derivatives, i.e. containing the group —O—CO—N<; Thio analogues thereof

- A01N47/12—Carbamic acid derivatives, i.e. containing the group —O—CO—N<; Thio analogues thereof containing a —O—CO—N< group, or a thio analogue thereof, neither directly attached to a ring nor the nitrogen atom being a member of a heterocyclic ring

-

- A—HUMAN NECESSITIES

- A01—AGRICULTURE; FORESTRY; ANIMAL HUSBANDRY; HUNTING; TRAPPING; FISHING

- A01N—PRESERVATION OF BODIES OF HUMANS OR ANIMALS OR PLANTS OR PARTS THEREOF; BIOCIDES, e.g. AS DISINFECTANTS, AS PESTICIDES OR AS HERBICIDES; PEST REPELLANTS OR ATTRACTANTS; PLANT GROWTH REGULATORS

- A01N51/00—Biocides, pest repellants or attractants, or plant growth regulators containing organic compounds having the sequences of atoms O—N—S, X—O—S, N—N—S, O—N—N or O-halogen, regardless of the number of bonds each atom has and with no atom of these sequences forming part of a heterocyclic ring

-

- C—CHEMISTRY; METALLURGY

- C05—FERTILISERS; MANUFACTURE THEREOF

- C05G—MIXTURES OF FERTILISERS COVERED INDIVIDUALLY BY DIFFERENT SUBCLASSES OF CLASS C05; MIXTURES OF ONE OR MORE FERTILISERS WITH MATERIALS NOT HAVING A SPECIFIC FERTILISING ACTIVITY, e.g. PESTICIDES, SOIL-CONDITIONERS, WETTING AGENTS; FERTILISERS CHARACTERISED BY THEIR FORM

- C05G3/00—Mixtures of one or more fertilisers with additives not having a specially fertilising activity

- C05G3/60—Biocides or preservatives, e.g. disinfectants, pesticides or herbicides; Pest repellants or attractants

-

- A—HUMAN NECESSITIES

- A01—AGRICULTURE; FORESTRY; ANIMAL HUSBANDRY; HUNTING; TRAPPING; FISHING

- A01G—HORTICULTURE; CULTIVATION OF VEGETABLES, FLOWERS, RICE, FRUIT, VINES, HOPS OR SEAWEED; FORESTRY; WATERING

- A01G24/00—Growth substrates; Culture media; Apparatus or methods therefor

- A01G24/30—Growth substrates; Culture media; Apparatus or methods therefor based on or containing synthetic organic compounds

- A01G24/35—Growth substrates; Culture media; Apparatus or methods therefor based on or containing synthetic organic compounds containing water-absorbing polymers

-

- Y—GENERAL TAGGING OF NEW TECHNOLOGICAL DEVELOPMENTS; GENERAL TAGGING OF CROSS-SECTIONAL TECHNOLOGIES SPANNING OVER SEVERAL SECTIONS OF THE IPC; TECHNICAL SUBJECTS COVERED BY FORMER USPC CROSS-REFERENCE ART COLLECTIONS [XRACs] AND DIGESTS

- Y02—TECHNOLOGIES OR APPLICATIONS FOR MITIGATION OR ADAPTATION AGAINST CLIMATE CHANGE

- Y02P—CLIMATE CHANGE MITIGATION TECHNOLOGIES IN THE PRODUCTION OR PROCESSING OF GOODS

- Y02P60/00—Technologies relating to agriculture, livestock or agroalimentary industries

- Y02P60/20—Reduction of greenhouse gas [GHG] emissions in agriculture, e.g. CO2

- Y02P60/21—Dinitrogen oxide [N2O], e.g. using aquaponics, hydroponics or efficiency measures

Definitions

- Plant protection products e.g. pesticides

- Plant protection products are commonly applied using methods which include foliar spraying, soil drenching, above ground distribution (granular products), and soil spraying (mainly herbicides).

- the choice of application method is subject to the crop type and phenology, prevailing climatic conditions, target pest or weed species and its phenology, and soil type.

- These application methods can be suboptimal because not all of the PPPs applied reach the actual target because of drift, run off, leaching, degradation and breakdown. For example, efficiency can be decreased due to variable environmental conditions (e.g., rainfall, heat waves), and photo chemical degradation following foliar spraying.

- Unknown spatial distribution of the targeted roots relevant to drenching and above ground application

- the invention provides a unit for delivery of agrochemicals to the roots of a plant comprising: one or more root development zones; optionally, one or more agrochemical zones; and a pesticide; wherein the agrochemical zones are formulated to release at least one agrochemical into the root development zones in a controlled release manner when the root development zones are swelled; and wherein the dry weight ratio of the root development zones to the agrochemical zones in a dry unit is 0.05: 1 to 20: 1, or wherein the total volume of the root development zones in the unit is at least 0.2 mL when the unit is fully swelled.

- the invention provides a unit for delivery of agrochemicals to the roots of a plant comprising:

- agrochemical zones are formulated to release the fertilizer into the root development zones in a controlled release manner when the root development zones are swelled

- the total amount of pesticide in the dry unit is 0.0004% to 0.5% of the total weight of the unit, wherein the weight ratio of pesticide to fertilizer in the unit is 5 x 10-6: 1 to 6 x 10-3: 1, or wherein the total amount of pesticide in the unit is less than 50 mg, and

- the invention provides a unit for delivery of agrochemicals to the roots of a plant comprising:

- agrochemical zones are formulated to release the at least one agrochemical into the root development zones in a controlled release manner when the root development zones are swelled

- the invention provides a method of growing a plant, comprising adding at least one unit of the invention to the medium in which the plant is grown.

- the invention provides a method of reducing environmental damage caused by a fertilizer, a pesticide, or a fertilizer and a pesticide, comprising delivering the fertilizer and the pesticide to the root of a plant by adding at least one unit of the invention to the medium of the plant.

- the invention provides a method of reducing environmental damage caused by agrochemicals, comprising delivering the agrochemicals to the root of a plant by adding at least one unit of the invention to the medium of the plant.

- the invention provides a method of minimizing exposure to a fertilizer, a pesticide, or a fertilizer and a pesticide, comprising delivering the fertilizer and the pesticide to the root of a plant by adding at least one unit of the invention to the medium of the plant.

- the invention provides a method of generating an artificial zone with predetermined chemical properties within the root zone of a plant, comprising:

- the invention provides a method of fertilizing a plant comprising adding at least one unit of the invention to the medium in which the plant is grown.

- the invention provides a method of protecting a plant from a pest comprising adding at least one unit of the invention to the medium in which the plant is grown.

- FIG. 1A-G (A) Pea roots growth in CMC - Lab. (B) Corn roots growth in Alginate - Lab. (C) Pea root growth in k-Carrageenan - Lab. (D) Pea root growth on CMC - Lab. (E) Corn root grown in Fully synthetic - Lab. (F) Corn root grown in Fully synthetic - Lab. (G) Corn roots growth in Alginate - Lab. Figure 2.

- Phase 1 Banding and incorporating dry "beads", made from an external zone (hydrogel) and internal zone (coated minerals) into the upper soil profile.

- Phase 2 Following watering, the beads swell (up to, e.g., 5 cm in diameter) and agrochemicals diffuse to the external zone & soil.

- Phase 3 Roots grow and are sustained in/near the external zone, and uptake lasts a few weeks (6-8).

- FIG. 1 Soil temperatures at the experimental site of Example 3. Top line shows maximum soil temperatures and bottom line shows minimum soil temperatures.

- Figure 10 Minimal distance of the hydrogel units of Example 3 versus time.

- Figure 11. Final stiffness values of the hydrogel units of Example 3.

- Figure 12. Stiffness of the hydrogel units of Example 3 versus time.

- Figure 13A-I Photos of the hydrogels of Example 3 from plots A-C at the end of the experiment.

- Figure 13A fully synthetic;

- Figure 13B Semisynthetic CMC 6% A Am;

- Figure 13C Semisynthetic CMC 6%AA;

- Figure 13D Semisynthetic CMC 25%AA;

- Figure 13E Semisynthetic CMC 50% AA;

- Figure 13F Polysugars Alginate;

- Figure 13G Semisynthetic CMC 6% AAm-Large;

- Figure 13H Semisynthetic CMC

- Figure 14A-H Photos of the hydrogels of Example 3 from plot D at the end of the experiment.

- Left panels of Figures 14A-G show hydrogels in situ.

- Right panels of Figures 14A-G show samples where roots penetrated through the hydrogel.

- Figure 14A fully synthetic;

- Figure 14B Semisynthetic CMC 6% AAm;

- Figure 14C Semisynthetic CMC 6%AA;

- Figure 14D Semisynthetic CMC 25%AA;

- Figure 14E Semisynthetic CMC 50% AA;

- Figure 14F Semisynthetic CMC 6% AAm-Large;

- Figure 14G Semisynthetic CMC 50% AAm-Large;

- Figure 14H Semisynthetic CMC 25% AA.

- Figure 16 A fully swelled fertilizer unit made according to the process of Example 4 compared to a dried fertilizer unit made according to the process of Example 4.

- Figure 17 Example of the visual notation scale of fertilizer/insecticide unit colonization by roots in Example 5.

- Figure 17A Notation 0, No roots;

- Figure 17B notation 0.5, Weak colonization;

- Figure 17C Notation 1: colonization;

- Figure 17D Notation 2, Important colonization;

- Figure 17E Notation 3, Very Important colonization.

- Figure 18 Efficacies of the different treatments and doses on both adults and larvae 1, 4 and 7 days after infestation (DAI) in Example 5. Values are the mean percentage of efficacy determined from the number of both living adults and larvae of 4 repetitions of 4 to 6 plants. Two conditions with the same letter of the same color are not significantly different from each other in the Newman-Keuls test.

- Figure 19 Disease kinetics following M. majus inoculation in Example 6.

- Figure 20 Transects of six units of variable sizes of Example 7.

- Figure 21 A single root image within the outer casing of hydrogel (x4) (Example 7).

- Figure 22 Number of visible roots for each unit size of Example 7.

- Figure 23 Number of roots per equivalent transect of each size unit of Example 7.

- Figure 24 Total root length within each size unit of Example 7.

- Figure 25 Production stages of the fertilizer units of Example 7.

- Left panel core; middle panel: core covered with cotton fibers; right panel: fertilizer unit following polymerization of the root development zone.

- Figure 26 Root penetration and development for fertilizer units of each ratio of Example 8.

- Figure 26A Root penetration and development after two weeks (ratio 1:5)

- Figure 26B Root penetration and development over time (ratio 1:5)

- Figure 26C Root penetration and development after two weeks (ratio 1:6.7)

- Figure 26D Root penetration and development after two weeks (ratio 1:7.2)

- Figure 26E Root penetration and development after two weeks (ratio 1:8.2)

- Figure 26F Root penetration and development after two weeks (ratio 1: 10).

- Figures 27 A, 27B Pesticide content with variable doses submerged in water over time.

- Figures 28A-28C Crop selectivity.

- Figures 29A-29E Weed development and mortality.

- Figures 30A, 30B Fertilizer application rate.

- Figure 31 Root growth.

- Figure 32 Root growth.

- the invention provides a unit for delivery of agrochemicals to the roots of a plant comprising: one or more root development zones; optionally, one or more agrochemical zones; and a pesticide; wherein the agrochemical zones are formulated to release at least one agrochemical into the root development zones in a controlled release manner when the root development zones are swelled; and wherein the dry weight ratio of the root development zones to the agrochemical zones in a dry unit is 0.05: 1 to 20: 1, or wherein the total volume of the root development zones in the unit is at least 0.2 mL when the unit is fully swelled.

- the unit does not contain an agrochemical zone.

- the unit does not contain a fertilizer.

- the unit contains one or more agrichemical zones wherein the one or more agrochemical zones contains a fertilizer.

- the one or more of the agrochemical zones contains a fertilizer and the weight ratio of the pesticide to the fertilizer is at least or greater than 6 x 10 -3 : 1.

- the total amount of the pesticide in the dry unit is 0.0004% to 20%, 0.01% to 20%, 0.05% to 10%, or 0.1% to 1% of the total weight of the dry unit.

- the weight ratio of the pesticide to the fertilizer is 6 x 10 -3 : 1 to 1: 1, 1 x 10 -2 : 1, or 0.1 : 1 to 1 : 1.

- the unit contains one or more agrichemical zones and wherein the dry weight ratio of the root development zones to the agrochemical zones in a dry unit is 0.05: 1 to 10: 1, 0.1 : 1 to 10: 1, or 0.5: 1 to 5: 1.

- the unit contains one or more agrichemical zones and wherein the dry weight ratio of the root development zones to the agrochemical zones in a dry unit is 0.05: 1 to 10: 1, 0.1 : 1 to 10: 1, or 0.5: 1 to 5: 1.

- the invention provides a unit for delivery of agrochemicals to the roots of a plant comprising:

- the agrochemical zones are formulated to release the fertilizer into the root development zones in a controlled release manner when the root development zones are swelled, wherein the total amount of pesticide in the dry unit is 0.0004% to 0.5% of the total weight of the unit, wherein the weight ratio of pesticide to fertilizer in the unit is 5 x 10-6: 1 to 6 x 10-3: 1 , or wherein the total amount of pesticide in the unit is less than 50 mg, and

- the dry weight ratio of the root development zones to the agrochemical zones in a dry unit is 0.05: 1 to 0.32: 1, or wherein the total volume of the root development zones in the unit is at least 0.2 mL when the unit is fully swelled.

- the total amount of pesticide in the dry unit is 0.0004% to 0.5% of the total weight of the unit.

- the total amount of pesticide in the dry unit is 0.01% to 0.05%, 0.0005% to 0.1%, 0.01% to 0.05%, or 0.01% to 0.3% of the total weight of the unit. In some embodiments, the total amount of pesticide in the dry unit is 0.06% of the total dry weight of the unit.

- the weight ratio of pesticide to fertilizer in the unit is 5 x 10 -6 : 1 to 6 x 10 '3 : 1.

- the weight ratio of pesticide to fertilizer in the unit is 4.6 x 10 -4 : 1.

- the total amount of pesticide in the unit is less than 50 mg. In some embodiments, the total weight of the pesticide in the unit is less than 45 mg, less than 40 mg, less than 35 mg, less than 30 mg, less than 25 mg, less than 20 mg, less than 15 mg, less than 10 mg, less than 5 mg, or less than 1 mg.

- the total weight of the pesticide in the unit is 0.01 to 0.1 mg, 0.1 to 1 mg, 1 mg to 5 mg, 5 mg to 10 mg, 10 mg to 15 mg, 15 mg to 20 mg, 20 mg to 25 mg, 25 mg to 30 mg, 30 mg to 35 mg, 35 mg to 40 mg, 40 mg to 45 mg, or 45 mg to less than 50 mg.

- the total weight of the pesticide in the unit is 0.01 mg, less than 0.1 mg, 0.1 mg, less than 0.5 mg, 0.5 mg, 0.7 mg, 0.75 mg, 1 mg, 1.4 mg, 1.5 mg, 2 mg, 2.8 mg, 3 mg, 4 mg, 5 mg, 6 mg, 7 mg, 8 mg, 9 mg, 10 mg, 15 mg, 20 mg, 25 mg, 30 mg, 35 mg, 40 mg, or 45 mg.

- the pesticide is in one or more agrochemical zones.

- the agrochemical zones containing the pesticide are formulated to release the pesticide into the root development zones in a controlled release manner when the root development zones are swelled.

- the fertilizer and the pesticide are together in one or more agrochemical zones.

- the fertilizer and the pesticide are each in different agrochemical zones.

- the pesticide is dispersed throughout one or more root development zones and outside of an agrochemical zone.

- the pesticide is an insecticide, a fungicide, a nematicide, or an herbicide.

- the pesticide is an insecticide. In some embodiments, the pesticide is a fungicide. In some embodiments, the pesticide is a nematicide. In some embodiments, the pesticide is an herbicide.

- the unit comprises an insecticide which is imidacloprid, dinotefuran, thiacloprid, thiamethoxam, clothianidin, sulfoxaflor, spirotetramat, spiromesafen, spirodiclofen, acephate, or acetamiprid.

- the unit comprises a fungicide which is azoxystrobin, flutriafol, thiophanate methyl, imazalil, prochloraz, tebuconazole, fosetyl-Al, methalaxyl, mefenoxam, triadimenol, or propamocarb.

- a fungicide which is azoxystrobin, flutriafol, thiophanate methyl, imazalil, prochloraz, tebuconazole, fosetyl-Al, methalaxyl, mefenoxam, triadimenol, or propamocarb.

- the unit comprises an herbicide which is atrazine, glyphosate, imazethapyr, imazapic, imazamox, tribenuron, isoxaflutole, bromacyl, carbetamide, clomazone, diclosulam, diuron, florasulam, flufenacet, flumioxazine, fluorocloridone, hexazinone, metamitron, metazachlor, metribuzine, metsulfuron, pendimethalin, sulfentrazone, or trifloxysulfuron.

- an herbicide which is atrazine, glyphosate, imazethapyr, imazapic, imazamox, tribenuron, isoxaflutole, bromacyl, carbetamide, clomazone, diclosulam, diuron, florasulam, flufenacet, flumioxazine, fluoroclorid

- the pesticide is a pesticide for soil pests and pathogens which is fluensulfone, propamocarb, flutolanil, fludioxonil, abamectin, fluopyram, or oxamyl.

- the pesticide is imidacloprid.

- the unit contains 0.7 mg, 1.4 mg, or 2.8 mg of imidacloprid.

- the pesticide is azoxystrobin.

- the unit contains 0.75 mg, 1.5 mg, or 3 mg of azoyxstrobin. In some embodiments, the unit contains two or more pesticides. In some embodiments, at least two of the two or more pesticides are together in at least one agrochemical zone.

- At least two of the two or more pesticides are each in different agrochemical zones.

- At least one of the two or more pesticides is dispersed throughout one or more root development zones and outside of an agrochemical zone.

- the unit contains two or more fertilizers.

- At least two of the two or more fertilizers are together in at least one agrochemical zone.

- At least two of the two or more fertilizers are each in different agrochemical zones.

- At least one of the two or more fertilizers is in an agrochemical zone which is formulated to release the fertilizers contained therein over a period of less than one week when the unit is swelled.

- the agrochemical zones contain a second fertilizer, wherein the agrochemical zones are not formulated to release the second fertilizer into the root development zones in a controlled release manner.

- the root development zones do not contain fertilizer or pesticide before the unit is swelled for the first time.

- the root development zones further comprise a fertilizer, a pesticide, or a fertilizer and a pesticide before the unit is swelled for the first time.

- the amount of the fertilizer, the pesticide, or the fertilizer and the pesticide in the root development zones is about 5%, 10%, 15% or 20% (w/w) of the amount of the fertilizer, pesticide, or the fertilizer and the pesticide, that is in the agrochemical zones.

- the weight ratio of the root development zones to the agrochemical zones in a dry unit is 0.05: 1 to 0.32: 1.

- the weight ratio of the root development zones to the agrochemical zones in a dry unit is 0.05: 1, 0.1 : 1, 0.15: 1 , 0.2: 1 , 0.25: 1 , or 0.3: 1. In some embodiments, the weight ratio of the root development zones to the agrochemical zones in a dry unit is 0.01: 1 to 0.5: 1, 0.01 : 1 to 0.02: 1, 0.01: 1 to 0.03: 1, 0.01 : 1 to 0.04: 1, 0.01 : 1 to 0.05: 1, 0.3: 1 to 0.4: 1, 0.3: 1 to 0.4: 1, 0.3: 1 to 0.4: 1, 0.3: 1 to 0.5: 1

- the invention provides a unit for delivery of agrochemicals to the roots of a plant comprising: i) one or more root development zones, and

- agrochemical zones are formulated to release the at least one agrochemical into the root development zones in a controlled release manner when the root development zones are swelled

- weight ratio of the root development zones to the agrochemical zones in a dry unit is 0.12: 1, 0.14: 1, or 0.21: 1.

- the total volume of the root development zones in the unit is at least 2 mL when the unit is 1 %, 5%, 10%, 15%, 20%, 25%, 30%, 35%, 40%, 45%, 50%, 1-50%, or 5-50% swelled.

- the total volume of the root development zones in the unit is greater than 2 mL, 2- 3 mL, 3-4 mL, 4-5 mL, 2-5 mL, 2-10 mL, 5-10 mL, 5-20 mL, 10-15 mL, 10-20 mL, 15-20 mL, 10-40 mL, 20-40 mL, 20-80 mL, 40-80 mL, 50-100 mL, 75-150 mL, 100-150 mL, 150-300 mL, 200-400 mL , 300- 600 mL, or 600-1000 mL when the unit is 1%, 5%, 10%, 15%, 20%, 25%, 30%, 35%, 40%, 45%, 50%, 1- 50%, or 5-50% swelled.

- the total volume of the root development zones in the unit is at least 0.2 mL when the unit is fully swelled.

- the total volume of the root development zones in the unit is at least 2 mL when the unit is fully swelled.

- the total volume of the root development zones in the unit is at least at least 0.2 mL, at least 0.5 mL, at least 1 mL, at least 2 mL, at least 5 mL, at least 10 mL, at least 20 mL, at least 30 mL, at least 40 mL, at least 50 mL, at least 60 mL, at least 70 mL, at least 80 mL, at least, 90 mL, at least 100 mL, at least 150 mL, at least 200 mL, at least 250 mL, at least 300 mL, at least 350 mL, at least 400 mL, at least 450 mL, at least 500 mL, at least 550 mL, at least 600 mL or larger than 600 mL when the unit is fully swelled.

- the total volume of the root development zones in the unit is greater than 2 mL, 2- 3 mL, 3-4 mL, 4-5 mL, 2-5 mL, 2-10 mL, 5-10 mL, 5-20 mL, 10-15 mL, 10-20 mL, 15-20 mL, 10-40 mL, 20-40 mL, 20-80 mL, 40-80 mL, 50-100 mL, 75-150 mL, 100-150 mL, 150-300 mL, 200-400 mL , 300- 600 mL, or 600-1000 mL when the unit is fully swelled.

- the total volume of the root development zones when the unit is 1-100% swelled is large enough to contain 10-50 mm of a root having a diameter of 0.5-5 mm.

- the total volume of the root development zones when the unit is 1%-100% swelled is large enough to contain at least 10 mm of a root having a diameter of 0.5 mm.

- the total volume of the root development zones when the unit is 1%, 5%, 10%, 15%, 20%, 25%, 30%, 35%, 40%, 45%, 50%, 1-50% or 5-50% swelled is large enough to contain 10-50 mm of a root having a diameter of 0.5-5 mm.

- the total volume of the root development zones when the unit is 1 %, 5%, 10%, 15%, 20%, 25%, 30%, 35%, 40%, 45%, 50%, 1-50% or 5-50% swelled is large enough to contain at least 10 mm of a root having a diameter of 0.5 mm.

- the unit has a dry weight of 0.1 g to 20 g.

- weight of the dry unit is 1-10 g. In some embodiments, the weight of the dry unit is 0.1, 1, 2, 3, 4, 5, 6, 7, 8, 9, or 10 g.

- the total weight of the agrochemical zones of the unit is 0.05 to 5 grams. In some embodiments, the total weight of the agrochemical zones of the unit is 5 grams. In some embodiments, the total weight of the agrochemical zones of the unit is 1.5 to 2 g. In some embodiments, the total weight of the agrochemical zones of the unit is 1.5 g. In some embodiments, the unit is in the shape of a cylinder. In some embodiments, the unit is in the shape of a polyhedron. In some embodiments, the unit is in the shape of a cube. In some embodiments, the unit is in the shape of a disc. In some embodiments, the unit is in the shape of a sphere.

- the agrochemical zones and the root development zones are adjoined.

- the unit consists of one root development zone which is next to one agrochemical zone.

- the agrochemical zones are partially contained within the root development zones such that the surface of the unit is formed by both the root development zones and the agrochemical zones.

- the unit is a bead comprising an external zone surrounding an internal zone, wherein the root development zones form the external zone and the agrochemical zones form the internal zone.

- the unit comprises one root development zone and one agrochemical zone. In some embodiments, the unit comprises more than one agrochemical zone.

- the root development zones are partially contained within the agrochemical zones such that the surface of the unit is formed by both the root development zones and the agrochemical zones.

- an agrochemical zone is sandwiched between two root development zones.

- the agrochemical zone is surrounded by a root development zone which forms a perimeter around the agrochemical zone but which covers less than all of the surface of the agrochemical zone, or vice versa.

- the perimeter is ring shaped.

- the root development zones comprise a super absorbent polymer (SAP).

- SAP super absorbent polymer

- the root development zones are capable of absorbing at least about 10, 15, 20, 25, 30, 35, 40, 45, 50, 75, 80, 85, 90, 95, 100, 200, 300, 400, 500, or 1000 times their weight in water. In some embodiments, the root development zones are capable of absorbing at least about 20-30 times their weight in water. some embodiments, the root development zones are permeable to oxyg ⁇

- the root development zones are permeable to oxygen such that at least about 6 mg/L of dissolved oxygen is maintained in the root development zones when the root development zones are swelled. In some embodiments, the root development zones when fully swelled are at least about 70, 75, 80, 85, 90, 95, or 100% as permeable to oxygen as swelled alginate or swelled semi-synthetic CMC.

- the root development zones comprise an aerogel.

- the root development zones comprise a geotextile.

- the root development zones comprise a sponge.

- the root development zones further comprise a polymer, a porous inorganic material, a porous organic material, or any combination thereof.

- the agrochemical zones further comprise an aerogel, a hydrogel, an organogel, a polymer, a porous inorganic material, a porous organic material, or any combination thereof.

- the unit further comprises cotton fibers.

- the root development zones are capable of being penetrated by the root of a plant when the root development zones are about 1%, 5%, 10%, 15%, 20%, 25%, 30%, 35%, 40%, 45%, 50%, 1-50%, or 5-50% swelled.

- roots of a plant are capable of growing within the root development zones when the root development zones are swelled.

- roots of a plant are capable of growing within the root development zones when the root development zones are about 1%, 5%, 10%, 15%, 20%, 25%, 30%, 35%, 40%, 45%, 50%, 1-50% or 5-50% swelled.

- the plant is a crop plant.

- the crop plant is a wheat plant, a maize plant, a soybean plant, a rice plant, a barley plant, a cotton plant, a pea plant, a potato plant, a tree crop plant, or a vegetable plant.

- the root development zones are biodegradable. In some embodiments, the root development zones are about 1%, 5%, 10%, 15%, 20%, 25%, 30%, 35%, 40%, 45%, 50%, 1-50% or 5-50% swelled, the total weight of the root development zones is at least about 2, 3, 4, 5, 6, 7, 8, 9, 10, 20, 30, 40, 50, 60, 70, 80, 90, 100 or more than 100 times greater than the total weight of the agrochemical zones.

- the root development zones comprise a synthetic hydrogel, a natural carbohydrate hydrogel, or a pectin or protein hydrogel, or any combination thereof.

- the root development zones comprise an aerogel, a hydrogel or an organogel. In some embodiments, the root development zones comprise a hydrogel. In some embodiments, the hydrogel comprises hydroxyethyl acrylamide.

- the synthetic hydrogel comprises acrylamide, an acrylic derivative, or any combination thereof.

- the natural carbohydrate hydrogel comprises agar, cellulose, chitosan, starch, hyaluronic acid, a dextrine, a natural gum, a sulfated polysaccharide, or any combination thereof.

- the pectin or protein hydrogel comprises gelatin, a gelatin derivative, collagen, a collagen derivative, or any combination thereof.

- the root development zones comprise a natural super absorbent polymer (SAP), a poly-sugar SAP, a semi-synthetic SAP, a fully-synthetic SAP, or any combination thereof.

- SAP super absorbent polymer

- poly-sugar SAP poly-sugar SAP

- semi-synthetic SAP semi-synthetic SAP

- fully-synthetic SAP or any combination thereof.

- the root development zones are capable of absorbing at least about 10, 15, 20, 25, 30, 35, 40, 45, 50, 75, 80, 85, 90, 95, 100, 200, 300, 400, 500, or 1000 times their weight in water.

- the root development zones further comprise at least one oxygen carrier that increases the amount of oxygen in the root development zones compared to corresponding root development zones not comprising the oxygen carrier.

- the at least one oxygen carrier is a perfluorocarbon.

- the agrochemical zones comprise an organic polymer, a natural polymer, or an inorganic polymer, or any combination thereof.

- the agrochemical zones are partially or fully coated with a coating system.

- the coating system dissolves into the root development zones when the root development zones are swelled.

- the coating system slows the rate at which at least one agrochemical in the agrochemical zones dissolves into the root development zones when the root development zones are swelled.

- the units comprise a coating system which covers all surfaces of the agrochemical zones which would otherwise be on the surface of the unit and which is impermeable to at least one agrochemical in the agrochemical zones.

- the coating system comprises sulfur, pentadiene, and D-triethylphosphate. In some embodiments, the coating system is silicate or silicon dioxide.

- the coating system is a polymer.

- the coating system is an agrochemical.

- the units comprise a fertilizer, a pesticide, a hormone compound, a drug compound, a chemical growth agent, an enzyme, a growth promoter, a microelement, or any combination thereof.

- the root development zones are capable of repeated swelling cycles that each comprises hydration followed by dehydration.

- the root development zones are capable of repeated swelling cycles in soil that each comprise hydration followed by dehydration while in the soil.

- the unit is in the shape of a sphere or an equivalent polyhedron after repeated swelling cycles.

- the root development zones when swelled, maintain at least about 75%, 80%, 85%, 90%, or 95% of their water content over a period of at least about 25, 50, 100, or 150 hours in soil.

- the root development zones when swelled, maintain at least about 75%, 80%, 85%, 90%, or 95% of their water content over a period of at least about 25, 50, 100, or 150 hours in sandy soil.

- the root development zones when swelled, maintain at least about 75%, 80%, 85%, 90%, or 95% of their volume over a period of at least about 25, 50, 100, or 150 hours in soil.

- the root development zones when swelled, maintain at least about 75%, 80%, 85%, 90%, or 95% of their volume over a period of at least about 25, 50, 100, or 150 hours in sandy soil.

- the root development zones when swelled, maintain their shape over a period of at least about 25, 50, 100, or 150 hours in soil.

- the root development zones when swelled, maintain their shape over a period of at least about 25, 50, 100, or 150 hours in sandy soil.

- the root development zones when swelled, maintain their shape after repeated swelling cycles that each comprises hydration followed by dehydration.

- the root development zones when swelled maintain their shape after at least 3 swelling cycles that each comprises hydration followed by dehydration.

- the root development zones when swelled in soil, have a pH or osmotic pressure that differs from the pH or osmotic pressure of the surrounding soil by at least about 10%.

- the widest part of the unit is about 1, 2, 3, 4, 5, 6, 7, 8, 9, 10 cm, or more than 10 cm when the root development zones are about 1%, 5%, 10%, 15%, 20%, 25%, 30%, 35%, 40%, 45%, 50%, 1-50% or 5-50% swelled.

- the total weight of the root development zones is at least about 2, 3, 4, 5, 6, 7, 8, 9, 10, 20, 30, 40, 50, 60, 70, 80, 90, 100 or more than 100 times greater than the total weight of the agrochemical zones.

- the root development zones comprise a natural super absorbent polymer (SAP), a poly-sugar SAP, a semi-synthetic SAP, a fully-synthetic SAP, or any combination thereof.

- SAP super absorbent polymer

- poly-sugar SAP poly-sugar SAP

- semi-synthetic SAP semi-synthetic SAP

- fully-synthetic SAP or any combination thereof.

- the root development zones comprise a combination of at least one natural SAP and at least one semi-synthetic or synthetic SAP. In some embodiments, the root development zones comprise a poly-sugar SAP.

- the poly-sugar SAP is alginate.

- the alginate is at least about 0.2% alginate.

- the root development zones comprise a semi-synthetic SAP.

- the semi-synthetic SAP is a CMC-g-polyacrylic acid SAP.

- the Carboxymethyl cellulose (CMC) grafted polyacrylic acid SAP comprises 6% CMC relative to the acrylic monomers (Acrylamide-acrylic), 6% CMC relative to acrylic acid, 25% CMC relative to acrylic acid, or CMC 50% AA.

- the CMC grafted SAP comprises 5-50% CMC relative the acrylic monomers. In some embodiments, the CMC grafted SAP comprises 6-12% CMC relative the acrylic monomers.

- the semi-synthetic SAP is k-carrageenan cross-linked-polyacrylic acid SAP.

- the SAP is other than alginate or a k-carrageenan cross-linked-polyacrylic acid SAP.

- the root development zones comprise a fully synthetic SAP.

- the fully synthetic SAP is acrylic acid or acrylic amide or any of the combinations thereof.

- the amount of cross-linker in the root development zones is below 5% relative to the total monomer content by weight. In some embodiments, the amount of cross-linker in the root development zones is below 2% relative to the total monomer content by weight. In some embodiments, the amount of cross-linker in the root development zones is below 1 % relative to the total monomer content by weight.

- the polymer content of a swelled unit is below 5% by weight. In some embodiments, the polymer content of a swelled unit is below 4%, below 3%, below 2%, or below 1% by weight.

- the agrochemical zones comprise an organic polymer, a natural polymer, or an inorganic polymer, or any combination thereof.

- the agrochemical zones comprise a polymer.

- the polymer is a highly cross-linked polymer.

- the highly cross-linked polymer is a poly-sugar or a poly-acrylic polymer.

- the agrochemical zones comprises a filler.

- the filler comprises a cellulosic material, a cellite, a polymeric material, a silicon dioxide, a phyllosilicate, a clay mineral, metal oxide particles, porous particles, or any combination thereof. In some embodiments, the filler comprises a phyllosilicate of the serpentine group.

- the phyllosilicate of the serpentine group is antigorite (Mg3Si 2 05(OH)4), chrysotile (Mg 3 Si 2 0 5 (OH)4), or lizardite (Mg3Si 2 0 5 (OH)4).

- the filler comprises a clay mineral, which is halloysite (Al2Si20s(OH)4), kaolinite

- the filler comprises a phyllosilicate of the mica group.

- the phyllosilicate of the mica group is biotite (K(Mg,Fe) 3 (AlSi 3 )Oio(OH) 2 ), muscovite (KAl 2 (AlSi 3 )O 10 (OH) 2 ), phlogopite (KMg 3 (AlSi 3 )O10(OH) 2 ), lepidolite (K(Li,Al) 2 - 3(AlSi 3 )Oio(OH) 2 ), margarite (CaAl 2 (Al 2 Si 2 )Oio(OH) 2 ), glauconite ((K,Na)(Al,Mg,Fe) 2 (Si,Al) 4 O 10 (OH) 2 ), or any combination thereof.

- the filler comprises a phyllosilicate of the chlorite group.

- the a phyllosilicate of the chlorite group is chlorite ((Mg,Fe) 3 (Si,Al)4O 10 (OH) 2 -(Mg,Fe) 3 (OH) 6 ).

- the filler forms a beehive-like structure.

- the beehive-like structure is microscopic.

- the filler comprises clay.

- the filler comprises zeolite.

- the agrochemical zones comprise at least about 0.05, 0.1, 0.2, 0.3, 0.4, 0.5, 0.6, 0.7, 0.8, 0.9, or 1 grams of the at least one agrochemical.

- the agrochemical zones comprise 1-10 grams of the at least one agrochemical.

- the agrochemical zones are about 30%, 35%, 40%, 45%, 50%, 55%, or 60% of the at least one agrochemical by weight.

- the agrochemical zones are biodegradable. In some embodiments, the unit comprises one agrochemical zone.

- the unit comprises 2, 3, 4, 5, 6, 7, 8, 9, 10 or more than 10 agrochemical zones. In some embodiments, the unit comprises 2, 3, 4, 5, 6, 7, 8, 9, 10 or more than 10 root development zones.

- the at least one agrochemical is:

- the fertilizer compound is a natural fertilizer. In some embodiments, the fertilizer compound is a synthetic fertilizer.

- the pesticide is:

- the insecticide compound is imidacloprid. In some embodiments, the herbicide compound is pendimethalin. In some embodiments, the fungicide compound is azoxystrobin. In some embodiments, the nematicide compound is fluensulfone.

- the fertilizer is PO 4 , NO 3 , (NH 4 ) 2 SO 2 , NH 4 H 2 PO 4 , KCI, or any combination thereof.

- the fertilizer is one or more macro nutrients selected from N,P, K, Ca, Mg, and S and, optionally, one or more micro nutrients selected from B, Cu, Fe, Zn, Mn and Mb with or without one or more pesticides.

- the fertilizer comprises urea and KC1. In some embodiments, the fertilizer is 60% urea and 30% KC1 by weight.

- the fertilizer comprises multiple fertilizer compounds which include PO 4 , NO 3 , (NH 4 )2SO 2 , NH 4 H 2 PO 4 , and/or KC1.

- the pesticide is at least one pesticide compound that is not suitable for application to an agricultural field.

- the pesticide is a pesticide which is not suitable for application to an agricultural field because it is too toxic to be applied to an agricultural field using conventional soil treatment.

- the pesticide is toxic to animals other than arthropods or mollusks when applied to an agricultural field in an amount that is sufficient to kill an arthropod or a mollusk.

- the fertilizer, the pesticide, or the fertilizer and the pesticide is released from the agrochemical zones over a period of at least about one week when the root development zones are swelled.

- the fertilizer, the pesticide, or the fertilizer and the pesticide is released from the agrochemical zones into the root development zones over a period of at least about 2, 3, 4, 5, 6, 7, 8, 9, 10, or 20 weeks when the root development zones are swelled. In some embodiments, the fertilizer, the pesticide, or the fertilizer and the pesticide is released from the agrochemical zones into the root development zones over a period of at least about 2, 3, 4, 5, 6, 7, 8, 9, 10, or 20 weeks when the root development zones are about 1%, 5%, 10%, 15%, 20%, 25%, 30%, 35%, 40%, 45%, 50%, 1-50% or 5-50% swelled.

- the fertilizer, the pesticide, or the fertilizer and the pesticide diffuses from the surface of the unit into the surrounding soil at a linear rate beginning about 25 days after hydration. In some embodiments, when the root development zones of the unit are swelled and the unit is in soil, the fertilizer, the pesticide, or the fertilizer and the pesticide diffuses from the surface of the unit into the surrounding soil for at least about 50 or 90 days after hydration. In some embodiments, the unit is not swelled.

- the unit contains less than about 35%, 30%, 25%, 20%, 15%, or 10% water by weight.

- the unit comprises one or more interface zone between the agrochemical zones and the root development zones, which interface zone is formed by at least one insoluble salt or solid, at least one cross-linking agent, or at least one inorganic compound.

- diffusion between the root development zones and the agrochemical zones is limited by altering the pH or the cation concentration in the agrochemical zones, the root development zones, or the interface zone.

- diffusion between the root development zones and the agrochemical zones is limited by altering the pH and/or cation concentration in the agrochemical zone or the root development zone.

- the pH in the agrochemical zones or the root development zones is altered by a buffer.

- the pH in the agrochemical zones, the interface zones, and the root development zones is altered by a buffer.

- the invention provides a method of growing a plant, comprising adding at least one unit of the invention to the medium in which the plant is grown.

- the method comprises a step of selecting the size of the unit based upon the specific plant to be grown. For example, it may be desirable to select a unit having a large swelled size when growing a plant having large diameter roots and it may be desirable to select a unit having a smaller swelled size when growing a plant having small diameter roots. In some embodiments, it may be desirable to use more units of a given size when growing a plant having a large root system than when growing a plant having a small root system.

- the medium in which the plant is grown comprises soil.

- the medium in which the plant is grown is soil.

- the soil comprises sand, silt, clay, or any combination thereof.

- the soil is clay, loam, clay-loam, or silt-loam.

- the soil is an Andisol.

- the at least one unit is added to the soil at one or more depths below the soil surface. In some embodiments, the at least one unit is added at a depth of 5-50 cm. In some embodiments, the at least one unit is added at a depth of 5 cm, 10 cm, 15 cm, 20 cm, 25 cm, 30 cm, 35 cm, 40 cm, 45 cm, or 50 cm, or any combination of 2, 3, or 4 of the foregoing depths.

- the invention provides a method of reducing environmental damage caused by a fertilizer, a pesticide, or a fertilizer and a pesticide, comprising delivering the fertilizer and the pesticide to the root of a plant by adding at least one unit of the invention to the medium of the plant.

- the invention provides a method of reducing environmental damage caused by agrochemicais, comprising delivering the agrochemicais to the root of a plant by adding at least one unit of the invention to the medium of the plant.

- minimizing exposure to the fertilizer, the pesticide, or the fertilizer and the pesticide is minimizing the exposure of a farmer to the fertilizer, the pesticide, or the fertilizer and the pesticide.

- minimizing exposure to the fertilizer, the pesticide, or the fertilizer and the pesticide is minimizing exposure of a person other than the farmer to the fertilizer, the pesticide, or the fertilizer and the pesticide.

- the present invention provides a method of generating an artificial zone with predetermined chemical properties within the root zone of a plant, comprising:

- step i) comprises adding at least two different units to the medium of the root zone of the plant; and step ii) comprises adding at least two different units to the anticipated root zone of the medium in which the plant is anticipated to grow, wherein at least one of the at least two different units is a unit of the invention.

- each of the at least two different units contains at least one agrochemical that is not contained within one of the other at least two different units.

- the invention provides a method of fertilizing a plant comprising adding at least one unit of the invention to the medium in which the plant is grown.

- the invention provides a method of protecting a plant from a pest comprising adding at least one unit of the invention to the medium in which the plant is grown.

- the amount of the pesticide contained in all of the units added to the medium is substantially less than the amount of the pesticide which would be needed to achieve the same level of pest protection when applying the pesticide by foliar spraying, soil drenching, above ground distribution, or soil spraying.

- the amount of pesticide contained in all of the units added to the medium is less than 90%, less than 80%, less than 70%, less than 60%, or less than 50% of the amount of the pesticide which would be needed to achieve the same level of pest protection when applying the pesticide by foliar spraying, soil drenching, above ground distribution, or soil spraying.

- 300,000 to 700,000 units are added per hectare of medium.

- the units comprise 1.5 g of fertilizer, and 500,000 units are added per hectare of medium.

- the unit contains an insecticide, and the number of units added per hectare of medium contain 100 to 500 g of insecticide. In some embodiments, the unit contains an herbicide, and the number of units added per hectare of medium contain 5 to 1000 g of herbicide.

- the unit contains a fungicide, and the number of units added per hectare of medium contains 100 to 500 g of fungicide.

- the unit contains a pesticide for soil pests and pathogens

- the number of units added her hectare of medium contains 100 to 3000 g of the pesticide for soil pests and pathogens.

- the unit contains an herbicide, and the plant is resistant to the herbicide.

- the plant is a soybean plant and the herbicide is an imidazolinone.

- the plant is wheat, canola, or sunflower and the herbicide is pendimethalin.

- the plant is genetically modified crop with herbicide resistance.

- the plant is genetically modified soybean, genetically modified alfalfa, genetically modified corn, genetically modified cotton, genetically modified canola, or genetically modified sugarbeets, and the herbicide is glyphosate.

- 4-20 units are added to the medium per plant.

- the plant is grown in a field.

- the plant is a crop plant.

- the crop plant is a grain or a tree crop plant.

- the crop plant is a fruit or a vegetable plant.

- the plant is a banana, barley, bean, cassava, corn, cotton, grape, orange, pea, potato, rice, soybean, sugar beet, tomato, or wheat plant.

- the plant is a sunflower, cabbage plant, lettuce, or celery plant.

- the units are added to the medium where the plant is growing. In some embodiments, the units are added to the medium where the plant is to be grown.

- seeds for growing the plant are added to the medium before the units are added to the medium.

- seeds for growing the plant are added to the medium at the same time the units are added to the medium. In some embodiments, seeds for growing the plant are added to the medium after the units are added to the medium.

- the medium is soil.

- the units comprise one fertilizer compound. In some embodiments, the units comprise two fertilizer compounds. In some embodiments, the units comprise three fertilizer compounds. In some embodiments, the units comprise more than three fertilizer compounds.

- the units comprise one to three fertilizer compounds, such that the total N, P, and/or K content as (NH.O 2 SO 2 , NH 4 H 2 PO 4 , and KC1 in the medium as part of the units is about 5-50, 1-10, and 5- 60 g/m 2 , respectively.

- the units comprise three fertilizer compounds, such that the total N, P, and K content as ( NH 4 ) 2 SO 2 , NH 4 H 2 PO 4 , and KC1 in the medium as part of the units is about 25, 5, and 30 g/m 2 , respectively.

- roots of a crop plant are capable of penetrating the hydrogel when the hydrogel is about 1%, 5%, 10%, 15%, 20%, 25%, 30%, 35%, 40%, 45%, 50%, 1-50% or 5-50% hydrated.

- roots of a crop plant are capable of growing within the hydrogel when the hydrogel is hydrated.

- roots of a crop plant are capable of growing within the hydrogel when the hydrogel is about 1%, 5%, 10%, 15%, 20%, 25%, 30%, 35%, 40%, 45%, 50%, 1-50% or 5-50% hydrated.

- the crop plant is a sunflower plant.

- the crop plant is a cabbage plant.

- the crop plant is wheat plant.

- the crop plant is maize plant.

- the crop plant is a soybean plant.

- the crop plant is a rice plant.

- the crop plant is a barley plant.

- the crop plant is a cotton plant.

- the crop plant is a pea plant.

- the crop plant is a potato plant.

- the crop plant is a tree crop plant.

- the crop plant is a vegetable plant.

- 0.2-5 mg/kg/day is a disclosure of 0.2 mg/kg/day, 0.3 mg/kg/day, 0.4 mg/kg/day, 0.5 mg/kg/day, 0.6 mg/kg/day etc. up to 5.0 mg/kg/day.

- a value refers to the amount of active ingredient (a.i.) of the pesticide.

- an "agrochemical zone” is a component of a unit of the invention which contains at least one agrochemical and which releases the at least one agrochemical into the root development zones of a unit of the invention.

- the at least one agrochemical is released into the root development zones of a unit of the invention by diffusion when the root development zones of the unit are hydrated.

- coating system means one or more compounds which delays or prevents the release of an agrochemical from the surface of an agrochemical zone which is covered by the coating system.

- the coating system comprises a single coat compound.

- the coating system comprises more than one coat compound.

- the coating system comprises more than one layer.

- each layer of the coating system is of the same composition. In some embodiments, each layer of the coating composition is of a different composition. In some embodiments, the coating system comprises two, three, or four layers.

- controlled release when used to refer to an agrochemical zone means that the agrochemical zone is formulated to release one or more agrochemicals of the agrochemical zone gradually over time. In some embodiments, the agrochemical zones are formulated to release at least one agrochemical into the root development zones over a period of at least about one week when the root development zones are swelled.

- the agrochemical zones are formulated to release at least one agrochemical into the root development zones over a period greater than one week when the root development zones are swelled.

- Controlled release is interchangeable with the term “slow release” ("SR").

- DAP means days after planting.

- a "unit” refers to a unit for delivery of agrochemicals to the roots of a plant as described herein.

- a “fertilizer unit” refers to a unit for delivery of agrochemicals to the roots of a plant as described herein which comprises a fertilizer.

- a “fertilizer/pesticide unit” refers to a unit for delivery of agrochemicals to the roots of a plant as described herein which comprises a fertilizer and a pesticide.

- An “empty unit” comprises the root development zone component of a unit of the invention unaccompanied by the agrochemical zone component.

- an empty unit has the same shape and/or dimensions as the corresponding unit of the invention.

- a "root development zone” is a component of a unit of the invention which, when hydrated, can be penetrated by a growing root.

- the growing root can grow and develop within the root development zone of a unit.

- a root development zone is a super absorbent polymer (SAP).

- the root development zone is an aerogel, a geotextile, or a sponge.

- the root development zone will take up water from the surrounding environment when, for example, the unit is placed in soil which is subsequently irrigated.

- the hydrated root development zones create an artificial environment in which a growing root can uptake water and nutrients.

- the root development zones of a unit are formulated to contain one or more agrochemicals which are the same or different than the agrochemicals of the agrochemical zones of the unit. While the invention described herein is not limited to any particular mechanism of action, it is believed that a growing root is attracted to the root development zones of a unit because of the presence of water and/or agrochemicals (e.g. minerals) in the root development zones. It is believed that roots can continue to grow and develop within the root development zones of units because of the continued availability of water and/or agrochemicals in the units.

- root development zones means one or more root development zones and use of the term "agrochemical zones” means one or more agrochemical zones unless stated otherwise or required otherwise by context.

- Plants provided by or contemplated for use in embodiments of the present invention include both monocotyledons and dicotyledons.

- a plant is a crop plant.

- a "crop plant” is a plant which is grown commercially.

- the plants of the present invention are crop plants (for example, cereals and pulses, maize, wheat, potatoes, tapioca, rice, sorghum, millet, cassava, barley, or pea), or other legumes.

- the crop plants may be grown for production of edible roots, tubers, leaves, stems, flowers or fruit.

- the plants may be vegetable or ornamental plants.

- crop plants of the invention include: Acrocomia aculeata (macauba palm), Arabidopsis thaliana, Aracinis hypogaea (peanut), Astrocaryum murumuru (murumuru), Astrocaryum vulgare (tucuma), Attalea geraensis (Indaia-rateiro), Attalea humilis (American oil palm), Attalea oleifera (andaia), Attalea phalerata (uricuri), Attalea speciosa (babassu), Avena sativa (oats), Beta vulgaris (sugar beet), Brassica sp. such as Brassica carinata, Brassica juncea, Brassica napobrassica,

- Brassica napus canola

- Camelina sativa false flax

- Cannabis sativa hemp

- Carthamus tinctorius safflower

- Caryocar brasiliense pequi

- Cocos nucifera Coconut

- Crambe abyssinica Abyssinian kale

- Cucumis melo melon

- Elaeis guineensis Africann palm

- Glycine max sinoybean

- Gossypium hirsutum cotton

- Helianthus sp Helianthus sp.

- Lemna sp. such as Helianthus annuus (sunflower), Hordeum vulgare (barley), Jatropha curcas (physic nut), Joannesia princeps (arara nut-tree), Lemna sp. (duckweed) such as Lemna aequinoctialis, Lemna disperma, Lemna ecuadoriensis, Lemna gibba (swollen duckweed), Lemna japonica, Lemna minor, Lemna minuta, Lemna obscura, Lemna paucicostata, Lemna perpusilla, Lemna tenera, Lemna trisulca, Lemna turionifera, Lemna valdiviana, Lemna yachesis, Licania rigida (oiticica), Linum usitatissimum (flax), Lupinus angustifolius (lupin), Mauritia

- Nicotiana sp. such as Miscanthus x giganteus and Miscanthus sinensis, Nicotiana sp. (tabacco) such as Nicotiana tabacum or Nicotiana benthamiana, Oenocarpus bacaba (bacaba-do-azeite), Oenocarpus bataua (pataua), Oenocarpus distichus (bacaba-de-leque), Oryza sp.

- rice such as Oryza sativa and Oryza glaberrima, Panicum virgatum (switchgrass), Paraqueiba paraensis (mari), Persea amencana (avocado), Pongamia pinnata (Indian beech), Populus trichocarpa, Ricinus communis (castor), Saccharum sp. (sugarcane), Sesamum indicum (sesame), Solanum tuberosum (potato), Sorghum sp.

- Triticum sp. such as Sorghum bicolor, Sorghum vulgare, Theobroma grandi forum (cupuassu), Trifolium sp., Trithrinax brasiliensis (Brazilian needle palm), Triticum sp. (wheat) such as Triticum aestivum, Zea mays (corn), alfalfa (Medicago sativa), rye (Secale cerale), sweet potato (Lopmoea batatus), cassava (Manihot esculenta), coffee (Cofea spp.), pineapple (Anana comosus), citris tree ⁇ Citrus spp.), cocoa ⁇ Theobroma cacao), tea ⁇ Camellia senensis), banana ⁇ Musa spp.), avocado ⁇ Persea americana), fig ⁇ Ficus casica), guava ⁇ Psidium guajava), mango ⁇ Mang

- swelled means that a material has an absorbed amount of water which is at least about 1% of the amount of water that would be absorbed by the material if placed in deionized water for 24 hours at 21°C.

- a “swelled” hydrogel can be referred to as a "hydrated” hydrogel.

- a swelled material has an absorbed amount of water which is at least about 2% of the amount of water that would be absorbed by the material if placed in deionized water for 24 hours at 21°C.

- a swelled material has an absorbed amount of water which is at least about 3% of the amount of water that would be absorbed by the material if placed in deionized water for 24 hours at 21°C. In some embodiments, a swelled material has an absorbed amount of water which is at least about 4% of the amount of water that would be absorbed by the material if placed in deionized water for 24 hours at 21°C. In some embodiments, a swelled material has an absorbed amount of water which is at least about 5% of the amount of water that would be absorbed by the material if placed in deionized water for 24 hours at 21°C.

- hydrated means at least about 1% hydrated. In some embodiments, “hydrated” means at least about 2% hydrated. In some embodiments, “hydrated” means at least about 3% hydrated. In some embodiments, “hydrated” means at least about 4% hydrated. In some embodiments, “hydrated” means at least about 5% hydrated.

- a "fully swelled" unit of the invention is a unit which contains an amount of absorbed water which is equal to the amount of water the unit would absorb if placed in deionized water for 24 hours at 21 °C.

- an artificial environment means a media located within the root zone of an agricultural field or a garden plant loaded with at least one agrochemical, encourages root growth and uptake activity within its internal periphery.

- agrochemicals include pesticides, including insecticides, herbicides, and fungicides.

- Agrochemicals may also include natural and synthetic fertilizers, hormones and other chemical growth agents.

- the agrochemical zone may contain the input (fertilizer, pesticide, or other agrochemical) in a structure that controls its release into the root development zone.

- the release rate is designed to meet plant demands throughout the growing season. In some embodiments, no input residuals remain at the end of a predetermined action period.

- Units made with a water soluble pesticide may be formulated so that the water soluble pesticide is contained in one or more agrochemical zones together with or without other agrochemicals, e.g. fertilizers. These agrochemical zones may be formulated to release the pesticide into the root development zones in a controlled release manner.

- Units made with hydrophobic pesticides may be formulated so that the hydrophobic pesticide is contained in one or more agrochemical zone together with or without other agrochemicals, e.g. fertilizers. These agrochemical zones do not need to be formulated with a controlled release mechanism, e.g. a coating system, because the hydrophobic nature of the pesticide will limit its rate of release into the root development zones.

- hydrophobic pesticides can be dispersed throughout a root development zone without being contained in any agrochemical zone. The hydrophobic nature of the pesticide will limit the rate at which the pesticide leaches from the unit into the surrounding medium.

- the agrochemical zone comprises one or more fertilizers, pesticides, and/or other agrochemicals such as nitrogen, phosphorus, potassium, etc., in a beehive like structure made from highly cross linked polymer coated with silica or highly cross linked poly acrylic acid/poly sugar with a clay filler.

- the agrochemical zone comprises fertilizer, pesticide, and/or at least one other agrochemical in a beehive like structure with or without an external coating.

- a root development zone which surrounds an agrochemical zone may be referred to herein as a "shell.”

- Root development zones of the present invention are sustainable in soils, and encourage root penetration, uptake activity, and growth and/or development in the root development zone.

- a super absorbent polymer may serve as the root development zone since during watering it can absorb soil moisture, swell and maintain its high water content over long period of time.

- the root development zone has features such as mechanical resistance (in order to maintain its shape and geometry in the soil); swelling cycle capability (capable of repeated hydration and dehydration in response to soil water content); oxygen permeability- (maintaining sufficient oxygen level to support root activity, such as root development); and root penetration (allowing the growth of roots into it).

- Materials that may be used in the present invention include but are not limited to: 1) clay 2) zeolite 3) tuff 4) fly ash 5) hydrogel 6) foam.

- an artificial environment of the present invention serves as a buffer for soil type and pH to provide universal root growth environment.

- an artificial environment of the present invention contains needed materials and nutrients in the desired conditions, such as but not limited to water, fertilizers, drugs, and other additives.

- aspects of the present invention relate to root development zones having SAPs that are permeable to oxygen when hydrated. Roots use oxygen for growth and development (Drew, 1997; Hopkins 1950). Therefore, the oxygen permeability of a SAP is an important factor in determining whether it will support root growth and development within a root development zone that comprises the SAP.

- hydrogels of the present invention supply water, nutrients and weak resistance

- the data hereinbelow show that provided the gas diffusion is high enough, roots will develop in most types of small-volume hydrogels and hydrogel containing units, installed in a field soil.

- alginate hydrogel which is suitably permeable to oxygen, encourages root development

- starch hydrogel which is poorly permeable to oxygen does not encourage root development.

- semi-synthetic CMC is also suitably permeable to oxygen. The ability of oxygen to diffuse into root development zones of the present invention is important for root development within them.

- aspects of the present invention relate to the selection of SAPs, such as hydrogels, that are sufficiently permeable to oxygen when hydrated.

- Oxygen permeability may be measured to determine whether a hydrated SAP is sufficiently permeable to oxygen for use in embodiments of the present invention.

- the SAP is permeable to oxygen such that it supports root growth and/or development.

- the SAP when hydrated is at least about 70, 75, 80, 85, 90, 95, or 100% as permeable to oxygen as hydrated alginate.

- the SAP when hydrated is at least about 70, 75, 80, 85, 90, 95, or 100% as permeable to oxygen as hydrated semi-synthetic CMC.

- Oxygen permeability may be measured according to assays that are well known in the art. Non-limiting examples of methods that may be useful for measuring oxygen permeability of SAPs of the invention are described in Aiba et al. ( 1968) "Rapid Determination of Oxygen Permeability of Polymer Membranes” Ind. Eng. Chem.

- permeability of a SAP may be measured when it is partially or fully hydrated, e.g. when the SAP is 5%, 10%, 15%, 20%, 25%, 30%, 35%, 40%, 45%, 50%, or 5-50% hydrated.

- the root development zones of a unit of the invention are both i) sufficiently permeable to oxygen to encourage root growth, and ii) do not disintegrate in soil.

- the root development zones of a unit of the invention are mechanically resistant, i.e., are capable of repeated swelling cycles in soil without fragmenting in the soil.

- all of the SAP of the root development zones remains part of the root development zones after repeated swelling cycles.

- alginate's permeability to oxygen root development zones consisting of alginate are not suitable in preferred embodiments of the invention because alginate tends to disintegrate in soil.

- semisynthetic CMC which does not tend to disintegrate and is capable of repeated swelling cycles without fragmenting in soil (i.e., is mechanically resistant), is suitable for use in root development zones in preferred embodiments the invention.

- Phase 1 Banding and incorporating into the upper soil profile.

- Root development zones comprising, e.g. a SAP

- the root development zones absorbs moisture from the soil and swells; water penetrates the coating (if present) and dissolves the fertilizer, pesticides and/or other agrochemical(s) which then diffuse into the root development zones (e.g. towards the periphery of a bead).

- Phase 3 Roots grow, develop, and remain in the root development zones where uptake lasts a predetermined period.

- root development zones e.g. bead shells

- •Distribute empty units e.g. shells of different sizes in a pot.

- empty units of three sizes are used.

- the shells may have a dry radius of, e.g., 0.5, 1, 1.5, 2. 2.5, 3, 3.5, 4, 4.5, or 5 cm or a length of, e.g., 0.5, 1, 1.5, 2. 2.5, 3, 3.5, 4, 4.5, 5, 6, 7, 8, 9, or 10 cm.

- a 10, 1 1, 12, 13, 14, 15, 20, 25, or 30 liter pot is used.

- the empty units are distributed in the pot with soil.

- the soil is sandy soil.

- the final geometry is spherical, cylindrical, or box shaped.

- the cell is made of Perspex- and is 60 X 2 X 30 cm).

- the empty units are distributed with soil.

- the soil is sandy soil.

- root location and empty status is monitored by photography or/and scanning.

- root development zones e.g. bead shells

- the pot is a 10, 11, 12, 13, 14, 15, 20, 25, or 30 liter pot. •Installing filter paper cups to monitor concentrations in the root zone and drainage over time.

- the soil is sandy soil.

- Super Absorbent Polymers are polymers that can absorb and retain extremely large amounts of a liquid relative to their own mass.

- SAPs that are useful in embodiments of the subject invention are described in K. Horie, M. Baron, R. B. Fox, J. He, M. Hess, J. Kahovec, T. Kitayama, P. Kubisa, E. Marechal, W. Mormann, R. F. T. Stepto, D. Tabak, J. Vohlidal, E. S. Wilks, and W. J. Work (2004). "Definitions of terms relating to reactions of polymers and to functional polymeric materials (IUPAC Recommendations 2003)". Pure and Applied Chemistry 76 (4): 889-906; Kabiri, K.

- hydrogels that are useful in embodiments of the subject invention are described in Mathur et al., 1996. "Methods for Synthesis of Hydrogel Networks: A Review” Journal of Macromolecular Science, Part C: Polymer Reviews Volume 36, Issue 2, 405-430; and Kabiri et al., 2010. "Superabsorbent hydrogel composites and nanocomposites: A review” Volume 32, Issue 2, pages 277-289, the entire contents of each of which are hereby incorporated herein by reference.

- Geotextiles are permeable fabrics which are typically used to prevent the movement of soil or sand when placed in contact with the ground.

- Non-limiting examples of geotextiles that are useful in embodiments of the subject invention are described in U.S. Pat. Nos. 3,928,696, 4,002,034, 6,315,499, 6,368,024, and 6,632,875, the entire contents of each of which are hereby incorporated herein by reference.

- Aerogels are gels formed by the dispersion of air in a solidified matrix.

- Non-limiting examples of aerogels that are useful in embodiments of the subject invention are described in Aegerter, M., ed. (2011) Aerogels Handbook. Springer, the entire contents of which is hereby incorporated herein by reference.

- a fertilizer is any organic or inorganic material of natural or synthetic origin (other than living materials) that is added to a plant medium to supply one or more nutrients that promotes growth of plants.

- Non-limiting examples of fertilizers that are useful in embodiments of the subject invention are described in Stewart, W.M.; Dibb, D.W.; Johnston, A.E.; Smyth, T.J. (2005). "The Contribution of Commercial Fertilizer Nutrients to Food Production”. Agronomy Journal 97: 1-6.; Erisman, Jan Willem; MA Sutton, J Galloway, Z Klimont, W Winiwarter (October 2008). "How a century of ammonia synthesis changed the world”. Nature Geoscience 1 ( 10): 636.; G. J.

- Non-limiting examples of fertilizers which may be useful in embodiments of the present invention include Ammonium nitrate, Ammonium sulfate, anhydrous ammonia, calcium nitrate/urea, oxamide, potassium nitrate, urea, urea sulfate, ammoniated superphosphate, diammonium phosphate, nitric phosphate, potassium carbonate, potassium metaphosphate, calcium chloride, magnesium ammonium phosphate, magnesium sulfate, ammonium sulfate, potassium sulfate, and others disclosed herein. Pesticides,

- Pesticides are substances or mixtures of substances capable of preventing, destroying, repelling or mitigating any pest. Pesticides include insecticides, nematicides, herbicides and fungicides. Insecticides

- Insecticides are pesticides that are useful against insects, and include but are not limited to organochloride, organophosphate, carbamate, pyrethroid, neonicotinoid, and ryanoid insecticides.

- Non-limiting examples of insecticides that are useful in embodiments of the subject invention are described in van Emden HF, Pealall DB (1996) Beyond Silent Spring, Chapman & Hall, London, 322pp; Rosemary A. Cole “Isothiocyanates, nitriles and thiocyanates as products of autolysis of glucosinolates in Cruciferae” Phytochemutry, 1976. Vol. 15, pp. 759-762; and Robert L. Metcalf “Insect Control” in Ullmann's Encyclopedia of Industrial Chemistry” Wiley- VCH, Weinheim, 2002, the entire contents of each of which are incorporated herein by reference.

- Exemplary insecticides include Aldicarb, Bendiocarb, Carbofuran, Ethienocarb, Fenobucarb, Oxamyl, Methomyl, Acetamiprid, Clothianidin, Dinotefuran, Imidacloprid, Nitenpyram, Nithiazine, Thiacloprid, Thiamethoxam, Mirex, Tetradifon, Phenthoate, Phorate, Pirimiphos- methyl, Quinalphos, Terbufos, Tribufos, Trichlorfon, Tralomethrin, Transfluthrin, Fenoxycarb, Fipronil, Hydramethylnon, Indoxacarb, and Limonene.

- Additional exemplary insecticides include Carbaryl, Propoxur, Endosulfan, Endrin, Heptachlor, Kepone, Lindane, Methoxychlor, Toxaphene, Parathion, Parathion-methyl, Phosalone, Phosmet, Phoxim, Temefos, Tebupirimfos, and Tetrachlorvinphos.

- Nematicides are pesticides that are useful against plant-parasitic nematodes.

- Non-limiting examples of nematicides that are useful in embodiments of the subject invention are described in D. J. Chitwood, "Nematicides,” in Encyclopedia of Agrochemicals (3), pp. 1104-1115, John Wiley & Sons, New York, NY, 2003; and S. R. Gowen, "Chemical control of nematodes: efficiency and side- effects," in Plant Nematode Problems and their Control in the Near East Region (FAO Plant Production and Protection Paper - 144), 1992, the entire contents of each of which are incorporated herein by reference.

- Herbicides are pesticides that are useful against unwanted plants.

- Non-limiting examples of herbicides that are useful in embodiments of the subject invention include 2,4-D, aminopyralid, atrazine, clopyralid, dicamba, glufosinate ammonium, fluazifop, fluroxypyr, imazapyr, imazamox, metolachlor, pendimethalin, picloram, triclopyr, mesotrione, and glyphosate.

- Fungicides are pesticides that are useful against fungi and/or fungal spores.

- Non-limiting examples of fungicides that are useful in embodiments of the subject invention are described in Pesticide Chemistry and Bioscience edited by G.T Brooks and T.R Roberts. 1999. Published by the Royal Society of Chemistry; Metcalfe, R.J. et al. (2000) The effect of dose and mobility on the strength of selection for DMI (sterol demethylation inhibitors) fungicide resistance in inoculated field experiments.

- DMI sterol demethylation inhibitors

- fungicides include azoxystrobin, cyazofamid, dimethirimol, fludioxonil, kresoxim-methyl, fosetyl-Al, triadimenol, tebuconazole, and flutolanil.

- Non-limiting examples of microelements that are useful in embodiments of the subject invention include iron, manganese, boron, zinc, copper, molybdenum, chlorine, sodium, cobalt, silicon, and nickel. Hormones

- Plant hormones may be used to affect plant processes.

- Non-limiting examples of plant hormones that are useful in embodiments of the subject invention include but are not limited to, auxins (such as heteroauxin and its analogues, indolylbutyric acid and a- naphthylacetic acid), gibberellins, and cytokinins.

- auxins such as heteroauxin and its analogues, indolylbutyric acid and a- naphthylacetic acid

- gibberellins such as gibberellins, and cytokinins.

- Root penetration- allows the growth of root into it.

- CMC Carboxymethyl cellulose sodium Salt

- AA Acrylic Acid

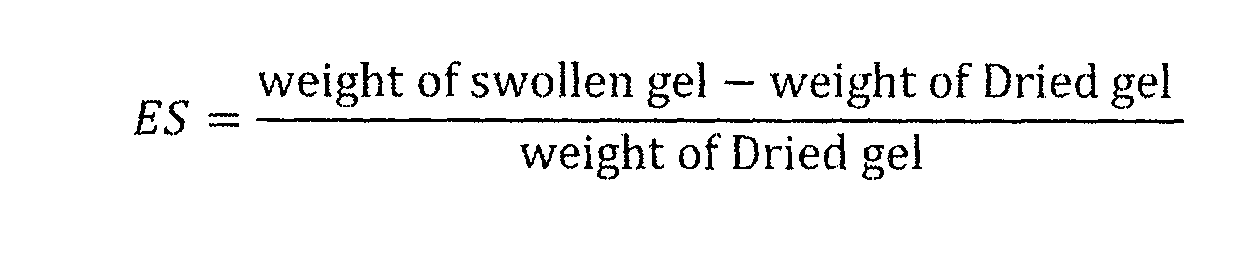

- MBA N-N methylene bis acrylamide