WO2014024666A1 - Gas-static bearing unit - Google Patents

Gas-static bearing unit Download PDFInfo

- Publication number

- WO2014024666A1 WO2014024666A1 PCT/JP2013/069767 JP2013069767W WO2014024666A1 WO 2014024666 A1 WO2014024666 A1 WO 2014024666A1 JP 2013069767 W JP2013069767 W JP 2013069767W WO 2014024666 A1 WO2014024666 A1 WO 2014024666A1

- Authority

- WO

- WIPO (PCT)

- Prior art keywords

- shaft

- radial bearing

- thrust bearing

- thrust

- air

- Prior art date

Links

Images

Classifications

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F16—ENGINEERING ELEMENTS AND UNITS; GENERAL MEASURES FOR PRODUCING AND MAINTAINING EFFECTIVE FUNCTIONING OF MACHINES OR INSTALLATIONS; THERMAL INSULATION IN GENERAL

- F16C—SHAFTS; FLEXIBLE SHAFTS; ELEMENTS OR CRANKSHAFT MECHANISMS; ROTARY BODIES OTHER THAN GEARING ELEMENTS; BEARINGS

- F16C32/00—Bearings not otherwise provided for

- F16C32/06—Bearings not otherwise provided for with moving member supported by a fluid cushion formed, at least to a large extent, otherwise than by movement of the shaft, e.g. hydrostatic air-cushion bearings

- F16C32/0603—Bearings not otherwise provided for with moving member supported by a fluid cushion formed, at least to a large extent, otherwise than by movement of the shaft, e.g. hydrostatic air-cushion bearings supported by a gas cushion, e.g. an air cushion

- F16C32/0614—Bearings not otherwise provided for with moving member supported by a fluid cushion formed, at least to a large extent, otherwise than by movement of the shaft, e.g. hydrostatic air-cushion bearings supported by a gas cushion, e.g. an air cushion the gas being supplied under pressure, e.g. aerostatic bearings

- F16C32/0618—Bearings not otherwise provided for with moving member supported by a fluid cushion formed, at least to a large extent, otherwise than by movement of the shaft, e.g. hydrostatic air-cushion bearings supported by a gas cushion, e.g. an air cushion the gas being supplied under pressure, e.g. aerostatic bearings via porous material

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F16—ENGINEERING ELEMENTS AND UNITS; GENERAL MEASURES FOR PRODUCING AND MAINTAINING EFFECTIVE FUNCTIONING OF MACHINES OR INSTALLATIONS; THERMAL INSULATION IN GENERAL

- F16C—SHAFTS; FLEXIBLE SHAFTS; ELEMENTS OR CRANKSHAFT MECHANISMS; ROTARY BODIES OTHER THAN GEARING ELEMENTS; BEARINGS

- F16C32/00—Bearings not otherwise provided for

- F16C32/06—Bearings not otherwise provided for with moving member supported by a fluid cushion formed, at least to a large extent, otherwise than by movement of the shaft, e.g. hydrostatic air-cushion bearings

- F16C32/0603—Bearings not otherwise provided for with moving member supported by a fluid cushion formed, at least to a large extent, otherwise than by movement of the shaft, e.g. hydrostatic air-cushion bearings supported by a gas cushion, e.g. an air cushion

- F16C32/0614—Bearings not otherwise provided for with moving member supported by a fluid cushion formed, at least to a large extent, otherwise than by movement of the shaft, e.g. hydrostatic air-cushion bearings supported by a gas cushion, e.g. an air cushion the gas being supplied under pressure, e.g. aerostatic bearings

- F16C32/0622—Bearings not otherwise provided for with moving member supported by a fluid cushion formed, at least to a large extent, otherwise than by movement of the shaft, e.g. hydrostatic air-cushion bearings supported by a gas cushion, e.g. an air cushion the gas being supplied under pressure, e.g. aerostatic bearings via nozzles, restrictors

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F16—ENGINEERING ELEMENTS AND UNITS; GENERAL MEASURES FOR PRODUCING AND MAINTAINING EFFECTIVE FUNCTIONING OF MACHINES OR INSTALLATIONS; THERMAL INSULATION IN GENERAL

- F16C—SHAFTS; FLEXIBLE SHAFTS; ELEMENTS OR CRANKSHAFT MECHANISMS; ROTARY BODIES OTHER THAN GEARING ELEMENTS; BEARINGS

- F16C32/00—Bearings not otherwise provided for

- F16C32/06—Bearings not otherwise provided for with moving member supported by a fluid cushion formed, at least to a large extent, otherwise than by movement of the shaft, e.g. hydrostatic air-cushion bearings

- F16C32/0681—Construction or mounting aspects of hydrostatic bearings, for exclusively rotary movement, related to the direction of load

- F16C32/0685—Construction or mounting aspects of hydrostatic bearings, for exclusively rotary movement, related to the direction of load for radial load only

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F16—ENGINEERING ELEMENTS AND UNITS; GENERAL MEASURES FOR PRODUCING AND MAINTAINING EFFECTIVE FUNCTIONING OF MACHINES OR INSTALLATIONS; THERMAL INSULATION IN GENERAL

- F16C—SHAFTS; FLEXIBLE SHAFTS; ELEMENTS OR CRANKSHAFT MECHANISMS; ROTARY BODIES OTHER THAN GEARING ELEMENTS; BEARINGS

- F16C32/00—Bearings not otherwise provided for

- F16C32/06—Bearings not otherwise provided for with moving member supported by a fluid cushion formed, at least to a large extent, otherwise than by movement of the shaft, e.g. hydrostatic air-cushion bearings

- F16C32/0681—Construction or mounting aspects of hydrostatic bearings, for exclusively rotary movement, related to the direction of load

- F16C32/0696—Construction or mounting aspects of hydrostatic bearings, for exclusively rotary movement, related to the direction of load for both radial and axial load

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F16—ENGINEERING ELEMENTS AND UNITS; GENERAL MEASURES FOR PRODUCING AND MAINTAINING EFFECTIVE FUNCTIONING OF MACHINES OR INSTALLATIONS; THERMAL INSULATION IN GENERAL

- F16C—SHAFTS; FLEXIBLE SHAFTS; ELEMENTS OR CRANKSHAFT MECHANISMS; ROTARY BODIES OTHER THAN GEARING ELEMENTS; BEARINGS

- F16C2300/00—Application independent of particular apparatuses

- F16C2300/20—Application independent of particular apparatuses related to type of movement

- F16C2300/22—High-speed rotation

Definitions

- the present invention relates to a structure of a double-sided hydrostatic gas bearing unit that can support a component such as a pulley that rotates at a high speed with a simple structure and more stably without contact.

- Patent Document 1 describes an air bearing unit (static pressure air bearing device) that supports a rotating shaft in a non-contact manner.

- the shaft thrust load and radial load are respectively provided on both ends of the inner periphery of the cylindrical housing into which the shaft (rotating shaft) is inserted, and the individual bearing surfaces (thrust bearing surface, radial bearing surface)

- One air bearing (static air bearing) of a porous drawing type (a porous body such as porous graphite) received by each is provided.

- the radial bearing surface is opposed to the outer peripheral surface of the shaft and a radial bearing gap is formed between the radial bearing surface and the thrust bearing surface is opposed to the flange formed on the outer periphery of the shaft.

- a thrust bearing gap is formed between the flange and the flange.

- an exhaust groove is formed in the circumferential direction on the opposite side of the thrust bearing surface (center side of the inner peripheral surface of the housing) across the radial bearing surface of the air bearing

- An exhaust hole penetrating the outer peripheral surface of the housing is formed at the bottom of the exhaust groove.

- an exhaust groove is formed in the circumferential direction at a position near the thrust bearing surface of the air bearing on the outer peripheral surface of the shaft, and the exhaust groove and the inner peripheral surface of the housing are exhausted inside the shaft. Exhaust holes that connect the grooves are formed.

- the air supplied to the air bearing is ejected from the thrust bearing surface and the radial bearing surface of the air bearing.

- the air ejected from the thrust bearing surface flows in the thrust bearing gap toward the outer periphery of the flange, and is discharged to the outside through the thrust bearing gap.

- the air ejected from the radial bearing surface flows in the radial bearing gap toward the exhaust groove near the thrust bearing surface and the exhaust groove on the opposite side of the thrust bearing surface, and flows into these exhaust grooves. Then, the air is exhausted to the outside of the housing through the exhaust hole.

- the radial bearing gap is supplied to a position near the thrust bearing surface and a position on the opposite side of the thrust bearing surface across the radial bearing surface. It is necessary to form an exhaust groove for discharging the generated air. Further, it is necessary to form exhaust holes for discharging the air flowing into these exhaust grooves to the outside of the housing on both the housing and the shaft. Further, it is necessary to separately provide a thrust bearing surface and a radial bearing surface for ejecting compressed air on the inner periphery of the housing. This complicates the structure.

- the exhaust hole on the shaft side is formed along the axial direction of the shaft so as to connect the exhaust groove on the outer peripheral surface of the shaft and the exhaust groove on the inner peripheral surface of the housing. Thickness is required. For this reason, when the shaft becomes heavy, the shaft may be bent by its own weight, for example. Since the radial bearing gap formed between the radial bearing surface of the air bearing (hydrostatic air bearing) on the inner periphery of the housing and the outer peripheral surface of the shaft is very narrow, if the shaft is bent, the shaft and the air ring There is a possibility that the shaft cannot be held stably.

- the present invention has been made in view of the above circumstances, and an object of the present invention is to provide a structure of a double-sided hydrostatic gas bearing unit that supports a rotating body that rotates at a high speed with a simple structure and more stably in a non-contact manner. It is to provide.

- a shaft unit that is inserted into a shaft insertion hole formed in the rotating body in the axial direction of the rotating body and supports the rotating body in a non-contact manner is provided as a shaft of the rotating body. Fix the insertion hole at the position where it is sandwiched from both sides in the axial direction.

- the gas ejected from the radial bearing surface formed on the outer peripheral surface of the shaft unit opposite to the inner peripheral surface of the shaft insertion hole of the rotating body causes the radial bearing surface and the inner peripheral surface of the shaft insertion hole of the rotating body to A gas film is formed in the radial bearing gap, and the gas is exhausted from the radial bearing gap into the thrust bearing gap between the thrust bearing surface of the shaft unit and each end face of the rotating body.

- a gas film is also formed in the thrust bearing gap using the exhausted gas.

- the present invention is a hydrostatic gas bearing unit that supports a rotating body that rotates in a direction around an axis center in a non-contact manner by a gas film interposed between a radial bearing gap and first and second thrust bearing gaps.

- a shaft unit that is inserted into a shaft insertion hole that penetrates both end faces of the rotating body; Shaft holding means for holding the shaft unit at positions on both sides of the shaft insertion hole of the rotating body,

- the shaft unit is A radial bearing surface that opposes the inner peripheral surface of the shaft insertion hole, forms the radial bearing gap between the inner peripheral surface, and ejects gas for forming the gas film in the radial bearing gap;

- a first thrust bearing gap is formed adjacent to the radial bearing surface, opposed to one end face of the rotating body, and connected to one end side of the radial bearing gap between the end face and the first thrust bearing gap.

- a thrust bearing surface of A second thrust bearing gap is formed adjacent to the radial bearing surface, opposite the other end face of the rotating body, and between the end face and the second thrust bearing gap connected to the other end side of the radial bearing gap.

- a thrust bearing surface of The gas is It flows in the radial bearing gap toward the first thrust bearing gap and the second thrust bearing gap, and exhausts from the radial bearing gap to the first thrust bearing gap and the second thrust bearing gap, respectively. Then, the gas film is formed in the first thrust bearing gap and in the second thrust bearing gap, respectively.

- the present invention formed between the inner peripheral surface of the shaft insertion hole of the rotating body and the radial bearing surface formed on the outer peripheral surface of the shaft unit facing the inner peripheral surface of the shaft insertion hole of the rotating body.

- the compressed gas exhausted from the radial bearing gap is supplied to the thrust bearing gap formed between each end face of the rotating body and the thrust bearing surface of the shaft unit, and then exhausted to form a gas film in the thrust bearing gap. Therefore, there is no need to separately provide a groove and a hole for exhausting compressed gas from the radial bearing gap and a thrust bearing surface for ejecting compressed gas into the thrust bearing gap.

- the shaft unit that supports the rotating body in a non-contact manner is fixed at both ends, even when the shaft unit is elongated according to the size of the rotating body, the bending can be suppressed. And the shaft unit can be prevented from contacting each other. For this reason, it is possible to realize a double-sided static pressure gas bearing unit capable of supporting a rotating body rotating at high speed with a simple structure and more stably in a non-contact manner.

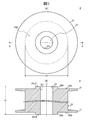

- FIG. 1 is an external view (without pulley 2) of a double-supported air bearing unit 4 according to an embodiment of the present invention.

- FIG. 2 is a side view of a double-ended air bearing unit 4 with the pulley 2 assembled according to an embodiment of the present invention.

- 3A is a front view of the pulley 2

- FIG. 3B is a cross-sectional view taken along the line AA in FIG. 4A.

- FIG. 4 is a part development view of the air shaft unit 1 according to the embodiment of the present invention.

- 5A is a front view of the air shaft 11

- FIG. 5B is a cross-sectional view taken along the line BB of FIG. 5A

- FIG. 5C is a bottom view of the air shaft 11.

- FIG. 5A is a front view of the air shaft 11

- FIG. 5B is a cross-sectional view taken along the line BB of FIG. 5A

- FIG. 5C is a bottom view of the air shaft 11.

- FIG. 5D is an enlarged partial cross-sectional view of the radial bearing portion 114.

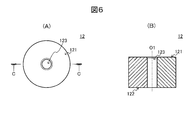

- 6A is a front view of the thrust plate 12, and

- FIG. 6B is a cross-sectional view taken along the line CC in FIG. 6A.

- FIG. 7 is a diagram schematically showing a support state of the pulley 2 during supply of air to the air shaft 11.

- a double-ended air bearing unit 4 suitable for non-contact support of a rotating body that is long in the direction of the axis O, such as a pulley 2 that feeds a wire such as an optical fiber or carbon fiber, is taken as an example.

- FIG. 1 is an external view of a double-sided air bearing unit 4 according to the present embodiment

- FIG. 2 is a side view of the double-sided air bearing unit 4 in a state where a pulley 2 to be supported is assembled. is there.

- a double-supported air bearing unit 4 includes an air shaft unit 1 that supports a pulley 2 that is long in the direction of the axis O in a non-contact manner, and an air shaft unit 1. And two shaft holders 3A and 3B that support both ends.

- the air shaft unit 1 is an assembly of an air shaft 11, a thrust plate 12 and a nut 13 (see FIG. 4), and the pulley 2 is for inserting an air shaft formed in the axial direction of the pulley 2.

- the air shaft 11 radial bearing portion 114 with the porous sintered layer 112 formed

- the air shaft 11 the screw portion 1151 of the rod portion 115

- the nut 13 through the thrust plate 12 are inserted.

- the air shaft unit 1 is assembled so as to be rotatable in a non-contact state.

- each shaft holder 3 ⁇ / b> A, 3 ⁇ / b> B has the end of the air shaft unit 1 (thrust plate 12, base portion 113 of the air shaft 11) with the axis O oriented substantially parallel to the base as the maximum diameter of the pulley 2. Hold at the appropriate height.

- Each of the shaft holders 3A and 3B includes, for example, a lower block member 33 with a flange 35 fixed to a pedestal with bolts, an upper block member 32 placed on the upper surface of the lower block member 33, and a lower block member. And two bolts 34 for adjusting the distance t1 between the upper surface of 33 and the bottom surface of the upper block member 33. Grooves having a semicircular cross section are formed in the thickness t2 direction on the upper surface of the lower block member 33 and the bottom surface of the upper block member 32, respectively, and these shafts face each other so that the shaft is positioned at a predetermined height. A fixing hole 31 is formed. The two bolts 34 are fastened to the screw holes of the lower block member 33 through the bolt holes of the upper block member 33 at positions on both sides of the shaft fixing hole 31.

- the end portions of the air shaft unit 1 (the thrust plate 12 and the base portion 113 of the air shaft 11) are respectively inserted into the shaft fixing holes 31 of the two shaft holders 3A and 3B arranged to face each other, and the respective shaft holders 3A and 3B are inserted.

- the two bolts 34 are tightened, the interval t1 between the lower block member 33 and the upper block member 32 is narrowed, and both end portions of the air shaft unit 1 (the thrust plate 12 and the base portion 113 of the air shaft 11) are fixed. Is done.

- attached to the air shaft unit 1 is hold

- the two shaft holders 3A and 3B are used to adjust the interval t1 between the lower block member 33 with the flange 35 and the upper block member 32 with the two bolts 34, but the air shaft Any type of shaft holder may be used as long as the unit 1 can be held at both ends thereof (thrust plate 12, base portion 113 of the air shaft 11).

- FIG. 3 (A) is a front view of the pulley 2

- FIG. 3 (B) is a cross-sectional view taken along the line AA in FIG. 3 (A).

- the pulley 2 to be supported has, for example, a substantially cylindrical shape that is longer in the direction of the axis O than the diameter r2, and a wire rod is applied to the outer circumferential surface 23 in the circumferential direction.

- the pulley 2 is formed with an air shaft insertion hole 22 penetrating from one end face 25A to the other end face 25B at a position through which the axis O passes, and in the air shaft insertion hole 22, A radial bearing 114 with a porous sintered layer 112 of the air shaft 11 is slidably inserted.

- Bosses 24A and 24B surrounding the air shaft insertion hole 22 are formed on both end faces 25A and 25B of the pulley 2, respectively. End surfaces 241A and 241B of the bosses 24A and 24B are finished flat.

- the end surface 241A of one boss 24A has a slight gap (thrust bearing gap) and a step surface (thrust) (to be described later) of the air shaft 11 described later.

- Bearing surface) 1132 and the end surface 241B of the other boss 24B faces one end surface (thrust bearing surface) 121 of the thrust plate 12 with a slight gap (thrust bearing gap) (FIGS. 5 and 6). reference).

- annular flange portions 21 projecting radially from the outer peripheral surface 23 may be formed at both ends of the pulley 2.

- FIG. 4 is a component development view of the air shaft unit 1.

- the air shaft unit 1 is inserted into the air shaft insertion hole 22 of the pulley 2 and supports the pulley 2 in a non-contact manner so as to be rotatable around the axis O, and from the air shaft 11

- a thrust plate 12 that prevents the pulley 2 from falling off and a nut 13 that fixes the thrust plate 12 to the air shaft 11 are provided.

- FIG. 5A is a front view of the air shaft 11

- FIG. 5B is a cross-sectional view taken along the line BB of FIG. 5A

- FIG. 5C is a bottom view of the air shaft 11.

- FIG. 5D is an enlarged partial cross-sectional view of the radial bearing portion 114.

- the air shaft 11 includes a stepped columnar back metal 111 and a porous sintered layer 112 formed on the outer peripheral surface 1142 of the middle step portion (radial bearing portion) 114 of the back metal 111. I have.

- the back metal 111 includes a base portion 113 having substantially the same diameter as the outer diameters of the bosses 24 ⁇ / b> A and 24 ⁇ / b> B of the pulley 2, a radial bearing portion 114 having a smaller diameter than the base portion 113, and a rod portion 115 having a smaller diameter than the radial bearing portion 114. And are integrally provided.

- an air passage 116 is formed from the end surface 1131 through the inside of the base portion 113 to reach the inside of the radial bearing portion 114.

- a threaded portion 118 into which a coupler 40 (see FIG. 2) for connecting the air supply pipe 41 of the pump is screwed is formed at an opening (air supply port) 117 of the air passage 116 on one end surface 1131.

- the base portion 113 is inserted into the shaft fixing hole 31 of the one shaft holder 3A from the shaft fixing hole 31 of the one shaft holder 3A to the position where the other end surface 1132 protrudes toward the other shaft holder 3B (FIG. 2). reference). In this state, the two bolts 34 of the one shaft holder 3A are tightened, whereby the base portion 113 is fixed in the shaft fixing hole 31 of the one shaft holder 3A.

- the radial bearing 114 is formed integrally with the other end surface (step surface that functions as a thrust bearing surface) 1132 of the base 113, and a porous material having air permeability over the entire outer peripheral surface 1142 of the radial bearing 114.

- a sintered layer 112 is formed.

- a hole 1144 connected to the air passage 116 is formed.

- the number and layout of the annular grooves 1143 positioned on the outer peripheral surface 1142 of the radial bearing portion 114 may be determined as appropriate so that the compressed air is uniformly ejected from the entire outer peripheral surface 1121 of the porous sintered layer 112.

- a number of annular grooves 1143 corresponding to the length of the radial bearing portion 114 (width of the porous sintered layer 112) t4 and the like are arranged at substantially equal intervals in the axial center O direction of the porous sintered layer 112. Also good.

- the pressure of the entire radial bearing gap 60 such as a position away from the center position of the radial bearing portion 114 (a position inside t4 / 2 from one end of the radial bearing portion 114) to the base portion 113 side and the rod portion 115 side.

- the annular groove 1143 may be formed at a position where the height can be maintained high.

- the radial bearing 114 on which the porous sintered layer 112 is formed is inserted into the air shaft insertion hole 22 of the pulley 2.

- the outer diameter R1 of the radial bearing 114 including the porous sintered layer 112 is designed to be smaller than the inner diameter r1 (see FIG. 3) of the air shaft insertion hole 22 of the pulley 2 by a predetermined dimension. For this reason, when the radial bearing portion 114 is inserted into the air shaft insertion hole 22 of the pulley 2, the porous holes formed on the inner peripheral surface 221 of the air shaft insertion hole 22 and the outer peripheral surface 1142 of the radial bearing portion 114.

- a radial bearing gap 60 is formed between the outer peripheral surface (radial bearing surface) 1121 of the quality sintered layer 112 (see FIG. 7).

- a high-pressure air film is formed in the radial bearing gap 60 by the compressed air ejected from the outer peripheral surface (radial bearing surface) 1121 of the porous sintered layer 112 after the supply of air from the pump to the air shaft 11 is started. .

- the radial load is supported by the pressure of the air film.

- the length (distance between the stepped surfaces 1132 and 1141) t4 of the radial bearing 114 is based on the distance between the end surfaces 241A and 241B of the bosses 24A and 24B of the both ends 25A and 25B of the pulley 2 (length of the pulley 2) t3. Is designed to be larger by a predetermined dimension. For this reason, after the supply of air from the pump to the air shaft 11 is started, the end surface 241A of one boss 24A of the pulley 2 inserted into the radial bearing portion 114 and the other end surface of the base portion 113 (the radial bearing portion 114 and the base portion).

- a thrust bearing gap 61 a that is connected to the radial bearing gap 60 is formed between the outer diameter difference 113 and the step surface 1132 that functions as a thrust bearing surface. Similarly, it contacts the end surface 241B of the other boss 24B of the pulley 2 and the end surface of the radial bearing portion 114 (stepped surface formed by the difference in the outer diameter of the radial bearing portion 114 and the rod portion 115) 1141 as a thrust bearing surface.

- a thrust bearing gap 61b connected to the radial bearing gap 60 is also formed between one end surface 121 of a functioning thrust plate 12 described later (see FIG. 7). In order to prevent the occurrence of self-excited vibration, it is preferable to improve the assembling accuracy of the thrust plate 12 by finishing so that the edge portion 11411 of the end surface 1141 of the radial bearing portion 114 does not fall.

- the rod portion 115 is formed continuously with the end surface 1141 of the radial bearing portion 114, and is inserted into a shaft insertion hole 123 of the thrust plate 12 described later. Further, a screw portion 1151 that is screwed into the nut 13 is formed at the tip of the rod portion 115.

- FIG. 6A is a front view of the thrust plate 12, and FIG. 6B is a cross-sectional view taken along the line CC of FIG. 6A.

- the thrust plate 12 has a cylindrical shape having an outer diameter substantially the same as the outer diameter of the base portion 113 of the air shaft 11, and extends from one end surface 121 to the other surface 122 at a position through which the axis O passes.

- a penetrating shaft insertion hole 123 is formed. The rod portion 115 of the air shaft 11 is inserted into the shaft insertion hole 123.

- the air shaft unit 1 having the above-described configuration is assembled as follows.

- the pulley 2 is assembled to the air shaft unit 1. Specifically, the air shaft 11 is moved to the air shaft insertion hole 22 of the pulley 2 so that the radial bearing portion 114 on which the porous sintered layer 112 is formed is positioned in the air shaft insertion hole 22 of the pulley 2. Then, the air shaft 11 into which the pulley 2 is inserted is further inserted into the shaft insertion hole 123 of the thrust plate 12 so that the rod portion 115 is positioned in the shaft insertion hole 123 of the thrust plate 12.

- both ends thereof are It is fixed to two shaft holders 3A and 3B that are opposed to each other at a predetermined interval (see FIG. 2).

- the other end surface (step surface that functions as a thrust bearing surface) 1132 of the base portion 113 of the air shaft 11 protrudes from the shaft fixing hole 31 of one shaft holder 3A to the other shaft holder 3B side.

- the base portion 113 of the air shaft 11 is inserted into the shaft fixing hole 31 of one shaft holder 3A, and one end surface (end surface functioning as a thrust bearing surface) 121 of the thrust plate 12 is the shaft of the other shaft holder 3B.

- the thrust plate 12 is inserted into the shaft fixing hole 31 of the other shaft holder 3B so as to protrude from the fixing hole 31 toward the one shaft holder 3A. In this state, by tightening the two bolts 34 of the shaft holders 3A and 3B, the base portion 113 of the air shaft 11 and the thrust plate 12 are fixed in the shaft fixing holes 31 of the shaft holders 3A and 3B.

- a thrust bearing gap 61 a is formed between the end face 241 B of the other boss 24 B of the pulley 2 and one end face (thrust bearing face) 121 of the thrust plate 12. Is done. Compressed air exhausted from the radial bearing gap 60 flows into the thrust bearing gaps 61a and 61b, and a high-pressure air film is formed. The thrust load is supported by the pressure of the air film.

- the length t4 of the radial bearing 114 is such that the thickness s1 (see FIG. 7) of the thrust bearing gaps 61a and 61b on both sides of the pulley 2 is larger than the thickness s2 of the radial bearing gap 60 to the extent that no self-excited vibration is generated. Is also set to be large.

- the thrust bearing gaps 61a and 61b having a thickness s1 that does not generate self-excited vibration are a slight movement that occurs in the pulley 2 in a no-load state in the thrust direction, so that the pulley 2 is one thrust bearing.

- the thrust bearing gaps 61a and 61b are wide enough that they do not suddenly push back toward the other thrust bearing surface 121 or 1322, even if they are slightly closer to the surfaces 1132 and 121.

- the thickness s1 of the thrust bearing gaps 61a and 61b is about 22.5 to 37 ⁇ m.

- FIG. 7 is a diagram schematically showing the support state of the pulley 2 during the supply of air to the air shaft 11.

- a pump air supply pipe (not shown) is connected to the air supply port 117 of the air shaft 11 and compressed air from the pump is connected.

- this compressed air f is supplied to each annular groove 1143 located on the outer peripheral surface 1142 of the radial bearing portion 114 via the air passage 116 and the hole 1144 of the air shaft 11, and porous sintering is performed. It is ejected from the outer peripheral surface (radial bearing surface) 1121 of the layer 112 into the radial bearing gap 60. For this reason, a high-pressure air film is formed in the radial bearing gap 60, and the radial load is supported by the pressure. Thereby, the movement to the radial direction of the pulley 2 is restrained.

- the compressed air f in the radial bearing gap 60 extends along the outer peripheral surface (radial bearing surface) 1121 of the porous sintered layer 112 on the one end surface (thrust bearing surface) 121 side of the thrust plate 12 and the base portion 113.

- the thrust bearing gap 61a between the end surface 241A of one boss 24A of the pulley 2 and the thrust bearing surface 1132 of the base portion 113 and the pulley 2 flows toward the other end surface (thrust bearing surface) 1132 side of the pulley 2.

- Compressed air f1 that has flowed into the thrust bearing gaps 61a and 61b flows radially toward the outer periphery of each boss 24A and 24B, and is finally released to the outside (atmospheric pressure).

- the pressure in each of the thrust bearing gaps 61a and 61b is high on the inner peripheral side of the pulley 2 into which the compressed gas f1 exhausted from the radial bearing gap 60 flows, and gradually increases toward the outer periphery of the bosses 24A and 24B. Decrease. For this reason, an air film having a high average pressure is formed in the thrust bearing gaps 61a and 61b, and the thrust load is supported by the pressure. Thereby, the movement of the pulley 2 in the thrust direction is restricted.

- the pressure distribution in the thrust bearing gaps 61a and 61b changes, and self-excited vibration may occur.

- the pressure increases due to the increase in resistance

- the pressure decreases due to the decrease in resistance. Moves along the axis O so as to be pushed back toward the other thrust bearing surface 121, 1322 only slightly closer to one thrust bearing surface 1132, 121. This is repeated.

- the thickness s1 has a margin enough to prevent the pulley 2 from being suddenly pushed back to the other thrust bearing surface 121, 1322 side. Since the thrust bearing gaps 61a and 61b are provided, the occurrence of self-excited vibration can be suppressed.

- compressed air is supplied from the porous sintered layer 112 facing the inner peripheral surface 221 of the pulley 2 to the radial bearing gap 60, and this radial bearing gap

- the compressed air exhausted from 60 is introduced into the thrust bearing gaps 61a and 61b on both sides of the pulley 2 while maintaining the pressure, so that the pressure of the air film in the radial bearing gap 60 and the thrust bearing gap 61a,

- the radial load and thrust load of the pulley 2 can be supported in a non-contact manner by the pressure of the air film in 61b. For this reason, since the power loss hardly occurs, the pulley 2 can be rotated at a high speed.

- the structure of the air bearing unit 4 can be further simplified, and the air bearing unit 4 can be reduced in manufacturing cost.

- the air shaft unit 1 is held at both ends thereof, even if the air shaft 11 is elongated to hold the long pulley 2, the air shaft 11 can be prevented from being bent by its own weight. Can do. Therefore, contact between the inner peripheral surface 221 of the air shaft insertion hole 22 of the pulley 2 and the outer peripheral surface (radial bearing surface) 1121 of the porous sintered layer 112 facing each other with a slight radial bearing gap 60 is prevented. can do. For this reason, even if the pulley 2 to be supported is elongated in the direction of the axis O, the pulley 2 can be stably supported in a non-contact manner.

- the thickness of the pulley 2 can be made thinner. For this reason, even if the pulley 2 is elongated in the direction of the axis O, the pulley 2 can be reduced in weight by making the pulley 2 thinner. Accordingly, the long pulley 2 can be rotated at a higher speed, and the load applied to the air shaft 11 is reduced, so that the bending of the air shaft 11 is further suppressed. For this reason, the pulley 2 that rotates at high speed can be supported in a non-contact manner more stably.

- the air bearing unit 4 it is only necessary that the compressed air is ejected from the radial bearing surface 1121 to the radial bearing gap 60, and the compressed gas is emitted from each of the thrust bearing surfaces 1132 and 121 and the radial bearing surface 1121. It is not necessary to attach a thick porous body that erupts. Therefore, the porous sintered layer 112 having a thickness of several millimeters (for example, about 2.5 mm) may be integrally formed with the back metal 111. For this reason, the air bearing unit 4 can be made compact.

- the air shaft 11 is inserted into the pulley 2 to be supported. It is sufficient if the air shaft insertion hole 22 is formed, and it is not necessary to form a special part. For this reason, the manufacturing cost of the pulley 2 which is a replacement part can be reduced, and the running cost can be reduced.

- the thickness s1 of the thrust bearing gaps 61a and 61b is increased to such an extent that no self-excited vibration is generated, the occurrence of self-excited vibration can be prevented. For this reason, the pulley 2 that rotates at high speed can be supported in a non-contact manner more stably.

- the stepped columnar back metal 111 is used, but the back metal 111 may have a hollow structure, for example.

- the air bearing unit 4 that supports the long pulley 2 is taken as an example, but a rotating body other than the long pulley 2 may be supported.

- a plurality of ordinary pulleys may be supported.

- the present invention can also be used as, for example, a dual-support type air bearing unit suitable for non-contact support of a rotating body such as a pulley for feeding a wire such as an optical fiber or carbon fiber.

- Air shaft unit 2: Pulley, 3A, 3B: Shaft holder, 4: Air bearing unit, 11: Air shaft, 12: Thrust plate, 13: Nut, 21: Flange, 22: Air shaft insertion hole, 23: Outer peripheral surface of boss, 24A, 24B: Boss, 25A, 25B: End surface of pulley, 111: Back metal, 112: Porous sintered layer, 113: Base portion, 114: Radial bearing portion, 115: Rod portion, 116: Air passage, 117: Air supply port, 118: Screw part, 121: End surface of thrust plate (thrust bearing surface), 122: End surface of thrust plate, 123: Hole for shaft insertion, 221: Inner peripheral surface of pulley, 241A, 241B: end face of the boss, 1121: outer peripheral surface of the porous sintered layer (radial bearing surface), 1131: base 1132: end surface of the base portion (step surface, thrust bearing surface), 1141: end surface of the radial bearing portion (step

Abstract

Provided is a compact, gas-static bearing unit for more stably supporting a rotating body without contact using a simple structure, the rotating body rotating at high speed.

The opposite ends (113, 12) of an air shaft unit (1) for supporting a pulley (2) without contact are affixed to two shaft holders (3A, 3B). Gas (f) is supplied from the radial bearing surface (1121) of the air shaft unit (1) to the radial bearing gap (60) between the radial bearing surface (1121) and the inner peripheral surface (221) of the pulley (2) to form a gas film within the radial bearing gap (60), and the gas (f) is discharged from the radial bearing gap (60) to the thrust bearing gaps (61a, 61b) between the thrust bearing surfaces (1132, 121) of the air shaft unit (1) and the boss end surfaces (241A, 241B) of the pulley (2), the thrust bearing gaps (61a, 61b) connecting to the radial bearing gap (60). A gas film is also formed within the thrust bearing gaps (61a, 61b) utilizing the discharge gas (f1).

Description

本発明は、高速回転するプーリ等の部品を、簡易な構造で、より安定して非接触支持可能な両持ちタイプの静圧気体軸受ユニットの構造に関する。

The present invention relates to a structure of a double-sided hydrostatic gas bearing unit that can support a component such as a pulley that rotates at a high speed with a simple structure and more stably without contact.

特許文献1には、回転軸を非接触で支持するエアベアリングユニット(静圧空気軸受装置)が記載されている。

Patent Document 1 describes an air bearing unit (static pressure air bearing device) that supports a rotating shaft in a non-contact manner.

このエアベアリングユニットには、シャフト(回転軸)が挿入される円筒形のハウジングの内周の両端側に、シャフトのスラスト荷重およびラジアル荷重をそれぞれ個別の軸受面(スラスト軸受面、ラジアル軸受面)で受ける多孔質絞り型(多孔質グラファイト等の多孔質体)のエアベアリング(静圧空気軸受)がそれぞれ一つ設けられている。ここで、ラジアル軸受面は、シャフトの外周面に対向して、この外周面との間にラジアル軸受隙間を形成し、スラスト軸受面は、シャフトの外周に形成されたフランジに対向して、このフランジとの間にスラスト軸受隙間を形成している。

In this air bearing unit, the shaft thrust load and radial load are respectively provided on both ends of the inner periphery of the cylindrical housing into which the shaft (rotating shaft) is inserted, and the individual bearing surfaces (thrust bearing surface, radial bearing surface) One air bearing (static air bearing) of a porous drawing type (a porous body such as porous graphite) received by each is provided. Here, the radial bearing surface is opposed to the outer peripheral surface of the shaft and a radial bearing gap is formed between the radial bearing surface and the thrust bearing surface is opposed to the flange formed on the outer periphery of the shaft. A thrust bearing gap is formed between the flange and the flange.

ここで、エアベアリング毎に、ハウジングの内周面には、エアベアリングのラジアル軸受面を挟んでスラスト軸受面と反対側(ハウジングの内周面の中央側)に排気用溝が周方向に形成され、この排気用溝の溝底には、ハウジングの外周面に貫通する排気孔が形成されている。また、シャフトの外周面には、エアベアリングのスラスト軸受面寄りの位置に排気用溝が周方向に形成されており、シャフトの内部には、この排気用溝とハウジングの内周面の排気用溝とをつなぐ排気孔が形成されている。

Here, for each air bearing, on the inner peripheral surface of the housing, an exhaust groove is formed in the circumferential direction on the opposite side of the thrust bearing surface (center side of the inner peripheral surface of the housing) across the radial bearing surface of the air bearing An exhaust hole penetrating the outer peripheral surface of the housing is formed at the bottom of the exhaust groove. Further, an exhaust groove is formed in the circumferential direction at a position near the thrust bearing surface of the air bearing on the outer peripheral surface of the shaft, and the exhaust groove and the inner peripheral surface of the housing are exhausted inside the shaft. Exhaust holes that connect the grooves are formed.

このような構成において、エアベアリングに供給された空気は、エアベアリングのスラスト軸受面およびラジアル軸受面からそれぞれ噴出する。スラスト軸受面から噴出した空気は、スラスト軸受隙間内をフランジの外周に向かって流れ、スラスト軸受隙間から外部に放出される。一方、ラジアル軸受面から噴出した空気は、ラジアル軸受隙間内を、スラスト軸受面寄りの排気用溝とスラスト軸受面の反対側の排気用溝とに向かって流れて、これらの排気用溝に流入し、排気孔を介してハウジングの外部に排気される。

In such a configuration, the air supplied to the air bearing is ejected from the thrust bearing surface and the radial bearing surface of the air bearing. The air ejected from the thrust bearing surface flows in the thrust bearing gap toward the outer periphery of the flange, and is discharged to the outside through the thrust bearing gap. On the other hand, the air ejected from the radial bearing surface flows in the radial bearing gap toward the exhaust groove near the thrust bearing surface and the exhaust groove on the opposite side of the thrust bearing surface, and flows into these exhaust grooves. Then, the air is exhausted to the outside of the housing through the exhaust hole.

しかしながら、特許文献1に記載のエアベアリングユニットでは、エアベアリング毎に、スラスト軸受面寄りの位置と、ラジアル軸受面を挟んでスラスト軸受面の反対側の位置とに、それぞれ、ラジアル軸受隙間に供給された空気を排出するための排気用溝を形成しておく必要がある。また、これらの排気用溝に流入した空気をハウジングの外部に排出するための排気孔を、ハウジングおよびシャフトの双方に形成しておく必要がある。さらに、ハウジングの内周には、圧縮空気を噴出するスラスト軸受面およびラジアル軸受面を個別に設けておく必要がある。このため、構造が複雑化する。

However, in the air bearing unit described in Patent Document 1, for each air bearing, the radial bearing gap is supplied to a position near the thrust bearing surface and a position on the opposite side of the thrust bearing surface across the radial bearing surface. It is necessary to form an exhaust groove for discharging the generated air. Further, it is necessary to form exhaust holes for discharging the air flowing into these exhaust grooves to the outside of the housing on both the housing and the shaft. Further, it is necessary to separately provide a thrust bearing surface and a radial bearing surface for ejecting compressed air on the inner periphery of the housing. This complicates the structure.

また、シャフト側の排気孔は、シャフトの外周面の排気用溝とハウジングの内周面の排気用溝とをつなぐようにシャフトの軸心方向に沿って形成されるため、シャフトにはある程度の肉厚が必要となる。このため、シャフトが重量化すると、例えば自重によってシャフトが撓む可能性がある。ハウジング内周のエアベアリング(静圧空気軸受)のラジアル軸受面とシャフトの外周面との間に形成されるラジアル軸受隙間は非常に狭いため、シャフトに撓みが発生すると、シャフトとエアリングとが接触し、シャフトを安定に保持できない可能性がある。

Further, the exhaust hole on the shaft side is formed along the axial direction of the shaft so as to connect the exhaust groove on the outer peripheral surface of the shaft and the exhaust groove on the inner peripheral surface of the housing. Thickness is required. For this reason, when the shaft becomes heavy, the shaft may be bent by its own weight, for example. Since the radial bearing gap formed between the radial bearing surface of the air bearing (hydrostatic air bearing) on the inner periphery of the housing and the outer peripheral surface of the shaft is very narrow, if the shaft is bent, the shaft and the air ring There is a possibility that the shaft cannot be held stably.

ところで、高速回転するプーリ等の回転体をエアベアリングで保持すると、給気時に自励振動が発生することがある。これにより系が共振すると、例えば搬送物の安定な走行の妨げ等となる。

By the way, if a rotating body such as a pulley that rotates at high speed is held by an air bearing, self-excited vibration may occur during air supply. Thus, if the system resonates, for example, it may hinder stable traveling of the conveyed product.

本発明は上記事情に鑑みてなされたものであり、その目的は、高速回転する回転体を、簡易な構造で、より安定して非接触支持する両持ちタイプの静圧気体軸受ユニットの構造を提供することにある。

The present invention has been made in view of the above circumstances, and an object of the present invention is to provide a structure of a double-sided hydrostatic gas bearing unit that supports a rotating body that rotates at a high speed with a simple structure and more stably in a non-contact manner. It is to provide.

上記課題を解決するために、本発明においては、回転体に当該回転体の軸方向に形成されたシャフト挿入穴内に挿入され、この回転体を非接触で支持するシャフトユニットを、回転体のシャフト挿入穴を軸方向両側から挟み込む位置で固定する。また、回転体のシャフト挿入穴の内周面に対向する、シャフトユニットの外周面に形成されたラジアル軸受面から噴出する気体により、ラジアル軸受面と回転体のシャフト挿入穴の内周面との間のラジアル軸受隙間内に気体膜を形成し、その気体を、ラジアル軸受隙間から、シャフトユニットのスラスト軸受面と回転体の各端面との間のスラスト軸受隙間内に排気させる。この排気された気体を利用してスラスト軸受隙間内にも気体膜を形成する。

In order to solve the above problems, in the present invention, a shaft unit that is inserted into a shaft insertion hole formed in the rotating body in the axial direction of the rotating body and supports the rotating body in a non-contact manner is provided as a shaft of the rotating body. Fix the insertion hole at the position where it is sandwiched from both sides in the axial direction. Further, the gas ejected from the radial bearing surface formed on the outer peripheral surface of the shaft unit opposite to the inner peripheral surface of the shaft insertion hole of the rotating body causes the radial bearing surface and the inner peripheral surface of the shaft insertion hole of the rotating body to A gas film is formed in the radial bearing gap, and the gas is exhausted from the radial bearing gap into the thrust bearing gap between the thrust bearing surface of the shaft unit and each end face of the rotating body. A gas film is also formed in the thrust bearing gap using the exhausted gas.

例えば、本発明は、軸心周りの方向に回転する回転体を、ラジアル軸受隙間と第一および第二のスラスト軸受隙間とに介在する気体膜により非接触で支持する静圧気体軸受ユニットであって、

前記回転体の両端面を貫通するシャフト挿入穴内に挿入されるシャフトユニットと、

前記シャフトユニットを前記回転体のシャフト挿入穴の両側の位置で保持するシャフト保持手段と、を備え、

前記シャフトユニットは、

前記シャフト挿入穴の内周面に対向して、当該内周面との間に前記ラジアル軸受隙間を形成し、前記ラジアル軸受隙間に前記気体膜を形成するための気体を噴出するラジアル軸受面と、

前記ラジアル軸受面と隣り合い、前記回転体の一方の端面に対向して、当該端面との間に、前記ラジアル軸受隙間の一方の端側に繋がる前記第一のスラスト軸受隙間を形成する第一のスラスト軸受面と、

前記ラジアル軸受面と隣り合い、前記回転体の他方の端面に対向して、当該端面との間に、前記ラジアル軸受隙間の他方の端側に繋がる前記第二のスラスト軸受隙間を形成する第二のスラスト軸受面と、を有し、

前記気体は、

前記ラジアル軸受隙間内を前記第一のスラスト軸受隙間および前記第二のスラスト軸受隙間に向かって流れて、当該ラジアル軸受隙間から前記第一のスラスト軸受隙間および前記第二のスラスト軸受隙間にそれぞれ排気され、当該第一のスラスト軸受隙間内および当該第二のスラスト軸受隙間にそれぞれ前記気体膜を形成する。 For example, the present invention is a hydrostatic gas bearing unit that supports a rotating body that rotates in a direction around an axis center in a non-contact manner by a gas film interposed between a radial bearing gap and first and second thrust bearing gaps. And

A shaft unit that is inserted into a shaft insertion hole that penetrates both end faces of the rotating body;

Shaft holding means for holding the shaft unit at positions on both sides of the shaft insertion hole of the rotating body,

The shaft unit is

A radial bearing surface that opposes the inner peripheral surface of the shaft insertion hole, forms the radial bearing gap between the inner peripheral surface, and ejects gas for forming the gas film in the radial bearing gap; ,

A first thrust bearing gap is formed adjacent to the radial bearing surface, opposed to one end face of the rotating body, and connected to one end side of the radial bearing gap between the end face and the first thrust bearing gap. A thrust bearing surface of

A second thrust bearing gap is formed adjacent to the radial bearing surface, opposite the other end face of the rotating body, and between the end face and the second thrust bearing gap connected to the other end side of the radial bearing gap. A thrust bearing surface of

The gas is

It flows in the radial bearing gap toward the first thrust bearing gap and the second thrust bearing gap, and exhausts from the radial bearing gap to the first thrust bearing gap and the second thrust bearing gap, respectively. Then, the gas film is formed in the first thrust bearing gap and in the second thrust bearing gap, respectively.

前記回転体の両端面を貫通するシャフト挿入穴内に挿入されるシャフトユニットと、

前記シャフトユニットを前記回転体のシャフト挿入穴の両側の位置で保持するシャフト保持手段と、を備え、

前記シャフトユニットは、

前記シャフト挿入穴の内周面に対向して、当該内周面との間に前記ラジアル軸受隙間を形成し、前記ラジアル軸受隙間に前記気体膜を形成するための気体を噴出するラジアル軸受面と、

前記ラジアル軸受面と隣り合い、前記回転体の一方の端面に対向して、当該端面との間に、前記ラジアル軸受隙間の一方の端側に繋がる前記第一のスラスト軸受隙間を形成する第一のスラスト軸受面と、

前記ラジアル軸受面と隣り合い、前記回転体の他方の端面に対向して、当該端面との間に、前記ラジアル軸受隙間の他方の端側に繋がる前記第二のスラスト軸受隙間を形成する第二のスラスト軸受面と、を有し、

前記気体は、

前記ラジアル軸受隙間内を前記第一のスラスト軸受隙間および前記第二のスラスト軸受隙間に向かって流れて、当該ラジアル軸受隙間から前記第一のスラスト軸受隙間および前記第二のスラスト軸受隙間にそれぞれ排気され、当該第一のスラスト軸受隙間内および当該第二のスラスト軸受隙間にそれぞれ前記気体膜を形成する。 For example, the present invention is a hydrostatic gas bearing unit that supports a rotating body that rotates in a direction around an axis center in a non-contact manner by a gas film interposed between a radial bearing gap and first and second thrust bearing gaps. And

A shaft unit that is inserted into a shaft insertion hole that penetrates both end faces of the rotating body;

Shaft holding means for holding the shaft unit at positions on both sides of the shaft insertion hole of the rotating body,

The shaft unit is

A radial bearing surface that opposes the inner peripheral surface of the shaft insertion hole, forms the radial bearing gap between the inner peripheral surface, and ejects gas for forming the gas film in the radial bearing gap; ,

A first thrust bearing gap is formed adjacent to the radial bearing surface, opposed to one end face of the rotating body, and connected to one end side of the radial bearing gap between the end face and the first thrust bearing gap. A thrust bearing surface of

A second thrust bearing gap is formed adjacent to the radial bearing surface, opposite the other end face of the rotating body, and between the end face and the second thrust bearing gap connected to the other end side of the radial bearing gap. A thrust bearing surface of

The gas is

It flows in the radial bearing gap toward the first thrust bearing gap and the second thrust bearing gap, and exhausts from the radial bearing gap to the first thrust bearing gap and the second thrust bearing gap, respectively. Then, the gas film is formed in the first thrust bearing gap and in the second thrust bearing gap, respectively.

本発明によれば、回転体のシャフト挿入穴の内周面と、回転体のシャフト挿入穴の内周面に対向する、シャフトユニットの外周面に形成されたラジアル軸受面との間に形成されたラジアル軸受隙間から排気された圧縮気体が、回転体の各端面とシャフトユニットのスラスト軸受面との間に形成されたスラスト軸受隙間に供給された後に排気され、スラスト軸受隙間に気体膜を形成するために利用されるため、ラジアル軸受隙間からの圧縮気体を排気するための溝および孔や、スラスト軸受隙間に圧縮気体を噴出するスラスト軸受面を別途設ける必要がない。また、回転体を非接触支持するシャフトユニットが両端固定されるため、回転体のサイズに応じてシャフトユニットが長尺化された場合であっても、その撓みを抑制することができ、回転体とシャフトユニットとの接触を防止することができる。このため、高速回転する回転体を、簡易な構造で、より安定して非接触支持可能な両持ちタイプの静圧気体軸受ユニットを実現することができる。

According to the present invention, formed between the inner peripheral surface of the shaft insertion hole of the rotating body and the radial bearing surface formed on the outer peripheral surface of the shaft unit facing the inner peripheral surface of the shaft insertion hole of the rotating body. The compressed gas exhausted from the radial bearing gap is supplied to the thrust bearing gap formed between each end face of the rotating body and the thrust bearing surface of the shaft unit, and then exhausted to form a gas film in the thrust bearing gap. Therefore, there is no need to separately provide a groove and a hole for exhausting compressed gas from the radial bearing gap and a thrust bearing surface for ejecting compressed gas into the thrust bearing gap. In addition, since the shaft unit that supports the rotating body in a non-contact manner is fixed at both ends, even when the shaft unit is elongated according to the size of the rotating body, the bending can be suppressed. And the shaft unit can be prevented from contacting each other. For this reason, it is possible to realize a double-sided static pressure gas bearing unit capable of supporting a rotating body rotating at high speed with a simple structure and more stably in a non-contact manner.

以下、添付図面を参照しながら、本発明の実施の形態について説明する。

Hereinafter, embodiments of the present invention will be described with reference to the accompanying drawings.

まず、本実施の形態に係る両持ちタイプの静圧気体軸受ユニットの全体構造について説明する。ここでは、光ファイバ、カーボン繊維等の線材を送るプーリ2等の、軸心O方向に長尺な回転体の非接触支持に適した両持ちタイプのエアベアリングユニット4を一例に挙げる。

First, the overall structure of a double-sided static pressure gas bearing unit according to the present embodiment will be described. Here, a double-ended air bearing unit 4 suitable for non-contact support of a rotating body that is long in the direction of the axis O, such as a pulley 2 that feeds a wire such as an optical fiber or carbon fiber, is taken as an example.

図1は、本実施の形態に係る両持ちタイプのエアベアリングユニット4の外観図であり、図2は、支持対象のプーリ2を組み付けた状態の両持ちタイプのエアベアリングユニット4の側面図である。

FIG. 1 is an external view of a double-sided air bearing unit 4 according to the present embodiment, and FIG. 2 is a side view of the double-sided air bearing unit 4 in a state where a pulley 2 to be supported is assembled. is there.

図示するように、本実施の形態に係る両持ちタイプのエアベアリングユニット4は、軸心O方向に長尺なプーリ2を回転可能に非接触支持するエアシャフトユニット1と、エアシャフトユニット1を両端支持する2台のシャフトホルダ3A,3Bと、を備えている。

As shown in the figure, a double-supported air bearing unit 4 according to the present embodiment includes an air shaft unit 1 that supports a pulley 2 that is long in the direction of the axis O in a non-contact manner, and an air shaft unit 1. And two shaft holders 3A and 3B that support both ends.

後述するように、エアシャフトユニット1は、エアシャフト11とスラストプレート12とナット13との組立体であり(図4参照)、プーリ2は、プーリ2の軸方向に形成されたエアシャフト挿入用穴22内にエアシャフト11(多孔質焼結層112が形成されたラジアル軸受部114)が挿入された後、スラストプレート12を介したエアシャフト11(ロッド部115のネジ部1151)とナット13との締め付けによりエアシャフトユニット1に非接触状態で回転可能に組み付けられる。

As will be described later, the air shaft unit 1 is an assembly of an air shaft 11, a thrust plate 12 and a nut 13 (see FIG. 4), and the pulley 2 is for inserting an air shaft formed in the axial direction of the pulley 2. After the air shaft 11 (radial bearing portion 114 with the porous sintered layer 112 formed) is inserted into the hole 22, the air shaft 11 (the screw portion 1151 of the rod portion 115) and the nut 13 through the thrust plate 12 are inserted. By being tightened, the air shaft unit 1 is assembled so as to be rotatable in a non-contact state.

一方、2台のシャフトホルダ3A,3Bは、例えば石定盤等の台座上に、エアシャフトユニット1の長さに応じた間隔で対向するように配置されて固定される。各シャフトホルダ3A,3Bは、軸心Oが台座に対してほぼ平行に向けられたエアシャフトユニット1の端部(スラストプレート12、エアシャフト11のベース部113)を、プーリ2の最大径に応じた高さの位置で保持する。

On the other hand, the two shaft holders 3A and 3B are arranged and fixed so as to face each other at an interval corresponding to the length of the air shaft unit 1 on a base such as a stone surface plate. Each shaft holder 3 </ b> A, 3 </ b> B has the end of the air shaft unit 1 (thrust plate 12, base portion 113 of the air shaft 11) with the axis O oriented substantially parallel to the base as the maximum diameter of the pulley 2. Hold at the appropriate height.

各シャフトホルダ3A,3Bは、それぞれ、例えば、台座にボルトで固定されるフランジ35付き下側ブロック材33と、下側ブロック材33の上面に載せられた上側ブロック材32と、下側ブロック材33の上面と上側ブロック材33の底面との間隔t1を調整するための2本のボルト34と、を有している。下側ブロック材33の上面と上側ブロック材32の底面にはそれぞれ断面半円形状の溝が厚さt2方向に形成されており、これらの溝が対向することにより所定の高さの位置にシャフト固定穴31が形成されている。2本のボルト34は、シャフト固定穴31両側の位置において、上側ブロック材33のボルト穴を介して下側ブロック材33のネジ穴に締結されている。

Each of the shaft holders 3A and 3B includes, for example, a lower block member 33 with a flange 35 fixed to a pedestal with bolts, an upper block member 32 placed on the upper surface of the lower block member 33, and a lower block member. And two bolts 34 for adjusting the distance t1 between the upper surface of 33 and the bottom surface of the upper block member 33. Grooves having a semicircular cross section are formed in the thickness t2 direction on the upper surface of the lower block member 33 and the bottom surface of the upper block member 32, respectively, and these shafts face each other so that the shaft is positioned at a predetermined height. A fixing hole 31 is formed. The two bolts 34 are fastened to the screw holes of the lower block member 33 through the bolt holes of the upper block member 33 at positions on both sides of the shaft fixing hole 31.

対向配置された2台のシャフトホルダ3A,3Bのシャフト固定穴31にそれぞれエアシャフトユニット1の端部(スラストプレート12、エアシャフト11のベース部113)が挿入され、それぞれのシャフトホルダ3A,3Bを2本のボルト34が締め付けることによって、下側ブロック材33と上側ブロック材32との間隔t1が狭まり、エアシャフトユニット1の両端部(スラストプレート12、エアシャフト11のベース部113)が固定される。これにより、エアシャフトユニット1に組み付けられたプーリ2は、所定の高さの位置で軸心O方向回りに非接触状態で回転可能に保持される。

The end portions of the air shaft unit 1 (the thrust plate 12 and the base portion 113 of the air shaft 11) are respectively inserted into the shaft fixing holes 31 of the two shaft holders 3A and 3B arranged to face each other, and the respective shaft holders 3A and 3B are inserted. When the two bolts 34 are tightened, the interval t1 between the lower block member 33 and the upper block member 32 is narrowed, and both end portions of the air shaft unit 1 (the thrust plate 12 and the base portion 113 of the air shaft 11) are fixed. Is done. Thereby, the pulley 2 assembled | attached to the air shaft unit 1 is hold | maintained rotatably at the position of predetermined | prescribed height in the non-contact state around the shaft center O direction.

なお、本実施の形態では、フランジ35付き下側ブロック材33と上側ブロック材32との間隔t1を2本のボルト34で調整する2台のシャフトホルダ3A,3Bを用いているが、エアシャフトユニット1をその両端部(スラストプレート12、エアシャフト11のベース部113)で保持可能であれば、どのような形態のシャフトホルダを用いてもよい。

In this embodiment, the two shaft holders 3A and 3B are used to adjust the interval t1 between the lower block member 33 with the flange 35 and the upper block member 32 with the two bolts 34, but the air shaft Any type of shaft holder may be used as long as the unit 1 can be held at both ends thereof (thrust plate 12, base portion 113 of the air shaft 11).

つぎに、プーリ2、および、このプーリ2を軸心O回りに回転可能に非接触支持するエアシャフトユニット1の詳細を説明する。

Next, details of the pulley 2 and the air shaft unit 1 that supports the pulley 2 in a non-contact manner so as to be rotatable around the axis O will be described.

図3(A)は、プーリ2の正面図であり、図3(B)は、図3(A)のA-A断面図である。

3 (A) is a front view of the pulley 2, and FIG. 3 (B) is a cross-sectional view taken along the line AA in FIG. 3 (A).

図示するように、支持対象のプーリ2は、例えば直径r2よりも軸心O方向に長尺な略円柱形状を有しており、その外周面23には、周方向に線材がかけられる。また、プーリ2には、軸心Oが通過する位置に、一方の端面25Aから他方の端面25Bに貫通したエアシャフト挿入用穴22が形成されており、このエアシャフト挿入用穴22内に、エアシャフト11の多孔質焼結層112付きラジアル軸受部114がスライド可能に挿入される。

As shown in the figure, the pulley 2 to be supported has, for example, a substantially cylindrical shape that is longer in the direction of the axis O than the diameter r2, and a wire rod is applied to the outer circumferential surface 23 in the circumferential direction. The pulley 2 is formed with an air shaft insertion hole 22 penetrating from one end face 25A to the other end face 25B at a position through which the axis O passes, and in the air shaft insertion hole 22, A radial bearing 114 with a porous sintered layer 112 of the air shaft 11 is slidably inserted.

プーリ2の両端面25A、25Bには、エアシャフト挿入用穴22を囲むボス24A、24Bがそれぞれ形成されている。各ボス24A、24Bの端面241A、241Bは平坦に仕上げられている。プーリ2を組み付けた状態(図2の状態)のエアベアリングユニット4において、一方のボス24Aの端面241Aは、わずかな間隔(スラスト軸受隙間)をおいて、エアシャフト11の後述する段差面(スラスト軸受面)1132に対向し、他方のボス24Bの端面241Bは、わずかな間隔(スラスト軸受隙間)をおいてスラストプレート12の一方の端面(スラスト軸受面)121に対向する(図5、図6参照)。

Bosses 24A and 24B surrounding the air shaft insertion hole 22 are formed on both end faces 25A and 25B of the pulley 2, respectively. End surfaces 241A and 241B of the bosses 24A and 24B are finished flat. In the air bearing unit 4 in a state where the pulley 2 is assembled (the state shown in FIG. 2), the end surface 241A of one boss 24A has a slight gap (thrust bearing gap) and a step surface (thrust) (to be described later) of the air shaft 11 described later. Bearing surface) 1132 and the end surface 241B of the other boss 24B faces one end surface (thrust bearing surface) 121 of the thrust plate 12 with a slight gap (thrust bearing gap) (FIGS. 5 and 6). reference).

なお、図示したように、プーリ2の両端部には、外周面23から径方向に張り出した環状のフランジ部21が形成されていてもよい。

In addition, as shown in the figure, annular flange portions 21 projecting radially from the outer peripheral surface 23 may be formed at both ends of the pulley 2.

図4は、エアシャフトユニット1の部品展開図である。

FIG. 4 is a component development view of the air shaft unit 1.

図示するように、エアシャフトユニット1は、プーリ2のエアシャフト挿入用穴22内に挿入され、プーリ2を軸心O回りに回転可能に非接触支持するエアシャフト11と、エアシャフト11からのプーリ2の抜け落ちを阻止するスラストプレート12と、エアシャフト11にスラストプレート12を固定するナット13と、を備えている。

As shown in the figure, the air shaft unit 1 is inserted into the air shaft insertion hole 22 of the pulley 2 and supports the pulley 2 in a non-contact manner so as to be rotatable around the axis O, and from the air shaft 11 A thrust plate 12 that prevents the pulley 2 from falling off and a nut 13 that fixes the thrust plate 12 to the air shaft 11 are provided.

図5(A)は、エアシャフト11の正面図であり、図5(B)は、図5(A)のB-B断面図であり、図5(C)は、エアシャフト11の底面図であり、図5(D)は、ラジアル軸受部114の拡大部分断面図である。

5A is a front view of the air shaft 11, FIG. 5B is a cross-sectional view taken along the line BB of FIG. 5A, and FIG. 5C is a bottom view of the air shaft 11. FIG. 5D is an enlarged partial cross-sectional view of the radial bearing portion 114.

図示するように、エアシャフト11は、段付き円柱状のバックメタル111と、バックメタル111の中段部(ラジアル軸受部)114の外周面1142上に形成された多孔質焼結層112と、を備えている。

As shown in the figure, the air shaft 11 includes a stepped columnar back metal 111 and a porous sintered layer 112 formed on the outer peripheral surface 1142 of the middle step portion (radial bearing portion) 114 of the back metal 111. I have.

バックメタル111は、プーリ2のボス24A、24Bの外径とほぼ同径のベース部113と、ベース部113よりも小径のラジアル軸受部114と、ラジアル軸受部114よりもさらに小径のロッド部115と、を一体的に備えている。

The back metal 111 includes a base portion 113 having substantially the same diameter as the outer diameters of the bosses 24 </ b> A and 24 </ b> B of the pulley 2, a radial bearing portion 114 having a smaller diameter than the base portion 113, and a rod portion 115 having a smaller diameter than the radial bearing portion 114. And are integrally provided.

ベース部113の一方の端面1131には、この端面1131からベース部113の内部を通過してラジアル軸受部114の内部に至る通気路116が形成されている。一方の端面1131における通気路116の開口部(給気口)117には、ポンプの給気管41を連結するためのカプラ40(図2参照)をねじ込むネジ部118が形成されている。

On one end surface 1131 of the base portion 113, an air passage 116 is formed from the end surface 1131 through the inside of the base portion 113 to reach the inside of the radial bearing portion 114. A threaded portion 118 into which a coupler 40 (see FIG. 2) for connecting the air supply pipe 41 of the pump is screwed is formed at an opening (air supply port) 117 of the air passage 116 on one end surface 1131.

このベース部113は、他方の端面1132が一方のシャフトホルダ3Aのシャフト固定穴31から他方のシャフトホルダ3B側に突き出す位置まで一方のシャフトホルダ3Aのシャフト固定穴31内に挿入される(図2参照)。この状態で一方のシャフトホルダ3Aの2本のボルト34が締め付けられ、これにより、ベース部113は一方のシャフトホルダ3Aのシャフト固定穴31内に固定される。

The base portion 113 is inserted into the shaft fixing hole 31 of the one shaft holder 3A from the shaft fixing hole 31 of the one shaft holder 3A to the position where the other end surface 1132 protrudes toward the other shaft holder 3B (FIG. 2). reference). In this state, the two bolts 34 of the one shaft holder 3A are tightened, whereby the base portion 113 is fixed in the shaft fixing hole 31 of the one shaft holder 3A.

ラジアル軸受部114は、ベース部113の他方の端面(スラスト軸受面として機能する段差面)1132に一体的に形成され、このラジアル軸受部114の外周面1142の全域に、通気性を有する多孔質焼結層112が形成されている。ラジアル軸受部114の外周面1142には、多孔質焼結層112との境界部に位置する複数の環状溝1143が周方向に形成されており、各環状溝1143の溝底には、それぞれ、通気路116につながる孔1144が形成されている。これにより、給気口117に連結されたポンプの給気管41からの給気が開始されると、ポンプから送られてきた圧縮空気が、通気路116および孔1144を介して、ラジアル軸受部114の外周面1142に位置する周方向の各環状溝1143に供給され、多孔質焼結層112内の細孔を通過して、ラジアル軸受面として機能する多孔質焼結層112の外周面1121から噴出する。

The radial bearing 114 is formed integrally with the other end surface (step surface that functions as a thrust bearing surface) 1132 of the base 113, and a porous material having air permeability over the entire outer peripheral surface 1142 of the radial bearing 114. A sintered layer 112 is formed. On the outer peripheral surface 1142 of the radial bearing portion 114, a plurality of annular grooves 1143 located at the boundary with the porous sintered layer 112 are formed in the circumferential direction, and the groove bottoms of the respective annular grooves 1143 are respectively A hole 1144 connected to the air passage 116 is formed. As a result, when supply of air from the supply pipe 41 of the pump connected to the supply port 117 is started, the compressed air sent from the pump passes through the air passage 116 and the hole 1144 to the radial bearing portion 114. From the outer peripheral surface 1121 of the porous sintered layer 112 that is supplied to each annular groove 1143 in the circumferential direction located on the outer peripheral surface 1142 and passes through the pores in the porous sintered layer 112 and functions as a radial bearing surface Erupts.

なお、ラジアル軸受部114の外周面1142に位置する環状溝1143の本数およびレイアウトは、多孔質焼結層112の外周面1121全域から圧縮空気が均一に噴出するように適宜定めればよい。例えば、ラジアル軸受部114の長さ(多孔質焼結層112の幅)t4等に応じた本数の環状溝1143を、多孔質焼結層112の軸心O方向にほぼ等間隔で配置してもよい。また、ラジアル軸受部114の中央位置(ラジアル軸受部114の一方の端からt4/2だけ内側の位置)からベース部113側およびロッド部115側に離れた位置等、ラジアル軸受隙間60全体の圧力を高く維持可能な位置に環状溝1143を形成してもよい。

Note that the number and layout of the annular grooves 1143 positioned on the outer peripheral surface 1142 of the radial bearing portion 114 may be determined as appropriate so that the compressed air is uniformly ejected from the entire outer peripheral surface 1121 of the porous sintered layer 112. For example, a number of annular grooves 1143 corresponding to the length of the radial bearing portion 114 (width of the porous sintered layer 112) t4 and the like are arranged at substantially equal intervals in the axial center O direction of the porous sintered layer 112. Also good. Further, the pressure of the entire radial bearing gap 60 such as a position away from the center position of the radial bearing portion 114 (a position inside t4 / 2 from one end of the radial bearing portion 114) to the base portion 113 side and the rod portion 115 side. The annular groove 1143 may be formed at a position where the height can be maintained high.

多孔質焼結層112が形成されたラジアル軸受部114は、プーリ2のエアシャフト挿入用穴22内に挿入される。多孔質焼結層112を含めたラジアル軸受部114の外径R1は、プーリ2のエアシャフト挿入用穴22の内径r1(図3参照)よりも所定の寸法だけ小さく設計されている。このため、ラジアル軸受部114がプーリ2のエアシャフト挿入用穴22内に挿入されると、このエアシャフト挿入用穴22の内周面221とラジアル軸受部114の外周面1142に形成された多孔質焼結層112の外周面(ラジアル軸受面)1121との間にラジアル軸受隙間60が形成される(図7参照)。そして、ポンプからエアシャフト11への給気開始後、多孔質焼結層112の外周面(ラジアル軸受面)1121から噴出する圧縮空気により、このラジアル軸受隙間60に高圧の空気膜が形成される。この空気膜の圧力によってラジアル荷重が支えられる。

The radial bearing 114 on which the porous sintered layer 112 is formed is inserted into the air shaft insertion hole 22 of the pulley 2. The outer diameter R1 of the radial bearing 114 including the porous sintered layer 112 is designed to be smaller than the inner diameter r1 (see FIG. 3) of the air shaft insertion hole 22 of the pulley 2 by a predetermined dimension. For this reason, when the radial bearing portion 114 is inserted into the air shaft insertion hole 22 of the pulley 2, the porous holes formed on the inner peripheral surface 221 of the air shaft insertion hole 22 and the outer peripheral surface 1142 of the radial bearing portion 114. A radial bearing gap 60 is formed between the outer peripheral surface (radial bearing surface) 1121 of the quality sintered layer 112 (see FIG. 7). A high-pressure air film is formed in the radial bearing gap 60 by the compressed air ejected from the outer peripheral surface (radial bearing surface) 1121 of the porous sintered layer 112 after the supply of air from the pump to the air shaft 11 is started. . The radial load is supported by the pressure of the air film.

ラジアル軸受部114の長さ(段差面1132、1141間の距離)t4は、プーリ2の両端面25A、25Bのボス24A、24Bの端面241A、241B間の距離(プーリ2の長さ)t3よりも所定の寸法だけ大きく設計されている。このため、ポンプからエアシャフト11への給気開始後、ラジアル軸受部114に挿入されたプーリ2の一方のボス24Aの端面241Aと、ベース部113の他方の端面(ラジアル軸受部114およびベース部113の外径差により形成され、スラスト軸受面として機能する段差面)1132との間には、ラジアル軸受隙間60と繋がるスラスト軸受隙間61aが形成される。同様に、プーリ2の他方のボス24Bの端面241Bと、ラジアル軸受部114の端面(ラジアル軸受部114およびロッド部115の外径差により形成された段差面)1141に接触し、スラスト軸受面として機能する後述のスラストプレート12の一方の端面121との間にも、ラジアル軸受隙間60と繋がるスラスト軸受隙間61bが形成される(図7参照)。なお、自励振動発生防止のため、ラジアル軸受部114の端面1141のエッジ部11411がだれないように仕上げることによって、スラストプレート12の組み付け精度を向上させることが好ましい。

The length (distance between the stepped surfaces 1132 and 1141) t4 of the radial bearing 114 is based on the distance between the end surfaces 241A and 241B of the bosses 24A and 24B of the both ends 25A and 25B of the pulley 2 (length of the pulley 2) t3. Is designed to be larger by a predetermined dimension. For this reason, after the supply of air from the pump to the air shaft 11 is started, the end surface 241A of one boss 24A of the pulley 2 inserted into the radial bearing portion 114 and the other end surface of the base portion 113 (the radial bearing portion 114 and the base portion). A thrust bearing gap 61 a that is connected to the radial bearing gap 60 is formed between the outer diameter difference 113 and the step surface 1132 that functions as a thrust bearing surface. Similarly, it contacts the end surface 241B of the other boss 24B of the pulley 2 and the end surface of the radial bearing portion 114 (stepped surface formed by the difference in the outer diameter of the radial bearing portion 114 and the rod portion 115) 1141 as a thrust bearing surface. A thrust bearing gap 61b connected to the radial bearing gap 60 is also formed between one end surface 121 of a functioning thrust plate 12 described later (see FIG. 7). In order to prevent the occurrence of self-excited vibration, it is preferable to improve the assembling accuracy of the thrust plate 12 by finishing so that the edge portion 11411 of the end surface 1141 of the radial bearing portion 114 does not fall.

ロッド部115は、ラジアル軸受部114の端面1141に連続して形成されており、後述するスラストプレート12のシャフト挿入用穴123内に挿入される。また、このロッド部115の先端には、ナット13と螺合するネジ部1151が形成されている。

The rod portion 115 is formed continuously with the end surface 1141 of the radial bearing portion 114, and is inserted into a shaft insertion hole 123 of the thrust plate 12 described later. Further, a screw portion 1151 that is screwed into the nut 13 is formed at the tip of the rod portion 115.

図6(A)は、スラストプレート12の正面図であり、図6(B)は、図6(A)のC-C断面図である。

6A is a front view of the thrust plate 12, and FIG. 6B is a cross-sectional view taken along the line CC of FIG. 6A.

図示するように、スラストプレート12は、エアシャフト11のベース部113の外径とほぼ同じ外径の円筒形状であり、軸心Oが通過する位置に、一方の端面121から他方の面122に貫通するシャフト挿入用穴123が形成されている。このシャフト挿入用穴123には、エアシャフト11のロッド部115が挿入される。

As shown in the figure, the thrust plate 12 has a cylindrical shape having an outer diameter substantially the same as the outer diameter of the base portion 113 of the air shaft 11, and extends from one end surface 121 to the other surface 122 at a position through which the axis O passes. A penetrating shaft insertion hole 123 is formed. The rod portion 115 of the air shaft 11 is inserted into the shaft insertion hole 123.

さて、上記構成を有するエアシャフトユニット1は、以下のように組み立てられる。

Now, the air shaft unit 1 having the above-described configuration is assembled as follows.

まず、エアシャフトユニット1にプーリ2が組み付けられる。具体的には、多孔質焼結層112が形成されたラジアル軸受部114がプーリ2のエアシャフト挿入用穴22内に位置するように、エアシャフト11をプーリ2のエアシャフト挿入用穴22に挿入し、ついで、ロッド部115がスラストプレート12のシャフト挿入用穴123内に位置するように、プーリ2が挿入されたエアシャフト11をスラストプレート12のシャフト挿入用穴123にさらに挿入する。この状態で、ロッド部115の先端に形成されたネジ部1151にナット13が締結されると、スラストプレート12は、一方の端面121が、ラジアル軸受部114およびロッド部115の外径差により形成される段差面(ラジアル軸受部114の端面)1141に接触した位置で固定される。

First, the pulley 2 is assembled to the air shaft unit 1. Specifically, the air shaft 11 is moved to the air shaft insertion hole 22 of the pulley 2 so that the radial bearing portion 114 on which the porous sintered layer 112 is formed is positioned in the air shaft insertion hole 22 of the pulley 2. Then, the air shaft 11 into which the pulley 2 is inserted is further inserted into the shaft insertion hole 123 of the thrust plate 12 so that the rod portion 115 is positioned in the shaft insertion hole 123 of the thrust plate 12. In this state, when the nut 13 is fastened to the screw portion 1151 formed at the tip of the rod portion 115, one end surface 121 of the thrust plate 12 is formed by the outer diameter difference between the radial bearing portion 114 and the rod portion 115. Is fixed at a position in contact with the stepped surface (end surface of the radial bearing portion 114) 1141.

その後、このようにしてプーリ2が組み付けられたエアシャフトユニット1の軸心Oを台座に対してほぼ平行に向けた状態で、その両端(スラストプレート12、エアシャフト11のベース部113)が、所定の間隔で対向配置された2台のシャフトホルダ3A,3Bに固定される(図2参照)。具体的には、エアシャフト11のベース部113の他方の端面(スラスト軸受面として機能する段差面)1132が一方のシャフトホルダ3Aのシャフト固定穴31から他方のシャフトホルダ3B側に突き出すように、エアシャフト11のベース部113が一方のシャフトホルダ3Aのシャフト固定穴31内に挿入されるとともに、スラストプレート12の一方の端面(スラスト軸受面として機能する端面)121が他方のシャフトホルダ3Bのシャフト固定穴31から一方のシャフトホルダ3A側に突き出すように、スラストプレート12が他方のシャフトホルダ3Bのシャフト固定穴31内に挿入される。この状態で各シャフトホルダ3A,3Bの2本のボルト34の締め付けにより、エアシャフト11のベース部113およびスラストプレート12が各シャフトホルダ3A,3Bのシャフト固定穴31内に固定される。

Thereafter, in a state where the axis O of the air shaft unit 1 to which the pulley 2 is assembled in this way is oriented substantially parallel to the pedestal, both ends thereof (the thrust plate 12 and the base portion 113 of the air shaft 11) are It is fixed to two shaft holders 3A and 3B that are opposed to each other at a predetermined interval (see FIG. 2). Specifically, the other end surface (step surface that functions as a thrust bearing surface) 1132 of the base portion 113 of the air shaft 11 protrudes from the shaft fixing hole 31 of one shaft holder 3A to the other shaft holder 3B side. The base portion 113 of the air shaft 11 is inserted into the shaft fixing hole 31 of one shaft holder 3A, and one end surface (end surface functioning as a thrust bearing surface) 121 of the thrust plate 12 is the shaft of the other shaft holder 3B. The thrust plate 12 is inserted into the shaft fixing hole 31 of the other shaft holder 3B so as to protrude from the fixing hole 31 toward the one shaft holder 3A. In this state, by tightening the two bolts 34 of the shaft holders 3A and 3B, the base portion 113 of the air shaft 11 and the thrust plate 12 are fixed in the shaft fixing holes 31 of the shaft holders 3A and 3B.

上述したように、ラジアル軸受部114の長さt4は、プーリ2の長さt3よりも所定の寸法だけ長いため、プーリ2の一方のボス24Aの端面241Aとベース部113の他方の端面(スラスト軸受面)1132との間にスラスト軸受隙間61aが形成され、プーリ2の他方のボス24Bの端面241Bとスラストプレート12の一方の端面(スラスト軸受面)121との間にスラスト軸受隙間61bが形成される。これらのスラスト軸受隙間61a、61b内には、ラジアル軸受隙間60から排気された圧縮空気が流入し、高圧の空気膜が形成される。この空気膜の圧力によってスラスト荷重が支えられる。

As described above, since the length t4 of the radial bearing portion 114 is longer than the length t3 of the pulley 2 by a predetermined dimension, the end surface 241A of one boss 24A of the pulley 2 and the other end surface of the base portion 113 (thrust) A thrust bearing gap 61 a is formed between the end face 241 B of the other boss 24 B of the pulley 2 and one end face (thrust bearing face) 121 of the thrust plate 12. Is done. Compressed air exhausted from the radial bearing gap 60 flows into the thrust bearing gaps 61a and 61b, and a high-pressure air film is formed. The thrust load is supported by the pressure of the air film.

ここで、ラジアル軸受部114の長さt4は、自励振動を発生しない程度にプーリ2両側のスラスト軸受隙間61a、61bの厚さs1(図7参照)がラジアル軸受隙間60の厚さs2よりも大きくなるように設定されている。ここで、自励振動を発生しない程度の厚さs1のスラスト軸受隙間61a、61bとは、スラスト方向に無負荷状態のプーリ2において発生する程度のわずかな移動により、プーリ2が一方のスラスト軸受面1132、121側に僅かに近づいても、他方のスラスト軸受面121、1132側へ急激に押し戻されない程度に広いスラスト軸受隙間61a、61bのことである。例えば、プーリ2のボス24A、24Bの外径が約22mm、ラジアル軸受隙間60の厚さが約9~10μmの場合、スラスト軸受隙間61a、61bの厚さs1が約22.5~37μmとなるようにラジアル軸受部114の長さt4を設定し、さらに開放流量520NL/hr以下の範囲で給気圧0.5Mpaの圧縮空気の流量調整を行うことによって、自励振動の発生が防止される。

Here, the length t4 of the radial bearing 114 is such that the thickness s1 (see FIG. 7) of the thrust bearing gaps 61a and 61b on both sides of the pulley 2 is larger than the thickness s2 of the radial bearing gap 60 to the extent that no self-excited vibration is generated. Is also set to be large. Here, the thrust bearing gaps 61a and 61b having a thickness s1 that does not generate self-excited vibration are a slight movement that occurs in the pulley 2 in a no-load state in the thrust direction, so that the pulley 2 is one thrust bearing. The thrust bearing gaps 61a and 61b are wide enough that they do not suddenly push back toward the other thrust bearing surface 121 or 1322, even if they are slightly closer to the surfaces 1132 and 121. For example, when the outer diameters of the bosses 24A and 24B of the pulley 2 are about 22 mm and the radial bearing gap 60 is about 9 to 10 μm, the thickness s1 of the thrust bearing gaps 61a and 61b is about 22.5 to 37 μm. Thus, by setting the length t4 of the radial bearing 114 and adjusting the flow rate of the compressed air with a supply air pressure of 0.5 Mpa within the range of the open flow rate of 520 NL / hr or less, generation of self-excited vibration is prevented.

つぎに、エアシャフト11への給気中におけるプーリ2の支持状態について説明する。

Next, the support state of the pulley 2 during the supply of air to the air shaft 11 will be described.

図7は、エアシャフト11への給気中におけるプーリ2の支持状態を模式的に示した図である。

FIG. 7 is a diagram schematically showing the support state of the pulley 2 during the supply of air to the air shaft 11.

図示するように、プーリ2を組み付けた状態(図2の状態)のエアベアリングユニット4において、ポンプの給気管(不図示)をエアシャフト11の給気口117に連結し、ポンプからの圧縮空気fの供給を開始すると、この圧縮空気fは、エアシャフト11の通気路116および孔1144を介して、ラジアル軸受部114の外周面1142に位置する各環状溝1143に供給され、多孔質焼結層112の外周面(ラジアル軸受面)1121からラジアル軸受隙間60内に噴出する。このため、ラジアル軸受隙間60内に高圧の空気膜が形成され、その圧力によってラジアル荷重が支えられる。これにより、プーリ2のラジアル方向への移動が拘束される。

As shown in the drawing, in the air bearing unit 4 with the pulley 2 assembled (the state shown in FIG. 2), a pump air supply pipe (not shown) is connected to the air supply port 117 of the air shaft 11 and compressed air from the pump is connected. When the supply of f is started, this compressed air f is supplied to each annular groove 1143 located on the outer peripheral surface 1142 of the radial bearing portion 114 via the air passage 116 and the hole 1144 of the air shaft 11, and porous sintering is performed. It is ejected from the outer peripheral surface (radial bearing surface) 1121 of the layer 112 into the radial bearing gap 60. For this reason, a high-pressure air film is formed in the radial bearing gap 60, and the radial load is supported by the pressure. Thereby, the movement to the radial direction of the pulley 2 is restrained.

さらに、ラジアル軸受隙間60内の圧縮空気fは、多孔質焼結層112の外周面(ラジアル軸受面)1121に沿って、スラストプレート12の一方の端面(スラスト軸受面)121側およびベース部113の他方の端面(スラスト軸受面)1132側に向かって流れてゆき、プーリ2の一方のボス24Aの端面241Aとベース部113のスラスト軸受面1132との間のスラスト軸受隙間61a、および、プーリ2の他方のボス24Bの端面241Bとスラストプレート12の一方の端面(スラスト軸受面)121との間のスラスト軸受隙間61bに流入する。

Further, the compressed air f in the radial bearing gap 60 extends along the outer peripheral surface (radial bearing surface) 1121 of the porous sintered layer 112 on the one end surface (thrust bearing surface) 121 side of the thrust plate 12 and the base portion 113. The thrust bearing gap 61a between the end surface 241A of one boss 24A of the pulley 2 and the thrust bearing surface 1132 of the base portion 113 and the pulley 2 flows toward the other end surface (thrust bearing surface) 1132 side of the pulley 2. Flows into the thrust bearing gap 61b between the end surface 241B of the other boss 24B and the one end surface (thrust bearing surface) 121 of the thrust plate 12.

スラスト軸受隙間61a、61bに流入した圧縮空気f1は、各ボス24A、24Bの外周に向かって放射状に流れてゆき、最終的に外部(大気圧)に放出される。各スラスト軸受隙間61a、61b内の圧力は、ラジアル軸受隙間60から排気された圧縮気体f1が流入するプーリ2の内周側において高くなっており、ボス24A、24Bの外周に向かうにしたがって徐々に減少する。このため、スラスト軸受隙間61a、61b内には平均圧力の高い空気膜が形成されていることとなり、その圧力によってスラスト荷重が支えられる。これにより、スラスト方向へのプーリ2の移動が拘束される。