WO2012120864A1 - Disposable diaper - Google Patents

Disposable diaper Download PDFInfo

- Publication number

- WO2012120864A1 WO2012120864A1 PCT/JP2012/001475 JP2012001475W WO2012120864A1 WO 2012120864 A1 WO2012120864 A1 WO 2012120864A1 JP 2012001475 W JP2012001475 W JP 2012001475W WO 2012120864 A1 WO2012120864 A1 WO 2012120864A1

- Authority

- WO

- WIPO (PCT)

- Prior art keywords

- depressions

- core assembly

- disposable diaper

- fluid

- region

- Prior art date

Links

Images

Classifications

-

- A—HUMAN NECESSITIES

- A61—MEDICAL OR VETERINARY SCIENCE; HYGIENE

- A61F—FILTERS IMPLANTABLE INTO BLOOD VESSELS; PROSTHESES; DEVICES PROVIDING PATENCY TO, OR PREVENTING COLLAPSING OF, TUBULAR STRUCTURES OF THE BODY, e.g. STENTS; ORTHOPAEDIC, NURSING OR CONTRACEPTIVE DEVICES; FOMENTATION; TREATMENT OR PROTECTION OF EYES OR EARS; BANDAGES, DRESSINGS OR ABSORBENT PADS; FIRST-AID KITS

- A61F13/00—Bandages or dressings; Absorbent pads

- A61F13/15—Absorbent pads, e.g. sanitary towels, swabs or tampons for external or internal application to the body; Supporting or fastening means therefor; Tampon applicators

- A61F13/53—Absorbent pads, e.g. sanitary towels, swabs or tampons for external or internal application to the body; Supporting or fastening means therefor; Tampon applicators characterised by the absorbing medium

- A61F13/531—Absorbent pads, e.g. sanitary towels, swabs or tampons for external or internal application to the body; Supporting or fastening means therefor; Tampon applicators characterised by the absorbing medium having a homogeneous composition through the thickness of the pad

- A61F13/532—Absorbent pads, e.g. sanitary towels, swabs or tampons for external or internal application to the body; Supporting or fastening means therefor; Tampon applicators characterised by the absorbing medium having a homogeneous composition through the thickness of the pad inhomogeneous in the plane of the pad

- A61F13/533—Absorbent pads, e.g. sanitary towels, swabs or tampons for external or internal application to the body; Supporting or fastening means therefor; Tampon applicators characterised by the absorbing medium having a homogeneous composition through the thickness of the pad inhomogeneous in the plane of the pad having discontinuous areas of compression

-

- A—HUMAN NECESSITIES

- A61—MEDICAL OR VETERINARY SCIENCE; HYGIENE

- A61F—FILTERS IMPLANTABLE INTO BLOOD VESSELS; PROSTHESES; DEVICES PROVIDING PATENCY TO, OR PREVENTING COLLAPSING OF, TUBULAR STRUCTURES OF THE BODY, e.g. STENTS; ORTHOPAEDIC, NURSING OR CONTRACEPTIVE DEVICES; FOMENTATION; TREATMENT OR PROTECTION OF EYES OR EARS; BANDAGES, DRESSINGS OR ABSORBENT PADS; FIRST-AID KITS

- A61F13/00—Bandages or dressings; Absorbent pads

- A61F13/15—Absorbent pads, e.g. sanitary towels, swabs or tampons for external or internal application to the body; Supporting or fastening means therefor; Tampon applicators

- A61F13/53—Absorbent pads, e.g. sanitary towels, swabs or tampons for external or internal application to the body; Supporting or fastening means therefor; Tampon applicators characterised by the absorbing medium

- A61F13/534—Absorbent pads, e.g. sanitary towels, swabs or tampons for external or internal application to the body; Supporting or fastening means therefor; Tampon applicators characterised by the absorbing medium having an inhomogeneous composition through the thickness of the pad

- A61F13/537—Absorbent pads, e.g. sanitary towels, swabs or tampons for external or internal application to the body; Supporting or fastening means therefor; Tampon applicators characterised by the absorbing medium having an inhomogeneous composition through the thickness of the pad characterised by a layer facilitating or inhibiting flow in one direction or plane, e.g. a wicking layer

Definitions

- This disclosure relates to various types of disposable diapers.

- Disposable diapers are known to have a fluid-absorbent structure containing a mixture of fluff wood pulp fibers and superabsorbent polymer particles.

- an absorbent structure of the disposable diaper disclosed in JP 2002-315783 A contains a mixture of superabsorbent polymer particles and fluff wood pulp fibers in which the superabsorbent polymer particles have a liquid absorption ratio of 40 g/g or higher and a liquid absorption rate of 20 seconds or less, as measured by the Vortex method.

- JP H6-503983 A (PTL 2) teaches, concerning an absorbent structure used for a disposable diaper or the like, that an absorbent structure ideally should be able to absorb bodily fluids as soon as such excretion occurs.

- the absorbent structure disclosed therein uses an absorber gelling agent which can absorb artificial urine at least about 40% of its absorption capacity as quickly as within 10 seconds or less when the absorber gelling agent is tested under the Teabag Test.

- absorbent article described in JP 2009-61063 A is a disposable diaper and an absorbent structure in this absorbent article contains superabsorbent polymer particles assuring high liquid permeation rate, liquid absorption capacity and water absorption rate.

- diapers each having a fluid-absorbent structure containing superabsorbent polymer particles as a part of the core assembly are apt to be rapidly swollen to unacceptable bulk upon water absorption.

- the fluid-absorbent structure swollen to such a state may come into exceedingly tight contact with the wearer's skin or may close a gap between the fluid-absorbent structure and the wearer's skin and thereby create a feeling of discomfort against the wearer.

- the crotch region may abnormally bulge and make the external appearance visually out.

- a mother having visually recognized the abnormally swollen portion may misjudge that the diaper should be exchanged with a fresh one even if the fluid-absorbent structure still has available capacity to absorb bodily fluids.

- a disposable diaper having a longitudinal direction and a transverse direction, including: a front waist region, a rear waist region, and a crotch region located between the front and rear waist regions; and a fluid-absorbent structure formed at least in the crotch region and comprising: a core assembly formed from a mixture of fluid-absorbent materials containing fluff pulp fibers and superabsorbent polymer particles and wrapped with a wrapping sheet, and a liquid-pervious bodyside liner at least partially covering the core assembly.

- the core assembly is formed with a plurality of depressions depressed in a thickness direction of the core assembly and, in the depressions, the mixture and the wrapping sheet are bonded together with hot melt adhesive; in the depressions, the core assembly has a thickness corresponding to 80% or less of the thickness of the core assembly in a non-depressed region defined outside and between the adjacent depressions; a center-to-center distance between each one of the depressions and the depression closest to the one depression is in a range of about 2 to about 14 mm; and the superabsorbent polymer particles have a non-pressurized water absorption rate of 45 ml/g or less measured at 5 minutes after the initiation of the non-pressurized water absorption test and a water absorption rate under load of 14 g/g or less.

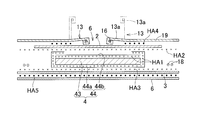

- Fig. 1 is a partially cutaway plan view of a disposable diaper.

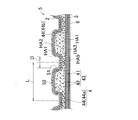

- Fig. 2 is a sectional view of the diaper of Fig. 1 taken along line II-II in Fig. 1.

- Fig. 3 is a scale-enlarged diagram illustrating an encircled region III in Fig. 1.

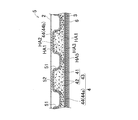

- Fig. 4 is a sectional view of the diaper of Fig. 1 taken along line IV-IV in Fig. 3.

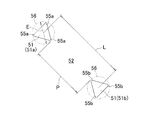

- Fig. 5 is a diagram similar to Fig. 3, exemplarily illustrating one embodiment.

- Fig. 6 is a view similar to Fig. 1, exemplarily illustrating another embodiment.

- Fig. 7 is a view similar to Fig. 4, exemplarily illustrating still another embodiment.

- Fig. 8 is a diagram exemplarily illustrating a distribution of depressions in accordance with yet another embodiment.

- a diaper 1 includes a liquid-pervious bodyside liner 2, a liquid-impervious backsheet 3 and a fluid-absorbent core assembly 4 interposed between these elements 2, 3.

- the core assembly 4, the segment of the bodyside liner 2 covering the upper surface of the core assembly 4 and the segment of the backsheet 3 covering the lower surface of the core assembly 4 cooperatively define a fluid-absorbent structure 5.

- the fluid-absorbent structure 5 extends across a crotch region 7 into a front waist region 8 and a rear waist region 9.

- an outer sheet 6 is laminated on an outer surface of the backsheet 3 (See Fig. 2).

- the diaper 1 has a longitudinal direction A and a transverse direction B wherein the crotch region 7 is defined in a midsection in the longitudinal direction A, the front waist region 8 is defined in front of the crotch region 7 and the rear waist region 9 is defined behind the crotch region 7.

- a plurality of front waist elastic members 11 extending in the transverse direction B and a plurality of rear waist elastic members 12 extending in the transverse direction B are interposed between the bodyside liner 2 and the backsheet 3, secured under tension between these elements 2,3.

- the diaper 1 is provided on both sides thereof in the transverse direction B with containment sheets 13 extending in the longitudinal direction A. Inner side edges 13a of the respective containment sheets 13 are formed with sleeves 14 within which elastic members 16 are secured under tension in the longitudinal direction A.

- the diaper 1 is further provided along opposite side edges 17 thereof with one or more leg elastic members 18 extending under tension in the longitudinal direction A secured between the backsheet 3 and outer side edges 19 of the respective containment sheets 13 with hot melt adhesive (not shown).

- the rear waist region 9 is provided on opposite side edges thereof with tape fasteners 21, respectively.

- the fasteners 21 respectively include fastening zones 22 adapted to be detachably fastened to a target zone (not shown) provided on the outer surface of the front waist region 8 when the diaper 1 is put on the wearer's body.

- the diaper 1 configured in this manner is symmetrically about a center line CL bisecting a dimension of the diaper 1 in the transverse direction B.

- a plurality of dots 23 illustrated on the bodyside liner 2 of the diaper 1 indicate a range in which depressions 51 to be described later are distributed.

- the core assembly 4 is interposed between the bodyside liner 2 and the backsheet 3.

- the core assembly 4 includes a mixture 43 of fluid-absorbent materials including at least fluff wood pulp fibers 41 and superabsorbent polymer particles 42 (See for example Fig. 4) and tissue paper 44 wrapping the mixture 43.

- the tissue paper 44 includes for example tissue paper 44a and tissue paper 44b.

- the mixture 43 and the tissue paper 44 may be bonded to each other with hot melt adhesive HA1.

- the core assembly 4 is bonded to the bodyside liner 2 with hot melt adhesive HA2 and bonded to the backsheet 3 with hot melt adhesive HA3.

- the core assembly 4 cooperates with the bodyside liner 2 and the backsheet 3 to form the fluid-absorbent structure 5 with a plurality of depressions (See for example Fig. 4).

- the bodyside liner 2 and the backsheet 3 may extend outward beyond a periphery of the core assembly 4 and these extensions have their inner surface bonded together with the hot melt adhesives HA2, HA3.

- the outer side edges 19 of the respective containment sheets 13 are bonded to the bodyside liner 2 with hot melt adhesive HA4.

- the inner side edges 13a of the respective containment sheets 13 are bonded at respective opposite ends thereof in the longitudinal direction A to the bodyside liner 2 in the front waist region 8 and the rear waist region 9 with hot melt adhesive (not shown), but these inner side edges 13a are not bonded to the bodyside liner 2 in the crotch region 7. With such an arrangement, when the diaper 1 is put on the wearer's body and the elastic members 16 contract, the inner side edges 13a raise themselves from the bodyside liner 2 as indicated by the imaginary lines in Fig. 2.

- the outer sheet 6 may be laminated on the outer surface of the backsheet 3 with hot melt adhesive HA5.

- the length of the fluid-absorbent structure 5 in the longitudinal direction A may be appropriately shortened.

- a nonwoven fabric may be used for the bodyside liner 2.

- the non-woven fabric may be made from thermoplastic synthetic fibers, for example, an air-through nonwoven fabric, a spun-bonded nonwoven fabric, and an SMS nonwoven fabric composed of a spun-bonded nonwoven fabric, a meltblown nonwoven fabric and a spun-bonded nonwoven fabric.

- an air-through nonwoven fabric conjugate fibers of polyethylene and polypropylene having fiber fineness in a range of about 1 to about 4dtex may be used at a basis mass in a range of about 10 to about 35 g/m 2 .

- a film made of thermoplastic synthetic resin for example, a polyethylene film having a thickness dimension in a range of about 5 to about 20 micrometers may be used.

- the outer sheet 6 is used for the purpose of preventing the outer surface of the diaper 1 from being plastic-like and making it cloth-like.

- a nonwoven fabric made from thermoplastic synthetic fibers having fiber fineness in a range of about 1 to about 4dtex and a basis mass in a range of about 10 to about 20 g/m 2 may be used for the outer sheet 6.

- Fluff wood pulp fibers 41 and superabsorbent polymer particles 42 (See Fig. 4) composing the mixture 43 in the core assembly 4 respectively preferably have a basis mass in a range of about 100 to about 350 g/m 2 and are used so that the mixture 43 may have total basis mass preferably in a range of about 300 to about 600 g/m 2 .

- tissue paper 44 wrapping the mixture 43 those commonly used or to be developed in the relevant technical field may be selectively used and, for example, the tissue paper having a basis mass in a range of about 15 to about 20 g/m 2 may be used.

- the containment sheets 13 may include a nonwoven fabric and, more preferably, a nonwoven fabric previously water-repellently processed to be substantially liquid-impervious when the diaper 1 is actually used.

- the fluid-absorbent structure 5 includes a plurality of depressions 51 depressed from the bodyside liner 2 in the thickness direction of the core assembly 4 and a non-depressed region 52 defined outside and between the adjacent depressions 51.

- each of the depressions 51 exemplarily illustrates the depressions 51 each having a circular bottom and a diameter D in a range of about 1.5 to about 5 mm.

- each of the depressions preferably has a planar shape inscribed within a circle 56 having a diameter E (See Fig. 5), preferably in a range of about 1.5 to about 5 mm.

- a "diameter" of a depression is the diameter of a circle inscribing the planar shape at the bottom of the depression.

- the diameter of the depression is the same as the diameter D of the circular planar shape.

- a "center-to-center distance" between two depressions is a distance between the centers of the circles respectively inscribing the planar shapes at the bottoms of the depressions.

- the planar shape as inscribed in the circle 56 preferably has at least three points. While a distribution pattern of the depressions 51 in the fluid-absorbent structure 5 is also not specified in particular, among center-to-center distances L between one of the depressions 51 and the adjacent two or more depressions 51, the minimum center-to-center distance L is preferably in a range of about 2 to about 14 mm.

- the center-to-center distance L between one of the depressions 51 and the depression closest to this one depression 51 is preferably in a range of about 2 to about 14 mm.

- the fluid-absorbent structure 5 may become excessively stiff to be smoothly deformed. While the depressions 51 are exemplarily illustrated to be uniformly distributed on the bodyside liner 2, the depressions 51 may be distributed irregularly.

- the fluid-absorbent structure 5 includes the core assembly 4, the bodyside liner 2 covering the upper surface side of the core assembly 4, the backsheet 3 covering the lower surface side of the core assembly 4.

- the depressions 51 are formed together with the bodyside liner 2.

- the core assembly 4 includes the mixture 43 of fluid-absorbent materials at least containing fluff wood pulp fibers 41 and superabsorbent polymer particles 42 and the liquid-pervious tissue paper 44 serving as the wrapping sheet.

- the fluid-absorbent structure 5 includes, in addition, the hot melt adhesive layers HA1, HA2, HA3 and HA5 used to bond these members one to another.

- Cross-sectional shapes of the core assembly 4 and the fluid-absorbent structure 5 illustrated in Fig. 4 may be visually confirmed by cutting the fluid absorbent structure 5 frozen with liquid nitrogen using a sharp cutting tool to obtain a cross section and by optically magnifying this in the order of 30 times.

- the quantity of the fluff wood pulp fibers 41 and the quantity of the superabsorbent polymer particles 42 per 1 cm 2 of the surface area of the fluid-absorbent structure 5 is substantially constant in any region of the fluid-absorbent structure 5.

- the quantity of the fluff wood pulp fibers 41 as well as the quantity of the superabsorbent polymer particles 42 per 1 cm 2 of the flat backsheet 3 illustrated in Fig. 4 are substantially constant.

- the core assembly 4 is depressed in the depressions 51 and, in consequence, the fluff wood pulp fibers 41 and the superabsorbent polymer particles 42 come closer to each other, and gather together to adhere tightly onto one another. This is true for the fluff wood pulp fibers 41 themselves and for the superabsorbent polymer particles 42 themselves. In this way, the superabsorbent polymer particles 42 are in a state in which formation of a gel block is possible.

- the core assembly 4 is not depressed at all or is not depressed as significantly as in the depressions 51, and therefore the fluff wood pulp fibers 41 and the superabsorbent polymer particles 42 are sufficiently dispersed to be discrete from each other.

- the bonding of the mixture 43 to the tissue paper 44 with the hot melt adhesive HA1 is configured to retain the shapes of the depressions 51 regardless of whether the diaper 1 is actually put on the wearer's body or not.

- the fluid-absorbent structure 5 in the state as illustrated in Figs. 3 and 4 may be obtained by debossing a fluid-absorbent structure having the same composition as that of the fluid-absorbent structure 5 and a uniform thickness dimension equal to or larger than the thickness dimension of non-depressed region 52.

- a roller having debossing bosses corresponding to the depressions 51 may be used so that these bosses at a room temperature or under heating may compress the fluid-absorbent structure.

- Thickness dimension values of the depressions 51 and the non-depressed region 52 in the fluid-absorbent structure 5 including the core assembly 4, the bodyside liner 2, the backsheet 3 and the outer sheet 6 were measured using a High-Accuracy 2D Laser Displacement Gauge manufactured by Keyence Corporation to be described later.

- ten (10) of the depressions 51 were selected from an area of 100 cm 2 and the thickness dimension values of the respective depressions 51 were measured by irradiating the bottoms of the respective depressions 51 with laser beams and the average value was calculated from the respective measured values.

- ten (10) zones having relatively large thickness dimensions were selected from an area of 100 cm 2 and the respective zones were irradiated with laser beams in order to measure the respective thickness dimension values, from which an average was calculated.

- the fluff wood pulp fibers 41 are tangled together and the superabsorbent polymer particles 42 are close to one another under the effect of depression. Consequentially, bulging of the fluff wood pulp fibers 41 is restricted and swelling of the superabsorbent polymer particles 42 due to the formation of gel block can be also restricted even upon discharge and absorption of bodily fluid. As a result, thickening of the fluid-absorbent structure 5 in the depressions 51 and peripheries thereof can be restricted.

- Thickening of the fluid-absorbent structure 5 in the non-depressed region 52 can be also restricted while it is not as significant as in the depressions 51, because movements of both sides of the non-depressed region 52 as viewed in Fig. 4 is kept under restraint by the respective depressions 51.

- the exemplarily illustrated fluid-absorbent structure 5 helps prevent the fluid-absorbent structure 5 from being unacceptably thickened in the crotch region 7 of the diaper 1.

- the fluid-absorbent structure 5 is unlikely to be excessively thickened such that it comes into close contact with the wearer's skin or unacceptably narrows the space between the structure 5 and the wearer's skin. In this way, the diaper is unlikely to create a feeling of discomfort against the wearer because of wetness. As another advantageous consequence, it is possible to prevent the fluid-absorbent structure 5 from being excessively thickened and abnormally bulge when such thickened fluid-absorbent structure 5 is squeezed between the wearer's legs.

- the superabsorbent polymer particles 42 In order to reliably achieve such effects, it is also desirable to specify the water absorption effect of the superabsorbent polymer particles 42.

- the superabsorbent polymer particles 42 to be used preferably exhibit a non-pressurized water absorption rate of 45 ml/g or less and a water absorption rate under load of 14g/g or less.

- the non-pressurized water absorption rate was measured using Demand Wettability Tester manufactured by Scientific Machine & Supply Co., Ltd. This tester is designed to use a 0.9% aqueous solution of NaCl as physiological saline and a 250 mesh nylon net (N-No. 250HD manufactured by NBC Industries). The quantity of superabsorbent polymer particles used for measurement was 1g.

- the non-pressurized water absorption rate means an absorption quantity measured at 5 minutes after the initiation of the non-pressurized water absorption test.

- a circular cylinder made of a plastic material having an inner diameter of 26 mm and a bottom formed of a 250 mesh nylon net were used.

- the superabsorbent polymer particles having a mass S was poured into this circular cylinder and a piston loaded thereon with a predetermined weight was set in the circular cylinder.

- the mass W1 of this assembly as a whole was then determined.

- the assembly including the circular cylinder was set up on a laboratory dish containing therein 25g of physiological saline and left at rest for 60 minutes.

- the mass W2 of the assembly including the circular cylinder when taken out from the laboratory dish was determined and the water absorption rate under load was calculated according to the following formula.

- the bodyside liner 2 may be replaced by a sheet member such as a nonwoven fabric which is liquid-pervious and, at the same time, has a high capability of dispersing fluids in the longitudinal direction of the diaper 1; or such a nonwoven fabric may be bonded to the entirety or a portion of the bodyside liner 2.

- a sheet member suitable to be used for such use is a nonwoven fabric in which more than half of component fibers are oriented in the longitudinal direction A of the diaper 1.

- the sheet member such as a nonwoven fabric having a high capability of dispersing fluids to disperse a portion of fluids discharged onto the crotch region in the longitudinal direction A is advantageous, to prevent leakage of fluids and to restrict a feeling of wetness.

- Fig. 5 illustrating one embodiment of this invention illustrates the depressions 51 in a larger scale than in Fig. 3 for convenience of the illustration.

- a bottom surface has a planar shape approximating an equilateral triangle having three angle portions (corners) 55a which are respectively inscribed in a circle 56.

- the diameter E of the circle 56 is in a range of about 1.5 to about 5mm for example.

- one of the three angle portions 55b in the depression 51b faces one of the three angle portions 55a in the depression 51a.

- the non-depressed region 52 is defined.

- a dimension P of the non-depressed region 52 extending between these two depressions 51a, 51b is relatively short in comparison to the case in which the angle portions 55a, 55b do not face each other between these two depressions 51a, 51b.

- change of the thickness due to absorption of bodily fluids is restricted to be relatively small in comparison to the case in which the dimension P is relatively large.

- the distribution density of the depressions 51 formed in the fluid-absorbent structure 5 over the bodyside liner 2 in other words, the number of the depressions 51 formed per 1 cm 2 of the bodyside liner 2 varies in the longitudinal direction A.

- the number of dots 23 plotted on the bodyside liner 2 in Fig. 6 per 1 cm 2 of the bodyside liner 2 is largest in a first zone 61 defined by a midsection of the crotch region 7 as viewed in the longitudinal direction A and gradually or step-wise reduced in second and third zones 62, 63 defined in this order toward the front waist region 8 and/or in fourth and fifth zones 64, 65 defined in this order toward the rear waist region 9.

- the number of the dots per 1 cm 2 represents the number of the depressions 51 and the number of the depressions 51 per 1 cm 2 is gradually or step-wise reduced from the midsection of the crotch region 7 toward the front waist region 8 and the rear waist region 9.

- any increase in the thickness of the fluid-absorbent structure 5 due to absorption of fluids can be restricted in the midsection of the crotch region 7 as viewed in the longitudinal direction A and fluids can be quickly absorbed in the second through fifth zones in which the fluid absorption rate is insignificantly (or less significantly) affected by the presence of the depressions 51 to prevent fluid from staying in the midsection of the crotch region.

- the diaper 1 is possible to form the diaper 1 with the first, second and third zones 61, 62, 63 only and without the fourth and fifth zones 64, 65. It is also possible to form the diaper 1 with the first, fourth and fifth zones 61, 64, 65 only and without the second and third zones 62, 63.

- depressions 51 are formed on the core assembly 4 and no portion of the bodyside liner 2 is included in any of the depressions 51.

- the mixture 43 and the tissue paper 44b are compressed in a direction extending from the bodyside liner 2 toward the backsheet 3, i.e., in the thickness direction of the core assembly 4, and thereby the core assembly 4 is formed with the depressions 51.

- the bodyside liner 2 extends flatly and is bonded to the non-depressed region 52 of the core assembly 4 with hot melt adhesive HA2.

- a relatively bulky nonwoven fabric having a soft texture is used as the bodyside liner 2 and such bodyside liner 2 is formed with the depressions 51, the intrinsic texture of the bodyside liner 2 might be deteriorated.

- the fluid-absorbent structure 5 according to the embodiment illustrated in Fig. 7.

- Concerning the tissue paper 44b a practically non-extensile tissue paper 44b is used in this embodiment so that the non-depressed region 52 defined between each pair of the adjacent depressions 51, 51 may come in contact with the mixture 43 in the course of forming the depressions 51 more closely than when a relatively extensile tissue paper is used.

- the non-depressed region 52 is unlikely to have its thickness increasing due to the absorption of fluids, and it is assured that the non-depressed region 52 may be well resistant to swelling even when absorption of the fluids occurs.

- the bodyside liner 2 is partially kept spaced apart from the tissue paper 44b and it is easy to prevent the color of urine on the core assembly 4 from being seen through the bodyside liner 2.

- the term "thickness of the depressions 51 and thickness of the non-depressed region 52" used with respect to the core assembly 4 in the embodiment illustrated in Fig. 7 refers the thickness values obtained from measurement made on the core assembly 4 not containing the bodyside liner 2, the backsheet 3 and the outer sheet 6.

- the core assembly 4 to be measured can be obtained by picking the core assembly 4 before the bodyside liner 2 and the backsheet 3 are bonded thereto in the process of making the fluid-absorbent structure 5.

- Fig. 8 is a diagram exemplarily illustrating a distribution pattern of the depressions 51 on the core assembly 4 having been used to observe a change in the thickness of the core assembly 4 as a result of water absorption.

- the core assembly 4 was obtained by wrapping a homogeneous mixture 43 (See Fig. 7) including (i) fluff wood pulp fibers having a basis mass of 220 g/m 2 and (ii) any one of several types of superabsorbent polymer particles having a basis mass of 220 g/m 2 with tissue paper having a basis mass of 17 g/m 2 to have a rectangular cross-sectional shape having a length dimension of 410 mm and a width dimension of 145 mm as illustrated in Fig. 7.

- the diagram illustrates the tissue paper 44b for the core assembly 4 and the depressions 51 formed in the tissue paper 44b.

- Each of the depressions 51 in Fig. 8 has a generally equilateral triangular planar shape of which a length Q of each side is 3 mm.

- the depressions 51 lie at respective angle portions (corners) of a regular hexagon indicated by an imaginary line wherein, between each pair of the adjacent depressions 51, the associated corners face each other at a distance P.

- the thickness of the core assembly 4 in the respective depressions 51 and the thickness of the core assembly 4 in the non-depression 52 are indicated in TABLE 2.

- a change in the thickness of the core assembly 4 when the core assembly 4 absorbed artificial urine replacing water was also observed and the result of this observation is indicated in TABLE 2.

- the water absorption ratios and water retention ratio in TABLE 1 were measured in accordance with JIS (Japanese Industrial Standards) K 7223. Specifically, 1.0 g of superabsorbent polymer particles was put into a mesh bag and was immersed into physiological saline for 1 hour. Then the mesh bag was pulled out from the physiological saline and suspended for 15 minutes to drain off the physiological saline. In this state, the quantity of physiological saline absorbed by superabsorbent polymer particles was measured in order to obtain a water absorption ratio. After draining off the physiological saline, the mesh bag was dewatered by a centrifugal machine and the mass of the mesh bag was measured to obtain a water retention ratio.

- JIS Japanese Industrial Standards

- aqueous solution of 200 g of urea, 80 g of sodium chloride, 80 g of magnesium sulfate, 80 g of calcium chloride and about 1 g of pigment (Blue No. 1) dissolved in 10 liters of ion-exchanged water was used as artificial urine.

- the artificial urine was colored in blue.

- 120 ml of the artificial urine was infused three times, 40 ml at a time, and with a 5 minute interval between successive infusions, into the midsection of the core assembly 4 as viewed in the longitudinal direction A as well as in the transverse direction B and left to be absorbed by the core assembly 4.

- a burette was used for infusing the artificial urine.

- the core assembly 4 to be infused with the artificial urine was placed on polyethylene film laid on a flat table.

- center-to-center distances listed in TABLE 2 indicates the center-to-center distances of pins on the peripheral surface of the debossing rolls (not illustrated) used to form the depressions and it was confirmed that these center-to-center distances substantially correspond to the center-to-center distances of the depressions formed on the core assembly.

- Thickness values of the depressions and the non-depressed regions listed in the column "Thickness of core assembly” are values which were obtained by noncontact measurement using a High-Accuracy 2D Laser Displacement Gauge LJ-G030 manufactured by Keyence Corporation conducted on the core assembly laid on a horizontal table before the core assembly is infused with artificial urine.

- Thickness values before infusion of artificial urine and after infusion of artificial urine are listed in the column "Change in thickness of non-depressed region" and are values which were obtained by contact measurement using a dial thickness gauge having a diameter of 50 mm. Specifically, a probe of the dial thickness gauge was put into contact, from above, with the core assembly 4 placed on a horizontal plane and the gauge was read under a measuring load of 6.5 g/cm 2 . The thickness values after infusion of artificial urine was measured five minutes after each infusion.

- the core assemblies 4 in which the thickness change after the third infusion of artificial urine is acceptably small are limited to the cases in which a thickness increment ((T - T 0 )/T 0 ) of the non-depressed region is 2.2 or less.

- the superabsorbent polymer particles being able to assure this increment is limited to SAP-A.

- the evaluated values in TABLE 1 indicate that the non-pressurized water absorption rate for SAP-A is preferably 45 ml/g or less, more preferably 40 ml/g or less measured at 5 minutes after the initiation of the non-pressurized water-absorption test, and the water absorption rate under load for SAP-A is preferably 14 g/g or less, more preferably 12 g/g or less.

- the thickness of the depressions measured by the noncontact method is preferably 80% or less of the thickness of the non-depressed region and the center-to-center distance L of the depressions is preferably in a range of about 2 to about 14 mm.

- the surface of the core assembly 4 facing the backsheet 3 with the depressions 51 wherein the depressions 51 may entrain the backsheet 3 or not.

- the disposable diaper exemplarily illustrated in the form of the open-type diaper 1 may be implemented in the form of pants-type diapers.

- a disposable diaper having a longitudinal direction and a transverse direction, including: a front waist region, a rear waist region, and a crotch region located between the front and rear waist regions; and a fluid-absorbent structure formed at least in the crotch region and comprising: a core assembly formed from a mixture of fluid-absorbent materials containing fluff pulp fibers and superabsorbent polymer particles and wrapped with a wrapping sheet, and a liquid-pervious bodyside liner at least partially covering an upper surface of the core assembly, wherein: a plurality of depressions depressed in a thickness direction of the core assembly are at least formed on the core assembly and, in the depressions, the mixture and the wrapping sheet are bonded together with hot melt adhesive; in the depressions, the core assembly has a thickness corresponding to 80% or less of the thickness of the core assembly in a non-depressed region defined outside and between the adjacent depressions; a

- the aspect(s) described in the above item (i) may provide one or more of the following advantageous effects: (a) A core assembly including fluff wood pulp fibers and superabsorbent polymer particles is formed with a plurality of depressions. With this treatment, it is possible to restrict a bulk and a thickness of the core assembly from increasing as fluff wood pulp fibers cooperates with superabsorbent polymer particles to absorb bodily fluids.

- the diaper including such improved fluid-absorbent structure can overcome or alleviate various problems, for example, the problem that the fluid-absorbent structure is partially swollen to an abnormal size and shape and/or the problem that the fluid-absorbent structure is put in exceedingly tight contact with the wearer's skin and create a feeling of discomfort against the wearer because of wetness.

- the aspect(s) described in the above item (i) may include at least the following embodiments: (ii) The depressions are formed facing the bodyside liner. (iii) The disposable diaper further includes a liquid-impervious backsheet at least partially covering a lower surface of the core assembly, wherein the depressions are formed facing the backsheet. (iv) The depressions are formed on the core assembly and the bodyside liner. (v) The bodyside liner is not included in the depressions. (vi) The backsheet is not included in the depressions. (vii) The fluid-absorbent structure extends across the crotch region into at least one of the front waist region and the rear waist region and the depressions are formed only in the crotch region.

- the fluid-absorbent structure extends across the crotch region into at least one of the front waist region and the rear waist region, and the depressions are formed also in a section of the fluid-absorbent structure extending into the at least one of the front waist region and the rear waist region.

- the number of the depressions formed in 1 cm 2 of the surface of the core assembly is decreased from a midsection of the crotch region toward at least one of the front waist region and the rear waist region.

- the number of the depressions formed in 1 cm 2 of the surface of the core assembly is consistent.

- the fluff pulp fibers and the superabsorbent polymer particles in the core assembly respectively have a basis mass in a range of about 100 to about 350 g/m 2 and the fluff pulp fibers and the superabsorbent polymer particles totally have a basis mass in a range of about 300 to about 600 g/m 2 .

- the superabsorbent polymer particles are present in the depressions more densely than in the non-depressed region.

- the superabsorbent polymer particles have the non-pressurized water absorption rate of 40 ml/g or less.

- the superabsorbent polymer particles have a water absorption rate under load less than 12 g/g.

- a circle in which the depression is inscribed has a diameter in a range of about 1.5 to about 5 mm. According to the embodiments in the above (ii) to (x), one or more of the advantageous effect(s) set forth at (a) is/are better ensured.

Landscapes

- Health & Medical Sciences (AREA)

- Epidemiology (AREA)

- Engineering & Computer Science (AREA)

- Biomedical Technology (AREA)

- Heart & Thoracic Surgery (AREA)

- Vascular Medicine (AREA)

- Life Sciences & Earth Sciences (AREA)

- Animal Behavior & Ethology (AREA)

- General Health & Medical Sciences (AREA)

- Public Health (AREA)

- Veterinary Medicine (AREA)

- Absorbent Articles And Supports Therefor (AREA)

Abstract

Description

a front waist region, a rear waist region, and a crotch region located between the front and rear waist regions; and

a fluid-absorbent structure formed at least in the crotch region and comprising:

a core assembly formed from a mixture of fluid-absorbent materials containing fluff pulp fibers and superabsorbent polymer particles and wrapped with a wrapping sheet, and

a liquid-pervious bodyside liner at least partially covering the core assembly.

in the depressions, the core assembly has a thickness corresponding to 80% or less of the thickness of the core assembly in a non-depressed region defined outside and between the adjacent depressions;

a center-to-center distance between each one of the depressions and the depression closest to the one depression is in a range of about 2 to about 14 mm; and

the superabsorbent polymer particles have a non-pressurized water absorption rate of 45 ml/g or less measured at 5 minutes after the initiation of the non-pressurized water absorption test and a water absorption rate under load of 14 g/g or less.

As used herein, a "diameter" of a depression is the diameter of a circle inscribing the planar shape at the bottom of the depression. When the depression has a circular planar shape, the diameter of the depression is the same as the diameter D of the circular planar shape.

As used herein, a "center-to-center distance" between two depressions is a distance between the centers of the circles respectively inscribing the planar shapes at the bottoms of the depressions.

In such depressions, having a planar shape other than a circular shape, the planar shape as inscribed in the

(i) A disposable diaper having a longitudinal direction and a transverse direction, including:

a front waist region, a rear waist region, and a crotch region located between the front and rear waist regions; and

a fluid-absorbent structure formed at least in the crotch region and comprising:

a core assembly formed from a mixture of fluid-absorbent materials containing fluff pulp fibers and superabsorbent polymer particles and wrapped with a wrapping sheet, and

a liquid-pervious bodyside liner at least partially covering an upper surface of the core assembly,

wherein:

a plurality of depressions depressed in a thickness direction of the core assembly are at least formed on the core assembly and, in the depressions, the mixture and the wrapping sheet are bonded together with hot melt adhesive;

in the depressions, the core assembly has a thickness corresponding to 80% or less of the thickness of the core assembly in a non-depressed region defined outside and between the adjacent depressions;

a center-to-center distance between each one of the depressions and the depression closest to the one depression is in a range of about 2 to about 14 mm; and

the superabsorbent polymer particles have a non-pressurized water absorption rate of 45 ml/g or less measured at 5 minutes after the initiation of the non-pressurized water absorption test and a water absorption rate under load of 14 g/g or less.

(a) A core assembly including fluff wood pulp fibers and superabsorbent polymer particles is formed with a plurality of depressions. With this treatment, it is possible to restrict a bulk and a thickness of the core assembly from increasing as fluff wood pulp fibers cooperates with superabsorbent polymer particles to absorb bodily fluids. The diaper including such improved fluid-absorbent structure can overcome or alleviate various problems, for example, the problem that the fluid-absorbent structure is partially swollen to an abnormal size and shape and/or the problem that the fluid-absorbent structure is put in exceedingly tight contact with the wearer's skin and create a feeling of discomfort against the wearer because of wetness.

(ii) The depressions are formed facing the bodyside liner.

(iii) The disposable diaper further includes a liquid-impervious backsheet at least partially covering a lower surface of the core assembly, wherein the depressions are formed facing the backsheet.

(iv) The depressions are formed on the core assembly and the bodyside liner.

(v) The bodyside liner is not included in the depressions.

(vi) The backsheet is not included in the depressions.

(vii) The fluid-absorbent structure extends across the crotch region into at least one of the front waist region and the rear waist region and the depressions are formed only in the crotch region.

(viii) The fluid-absorbent structure extends across the crotch region into at least one of the front waist region and the rear waist region, and the depressions are formed also in a section of the fluid-absorbent structure extending into the at least one of the front waist region and the rear waist region.

(ix) The number of the depressions formed in 1 cm2 of the surface of the core assembly is decreased from a midsection of the crotch region toward at least one of the front waist region and the rear waist region.

(x) The number of the depressions formed in 1 cm2 of the surface of the core assembly is consistent.

(xi) The fluff pulp fibers and the superabsorbent polymer particles in the core assembly respectively have a basis mass in a range of about 100 to about 350 g/m2 and the fluff pulp fibers and the superabsorbent polymer particles totally have a basis mass in a range of about 300 to about 600 g/m2.

(xii) The superabsorbent polymer particles are present in the depressions more densely than in the non-depressed region.

(xiii) The superabsorbent polymer particles have the non-pressurized water absorption rate of 40 ml/g or less.

(xiv) The superabsorbent polymer particles have a water absorption rate under load less than 12 g/g.

(xv) A circle in which the depression is inscribed has a diameter in a range of about 1.5 to about 5 mm.

According to the embodiments in the above (ii) to (x), one or more of the advantageous effect(s) set forth at (a) is/are better ensured.

Claims (15)

- A disposable diaper having a longitudinal direction and a transverse direction, comprising:

a front waist region, a rear waist region, and a crotch region located between the front and rear waist regions; and

a fluid-absorbent structure formed at least in the crotch region and comprising:

a core assembly formed from a mixture of fluid-absorbent materials containing fluff pulp fibers and superabsorbent polymer particles and wrapped with a wrapping sheet, and

a liquid-pervious bodyside liner at least partially covering an upper surface of the core assembly,

wherein:

a plurality of depressions depressed in a thickness direction of the core assembly are at least formed on the core assembly and, in the depressions, the mixture and the wrapping sheet are bonded together with hot melt adhesive;

in the depressions, the core assembly has a thickness corresponding to 80% or less of the thickness of the core assembly in a non-depressed region defined outside and between the adjacent depressions;

a center-to-center distance between each one of the depressions and the depression closest to the one depression is in a range of about 2 to about 14 mm; and

the superabsorbent polymer particles have a non-pressurized water absorption rate of 45 ml/g or less measured at 5 minutes after the initiation of the non-pressurized water absorption test and a water absorption rate under load of 14 g/g or less. - The disposable diaper defined by claim 1, wherein the depressions are formed facing the bodyside liner.

- The disposable diaper defined by claim 1, further comprising a liquid-impervious backsheet at least partially covering a lower surface of the core assembly, wherein the depressions are formed facing the backsheet.

- The disposable diaper defined by claim 1, wherein the depressions are formed on the core assembly and the bodyside liner.

- The disposable diaper defined by claim 2, wherein the bodyside liner is not included in the depressions.

- The disposable diaper defined by claim 3, wherein the backsheet is not included in the depressions.

- The disposable diaper defined by claim 1, wherein the fluid-absorbent structure extends across the crotch region into at least one of the front waist region and the rear waist region and the depressions are formed only in the crotch region.

- The disposable diaper defined by claim 1, wherein the fluid-absorbent structure extends across the crotch region into at least one of the front waist region and the rear waist region, and the depressions are formed also in a section of the fluid-absorbent structure extending into the at least one of the front waist region and the rear waist region.

- The disposable diaper defined by claim 1, wherein the number of the depressions formed in 1 cm2 of the surface of the core assembly is decreased from a midsection of the crotch region toward at least one of the front waist region and the rear waist region.

- The disposable diaper defined by claim 1, wherein the number of the depressions formed in 1 cm2 of the surface of the core assembly is consistent.

- The disposable diaper defined by claim 1, wherein the fluff pulp fibers and the superabsorbent polymer particles in the core assembly respectively have a basis mass in a range of about 100 to about 350 g/m2 and the fluff pulp fibers and the superabsorbent polymer particles totally have a basis mass in a range of about 300 to about 600 g/m2.

- The disposable diaper defined by claim 1, wherein the superabsorbent polymer particles are present in the depressions more densely than in the non-depressed region.

- The disposable diaper defined by claim 1, wherein the superabsorbent polymer particles have the non-pressurized water absorption rate of 40 ml/g or less.

- The disposable diaper defined by claim 12, wherein the superabsorbent polymer particles have a water absorption rate under load less than 12 g/g.

- The disposable diaper defined by claim 1, wherein a circle in which the depression is inscribed has a diameter in a range of about 1.5 to about 5 mm.

Priority Applications (2)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| CN2012800002612A CN102791237A (en) | 2011-03-04 | 2012-03-02 | Disposable diaper |

| JP2013537984A JP6025736B2 (en) | 2011-03-04 | 2012-03-02 | Disposable diapers |

Applications Claiming Priority (2)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| JP2011-048343 | 2011-03-04 | ||

| JP2011048343 | 2011-03-04 |

Publications (1)

| Publication Number | Publication Date |

|---|---|

| WO2012120864A1 true WO2012120864A1 (en) | 2012-09-13 |

Family

ID=46797836

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| PCT/JP2012/001475 WO2012120864A1 (en) | 2011-03-04 | 2012-03-02 | Disposable diaper |

Country Status (5)

| Country | Link |

|---|---|

| JP (1) | JP6025736B2 (en) |

| CN (1) | CN102791237A (en) |

| AR (1) | AR088312A1 (en) |

| TW (1) | TWI603725B (en) |

| WO (1) | WO2012120864A1 (en) |

Families Citing this family (9)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| JP5800959B1 (en) * | 2014-06-23 | 2015-10-28 | ユニ・チャーム株式会社 | Disposable diapers |

| JP6285812B2 (en) * | 2014-06-30 | 2018-02-28 | ユニ・チャーム株式会社 | Disposable diapers |

| JP6441628B2 (en) * | 2014-09-25 | 2018-12-19 | 大王製紙株式会社 | Absorbent articles |

| JP6035381B1 (en) * | 2015-06-30 | 2016-11-30 | ユニ・チャーム株式会社 | Pants-type disposable diaper |

| EP3072484B1 (en) * | 2015-03-26 | 2020-07-15 | The Procter and Gamble Company | Spool of a three-dimensional substrate |

| JP6710302B2 (en) * | 2018-12-12 | 2020-06-17 | 住友精化株式会社 | Water absorbent resin particles |

| JP6710303B1 (en) * | 2019-01-30 | 2020-06-17 | 住友精化株式会社 | Absorbent article and manufacturing method thereof |

| US20220015959A1 (en) * | 2018-12-12 | 2022-01-20 | Sumitomo Seika Chemicals Co., Ltd. | Water-absorbent resin particles, water-absorbent article, and method for manufacturing same |

| WO2020171176A1 (en) * | 2019-02-20 | 2020-08-27 | 王子ホールディングス株式会社 | Absorbent, and absorbent article provided with same |

Citations (4)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| JPS5865003A (en) * | 1981-09-22 | 1983-04-18 | コルゲ−ト・パ−モリブ・カンパニ− | Absorbable product |

| JPH0325258U (en) * | 1989-07-24 | 1991-03-15 | ||

| JP2008125602A (en) * | 2006-11-17 | 2008-06-05 | Kao Corp | Absorber and absorbent article using it |

| JP2011036554A (en) * | 2009-08-17 | 2011-02-24 | Livedo Corporation | Disposable diaper |

Family Cites Families (1)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| JP3025258U (en) * | 1995-11-29 | 1996-06-11 | 富堡工業股▲分▼有限公司 | Water absorbent pad |

-

2012

- 2012-03-02 JP JP2013537984A patent/JP6025736B2/en active Active

- 2012-03-02 CN CN2012800002612A patent/CN102791237A/en active Pending

- 2012-03-02 AR ARP120100695A patent/AR088312A1/en unknown

- 2012-03-02 WO PCT/JP2012/001475 patent/WO2012120864A1/en active Application Filing

- 2012-03-03 TW TW101107164A patent/TWI603725B/en not_active IP Right Cessation

Patent Citations (4)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| JPS5865003A (en) * | 1981-09-22 | 1983-04-18 | コルゲ−ト・パ−モリブ・カンパニ− | Absorbable product |

| JPH0325258U (en) * | 1989-07-24 | 1991-03-15 | ||

| JP2008125602A (en) * | 2006-11-17 | 2008-06-05 | Kao Corp | Absorber and absorbent article using it |

| JP2011036554A (en) * | 2009-08-17 | 2011-02-24 | Livedo Corporation | Disposable diaper |

Also Published As

| Publication number | Publication date |

|---|---|

| AR088312A1 (en) | 2014-05-28 |

| TWI603725B (en) | 2017-11-01 |

| CN102791237A (en) | 2012-11-21 |

| JP2014506804A (en) | 2014-03-20 |

| TW201249410A (en) | 2012-12-16 |

| JP6025736B2 (en) | 2016-11-16 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| WO2012120864A1 (en) | Disposable diaper | |

| US7851669B2 (en) | Flexible absorbent article with improved body fit | |

| EP1912603B1 (en) | Flexible absorbent article with improved body fit | |

| US7699825B2 (en) | Flexible absorbent article with improved body fit | |

| RU2636375C1 (en) | Absorbent product having receiving layer | |

| WO2012105212A1 (en) | Disposable wearing article | |

| CA2616904C (en) | Flexible absorbent article with improved body fit | |

| KR20190028421A (en) | Absorbent article | |

| US11679040B2 (en) | Absorbent core for disposable absorbent articles with increased absorption rate and improved integrity | |

| WO2012117710A1 (en) | Absorbent wearing article | |

| EP2623074A1 (en) | Disposable wear article | |

| CA2511657A1 (en) | Absorbent article having improved softness | |

| US20130165884A1 (en) | Liner for incontinence | |

| JP6907430B2 (en) | Absorbent article | |

| AU727728B2 (en) | Absorbent structure for use in an absorbent article | |

| JP7440234B2 (en) | disposable diapers | |

| WO2022203987A1 (en) | Multi-piece absorbent articles and arrays thereof | |

| JP7060348B2 (en) | Absorbent article | |

| WO2024070276A1 (en) | Absorbent article and method for manufacturing absorbing element used therefor | |

| WO2024070275A1 (en) | Absorbent article and method for manufacturing absorbent element used therein | |

| JP7372889B2 (en) | absorbent articles | |

| CN113784695B (en) | Absorbent article | |

| JP6992221B2 (en) | Absorbent article | |

| JP2021007680A (en) | Absorbent article |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| WWE | Wipo information: entry into national phase |

Ref document number: 201280000261.2 Country of ref document: CN |

|

| 121 | Ep: the epo has been informed by wipo that ep was designated in this application |

Ref document number: 12754333 Country of ref document: EP Kind code of ref document: A1 |

|

| ENP | Entry into the national phase |

Ref document number: 2013537984 Country of ref document: JP Kind code of ref document: A |

|

| NENP | Non-entry into the national phase |

Ref country code: DE |

|

| 122 | Ep: pct application non-entry in european phase |

Ref document number: 12754333 Country of ref document: EP Kind code of ref document: A1 |