WO2014034776A1 - Method for manufacturing absorptive article - Google Patents

Method for manufacturing absorptive article Download PDFInfo

- Publication number

- WO2014034776A1 WO2014034776A1 PCT/JP2013/073133 JP2013073133W WO2014034776A1 WO 2014034776 A1 WO2014034776 A1 WO 2014034776A1 JP 2013073133 W JP2013073133 W JP 2013073133W WO 2014034776 A1 WO2014034776 A1 WO 2014034776A1

- Authority

- WO

- WIPO (PCT)

- Prior art keywords

- absorbent

- core

- lower layer

- absorber

- absorbent core

- Prior art date

Links

Images

Classifications

-

- A—HUMAN NECESSITIES

- A61—MEDICAL OR VETERINARY SCIENCE; HYGIENE

- A61F—FILTERS IMPLANTABLE INTO BLOOD VESSELS; PROSTHESES; DEVICES PROVIDING PATENCY TO, OR PREVENTING COLLAPSING OF, TUBULAR STRUCTURES OF THE BODY, e.g. STENTS; ORTHOPAEDIC, NURSING OR CONTRACEPTIVE DEVICES; FOMENTATION; TREATMENT OR PROTECTION OF EYES OR EARS; BANDAGES, DRESSINGS OR ABSORBENT PADS; FIRST-AID KITS

- A61F13/00—Bandages or dressings; Absorbent pads

- A61F13/15—Absorbent pads, e.g. sanitary towels, swabs or tampons for external or internal application to the body; Supporting or fastening means therefor; Tampon applicators

- A61F13/15577—Apparatus or processes for manufacturing

- A61F13/15617—Making absorbent pads from fibres or pulverulent material with or without treatment of the fibres

- A61F13/15634—Making fibrous pads between sheets or webs

-

- A—HUMAN NECESSITIES

- A61—MEDICAL OR VETERINARY SCIENCE; HYGIENE

- A61F—FILTERS IMPLANTABLE INTO BLOOD VESSELS; PROSTHESES; DEVICES PROVIDING PATENCY TO, OR PREVENTING COLLAPSING OF, TUBULAR STRUCTURES OF THE BODY, e.g. STENTS; ORTHOPAEDIC, NURSING OR CONTRACEPTIVE DEVICES; FOMENTATION; TREATMENT OR PROTECTION OF EYES OR EARS; BANDAGES, DRESSINGS OR ABSORBENT PADS; FIRST-AID KITS

- A61F13/00—Bandages or dressings; Absorbent pads

- A61F13/15—Absorbent pads, e.g. sanitary towels, swabs or tampons for external or internal application to the body; Supporting or fastening means therefor; Tampon applicators

- A61F13/45—Absorbent pads, e.g. sanitary towels, swabs or tampons for external or internal application to the body; Supporting or fastening means therefor; Tampon applicators characterised by the shape

- A61F13/47—Sanitary towels, incontinence pads or napkins

- A61F13/472—Sanitary towels, incontinence pads or napkins specially adapted for female use

-

- A—HUMAN NECESSITIES

- A61—MEDICAL OR VETERINARY SCIENCE; HYGIENE

- A61F—FILTERS IMPLANTABLE INTO BLOOD VESSELS; PROSTHESES; DEVICES PROVIDING PATENCY TO, OR PREVENTING COLLAPSING OF, TUBULAR STRUCTURES OF THE BODY, e.g. STENTS; ORTHOPAEDIC, NURSING OR CONTRACEPTIVE DEVICES; FOMENTATION; TREATMENT OR PROTECTION OF EYES OR EARS; BANDAGES, DRESSINGS OR ABSORBENT PADS; FIRST-AID KITS

- A61F13/00—Bandages or dressings; Absorbent pads

- A61F13/15—Absorbent pads, e.g. sanitary towels, swabs or tampons for external or internal application to the body; Supporting or fastening means therefor; Tampon applicators

- A61F13/53—Absorbent pads, e.g. sanitary towels, swabs or tampons for external or internal application to the body; Supporting or fastening means therefor; Tampon applicators characterised by the absorbing medium

- A61F13/534—Absorbent pads, e.g. sanitary towels, swabs or tampons for external or internal application to the body; Supporting or fastening means therefor; Tampon applicators characterised by the absorbing medium having an inhomogeneous composition through the thickness of the pad

- A61F13/535—Absorbent pads, e.g. sanitary towels, swabs or tampons for external or internal application to the body; Supporting or fastening means therefor; Tampon applicators characterised by the absorbing medium having an inhomogeneous composition through the thickness of the pad inhomogeneous in the plane of the pad, e.g. core absorbent layers being of different sizes

- A61F13/536—Absorbent pads, e.g. sanitary towels, swabs or tampons for external or internal application to the body; Supporting or fastening means therefor; Tampon applicators characterised by the absorbing medium having an inhomogeneous composition through the thickness of the pad inhomogeneous in the plane of the pad, e.g. core absorbent layers being of different sizes having discontinuous areas of compression

-

- A—HUMAN NECESSITIES

- A61—MEDICAL OR VETERINARY SCIENCE; HYGIENE

- A61F—FILTERS IMPLANTABLE INTO BLOOD VESSELS; PROSTHESES; DEVICES PROVIDING PATENCY TO, OR PREVENTING COLLAPSING OF, TUBULAR STRUCTURES OF THE BODY, e.g. STENTS; ORTHOPAEDIC, NURSING OR CONTRACEPTIVE DEVICES; FOMENTATION; TREATMENT OR PROTECTION OF EYES OR EARS; BANDAGES, DRESSINGS OR ABSORBENT PADS; FIRST-AID KITS

- A61F13/00—Bandages or dressings; Absorbent pads

- A61F13/15—Absorbent pads, e.g. sanitary towels, swabs or tampons for external or internal application to the body; Supporting or fastening means therefor; Tampon applicators

- A61F13/53—Absorbent pads, e.g. sanitary towels, swabs or tampons for external or internal application to the body; Supporting or fastening means therefor; Tampon applicators characterised by the absorbing medium

- A61F13/534—Absorbent pads, e.g. sanitary towels, swabs or tampons for external or internal application to the body; Supporting or fastening means therefor; Tampon applicators characterised by the absorbing medium having an inhomogeneous composition through the thickness of the pad

- A61F13/535—Absorbent pads, e.g. sanitary towels, swabs or tampons for external or internal application to the body; Supporting or fastening means therefor; Tampon applicators characterised by the absorbing medium having an inhomogeneous composition through the thickness of the pad inhomogeneous in the plane of the pad, e.g. core absorbent layers being of different sizes

- A61F2013/5355—Absorbent pads, e.g. sanitary towels, swabs or tampons for external or internal application to the body; Supporting or fastening means therefor; Tampon applicators characterised by the absorbing medium having an inhomogeneous composition through the thickness of the pad inhomogeneous in the plane of the pad, e.g. core absorbent layers being of different sizes with terraced core

Definitions

- the present invention relates to a method for producing absorbent articles such as sanitary napkins and incontinence pads.

- the applicant first comprises an absorber having an upper layer absorber on the skin facing surface side and a lower layer absorber on the non-skin facing surface side, and when the absorber is viewed in plan view,

- the sanitary napkin which arranged regularly the compression point formed by compressing an upper layer absorber and a lower layer absorber in the thickness direction was proposed (refer to patent documents 2).

- the core wrap sheet that wraps the absorbent core constituting the absorbent body may be torn. It was. If the core wrap sheet can be prevented from being torn, the convex part of the roll forming the compression part or the compression point can be easily removed from the absorbent body during the production of the sanitary napkin, and the sanitary napkin can be stably produced. Can be expected. In addition, if the core wrap sheet can be prevented from being torn, the absorbent body composed of the absorbent core and the core wrap sheet is further integrated, making the absorbent body difficult to twist when worn, and further improvement in fit to the body is expected. it can.

- the present invention relates to a method for producing an absorbent article that is hard to be broken in a core wrap sheet when a compressed portion or a compression point is formed on an absorbent body by pressing with a convex portion of a roll.

- the manufacturing method of an absorbent article of the present invention is a manufacturing method of an absorbent article provided with an absorbent body in which an absorbent core is wrapped with a core wrap sheet, wherein the absorbent body is partly raised in the thickness direction.

- a continuous body of the absorbent body is supplied between a convex roll and a flat roll having a plurality of convex portions on a peripheral surface, and the convex portions of the absorbent body are supplied by the convex portions.

- seat enter to the inside of this protruding part is provided.

- Each convex part used for the concave part forming step has a tip part projecting stepwise, and has a projecting part at the tip part.

- the width (W1) of the projecting part and the tip of the projecting part The relationship with the protrusion height (h) is W1 ⁇ h.

- the absorbent article of the present invention is an absorbent article including an absorbent body in which an absorbent core is wrapped with a core wrap sheet, and the absorbent body has a raised portion that is partially raised in the thickness direction.

- the absorber has a plurality of the recesses that have entered the inside of the raised portion of the absorber.

- the core wrap sheet has a sheet that covers the non-skin facing side of the absorbent core, separate from the sheet that covers the skin facing side of the absorbent core, and covers the non-skin facing side. The sheet to be inserted penetrates into the raised portion in the concave portion.

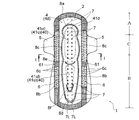

- FIG. 1 is a plan view showing a sanitary napkin obtained by an embodiment of the present invention.

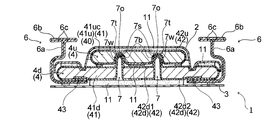

- 2 is a cross-sectional view taken along the line II shown in FIG.

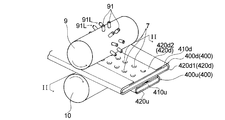

- FIG. 3 is a schematic perspective view showing a pair of convex rolls and flat rolls suitably used for carrying out the manufacturing method according to the embodiment of the present invention.

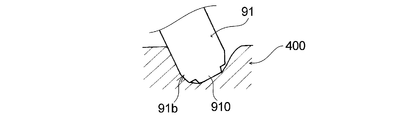

- FIG. 4 is an enlarged perspective view of a convex portion provided in the convex roll shown in FIG. 3. It is the schematic which looked at a pair of convex roll and flat roll which are shown in FIG. 5, FIG. 3 from the side. 6 is a cross-sectional view taken along the line II-II shown in FIG.

- FIG. 7 is an explanatory diagram when the concave portion is formed by the convex portion provided in the convex roll shown in FIG. 3.

- the manufacturing method of the absorbent article of this invention and the absorbent article of this invention are demonstrated, referring drawings based on the preferable embodiment.

- a sanitary napkin manufactured by the manufacturing method of this embodiment and a sanitary napkin which is an absorbent article of the present invention will be described with reference to FIGS.

- the sanitary napkin 1 has a vertically long shape.

- To the front of the excretory part facing area C, which is a part facing the excretion part of the wearer when worn, and the excretory part facing area C It has a front area A that extends and a rear area B that extends rearward of the excretory part facing area C.

- the sanitary napkin 1 has a liquid-permeable surface sheet 2 located on the skin-facing surface side disposed on the skin side of the wearer when worn, and a wearer when worn, as shown in FIG. 2.

- a liquid-impermeable or liquid-impermeable back sheet 3 located on the non-skin facing surface side, which is disposed on the opposite side to the skin side. Between the top sheet 2 and the back sheet 3, a liquid-retaining vertically long absorbent body 4 is disposed.

- the sanitary napkin 1 has a pair of wing portions 5 and 5 extending in the excretion portion facing area C from the left and right side portions to the side.

- the wing part 5 is formed as an extended portion of the back sheet 3 and / or the top sheet 2, or is formed from a member different from the back sheet 3 and the top sheet 2.

- An adhesive layer (not shown) is provided on the non-skin facing surface of the back sheet 3 and the wing part 5. The pressure-sensitive adhesive layer is used to fix the sanitary napkin 1 to the shorts when the sanitary napkin 1 is attached to the wearer's shorts.

- the sanitary napkin 1 is provided with a pair of leak-proof cuffs 6 extending in the vertical direction of the sanitary napkin 1 on the left and right side portions on the surface sheet 2 side. .

- the leak-proof cuff 6 is composed of a wall portion 6a that stands upward and an overhanging portion 6b that projects horizontally from the upper end of the wall portion 6a.

- the transverse cross section of the leak-proof cuff 6 has a substantially T-shape.

- the base of the wall 6 a is located between the absorber 4 and the back sheet 3.

- the overhanging portion 6b has a substantially flat upper surface so that when the sanitary napkin 1 is worn, the overhanging portion 6b comes into contact with the skin of the wearer.

- a plurality of elastic yarns 6c extending in the same direction as the direction in which the leak-proof cuff 6 extends are arranged in the overhanging portion 6b.

- the elastic yarn 6c is fixed to the overhanging portion 6b in an elongated state in the vertical direction.

- the elastic yarn 6c erects the wall portion 6a by contraction thereof, stabilizes the planar shape of the overhang portion 6b, and ensures contact of the overhang portion 6b with the skin.

- the overhanging portion 6 b is joined to the topsheet 2 at the position of the front end and the rear end in the vertical direction of the sanitary napkin 1. Further, the overhanging portion 6b is joined to the topsheet 2 also at the intermediate fixing portion 61 that is in the vicinity of the boundary portion with the excretory portion facing region C in the rear end region B of the sanitary napkin 1. By these joining, the leak-proof cuff 6 becomes more stable in standing.

- the absorbent body 4 included in the sanitary napkin 1 is formed by wrapping an absorbent core 41 with a core wrap sheet 42, and has a raised portion 40 that is partially raised in the thickness direction.

- the absorbent body 4 has a two-layer structure including a lower layer absorbent body 4d and an upper layer absorbent body 4u on the lower layer absorbent body 4d, as shown in FIGS.

- the upper-layer absorber 4u is formed to have a smaller width than the lower-layer absorber 4d, and the upper-layer absorber 4u is overlapped with the lateral central region of the lower-layer absorber 4d.

- the upper layer absorber 4u and the lower layer absorber 4d are formed with the same length.

- the absorbent core 41 includes a lower layer absorbent core 41d constituting the lower layer absorber 4d and an upper layer absorbent core 41u constituting the upper layer absorber 4u.

- the raised portion 40 is formed by the upper absorbent core 41u of the upper absorbent body 4u.

- the absorbent body 4 having the raised portion 40 is formed using the absorbent core 41 having a thickness difference partially raised in the thickness direction.

- the upper absorbent core 41u of the upper absorbent body 4u includes the upper absorbent core 41uc of the excretory part opposing region C disposed in the excretory part opposing region C and the rear region B.

- the absorbent core 41 has an upper layer of the excretory part facing region C in the lateral central region on the skin facing surface side of the lower layer absorbent core 41d disposed from the front region A to the rear region B.

- the absorbent core 41uc and the upper layer absorbent core 41ub in the rear region B are spaced apart in the vertical direction, and the sanitary napkin 1 is spaced apart in the vertical direction to form an absorbent core 41 having a thickness difference. ing. That is, the raised portions 40 are formed at intervals in the longitudinal direction of the sanitary napkin 1.

- the contour of the lower absorbent core 41d defines the contour of the absorbent core 41.

- the core wrap sheet 42 has a sheet that covers the non-skin facing surface side of the absorbent core 41, which is separate from the sheet that covers the skin facing surface side of the absorbent core 41.

- the sanitary napkin 1 has a lower layer core wrap sheet 42d that wraps the lower layer absorbent core 41d and an upper layer core wrap sheet 42u that wraps the upper layer absorbent core 41u.

- the lower layer core wrap sheet 42d is a first lower layer core wrap that covers the skin facing surface side of the lower layer absorbent core 41d (the surface side close to the upper layer absorbent core 41u) as shown in FIG.

- the sheet 42d1 and the second lower layer core wrap sheet 42d2 that covers the non-skin facing surface side (the surface side far from the upper layer absorbent core 41u) of the lower layer absorbent core 41d are provided.

- the sheet covering the non-skin facing surface side corresponds to the second lower layer core wrap sheet 42d2.

- the first lower layer core wrap sheet 42d1 is longer in the lateral direction than the lateral length of the lower layer absorbent core 41d.

- the first lower layer core wrap sheet 42d1 covers the entire area of the skin facing surface of the lower layer absorbent core 41d (surface close to the upper layer absorbent core 41u), and both left and right side portions of the lower layer absorbent core 41d.

- Each of the portions extending from the side to the side is folded to the non-skin-opposing surface side of the lower layer absorbent core 41d (the surface side far from the upper layer absorbent core 41u), and each of the folded tip portions is the lower layer absorbent core

- the left and right sides of the second lower layer core wrap sheet 42d2 covering the non-skin facing surface of 41d (the surface far from the upper layer absorbent core 41u) are covered, and the first lower layer core wrap sheet 42d1 and the second lower layer core wrap sheet 42d2 are covered. Is disposed on the non-skin facing surface side of the absorbent body 4.

- the first lower layer core wrap sheet 42d1 and the second lower layer core wrap sheet 42d2 are not joined at the overlapping portions 43 on the left and right side portions.

- the lower layer absorbent body 4d is formed of a lower layer absorbent core 41d and a lower layer core wrap sheet 42d (a first lower layer core wrap sheet 42d1 and a second lower layer core wrap sheet 42d2) that wraps the lower layer absorbent core 41d.

- the upper layer core wrap sheet 42u has a lateral length longer than the lateral length of the upper absorbent core 41u.

- the upper layer core wrap sheet 42u covers the entire skin-facing surface of the upper layer absorbent core 41u (the surface far from the lower layer absorbent core 41d) as shown in FIG.

- Each of the portions extending from the left and right side portions of 41u to the side is folded to the non-skin facing surface side (surface side close to the lower layer absorbent core 41d) of the upper layer absorbent core 41u, and the folded tip portions are respectively , Are overlapping.

- the upper absorbent core 41u is wrapped with the upper core wrap sheet 42u.

- the upper layer absorbent body 4u is formed of an upper layer absorbent core 41u (upper layer absorbent core 41uc and upper layer absorbent core 41ub) and an upper layer core wrap sheet 42u that wraps the upper layer absorbent core 41u.

- the upper absorbent core 41u wrapped by the upper core wrap sheet 42u and the lower absorbent core 41d wrapped by the first lower core wrap sheet 42d1 and the second lower core wrap sheet 42d2 As shown in FIG. 2, it is fixed by an adhesive 11 such as a hot-melt adhesive.

- an adhesive 11 such as a hot-melt adhesive.

- the upper layer core wrap sheet 42u and the upper layer absorbent core 41u are not fixed by an adhesive, and the first lower layer core wrap sheet 42d1 and the second lower layer core wrap sheet 42d2 are used.

- the lower absorbent core 41d is not fixed by an adhesive, and the overlapping portion between the first lower core wrap sheet 42d1 and the second lower core wrap sheet 42d2 is not fixed by the adhesive.

- the adhesive 11 is applied between the first lower-layer core wrap sheet 42d1 and the upper-layer core wrap sheet 42u, and the upper-layer absorbent body 4u and the lower-layer absorbent body 4d are fixed, and the absorbent body of the sanitary napkin 1 4 is formed. Moreover, the skin facing surface side of the absorbent body 4 is fixed with the top sheet 2, and the non-skin facing surface side is fixed with the back surface sheet 3 with the adhesive 11.

- the upper layer core wrap sheet 42u extends in the front region A and the rear region B where the upper layer absorbent core 41uc or the upper layer absorbent core 41ub does not exist and extends in the longitudinal direction of the sanitary napkin 1

- the wrap sheet 42u and the lower core wrap sheet 42d are formed with the same length.

- the upper layer absorbent body 4u for convenience.

- the upper absorbent core 41u of the upper absorbent body 4u and the lower absorbent core 41d of the lower absorbent body 4d may be made of the same material or different materials.

- the absorbent body 4 of the sanitary napkin 1 includes the lower layer absorbent body 4d in which the lower layer absorbent core 41d is wrapped with the lower layer core wrap sheet 42d (the first lower layer core wrap sheet 42d1 and the second lower layer core wrap sheet 42d2).

- the upper absorbent core 4u in which the upper absorbent core 41u in which the upper absorbent core 41uc and the upper absorbent core 41ub in the rear region B are separated in the vertical direction is covered with the upper core wrap sheet 42u, is disposed on the excretory part facing region C. It is formed and fixed.

- the thickness of the single-layer structure portion composed only of the lower layer absorber 4d in which the upper layer absorber 4u is not disposed is sufficient for the liquid retention and fit to the wearer's body. Therefore, under a load of 310 Pa, 2 mm or more is preferable, 3 mm or more is more preferable, 10 mm or less is preferable, 7 mm or less is more preferable, specifically, 2 mm or more and 10 mm or less is preferable, and 3 mm or more and 7 mm or less is preferable. Further preferred.

- the thickness of the two-layer structure part in which the upper layer absorber 4u is arranged on the lower layer absorber 4d is from the point that the excretory part facing area C is brought into contact with the wearer's body with good fit, under a load of 310 Pa, 3 mm or more is preferable, 5 mm or more is more preferable, 12 mm or less is preferable, 10 mm or less is more preferable, specifically, 3 mm or more and 12 mm or less is preferable, and 5 mm or more and 10 mm or less is more preferable.

- the absorbent core 41 of the sanitary napkin 1 quickly absorbs a large amount of excretion fluid (menstrual blood) and is excreted by the adjacent lower absorbent core 41d by the upper absorbent core 41uc disposed in the excretory part facing region C. Has the function of transferring liquid. Moreover, when the upper layer absorbent core 41ub disposed in the rear region B can prevent leakage from the buttocks, and when there is a large amount of excretory fluid (menstrual blood) that the upper layer absorbent core 41uc has a capacity shortage , Has the role of supplementary absorption.

- the lower layer absorbent core 41d has a function of preventing the return of fluid from the upper layer absorbent core 41u to the skin by diffusing the excretory fluid transmitted from the upper layer absorbent core 41u in the vertical direction. From this point of view, the concave portion 7 to be described later extends from the non-skin facing surface side of the lower layer absorbent core 41d to the upper layer absorbent core 41u, and reaches the inside of the upper layer absorbent core 41u. It is preferable from the point of liquid transmission to form so as not to penetrate.

- the sanitary napkin 1 is provided on the portion of the lower layer absorbent body 4d located outside the left and right sides of the upper layer absorbent core 41uc of the excretory part facing region C from the top sheet 2 side.

- a leak-proof groove 8c that is recessed toward the back sheet 3 side extends in the vertical direction.

- One end of each leak-proof groove 8c extends to the front area A of the sanitary napkin 1, and is smoothly connected to the arc-shaped leak-proof groove 8a formed in the front area A.

- the leak-proof groove 8a is formed to extend in the lateral direction in the upper layer absorber 4u and the lower layer absorber 4d located outside the front end portion of the upper layer absorbent core 41uc.

- each leak-proof groove 8c is formed in the lower layer absorbent body 4d located outside the left and right sides of the upper-layer absorbent core 41ub in the rear region B and extending vertically. It is smoothly connected to one end of 8b.

- the other end of each leak-proof groove 8b is smoothly connected to an arc-shaped leak-proof groove 8d that extends in the lateral direction near the rear end of the sanitary napkin 1.

- the leak-proof groove 8d is formed in the rear region B of the sanitary napkin 1 so as to extend in the lateral direction in the upper layer absorber 4u and the lower layer absorber 4d.

- the sanitary napkin 1 is formed with a groove having a closed shape composed of the leak-proof grooves 8a, 8b, 8c, and 8d, and the absorbent body 4 and the topsheet 2 are integrated.

- a closed groove formed of a leak-proof groove is formed in a portion located around the upper absorbent core 41u (upper absorbent cores 41uc, 41ub).

- the upper layer absorbent body 4u and the lower layer absorbent member positioned between the upper layer absorbent core 41uc of the excretory part facing region C and the upper layer absorbent core 41ub of the rear region B.

- An arc-shaped leak-proof groove 8e extending in the lateral direction is formed in the body 4d, and the upper-layer absorber 4u and the lower-layer absorber positioned between the rear end portion of the upper-layer absorbent core 41ub and the leak-proof groove 8d

- An arc-shaped leak-proof groove 8f extending in the lateral direction is formed in the portion 4d.

- the absorbent body 4 has a plurality of concave portions 7 that have entered the inside of the raised portion 40 of the absorbent body 4. Specifically, as shown in FIG. 1 and FIG. 2, the absorbent body 4 (absorbent core 41) enters the raised portion 40 from the non-raised surface side of the absorbent body 4 (absorbent core 41). A plurality of recesses 7 are provided. More specifically, as described above, in the sanitary napkin 1, the absorbent body 4 has a two-layer structure including the lower layer absorbent body 4d and the upper layer absorbent body 4u. The raised portion 40 is formed by the upper absorbent core 41u of the upper absorbent body 4u. Therefore, as shown in FIG.

- each recess 7 has a two-layer structure portion that faces the skin of the lower layer absorber 4 d from the non-skin facing surface side of the lower layer absorber 4 d (the surface side far from the upper layer absorber 4 u). It bulges toward the surface side (surface side close to the upper layer absorber 4u) and is formed so as to penetrate into the upper layer absorbent core 41u which is the contents of the upper layer absorber 4u.

- each recess 7 is 20% or more and 95% or less, particularly 50% or more and 95% of the thickness (under 310 Pa load) of the two-layer structure portion of the absorber 4 (upper layer absorber 4u, lower layer absorber 4d). It is preferable from the point of the reliable compression of the absorber 4 that it is the following.

- the sanitary napkin 1 is formed so as to be recessed stepwise inside the upper absorbent core 41u, and has a large-diameter recess 7b having a relatively large diameter and an outer portion of the bottom of the large-diameter recess 7b. It has a small-diameter recess 7s having a relatively small diameter, which is disposed on the inner side of the periphery and is recessed from the large-diameter recess 7b into the upper absorbent core 41u.

- each recess 7 reaching the inside of the upper absorbent core 41u is formed to protrude so as not to penetrate the upper absorbent core 41u.

- the absorbent body 4 is slightly recessed from the raised surface side of the absorbent body 4 toward the non-raised surface side at positions corresponding to the plurality of recessed portions 7 as shown in FIG. 2. It has a front surface side recess 7o. That is, the upper side absorbent core 41u of the sanitary napkin 1 has an upper layer absorbent property at a position corresponding to each of the plurality of concave portions 7 on the skin facing surface (surface far from the lower layer absorbent core 41d).

- the core 41u is recessed from the skin facing surface (surface far from the lower absorbent core 41d) side to the non-skin facing surface (surface close to the lower absorbent core 41d) side of the upper absorbent core 41u.

- the upper-side core wrap sheet 42u that covers the skin-facing surface of the upper-layer absorbent core 41u corresponds to the skin-facing surface (surface far from the lower-layer absorbent core 41d) and each of the plurality of recesses 7 In the position where it does, it is dented from the skin facing surface (surface far from the lower layer absorbent core 41d) side to the non-skin facing surface (surface near the lower layer absorbent core 41d) side.

- the sheet covering the non-skin facing surface side of the absorbent core 41 has entered the inside of the raised portion 40 in the recess 7.

- the sanitary napkin 1 when one of the plurality of recesses 7 is viewed, at least one of the recesses 7 includes the core wrap sheet 42 on the non-skin facing surface side.

- the second lower-layer core wrap sheet 42d2 corresponding to the sheet covering the surface is continuous from the wall surface 7w of the recess 7 to the bottom 7t of the recess 7.

- the core wrap sheet 42 includes the upper layer core wrap sheet 42u that wraps the upper layer absorbent core 41u and the lower layer core wrap sheet 42d that wraps the lower layer absorbent core 41d (first lower layer core wrap).

- the upper layer core wrap sheet 42u is also formed from the non-skin facing surface side of the lower layer absorbent core 41d (surface side far from the upper layer absorbent core 41u) to the skin facing surface side of the lower layer absorbent core 41d (to the upper layer absorbent core 41u).

- the upper core wrap sheet 42u of the upper absorber 4u and the lower core wrap sheet 42d of the lower absorber 4d are interposed.

- the lower absorbent core 41d of the consolidated lower absorbent body 4d is present.

- 7L is formed extending in the vertical direction.

- a plurality of such recess rows 7L are formed in the horizontal direction, and in the sanitary napkin 1, two rows are formed.

- the recess 7 forming the recess row 7L is composed of an upper layer absorber 4u and a lower layer absorber 4d in a two-layer structure portion composed of an upper layer absorber 4u and a lower layer absorber 4d. It is formed by being compressed in the thickness direction.

- the upper layer absorbent core 41uc of the upper part absorbent body 4u of the excretion part facing area C, the upper layer absorbent core 41uc of the upper part absorbent body 4u of the excretion part facing area C, and the upper layer absorbent core 41ub of the rear part B On the rear end side of the upper absorbent core 41ub of the upper absorbent body 4u in the rear region B, the concave portions 7 forming the concave row 7L are formed such that only the lower absorbent body 4d is in the thickness direction as the absorbent core 41. Compressed and formed. In this way, the recess row 7L formed by the plurality of recesses 7 is formed linearly from the front portion A to the rear portion B.

- the two rows of recesses 7L and 7L are formed at positions symmetrical to a vertical center line (not shown) extending in the longitudinal direction of the sanitary napkin 1, and one recess row

- the position of each recess 7 that forms 7L and the position of each recess 7 that forms the other recess row 7L are also arranged symmetrically with respect to the vertical center line (not shown).

- the two recess rows 7L and 7L are formed at positions symmetrical with respect to the vertical center line (not shown), but are not formed at positions symmetrical.

- the position of each recess 7 that forms one recess row 7L and the position of each recess 7 that forms the other recess row 7L are arranged symmetrically with respect to the vertical center line (not shown). It does not have to be.

- the distance (pitch) between the recesses 7, 7 adjacent in the longitudinal direction is the same. It has become. Also in the other recess row 7L, the distances (pitch) between the recesses 7 adjacent to each other in the longitudinal direction are the same. In the sanitary napkin 1, the distance (pitch) between the recesses 7 and 7 adjacent in the front and rear in one recess row 7L and the distance (pitch) between the recesses 7 and 7 adjacent in the front and rear in the other recess row 7L. ) Is the same as, but not necessarily.

- the distance (pitch) between the recesses 7 and 7 means a center-to-center distance between the center of one recess 7 and the center of the other recess 7.

- the distance (pitch) between the concave portions 7 and 7 adjacent to each other in the longitudinal direction forming the concave row 7L is the distance between the convex portions 91 and 91 adjacent to each other in the circumferential direction forming the convex row 91L of the convex roll 9 (described later). 4 mm or more, preferably 5 mm or more, more preferably 50 mm or less, further preferably 20 mm or less, specifically preferably 4 mm or more and 50 mm or less, and preferably 5 mm or more and 20 mm or less. More preferably it is.

- the interval between the two concave rows 7L, 7L adjacent in the horizontal direction corresponds to the distance (pitch) between the convex rows 91L, 91L adjacent in the rotation axis direction of the convex roll 9 described later, and is 4 mm or more. Is preferably 5 mm or more, more preferably 50 mm or less, further preferably 20 mm or less, specifically 4 mm or more and 50 mm or less, and more preferably 5 mm or more and 20 mm or less.

- the diameter of the bottom tip of the small-diameter recess 7s in the recess 7 corresponds to the width (W1) of the tip of the protrusion 910 of the convex roll 9 described later, preferably 1 mm or more, more preferably 1.5 mm or more, and 10 mm or less. Is preferably 5 mm or less, specifically 1 mm or more and 10 mm or less, more preferably 1.5 mm or more and 5 mm or less.

- the interval between the small-diameter recess 7s and the large-diameter recess 7b in the recess 7 corresponds to the interval (W2) between the protrusion 910 of the convex roll 9 described later and the outer peripheral edge located at the boundary between the protrusion 910 of the protrusion 91.

- the protruding height of the small-diameter concave portion 7s from the large-diameter concave portion 7b in the concave portion 7 corresponds to the protruding height (h) of the protruding portion 910 of the convex roll 9 described later, and is preferably 0.1 mm or more, and 0.2 mm.

- the above is more preferable, 3 mm or less is preferable, 2 mm or less is more preferable, specifically 0.1 mm or more and 3 mm or less is preferable, and 0.2 mm or more and 2 mm or less is more preferable.

- a material for forming the sanitary napkin 1 of the present embodiment will be described.

- the top sheet 2 and the back sheet 3 any one can be used without particular limitation as long as it is usually used for absorbent articles such as sanitary napkins.

- a liquid-permeable nonwoven fabric, a resin film having an opening, or the like can be used as the top sheet 2

- a liquid-impermeable or water-repellent resin film alone or a nonwoven fabric on the resin film can be used as the back sheet 3.

- the absorbent core 41 of the absorbent body 4 can be made of fiber material such as pulp or absorbent polymer particles

- the core wrap sheet 42 is made of tissue paper or water-permeable nonwoven fabric. Can be used.

- any sheet that is usually used for absorbent articles such as sanitary napkins can be used without particular limitation.

- the same sheet as the back sheet 3 can be used. it can.

- a laminated sheet or the like can be used.

- the elastic yarn 6c for forming the leak-proof cuff 6 is made of natural rubber, polyurethane, polystyrene-polyisoprene copolymer, polystyrene-polybutadiene copolymer, polyethylene- ⁇ -olefin copolymer such as ethyl acrylate-ethylene, or the like.

- a thread-like stretchable material can be used.

- an adhesive such as a hot melt adhesive usually used for absorbent articles such as sanitary napkins, heat embossing, ultrasonic embossing, etc.

- a fusion means such as high-frequency embossing is used.

- the sanitary napkin 1 includes a first core wrap sheet (first lower layer core wrap sheet 42 d 1 or upper layer core wrap sheet 42 u 1) in which the core wrap sheet 42 covers the skin facing surface side of the absorbent core 41. ) And a second core wrap sheet (second lower layer core wrap sheet 42d2) that covers the non-skin facing surface side, and the second core wrap sheet enters the inside of the raised portion 40 in the concave portion 7. It is out.

- the lower layer core wrap sheet 42 includes the first lower layer core wrap sheet 42d1 that covers the skin facing surface side of the lower layer absorbent core 41d and the second lower layer core that covers the non-skin facing surface side.

- the second lower layer core wrap sheet 42d2 is provided on the skin facing surface side of the lower absorbent core 41d from the non-skin facing surface side of the lower absorbent core 41d (the surface side far from the upper absorbent core 41u). It protrudes toward (the surface side close to the upper absorbent core 41u) and enters the upper absorbent core 41u.

- the core wrap sheet 42 includes the first core wrap sheet that covers the skin facing surface side of the absorbent core 41 and the second core wrap sheet that covers the non-skin facing surface side. Since the tension in the width direction is difficult to be applied when the convex portion of the roll is pushed in, the core wrap sheet 42 is difficult to break, and the concave portion 7 that enters the inside of the raised portion 40 is easily formed. In particular, in the sanitary napkin 1, since the overlapping portion 43 of the first lower layer core wrap sheet 42d1 and the second lower layer core wrap sheet 42d2 is not fixed by the adhesive and separated, the convex portion of the convex roll The core wrap sheet 42 is less likely to be torn because it becomes difficult to apply tension when pushing in. Such an effect is particularly effective when the absorbent body 4 is thick.

- the sanitary napkin 1 has a plurality of concave portions 7 in which the absorbent body 4 has entered the bulged portion 40 (upper absorbent core 41 u), so that it is absorbable when worn.

- the raised portion 40 (upper absorbent core 41u) of the core 41 is not easily deformed, the absorbent body 4 is difficult to twist, and the fit to the body is improved.

- the core wrap sheet 42 of the absorbent body 4 penetrates into the raised portion 40 (upper absorbent core 41 u) in the recess 7, and one recess 7, the core wrap sheet 42 is continuous from the wall surface 7 w of the recess 7 to the bottom 7 t of the recess 7.

- the absorbent body 4 has a plurality of recesses 7, so that the upper layer absorbent body 4 u and the lower layer absorbent body 4 d are easy to adhere firmly, Furthermore, excretion fluid (menstrual blood) can be transferred from the bottom of the concave portion 7 along the periphery of the concave portion 7 through the portion where the pulp density is high, and excretion fluid (menstrual blood) from the upper layer absorbent 4u to the lower layer absorber 4d. ) Transitions smoothly.

- excretion fluid Menstrual blood

- the sanitary napkin 1 has a core wrap sheet 42 that extends from the wall surface 7w of the recess 7 to the bottom 7t of the recess 7 when one recess 7 is viewed, Since it is not torn, when the absorbent body 4 and the back sheet 3 are fixed, the back sheet 3 is unlikely to float, and the absorbent body 4 is difficult to twist when worn, and the fit to the body is improved.

- the sanitary napkin 1 includes a step including a bottom 7t of each recess 7 that has entered the upper layer absorbent core 41u in a stepwise manner from a large diameter recess 7b and a small diameter recess 7s. Is formed. Therefore, it is difficult to make a sharp thickness difference at the corner of the embossed portion 7s, and the thickness of the embossed portion 7s can be maintained.

- the sanitary napkin 1 is a surface that is recessed from the skin facing surface side of the upper absorbent core 41u at a position corresponding to each of the plurality of recesses 7 on the skin facing surface of the upper absorbent core 41u. It has a side recess 7o. Therefore, when the surface sheet 2 is subjected to pressure (force applied in the thickness direction of the surface sheet 2) due to the user sitting or the like when the sanitary napkin 1 is mounted, the surface-side concave portion 7o of the absorbent body 4 becomes another The effect is that compression is less likely to occur than the portion, and the liquid can easily enter.

- the sanitary napkin 1 is formed with two rows of recessed portions 7L extending in the longitudinal direction in which the recessed portions 7 are arranged at intervals in the longitudinal direction. Therefore, a portion located laterally outward from the two recess rows 7L starting from the two recess rows 7L is located on the skin facing surface side when worn by the contraction force of the elastic yarn 6c of the leak-proof cuff 6 It is easy to bend, and the portion between the two rows of recesses 7L can be easily fitted to the body, and side leakage of excretory fluid (menstrual blood) can be prevented.

- excretory fluid menstrual blood

- FIG. 3 schematically shows a pair of convex rolls 9 and flat rolls 10 that are preferably used in the method for producing the sanitary napkin 1 of the present embodiment.

- the pair of convex rolls 9 and flat rolls 10 are of a cylindrical shape made of metal such as aluminum alloy or steel.

- the convex roll 9 has a plurality of convex portions 91 on its peripheral surface.

- the pair of convex rolls 9 and the flat roll 10 are configured to rotate in conjunction with a direction indicated by an arrow when a driving force from a driving means (not shown) is transmitted to the rotation shaft.

- the rotational speed of the convex roll 9 is controlled by a control unit (not shown) provided in the sanitary napkin 1 manufacturing apparatus.

- a plurality of convex portions 91 form a convex portion row 91 ⁇ / b> L at regular intervals in the circumferential direction of the convex roll 9, and the convex portion row 91 ⁇ / b> L is the convex roll 9.

- Two rows are formed in the axial length direction.

- column 91L corresponds with the number of the recessed part row

- the number of the plurality of recesses 7 forming the recess array 7L formed in the absorber 4 is the same.

- Each convex portion 91 of the convex roll 9 has a height from the peripheral surface of the convex roll 9 to the tip of the convex portion 91 of preferably 2 mm or more, more preferably 3 mm or more, and preferably 20 mm or less, more preferably 10 mm or less. Specifically, it is preferably 2 mm or more and 20 mm or less, more preferably 3 mm or more and 10 mm or less.

- the distance (pitch) between the convex portions 91 and 91 adjacent to each other in the circumferential direction forming the convex row 91L is preferably 4 mm or more, more preferably 5 mm or more, more preferably 50 mm or less, still more preferably 20 mm or less.

- the distance (pitch) between the protrusions 91L and 91L adjacent in the rotation axis direction is preferably 4 mm or more, more preferably 5 mm or more, more preferably 50 mm or less, still more preferably 20 mm or less, specifically 4 mm or more and 50 mm. Or less, more preferably 5 mm or more and 20 mm or less.

- the distance between the tip of each convex portion 91 of the convex roll 9 and the peripheral surface of the flat roll 10 is preferably 0.01 mm or more, more preferably 0.05 mm or more, and preferably 10 mm or less, more preferably 2 mm or less.

- the diameter of the flat roll 10 is preferably 50 mm or more and 300 mm or less.

- Each convex portion 91 used in the concave portion forming process has a tip portion 91b protruding in a stepwise manner, and has a protruding portion 910 at the tip portion 91b.

- the projecting portion 910 forms the top of the convex portion 91, and as shown in FIG.

- the term “tip is flat” includes a curved surface (curved surface parallel to the peripheral surface of the convex roll) formed by the tops of the plurality of convex portions 91 and the same curvature.

- Each protrusion 91 has a relationship between the width (W1) of the tip of the protrusion 910 and the protrusion height (h) to the tip of the protrusion 910 such that W1 ⁇ h.

- the ratio relationship (W1 / h) between the width (W1) of the leading end of the protruding portion 91s and the protruding height (h) of the protruding portion 910 is a viewpoint that the core wrap sheet is not easily torn during pushing. Therefore, it is preferably 1 or more, more preferably 2.5 or more, preferably 50 or less, more preferably 20 or less, specifically 1 or more and 50 or less. Is more preferably 2.5 or more and 20 or less.

- the relationship between the width (W1) of the tip of the protrusion 910 and the distance (W2) between the outer periphery located at the boundary between the protrusion 910 and the protrusion 910 of the protrusion 91 is , W1> W2.

- the ratio (W1 / W2) between the width (W1) of the tip of the protrusion 910 and the distance (W2) between the outer periphery located at the boundary between the protrusion 910 and the protrusion 910 of the protrusion 91. ) Is preferably 1.1 or more, more preferably 2 or more, and preferably 20 or less, preferably 6 or less, from the viewpoint of the difficulty of tearing the core wrap sheet during pressing.

- the outer peripheral edge located at the boundary of the protrusion 91 with the protrusion 910 is located at the boundary between the protrusion 910 and a portion positioned below the protrusion 91 in the height direction of the protrusion 91. This is the outer peripheral edge of the convex portion 91.

- the width (W1) of the tip of the protruding portion 910 is preferably 1 mm or more, more preferably 1.5 mm or more, more preferably 10 mm or less, still more preferably 5 mm or less, and specifically 1 mm or more and 10 mm or less. Is preferably 1.5 mm or more and 5 mm or less.

- the interval (W2) between the protrusion 910 and the outer peripheral edge located at the boundary between the protrusions 910 of the protrusion 91 is preferably 0.1 mm or more, more preferably 0.2 mm or more, and preferably 10 mm or less, 3 mm

- the following is more preferable, specifically, 0.1 mm or more and 10 mm or less is preferable, and 0.2 mm or more and 3 mm or less is more preferable.

- the protrusion height (h) of the protrusion 910 is preferably 0.1 mm or more, more preferably 0.2 mm or more, more preferably 3 mm or less, still more preferably 2 mm or less, and specifically 0.1 mm or more and 3 mm.

- the width W3 at the base of the convex portion 91 is preferably 0.8 mm or more, more preferably 2 mm or more, preferably 30 mm or less, more preferably 8 mm or less, specifically 0.8 mm or more and 30 mm or less. It is preferable that it is 2 mm or more and 8 mm or less.

- the tip portion 91 b of the convex portion 91 has a width between both side edges of the tip portion 91 b as viewed from the side. It is preferable that the tapered portion gradually decreases toward the tip of the convex portion 91.

- the taper angle ⁇ of the tip 91b of the convex portion 91 is preferably 10 ° or more, more preferably 20 ° or more, more preferably 150 ° or less, still more preferably 90 ° or less, specifically 10 ° or more and 150. It is preferably not more than °, more preferably not less than 20 ° and not more than 90 °. Furthermore, as shown in FIG.

- the width between both side edges of the protruding portion 910 is a tapered portion that gradually decreases toward the tip of the convex portion 91. It is preferable.

- the taper angle ⁇ of the protrusion 910 is preferably 10 ° or more, more preferably 20 ° or more, more preferably 150 ° or less, still more preferably 90 ° or less, and specifically preferably 10 ° or more and 150 ° or less. More preferably, it is 20 ° or more and 90 ° or less.

- the core wrap sheet 42 is not easily broken when the concave portion 7 is formed.

- the convex portion 91 is easily separated, and the productivity is improved.

- chamfering processing is performed on the leading edge portion of the convex portion 91 (the outer circumferential edge located at the boundary between the distal end of the protruding portion 910 and the protruding portion 910 of the protruding portion 91). In the manufacturing apparatus for the sanitary napkin 1 shown in FIG. 4, R processing of about 0.1 mm is performed.

- each convex portion 91 of the convex roll 9 and the top end of each convex portion 91 (the shape of the distal end of the convex portion 91 and the protruding portion 910), and examples thereof include a circle, a polygon, and an ellipse.

- the area of the planar tip of the protruding portion 910 of each protrusion 91 is preferably 0.78 mm 2 or more 80 mm 2 or less, and more preferably 1.77 mm 2 or more 20 mm 2 or less.

- the width (W1) or interval (W2) of the leading end or the width (W3) at the root of the convex portion 91 is the narrowest position. Means the value at.

- the method for manufacturing the sanitary napkin 1 according to the present embodiment is a method for manufacturing a so-called longitudinal flow type sanitary napkin, in which a continuous body of the absorbent body 4 is flattened with a convex roll 9 having a plurality of convex portions 91 on its peripheral surface and a flat surface.

- a recess that is supplied between the roll 10 and that forms the recess 7 that enters the inside of the raised portion 40 of the absorbent body 4 by each of the convex portions 91 and that allows the core wrap sheet 42 to enter the inside of the raised portion 40.

- a forming step is provided. This will be specifically described below.

- a continuous body 400 of the absorber 4 is prepared.

- the continuum 400 of the absorbent body 4 shown in FIG. 3 wraps the continuum 410d of the lower layer absorbent core 41d with the continuum 420d1 of the first lower layer core wrap sheet 42d1 and the continuum 420d2 of the second lower layer core wrap sheet 42d2.

- a continuum 410u in which two types of upper layer absorbent cores 41uc and upper layer absorbent cores 41ub are alternately arranged in the conveying direction is formed by a continuum 420u of upper layer core wrap sheet 42u.

- the continuous body 400u of the wrapped upper layer absorbent body 4u is formed by being fixed with an adhesive 11 such as a hot-melt adhesive.

- an adhesive 11 such as a hot-melt adhesive.

- the continuum 400d of the lower layer absorbent body 4d is coated with a continuum 420d2 of the second lower layer core wrap sheet 42d2 on the surface side far from the upper absorbent core 41u of the continuum 410d of the lower layer absorbent core 41d.

- the surface of the lower layer absorbent core 41d that is close to the upper layer absorbent core 41u is covered with the continuum 420d1 of the first lower layer core wrap sheet 42d1, and the side from the left and right sides of the lower layer absorbent core 41d.

- Each portion of the continuous body 420d1 of the first lower core wrap sheet 42d1 extending in the direction is folded to the surface side far from the upper absorbent core 41u of the lower absorbent core 41d, and each folded tip portion is The lower layer core wrap sheet 42d2 is formed so as to cover the left and right sides of the continuous body 420d2.

- the continuum 400u of the upper layer absorbent body 4u is coated with a continuum 420u of the upper layer core wrap sheet 42u on the surface side far from the lower layer absorbent core 41d of the continuum 410u of the upper layer absorbent core 41u.

- each portion of the continuous body 420u of the upper layer core wrap sheet 42u extending from the left and right sides of the upper layer absorbent core 41u to the side is folded to the surface side of the upper layer absorbent core 41u close to the lower layer absorbent core 41d,

- the folded tip portions are formed to overlap each other.

- the continuum 400 of the absorbent body 4 is arranged on the convex roll 9 side, and the continuum 400u of the upper layer absorbent body 4u is on the flat roll 10 side.

- the convex roll 9 and the flat roll 10 are supplied.

- the recessed part 7 which entered into the inside of the protruding part 40 from the non-raised surface side of the absorber 4 is formed by each convex part 91 of the convex roll 9.

- the continuous body 420d (lower layer core wrap sheet

- the core 41d is inserted into the upper absorbent core 41u from the surface far from the upper absorbent core 41u toward the surface closer to the upper absorbent core 41u.

- the lower layer absorbent body 4 d and the upper layer absorbent body 4 u are integrated and correspond to the respective concave sections 7 formed.

- a side recess 7o is formed.

- a continuous body 420d of a lower layer core wrap sheet 42d (a continuous body 420d1 of a first lower layer core wrap sheet 42d1, a continuous body 420d2 of a second lower layer core wrap sheet 42d2) and a wrapping body 410d of the lower layer absorbent core 41d.

- the continuous body 420u including only the upper layer core wrap sheet 42u of the upper layer absorbent body 4u is moved upward from the surface far from the upper layer absorbent core 41u of the lower layer absorbent core 41d. Toward side closer to the absorbent core 41 u, to get inside the recess 7.

- the tip portions of the convex portions 91 of the convex roll 9 used in the concave portion forming step protrude stepwise,

- the relationship between the width (W1) and the protrusion height (h) to the tip of the protrusion 910 is W1 ⁇ h. Therefore, since the pressure state at the tip of the convex portion is unlikely to change greatly, the core wrap sheet 42 is not easily broken, and the sanitary napkin 1 can be manufactured more stably and continuously.

- the method for manufacturing the sanitary napkin 1 includes the width (W1) of the tip of the protruding portion 910 and the distance between the outer peripheral edge located at the boundary between the protruding portion 910 and the protruding portion 910 of the protruding portion 91 ( The relationship with W2) is W1> W2. Therefore, as shown in FIG. 7, the continuous body 400 of the absorbent body 4 is compressed at two tip corners of the tip of the projection 91 and the tip of the projection 910 at the tip of each projection 91. Therefore, when the concave portion 7 is formed in the continuous body 400 of the absorbent body 4, the core wrap sheet 42 is hardly broken.

- the sanitary napkin 1 of the present embodiment after forming the recesses 7 in the absorbent body 4, the tip portions of the convex sections 91 of the convex rolls 9 are easily removed from the absorbent body 4, and Since the core wrap sheet 42 is difficult to wind around the tip portion of the portion 91, the sanitary napkin 1 can be manufactured stably and continuously.

- the continuous body of the absorbent body 4 manufactured as described above is cut to the length used for each sanitary napkin in the same manner as in the conventional longitudinal flow method, and the upper absorbent body 4u is then cut.

- the absorbent body 4 is interposed between the continuous body of the top sheet 2 and the continuous body of the back sheet 3, and after joining the top sheet and the back sheet outside the absorbent body 4, it is cut into a predetermined contour shape,

- the sanitary napkin 1 is manufactured.

- the continuous body of the surface sheet 2 before arranging the absorbent body 4 is used for forming a leak-proof cuff 6 in which elastic yarns 6c in an extended state are fixed to an overhanging portion 6b that is folded on each of both sides thereof.

- the continuous body of side sheets is overlapped and joined.

- the absorbent body 4 is arranged with the top sheet 2 and the back sheet 3

- an adhesive is applied to predetermined portions of the absorbent body 4, the top sheet 2, and the back sheet 3.

- the wing portion 5 is formed by bonding the wing forming sheet to each of both side portions of the continuous body of the top sheet 2 or the back sheet 3 before joining the absorber 4 or the top sheet 2.

- the back sheet 3 is formed by processing into the shape of the wing portion 5.

- the manufacturing method of the absorbent article of the present invention is not limited to the above-described embodiment, and can be changed as appropriate.

- each convex portion 91 used in the concave portion forming process has a tip portion 91b protruding one step, and the tip portion 91b has a protruding portion 910, but protrudes two or more steps. It may be.

- the tip 91b and the protrusion 910 of the protrusion 91 have a width between both side edges of the tip 91b of the protrusion 91 and the protrusion when the protrusion 91 is viewed from the side.

- the width between the side edges of the portion 910 is a tapered portion that gradually decreases toward the tip of the convex portion 91, it does not have to have a tapered portion.

- the outer peripheral edge located at the boundary with the protruding portion 910 at the interval (W2) is a portion of the outer diameter of the convex portion 91.

- the absorber 4 as shown in FIG. 2, a two-layer structure composed of the lower layer absorber 4d and the upper layer absorber 4u on the lower layer absorber 4d is used.

- the absorber 4 a one-layer structure may be used.

- the raised portion has a pulp basis weight that is greater than that of the surrounding portion, whereby the protruding portion is formed thicker than the surrounding portion.

- the core wrap sheet 42 is, as shown in FIG. 2, the first lower layer core wrap sheet 42d1 and the second lower layer core wrap sheet 42d2 of the lower layer core wrap sheet 42d that wraps the lower layer absorbent core 41d.

- the upper core wrap sheet 42u that wraps the upper absorbent core 41u is formed from three sheets, but it may be formed from two core wrap sheets. Specifically, when the absorbent core 41 is formed of only the lower layer absorbent core 41d, the first core wrap sheet and the lower layer absorbent core 41d covering the skin facing surface side of the lower layer absorbent core 41d.

- the manufacturing method of the absorbent article of this invention was formed with the lower layer absorbent body 4d and the upper layer absorbent body 4u which each coated the lower layer absorbent core 41d and the upper layer absorbent core 41u with one core wrap sheet.

- the absorber 4 may be used.

- the upper absorbent core 41u is arranged such that the upper absorbent core 41uc of the excretory part facing area C and the upper absorbent core 41ub of the rear area B are spaced apart in the vertical direction.

- the upper absorbent core 41u may be continuous without being separated.

- the sanitary napkin 1 is manufactured.

- the manufacturing method of the absorbent article of the present invention can also be used for other absorbents such as disposable diapers, incontinence pads, and liners. It is also suitable for manufacturing articles.

- a method for producing an absorbent article comprising an absorbent body in which an absorbent core is wrapped with a core wrap sheet,

- the absorber has a raised portion that is partially raised in the thickness direction,

- a continuous body of the absorbent body is supplied between a convex roll and a flat roll having a plurality of convex portions on the peripheral surface, and the concave portions that have entered the inside of the raised portion of the absorbent body by the convex portions.

- Each convex part used in the concave part forming step has a tip part projecting stepwise, and has a projecting part at the tip part.

- the absorbent body is formed such that a recessed portion row in which the recessed portions are arranged at intervals in the longitudinal direction extends in the longitudinal direction, and the recessed portion row is formed in a plurality of rows in the lateral direction.

- the plurality of rows of recesses are formed at positions symmetrical with respect to the longitudinal center line extending in the longitudinal direction of the absorbent article, and each recess forming one recess row and each forming the other recess row.

- ⁇ 3> The relationship between the width (W1) of the tip of the protrusion and the distance (W2) between the outer periphery located at the boundary between the protrusion and the protrusion of the protrusion is W1> W2.

- the convex portions of the convex roll form concave portions that enter from the non-raised surface side of the absorbent body to the inside of the raised portions by the convex portions.

- ⁇ 1> to ⁇ 3 > The manufacturing method of the absorbent article of any one of>.

- ⁇ 5> As the absorber, a two-layer structure composed of a lower layer absorber and an upper layer absorber on the lower layer absorber is used.

- the lower layer absorber and the upper layer absorber each have a lower layer absorbent core and an upper layer absorbent core,

- the continuum of the lower layer absorbent core has a surface side far from the upper layer absorbent core of the continuum of the lower layer absorbent core and is coated with a continuum of the second lower layer core wrap sheet.

- the portion of the first lower core wrap sheet continuous body that is coated with a continuous body of the first lower core wrap sheet on the surface side close to the upper absorbent core and extends laterally from the left and right sides of the lower absorbent core Each is folded to the surface side far from the upper absorbent core of the lower layer absorbent, and the folded tip portions are formed so as to cover the left and right sides of the continuous body of the second lower layer core wrap sheet.

- the continuum of the upper absorbent core has a surface side far from the lower absorbent core of the upper absorbent core continuum, and is covered with a continuum of the upper core wrap sheet.

- Each part of the continuous body of the upper layer core wrap sheet extending to the side is folded to the surface side of the upper layer absorbent core close to the lower layer absorbent core, and each of the folded tip portions is overlapped.

- the ratio (W1 / h) is preferably 1 or more, more preferably 2.5 or more, preferably 50 or less, more preferably 20 or less, specifically The method for producing an absorbent article according to any one of ⁇ 1> to ⁇ 7>, preferably 1 or more and 50 or less, and more preferably 2.5 or more and 20 or less.

- the ratio (W1 / W2) is preferably 1.1 or more, more preferably 2 or more, preferably 20 or less, more preferably 6 or less, Specifically, the method for producing an absorbent article according to any one of the above ⁇ 3> to ⁇ 8>, preferably 1.1 or more and 20 or less, and more preferably 2 or more and 6 or less.

- the width (W1) of the tip of the protrusion is preferably 1 mm or more, more preferably 1.5 mm or more, more preferably 10 mm or less, still more preferably 5 mm or less, and specifically 1 mm or more and 10 mm or less.

- the interval (W2) between the protruding portion and the outer peripheral edge located at the boundary between the protruding portions of the convex portion is preferably 0.1 mm or more, more preferably 0.2 mm or more, and preferably 10 mm or less, 3 mm or less is more preferable, specifically, it is preferably 0.1 mm or more and 10 mm or less, and more preferably 0.2 mm or more and 3 mm or less, according to any one of the above ⁇ 3> to ⁇ 10> Manufacturing method of absorbent article.

- the protrusion height (h) of the protrusion is preferably 0.1 mm or more, more preferably 0.2 mm or more, more preferably 3 mm or less, still more preferably 2 mm or less.

- ⁇ 13> The above-described ⁇ 1> to ⁇ 1>, wherein the width between both side edges of the tip portion of the convex portion is a tapered portion that gradually decreases toward the tip of the convex portion when the convex portion is viewed from the side.

- ⁇ 14> The above-described ⁇ 1> to ⁇ 13, wherein the convex portion has a tapered portion in which a width between both side edges of the protruding portion gradually decreases toward the tip of the convex portion when viewed from the side.

- the taper angle of the tip portion of the convex portion or the taper angle of the protrusion is preferably 10 ° or more, more preferably 20 ° or more, and preferably 150 ° or less, more preferably 90 ° or less. Is preferably 10 ° or more and 150 ° or less, and more preferably 20 ° or more and 90 ° or less.

- the continuum of the manufactured absorbent body is cut to have a length used for individual absorbent articles (such as sanitary napkins), and absorbed between the continuum of the top sheet and the continuum of the back sheet.

- ⁇ 17> The method for producing an absorbent article according to any one of ⁇ 1> to ⁇ 16>, wherein the absorbent article is a sanitary napkin, a disposable diaper, an incontinence pad, or a liner.

- An absorbent article including an absorbent body in which an absorbent core is wrapped with a core wrap sheet,

- the absorber has a raised portion that is partially raised in the thickness direction,

- the absorber has a plurality of the recesses that have entered the inside of the raised portion of the absorber,

- the core wrap sheet has a sheet that covers the non-skin facing side of the absorbent core, separate from the sheet that covers the skin facing side of the absorbent core, and covers the non-skin facing side.

- ⁇ 19> The overlapping portion of the sheet covering the skin facing surface side of the absorbent core and the sheet covering the non-skin facing surface side is disposed on the non-skin facing surface side of the absorbent body. 18>. ⁇ 20> When one of the plurality of recesses is viewed, the sheet covering the non-skin facing surface side is continuous from the wall surface of the recess to the bottom of the recess. 18> or the absorbent article as described in said ⁇ 19>.

- the absorber comprises a two-layer structure comprising a lower layer absorber and an upper layer absorber on the lower layer absorber, The lower layer absorber and the upper layer absorber each have a lower layer absorbent core and an upper layer absorbent core,

- the raised portions are formed at intervals in a longitudinal direction of the absorbent article.

- the absorbent article according to ⁇ 22> wherein the absorbent body includes a lower layer core wrap sheet that wraps the lower layer absorbent core and an upper layer core wrap sheet that wraps the upper layer absorbent core.

- the lower layer core wrap sheet includes a first lower layer core wrap sheet that covers the skin facing surface side of the lower layer absorbent core, and a second lower layer core wrap that covers the non-skin facing surface side of the lower layer absorbent core.

- the absorbent article according to ⁇ 24> further comprising a sheet.

- ⁇ 26> The absorbent article according to ⁇ 25>, wherein the sheet covering the non-skin facing surface side of the lower layer absorbent core is the second lower layer core wrap sheet.

- the distance (pitch) between the concave portions adjacent to each other in the longitudinal direction forming the concave row is preferably 4 mm or more, more preferably 5 mm or more, more preferably 50 mm or less, and still more preferably 20 mm or less.

- the interval between the recess rows adjacent in the lateral direction is preferably 4 mm or more, more preferably 5 mm or more, more preferably 50 mm or less, further preferably 20 mm or less, and specifically 4 mm or more and 50 mm or less.

- the concave portions forming the concave row are formed by compressing the upper layer absorber and the lower layer absorber in the thickness direction in a two-layer structure portion composed of the upper layer absorber and the lower layer absorber.

- the portion including the bottom of the concave portion is formed in a stepwise recess in the upper absorbent core, and has a relatively large diameter concave portion and an outer peripheral edge of the bottom portion of the large diameter concave portion.

- ⁇ 34> The absorbent article according to any one of ⁇ 18> to ⁇ 33>, wherein the absorbent article is a sanitary napkin, a disposable diaper, an incontinence pad, or a liner.

- Example 1 Using the pair of convex rolls and flat rolls shown in FIG. 3, a continuous body of the absorbent body of Example 1 of the sanitary napkin shown in FIGS.

- a lower layer absorbent core (basis weight 250 g / m 2 ) continuum 410 d is replaced with a first lower layer core wrap sheet continuum 420 d 1 (basis weight 16 g / m 2 tissue paper).

- a second lower layer core wrap sheet continuous body 420d2 tissue paper having a basis weight of 16 g / m 2

- an upper layer absorbent core 41uc (basis weight 400 g / m 2 )

- a continuous body 410u in which upper layer absorbent cores 41ub (basis weight 400 g / m 2 ) are alternately arranged in the conveying direction are wrapped with a continuous body 420u of upper layer core wrap sheet (tissue paper having a basis weight of 16 g / m 2 ).

- the upper layer absorber continuous body 400u was fixed with a hot-melt adhesive (coating amount 5 g / m 2 ).

- Each convex portion 91 of the convex roll has a tip portion projecting stepwise, the entire height is 5 mm, the diameter of the convex portion 91 is ⁇ 4 mm, and the convex portions 91, 91 adjacent in the circumferential direction are adjacent to each other.

- the distance (pitch) between them was 10 mm, and the distance (pitch) between the convex row 91L, 91L adjacent in the rotation axis direction was 10 mm. Further, each convex portion 91 will be described in detail.

- the width (W1) of the tip of the protruding portion 910 is ⁇ 2 mm, and the distance (W2) between the outer peripheral edge located at the boundary between the protruding portion 910 and the protruding portion 910 of the convex portion 91. ) was 0.65 mm, and the protrusion height (h) of the protrusion 910 was 0.5 mm. That is, the ratio relationship (W1 / h) was 4, and the ratio relationship (W1 / W2) was 3.3. Moreover, the area of the flat front-end

- the taper angle ⁇ of the tip 91b of the convex portion 91 was 40 °, and the taper angle ⁇ of the protruding portion 910 was 40 °.

- a continuous body of the absorbent body of Example 1 was manufactured by adjusting the distance between the tip of each convex portion 91 of the convex roll 9 and the peripheral surface of the flat roll 10 to 0.3 mm.

- Example 2 A continuous body of the absorbent body of Example 2 was manufactured in the same manner as in Example 1 except that the distance between the tip of each convex portion 91 of the convex roll 9 and the peripheral surface of the flat roll 10 was adjusted to 0.4 mm. .

- Example 3 A continuous body of the absorbent body of Example 3 was produced in the same manner as in Example 1 except that the distance between the tip of each convex portion 91 of the convex roll 9 and the peripheral surface of the flat roll 10 was adjusted to 0.5 mm. .

- Comparative Example 1 The continuous body 400 of the absorber 4 same as Example 1 was used as a raw material.

- Each convex part of the convex roll used in Comparative Example 1 is different from each convex part of the convex roll used in Example 1, and compared with a sanitary napkin using a normal pin emboss that does not protrude stepwise.

- the absorbent body of Example 1 was produced.

- the pin embossment of the convex roll has an overall height of 5 mm, the diameter of the convex portion 91 is 3 mm, the distance (pitch) between the pin embosses adjacent in the circumferential direction is 10 mm, and is adjacent in the rotation axis direction.

- the distance (pitch) between rows of matching pin embossments was 10 mm. Further, the width of the tip of the pin emboss was 2 mm, and the area of the flat tip of the pin emboss was 3.14 mm 2 .

- the distance between the tip of each pin emboss of the convex roll and the peripheral surface of the flat roll was adjusted to 0.3 mm, and an absorbent body of Comparative Example 1 was produced.

- Comparative Example 2 A continuous body of the absorbent body of Comparative Example 2 was produced in the same manner as Comparative Example 1, except that the distance between the tip of each pin embossment of the convex roll and the peripheral surface of the flat roll was adjusted to 0.4 mm.

- Comparative Example 3 A continuous body of the absorbent body of Comparative Example 3 was produced in the same manner as Comparative Example 1 except that the distance between the tip of each pin embossment of the convex roll and the peripheral surface of the flat roll was adjusted to 0.5 mm.

- the continuous body of the absorbent bodies of Examples 1 to 3 has a tear rate (%) of the core wrap sheet as compared with the continuous body of the absorbent bodies of Comparative Examples 1 to 3. It turned out to be low. Therefore, if a pair of convex rolls and flat rolls for producing a continuous body of the absorbent bodies of Examples 1 to 3 is used, the absorbent body can be stably produced, and further the absorbent article can be stably produced. Can be expected.

- the core wrap sheet is hardly broken when the concave portion is formed in the absorbent body by the convex portion of the convex roll. Therefore, according to the manufacturing method of an absorbent article of the present invention, it can be expected that the absorbent article is stably manufactured. Moreover, the absorbent article of the present invention makes it difficult for the absorbent body to be twisted when worn, and further improvement in fit to the body can be expected.

Abstract

This manufacturing method is a method for manufacturing an absorptive article which is provided with an absorption body (4) formed by wrapping an absorptive core (41) with a core wrapping sheet (42). The absorption body (4) has a raised section (40) which is partially raised in the thickness direction. This manufacturing method is provided with a recess forming step for supplying the continuous body (400) of the absorption body between a protrusion roller (9), which has protrusions (91) on the outer peripheral surface thereof, and a flat roller (10) to form, by means of the protrusions (91), recesses (7) entering the inside of the raised section (40) and to cause the core wrapping sheet (42) to enter the inside of the raised section (40). The protrusions (91) are configured in such a manner that the tip portion (91b) of each of the protrusions (91) protrudes stepwise and that the tip portion (91b) has a sticking-out section (910). The relationship between the width (W1) of the tip of the sticking-out section (910) and the height (h) of protrusion of the sticking-out section (910) to the tip thereof is set to W1 ≥h.

Description

本発明は、生理用ナプキン、失禁パッド等の吸収性物品の製造方法に関する。

The present invention relates to a method for producing absorbent articles such as sanitary napkins and incontinence pads.

身体へのフィット性を良好にする観点から、本出願人は、先に、横方向中央領域に層数の多い部分を有する吸収性層を備え、該層数の多い部分に着用形状を安定化させる圧縮部が押圧されて設けられている生理用ナプキンを提案した(特許文献1参照)。

From the viewpoint of improving the fit to the body, the applicant previously provided an absorbent layer having a large number of layers in the lateral central region, and stabilized the wearing shape in the large number of layers. The sanitary napkin which the compression part to be pressed was provided was proposed (refer patent document 1).

また、同様の観点から、本出願人は、先に、肌対向面側に上層吸収体、非肌対向面側に下層吸収体を有する吸収体を備え、該吸収体を平面視したときに、上層吸収体と下層吸収体とが厚み方向に圧縮されてなる圧縮点を規則的に配列した生理用ナプキンを提案した(特許文献2参照)。

Further, from the same viewpoint, the applicant first comprises an absorber having an upper layer absorber on the skin facing surface side and a lower layer absorber on the non-skin facing surface side, and when the absorber is viewed in plan view, The sanitary napkin which arranged regularly the compression point formed by compressing an upper layer absorber and a lower layer absorber in the thickness direction was proposed (refer to patent documents 2).

しかし、特許文献1,2に記載の生理用ナプキンにおいては、圧縮部又は圧縮点を押圧して形成する際に、吸収体を構成する吸収性コアを包むコアラップシートが破れてしまうことがあった。このようなコアラップシートの破れを防止できると、生理用ナプキンの製造時に、圧縮部又は圧縮点を形成するロールの凸部が吸収体から抜け易くなり、生理用ナプキンを安定的に製造することが期待できる。また、コアラップシートの破れが防止できると、吸収性コアとコアラップシートとからなる吸収体が更に一体化され、着用時に吸収体がヨレ難くなり、身体へのフィット性の更なる向上が期待できる。

However, in the sanitary napkin described in Patent Documents 1 and 2, when the compression part or the compression point is pressed and formed, the core wrap sheet that wraps the absorbent core constituting the absorbent body may be torn. It was. If the core wrap sheet can be prevented from being torn, the convex part of the roll forming the compression part or the compression point can be easily removed from the absorbent body during the production of the sanitary napkin, and the sanitary napkin can be stably produced. Can be expected. In addition, if the core wrap sheet can be prevented from being torn, the absorbent body composed of the absorbent core and the core wrap sheet is further integrated, making the absorbent body difficult to twist when worn, and further improvement in fit to the body is expected. it can.

本発明は、ロールの凸部により押圧して、吸収体に圧縮部又は圧縮点等を形成する際に、コアラップシートに破れが生じ難い吸収性物品の製造方法に関する。