WO2015151795A1 - Optical film, polarizing plate, method for producing polarizing plate, image display device and method for manufacturing image display device - Google Patents

Optical film, polarizing plate, method for producing polarizing plate, image display device and method for manufacturing image display device Download PDFInfo

- Publication number

- WO2015151795A1 WO2015151795A1 PCT/JP2015/057845 JP2015057845W WO2015151795A1 WO 2015151795 A1 WO2015151795 A1 WO 2015151795A1 JP 2015057845 W JP2015057845 W JP 2015057845W WO 2015151795 A1 WO2015151795 A1 WO 2015151795A1

- Authority

- WO

- WIPO (PCT)

- Prior art keywords

- film

- optical film

- hard coat

- coat layer

- acid

- Prior art date

Links

- YSWFXKKDKNCPPW-UHFFFAOYSA-N CC(COC(c(cc1)cc(cc2)c1cc2C(OCC(C)OC(c(ccc1c2)cc1ccc2C(OCC(C)OC(c1cc(cc(cc2)C(OCC(C)O)=O)c2cc1)=O)=O)=O)=O)=O)O Chemical compound CC(COC(c(cc1)cc(cc2)c1cc2C(OCC(C)OC(c(ccc1c2)cc1ccc2C(OCC(C)OC(c1cc(cc(cc2)C(OCC(C)O)=O)c2cc1)=O)=O)=O)=O)=O)O YSWFXKKDKNCPPW-UHFFFAOYSA-N 0.000 description 2

- SGBYRRAMVXCDBS-UHFFFAOYSA-N CC(COC(c(cc1)ccc1-c(cc1)ccc1C(OCC(C)O)=O)=O)O Chemical compound CC(COC(c(cc1)ccc1-c(cc1)ccc1C(OCC(C)O)=O)=O)O SGBYRRAMVXCDBS-UHFFFAOYSA-N 0.000 description 2

- JLWGDDMGHDXVCL-UHFFFAOYSA-N CC(COC(c(ccc1c2)cc1ccc2C(OC(C)CO)=O)=O)O Chemical compound CC(COC(c(ccc1c2)cc1ccc2C(OC(C)CO)=O)=O)O JLWGDDMGHDXVCL-UHFFFAOYSA-N 0.000 description 2

Images

Classifications

-

- G—PHYSICS

- G02—OPTICS

- G02B—OPTICAL ELEMENTS, SYSTEMS OR APPARATUS

- G02B1/00—Optical elements characterised by the material of which they are made; Optical coatings for optical elements

- G02B1/10—Optical coatings produced by application to, or surface treatment of, optical elements

- G02B1/14—Protective coatings, e.g. hard coatings

-

- C—CHEMISTRY; METALLURGY

- C08—ORGANIC MACROMOLECULAR COMPOUNDS; THEIR PREPARATION OR CHEMICAL WORKING-UP; COMPOSITIONS BASED THEREON

- C08F—MACROMOLECULAR COMPOUNDS OBTAINED BY REACTIONS ONLY INVOLVING CARBON-TO-CARBON UNSATURATED BONDS

- C08F232/00—Copolymers of cyclic compounds containing no unsaturated aliphatic radicals in a side chain, and having one or more carbon-to-carbon double bonds in a carbocyclic ring system

- C08F232/08—Copolymers of cyclic compounds containing no unsaturated aliphatic radicals in a side chain, and having one or more carbon-to-carbon double bonds in a carbocyclic ring system having condensed rings

-

- C—CHEMISTRY; METALLURGY

- C08—ORGANIC MACROMOLECULAR COMPOUNDS; THEIR PREPARATION OR CHEMICAL WORKING-UP; COMPOSITIONS BASED THEREON

- C08F—MACROMOLECULAR COMPOUNDS OBTAINED BY REACTIONS ONLY INVOLVING CARBON-TO-CARBON UNSATURATED BONDS

- C08F32/00—Homopolymers and copolymers of cyclic compounds having no unsaturated aliphatic radicals in a side chain, and having one or more carbon-to-carbon double bonds in a carbocyclic ring system

- C08F32/08—Homopolymers and copolymers of cyclic compounds having no unsaturated aliphatic radicals in a side chain, and having one or more carbon-to-carbon double bonds in a carbocyclic ring system having two condensed rings

-

- G—PHYSICS

- G02—OPTICS

- G02B—OPTICAL ELEMENTS, SYSTEMS OR APPARATUS

- G02B5/00—Optical elements other than lenses

- G02B5/30—Polarising elements

- G02B5/3025—Polarisers, i.e. arrangements capable of producing a definite output polarisation state from an unpolarised input state

- G02B5/3033—Polarisers, i.e. arrangements capable of producing a definite output polarisation state from an unpolarised input state in the form of a thin sheet or foil, e.g. Polaroid

-

- G—PHYSICS

- G02—OPTICS

- G02F—OPTICAL DEVICES OR ARRANGEMENTS FOR THE CONTROL OF LIGHT BY MODIFICATION OF THE OPTICAL PROPERTIES OF THE MEDIA OF THE ELEMENTS INVOLVED THEREIN; NON-LINEAR OPTICS; FREQUENCY-CHANGING OF LIGHT; OPTICAL LOGIC ELEMENTS; OPTICAL ANALOGUE/DIGITAL CONVERTERS

- G02F1/00—Devices or arrangements for the control of the intensity, colour, phase, polarisation or direction of light arriving from an independent light source, e.g. switching, gating or modulating; Non-linear optics

- G02F1/01—Devices or arrangements for the control of the intensity, colour, phase, polarisation or direction of light arriving from an independent light source, e.g. switching, gating or modulating; Non-linear optics for the control of the intensity, phase, polarisation or colour

- G02F1/13—Devices or arrangements for the control of the intensity, colour, phase, polarisation or direction of light arriving from an independent light source, e.g. switching, gating or modulating; Non-linear optics for the control of the intensity, phase, polarisation or colour based on liquid crystals, e.g. single liquid crystal display cells

- G02F1/133—Constructional arrangements; Operation of liquid crystal cells; Circuit arrangements

- G02F1/1333—Constructional arrangements; Manufacturing methods

- G02F1/1335—Structural association of cells with optical devices, e.g. polarisers or reflectors

- G02F1/133528—Polarisers

-

- G—PHYSICS

- G02—OPTICS

- G02F—OPTICAL DEVICES OR ARRANGEMENTS FOR THE CONTROL OF LIGHT BY MODIFICATION OF THE OPTICAL PROPERTIES OF THE MEDIA OF THE ELEMENTS INVOLVED THEREIN; NON-LINEAR OPTICS; FREQUENCY-CHANGING OF LIGHT; OPTICAL LOGIC ELEMENTS; OPTICAL ANALOGUE/DIGITAL CONVERTERS

- G02F2201/00—Constructional arrangements not provided for in groups G02F1/00 - G02F7/00

- G02F2201/50—Protective arrangements

Definitions

- the present invention relates to an optical film having a hard coat layer on at least one surface of a film substrate, a polarizing plate having the optical film and a manufacturing method thereof, an image display device having the polarizing plate, and a manufacturing method thereof. It is.

- a polarizing plate used in an image display device such as a liquid crystal display device (LCD).

- LCD liquid crystal display device

- a hard coat layer that is cured by irradiation with active energy rays on a film substrate such as a cellulose ester film and arrange it as a polarizing plate protective film.

- the cellulose ester film may contain a specific organic acid, a specific phenol compound, or a specific polymer containing a benzene ring in the main chain. It is known to add (for example, refer to Patent Document 2).

- a transparent protective part made of glass or plastic is provided from the viewpoint of improving mechanical strength and designability.

- a gap layer exists between the polarizing plate protective film on the surface of the liquid crystal display panel and the protective part, light reflection or reflection at the interface between the liquid crystal display panel and the gap layer or between the protective part and the gap layer may occur.

- the contrast and brightness decrease due to scattering.

- a technique for avoiding the above inconvenience by filling the gap layer with a filler such as a photocurable resin for example, see Patent Document 3).

- a film base material with a hindered amine compound, a specific organic acid, a specific phenol compound, or a specific polymer containing a benzene ring in the main chain hereinafter these are collectively referred to as a compound or the like.

- a compound or the like Is added to the hard coat layer of the polarizing plate protective film, and a specific system in which a protective part is provided via the filling layer, a compound or the like diffuses from the film substrate to the filling layer, and a radical of the compound or the like.

- a new problem has been discovered in which unevenness of curing of the resin occurs in the filling layer due to the trapping action, thereby causing poor adhesion between the protective portion and the filling layer, and in turn causing poor display (display unevenness).

- the present invention has been made in order to solve the above-described problems, and the object thereof is to provide a non-uniform curing of the filling layer and a display thereby when a protective part is provided on the hard coat layer via the filling layer.

- the optical film capable of suppressing the diffusion of the compound contained in the film substrate to the hard coat layer surface, the polarizing plate having the optical film, the production method thereof, and the polarizing plate are provided.

- An object of the present invention is to provide an image display device and a manufacturing method thereof.

- An optical film according to one aspect of the present invention is an optical film having a hard coat layer on at least one surface of a film substrate,

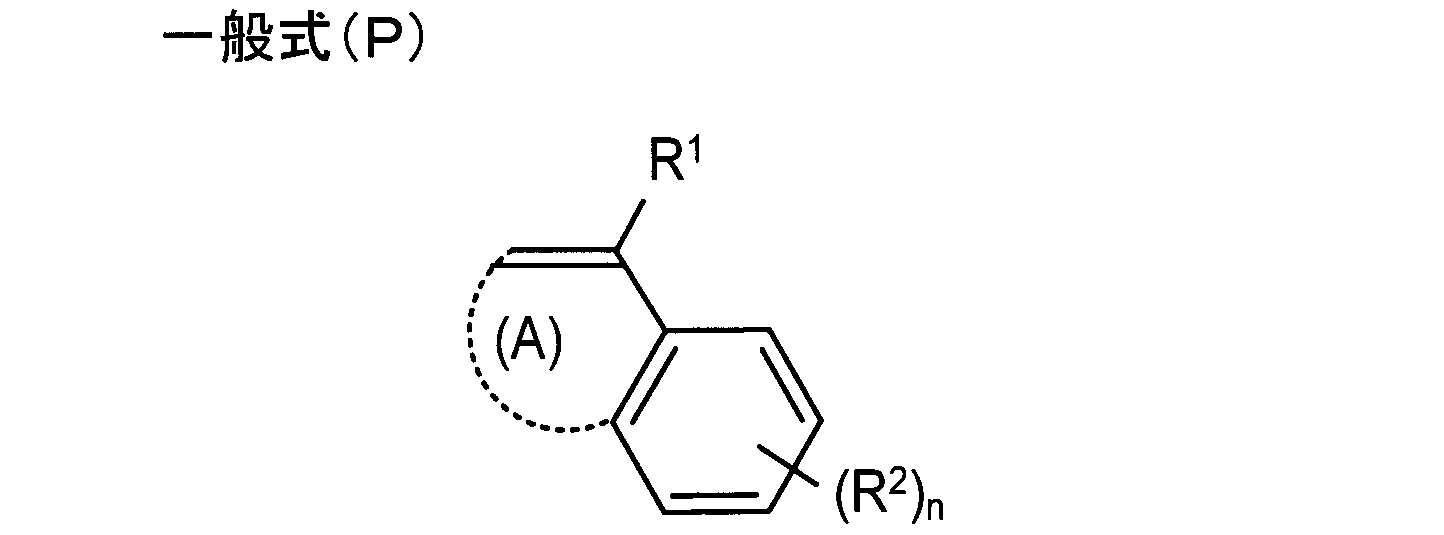

- the film substrate includes a hindered amine compound, a polymer containing a repeating unit derived from a monomer represented by the following general formula (P), an organic acid represented by the following general formula (Q), and the following general formula (S). Containing at least one of the compounds represented by:

- the hard coat layer has a surface free energy of 30 mN / m or more after alkali treatment.

- R 1 represents a hydrogen atom or an aliphatic group having 1 to 4 carbon atoms.

- R 2 represents a substituent.

- (A) is necessary for forming a 5- or 6-membered ring.

- R 26 represents an aryl group

- R 27 and R 28 each independently represents a hydrogen atom, an alkyl group, or an aryl group.

- R 1 represents a hydrogen atom or a substituent

- R 2 represents a substituent represented by the following general formula (a).

- N1 represents an integer of 0 to 4, and n1 is 2

- a plurality of R 1 may be the same or different from each other

- n2 represents an integer of 1 to 5

- a plurality of R 2 may be the same or different from each other May be.

- A represents a substituted or unsubstituted aromatic ring

- R 3 and R 4 are each independently a hydrogen atom, an alkyl group having 1 to 5 carbon atoms, or the following general formula (b

- R 5 represents a single bond or an alkylene group having 1 to 5 carbon atoms

- X represents a substituted or unsubstituted aromatic ring

- n3 represents an integer of 0 to 10

- the plurality of R 5 and X may be the same or different.

- X represents a substituted or unsubstituted aromatic ring

- R 6 , R 7 , R 8 , and R 9 are each independently a hydrogen atom or an alkyl having 1 to 5 carbon atoms.

- N5 represents an integer of 1 to 11, and when n5 is 2 or more, a plurality of R 6 , R 7 , R 8 and X may be the same or different. It is.

- the hard coat layer of the optical film is hydrophilized with a surface free energy of 30 mN / m or more, the hindered amine compound contained in the film base material diffuses to the hard coat layer side in this hydrophilized state. Even so, the compound and the like can be trapped in the hydrophilic portion of the hard coat layer. That is, diffusion of the compound or the like to the hard coat layer surface can be suppressed.

- FIG. 1 is a cross-sectional view illustrating a schematic configuration of an image display device according to an embodiment of the present invention. It is a top view which shows typically the structure of the outline of the manufacturing apparatus of the diagonally stretched film used by the said embodiment. It is a top view which shows typically an example of the rail pattern of the extending

- the inventors of the present application have studied various methods for improving the curing unevenness of the filled layer when an optical film (polarizing plate protective film) containing a hindered amine compound or the like is used.

- the hard coat layer on the polarizer protective film is hydrophilized so that the surface free energy is 30 mN / m or more, so that the compound diffused from the film substrate is trapped in the hard coat layer, and then filled into the filling layer. It was found that preventing the spread of Thereby, it is possible to provide a filling layer on the polarizing plate protective film without causing uneven curing, poor adhesion between the protective part and the filling layer, and poor appearance or display failure of the image display device due to uneven curing. Etc. could be prevented.

- the image display apparatus of this embodiment will be described.

- FIG. 1 is a cross-sectional view illustrating a schematic configuration of an image display device 1 according to the present embodiment.

- the image display device 1 is configured by attaching a protective part 3 to a polarizing plate 5 (particularly on an optical film 15 described later) of the liquid crystal display panel 2 via a filling layer 31.

- the filling layer 31 is an adhesive layer (void filler) made of a photocurable resin such as acrylic, and is formed on the entire surface of the polarizing plate 5 of the liquid crystal display panel 2.

- the protection unit 3 protects the surface of the liquid crystal display panel 2 and is formed of a front plate made of acrylic resin or glass, for example.

- a touch panel (such as a capacitance method or a resistance film method) may be used as the protection unit 3 instead of the front plate.

- the liquid crystal display panel 2 is configured by disposing polarizing plates 5 and 6 on both sides of a liquid crystal cell 4 (display cell) in which a liquid crystal layer is sandwiched between a pair of substrates.

- the polarizing plate 5 is attached to one surface side (for example, the viewing side) of the liquid crystal cell 4 via the adhesive layer 7.

- the polarizing plate 6 is attached to the other surface side (for example, the backlight 9 side) of the liquid crystal cell 4 through the adhesive layer 8.

- the driving method of the liquid crystal display panel 2 is not particularly limited, and various driving methods such as an IPS (In Plane Switching) type and a TN (Twisted Nematic) method can be employed.

- the polarizing plate 5 includes a polarizer 11 that transmits predetermined linearly polarized light, a film base 12 and a hard coat layer 13 that are sequentially laminated on the protective portion 3 side of the polarizer 11, and a liquid crystal cell 4 side of the polarizer 11. It is comprised with the optical film 14 laminated

- the film base 12 and the hard coat layer 13 constitute an optical film 15 as a protective film formed on the surface on the viewing side of the polarizer 11.

- the film substrate 12 is made of, for example, a cellulose ester film, but is not limited to this cellulose ester film.

- the optical film 14 is provided to protect the back surface of the polarizing plate 5.

- the optical film 14 may be made of the same material as the film substrate 12 (for example, cellulose ester) or may be made of other materials.

- the film substrate 12 may be composed of a ⁇ / 4 film.

- the ⁇ / 4 film is a layer that imparts an in-plane retardation of about 1 ⁇ 4 of the wavelength to transmitted light, and in the present embodiment, the ⁇ / 4 film is composed of a film that has been subjected to oblique stretching described later.

- the angle (crossing angle) formed between the slow axis of the ⁇ / 4 film and the absorption axis of the polarizer 11 is 30 ° to 60 °, whereby the linearly polarized light from the polarizer 11 is converted into the ⁇ / 4 film ( It is converted into circularly polarized light or elliptically polarized light by the film substrate 12).

- the polarizing plate can be used regardless of how the transmission axis of the polarizer 11 (perpendicular to the absorption axis) and the transmission axis of the polarized sunglasses are misaligned.

- the light component parallel to the transmission axis of the polarized sunglasses contained in the light emitted from 5 (circularly polarized light or elliptically polarized light) can be guided to the eyes of the observer. Thereby, it can suppress that it becomes difficult to see a display image with the angle to observe.

- the film substrate 12 may contain a hindered amine compound.

- the optical film 15 in which the hard coat layer 13 is formed on the film substrate 12 is bonded (UV bonded) to the polarizer 11 by, for example, ultraviolet irradiation. By this UV irradiation, the film substrate 12 and the hard coat layer are bonded. 13 (light-resistant adhesion) may deteriorate. However, when the film base 12 contains a hindered amine compound, the above light-resistant adhesion can be improved.

- the film substrate 12 includes a specific organic acid, a specific phenol compound, or a specific polymer containing a benzene ring in the main chain. May be contained.

- the polarizing plate 6 includes a polarizer 21 that transmits predetermined linearly polarized light, an optical film 22 that is disposed on the liquid crystal cell 4 side of the polarizer 21, and an optical that is disposed on the opposite side of the polarizer 21 from the liquid crystal cell 4.

- the film 23 is laminated.

- the polarizer 21 is disposed so that the transmission axis is perpendicular to the polarizer 11 (crossed Nicol state).

- the optical films 22 and 23 are provided to protect the front and back surfaces of the polarizing plate 6, but they may be made of the same material (for example, cellulose ester) as the film substrate 12 of the polarizing plate 5. However, it may be composed of other materials.

- the above-described optical film 15 can be used for purposes other than the polarizing plate.

- the hard coat layer 13 may be provided on both surfaces of the film substrate 12. Therefore, in the optical film 15, it can be said that the hard coat layer 13 may be formed on at least one surface of the film substrate 12.

- the hard coat layer 13 of the optical film 15 is a layer having a surface free energy of 30 mN / m or more.

- the surface free energy of the hard coat layer 13 is a polar component a (mN / m), a hydrogen bond component b (mN / m), and a dispersion component c (mN / m) of the surface free energy of the hard coat layer 13. Refers to the sum of In addition, the calculation method of these components is mentioned later.

- the hard coat layer 13 is hydrophilized with a surface free energy of 30 mN / m or more. In this hydrophilized state, even if a hindered amine compound or the like contained in the film substrate 12 is diffused to the hard coat layer 13 side, the compound or the like can be trapped in the hydrophilized portion of the hard coat layer 13. it can. That is, the diffusion of the compound or the like to the hard coat layer 13 surface can be suppressed.

- the diffusion of the compound or the like in the film substrate 12 to the filling layer 31 is suppressed.

- production of the nonuniformity of hardening can be suppressed in the filling layer 31, and the adhesion failure of the protection part 3 and the filling layer 31 by this hardening nonuniformity can be suppressed.

- the surface free energy of the hard coat layer 13 is 40 mN / m or more from the viewpoint of easily obtaining the target effect of the present embodiment.

- the hard coat layer 13 is preferably subjected to an alkali treatment under the following alkaline conditions.

- Alkali treatment conditions Alkaline solution: 2 mol / L sodium hydroxide solution Treatment temperature: 50 ° C Processing time: 120 seconds

- the surface free energy of the hard coat layer 13 can be increased by increasing the content of fine particles, which will be described later. However, if the fine particles are contained to exceed 100 mN / m, the transparency and water resistance of the hard coat layer 13 are increased. Decreases. For this reason, the surface free energy of the hard coat layer 13 is preferably 100 mN / m or less.

- the hard coat layer 13 contains fine particles, and above all, it is desirable that the hard coat layer 13 contains fine particles coated with a polymer silane coupling agent.

- the surface free energy of the hard coat layer 13 can be easily realized as 30 mN / m or more.

- the concentration of the polymer silane coupling agent-coated fine particles on the surface of the hard coat layer 13 is larger than the concentration of the polymer silane coupling agent-coated fine particles in the entire hard coat layer 13.

- the concentration of the polymer silane coupling agent-coated fine particles on the surface of the hard coat layer 13 may be a concentration at a portion of the hard coat layer 13 that is 10% or less of the entire thickness of the hard coat layer 13. .

- the optical film 15 is allowed to stand for 12 hours under conditions of a temperature of 23 ° C. and a humidity of 55%, and then contact angles of three types of droplets (pure water, ethylene glycol, diethylene glycol) with respect to the surface of the hard coat layer 13 of the optical film 15.

- ( ⁇ ) is measured under the conditions of a temperature of 23 ° C. and a humidity of 55% using a product name Drop Master DM100 manufactured by Kyowa Interface Science Co., Ltd.

- the measurement of the contact angle of each droplet is performed 5 times, and the average value thereof is used.

- the dispersion component ⁇ L d, the polar component ⁇ L p, and the hydrogen bond component ⁇ L h of the surface free energy of the three types of droplets are described in Japan Adhesion Association Vol. 15, no. 3, the numerical value described in p96 is used.

- the difference ⁇ in the contact angle of water before and after the alkali treatment in the hard coat layer 13 is desirably 10 ° or more, and more preferably 20 ° or more. desirable.

- the contact angle difference ⁇ is desirably 55 ° or less.

- the difference ⁇ in the contact angle before and after the alkali treatment will be described.

- the difference ⁇ (°) in the water contact angle before and after the alkali treatment is alkali-treated under the following conditions at least from the water contact angle ⁇ a (°) before the alkali treatment of the hard coat layer 13 of the optical film 15. This is a value obtained by subtracting the water contact angle ⁇ b (°) of the hard coat layer 13 after the heat treatment.

- the alkali treatment conditions are conditions in which the optical film 15 is immersed in a 2 mol / L sodium hydroxide solution at 50 ° C. for 60 seconds.

- the water contact angle is a value obtained by averaging the measured values after performing the measurement for 5 times using the contact angle meter described above after standing for 12 hours under the conditions of 23 ° C. and 55% RH.

- the surface free energy of the hard coat layer 13 is increased after the alkali treatment, the adhesion at the interface between the filling layer 31 (photocurable resin) and the hard coat layer 13 is increased, and the interlayer adhesion after the durability test is excellent. It is done. Moreover, it is a preferable aspect in this embodiment that a water contact angle falls after alkali treatment.

- the alkali treatment in the present embodiment includes a step of rinsing at least the optical film 15 in an alkali solution (hereinafter also referred to as a saponification step) and then washing and drying, and the conditions for the alkali treatment are the above-described conditions. Further, after the alkali treatment, neutralization in an acidic water step may be performed, followed by washing with water and drying.

- an alkali solution hereinafter also referred to as a saponification step

- neutralization in an acidic water step may be performed, followed by washing with water and drying.

- the difference ⁇ in the contact angle of water before and after the alkali treatment satisfies the above range. Can be adjusted as follows.

- the hard coat layer may be surface-modified.

- the surface modification method include plasma irradiation treatment, corona irradiation treatment, solvent treatment and the like. These surface modification methods may be performed singly or in combination.

- the hard coat layer of the present embodiment is a layer composed mainly of a resin. Specifically, it is preferable to contain an actinic radiation curable resin from the viewpoint of excellent mechanical film strength (abrasion resistance, pencil hardness). That is, it is a layer mainly composed of a resin that is cured through a crosslinking reaction by irradiation with active rays (also called active energy rays) such as ultraviolet rays and electron beams.

- active rays also called active energy rays

- an actinic radiation curable resin a component containing a monomer having an ethylenically unsaturated double bond is preferably used, and an actinic radiation curable resin layer is formed by curing by irradiation with actinic radiation such as ultraviolet rays or electron beams.

- Typical examples of the actinic radiation curable resin include an ultraviolet curable resin and an electron beam curable resin, but a resin curable by ultraviolet irradiation is particularly excellent in mechanical film strength (abrasion resistance, pencil hardness). It is preferable from the point.

- the ultraviolet curable resin include an ultraviolet curable acrylate resin, an ultraviolet curable urethane acrylate resin, an ultraviolet curable polyester acrylate resin, an ultraviolet curable epoxy acrylate resin, an ultraviolet curable polyol acrylate resin, and an ultraviolet curable resin.

- a curable epoxy resin or the like is preferably used, and an ultraviolet curable acrylate resin is particularly preferable.

- polyfunctional acrylate is preferable.

- the polyfunctional acrylate is preferably selected from the group consisting of pentaerythritol polyfunctional acrylate, dipentaerythritol polyfunctional acrylate, pentaerythritol polyfunctional methacrylate, and dipentaerythritol polyfunctional methacrylate.

- the polyfunctional acrylate is a compound having two or more acryloyloxy groups or methacryloyloxy groups in the molecule.

- the polyfunctional acrylate monomer include ethylene glycol diacrylate, diethylene glycol diacrylate, 1,6-hexanediol diacrylate, neopentyl glycol diacrylate, trimethylolpropane triacrylate, trimethylolethane triacrylate, and tetramethylolmethane triacrylate.

- the hard coat layer of the optical film may contain a polybasic acidic acrylate.

- polybasic acidic acrylates include dipentaerythritol pentaacrylate succinic acid modification, pentaerythritol triacrylate succinic acid modification, dipentaerythritol pentaacrylate phthalic acid modification, pentaerythritol triacrylate phthalic acid modification, polybasic acid modified acrylic An oligomer etc. can be mentioned.

- Examples of commercially available products include Aronix M-510, Aronix M-520 (manufactured by Toagosei Co., Ltd.), DPE6A-MS, PE3A-MP, DPE6A-MP, PE3A-MP (manufactured by Kyoeisha Chemical Co., Ltd.) and the like.

- the content is preferably 30% or more by mass ratio, more preferably 50% or more by mass ratio, assuming that the resin component forming the hard coat layer film is 100.

- Adekaoptomer N series Sun Rad H-601, RC-750, RC-700, RC-600, RC-500, RC-611, RC-612 (Sanyo Chemical Industries ( Alonix M-6100, M-8030, M-8060, Aronix M-215, Aronix M-315, Aronix M-313, Aronix M-327 (manufactured by Toagosei Co., Ltd.), NK-Ester A -TMM-3L, NK-ester AD-TMP, NK-ester ATM-35E, NK ester A-DOG, NK ester A-IBD-2E, A-9300, A-9300-1CL (Shin Nakamura Chemical Co., Ltd.) ), PE-3A (Kyoeisha Chemical) and the like.

- Adekaoptomer N series Sun Rad H-601, RC-750, RC-700, RC-600, RC-500, RC-611, RC-612 (Sanyo Chemical

- the actinic radiation curable resins may be used alone or in combination of two or more.

- a monofunctional acrylate may be used.

- Monofunctional acrylates include isobornyl acrylate, 2-hydroxy-3-phenoxypropyl acrylate, isostearyl acrylate, benzyl acrylate, ethyl carbitol acrylate, phenoxyethyl acrylate, lauryl acrylate, isooctyl acrylate, tetrahydrofurfuryl acrylate, behenyl Examples thereof include acrylate, 4-hydroxybutyl acrylate, 2-hydroxyethyl acrylate, 2-hydroxypropyl acrylate, and cyclohexyl acrylate.

- Such monofunctional acrylates can be obtained from Nippon Kasei Kogyo Co., Ltd., Shin-Nakamura Chemical Co., Ltd., Osaka Organic Chemical Co., Ltd., etc.

- the hard coat layer preferably contains a photopolymerization initiator to accelerate the curing of the actinic radiation curable resin.

- Specific examples of the photopolymerization initiator include alkylphenone series, acetophenone, benzophenone, hydroxybenzophenone, Michler's ketone, ⁇ -amyloxime ester, thioxanthone and the like, and derivatives thereof. It is not something.

- Commercially available products may be used as the photopolymerization initiator, and preferred examples include Irgacure 184, Irgacure 907, and Irgacure 651 manufactured by BASF Japan.

- the hard coat layer contains fine particles because the surface free energy of the hard coat layer after the alkali treatment can be increased.

- a hard-coat layer As a microparticle, A silica, an alumina, a zirconia, a titanium oxide, an antimony pentoxide etc. are mentioned, Preferably it is a silica.

- the silica fine particles may be hollow particles having cavities inside.

- the hard coat layer contains fine particles formed by coating with a polymer silane coupling agent, which can exhibit good performance particularly with respect to adhesion after a durability test.

- the polymer silane coupling agent refers to a reaction product of a polymerizable monomer and a silane coupling agent (silane compound).

- a polymer silane coupling agent can be obtained, for example, according to the method for producing a reaction product of a polymerizable monomer and a reactive silane compound disclosed in JP-A-11-116240.

- polymerizable monomer examples include (meth) acrylic acid, methyl (meth) acrylate, ethyl (meth) acrylate, (meth) acrylic acid-n-propyl, (meth) acrylic acid isopropyl, (meth) -N-butyl, isobutyl (meth) acrylate, (meth) acrylic acid-n-hexyl, (meth) acrylic acid cyclohexyl, (meth) acrylic acid-n-heptyl, (meth) acrylic acid-n-octyl, ( 2-ethylhexyl (meth) acrylate, nonyl (meth) acrylate, decyl (meth) acrylate, dodecyl (meth) acrylate, phenyl (meth) acrylate, toluyl (meth) acrylate, benzyl (meth) acrylate , 2-methoxyethyl (meth) acrylate

- (Meth) acryl means acryl or methacryl

- (meth) acrylate means acrylate or methacrylate.

- an organosilicon compound represented by the following formula (1) is preferably used as the reactive silane compound.

- XR-Si (OR) 3 (1) (In the formula, R represents an organic group having 1 to 10 carbon atoms selected from a substituted or unsubstituted hydrocarbon group.

- X represents a (meth) acryloyl group, an epoxy group (glycid group), a urethane group, an amino group, One or more functional groups selected from fluoro groups.)

- organosilicon compound represented by the formula (1) examples include 3,3,3-trifluoropropyltrimethoxysilane, methyl-3,3,3-trifluoropropyldimethoxysilane, ⁇ - (3, 4-epoxycyclohexyl) ethyltrimethoxysilane, ⁇ -glycidoxymethyltrimethoxysilane, ⁇ -glycidoxymethyltriethoxysilane, ⁇ -glycidoxyethyltrimethoxysilane, ⁇ -glycidoxyethyltriethoxysilane, ⁇ -glycidoxypropyltrimethoxysilane, ⁇ -glycidoxypropyltrimethoxysilane, ⁇ -glycidoxypropyltrimethoxysilane, ⁇ -glycidoxypropyltriethoxysilane, ⁇ -glycidoxypropyltriethoxysilane, ⁇ -glycidoxypropyltrie

- Polymeric silane coupling agent is prepared by reacting a polymerizable monomer with a reactive silane compound. Specifically, an organic solvent solution in which a reactive silane compound is mixed in an amount of 0.5 to 20 parts by weight, further 1 to 10 parts by weight with respect to 100 parts by weight of the polymerizable monomer is prepared, and polymerization is started. It can be obtained by adding an agent and heating.

- organic solvent examples include aromatic hydrocarbons such as benzene, toluene and xylene, esters such as ethyl acetate and ethylene glycol monomethyl ether, ketones such as acetone, methyl ethyl ketone and methyl isobutyl ketone, and ethers such as tetrahydrofuran and dioxane. , Alcohols such as methanol and isopropanol, and halogenated hydrocarbons such as chloroform. These can also be mixed and used.

- the total concentration of the polymerizable monomer and the reactive silane compound is preferably in the range of 1 to 40% by weight, more preferably 2 to 30% by weight as the solid content.

- Polymerization initiators include azoisobutyl nitrile, lauroyl peroxide, benzoyl peroxide, di-t-butyl peroxide, t-butylperoxy-2-ethylhexinoate, t-butylperoxyisobutyrate, t- Peroxide polymerization initiators such as butyl peroxypivalate, t-butyl peroxybenzoate, t-butyl peroxyacetate, 2,2-azobisisobutyronitrile, 2,2-azobis (2,4-dimethyl) And azo compounds such as 2,2-azobis (4-methoxy-2,4-dimethylvaleronitrile).

- the reaction temperature is preferably in the range of 30 to 100 ° C, more preferably 50 to 95 ° C. If the reaction temperature is low, the reaction is slow and it may take too long to prepare a polymeric silane coupling agent with a large molecular weight. On the other hand, if the reaction temperature is too high, the reaction rate may be too high and the desired molecular weight may not be controlled.

- the molecular weight of the polymer silane coupling agent is preferably in the range of 2,500 to 150,000, more preferably 2,000 to 100,000 in terms of polystyrene.

- the thickness of the coating layer of the polymer silane coupling agent is preferably 1 to 10 nm, more preferably 1 to 5 nm. If the coating layer is thin, dispersibility of the fine particles in the matrix component may be insufficient. Moreover, when the coating layer is too thick, there is a problem that productivity is lowered.

- the content of the coating layer in the polymer silane coupling agent-coated fine particles is preferably in the range of 0.5 to 20% by weight, more preferably 1 to 15% by weight as the solid content.

- the polymer silane coupling agent-coated fine particles can be prepared by adding a polymer silane coupling agent to a fine particle organic solvent dispersion and coating the fine particles with the polymer silane coupling agent in the presence of an alkali.

- Organic solvents include methanol, ethanol, propanol, 2-propanol (IPA), butanol, diacetone alcohol, furfuryl alcohol, tetrahydrofurfuryl alcohol, ethylene glycol, hexylene glycol, isopropyl glycol and other alcohols; acetic acid methyl ester , Esters such as ethyl acetate, butyl acetate; ethers such as diethyl ether, ethylene glycol monomethyl ether, ethylene glycol monoethyl ether, ethylene glycol monobutyl ether, diethylene glycol monomethyl ether, diethylene glycol monoethyl ether, propylene glycol monomethyl ether; acetone , Methyl ethyl ketone, methyl isobutyl ketone, acetylacetone Ketones such as acetoacetate, methyl cellosolve, ethyl cellosolve, butyl cellosolve, to

- the total concentration of the fine particles and the polymer silane coupling agent in the dispersion is preferably 1 to 30% by weight, more preferably 2 to 25% by weight as the solid content.

- ⁇ Alkali is added to the dispersion to adsorb the polymer silane coupling agent to the fine particles.

- an alkali By adding an alkali, the surface of the fine particles is activated (generation of OH groups), and the affinity between the polymer silane coupling agent and the fine particles is increased and bonded.

- the dehydration reaction between the OH group of the polymer silane coupling agent and the OH group of the fine particles is promoted to promote bonding.

- basic nitrogen compounds such as ammonia and amines are used as the alkali.

- a basic nitrogen compound is preferable in that the adsorption and bonding of the polymer silane coupling agent to the fine particles are promoted and the amount of the unadsorbed polymer silane coupling agent is small.

- the amount of alkali used varies depending on the type of metal oxide particles, the average particle size, etc., but is in the range of 0.001 to 0.2 parts by weight, more preferably 0.005 to 0.1 parts by weight of the fine particles. Is preferred.

- the polymer silane coupling agent-coated fine particles can be obtained by separating and drying the fine particles adsorbed with the polymer silane coupling agent.

- the average particle size of the obtained polymer silane coupling agent-coated fine particles is preferably 5 to 500 nm, more preferably 10 to 200 nm, from the viewpoint of securing optical properties when used for an optical film.

- the content of the polymer silane coupling agent-coated fine particles in the hard coat layer is 0.5 to 80 parts by mass, more preferably 1 to 60 parts by mass as a solid content. To preferred.

- the hard coat layer may contain a conductive agent in order to impart antistatic properties.

- Preferred conductive agents include metal oxide particles or ⁇ -conjugated conductive polymers.

- An ionic liquid is also preferably used as the conductive compound.

- the hard coat layer may contain a fluorine-siloxane graft compound, a fluorine compound, a silicone compound, or a compound having an HLB value of 3 to 18 from the viewpoint of improving the coatability.

- the hydrophilicity can be easily controlled by adjusting the types and amounts of these additives.

- the HLB value is Hydrophile-Lipophile-Balance, that is, a hydrophilic-lipophilic balance, and is a value indicating the hydrophilicity or lipophilicity of a compound.

- the HLB value can be obtained by the following calculation formula.

- HLB 7 + 11.7Log (Mw / Mo)

- Mw represents the molecular weight of the hydrophilic group

- Mo represents the molecular weight of the lipophilic group

- Mw + Mo M (molecular weight of the compound).

- HLB value 20 ⁇ total formula weight of hydrophilic part / molecular weight (J. Soc. Cosmetic Chem., 5 (1954), 294) and the like.

- Emulgen 102KG (6.3), Emulgen 103 (8.1), Emulgen 104P (9.6), Emulgen 105 (9.7), Emulgen 106 (10.5), Emulgen 108 (12. 1), Emulgen 109P (13.6), Emulgen 120 (15.3), Emulgen 123P (16.9), Emulgen 147 (16.3), Emulgen 210P (10.7), Emulgen 220 (14.2) , Emulgen 306P (9.4), Emulgen 320P (13.9), Emulgen 404 (8.8), Emulgen 408 (10.0), Emulgen 409PV (12.0), Emulgen 420 (13.6), Emulgen 430 (16.2), Emulgen 705 (10.5), Emulgen 707 (12.1), Emulgen 09 (13.3), Emulgen 1108 (13.5), Emulgen 1118S-70 (16.4), Emulgen 1135S-70 (17.9), Emulgen 2020G-HA (13.0), Emulgen 2025G (15.

- Emulgen LS-106 (12.5), Emulgen LS-110 (13.4), Emulgen LS-114 (14.0), manufactured by Nissin Chemical Industry Co., Ltd .: Surfynol 104E (4), Surfynol 104H (4), Surfinol 104A (4), Surfinol 104BC (4), Surfinol 104DPM (4), Surfinol 104PA (4), Surfinol 104PG-50 (4), Surfinol 104S (4), Surfi Knoll 420 (4), Surfynol 440 (8), Surfynol 4 5 (13), Surfynol 485 (17), Surfynol SE (6), Shin-Etsu Chemical Co., Ltd.: X-22-4272 (7), X-22-6266 (8).

- the fluorine-siloxane graft compound refers to a copolymer compound obtained by grafting polysiloxane and / or organopolysiloxane containing siloxane and / or organosiloxane alone on at least a fluorine resin.

- a fluorine-siloxane graft compound can be prepared by a method as described in Examples described later.

- examples of commercially available products include ZX-022H, ZX-007C, ZX-049, and ZX-047-D manufactured by Fuji Chemical Industry Co., Ltd.

- fluorine-based compound examples include Megafac series (F-477, F-487, F-569, etc.) manufactured by DIC Corporation, OPTOOL DSX, OPTOOL DAC, etc. manufactured by Daikin Industries, Ltd.

- silicone compounds are Shin-Etsu Chemical Co., Ltd .: KF-351, KF-352, KF-353, KF-354L, KF-355A, KF-615A, KF-945, KF-618, KF-6011, KF. -6015, KF-6004, manufactured by BYK Japan, Inc .: BYK-UV3576, BYK-UV3535, BYK-UV3510, BYK-UV3505, BYK-UV3500, and the like. These components are preferably added in the range of 0.005 parts by mass or more and 10 parts by mass or less with respect to the solid component in the hard coat layer composition. Two or more kinds of these components may be added as long as the total additive amount is in the range of 0.005 parts by mass or more and 10 parts by mass or less.

- a hard-coat layer may further contain the ultraviolet absorber demonstrated by the cellulose-ester film mentioned later.

- the hard coat layer in contact with the film substrate contains the ultraviolet absorber.

- the film thickness of the hard coat layer in contact with the film substrate is preferably in the range of 0.05 to 2 ⁇ m.

- Two or more layers may be formed as a simultaneous multilayer.

- the simultaneous multi-layering is to form a hard coat layer by applying two or more hard coat layers on a base material without going through a drying step.

- the layers are stacked one after another by an extrusion coater or with a slot die having a plurality of slits. Simultaneous layering may be performed.

- the hard coat layer is formed by diluting the above-described components forming the hard coat layer with a solvent that swells or partially dissolves the film base material, and is applied onto the film base material as follows. It is preferable to provide by drying and curing.

- Solvents include ketones (methyl ethyl ketone, acetone, etc.) and / or acetate esters (methyl acetate, ethyl acetate, butyl acetate, etc.), alcohols (ethanol, methanol, normal propanol, isopropanol), propylene glycol monomethyl ether, cyclohexanone, methyl isobutyl ketone. Etc. are preferable.

- the coating amount of the hard coat layer composition is suitably an amount that results in a wet film thickness of 0.1 to 80 ⁇ m, and preferably an amount that results in a wet film thickness of 0.5 to 30 ⁇ m.

- the dry film thickness is in the range of an average film thickness of 0.01 to 20 ⁇ m, preferably in the range of 1 to 15 ⁇ m. More preferably, it is in the range of 2 to 12 ⁇ m.

- the coating method of the hard coat layer composition may be a known method such as a gravure coater, a dip coater, a reverse coater, a wire bar coater, a die coater, or an ink jet method.

- Hard coat layer forming method After application of the hard coat layer composition, it may be dried and cured (irradiated with active rays (also referred to as UV curing treatment)), and if necessary, may be heat treated after UV curing.

- the heat treatment temperature after UV curing is preferably 80 ° C. or higher, more preferably 100 ° C. or higher, and particularly preferably 120 ° C. or higher.

- Drying is preferably performed at a temperature of 30% or more in the rate of drying section. More preferably, the temperature of the decreasing rate drying section is 50 ° C. or higher.

- drying process changes from a constant state to a gradually decreasing state when drying starts.

- a section in which the drying speed is constant is called a constant rate drying section, and a section in which the drying speed decreases is called a decreasing rate drying section.

- any light source that generates ultraviolet rays can be used without limitation.

- a low pressure mercury lamp, a medium pressure mercury lamp, a high pressure mercury lamp, an ultrahigh pressure mercury lamp, a carbon arc lamp, a metal halide lamp, a xenon lamp, or the like can be used.

- Irradiation conditions vary depending on each lamp, but the irradiation amount of active rays is usually in the range of 50 to 1000 mJ / cm 2 , preferably in the range of 50 to 300 mJ / cm 2 .

- oxygen removal for example, replacement with an inert gas such as nitrogen purge

- the cured state of the surface can be controlled by adjusting the removal amount of the oxygen concentration. This makes it possible to control the presence state of the additive on the hard coat layer surface, and as a result, it is easy to control the contact angle difference ⁇ within the above-described range.

- the tension to be applied is preferably 30 to 300 N / m.

- the method for applying tension is not particularly limited, and tension may be applied in the conveying direction on the back roller, or tension may be applied in the width direction or biaxial direction by a tenter. Thereby, a film having further excellent flatness can be obtained.

- Back coat layer It is preferable to provide a backcoat layer on the surface opposite to the side on which the hard coat layer of the optical film (for example, hard coat film) of the present embodiment is provided.

- the back coat layer is provided to correct curl caused by providing a hard coat layer or other layers by coating or CVD. That is, the degree of curling can be balanced by imparting the property of being rounded with the surface on which the backcoat layer is provided facing inward.

- the back coat layer is preferably applied as an anti-blocking layer. In that case, it is preferable that fine particles are added to the back coat layer coating composition in order to provide an anti-blocking function. .

- This back coat layer may satisfy the above-described conditional expressions (1) and (2).

- examples of inorganic compounds include silicon dioxide, titanium dioxide, aluminum oxide, zirconium oxide, calcium carbonate, calcium carbonate, talc, clay, calcined kaolin, calcined calcium silicate, tin oxide, and oxide. Mention may be made of indium, zinc oxide, ITO, hydrated calcium silicate, aluminum silicate, magnesium silicate and calcium phosphate. Fine particles containing silicon are preferable in terms of low haze, and silicon dioxide is particularly preferable.

- These fine particles are commercially available under the trade names of, for example, Aerosil R972, R972V, R974, R812, 200, 200V, 300, R202, OX50, and TT600 (manufactured by Nippon Aerosil Co., Ltd.). .

- Zirconium oxide fine particles are commercially available, for example, under the trade names Aerosil R976 and R811 (manufactured by Nippon Aerosil Co., Ltd.) and can be used.

- the polymer fine particles include a silicone resin, a fluororesin, and an acrylic resin. Silicone resins are preferable, and those having a three-dimensional network structure are particularly preferable. For example, Tospearl 103, 105, 108, 120, 145, 3120, and 240 (manufactured by Toshiba Silicone Co., Ltd.) It is marketed by name and can be used.

- Aerosil 200V and Aerosil R972V are particularly preferably used because they have a large anti-blocking effect while keeping haze low.

- the optical film (eg, hard coat film) used in this embodiment preferably has a dynamic friction coefficient of 0.9 or less, particularly 0.1 to 0.9, on the back side of the functional layer (eg, hard coat layer). .

- the fine particles contained in the backcoat layer are preferably contained in an amount of 0.1 to 50% by weight, more preferably 0.1 to 10% by weight, based on the binder.

- the increase in haze when the backcoat layer is provided is preferably 1% or less, more preferably 0.5% or less, and particularly preferably 0.0 to 0.1%.

- the back coat layer is preferably formed by applying a composition containing a solvent that dissolves or swells the transparent resin film.

- the solvent to be used may include a solvent to be dissolved and / or a solvent to be swollen in addition to a solvent to be swelled, a composition in which these are mixed at an appropriate ratio depending on the degree of curl of the transparent resin film and the type of resin, and What is necessary is just to form by the application quantity.

- Examples of the solvent for dissolving or swelling the transparent resin film contained in such a mixed composition include dioxane, acetone, methyl ethyl ketone, N, N-dimethylformamide, methyl acetate, ethyl acetate, cyclohexane, diacetone alcohol, 1 , 3-dioxolane, N-methylpyrrolidone, propylene glycol monomethyl ether acetate, propylene carbonate, cyclopentanone, 3-pentanone, 1,2-dimethoxyethane, tetrahydrofuran, ethyl lactate, bis (2-methoxyethyl) ether, acetic acid 2 -Methoxyethyl, propylene glycol dimethyl ether, trichloroethylene, methylene chloride, ethylene chloride, tetrachloroethane, trichloroethane, chloroform and the like.

- solvent that does not dissolve examples include methanol, ethanol, n-propyl alcohol, i-propyl alcohol, n-butanol, propylene glycol monomethyl ether, and hydrocarbons (toluene, xylene, cyclohexanol).

- the back coat layer may contain a resin as a binder.

- the resin used as the binder for the backcoat layer include vinyl chloride-vinyl acetate copolymer, vinyl chloride resin, vinyl acetate resin, vinyl acetate-vinyl alcohol copolymer, partially hydrolyzed vinyl chloride-vinyl acetate copolymer.

- Vinyl polymer or copolymer nitrocellulose, cellulose acetate propionate (preferably acetyl group substitution degree 1.8-2.3, propionyl group substitution degree 0.1-1.0), diacetylcellulose, cellulose Cellulose derivatives such as acetate butyrate resin, maleic acid and / or Or acrylic acid copolymer, acrylic ester copolymer, acrylonitrile-styrene copolymer, chlorinated polyethylene, acrylonitrile-chlorinated polyethylene-styrene copolymer, methyl methacrylate-butadiene-styrene copolymer, acrylic resin Rubber resins such as polyvinyl acetal resin, polyvinyl butyral resin, polyester polyurethane resin, polyether polyurethane resin, polycarbonate polyurethane resin, polyester resin, polyether resin, polyamide resin, amino resin, styrene-butadiene resin, butadiene-acrylonitrile resin, Examples thereof include, but are

- acrylic resins Acrypet MD, VH, MF, V (manufactured by Mitsubishi Rayon Co., Ltd.), Hyperl M4003, M-4005, M-4006, M-4202, M-5000, M-5001, M-4501 (manufactured by Negami Kogyo Co., Ltd.), Dialnal BR-50, BR-52, BR-53, BR-60, BR-64, BR-73, BR-75, BR-77, BR-79, BR -80, BR-82, BR-83, BR-85, BR-87, BR-88, BR-90, BR-93, BR-95, BR-100, BR-101, BR-102, BR-105 BR-106, BR-107, BR-108, BR-112, BR-113, BR-115, BR-116, BR-117, BR-118, etc. (Mitsubishi Rayon Co., Ltd.) acrylic

- cellulose resin layers such as diacetyl cellulose and cellulose acetate propionate.

- the order of coating the backcoat layer may be before or after coating the optical film on the side opposite to the backcoat layer (hard coat layer or other layer such as an antistatic layer).

- the back coat layer also serves as an anti-blocking layer, it is desirable to coat it first.

- the back coat layer can be applied in two or more times before and after the coating of the hard coat layer.

- the arithmetic average roughness Ra (JIS B0601: 2001) of the hard coat layer is preferably in the range of 2 to 100 nm, particularly preferably in the range of 2 to 20 nm. By setting the arithmetic average roughness Ra within the above range, the visibility and the clearness are excellent.

- the arithmetic average roughness Ra is a value measured with an optical interference surface roughness meter (manufactured by ZYGO, NewView) according to JIS B0601: 2001.

- the haze of the optical film is preferably in the range of 0.05% to 10% in view of visibility when used in an image display device.

- the haze can be measured according to JIS-K7105 and JIS K7136.

- the pencil hardness which is a parameter

- the pencil hardness is determined by conditioning the prepared optical film at a temperature of 23 ° C. and a relative humidity of 55% for 2 hours or more, and then using a test pencil specified by JIS S 6006 under a load of 500 g, It is a value measured according to the pencil hardness evaluation method specified by K5400.

- the film substrate is easy to produce, has good adhesion to the hard coat layer, isotropic optically, and transparent.

- the material for the film substrate is not particularly limited as long as it has the above-mentioned properties.

- cellulose esters such as cellulose diacetate film, cellulose triacetate film, cellulose acetate propionate film, cellulose acetate butyrate film, etc.

- polyester film polyester film, polycarbonate film, polyarylate film, polysulfone (including polyethersulfone) film, polyester film such as polyethylene terephthalate and polyethylene naphthalate, polyethylene film, polypropylene film, cellophane, polyvinylidene chloride film , Polyvinyl alcohol film, ethylene vinyl alcohol film, syndiotactic polystyrene film Cycloolefin polymer film (Arton (manufactured by JSR), ZEONEX, ZEONOR (manufactured by Nippon Zeon)), polymethylpentene film, polyetherketone film, polyetherketoneimide film, polyamide film, fluororesin film, nylon film , Polymethylmethacrylate film, acrylic film, polylactic acid film, glass plate, and the like.

- a cellulose ester film, a polycarbonate film, and a cycloolefin polymer film are preferable, and a cellulose ester film is particularly preferable.

- cellulose ester film examples include a triacetyl cellulose film, a cellulose acetate propionate film, a cellulose diacetate film, and a cellulose acetate butyrate film.

- the cellulose ester film may be used in combination with polyester resins such as polyethylene terephthalate and polyethylene naphthalate, polycarbonate resins, polyethylene resins, polypropylene resins, norbornene resins, fluororesins, and cycloolefin polymers.

- Examples of the commercially available cellulose ester film include Konica Minoltak KC8UX, KC4UX, KC8UY, KC4UY, KC6UA, KC4UA, KC2UA, KC4UE and KC4UZ (manufactured by Konica Minolta, Inc.).

- the refractive index of the cellulose ester film is preferably 1.45 to 1.55.

- the refractive index can be measured according to JIS K7142-2008.

- the cellulose ester resin (hereinafter also referred to as cellulose ester or cellulose resin) contained in the cellulose ester film is preferably a lower fatty acid ester of cellulose.

- Lower fatty acid means a fatty acid having 6 or less carbon atoms.

- Examples of the lower fatty acid ester of cellulose include, for example, cellulose acetate, cellulose diacetate, cellulose triacetate, cellulose propionate, cellulose butyrate and the like, and mixed fatty acid esters such as cellulose acetate propionate and cellulose acetate butyrate. it can.

- Particularly preferably used lower fatty acid esters of cellulose are cellulose diacetate, cellulose triacetate, and cellulose acetate propionate. These cellulose esters can be used alone or in combination.

- Cellulose diacetate preferably has an average degree of acetylation (bound acetic acid amount) of 51.0% to 56.0%.

- Commercially available products include L20, L30, L40, and L50 manufactured by Daicel Corporation, and Ca398-3, Ca398-6, Ca398-10, Ca398-30, and Ca394-60S manufactured by Eastman Chemical Japan Co., Ltd. .

- the cellulose triacetate preferably has an average degree of acetylation (bound acetic acid amount) of 54.0 to 62.5%, and more preferably cellulose triacetate having an average degree of acetylation of 58.0 to 62.5%. is there.

- the cellulose triacetate preferably contains cellulose triacetate A and cellulose triacetate B.

- Cellulose triacetate A is a cellulose triacetate having a number average molecular weight (Mn) of 125,000 or more and less than 155000, a weight average molecular weight (Mw) of 265,000 or more and less than 310,000, and Mw / Mn of 1.9 to 2.1.

- Cellulose triacetate B has an acetyl group substitution degree of 2.75 to 2.90, Mn of 155,000 or more and less than 180,000, Mw of 290000 or more and less than 360,000, and Mw / Mn of 1.8 to 2.0.

- Cellulose acetate propionate has an acyl group having 2 to 4 carbon atoms as a substituent, and when the substitution degree of acetyl group is X and the substitution degree of propionyl group or butyryl group is Y, the following formula (I ) And (II) are preferably satisfied at the same time.

- the method for measuring the degree of substitution of the acyl group can be measured according to ASTM-D817-96.

- the number average molecular weight (Mn) and molecular weight distribution (Mw) of the cellulose ester can be measured using high performance liquid chromatography.

- the measurement conditions are as follows. Solvent: Methylene chloride Column: Shodex K806, K805, K803G (Used by connecting three Showa Denko Co., Ltd.) Column temperature: 25 ° C Sample concentration: 0.1% by mass Detector: RI Model 504 (GL Science Co., Ltd.) Pump: L6000 (manufactured by Hitachi, Ltd.) Flow rate: 1.0 ml / min

- the film substrate may be configured by using a thermoplastic acrylic resin in combination with a cellulose ester resin.

- Acrylic resin includes methacrylic resin.

- the acrylic resin is not particularly limited but is preferably composed of 50 to 99% by mass of methyl methacrylate units and 1 to 50% by mass of other monomer units copolymerizable therewith.

- Examples of other copolymerizable monomers include alkyl methacrylates having 2 to 18 alkyl carbon atoms, alkyl acrylates having 1 to 18 carbon atoms, alkyl acrylates such as acrylic acid and methacrylic acid.

- Unsaturated group-containing divalent carboxylic acids such as saturated acid, maleic acid, fumaric acid and itaconic acid, aromatic vinyl compounds such as styrene and ⁇ -methylstyrene, ⁇ , ⁇ -unsaturated nitriles such as acrylonitrile and methacrylonitrile, Examples thereof include maleic anhydride, maleimide, N-substituted maleimide, glutaric anhydride, and the like. These may be used alone or in combination of two or more.

- methyl acrylate, ethyl acrylate, n-propyl acrylate, n-butyl acrylate, s-butyl acrylate, 2-ethylhexyl acrylate, and the like are preferable from the viewpoint of thermal decomposition resistance and fluidity of the copolymer.

- -Butyl acrylate is particularly preferably used.

- the weight average molecular weight (Mw) is preferably 80,000 to 500,000, more preferably 110,000 to 500,000.

- the weight average molecular weight of the acrylic resin can be measured by gel permeation chromatography.

- Commercially available acrylic resins include, for example, Delpet 60N, 80N (Asahi Kasei Chemicals Corporation), Dianal BR52, BR80, BR83, BR85, BR88 (Mitsubishi Rayon Co., Ltd.), KT75 (Electrochemical Industry Co., Ltd.) )) And the like. Two or more acrylic resins can be used in combination.

- a ⁇ / 4 film may be used as the film substrate.

- a ⁇ / 4 film as the film substrate, when the optical film of the present embodiment is incorporated into an image display device, it is preferable from the viewpoint of excellent visibility and crosstalk.

- a ⁇ / 4 film refers to a film having an in-plane retardation of the film of about 1 ⁇ 4 with respect to a predetermined light wavelength (usually in the visible light region).

- the ⁇ / 4 film is preferably a broadband ⁇ / 4 film having a phase difference of approximately 1 ⁇ 4 of the wavelength in the visible light wavelength range in order to obtain almost perfect circularly polarized light in the visible light wavelength range. .

- the ⁇ / 4 film has an in-plane retardation value Ro (550) measured at a wavelength of 550 nm, preferably in the range of 60 nm to 220 nm, more preferably in the range of 80 nm to 200 nm, and more preferably in the range of 90 nm to 190 nm. More preferably, it is the range.

- nx and ny are the maximum refractive index in the plane of the film (also referred to as the refractive index in the slow axis direction) out of the refractive index at 23 ° C. and 55% RH and the wavelength of 550 nm, and in the plane of the film. It is the refractive index in the direction perpendicular to the slow axis, and d is the thickness (nm) of the film.

- Ro can be calculated by measuring the birefringence at each wavelength in an environment of 23 ° C. and 55% RH using an automatic birefringence meter KOBRA-21ADH (manufactured by Oji Scientific Instruments).

- Ro (A) indicates an in-plane retardation value measured at a wavelength of Anm.

- a circularly polarizing plate is obtained by laminating so that the angle between the slow axis of the ⁇ / 4 film and the transmission axis of the polarizer described later is substantially 45 °.

- Substantially 45 ° means in the range of 30 ° to 60 °, more preferably in the range of 40 ° to 50 °.

- the angle between the in-plane slow axis of the ⁇ / 4 film and the transmission axis of the polarizer is preferably 41 to 49 °, more preferably 42 to 48 °, and 43 to 47 °. Is more preferably 44 to 46 °.

- the ⁇ / 4 film is not particularly limited as long as it is an optically transparent resin.

- the cellulose-based resin described above can be used.

- the ⁇ / 4 film is preferably a cellulose resin or a polycarbonate resin.

- the ⁇ / 4 film is preferably a cellulose resin.

- the retardation adjustment of ⁇ / 4 can be performed by adding the following retardation adjuster to the resin film described above.

- an aromatic compound having two or more aromatic rings as described in the specification of European Patent 911,656A2 can be used.

- the aromatic ring of the aromatic compound includes an aromatic heterocycle in addition to an aromatic hydrocarbon ring. Particularly preferred is an aromatic heterocycle, and the aromatic heterocycle is generally an unsaturated heterocycle. Of these, a 1,3,5-triazine ring is particularly preferred.

- a polycarbonate resin can also be used for the film substrate.

- Various polycarbonate resins can be used without particular limitation, and aromatic polycarbonate resins are preferred from the viewpoint of chemical properties and physical properties, and bisphenol A polycarbonate resins are particularly preferred.

- those using a bisphenol A derivative in which a benzene ring, a cyclohexane ring, an aliphatic hydrocarbon group and the like are introduced into bisphenol A are more preferable.

- a polycarbonate resin having a structure in which the anisotropy in the unit molecule is reduced, obtained by using a derivative in which the functional group is introduced asymmetrically with respect to the central carbon of bisphenol A is particularly preferable.

- a polycarbonate resin for example, two methyl groups in the center carbon of bisphenol A are replaced by benzene rings, and one hydrogen of each benzene ring of bisphenol A is centered by a methyl group or a phenyl group.

- a polycarbonate resin obtained by using an asymmetrically substituted carbon is particularly preferable.

- 4,4′-dihydroxydiphenylalkane or a halogen-substituted product thereof can be obtained by a phosgene method or a transesterification method.

- 4,4′-dihydroxydiphenylmethane, 4,4′-dihydroxydiphenyl Examples include ethane and 4,4'-dihydroxydiphenylbutane.

- JP 2006-215465 A, JP 2006-91836 A, JP 2005-121813 A, JP 2003-167121 A, JP 2009-126128 A, JP Examples thereof include polycarbonate resins described in 2012-31369, JP 2012-67300 A, International Publication No. 00/26705, and the like.

- the polycarbonate resin may be used by mixing with a transparent resin such as polystyrene resin, methyl methacrylate resin, and cellulose acetate resin. Moreover, you may laminate

- the polycarbonate-based resin preferably has a glass transition point (Tg) of 110 ° C. or higher and a water absorption (a value measured under conditions of 23 ° C. water and 24 hours) of 0.3% or less. Moreover, Tg is 120 degreeC or more, and a water absorption rate is 0.2% or less more preferable.

- Tg glass transition point

- water absorption a value measured under conditions of 23 ° C. water and 24 hours

- the polycarbonate resin film can be formed by a known method, and among them, the solution casting method and the melt casting method are preferable.

- an alicyclic olefin polymer resin As the film substrate, an alicyclic olefin polymer resin can also be used.

- the alicyclic olefin polymer-based resin include cyclic olefin random multi-component copolymers described in JP-A No. 05-310845, hydrogenated polymers described in JP-A No. 05-97978, and JP-A No. 11

- the thermoplastic dicyclopentadiene ring-opening polymer and hydrogenated product thereof described in JP-A-124429 can be employed.

- the alicyclic olefin polymer resin is a polymer having an alicyclic structure such as a saturated alicyclic hydrocarbon (cycloalkane) structure or an unsaturated alicyclic hydrocarbon (cycloalkene) structure.

- the number of carbon atoms constituting the alicyclic structure is not particularly limited, but when it is usually in the range of 4 to 30, preferably 5 to 20, more preferably 5 to 15, the mechanical strength, The properties of heat resistance and formability of the long film are highly balanced and suitable.

- the proportion of the repeating unit containing the alicyclic structure in the alicyclic olefin polymer may be appropriately selected, but is preferably 55% by weight or more, more preferably 70% by weight or more, and particularly preferably 90% by weight. That's it.

- the ratio of the repeating unit having an alicyclic structure in the alicyclic polyolefin resin is within this range, the transparency and heat resistance of an optical material such as a retardation film obtained from the long obliquely stretched film of the present embodiment are improved. Since it improves, it is preferable.

- olefin polymer resin having an alicyclic structure examples include norbornene resins, monocyclic olefin resins, cyclic conjugated diene resins, vinyl alicyclic hydrocarbon resins, and hydrides thereof.

- norbornene-based resins can be suitably used because of their good transparency and moldability.

- Examples of the norbornene-based resin include a ring-opening polymer of a monomer having a norbornene structure, a ring-opening copolymer of a monomer having a norbornene structure and another monomer, a hydride thereof, and a norbornene structure. And an addition copolymer of a monomer having a norbornene structure and an addition copolymer of another monomer or a hydride thereof.

- a ring-opening (co) polymer hydride of a monomer having a norbornene structure is particularly suitable from the viewpoints of transparency, moldability, heat resistance, low hygroscopicity, dimensional stability and lightness. Can be used.

- melt extrusion method examples include an inflation method using a die, but a method using a T die is preferable in terms of excellent productivity and thickness accuracy.

- a sheet-like thermoplastic resin extruded from a die is brought into close contact with a cooling drum under a pressure of 50 kPa or less; 2) melting When producing a long film by extrusion, the enclosure member covers from the die opening to the first cooling drum that is in close contact, and the distance from the enclosure member to the die opening or the first contact cooling drum is 100 mm or less.

- Method 3 Method of heating the temperature of the atmosphere within 10 mm to a specific temperature from the sheet-like thermoplastic resin extruded from the die opening when producing a long film by the melt extrusion method; A sheet-like thermoplastic resin extruded from a die so as to satisfy the above condition is taken into close contact with a cooling drum under a pressure of 50 kPa or less; A method in which a wind having a speed difference of 0.2 m / s or less from the cooling speed of the cooling drum that is first brought into close contact with the sheet-like thermoplastic resin extruded from the die opening is produced. It is done.

- This long film may be a single layer or a laminated film of two or more layers.

- the laminated film can be obtained by a known method such as a coextrusion molding method, a co-casting molding method, a film lamination method, or a coating method. Of these, the coextrusion molding method and the co-casting molding method are preferable.

- the film substrate of the present embodiment has, for example, acrylic particles, silicon dioxide, titanium dioxide, aluminum oxide, zirconium oxide, calcium carbonate, kaolin, talc, calcined calcium silicate, and hydrated calcium silicate. It is preferable to contain a matting agent such as inorganic fine particles such as aluminum silicate, magnesium silicate and calcium phosphate and a crosslinked polymer.

- the acrylic particles are not particularly limited, but are preferably multi-layered acrylic granular composites.

- silicon dioxide is preferable in that the haze of the film substrate can be reduced.

- the primary average particle diameter of the fine particles is preferably 20 nm or less, more preferably in the range of 5 to 16 nm, and particularly preferably in the range of 5 to 12 nm.

- the film base material of this embodiment contains the ester compound or sugar ester represented by the following general formula (X) from the dimensional stability by an environmental change.

- the ester compound represented by the general formula (X) will be described.

- B is a hydroxy group or carboxylic acid residue

- G is an alkylene glycol residue having 2 to 12 carbon atoms, an aryl glycol residue having 6 to 12 carbon atoms, or an oxyalkylene glycol residue having 4 to 12 carbon atoms.

- A represents an alkylene dicarboxylic acid residue having 4 to 12 carbon atoms or an aryl dicarboxylic acid residue having 6 to 12 carbon atoms

- n represents an integer of 1 or more.

- the alkylene glycol component having 2 to 12 carbon atoms includes ethylene glycol, 1,2-propylene glycol, 1,3-propylene glycol, 1,2-butanediol, 1,3-butanediol, 1,2-propanediol, 2-methyl 1,3-propanediol, 1,4-butanediol, 1,5-pentanediol, 2,2-dimethyl-1,3-propanediol (neopentyl glycol), 2 , 2-diethyl-1,3-propanediol (3,3-dimethylolpentane), 2-n-butyl-2-ethyl-1,3-propanediol (3,3-dimethylolheptane), 3-methyl- 1,5-pentanediol 1,6-hexanediol, 2,2,4-trimethyl 1,3-pentanediol, 2-ethyl

- alkylene glycols having 2 to 12 carbon atoms are particularly preferable because of excellent compatibility with cellulose acetate.

- aryl glycol component having 6 to 12 carbon atoms include hydroquinone, resorcin, bisphenol A, bisphenol F, bisphenol and the like, and these glycols can be used as one kind or a mixture of two or more kinds.

- Examples of the oxyalkylene glycol component having 4 to 12 carbon atoms include diethylene glycol, triethylene glycol, tetraethylene glycol, dipropylene glycol, and tripropylene glycol. These glycols may be used alone or in combination of two or more. Can be used as a mixture.

- Examples of the alkylene dicarboxylic acid component having 4 to 12 carbon atoms include succinic acid, maleic acid, fumaric acid, glutaric acid, adipic acid, azelaic acid, sebacic acid, dodecanedicarboxylic acid, and the like. Used as a mixture of two or more.

- arylene dicarboxylic acid component having 6 to 12 carbon atoms examples include phthalic acid, terephthalic acid, isophthalic acid, 1,5 naphthalene dicarboxylic acid, and 1,4 naphthalene dicarboxylic acid.

- Specific examples of the compound represented by formula (X) (compound X-1 to compound X-17) are shown below, but are not limited thereto.

- the sugar ester compound is an ester other than cellulose ester, and is a compound obtained by esterifying all or part of the OH group of a sugar such as the following monosaccharide, disaccharide, trisaccharide or oligosaccharide.

- sugar examples include glucose, galactose, mannose, fructose, xylose, arabinose, lactose, sucrose, nystose, 1F-fructosyl nystose, stachyose, maltitol, lactitol, lactulose, cellobiose, maltose, cellotriose, maltotriose, raffinose And kestose.

- gentiobiose, gentiotriose, gentiotetraose, xylotriose, galactosyl sucrose, and the like are also included.

- compounds having a furanose structure and / or a pyranose structure are particularly preferable.

- sucrose, kestose, nystose, 1F-fructosyl nystose, stachyose and the like are preferable, and sucrose is more preferable.

- oligosaccharides maltooligosaccharides, isomaltooligosaccharides, fructooligosaccharides, galactooligosaccharides, and xylo-oligosaccharides can also be preferably used.

- the monocarboxylic acid used for esterifying the sugar is not particularly limited, and known aliphatic monocarboxylic acid, alicyclic monocarboxylic acid, aromatic monocarboxylic acid and the like can be used.

- the carboxylic acid to be used may be one kind or a mixture of two or more kinds.

- Preferred aliphatic monocarboxylic acids include acetic acid, propionic acid, butyric acid, isobutyric acid, valeric acid, caproic acid, enanthic acid, caprylic acid, pelargonic acid, capric acid, 2-ethyl-hexanecarboxylic acid, undecylic acid, lauric acid , Saturated fatty acids such as tridecylic acid, myristic acid, pentadecylic acid, palmitic acid, heptadecylic acid, stearic acid, nonadecanoic acid, arachidic acid, behenic acid, lignoceric acid, serotic acid, heptacosanoic acid, montanic acid, melicic acid, and laccelic acid And unsaturated fatty acids such as undecylenic acid, oleic acid, sorbic acid, linoleic acid, linolenic acid, arachidonic acid and octeno

- Examples of preferred alicyclic monocarboxylic acids include cyclopentane carboxylic acid, cyclohexane carboxylic acid, cyclooctane carboxylic acid, or derivatives thereof.

- Examples of preferred aromatic monocarboxylic acids include benzoic acid, aromatic monocarboxylic acids having an alkyl group or alkoxy group introduced into the benzene ring of benzoic acid, cinnamic acid, benzylic acid, biphenylcarboxylic acid, naphthalenecarboxylic acid, tetralin

- An aromatic monocarboxylic acid having two or more benzene rings such as carboxylic acid, or a derivative thereof can be mentioned, and more specifically, xylic acid, hemelic acid, mesitylene acid, planicylic acid, ⁇ -isojurylic acid, Julylic acid, mesitic acid, ⁇ -isoduric acid, cumic acid, ⁇ -toluic acid, hydroatropic acid

- ester compounds esterified an acetyl compound into which an acetyl group has been introduced by esterification is preferable.

- the specific example of the sugar ester compound which can be used for this embodiment below is shown, it is not limited to these.

- the sugar ester compound is preferably a compound represented by the general formula (Y). Below, the compound shown by general formula (Y) is demonstrated.

- R 1 ⁇ R 8 is a hydrogen atom, a substituted or unsubstituted alkylcarbonyl group having 2 to 22 carbon atoms, or a substituted or unsubstituted arylcarbonyl group having 2 to 22 carbon atoms, R 1 R 8 may be the same or different.

- the substitution degree distribution can be adjusted to the desired substitution degree by adjusting the esterification reaction time or mixing compounds with different substitution degrees.

- the ester compound or sugar ester compound represented by the general formula (X) is preferably contained in the cellulose acetate film in an amount of 1 to 30% by mass, more preferably 5 to 25% by mass. It is particularly preferred that

- the film base material of this embodiment may contain a plasticizer as needed.

- the plasticizer is not particularly limited, but is a polyvalent carboxylic ester plasticizer, glycolate plasticizer, phthalate ester plasticizer, phosphate ester plasticizer, and polyhydric alcohol ester plasticizer, acrylic. A plasticizer etc. are mentioned. In these, an acrylic plasticizer is preferable from the viewpoint of easily controlling the cellulose ester film to the retardation value described later.

- the polyhydric alcohol ester plasticizer is a plasticizer composed of an ester of a divalent or higher aliphatic polyhydric alcohol and a monocarboxylic acid, and preferably has an aromatic ring or a cycloalkyl ring in the molecule.

- a divalent to 20-valent aliphatic polyhydric alcohol ester is preferred.

- Specific examples of the polyhydric alcohol ester plasticizer are shown below, but are not limited thereto.

- the glycolate plasticizer is not particularly limited, but alkylphthalylalkyl glycolates can be preferably used.

- alkyl phthalyl alkyl glycolates include methyl phthalyl methyl glycolate, ethyl phthalyl ethyl glycolate, propyl phthalyl propyl glycolate, butyl phthalyl butyl glycolate, octyl phthalyl octyl glycolate, methyl phthalyl ethyl Glycolate, ethyl phthalyl methyl glycolate, ethyl phthalyl propyl glycolate, methyl phthalyl butyl glycolate, ethyl phthalyl butyl glycolate, butyl phthalyl methyl glycolate, butyl phthalyl ethyl glycolate, propyl phthalyl butyl glycol Butyl phthalyl propyl glycolate, methyl phthalyl octyl

- phthalate ester plasticizer examples include diethyl phthalate, dimethoxyethyl phthalate, dimethyl phthalate, dioctyl phthalate, dibutyl phthalate, di-2-ethylhexyl phthalate, dioctyl phthalate, dicyclohexyl phthalate, and dicyclohexyl terephthalate.

- phosphate ester plasticizer examples include triphenyl phosphate, tricresyl phosphate, cresyl diphenyl phosphate, octyl diphenyl phosphate, diphenyl biphenyl phosphate, trioctyl phosphate, tributyl phosphate, and the like.

- the polycarboxylic acid ester plasticizer is a compound composed of an ester of a divalent or higher, preferably a divalent to 20-valent polyvalent carboxylic acid and an alcohol.

- Specific examples include triethyl citrate, tributyl citrate, acetyl triethyl citrate (ATEC), acetyl tributyl citrate (ATBC), benzoyl tributyl citrate, acetyl triphenyl citrate, acetyl tribenzyl citrate, dibutyl tartrate, tartaric acid

- examples include, but are not limited to, diacetyldibutyl, tributyl trimellitic acid, tetrabutyl pyromellitic acid, and the like.

- the acrylic plasticizer is preferably an acrylic polymer, and the acrylic polymer is preferably a homopolymer or copolymer of acrylic acid or alkyl methacrylate.

- the acrylate monomer include methyl acrylate, ethyl acrylate, propyl acrylate (i-, n-), butyl acrylate (n-, i-, s-, t-), pentyl acrylate ( n-, i-, s-), hexyl acrylate (n-, i-), heptyl acrylate (n-, i-), octyl acrylate (n-, i-), nonyl acrylate (n-, i-), myristyl acrylate (n-, i-), acrylic acid (2-ethylhexyl), acrylic acid ( ⁇ -caprolactone), acrylic acid (2-hydroxyethyl), acrylic acid (2-hydroxypropyl), acrylic Acid (3-hydroxypropyl), acrylic

- the acrylic polymer is a homopolymer or copolymer of the above monomer, but preferably has 30% by mass or more of acrylic acid methyl ester monomer units, and has 40% by mass or more of methacrylic acid methyl ester monomer units. It is preferable. In particular, a homopolymer of methyl acrylate or methyl methacrylate is preferred.