WO2014057664A1 - Light source unit and illumination fixture - Google Patents

Light source unit and illumination fixture Download PDFInfo

- Publication number

- WO2014057664A1 WO2014057664A1 PCT/JP2013/006009 JP2013006009W WO2014057664A1 WO 2014057664 A1 WO2014057664 A1 WO 2014057664A1 JP 2013006009 W JP2013006009 W JP 2013006009W WO 2014057664 A1 WO2014057664 A1 WO 2014057664A1

- Authority

- WO

- WIPO (PCT)

- Prior art keywords

- light source

- source unit

- suspension bolt

- power supply

- instrument body

- Prior art date

Links

Images

Classifications

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F21—LIGHTING

- F21V—FUNCTIONAL FEATURES OR DETAILS OF LIGHTING DEVICES OR SYSTEMS THEREOF; STRUCTURAL COMBINATIONS OF LIGHTING DEVICES WITH OTHER ARTICLES, NOT OTHERWISE PROVIDED FOR

- F21V21/00—Supporting, suspending, or attaching arrangements for lighting devices; Hand grips

- F21V21/02—Wall, ceiling, or floor bases; Fixing pendants or arms to the bases

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F21—LIGHTING

- F21S—NON-PORTABLE LIGHTING DEVICES; SYSTEMS THEREOF; VEHICLE LIGHTING DEVICES SPECIALLY ADAPTED FOR VEHICLE EXTERIORS

- F21S8/00—Lighting devices intended for fixed installation

- F21S8/04—Lighting devices intended for fixed installation intended only for mounting on a ceiling or the like overhead structures

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F21—LIGHTING

- F21Y—INDEXING SCHEME ASSOCIATED WITH SUBCLASSES F21K, F21L, F21S and F21V, RELATING TO THE FORM OR THE KIND OF THE LIGHT SOURCES OR OF THE COLOUR OF THE LIGHT EMITTED

- F21Y2115/00—Light-generating elements of semiconductor light sources

- F21Y2115/10—Light-emitting diodes [LED]

Definitions

- the present invention relates to a light source unit and a lighting fixture.

- Document 1 Japanese Published Patent Publication No. 2011-142063 discloses a ceiling-mounted lighting fixture that is attached to a ceiling using a mounting screw.

- This lighting fixture includes a base plate that is formed in a horizontally long and long shape, a wing portion that is disposed on the opposite side of the ceiling with respect to the base plate, and an LED unit that is attached to the wing portion using a plurality of holders.

- a plurality of screw holes for passing the mounting screws are provided along the longitudinal direction at the approximate center of the base plate.

- the LED unit also includes a plurality of LED modules, a support member that supports the plurality of LED modules, a cover that is attached to the support member so as to cover the plurality of LED modules, and for supplying power to the plurality of LEDs.

- attached integrally is attached to a wing part using a some holder in the state accommodated in the recessed part provided in the wing part.

- the mounting screw is not allowed to enter the recess of the wing portion when attached to the ceiling, and the space for placing the screw head of the mounting screw is not the base plate and the wing. It is provided between the parts. Therefore, the height dimension of the entire instrument is increased, and as a result, the amount of protrusion from the ceiling is increased.

- the present invention has been made in view of the above problems, and an object of the present invention is to provide a light source unit and a lighting fixture in which the amount of protrusion from the ceiling is kept low.

- the light source unit has a hole for passing a suspension bolt, and is detachably attached to a fixture main body attached to a ceiling material by the suspension bolt passed through the hole.

- the light source unit includes an LED board on which a plurality of LEDs are mounted, and an attachment member for attaching the LED board to the instrument body such that the LED board is disposed between the plurality of LEDs and the instrument body.

- a power supply device that supplies lighting power to the plurality of LEDs.

- the attachment member has a housing portion in which at least a part of the suspension bolt and the power supply device are disposed at a portion facing the instrument body.

- the power supply device is disposed at a position where it does not interfere with the suspension bolt in the housing portion in a state where the light source unit is attached to the instrument body.

- the attachment member in the first aspect, includes a bottom surface formed in a long and rectangular plate shape, and the bottom surface from both sides in the width direction of the bottom surface. Are formed with a pair of side portions protruding in a direction intersecting with each other, and the housing portion is constituted by a space surrounded by the bottom portion and the pair of side portions.

- the lighting fixture of the 3rd form which concerns on this invention is equipped with the fixture main body formed in elongate shape and attached to a ceiling material using a suspension bolt, and the light source unit attached to the said fixture main body so that attachment or detachment is possible.

- An accommodation recess is provided along the longitudinal direction of the instrument body on the opposite side of the ceiling body of the instrument body, and a hole for passing the suspension bolt is provided in the bottom surface of the accommodation recess.

- the light source unit includes an LED substrate on which a plurality of LEDs are mounted, an attachment member for attaching the LED substrate to the instrument body so that the plurality of LEDs face the outside of the housing recess, and the plurality of LEDs And a power supply device for supplying lighting power.

- the attachment member includes a housing portion in which at least a part of the suspension bolt and the power supply device are disposed at a portion of the instrument body that faces the housing recess.

- the power supply device is disposed at a position where it does not interfere with the suspension bolt in the housing portion in a state where the light source unit is attached to the instrument body.

- the lighting fixture of the 4th form which concerns on this invention is the bottom face part from the both sides in the width direction of the said bottom face part in the width direction of the said bottom face part, and the said attachment member in the 3rd form in the 3rd form.

- the housing portion is constituted by a space surrounded by the bottom portion and the pair of side portions.

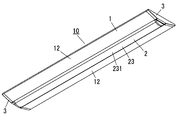

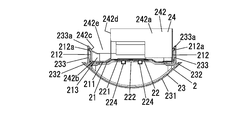

- FIG. 1A is a cross-sectional view in which the lighting fixture of the present embodiment is partially omitted when viewed from the width direction

- FIG. 1B is a cross-sectional view of the lighting fixture of the present embodiment viewed from the longitudinal direction. It is a disassembled perspective view of the lighting fixture of this embodiment. It is a whole perspective view of the lighting fixture of this embodiment. It is a perspective view of the state where the light source unit was removed from the lighting fixture of this embodiment. It is sectional drawing of the light source unit used for the lighting fixture of this embodiment.

- FIGS. 1A to 5 an embodiment of the lighting apparatus 10 will be described with reference to FIGS. 1A to 5.

- the vertical and horizontal directions are defined in the orientation shown in FIG. 1B, and the direction perpendicular to the paper surface in FIG.

- the lighting fixture 10 of the present embodiment is a ceiling-mounted lighting fixture, and the fixture main body 1 attached to the ceiling member 100 using a suspension bolt 200 (see FIG. 1B)

- the light source unit 2 is detachably attached to the instrument body 1.

- the suspension bolt 200 is attached to the beam 400 provided on the back of the ceiling, and the suspension bolt 200 is placed on the indoor side (lower side) through the hole provided in the ceiling material 100. Exposed.

- the instrument main body 1 is formed into a flat box shape that is long and has an upper surface (a surface facing the ceiling material 100) opened by bending the sheet metal, and on the side opposite to the ceiling material 100 (that is, the lower side).

- a rectangular housing recess 11 for housing the light source unit 2 is provided over the entire length of the instrument body 1.

- inclined surfaces 12 that extend from the opening edge of the housing recess 11 and incline upward (toward the ceiling material 100) toward the outside. 12 are provided.

- a plurality of holes (5 in FIG. 2) are provided in the bottom surface portion 111 of the housing recess 11 along the front-rear direction (longitudinal direction) for passing the electric wire, and further, the suspension bolt 200 is passed through.

- Two holes 111b are provided at positions near both ends in the front-rear direction.

- end caps 3 are respectively attached to both ends of the instrument body 1 in the front-rear direction.

- the light source unit 2 includes a plurality of (two in FIG. 2) LED boards 22, a mounting member 21 to which the LED boards 22 are attached, and a mounting member that covers the LED boards 22. Cover member 23 attached to 21.

- the light source unit 2 includes a power supply device 24 that supplies predetermined lighting power to the LED substrate 22 and a terminal block block 25.

- the LED board 22 includes a printed board 221 formed in a rectangular plate shape that is long in the front-rear direction.

- a plurality of LEDs (light emitting diodes) 222 are mounted on the lower surface of the printed board 221 along the front-rear direction (longitudinal direction).

- a connector 223 for electrically connecting the power supply device 24 is mounted on one end (right end) of the LED substrate 22 on one side (right side in FIG. 2).

- An electric wire (not shown) is connected to the connector 223, and the LED substrate 22 and the power supply device 24 are electrically connected by connecting the end of the electric wire to the power supply device 24.

- a power supply connector 224 is mounted on each LED substrate 22 at the end facing the adjacent LED substrate 22. Then, by connecting the connectors 224 and 224 of the LED boards 22 and 22, the power is supplied from the LED board 22 on one side (right side in FIG. 2) to the LED board 22 on the other side (left side in FIG. 2). Can do.

- the mounting member 21 is formed in a U shape by bending a sheet metal, and is a bottom surface portion 211 formed in a long and rectangular plate shape, and a vertical direction from both ends in the left-right direction (width direction) of the bottom surface portion 211. It is comprised by a pair of side part 212 extended in (the direction orthogonal to the bottom face part 211). As shown in FIG. 5, inclined portions 212 a that are inclined in directions away from each other are provided at the tips of the side portions 212 over the entire length.

- a hole 211a is formed in one end portion (right end portion in FIG. 2) of the bottom surface portion 211 in the front-rear direction (longitudinal direction). Yes.

- a rectangular recess 211b formed by projecting a part of the bottom surface portion 211 upward is provided at a substantially center in the front-rear direction of the bottom surface portion 211.

- the concave portion 211 b is for securing an insulation distance between the connector 224 and the bottom surface portion 211 of the mounting member 21 in a state where both the LED boards 22 and 22 are mounted on the mounting member 21.

- the LED board 22 mentioned above is fixed to the attachment member 21 by the latching claw (not shown) formed by, for example, raising a part of the bottom face part 211 of the attachment member 21.

- the cover member 23 is formed in a long shape whose upper surface (surface on the mounting member 21 side) is opened by a diffusible material (for example, milky white acrylic resin).

- the cover member 23 has a convex lens-shaped diffusing surface 231 in which the amount of protrusion downward increases from the both end sides to the center side in the left-right direction (width direction) (see FIG. 5).

- both ends of the cover member 23 in the left-right direction overlap with the opening edge of the housing recess 11 of the instrument main body 1 in the vertical direction with the light source unit 2 attached to the instrument main body 1.

- Each extending portion 232 is provided.

- projecting wall portions 233 projecting upward (on the attachment member 21 side) are provided on the inner sides of the extending portions 232 in the left-right direction of the cover member 23, respectively.

- Protrusions 233a projecting inward are provided at the tips.

- the power supply device 24 includes a power supply board 241 and a storage case 242 for storing the power supply board 241.

- the power supply board 241 includes a printed board 241a formed in a rectangular plate shape that is long in the front-rear direction.

- the printed board 241a includes at least circuit components (for example, a transformer, a diode, a capacitor, etc.) 241b for generating lighting power for the LEDs 222. Has been implemented.

- the storage case 242 has a rectangular box-shaped storage part 242 a that is open on one side (the surface facing the bottom surface part 211 of the mounting member 21) and is long in the front-rear direction.

- the storage case 242 includes a first extension portion 242b extending from the opening edge of the storage portion 242a to the side (left side in FIG. 5) and a first extension portion 242b extending upward from the tip of the first extension portion 242b.

- 2 has a groove portion 242e formed of a space surrounded by the side surface portion 242d of the storage portion 242a facing the second extension portion 242c and the second extension portion 242c.

- the groove portion 242e is used as a wiring space for passing an electric wire from the terminal block block 25 to the power supply device 24, an electric wire from the power supply device 24 to the LED board 22, an electric wire for sending electric power to the adjacent lighting fixture 10, and the like.

- this power supply device 24 is an attachment member using a screw etc., for example in the state in which at least one part was accommodated in the accommodating part 213 which consists of the space enclosed by the bottom face part 211 and the both-sides surface parts 212 and 212 of the attachment member 21. 21 is attached.

- the terminal block 25 has a terminal block 251 formed in a rectangular box shape and a mounting bracket 252 for mounting the terminal block 251 to the mounting member 21.

- a power line (not shown) exposed to the indoor side (lower side) through the ceiling member 100 is connected to the terminal block 251, and an electric wire (not shown) that electrically connects the power source 24. Is connected.

- this terminal block block 25 is attached to the attachment member 21 using a screw etc. in the state in which at least one part was accommodated in the accommodating part 213, for example.

- the operator attaches the power supply device 24 and the terminal block block 25 to the upper surface side of the attachment member 21, respectively, and further connects the power supply device 24 and the terminal block block 25 with electric wires. Thereafter, the operator fixes the LED board 22 to the bottom surface portion 211 of the mounting member 21 with the locking claws, and the electric wire led out from the connector 223 of the LED board 22 into the hole 211 a provided in the bottom surface portion 211 of the mounting member 21. After passing, the end is connected to the power supply device 24.

- the operator attaches the cover member 23 to the mounting member 21 with the opening side facing upward.

- the protrusions 233 a provided on the respective protruding wall portions 233 of the cover member 23 are hooked on the inclined portions 212 a provided on the respective side surface portions 212 of the attachment member 21, and the cover member 23 is attached to the attachment member 21.

- the light source unit 2 is assembled according to the above procedure.

- the said method of attaching the cover member 23 to the attachment member 21 is an example, and another method may be sufficient.

- the operator passes the power line exposed to the indoor side through the hole 111a provided in the instrument main body 1, passes the suspension bolt 200 exposed to the indoor side through the ceiling material 100, and then passes through the hole 111b.

- a nut 300 is screwed into 200 to fix the instrument body 1 to the ceiling material 100.

- the operator connects the power line to the terminal block 251, and fits provided in, for example, the instrument body 1 and the attachment member 21 so that at least the power supply device 24 and the terminal block block 25 are accommodated in the accommodating recess 11.

- the light source unit 2 is attached to the instrument body 1 by a combined structure (not shown).

- the lighting fixture 10 is constructed on the ceiling according to the above procedure.

- FIG. 1A and FIG. 1B are cross-sectional views of the state in which the lighting fixture 10 is attached to the ceiling material 100.

- a part of the suspension bolt 200 and a part of the power supply device 24 are attached to the attachment member 21. It arrange

- the longitudinal dimension L1 (dimension along the front-rear direction) of the power supply device 24 is smaller than the mounting pitch dimension P1 of the suspension bolt 200, it is suspended in the front-rear direction (left-right direction in FIG. 1A).

- the power supply device 24 can be arranged so as not to interfere with the bolt 200.

- the lighting fixture 10 which restrained the protrusion amount from the ceiling low can be provided.

- the housing portion 213 is used as a wiring space for passing an electric wire from the terminal block block 25 to the power supply device 24, an electric wire from the power supply device 24 to the LED substrate 22, an electric wire for sending electric power to the adjacent lighting fixture 10, and the like. You can also. Furthermore, by making the shape of the attachment member 21 U-shaped, it becomes easy to form, and as a result, the number of manufacturing steps can be reduced and the cost can be reduced.

- the light source unit 2 of the present embodiment has a hole 111b for allowing the suspension bolt 200 to pass through, and is detachably attached to the fixture body 1 attached to the ceiling material 100 by the suspension bolt 200 passed through the hole 111b.

- the light source unit 2 includes an LED substrate 22 on which a plurality of LEDs 222 are mounted, and an attachment for attaching the LED substrate 22 to the instrument body 1 such that the LED substrate 22 is disposed between the plurality of LEDs 222 and the instrument body 1.

- a member 21 and a power supply device 24 that supplies lighting power to the plurality of LEDs 222 are provided.

- the attachment member 21 has a housing portion 213 in which at least a part of the suspension bolt 200 and the power supply device 24 are disposed at a portion facing the instrument body 1.

- the power supply device 24 is disposed at a position that does not interfere with the suspension bolt 200 in the housing portion 213 in a state where the light source unit 2 is attached to the instrument body 1.

- the attachment member 21 includes a bottom surface portion 211 formed in a long and rectangular plate shape, and a direction intersecting the bottom surface portion 211 from both sides in the width direction of the bottom surface portion 211. It is preferable to be formed by a pair of protruding side surface portions 212.

- the housing portion 213 is configured by a space surrounded by the bottom surface portion 211 and the pair of side surface portions 212.

- the lighting fixture 10 of the present embodiment includes a fixture main body 1 that is formed in a long shape and is attached to the ceiling member 10 using a suspension bolt 200, and a light source unit 2 that is detachably attached to the fixture main body 1.

- a fixture main body 1 that is formed in a long shape and is attached to the ceiling member 10 using a suspension bolt 200

- a light source unit 2 that is detachably attached to the fixture main body 1.

- an accommodation recess 11 is provided along the longitudinal direction of the instrument body 1, and a hole 111 b for passing the suspension bolt 200 is provided on the bottom surface portion 111 of the accommodation recess 11. ing.

- the light source unit 2 includes an LED substrate 22 on which a plurality of LEDs 222 are mounted, an attachment member 21 for attaching the LED substrate 22 to the instrument body 1 such that the plurality of LEDs 222 face the outside of the housing recess 11, and a plurality of LEDs 222. And a power supply device 24 for supplying lighting power.

- the attachment member 21 has a housing portion 213 in which at least a part of the suspension bolt 200 and the power supply device 24 are disposed at a portion facing the housing recess 11 of the instrument body 1.

- the power supply device 24 is disposed at a position that does not interfere with the suspension bolt 200 in the housing portion 213 in a state where the light source unit 2 is attached to the instrument body 1.

- the attachment member 21 has a bottom surface portion 211 formed in a long and rectangular plate shape, and in a direction intersecting the bottom surface portion 211 from both sides in the width direction of the bottom surface portion 211. It is preferable to be formed by a pair of protruding side surface portions 212.

- the housing portion 213 is configured by a space surrounded by the bottom surface portion 211 and the pair of side surface portions 212.

Landscapes

- Engineering & Computer Science (AREA)

- General Engineering & Computer Science (AREA)

- Non-Portable Lighting Devices Or Systems Thereof (AREA)

- Arrangement Of Elements, Cooling, Sealing, Or The Like Of Lighting Devices (AREA)

- Fastening Of Light Sources Or Lamp Holders (AREA)

Abstract

This light source unit has a hole for a suspension bolt to pass through, and is removably attached to a fixture main body attached to a ceiling member by means of a suspension bolt passed through the hole. The light source unit is provided with: an LED substrate to which a plurality of LEDs are mounted; an attachment member for attaching to the fixture main body the LED substrate in a manner so that the LED substrate is disposed between the plurality of LEDs and the fixture main body; and a power source device that supplies lighting electrical power to the plurality of LEDs. The attachment member has a housing section at which the power source device and at least a portion of the suspension bolt are disposed at a site facing the fixture main body. The power source device is disposed at a position that does not interfere with the suspension bolt within the housing section in the state of the light source unit being attached to the fixture main body.

Description

本発明は、光源ユニット及び照明器具に関する。

The present invention relates to a light source unit and a lighting fixture.

例えば、文献1(日本国公開特許公報第2011-142063号)には、取付ねじを用いて天井に取り付けられる天井直付け型の照明器具が開示されている。この照明器具は、横長且つ長尺状に形成されたベースプレートと、ベースプレートに対して天井と反対側に配置されるウィング部と、複数のホルダを用いてウィング部に取り付けられるLEDユニットとを備える。ベースプレートの略中央には、取付ねじを通すためのねじ穴が長手方向に沿って複数設けられている。

For example, Document 1 (Japan Published Patent Publication No. 2011-142063) discloses a ceiling-mounted lighting fixture that is attached to a ceiling using a mounting screw. This lighting fixture includes a base plate that is formed in a horizontally long and long shape, a wing portion that is disposed on the opposite side of the ceiling with respect to the base plate, and an LED unit that is attached to the wing portion using a plurality of holders. A plurality of screw holes for passing the mounting screws are provided along the longitudinal direction at the approximate center of the base plate.

また、LEDユニットは、複数のLEDモジュールと、複数のLEDモジュールを支持する支持部材と、複数のLEDモジュールを覆うようにして支持部材に取り付けられるカバーと、複数のLEDに電力を供給するための電力変換部とを有する。そして、一体に組み付けられたLEDユニットは、その一部がウィング部に設けられた凹部に収容された状態で複数のホルダを用いてウィング部に取り付けられる。

The LED unit also includes a plurality of LED modules, a support member that supports the plurality of LED modules, a cover that is attached to the support member so as to cover the plurality of LED modules, and for supplying power to the plurality of LEDs. A power conversion unit. And the LED unit assembled | attached integrally is attached to a wing part using a some holder in the state accommodated in the recessed part provided in the wing part.

上述の文献1に示した照明器具では、天井に取り付けた状態で取付ねじがウィング部の凹部内に進入できるようになっておらず、取付ねじのねじ頭を配置するためのスペースがベースプレートとウィング部の間に設けられている。そのため、器具全体の高さ寸法が大きくなってしまい、その結果、天井からの突出量が大きくなっていた。

In the luminaire shown in the above-mentioned document 1, the mounting screw is not allowed to enter the recess of the wing portion when attached to the ceiling, and the space for placing the screw head of the mounting screw is not the base plate and the wing. It is provided between the parts. Therefore, the height dimension of the entire instrument is increased, and as a result, the amount of protrusion from the ceiling is increased.

本発明は上記問題点に鑑みて為されたものであり、その目的とするところは、天井からの突出量を低く抑えた光源ユニット及び照明器具を提供することにある。

The present invention has been made in view of the above problems, and an object of the present invention is to provide a light source unit and a lighting fixture in which the amount of protrusion from the ceiling is kept low.

本発明に係る第1の形態の光源ユニットは、吊ボルトを通すための孔を有し、前記孔に通された前記吊ボルトによって天井材に取り付けられる器具本体に対して着脱自在に取り付けられる。光源ユニットは、複数のLEDが実装されたLED基板と、前記LED基板が前記複数のLEDと前記器具本体との間に配置されるようにして前記LED基板を前記器具本体に取り付けるための取付部材と、前記複数のLEDに点灯電力を供給する電源装置とを備える。前記取付部材は、前記器具本体と対向する部位に前記吊ボルトの少なくとも一部及び前記電源装置が配置される収容部を有する。前記電源装置は、前記光源ユニットを前記器具本体に取り付けた状態で前記収容部内における前記吊ボルトと干渉しない位置に配置される。

The light source unit according to the first aspect of the present invention has a hole for passing a suspension bolt, and is detachably attached to a fixture main body attached to a ceiling material by the suspension bolt passed through the hole. The light source unit includes an LED board on which a plurality of LEDs are mounted, and an attachment member for attaching the LED board to the instrument body such that the LED board is disposed between the plurality of LEDs and the instrument body. And a power supply device that supplies lighting power to the plurality of LEDs. The attachment member has a housing portion in which at least a part of the suspension bolt and the power supply device are disposed at a portion facing the instrument body. The power supply device is disposed at a position where it does not interfere with the suspension bolt in the housing portion in a state where the light source unit is attached to the instrument body.

本発明に係る第2の形態の光源ユニットでは、第1の形態において、前記取付部材は、長尺且つ矩形板状に形成された底面部と、前記底面部の幅方向における両側から前記底面部と交差する方向に突出する一対の側面部とで形成されており、前記底面部と一対の前記側面部とで囲まれる空間により前記収容部が構成されている。

In the light source unit according to the second aspect of the present invention, in the first aspect, the attachment member includes a bottom surface formed in a long and rectangular plate shape, and the bottom surface from both sides in the width direction of the bottom surface. Are formed with a pair of side portions protruding in a direction intersecting with each other, and the housing portion is constituted by a space surrounded by the bottom portion and the pair of side portions.

本発明に係る第3の形態の照明器具は、長尺状に形成され吊ボルトを用いて天井材に取り付けられる器具本体と、前記器具本体に対して着脱自在に取り付けられる光源ユニットとを備える。前記器具本体における前記天井材と反対側には、前記器具本体の長手方向に沿って収容凹部が設けられ、前記収容凹部の底面部には前記吊ボルトを通すための孔が設けられている。前記光源ユニットは、複数のLEDが実装されたLED基板と、前記複数のLEDが前記収容凹部の外側を向くようにして前記LED基板を前記器具本体に取り付けるための取付部材と、前記複数のLEDに点灯電力を供給する電源装置とを有する。前記取付部材は、前記器具本体の前記収容凹部と対向する部位に前記吊ボルトの少なくとも一部及び前記電源装置が配置される収容部を有する。前記電源装置は、前記光源ユニットを前記器具本体に取り付けた状態で前記収容部内における前記吊ボルトと干渉しない位置に配置される。

The lighting fixture of the 3rd form which concerns on this invention is equipped with the fixture main body formed in elongate shape and attached to a ceiling material using a suspension bolt, and the light source unit attached to the said fixture main body so that attachment or detachment is possible. An accommodation recess is provided along the longitudinal direction of the instrument body on the opposite side of the ceiling body of the instrument body, and a hole for passing the suspension bolt is provided in the bottom surface of the accommodation recess. The light source unit includes an LED substrate on which a plurality of LEDs are mounted, an attachment member for attaching the LED substrate to the instrument body so that the plurality of LEDs face the outside of the housing recess, and the plurality of LEDs And a power supply device for supplying lighting power. The attachment member includes a housing portion in which at least a part of the suspension bolt and the power supply device are disposed at a portion of the instrument body that faces the housing recess. The power supply device is disposed at a position where it does not interfere with the suspension bolt in the housing portion in a state where the light source unit is attached to the instrument body.

本発明に係る第4の形態の照明器具は、第3の形態において、前記取付部材は、長尺且つ矩形板状に形成された底面部と、前記底面部の幅方向における両側から前記底面部と交差する方向に突出する一対の側面部とで形成されており、前記底面部と一対の前記側面部とで囲まれる空間により前記収容部が構成されている。

The lighting fixture of the 4th form which concerns on this invention is the bottom face part from the both sides in the width direction of the said bottom face part in the width direction of the said bottom face part, and the said attachment member in the 3rd form in the 3rd form. Are formed with a pair of side portions protruding in a direction intersecting with each other, and the housing portion is constituted by a space surrounded by the bottom portion and the pair of side portions.

以下に、照明器具10の実施形態について図1A~図5を参照して説明する。なお、以下の説明では特に断りがない限り、図1Bに示す向きにおいて上下左右の方向を規定し、さらに図1B中の紙面に垂直な方向を前後方向と規定して以下の説明を行う。

Hereinafter, an embodiment of the lighting apparatus 10 will be described with reference to FIGS. 1A to 5. In the following description, unless otherwise specified, the vertical and horizontal directions are defined in the orientation shown in FIG. 1B, and the direction perpendicular to the paper surface in FIG.

本実施形態の照明器具10は、図1A~図4に示すように、天井直付け型の照明器具であり、吊ボルト200(図1B参照)を用いて天井材100に取り付けられる器具本体1と、器具本体1に対して着脱自在に取り付けられる光源ユニット2とを備える。なお、本実施形態では、図1Aに示すように、天井裏に設けた梁400に吊ボルト200が取り付けられており、天井材100に設けた孔を通して吊ボルト200が室内側(下側)に露出している。

As shown in FIGS. 1A to 4, the lighting fixture 10 of the present embodiment is a ceiling-mounted lighting fixture, and the fixture main body 1 attached to the ceiling member 100 using a suspension bolt 200 (see FIG. 1B) The light source unit 2 is detachably attached to the instrument body 1. In the present embodiment, as shown in FIG. 1A, the suspension bolt 200 is attached to the beam 400 provided on the back of the ceiling, and the suspension bolt 200 is placed on the indoor side (lower side) through the hole provided in the ceiling material 100. Exposed.

器具本体1は、板金に曲げ加工を施すことで長尺且つ上面(天井材100との対向面)が開口する扁平な箱状に形成され、天井材100と反対側(つまり下側)には光源ユニット2を収容するための矩形の収容凹部11が器具本体1の全長に亘って設けられている。また、器具本体1の左右方向(幅方向)において収容凹部11の両側には、収容凹部11の開口端縁から延出し且つ外側に行くほど上側(天井材100側)に傾斜する傾斜面12,12がそれぞれ設けられている。

The instrument main body 1 is formed into a flat box shape that is long and has an upper surface (a surface facing the ceiling material 100) opened by bending the sheet metal, and on the side opposite to the ceiling material 100 (that is, the lower side). A rectangular housing recess 11 for housing the light source unit 2 is provided over the entire length of the instrument body 1. In addition, on both sides of the housing recess 11 in the left-right direction (width direction) of the instrument body 1, inclined surfaces 12 that extend from the opening edge of the housing recess 11 and incline upward (toward the ceiling material 100) toward the outside. 12 are provided.

また、収容凹部11の底面部111には、電線を通すための孔111aが前後方向(長手方向)に沿って複数(図2では5個)設けられており、さらに吊ボルト200を通すための孔111bが前後方向における両端寄りの位置にそれぞれ2個ずつ設けられている。さらに、器具本体1の前後方向における両端部には、図2~図4に示すように、エンドキャップ3がそれぞれ取り付けられている。

Further, a plurality of holes (5 in FIG. 2) are provided in the bottom surface portion 111 of the housing recess 11 along the front-rear direction (longitudinal direction) for passing the electric wire, and further, the suspension bolt 200 is passed through. Two holes 111b are provided at positions near both ends in the front-rear direction. Further, as shown in FIGS. 2 to 4, end caps 3 are respectively attached to both ends of the instrument body 1 in the front-rear direction.

光源ユニット2は、図2及び図5に示すように、複数(図2では2個)のLED基板22と、LED基板22が取り付けられる取付部材21と、LED基板22を覆うようにして取付部材21に取り付けられるカバー部材23とを有する。また、光源ユニット2は、LED基板22に所定の点灯電力を供給する電源装置24と、端子台ブロック25とを有する。

2 and 5, the light source unit 2 includes a plurality of (two in FIG. 2) LED boards 22, a mounting member 21 to which the LED boards 22 are attached, and a mounting member that covers the LED boards 22. Cover member 23 attached to 21. The light source unit 2 includes a power supply device 24 that supplies predetermined lighting power to the LED substrate 22 and a terminal block block 25.

LED基板22は、前後方向に長い矩形板状に形成されたプリント基板221からなり、プリント基板221の下面には複数のLED(発光ダイオード)222が前後方向(長手方向)に沿って実装されている。また、一方(図2中の右側)のLED基板22の一端部(右端部)には、電源装置24との間を電気的に接続するためのコネクタ223が実装されている。このコネクタ223には電線(図示せず)が接続されており、電線の端部を電源装置24に接続することでLED基板22と電源装置24とが電気的に接続される。

The LED board 22 includes a printed board 221 formed in a rectangular plate shape that is long in the front-rear direction. A plurality of LEDs (light emitting diodes) 222 are mounted on the lower surface of the printed board 221 along the front-rear direction (longitudinal direction). Yes. In addition, a connector 223 for electrically connecting the power supply device 24 is mounted on one end (right end) of the LED substrate 22 on one side (right side in FIG. 2). An electric wire (not shown) is connected to the connector 223, and the LED substrate 22 and the power supply device 24 are electrically connected by connecting the end of the electric wire to the power supply device 24.

また、各LED基板22において隣接するLED基板22と対向する端部には、電源供給用のコネクタ224がそれぞれ実装されている。そして、両LED基板22,22のコネクタ224,224を接続することで、一方(図2中の右側)のLED基板22から他方(図2中の左側)のLED基板22に電源を供給することができる。

Further, a power supply connector 224 is mounted on each LED substrate 22 at the end facing the adjacent LED substrate 22. Then, by connecting the connectors 224 and 224 of the LED boards 22 and 22, the power is supplied from the LED board 22 on one side (right side in FIG. 2) to the LED board 22 on the other side (left side in FIG. 2). Can do.

取付部材21は、板金に曲げ加工を施すことでU字状に形成され、長尺且つ矩形板状に形成された底面部211と、底面部211の左右方向(幅方向)における両端から上下方向(底面部211と直交する方向)に延出する一対の側面部212とで構成される。各側面部212の先端には、図5に示すように、互いに離れる方向に傾斜する傾斜部212aがそれぞれ全長に亘って設けられている。

The mounting member 21 is formed in a U shape by bending a sheet metal, and is a bottom surface portion 211 formed in a long and rectangular plate shape, and a vertical direction from both ends in the left-right direction (width direction) of the bottom surface portion 211. It is comprised by a pair of side part 212 extended in (the direction orthogonal to the bottom face part 211). As shown in FIG. 5, inclined portions 212 a that are inclined in directions away from each other are provided at the tips of the side portions 212 over the entire length.

底面部211の前後方向(長手方向)における一端部(図2中の右端部)には、LED基板22と電源装置24とを電気的に接続する上記電線を通すための孔211aが設けられている。また、底面部211の前後方向における略中央には、底面部211の一部を上向きに突出させることで形成された矩形の凹部211bが設けられている。この凹部211bは、両LED基板22,22を取付部材21に取り付けた状態で、コネクタ224と取付部材21の底面部211との間の絶縁距離を確保するためのものである。

A hole 211a is formed in one end portion (right end portion in FIG. 2) of the bottom surface portion 211 in the front-rear direction (longitudinal direction). Yes. In addition, a rectangular recess 211b formed by projecting a part of the bottom surface portion 211 upward is provided at a substantially center in the front-rear direction of the bottom surface portion 211. The concave portion 211 b is for securing an insulation distance between the connector 224 and the bottom surface portion 211 of the mounting member 21 in a state where both the LED boards 22 and 22 are mounted on the mounting member 21.

なお、上述したLED基板22は、例えば取付部材21の底面部211の一部を切り起こすことで形成された係止爪(図示せず)により取付部材21に固定される。

In addition, the LED board 22 mentioned above is fixed to the attachment member 21 by the latching claw (not shown) formed by, for example, raising a part of the bottom face part 211 of the attachment member 21.

カバー部材23は、拡散性を有する材料(例えば乳白色のアクリル樹脂)により上面(取付部材21側の面)が開口する長尺状に形成されている。このカバー部材23は、左右方向(幅方向)において両端側から中央側に行くほど下側への突出量が大きくなるような凸レンズ形状の拡散面231を有している(図5参照)。

The cover member 23 is formed in a long shape whose upper surface (surface on the mounting member 21 side) is opened by a diffusible material (for example, milky white acrylic resin). The cover member 23 has a convex lens-shaped diffusing surface 231 in which the amount of protrusion downward increases from the both end sides to the center side in the left-right direction (width direction) (see FIG. 5).

また、カバー部材23の左右方向における両端部には、図1Bに示すように、光源ユニット2を器具本体1に取り付けた状態で、上下方向において器具本体1の収容凹部11の開口端縁と重なる延出部232がそれぞれ設けられている。さらに、カバー部材23の左右方向において各延出部232の内側には、上側(取付部材21側)に突出する突壁部233がそれぞれ全長に亘って設けられており、各突壁部233の先端には内向きに突出する突起部233aがそれぞれ設けられている。

Further, as shown in FIG. 1B, both ends of the cover member 23 in the left-right direction overlap with the opening edge of the housing recess 11 of the instrument main body 1 in the vertical direction with the light source unit 2 attached to the instrument main body 1. Each extending portion 232 is provided. Furthermore, projecting wall portions 233 projecting upward (on the attachment member 21 side) are provided on the inner sides of the extending portions 232 in the left-right direction of the cover member 23, respectively. Protrusions 233a projecting inward are provided at the tips.

電源装置24は、電源基板241と、電源基板241を収納するための収納ケース242とを有する。電源基板241は、前後方向に長い矩形板状に形成されたプリント基板241aからなり、プリント基板241aには、少なくともLED222の点灯電力を生成するための回路部品(例えばトランスやダイオード、コンデンサなど)241bが実装されている。

The power supply device 24 includes a power supply board 241 and a storage case 242 for storing the power supply board 241. The power supply board 241 includes a printed board 241a formed in a rectangular plate shape that is long in the front-rear direction. The printed board 241a includes at least circuit components (for example, a transformer, a diode, a capacitor, etc.) 241b for generating lighting power for the LEDs 222. Has been implemented.

収納ケース242は、図5に示すように、一面(取付部材21の底面部211との対向面)が開口し且つ前後方向に長い矩形箱状の収納部242aを有する。また、収納ケース242は、収納部242aの開口端縁から側方(図5中の左側)に延出する第1延出部242b、第1延出部242bの先端から上側に延出する第2延出部242c、及び第2延出部242cと対向する収納部242aの側面部242dで囲まれる空間からなる溝部242eを有する。

As shown in FIG. 5, the storage case 242 has a rectangular box-shaped storage part 242 a that is open on one side (the surface facing the bottom surface part 211 of the mounting member 21) and is long in the front-rear direction. In addition, the storage case 242 includes a first extension portion 242b extending from the opening edge of the storage portion 242a to the side (left side in FIG. 5) and a first extension portion 242b extending upward from the tip of the first extension portion 242b. 2 has a groove portion 242e formed of a space surrounded by the side surface portion 242d of the storage portion 242a facing the second extension portion 242c and the second extension portion 242c.

この溝部242eは、端子台ブロック25から電源装置24への電線や、電源装置24からLED基板22への電線、隣接する照明器具10へ電力を送る電線などを通すための配線スペースとして利用される。そして、この電源装置24は、取付部材21の底面部211と両側面部212,212とで囲まれる空間からなる収容部213に少なくとも一部が収容された状態で、例えばねじなどを用いて取付部材21に取り付けられる。

The groove portion 242e is used as a wiring space for passing an electric wire from the terminal block block 25 to the power supply device 24, an electric wire from the power supply device 24 to the LED board 22, an electric wire for sending electric power to the adjacent lighting fixture 10, and the like. . And this power supply device 24 is an attachment member using a screw etc., for example in the state in which at least one part was accommodated in the accommodating part 213 which consists of the space enclosed by the bottom face part 211 and the both-sides surface parts 212 and 212 of the attachment member 21. 21 is attached.

端子台ブロック25は、矩形箱状に形成された端子台251と、端子台251を取付部材21に取り付けるための取付金具252とを有する。端子台251には、天井材100を通して室内側(下側)に露出する電源線(図示せず)が接続されるとともに、電源装置24との間を電気的に接続する電線(図示せず)が接続される。そして、この端子台ブロック25は、少なくとも一部が収容部213に収容された状態で、例えばねじなどを用いて取付部材21に取り付けられる。

The terminal block 25 has a terminal block 251 formed in a rectangular box shape and a mounting bracket 252 for mounting the terminal block 251 to the mounting member 21. A power line (not shown) exposed to the indoor side (lower side) through the ceiling member 100 is connected to the terminal block 251, and an electric wire (not shown) that electrically connects the power source 24. Is connected. And this terminal block block 25 is attached to the attachment member 21 using a screw etc. in the state in which at least one part was accommodated in the accommodating part 213, for example.

次に、光源ユニット2の組立手順について説明する。まず最初に、作業者は、電源装置24及び端子台ブロック25をそれぞれ取付部材21の上面側に取り付け、さらに電源装置24と端子台ブロック25の間を電線により接続する。その後、作業者は、上記係止爪によりLED基板22を取付部材21の底面部211に固定し、LED基板22のコネクタ223から導出する電線を取付部材21の底面部211に設けた孔211aに通した後、その端部を電源装置24に接続する。

Next, the assembly procedure of the light source unit 2 will be described. First, the operator attaches the power supply device 24 and the terminal block block 25 to the upper surface side of the attachment member 21, respectively, and further connects the power supply device 24 and the terminal block block 25 with electric wires. Thereafter, the operator fixes the LED board 22 to the bottom surface portion 211 of the mounting member 21 with the locking claws, and the electric wire led out from the connector 223 of the LED board 22 into the hole 211 a provided in the bottom surface portion 211 of the mounting member 21. After passing, the end is connected to the power supply device 24.

そして最後に、作業者は、開口側を上向きにした状態でカバー部材23を取付部材21に組み付ける。このとき、カバー部材23の各突壁部233にそれぞれ設けた突起部233aが、取付部材21の各側面部212にそれぞれ設けた傾斜部212aに引っ掛かり、カバー部材23が取付部材21に取り付けられる。以上のような手順に従って、光源ユニット2が組み立てられる。なお、カバー部材23を取付部材21に取り付ける上記方法は一例であり、他の方法であってもよい。

Finally, the operator attaches the cover member 23 to the mounting member 21 with the opening side facing upward. At this time, the protrusions 233 a provided on the respective protruding wall portions 233 of the cover member 23 are hooked on the inclined portions 212 a provided on the respective side surface portions 212 of the attachment member 21, and the cover member 23 is attached to the attachment member 21. The light source unit 2 is assembled according to the above procedure. In addition, the said method of attaching the cover member 23 to the attachment member 21 is an example, and another method may be sufficient.

続けて、照明器具10の施工手順について説明する。まず最初に、作業者は、室内側に露出する上記電源線を器具本体1に設けた孔111aに通し、天井材100を通して室内側に露出する吊ボルト200を孔111bに通した後、吊ボルト200にナット300をねじ込んで器具本体1を天井材100に固定する。

Next, the construction procedure of the lighting fixture 10 will be described. First, the operator passes the power line exposed to the indoor side through the hole 111a provided in the instrument main body 1, passes the suspension bolt 200 exposed to the indoor side through the ceiling material 100, and then passes through the hole 111b. A nut 300 is screwed into 200 to fix the instrument body 1 to the ceiling material 100.

その後、作業者は、上記電源線を端子台251に接続し、少なくとも電源装置24及び端子台ブロック25が収容凹部11に収容されるように、例えば器具本体1及び取付部材21にそれぞれ設けた嵌合構造(図示せず)により光源ユニット2を器具本体1に取り付ける。以上のような手順に従って、照明器具10が天井に施工される。

After that, the operator connects the power line to the terminal block 251, and fits provided in, for example, the instrument body 1 and the attachment member 21 so that at least the power supply device 24 and the terminal block block 25 are accommodated in the accommodating recess 11. The light source unit 2 is attached to the instrument body 1 by a combined structure (not shown). The lighting fixture 10 is constructed on the ceiling according to the above procedure.

ここで、図1A及び図1Bは照明器具10を天井材100に取り付けた状態の断面図であり、図1Bに示すように、吊ボルト200の一部及び電源装置24の一部が取付部材21の収容部213に配置される。また、図1Aに示すように、電源装置24の長手寸法L1(前後方向に沿った寸法)が吊ボルト200の取付ピッチ寸法P1よりも小さいため、前後方向(図1A中の左右方向)において吊ボルト200と干渉しないように電源装置24を配置することができる。

Here, FIG. 1A and FIG. 1B are cross-sectional views of the state in which the lighting fixture 10 is attached to the ceiling material 100. As shown in FIG. 1B, a part of the suspension bolt 200 and a part of the power supply device 24 are attached to the attachment member 21. It arrange | positions in the accommodating part 213 of. Further, as shown in FIG. 1A, since the longitudinal dimension L1 (dimension along the front-rear direction) of the power supply device 24 is smaller than the mounting pitch dimension P1 of the suspension bolt 200, it is suspended in the front-rear direction (left-right direction in FIG. 1A). The power supply device 24 can be arranged so as not to interfere with the bolt 200.

而して、本実施形態によれば、光源ユニット2を器具本体1に取り付けた状態では、吊ボルト200の少なくとも一部が取付部材21の収容部213に配置される。そのため、収容部を設けない場合に比べて器具全体の高さ寸法を小さくすることができ、その結果、天井からの突出量を低く抑えた照明器具10を提供することができる。

Thus, according to the present embodiment, in a state where the light source unit 2 is attached to the instrument main body 1, at least a part of the suspension bolt 200 is disposed in the accommodating portion 213 of the attachment member 21. Therefore, compared with the case where an accommodating part is not provided, the height dimension of the whole instrument can be made small, As a result, the lighting fixture 10 which restrained the protrusion amount from the ceiling low can be provided.

また、端子台ブロック25から電源装置24への電線や、電源装置24からLED基板22への電線、隣接する照明器具10へ電力を送る電線などを通すための配線スペースとして収容部213を利用することもできる。さらに、取付部材21の形状をU字状とすることで成形が容易になり、その結果製作工数を削減できてコストダウンを図ることができる。

Further, the housing portion 213 is used as a wiring space for passing an electric wire from the terminal block block 25 to the power supply device 24, an electric wire from the power supply device 24 to the LED substrate 22, an electric wire for sending electric power to the adjacent lighting fixture 10, and the like. You can also. Furthermore, by making the shape of the attachment member 21 U-shaped, it becomes easy to form, and as a result, the number of manufacturing steps can be reduced and the cost can be reduced.

本実施形態の光源ユニット2は、吊ボルト200を通すための孔111bを有し、孔111bに通された吊ボルト200によって天井材100に取り付けられる器具本体1に対して着脱自在に取り付けられる。光源ユニット2は、複数のLED222が実装されたLED基板22と、LED基板22が複数のLED222と器具本体1との間に配置されるようにしてLED基板22を器具本体1に取り付けるための取付部材21と、複数のLED222に点灯電力を供給する電源装置24とを備える。取付部材21は、器具本体1と対向する部位に吊ボルト200の少なくとも一部及び電源装置24が配置される収容部213を有する。電源装置24は、光源ユニット2を器具本体1に取り付けた状態で収容部213内における吊ボルト200と干渉しない位置に配置される。

The light source unit 2 of the present embodiment has a hole 111b for allowing the suspension bolt 200 to pass through, and is detachably attached to the fixture body 1 attached to the ceiling material 100 by the suspension bolt 200 passed through the hole 111b. The light source unit 2 includes an LED substrate 22 on which a plurality of LEDs 222 are mounted, and an attachment for attaching the LED substrate 22 to the instrument body 1 such that the LED substrate 22 is disposed between the plurality of LEDs 222 and the instrument body 1. A member 21 and a power supply device 24 that supplies lighting power to the plurality of LEDs 222 are provided. The attachment member 21 has a housing portion 213 in which at least a part of the suspension bolt 200 and the power supply device 24 are disposed at a portion facing the instrument body 1. The power supply device 24 is disposed at a position that does not interfere with the suspension bolt 200 in the housing portion 213 in a state where the light source unit 2 is attached to the instrument body 1.

また、本実施形態の光源ユニット2のように、取付部材21は、長尺且つ矩形板状に形成された底面部211と、底面部211の幅方向における両側から底面部211と交差する方向に突出する一対の側面部212とで形成されているのが好ましい。この場合、底面部211と一対の側面部212とで囲まれる空間により収容部213が構成されている。

Further, as in the light source unit 2 of the present embodiment, the attachment member 21 includes a bottom surface portion 211 formed in a long and rectangular plate shape, and a direction intersecting the bottom surface portion 211 from both sides in the width direction of the bottom surface portion 211. It is preferable to be formed by a pair of protruding side surface portions 212. In this case, the housing portion 213 is configured by a space surrounded by the bottom surface portion 211 and the pair of side surface portions 212.

本実施形態の照明器具10は、長尺状に形成され吊ボルト200を用いて天井材10に取り付けられる器具本体1と、器具本体1に対して着脱自在に取り付けられる光源ユニット2とを備える。器具本体1における天井材100と反対側には、器具本体1の長手方向に沿って収容凹部11が設けられ、収容凹部11の底面部111には吊ボルト200を通すための孔111bが設けられている。光源ユニット2は、複数のLED222が実装されたLED基板22と、複数のLED222が収容凹部11の外側を向くようにしてLED基板22を器具本体1に取り付けるための取付部材21と、複数のLED222に点灯電力を供給する電源装置24とを有する。取付部材21は、器具本体1の収容凹部11と対向する部位に吊ボルト200の少なくとも一部及び電源装置24が配置される収容部213を有する。電源装置24は、光源ユニット2を器具本体1に取り付けた状態で収容部213内における吊ボルト200と干渉しない位置に配置される。

The lighting fixture 10 of the present embodiment includes a fixture main body 1 that is formed in a long shape and is attached to the ceiling member 10 using a suspension bolt 200, and a light source unit 2 that is detachably attached to the fixture main body 1. On the opposite side of the instrument body 1 from the ceiling material 100, an accommodation recess 11 is provided along the longitudinal direction of the instrument body 1, and a hole 111 b for passing the suspension bolt 200 is provided on the bottom surface portion 111 of the accommodation recess 11. ing. The light source unit 2 includes an LED substrate 22 on which a plurality of LEDs 222 are mounted, an attachment member 21 for attaching the LED substrate 22 to the instrument body 1 such that the plurality of LEDs 222 face the outside of the housing recess 11, and a plurality of LEDs 222. And a power supply device 24 for supplying lighting power. The attachment member 21 has a housing portion 213 in which at least a part of the suspension bolt 200 and the power supply device 24 are disposed at a portion facing the housing recess 11 of the instrument body 1. The power supply device 24 is disposed at a position that does not interfere with the suspension bolt 200 in the housing portion 213 in a state where the light source unit 2 is attached to the instrument body 1.

また、本実施形態の照明器具10のように、取付部材21は、長尺且つ矩形板状に形成された底面部211と、底面部211の幅方向における両側から底面部211と交差する方向に突出する一対の側面部212とで形成されているのが好ましい。この場合、底面部211と一対の側面部212とで囲まれる空間により収容部213が構成されている。

Further, as in the lighting fixture 10 of the present embodiment, the attachment member 21 has a bottom surface portion 211 formed in a long and rectangular plate shape, and in a direction intersecting the bottom surface portion 211 from both sides in the width direction of the bottom surface portion 211. It is preferable to be formed by a pair of protruding side surface portions 212. In this case, the housing portion 213 is configured by a space surrounded by the bottom surface portion 211 and the pair of side surface portions 212.

Claims (4)

- 吊ボルトを通すための孔を有し、前記孔に通された前記吊ボルトによって天井材に取り付けられる器具本体に対して着脱自在に取り付けられる光源ユニットであって、

複数のLEDが実装されたLED基板と、前記LED基板が前記複数のLEDと前記器具本体との間に配置されるようにして前記LED基板を前記器具本体に取り付けるための取付部材と、前記複数のLEDに点灯電力を供給する電源装置とを備え、

前記取付部材は、前記器具本体と対向する部位に前記吊ボルトの少なくとも一部及び前記電源装置が配置される収容部を有し、

前記電源装置は、前記光源ユニットを前記器具本体に取り付けた状態で前記収容部内における前記吊ボルトと干渉しない位置に配置されることを特徴とする光源ユニット。 A light source unit having a hole for passing a suspension bolt, and detachably attached to an instrument body attached to a ceiling member by the suspension bolt passed through the hole;

An LED board on which a plurality of LEDs are mounted; an attachment member for attaching the LED board to the instrument body such that the LED board is disposed between the plurality of LEDs and the instrument body; A power supply for supplying lighting power to the LEDs of

The mounting member has a housing portion in which at least a part of the suspension bolt and the power supply device are arranged at a portion facing the instrument body,

The power supply device is disposed at a position where the power source device does not interfere with the suspension bolt in the housing portion in a state where the light source unit is attached to the instrument body. - 前記取付部材は、長尺且つ矩形板状に形成された底面部と、前記底面部の幅方向における両側から前記底面部と交差する方向に突出する一対の側面部とで形成されており、前記底面部と一対の前記側面部とで囲まれる空間により前記収容部が構成されていることを特徴とする請求項1記載の光源ユニット。 The attachment member is formed of a bottom surface portion formed in a long and rectangular plate shape, and a pair of side surface portions protruding in a direction intersecting the bottom surface portion from both sides in the width direction of the bottom surface portion, The light source unit according to claim 1, wherein the housing portion is configured by a space surrounded by a bottom surface portion and the pair of side surface portions.

- 長尺状に形成され吊ボルトを用いて天井材に取り付けられる器具本体と、前記器具本体に対して着脱自在に取り付けられる光源ユニットとを備え、

前記器具本体における前記天井材と反対側には、前記器具本体の長手方向に沿って収容凹部が設けられ、前記収容凹部の底面部には前記吊ボルトを通すための孔が設けられており、

前記光源ユニットは、複数のLEDが実装されたLED基板と、前記複数のLEDが前記収容凹部の外側を向くようにして前記LED基板を前記器具本体に取り付けるための取付部材と、前記複数のLEDに点灯電力を供給する電源装置とを有し、

前記取付部材は、前記器具本体の前記収容凹部と対向する部位に前記吊ボルトの少なくとも一部及び前記電源装置が配置される収容部を有し、

前記電源装置は、前記光源ユニットを前記器具本体に取り付けた状態で前記収容部内における前記吊ボルトと干渉しない位置に配置されることを特徴とする照明器具。 An instrument main body formed in a long shape and attached to a ceiling material using a suspension bolt, and a light source unit detachably attached to the instrument main body,

On the side opposite to the ceiling material in the instrument body, an accommodation recess is provided along the longitudinal direction of the instrument body, and a hole for passing the suspension bolt is provided in the bottom surface of the accommodation recess,

The light source unit includes an LED substrate on which a plurality of LEDs are mounted, an attachment member for attaching the LED substrate to the instrument body so that the plurality of LEDs face the outside of the housing recess, and the plurality of LEDs And a power supply device for supplying lighting power to

The attachment member has a housing portion in which at least a part of the suspension bolt and the power supply device are disposed at a portion facing the housing recess of the instrument body,

The said power supply device is arrange | positioned in the position which does not interfere with the said suspension bolt in the said accommodating part in the state which attached the said light source unit to the said instrument main body. - 前記取付部材は、長尺且つ矩形板状に形成された底面部と、前記底面部の幅方向における両側から前記底面部と交差する方向に突出する一対の側面部とで形成されており、前記底面部と一対の前記側面部とで囲まれる空間により前記収容部が構成されていることを特徴とする請求項3記載の照明器具。 The attachment member is formed of a bottom surface portion formed in a long and rectangular plate shape, and a pair of side surface portions protruding in a direction intersecting the bottom surface portion from both sides in the width direction of the bottom surface portion, The lighting device according to claim 3, wherein the housing portion is configured by a space surrounded by a bottom surface portion and the pair of side surface portions.

Priority Applications (2)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| CN201390000761.6U CN204693345U (en) | 2012-10-11 | 2013-10-09 | Light source cell and ligthing paraphernalia |

| IN3739DEN2015 IN2015DN03739A (en) | 2012-10-11 | 2013-10-09 |

Applications Claiming Priority (2)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| JP2012225954A JP5453503B1 (en) | 2012-10-11 | 2012-10-11 | Light source unit and lighting apparatus |

| JP2012-225954 | 2012-10-11 |

Publications (1)

| Publication Number | Publication Date |

|---|---|

| WO2014057664A1 true WO2014057664A1 (en) | 2014-04-17 |

Family

ID=50477146

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| PCT/JP2013/006009 WO2014057664A1 (en) | 2012-10-11 | 2013-10-09 | Light source unit and illumination fixture |

Country Status (4)

| Country | Link |

|---|---|

| JP (1) | JP5453503B1 (en) |

| CN (1) | CN204693345U (en) |

| IN (1) | IN2015DN03739A (en) |

| WO (1) | WO2014057664A1 (en) |

Families Citing this family (2)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| CN106151888B (en) * | 2015-05-11 | 2021-03-02 | 松下知识产权经营株式会社 | Light source unit and lighting fixture including the same |

| JP2022022819A (en) * | 2020-07-07 | 2022-02-07 | 深セン市兆馳照明股▲フン▼有限公司 | Lighting fixture |

Citations (5)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| JPH05242717A (en) * | 1992-02-28 | 1993-09-21 | Tokyo Electric Co Ltd | Luminaire |

| JPH0587732U (en) * | 1992-05-01 | 1993-11-26 | 松下電工株式会社 | lighting equipment |

| JP2000294030A (en) * | 1999-04-09 | 2000-10-20 | Toshiba Lighting & Technology Corp | Luminaire |

| JP2010192306A (en) * | 2009-02-19 | 2010-09-02 | Sharp Corp | Lighting device |

| JP2012054005A (en) * | 2010-08-31 | 2012-03-15 | Panasonic Electric Works Co Ltd | Lighting fixture |

-

2012

- 2012-10-11 JP JP2012225954A patent/JP5453503B1/en active Active

-

2013

- 2013-10-09 CN CN201390000761.6U patent/CN204693345U/en not_active Expired - Lifetime

- 2013-10-09 WO PCT/JP2013/006009 patent/WO2014057664A1/en active Application Filing

- 2013-10-09 IN IN3739DEN2015 patent/IN2015DN03739A/en unknown

Patent Citations (5)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| JPH05242717A (en) * | 1992-02-28 | 1993-09-21 | Tokyo Electric Co Ltd | Luminaire |

| JPH0587732U (en) * | 1992-05-01 | 1993-11-26 | 松下電工株式会社 | lighting equipment |

| JP2000294030A (en) * | 1999-04-09 | 2000-10-20 | Toshiba Lighting & Technology Corp | Luminaire |

| JP2010192306A (en) * | 2009-02-19 | 2010-09-02 | Sharp Corp | Lighting device |

| JP2012054005A (en) * | 2010-08-31 | 2012-03-15 | Panasonic Electric Works Co Ltd | Lighting fixture |

Also Published As

| Publication number | Publication date |

|---|---|

| JP5453503B1 (en) | 2014-03-26 |

| CN204693345U (en) | 2015-10-07 |

| IN2015DN03739A (en) | 2015-09-18 |

| JP2014078423A (en) | 2014-05-01 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| JP5954665B2 (en) | lighting equipment | |

| JP5954664B2 (en) | lighting equipment | |

| JP5914859B2 (en) | lighting equipment | |

| JP5572256B2 (en) | Light source unit and lighting apparatus | |

| JP2014179207A (en) | Light source unit and lighting fixture using the same | |

| JP5971591B2 (en) | lighting equipment | |

| JP2014179209A (en) | Lighting fixture | |

| JP2014170732A (en) | Light source unit and lighting fixture | |

| JP6111494B2 (en) | lighting equipment | |

| JP2014078427A (en) | Lighting fixture | |

| WO2014057664A1 (en) | Light source unit and illumination fixture | |

| JP2014137931A (en) | Light source device and lighting device using the same | |

| JP6041210B2 (en) | Light source unit and lighting apparatus using the same | |

| JP5866527B2 (en) | Light source unit and lighting apparatus | |

| JP5492344B2 (en) | Light source unit and lighting apparatus | |

| WO2014136160A1 (en) | Light source unit and lighting apparatus | |

| JP6372779B2 (en) | lighting equipment | |

| JP6541062B2 (en) | lighting equipment | |

| JP6566342B2 (en) | Connector, power supply device, and lighting fixture | |

| JP6179051B2 (en) | lighting equipment | |

| JP6406595B2 (en) | Lighting system | |

| JP7012246B2 (en) | lighting equipment | |

| JP2015032569A (en) | Lighting device | |

| JP2015176748A (en) | Light source unit and lighting fixture using the same | |

| JP6089270B2 (en) | lighting equipment |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| WWE | Wipo information: entry into national phase |

Ref document number: 201390000761.6 Country of ref document: CN |

|

| 121 | Ep: the epo has been informed by wipo that ep was designated in this application |

Ref document number: 13845877 Country of ref document: EP Kind code of ref document: A1 |

|

| NENP | Non-entry into the national phase |

Ref country code: DE |

|

| 122 | Ep: pct application non-entry in european phase |

Ref document number: 13845877 Country of ref document: EP Kind code of ref document: A1 |