WO2011007540A1 - Washing machine - Google Patents

Washing machine Download PDFInfo

- Publication number

- WO2011007540A1 WO2011007540A1 PCT/JP2010/004505 JP2010004505W WO2011007540A1 WO 2011007540 A1 WO2011007540 A1 WO 2011007540A1 JP 2010004505 W JP2010004505 W JP 2010004505W WO 2011007540 A1 WO2011007540 A1 WO 2011007540A1

- Authority

- WO

- WIPO (PCT)

- Prior art keywords

- washing liquid

- washing

- washing machine

- inner tub

- tub

- Prior art date

Links

Images

Classifications

-

- D—TEXTILES; PAPER

- D06—TREATMENT OF TEXTILES OR THE LIKE; LAUNDERING; FLEXIBLE MATERIALS NOT OTHERWISE PROVIDED FOR

- D06F—LAUNDERING, DRYING, IRONING, PRESSING OR FOLDING TEXTILE ARTICLES

- D06F39/00—Details of washing machines not specific to a single type of machines covered by groups D06F9/00 - D06F27/00

- D06F39/08—Liquid supply or discharge arrangements

- D06F39/083—Liquid discharge or recirculation arrangements

-

- D—TEXTILES; PAPER

- D06—TREATMENT OF TEXTILES OR THE LIKE; LAUNDERING; FLEXIBLE MATERIALS NOT OTHERWISE PROVIDED FOR

- D06F—LAUNDERING, DRYING, IRONING, PRESSING OR FOLDING TEXTILE ARTICLES

- D06F34/00—Details of control systems for washing machines, washer-dryers or laundry dryers

- D06F34/14—Arrangements for detecting or measuring specific parameters

- D06F34/22—Condition of the washing liquid, e.g. turbidity

-

- D—TEXTILES; PAPER

- D06—TREATMENT OF TEXTILES OR THE LIKE; LAUNDERING; FLEXIBLE MATERIALS NOT OTHERWISE PROVIDED FOR

- D06F—LAUNDERING, DRYING, IRONING, PRESSING OR FOLDING TEXTILE ARTICLES

- D06F2103/00—Parameters monitored or detected for the control of domestic laundry washing machines, washer-dryers or laundry dryers

- D06F2103/20—Washing liquid condition, e.g. turbidity

-

- D—TEXTILES; PAPER

- D06—TREATMENT OF TEXTILES OR THE LIKE; LAUNDERING; FLEXIBLE MATERIALS NOT OTHERWISE PROVIDED FOR

- D06F—LAUNDERING, DRYING, IRONING, PRESSING OR FOLDING TEXTILE ARTICLES

- D06F2103/00—Parameters monitored or detected for the control of domestic laundry washing machines, washer-dryers or laundry dryers

- D06F2103/38—Time, e.g. duration

-

- D—TEXTILES; PAPER

- D06—TREATMENT OF TEXTILES OR THE LIKE; LAUNDERING; FLEXIBLE MATERIALS NOT OTHERWISE PROVIDED FOR

- D06F—LAUNDERING, DRYING, IRONING, PRESSING OR FOLDING TEXTILE ARTICLES

- D06F2105/00—Systems or parameters controlled or affected by the control systems of washing machines, washer-dryers or laundry dryers

- D06F2105/06—Recirculation of washing liquids, e.g. by pumps or diverting valves

-

- D—TEXTILES; PAPER

- D06—TREATMENT OF TEXTILES OR THE LIKE; LAUNDERING; FLEXIBLE MATERIALS NOT OTHERWISE PROVIDED FOR

- D06F—LAUNDERING, DRYING, IRONING, PRESSING OR FOLDING TEXTILE ARTICLES

- D06F2105/00—Systems or parameters controlled or affected by the control systems of washing machines, washer-dryers or laundry dryers

- D06F2105/46—Drum speed; Actuation of motors, e.g. starting or interrupting

-

- D—TEXTILES; PAPER

- D06—TREATMENT OF TEXTILES OR THE LIKE; LAUNDERING; FLEXIBLE MATERIALS NOT OTHERWISE PROVIDED FOR

- D06F—LAUNDERING, DRYING, IRONING, PRESSING OR FOLDING TEXTILE ARTICLES

- D06F2105/00—Systems or parameters controlled or affected by the control systems of washing machines, washer-dryers or laundry dryers

- D06F2105/58—Indications or alarms to the control system or to the user

Definitions

- the present invention relates to a washing machine that controls operation according to the state of the washing liquid.

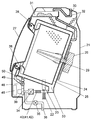

- FIG. 10 is a cross-sectional view of a washing machine disclosed in Patent Document 1.

- the washing machine includes a housing 1, an outer tub 2 supported inside the housing 1, and a bottomed cylindrical inner tub 3 that is rotatably provided inside the outer tub 2. And a drive motor 4 for rotating the inner tub 3.

- the rotation axis of the inner tank 3 is horizontal.

- the inner tub 3 accommodates laundry such as clothes.

- a circulation path 5 through which the washing liquid circulates is provided outside the outer tub 2.

- a turbidity sensor 6 for detecting the turbidity of the washing liquid is attached to the circulation path 5.

- the washing liquid circulates in the circulation path 5 by the rotation of the inner tub 3. Thereby, detergent and dirt do not accumulate at the bottom of the outer tub 2. Further, the concentration of the washing liquid in the outer tub 2 and the washing liquid in the circulation path 5 is made uniform. Since the concentration of the washing liquid is made uniform, the degree of contamination of the washing liquid can be detected by detecting the turbidity of the washing liquid. That is, the turbidity sensor 6 detects the degree of contamination of the washing liquid.

- the control unit 7 determines the dirt on the laundry based on the detected degree of dirt on the washing liquid. The controller 7 shortens the washing time when there is little dirt and optimally controls the washing time.

- the conventional washing machine circulates the washing liquid in the circulation path 5 by the rotation of the inner tub 3. Therefore, it is necessary to increase the rotational speed of the inner tub 3 in order to ensure a sufficient circulation amount of the washing liquid.

- the inner tub 3 functions as a stirring unit that stirs the laundry by rotation. That is, the laundry is lifted by the rotation of the inner tub 3, and then the laundry is dropped, thereby washing. This washing is called tapping.

- the inner tank 3 has an optimum rotation speed. When the inner tub 3 rotates at a rotation speed higher than the optimum rotation speed, the laundry is attached to the inner surface of the inner tub 3 and rotates. In such a state, the washing performance of the washing machine is deteriorated because tapping is not performed.

- the conventional washing machine rotates the inner tub 3 at an optimum rotation speed in order to maintain the washing performance by tapping. Therefore, the circulation amount of the washing liquid in the circulation path 5 is not sufficiently ensured. Thereby, equalization of the washing liquid in the outer tub 2 and the washing liquid in the circulation path 5 is delayed, and the detection accuracy of the turbidity sensor 6 is lowered.

- the present invention provides a washing machine that maintains the detection accuracy of the degree of contamination of the washing liquid without deteriorating the washing performance.

- the washing machine of the present invention includes a housing, an outer tub supported inside the housing, an inner tub that accommodates laundry and is rotatably provided inside the outer tub, and an agitation unit that agitates the laundry With. Furthermore, the washing machine of the present invention includes a circulation path that sucks the washing liquid accumulated in the outer tub and returns it to the inside of the outer tub, a circulation pump that is provided in the middle of the circulation path and circulates the washing liquid, and an agitator and a circulation pump. The control part which controls operation

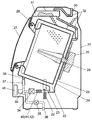

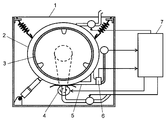

- FIG. 1 is a cross-sectional view of a washing machine according to Embodiment 1 of the present invention.

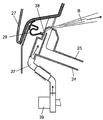

- FIG. 2 is a cross-sectional view of the discharge port of the washing machine in the same embodiment.

- FIG. 3 is a cross-sectional view of another discharge port of the washing machine in the same embodiment.

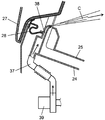

- FIG. 4 is a sectional view of another washing machine according to the embodiment.

- FIG. 5 is a cross-sectional view of the washing liquid state detection unit of the washing machine in the same embodiment.

- FIG. 6 is a cross-sectional view showing another operation of the discharge port of the washing machine in the same embodiment.

- FIG. 7 is a cross-sectional view of another washing machine according to the embodiment.

- FIG. 8 is a cross-sectional view of another washing machine according to the embodiment.

- FIG. 9 is a sectional view of another washing machine according to the embodiment.

- FIG. 10 is a cross-sectional view of a conventional washing machine.

- (Embodiment 1) 1 is a cross-sectional view of a washing machine according to Embodiment 1 of the present invention.

- An outer tub 24 supported by a spring 22, a damping portion 23, or the like that is a support portion is provided inside the housing 21.

- An inner tank 25 is rotatably provided in the outer tank 24.

- a drive motor 26 for rotating the inner tank 25 is provided on the back surface (right side in FIG. 1) of the outer tank 24.

- This washing machine is a so-called drum type washing machine, and the rotation axis of the inner tub 25 is inclined to be higher in the front (left side in FIG. 1) than the horizontal or horizontal.

- the door body 27 provided in the housing 21 opens and closes the front opening 24 a of the outer tub 24.

- the casing 21 and the door body 27 are sealed with a water seal packing 28.

- a plurality of protrusions 29 are provided on the inner surface of the cylindrical portion of the inner tank 25. The protrusion 29 lifts the laundry upward when the inner tub 25 is rotated at a low speed.

- a water supply valve 30 having a water supply port 30a for connecting one end of a water supply hose (not shown) and a detergent charging unit 31 for a user to add a detergent in advance are provided on the upper portion of the housing 21. . Further, a water supply path 32 for connecting the water supply valve 30 and the detergent charging unit 31 and the detergent charging unit 31 and the outer tub 24 is provided. The other end of the water supply hose is connected to the water supply.

- a water intake 33 is provided at the bottom of the outer tub 24.

- the water intake 33 is connected to a drainage path 36 via a drainage filter 34 and a drainage valve 35.

- the washing liquid is discharged from the drainage path 36 to the outside of the washing machine.

- a circulation path 37 branched from between the water intake 33 and the drain valve 35 is provided.

- the washing liquid taken from the water intake port 33 is returned to the outer tub 24 again by the circulation path 37.

- a discharge port 38 that is an outlet of the circulation path 37 is provided in the outer tub 24.

- the discharge port 38 ejects the washing liquid toward the inside of the inner tub 25.

- the route from the intake port 33 to the discharge port 38 is collectively referred to as a circulation route 37.

- the circulation path 37 is provided with a circulation pump 39 for circulating the washing liquid through the circulation path 37 and a washing liquid state detection unit 40 for detecting the state of the washing liquid.

- a circulation pump 39 for circulating the washing liquid through the circulation path 37

- a washing liquid state detection unit 40 for detecting the state of the washing liquid.

- the circulation path 37 demonstrated the case where it branched from between the water intake 33 and the drain valve 35, it is connected with the water intake (not shown) provided separately from the water intake 33 of the water discharge path 36, and is comprised. You can also

- FIG. 2 is a sectional view of the discharge port 38 of the circulation path 37 of the washing machine in the present embodiment.

- the discharge port 38 is provided between the outer tub 24 and the inner tub 25, and sprays the washing liquid toward the inside of the inner tub 25 through the gap between the outer tub 24 and the inner tub 25.

- a state of jetting the washing liquid is shown in FIG.

- the discharge port 38 may be configured so that the discharge port 38 is provided in an exposed portion of the outer tank 24 and sprayed toward the inside of the inner tank 25.

- FIG. 3C shows how the washing liquid is jetted in this case.

- a discharge port 38 is provided between the outer tub 24 and the inner tub 25, and the washing liquid is not sprayed into the inner tub 25. It can be set as the structure which injects a washing

- FIG. 5 is a cross-sectional view of the washing liquid state detection unit 40.

- the washing liquid state detection unit 40 includes an optical sensor 41 that detects the turbidity of the washing liquid and an electrode sensor 42 that detects the conductivity of the washing liquid.

- the optical sensor 41 includes a light emitting element 43 and a light receiving element 44.

- the light emitting element 43 is, for example, an LED

- the light receiving element 44 is, for example, a phototransistor.

- the light emitting element 43 and the light receiving element 44 are installed opposite to each other at a substantially horizontal position with the circulation path 37 interposed therebetween.

- the electrode sensor 42 includes a pair of electrodes 45 a and 45 b on one side of the side wall of the circulation path 37.

- the control unit 46 controls the operation of the drive motor 26, the water supply valve 30, the drain valve 35, the circulation pump 39, and the like. Further, the control unit 46 reads the output from the washing liquid state detection unit 40 and performs calculations. As a result, the degree of contamination of the washing liquid is detected.

- the user opens the door body 27, puts laundry such as clothes into the inner tub 25, and closes the door body 27.

- the start button is pushed, the operation of the washing machine is started.

- the control unit 46 drives the drive motor 26 and estimates the amount of clothing from the load of the drive motor 26 and the like.

- the control unit 46 displays a necessary amount of detergent on a display unit (not shown) according to the estimated amount of clothing.

- the control unit 46 opens the water supply valve 30 after a predetermined time has elapsed.

- water is supplied from a water supply (not shown).

- the supplied water is supplied to the outer tub 24 through the water supply path 32.

- the detergent charging unit 31 in which the detergent is charged it becomes a washing liquid containing the detergent and is supplied to the outer tub 24.

- the control unit 46 drives the drive motor 26 almost simultaneously with the start of water supply, whereby the inner tank 25 rotates.

- the water supply valve 30 is closed.

- the rotation of the inner tank 25 is continued. Since the three protrusions 29 are provided on the inner surface of the inner tub 25, the clothes are lifted when the inner tub 25 rotates. Thereafter, the laundry leaves the inner surface of the inner tub 25 and falls above the inner tub 25.

- This tapping washing promotes washing of the laundry. There is a suitable rotational speed for tapping, and the cleaning performance is degraded whether the rotational speed is higher or lower.

- the control unit 46 opens the drain valve 35 after washing the clothes for a predetermined time. As a result, the washing liquid is drained from the washing path 36 to the outside of the washing machine. Then, the control part 46 performs the spin-drying

- the optical sensor 41 detects the turbidity of the washing liquid.

- the portion of the circulation path 37 that is sandwiched between the light emitting element 43 and the light receiving element 44 is formed of a translucent resin material.

- the light receiving element 44 outputs a signal corresponding to the intensity of the received light.

- the control unit 46 such as a microcomputer takes in this signal, converts it into a voltage, and outputs it.

- the light passing through the washing liquid is attenuated according to the degree of turbidity of the washing liquid.

- the degree of turbidity of the washing liquid is large. That is, the washing liquid is dirty. Conversely, when the amount of light received by the light receiving element 44 is large, the degree of turbidity of the washing liquid is small. In this way, the turbidity of the washing liquid is quantitatively detected from the amount of light received by the light receiving element 44. Since the dirt contained in the laundry dissolves in the washing liquid and the washing liquid becomes cloudy, it can be estimated that the amount of dirt attached to the laundry is large when the washing liquid has a high degree of cloudiness.

- the electrode sensor 42 measures the conductivity of the washing liquid.

- the conductivity is measured by, for example, forming an RC oscillation circuit with the impedance of the washing liquid between the electrodes 45a and 45b and the capacitor (not shown) of the control circuit, and changing the impedance of the washing liquid with a frequency change. And the frequency change is converted into a voltage value. Since electrolyte components such as sweat contained in the laundry are dissolved in the laundry liquid, the conductivity of the laundry liquid is high when there is a lot of dirt such as sweat contained in the laundry. That is, by quantitatively detecting the conductivity of the washing liquid, the amount of dirt such as sweat attached to the laundry can be estimated.

- the degree of dirt on the laundry such as clothes is estimated by the optical sensor 41 and the electrode sensor 42.

- the degree of contamination is estimated by detecting a temporal change in the outputs of the optical sensor 41 and the electrode sensor 42 and performing a calculation such as taking a difference between certain periods.

- the degree of contamination is estimated by combining the output results of both the optical sensor 41 and the electrode sensor 42.

- Operation control of the washing step and the rinsing step is performed according to the estimated degree of dirt on the laundry. That is, when there is little dirt on the laundry, the time for the washing step is shortened. Alternatively, the amount of water used in the washing step and rinsing step is reduced. Thereby, water saving, power saving, and shortening of operation time are performed.

- the degree of turbidity of the washing liquid varies depending on the detergent contained in the washing liquid.

- the conductivity of the washing liquid may increase depending on the components of the detergent contained in the washing liquid.

- the washing liquid state detection unit 40 may detect not only the degree of contamination of the washing liquid but also the state of the washing liquid such as the type and amount of the detergent included based on the degree of turbidity and conductivity of the washing liquid. it can.

- the washing liquid state detection unit 40 In order to increase the correlation between the detection result by the washing liquid state detection unit 40 and the amount of dirt adhering to clothing, it is necessary to devise a determination algorithm such as the absolute value of the detection value and the change rate of the detection value. .

- a determination algorithm such as the absolute value of the detection value and the change rate of the detection value.

- the washing liquid state detection unit 40 since the washing liquid state detection unit 40 is provided in the circulation path 37, the structure that prevents the dirt from adhering to the optical sensor 41, the electrode sensor 42, or the like, or the influence of stirring of the washing liquid is affected. It can be configured to be difficult to receive. Therefore, any determination algorithm contributes to the improvement of detection accuracy, and the determination algorithm is not limited.

- the degree of stain of the washing liquid can be determined on the assumption that the degree of dirt on the laundry, and in this case, depending on the degree of dirt of the laundry liquid, the operation time in the washing step and the rinsing step of the washing machine The amount of water is controlled.

- cleaning liquid is detectable.

- the optical sensor 41 and the electrode sensor 42 were used in order to measure the turbidity and electrical conductivity of a washing liquid was demonstrated, another sensor can be used.

- the washing liquid that circulates in the circulation path 37 includes particles such as foam and sand. Since bubbles are lighter than water, they gather above the inside of the circulation path 37, and particles such as sand gather below the inside of the circulation path 37 because they are heavy. Therefore, if the light emitting element 43 and the light receiving element 44 are provided in a substantially horizontal direction across the vicinity of the center of the circulation path 37, the detection accuracy is improved.

- the present invention is not limited to this configuration, and it is possible to detect the degree of turbidity of the washing liquid even when the light emitting element 43 and the light receiving element 44 are provided in the vertical direction, the oblique direction, or one side of the circulation path 37. is there.

- the present invention is not limited to this configuration, and the conductivity of the washing liquid can be detected even when the electrode 45a and the electrode 45b are provided facing each other in the vertical direction or the diagonal direction with the circulation path 37 interposed therebetween. .

- the washing liquid accumulated in the outer tub 24 is sucked from the water intake port 33, passes through the washing liquid state detection unit 40 and the drainage filter 34, and is discharged from the discharge port 38 to the inside of the inner tub 25. It is injected toward The washing liquid cleans the laundry and is sucked again from the water intake 33.

- the dirt concentration of the washing liquid becomes more uniform. That is, the degree of dirt of the washing liquid detected by the washing liquid state detection unit 40 and the degree of dirt of the washing liquid in the outer tub 24 are substantially the same. For this reason, by providing the washing liquid state detection unit 40 in the circulation path 37, the degree of contamination of the washing liquid can be detected more accurately and quickly.

- the clothes can be quickly wetted after the start of the washing step. Further, the cleaning power is increased by the mechanical force due to the spraying of the washing liquid.

- the circulation of the washing liquid is forcibly performed by the circulation pump 39. Therefore, the circulation of the washing liquid is performed regardless of the rotation of the inner tub 25 that is a stirring unit for stirring clothes. That is, even when the rotational speed of the inner tub 25 is low, the washing liquid can be sufficiently circulated.

- the washing liquid with less dirt components circulates through the washing liquid state detection unit 40.

- the washing liquid with a small amount of dirt components cleans the washing liquid state detection unit 40. That is, the detergent component and dirt adhering at the washing step are removed, and the deterioration of the detection performance of the washing liquid state detection unit 40 is suppressed.

- the discharge port 38 of the circulation path 37 demonstrated the structure provided in one place under the outer tank 24, the circulation path 37 is branched, the discharge port 38 is provided in several places, and it goes to the inner tank 25.

- the structure which injects washing liquid simultaneously may be sufficient.

- the circulation pump 39 is intermittently operated repeatedly during driving and stopping during the washing step and the rinsing step.

- the circulation pump 39 is driven, bubbles and dirt particles are mixed and circulated in the washing liquid, so that the degree of dirt is detected to be large, and the detection value varies greatly.

- the washing liquid state detection unit 40 performs stable and highly accurate detection by detecting the state of the washing liquid while the circulation pump 39 is stopped. Therefore, the estimation accuracy of dirt is improved.

- the detected value is not stable for a while due to the influence of bubbles or the like. For this reason, the detection is performed after the circulation pump 39 is stopped for a predetermined time.

- the detection accuracy is improved by adopting it as a detection value. Further, by performing an operation such as averaging a plurality of detection values, errors are further eliminated and detection accuracy is increased. Further, the washing liquid state detection unit 40 can always perform measurement such as 1 second intervals and use only necessary information.

- the electrode sensor 42 is the same as the optical sensor 41, and the measurement accuracy is improved by measuring when the circulation pump 39 is stopped. Note that the turbidity detection by the optical sensor 41 and the conductivity detection by the electrode sensor 42 do not have to be performed at the same timing, and may be performed at a timing according to each feature. If there is no problem in accuracy, the degree of dirt on the laundry may be detected by detecting the degree of dirt on the laundry while the circulation pump 39 is being driven.

- the circulation of the washing liquid to the circulation path 37 is not performed by the rotation of the inner tub 25 that is the agitation unit, but is performed by the circulation pump 39.

- the circulation of can be stopped. For this reason, high detection accuracy can be obtained while ensuring cleaning power.

- higher detection accuracy can be obtained in consideration of the penetration of the washing liquid into the clothes, the degree of foaming, and the like. it can.

- the washing liquid in the outer tub 24 is stirred by the rotation of the inner tub 25 that is a stirring portion.

- the rotation of the inner tub 25 affects the detection of the washing liquid state detection unit 40 and causes a detection error.

- This detection error is reduced by synchronizing the operation of the circulation pump 39 and the operation of the drive motor 26 (that is, the rotation of the inner tank 25). That is, the control unit 46 drives and stops the circulation pump 39, drives the drive motor 26 in the forward direction (hereinafter referred to as forward rotation), and stops and drives in the direction opposite to the forward direction (hereinafter referred to as inversion).

- forward rotation drives the direction opposite to the forward direction

- the controller 46 repeats the operation of driving the circulation pump 39 for 1 minute and then stopping for 1 minute. This 2 minutes is one cycle.

- the control unit 46 repeats the operation of rotating the drive motor 26 normally for 30 seconds and then reversing for 30 seconds in one cycle twice. In this way, the operations of the circulation pump 39 and the drive motor 26 are synchronized.

- the above-described method of synchronization is an example, and the drive time and the stop time, or the forward rotation time and the inversion time are not necessarily the same.

- control unit 46 stops the drive motor 26 and stops the rotation of the inner tank 25 after a predetermined time after the circulation pump 39 is stopped, both the circulation pump 39 and the drive motor 26 are stopped.

- the detection by the washing liquid state detection unit 40 at this time or before and after this time, the error is reduced.

- the stop of the drive motor 26 is effective even if it is provided only slightly between the forward rotation and the reverse rotation.

- the discharge port 38 of the circulation path 37 is provided so as to inject the washing liquid from the gap between the outer tub 24 and the inner tub 25 toward the inside of the inner tub 25.

- the washing power of the washing machine is improved, for example, the circulated washing liquid hits the laundry such as clothes, and the wetting of the laundry is promoted.

- the washing liquid is injected into the inner tub 25 as shown in FIG. Circulate with.

- the rotational speed of the circulation pump 39 is equal to or lower than the predetermined rotational speed

- the washing liquid circulates inside the outer tub 24 as shown in FIG. That is, by controlling the rotational speed of the circulation pump 39, the washing liquid is switched between a state where the washing liquid does not enter the inside of the inner tub 25 and a state where the washing liquid is sprayed both inside and outside the inner tub 25 as necessary. be able to.

- the improvement of the detection accuracy of the washing liquid state detection unit 40 will be described below.

- the water supply valve 30 is opened, and the detergent introduced into the detergent introduction unit 31 together with the water supply flows into the outer tub 24.

- the circulation pump 39 is driven at a predetermined rotational speed or higher at the stage of water supply, a washing liquid having a high detergent concentration is jetted from the discharge port 38 into the inner tub 25.

- the detergent concentration of the laundry liquid accumulated in the outer tub 24 is lowered.

- the washing liquid immediately after the start of water supply is in a state where only the detergent is dissolved.

- the washing liquid in this state is detected by the washing liquid state detection unit 40, and the type of the detergent can be identified as a powder detergent or a liquid detergent.

- this detection result can be used as an initial value of the washing liquid before the start of the washing step.

- the rotational speed of the circulation pump 39 is set to a predetermined rotational speed or less, and the washing liquid does not spray from the discharge port 38 into the inner tub 25 but falls below the outer tub 24. Let This improves the accuracy of detecting the type of detergent and detecting the initial state of the washing liquid before the start of the washing step.

- the washing liquid collected in the washing liquid state detection unit 40 and the washing liquid collected in the outer tub 24 are made uniform. Is not performed, the detection accuracy deteriorates. That is, as described above, the washing liquid is dropped from the discharge port 38 to the lower side of the outer tub 24 and is circulated inside the outer tub 24, whereby the dissolution of the detergent is promoted and the washing liquid is made uniform. Thereafter, from the middle of the washing step, the washing effect is enhanced by spraying the washing liquid onto the laundry, and the dissolution of the dirt from the laundry is accelerated, and the amount of dirt can be estimated at an early stage. it can. In this way, by controlling the rotational speed of the circulation pump 39, it is possible to perform highly accurate soil determination using one circulation pump 39 and the circulation path 37.

- the detection accuracy is improved by reducing at least the amount of the washing liquid sprayed into the inner tub 25. That is, when at least the washing liquid does not enter the inner tub 25 and circulates in the outer tub 24, the detection accuracy is improved. In other words, it is not effective only when the washing liquid is not sprayed into the inner tub 25 at all. Even when a part of the washing liquid is sprayed into the inner tub 25, a part of the washing liquid is used. If it is injected between the outer tank 24 and the inner tank 25 and circulates inside the outer tank 24, the detection accuracy is improved.

- the state where the washing liquid is not sprayed into the inner tub 25 or the state where the washing liquid is sprayed both inside and outside the inner tub 25 is not effective only at the beginning of water supply.

- foaming can be further increased by spraying the washing liquid into the inner tub 25.

- foaming can be suppressed by stopping the injection of the washing liquid into the inner tub 25. That is, a decrease in detection accuracy due to bubbles is suppressed.

- by controlling the rotational speed of the circulation pump 39 it is possible to switch the injection of the washing liquid without adding a configuration.

- Water supplied from the water supply path 32 is supplied between the outer tank 24 and the inner tank 25. As shown in A of FIG. 1, the washing liquid state detection unit 40 is provided below the lowest point inside the inner tub 25. That is, the supplied water reaches the washing liquid state detection unit 40 before entering the inner tub 25.

- the water supplied from the water supply path 32 reaches the washing liquid state detection unit 40 without passing through laundry such as clothes including dirt and detergent.

- the washing liquid state detection unit 40 detects water that does not contain dirt or detergent, it is possible to detect a secular change due to dirt adhering to the washing liquid state detection unit 40 or the like. By correcting the measurement based on the detection result, it is possible to maintain the detection accuracy corresponding to the secular change.

- the water supplied from the water supply path 32 enters the washing liquid state detection unit 40 without entering the inner tub 25 as the washing liquid containing the detergent introduced into the detergent charging unit 31.

- the detergent component does not adhere to or is absorbed by the clothes or the like, and the washing liquid in which only the detergent is dissolved before the dirt component is melted from the clothes reaches the washing liquid state detection unit 40.

- the accuracy of discriminating whether the detergent is a powder detergent or a liquid detergent is increased.

- the accuracy as the initial value of the washing liquid in the washing step is increased, and the accuracy of detection of the degree of contamination of the washing liquid is increased. Based on this result, when there is little dirt, efficient washing, such as shortening the washing time or reducing the amount of water used, can be performed.

- the amount of water supply increases and the washing liquid containing the detergent enters the inner tub 25. Since the water supply path 32 supplies the washing liquid between the outer tub 24 and the inner tub 25, the amount of the detergent adhering to or adsorbing on the clothes is smaller than in the case of supplying water directly into the inner tub 25. . Further, even after the amount of water supply is increased and the water is supplied into the inner tub 25, the detection accuracy as the initial value of the washing liquid in the washing step is increased.

- the detergent can be dissolved quickly and the washing liquid can be quickly applied to the clothes.

- the laundry liquid containing the detergent reaches the laundry liquid state detection unit 40 before the circulation pump 39 is driven, so that the initial state of the laundry liquid is accurately detected before the laundry liquid is bubbled.

- the inner tub 25 in order to improve the washing performance of the washing machine, it is preferable to rotate the inner tub 25 as a stirring unit from an early stage.

- the washing liquid is foamed. This bubble may reduce the detection accuracy of the washing liquid state detection unit 40.

- the washing liquid containing the detergent reaches the washing liquid state detection unit 40. For this reason, the initial state of the washing liquid before the washing liquid is foamed is detected with high accuracy.

- the washing liquid state detection unit 40 is provided at a position away from the water intake 33 in the middle of the circulation path 37, and is provided at a position that does not directly face the inner tub 25. Thereby, the influence which rotation of the inner tub 25 has on the detection of the washing

- cleaning liquid state detection part 40 can be restrained few.

- a partition wall is provided between the inner tub 25 and the washing liquid state detection unit 40, thereby It can be set as the structure which does not oppose the tank 25 directly.

- the drum type washing machine in which the rotation axis of the inner tub 25 is substantially horizontal has been described, the same effect can be obtained even in other washing machines (pulsator type washing machines) as shown in the sectional view of FIG. Have.

- the same components as those in FIGS. 1 to 6 are described with the same reference numerals.

- the rotation axis of the inner tub 25 is vertical.

- rotation of the stirring body 47 provided in the bottom face of the inner tank 25 is operation

- the water supply path 32 supplies water between the inner tank 25 and the outer tank 24.

- the washing liquid is circulated to the circulation path 37 by the circulation pump 39, and the washing liquid state detection unit 40 is used.

- the state of the washing liquid can be detected. Even if the washing machine is a washing / drying machine having a drying function, the washing machine has the same effect at the time of washing.

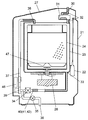

- FIG. 8 is a cross-sectional view of another washing machine according to the embodiment of the present invention.

- the difference from the above washing machine is that a switching valve 48 is provided in the circulation path 37 and the circulation path 37 is branched into an inner tank circulation path 49 and an outer tank circulation path 50.

- the washing machine can switch the circulation path 37 to the inner tank circulation path 49 or the outer tank circulation path 50 by the switching valve 48.

- the washing liquid does not directly enter the inner tank 25 by switching the path to the outer tank circulation path 50. In this case, it is possible to accurately detect the state in which only the detergent is dissolved in the washing liquid, that is, the initial state.

- the switching valve 48 is provided.

- a circulation pump 139 that can switch the output path between forward rotation and reverse rotation is provided. By using it, it becomes possible to switch and supply the washing liquid to each of the inner tank circulation path 49 and the outer tank circulation path 50, and the same effect is obtained.

- the washing machine according to the present invention can perform optimum operation control according to the degree of dirt by accurately detecting the degree of dirt of the washing liquid. That is, it can be used for a washing machine other than a washing machine for washing clothes and the like.

Landscapes

- Engineering & Computer Science (AREA)

- Textile Engineering (AREA)

- Control Of Washing Machine And Dryer (AREA)

- Detail Structures Of Washing Machines And Dryers (AREA)

- Main Body Construction Of Washing Machines And Laundry Dryers (AREA)

Abstract

A washing machine is provided with an outer tub (24) which is supported within a housing (21), an inner tub (25) which is rotatably provided within the outer tub (24) and contains and stirs laundry, a circulation path (37) which sucks a wash liquid held in the outer tub (24) and returns the wash liquid again to the inside of the outer tub (24), and a circulation pump (39) which is provided in the middle of the circulation path (37) and circulates the wash liquid. Also, a wash-liquid-condition detection section (40) which detects the condition of the wash liquid is provided in the middle of the circulation path (37), and this enables a sufficient amount of circulation of the wash liquid flowing through the wash-liquid-condition detection section (40) to be ensured without dependent on the operation of the inner tub (25). As a result, the accuracy of detection of the degree of soiling of the wash liquid can be maintained at a high level without a reduction in the cleaning performance of the washing machine.

Description

本発明は、洗濯液の状態に応じて運転を制御する洗濯機に関する。

The present invention relates to a washing machine that controls operation according to the state of the washing liquid.

従来の洗濯機としては、例えば、特許文献1に開示される洗濯機がある。図10は特許文献1に開示される洗濯機の断面図である。図10に示すように、洗濯機は、筐体1と、筐体1の内部で支持された外槽2と、外槽2の内部に回転自在に設けられた有底円筒状の内槽3と、内槽3を回転させる駆動モータ4とを備える。内槽3の回転軸は水平である。内槽3は、衣類等の洗濯物を収容する。外槽2の外側には、洗濯液が循環する循環経路5が設けられる。循環経路5には、洗濯液の濁度を検出する濁度センサ6が取り付けられる。

As a conventional washing machine, for example, there is a washing machine disclosed in Patent Document 1. FIG. 10 is a cross-sectional view of a washing machine disclosed in Patent Document 1. As shown in FIG. 10, the washing machine includes a housing 1, an outer tub 2 supported inside the housing 1, and a bottomed cylindrical inner tub 3 that is rotatably provided inside the outer tub 2. And a drive motor 4 for rotating the inner tub 3. The rotation axis of the inner tank 3 is horizontal. The inner tub 3 accommodates laundry such as clothes. A circulation path 5 through which the washing liquid circulates is provided outside the outer tub 2. A turbidity sensor 6 for detecting the turbidity of the washing liquid is attached to the circulation path 5.

内槽3の回転によって、洗濯液が循環経路5を循環する。これにより、外槽2の底部に洗剤や汚れが溜まらない。また、外槽2における洗濯液と循環経路5における洗濯液との濃度が均一化される。洗濯液の濃度が均一化されるため、洗濯液の濁度を検出することにより、洗濯液の汚れ度合いを検出することができる。つまり、濁度センサ6が洗濯液の汚れ度合いを検出する。制御部7は、検出した洗濯液の汚れ度合いに基づき洗濯物の汚れを判定する。制御部7は、汚れが少ない場合には洗濯時間を短縮し、洗濯時間を最適に制御する。

The washing liquid circulates in the circulation path 5 by the rotation of the inner tub 3. Thereby, detergent and dirt do not accumulate at the bottom of the outer tub 2. Further, the concentration of the washing liquid in the outer tub 2 and the washing liquid in the circulation path 5 is made uniform. Since the concentration of the washing liquid is made uniform, the degree of contamination of the washing liquid can be detected by detecting the turbidity of the washing liquid. That is, the turbidity sensor 6 detects the degree of contamination of the washing liquid. The control unit 7 determines the dirt on the laundry based on the detected degree of dirt on the washing liquid. The controller 7 shortens the washing time when there is little dirt and optimally controls the washing time.

上記従来の洗濯機は、内槽3の回転によって、循環経路5に洗濯液を循環させる。したがって、洗濯液の循環量を充分に確保するために、内槽3の回転速度を高める必要がある。一方、内槽3は、回転により洗濯物を撹拌させる撹拌部として機能する。つまり、内槽3の回転によって洗濯物が持ち上げられ、その後、洗濯物が落下することにより、洗いが行われる。この洗い方を叩き洗いと言う。この場合、内槽3には、最適な回転速度がある。この最適な回転速度より高い回転速度で内槽3が回転すると、洗濯物が内槽3の内面に貼り付いて回転する。この様な状態では、叩き洗いが行われないため、洗濯機の洗浄性能は低下する。従来の洗濯機は、叩き洗いによる洗浄性能を維持するために、最適な回転速度で内槽3を回転させる。したがって、循環経路5における、洗濯液の循環量が充分に確保されない。これにより、外槽2の洗濯液と循環経路5の洗濯液との均一化が遅れ、濁度センサ6の検出精度が低化する。

The conventional washing machine circulates the washing liquid in the circulation path 5 by the rotation of the inner tub 3. Therefore, it is necessary to increase the rotational speed of the inner tub 3 in order to ensure a sufficient circulation amount of the washing liquid. On the other hand, the inner tub 3 functions as a stirring unit that stirs the laundry by rotation. That is, the laundry is lifted by the rotation of the inner tub 3, and then the laundry is dropped, thereby washing. This washing is called tapping. In this case, the inner tank 3 has an optimum rotation speed. When the inner tub 3 rotates at a rotation speed higher than the optimum rotation speed, the laundry is attached to the inner surface of the inner tub 3 and rotates. In such a state, the washing performance of the washing machine is deteriorated because tapping is not performed. The conventional washing machine rotates the inner tub 3 at an optimum rotation speed in order to maintain the washing performance by tapping. Therefore, the circulation amount of the washing liquid in the circulation path 5 is not sufficiently ensured. Thereby, equalization of the washing liquid in the outer tub 2 and the washing liquid in the circulation path 5 is delayed, and the detection accuracy of the turbidity sensor 6 is lowered.

本発明は、洗浄性能を低下させることなく、洗濯液の汚れ度合いの検出精度を維持した洗濯機を提供する。

The present invention provides a washing machine that maintains the detection accuracy of the degree of contamination of the washing liquid without deteriorating the washing performance.

本発明の洗濯機は、筐体と、筐体の内部に支持された外槽と、洗濯物を収容し、外槽の内部に回転自在に設けた内槽と、洗濯物を撹拌する撹拌部とを備える。さらに本発明の洗濯機は、外槽に溜まった洗濯液を吸い込んで再び外槽の内部に戻す循環経路と、循環経路の途中に設けられ洗濯液を循環させる循環ポンプと、撹拌部および循環ポンプの運転を制御する制御部とを備える。さらに本発明の洗濯機は、循環経路の途中に、洗濯液の状態を検出する洗濯液状態検出部を備える。

The washing machine of the present invention includes a housing, an outer tub supported inside the housing, an inner tub that accommodates laundry and is rotatably provided inside the outer tub, and an agitation unit that agitates the laundry With. Furthermore, the washing machine of the present invention includes a circulation path that sucks the washing liquid accumulated in the outer tub and returns it to the inside of the outer tub, a circulation pump that is provided in the middle of the circulation path and circulates the washing liquid, and an agitator and a circulation pump. The control part which controls operation | movement of this. Furthermore, the washing machine of the present invention includes a washing liquid state detection unit that detects the state of the washing liquid in the middle of the circulation path.

この構成により、撹拌部の運転に依存せずに、洗濯液状態検出部を流れる洗濯液の循環量を確保することができる。したがって、洗浄性能を低下させることなく、洗濯液の汚れ度合いの検出精度が維持される。

With this configuration, it is possible to secure the circulation amount of the washing liquid flowing through the washing liquid state detection unit without depending on the operation of the stirring unit. Therefore, the detection accuracy of the degree of contamination of the washing liquid is maintained without deteriorating the cleaning performance.

(実施の形態1)

図1は、本発明の実施の形態1における洗濯機の断面図である。筐体21の内部には、支持部であるばね22や減衰部23等によって支持された外槽24が設けられる。外槽24の内部には、内槽25が回転自在に設けられる。外槽24の背面(図1において右側)には、内槽25を回転させるための駆動モータ26が設けられる。この洗濯機は、いわゆるドラム式洗濯機であり、内槽25の回転軸は、水平または水平よりも前方(図1において左側)が高く傾斜している。筐体21に設けられた扉体27は、外槽24の前面開口24aを開閉する。筐体21と扉体27とは、水封パッキン28によりシールされる。内槽25の筒状部の内面には、複数の突起体29が設けられる。突起体29は、内槽25を低速で回転させた場合に、洗濯物を上方に持ち上げる。 (Embodiment 1)

1 is a cross-sectional view of a washing machine according toEmbodiment 1 of the present invention. An outer tub 24 supported by a spring 22, a damping portion 23, or the like that is a support portion is provided inside the housing 21. An inner tank 25 is rotatably provided in the outer tank 24. A drive motor 26 for rotating the inner tank 25 is provided on the back surface (right side in FIG. 1) of the outer tank 24. This washing machine is a so-called drum type washing machine, and the rotation axis of the inner tub 25 is inclined to be higher in the front (left side in FIG. 1) than the horizontal or horizontal. The door body 27 provided in the housing 21 opens and closes the front opening 24 a of the outer tub 24. The casing 21 and the door body 27 are sealed with a water seal packing 28. A plurality of protrusions 29 are provided on the inner surface of the cylindrical portion of the inner tank 25. The protrusion 29 lifts the laundry upward when the inner tub 25 is rotated at a low speed.

図1は、本発明の実施の形態1における洗濯機の断面図である。筐体21の内部には、支持部であるばね22や減衰部23等によって支持された外槽24が設けられる。外槽24の内部には、内槽25が回転自在に設けられる。外槽24の背面(図1において右側)には、内槽25を回転させるための駆動モータ26が設けられる。この洗濯機は、いわゆるドラム式洗濯機であり、内槽25の回転軸は、水平または水平よりも前方(図1において左側)が高く傾斜している。筐体21に設けられた扉体27は、外槽24の前面開口24aを開閉する。筐体21と扉体27とは、水封パッキン28によりシールされる。内槽25の筒状部の内面には、複数の突起体29が設けられる。突起体29は、内槽25を低速で回転させた場合に、洗濯物を上方に持ち上げる。 (Embodiment 1)

1 is a cross-sectional view of a washing machine according to

筐体21の上部には、給水ホース(図示せず)の一端を接続するための給水口30aを有する給水弁30と、使用者が洗剤をあらかじめ投入するための洗剤投入部31とが設けられる。また、給水弁30と洗剤投入部31、および、洗剤投入部31と外槽24とを接続するための給水経路32が設けられる。なお、給水ホースは他端が水道に接続される。

A water supply valve 30 having a water supply port 30a for connecting one end of a water supply hose (not shown) and a detergent charging unit 31 for a user to add a detergent in advance are provided on the upper portion of the housing 21. . Further, a water supply path 32 for connecting the water supply valve 30 and the detergent charging unit 31 and the detergent charging unit 31 and the outer tub 24 is provided. The other end of the water supply hose is connected to the water supply.

外槽24の最下部には、取水口33が設けられる。取水口33は、排水フィルタ34および排水弁35を介して、排水経路36に接続される。洗濯液は、排水経路36から洗濯機の外へ排出される。また、取水口33と排水弁35との間から分岐した循環経路37が設けられる。循環経路37により、取水口33から取り込まれた洗濯液が、再び外槽24へ戻される。循環経路37の出口である吐出口38は外槽24に設けられる。吐出口38は、内槽25の内部へ向けて洗濯液を噴射する。なお、取水口33から吐出口38までの経路を合わせて循環経路37と呼ぶ。循環経路37には、循環経路37に洗濯液を循環させるための循環ポンプ39が設けられるとともに、洗濯液の状態を検出するための洗濯液状態検出部40が設けられる。なお、循環経路37は、取水口33と排水弁35との間から分岐した場合について説明したが、排水経路36の取水口33とは別に設けた取水口(図示せず)に連通させて構成することもできる。

A water intake 33 is provided at the bottom of the outer tub 24. The water intake 33 is connected to a drainage path 36 via a drainage filter 34 and a drainage valve 35. The washing liquid is discharged from the drainage path 36 to the outside of the washing machine. A circulation path 37 branched from between the water intake 33 and the drain valve 35 is provided. The washing liquid taken from the water intake port 33 is returned to the outer tub 24 again by the circulation path 37. A discharge port 38 that is an outlet of the circulation path 37 is provided in the outer tub 24. The discharge port 38 ejects the washing liquid toward the inside of the inner tub 25. The route from the intake port 33 to the discharge port 38 is collectively referred to as a circulation route 37. The circulation path 37 is provided with a circulation pump 39 for circulating the washing liquid through the circulation path 37 and a washing liquid state detection unit 40 for detecting the state of the washing liquid. In addition, although the circulation path 37 demonstrated the case where it branched from between the water intake 33 and the drain valve 35, it is connected with the water intake (not shown) provided separately from the water intake 33 of the water discharge path 36, and is comprised. You can also

図2は、本実施の形態における洗濯機の循環経路37の吐出口38の断面図である。吐出口38は、外槽24と内槽25との間に設けられ、外槽24と内槽25との隙間を通って、内槽25の内部に向けて洗濯液を噴射する。洗濯液の噴射の様子を、図2のBに示す。なお、吐出口38は、図3の断面図ように、吐出口38を外槽24の露出した部分に設け、内槽25の内部へ向けて噴射する構成とすることができる。この場合の洗濯液の噴射の様子を、図3のCに示す。また、図4の断面図ように、外槽24と内槽25との間に吐出口38を設け、洗濯液を内槽25の内部には噴射せず、外槽24と内槽25との間に洗濯液を噴射する構成とすることができる。

FIG. 2 is a sectional view of the discharge port 38 of the circulation path 37 of the washing machine in the present embodiment. The discharge port 38 is provided between the outer tub 24 and the inner tub 25, and sprays the washing liquid toward the inside of the inner tub 25 through the gap between the outer tub 24 and the inner tub 25. A state of jetting the washing liquid is shown in FIG. As shown in the cross-sectional view of FIG. 3, the discharge port 38 may be configured so that the discharge port 38 is provided in an exposed portion of the outer tank 24 and sprayed toward the inside of the inner tank 25. FIG. 3C shows how the washing liquid is jetted in this case. Further, as shown in the sectional view of FIG. 4, a discharge port 38 is provided between the outer tub 24 and the inner tub 25, and the washing liquid is not sprayed into the inner tub 25. It can be set as the structure which injects a washing | cleaning liquid in between.

図5は、洗濯液状態検出部40の断面図である。洗濯液状態検出部40は、洗濯液の濁度を検出する光センサ41と、洗濯液の導電率を検出する電極センサ42とにより構成される。光センサ41は、発光素子43と、受光素子44とにより構成される。発光素子43は、例えばLEDであり、受光素子44は、例えばフォトトランジスタである。発光素子43と受光素子44とは、循環経路37を挟んで略水平位置に対向して設置される。電極センサ42は、循環経路37の側壁の片側に1対の電極45aおよび電極45bで構成される。

FIG. 5 is a cross-sectional view of the washing liquid state detection unit 40. The washing liquid state detection unit 40 includes an optical sensor 41 that detects the turbidity of the washing liquid and an electrode sensor 42 that detects the conductivity of the washing liquid. The optical sensor 41 includes a light emitting element 43 and a light receiving element 44. The light emitting element 43 is, for example, an LED, and the light receiving element 44 is, for example, a phototransistor. The light emitting element 43 and the light receiving element 44 are installed opposite to each other at a substantially horizontal position with the circulation path 37 interposed therebetween. The electrode sensor 42 includes a pair of electrodes 45 a and 45 b on one side of the side wall of the circulation path 37.

制御部46は、駆動モータ26や給水弁30、排水弁35、循環ポンプ39などの運転制御を行う。さらに制御部46は、洗濯液状態検出部40からの出力を読み込み、演算等を行う。これにより、洗濯液の汚れ度合いの検出が行なわれる。

The control unit 46 controls the operation of the drive motor 26, the water supply valve 30, the drain valve 35, the circulation pump 39, and the like. Further, the control unit 46 reads the output from the washing liquid state detection unit 40 and performs calculations. As a result, the degree of contamination of the washing liquid is detected.

次に、本実施の形態の洗濯機の動作について説明する。使用者は、扉体27を開いて内槽25に衣類等の洗濯物を投入し、扉体27を閉じる。スタートボタンが押されることにより、洗濯機の運転が開始される。運転が開始されると、制御部46は、駆動モータ26を駆動して、駆動モータ26の負荷などから衣類の量を推定する。制御部46は、推定した衣類の量に応じて必要な洗剤の量を表示部(図示せず)に表示する。使用者は、洗剤投入部31を引き出し、表示された洗剤の量に基づいて洗剤を投入し、再度、洗剤投入部31をもとの位置に押し戻す。

Next, the operation of the washing machine of this embodiment will be described. The user opens the door body 27, puts laundry such as clothes into the inner tub 25, and closes the door body 27. When the start button is pushed, the operation of the washing machine is started. When the operation is started, the control unit 46 drives the drive motor 26 and estimates the amount of clothing from the load of the drive motor 26 and the like. The control unit 46 displays a necessary amount of detergent on a display unit (not shown) according to the estimated amount of clothing. The user pulls out the detergent insertion part 31, introduces the detergent based on the displayed amount of detergent, and pushes the detergent insertion part 31 back to the original position again.

制御部46は、所定時間が経過した後、給水弁30を開く。給水弁30が開くことにより、水道(図示せず)から水が給水される。給水された水は、給水経路32を通って、外槽24に供給される。このとき水は、洗剤を投入した洗剤投入部31を通るため、洗剤を含む洗濯液となり、外槽24に供給される。

The control unit 46 opens the water supply valve 30 after a predetermined time has elapsed. When the water supply valve 30 is opened, water is supplied from a water supply (not shown). The supplied water is supplied to the outer tub 24 through the water supply path 32. At this time, since the water passes through the detergent charging unit 31 in which the detergent is charged, it becomes a washing liquid containing the detergent and is supplied to the outer tub 24.

制御部46は、給水の開始とほぼ同時に駆動モータ26を駆動し、これにより、内槽25が回転する。洗濯液(水)が所定水量に到達すると、給水弁30が閉じられる。一方、内槽25の回転は継続される。内槽25の内面には3個の突起体29が設けられるため、内槽25が回転すれば、衣類は持ち上げられる。その後、内槽25の上方で洗濯物は内槽25の内面から離れ、落下する。この叩き洗いにより、洗濯物の洗浄が促進される。叩き洗いには、適した回転速度があり、この回転速度より高くても低くても洗浄性能は低下する。

The control unit 46 drives the drive motor 26 almost simultaneously with the start of water supply, whereby the inner tank 25 rotates. When the washing liquid (water) reaches a predetermined amount of water, the water supply valve 30 is closed. On the other hand, the rotation of the inner tank 25 is continued. Since the three protrusions 29 are provided on the inner surface of the inner tub 25, the clothes are lifted when the inner tub 25 rotates. Thereafter, the laundry leaves the inner surface of the inner tub 25 and falls above the inner tub 25. This tapping washing promotes washing of the laundry. There is a suitable rotational speed for tapping, and the cleaning performance is degraded whether the rotational speed is higher or lower.

制御部46は、衣類を所定時間洗浄した後、排水弁35を開く。これにより、洗濯液が、排水経路36から洗濯機の外に排水される。その後、制御部46は、内槽25を高速で回転させ、洗濯物に残った洗濯液を減少させる脱水ステップを行う。その後、制御部46は、内槽25を停止し、給水弁30を開いて所定水位まで給水し、再度、内槽25を回転させて濯ぎステップを行う。この脱水ステップと濯ぎステップとが2回程度繰り返され、最後に脱水ステップが実行され、洗濯物が脱水された状態で一連のステップが終了する。

The control unit 46 opens the drain valve 35 after washing the clothes for a predetermined time. As a result, the washing liquid is drained from the washing path 36 to the outside of the washing machine. Then, the control part 46 performs the spin-drying | dehydration step which rotates the inner tank 25 at high speed and reduces the washing | cleaning liquid which remained in the laundry. Then, the control part 46 stops the inner tank 25, opens the water supply valve 30, supplies water to a predetermined water level, rotates the inner tank 25 again, and performs a rinse step. This dehydrating step and rinsing step are repeated about twice, and finally the dehydrating step is executed, and the series of steps is completed with the laundry being dehydrated.

次に、洗濯液状態検出部40の動作について説明する。光センサ41は洗濯液の濁度を検出する。循環経路37であって、発光素子43と受光素子44とに挟まれた部分は、透光性の樹脂材料で形成される。これにより、発光素子43からの光が、循環経路37の中の洗濯液を通過して受光素子44で受光される。受光素子44は、受光した光の強さに応じた信号を出力する。マイコン等の制御部46は、この信号を取り込み、電圧に変換して出力する。洗濯液を通過する光は、洗濯液の濁り度合いに応じて減衰する。例えば、受光素子44の受光量が少ない場合は、洗濯液の濁り度合いが大きい。つまり、洗濯液が汚れている。逆に、受光素子44の受光量が大きい場合は、洗濯液の濁り度合いが小さい。この様にして、受光素子44の受光量から、洗濯液の濁り度合いが定量的に検出される。洗濯物に含まれる汚れが洗濯液に溶け込み、洗濯液の濁りとなるため、洗濯液の濁り度合いが多い場合は、洗濯物に付着した汚れの量が大きかったと推定できる。

Next, the operation of the washing liquid state detection unit 40 will be described. The optical sensor 41 detects the turbidity of the washing liquid. The portion of the circulation path 37 that is sandwiched between the light emitting element 43 and the light receiving element 44 is formed of a translucent resin material. As a result, the light from the light emitting element 43 passes through the washing liquid in the circulation path 37 and is received by the light receiving element 44. The light receiving element 44 outputs a signal corresponding to the intensity of the received light. The control unit 46 such as a microcomputer takes in this signal, converts it into a voltage, and outputs it. The light passing through the washing liquid is attenuated according to the degree of turbidity of the washing liquid. For example, when the amount of light received by the light receiving element 44 is small, the degree of turbidity of the washing liquid is large. That is, the washing liquid is dirty. Conversely, when the amount of light received by the light receiving element 44 is large, the degree of turbidity of the washing liquid is small. In this way, the turbidity of the washing liquid is quantitatively detected from the amount of light received by the light receiving element 44. Since the dirt contained in the laundry dissolves in the washing liquid and the washing liquid becomes cloudy, it can be estimated that the amount of dirt attached to the laundry is large when the washing liquid has a high degree of cloudiness.

一方、電極センサ42は、洗濯液の導電率を測定する。導電率の測定は、例えば、電極45aと電極45bとの間の洗濯液のインピーダンスと、制御回路のコンデンサ(図示せず)とでRC発振回路を構成し、洗濯液のインピーダンスの変化を周波数変化として出力し、さらにこの周波数変化を電圧値に変換することによって行なわれる。洗濯物に含まれる汗などの電解質成分が洗濯液に溶け込むため、洗濯物に含まれる汗などの汚れが多い場合、洗濯液の導電率は高い。つまり、洗濯液の導電率を定量的に検出することにより、洗濯物に付着した汗などの汚れの量を推定することができる。

On the other hand, the electrode sensor 42 measures the conductivity of the washing liquid. The conductivity is measured by, for example, forming an RC oscillation circuit with the impedance of the washing liquid between the electrodes 45a and 45b and the capacitor (not shown) of the control circuit, and changing the impedance of the washing liquid with a frequency change. And the frequency change is converted into a voltage value. Since electrolyte components such as sweat contained in the laundry are dissolved in the laundry liquid, the conductivity of the laundry liquid is high when there is a lot of dirt such as sweat contained in the laundry. That is, by quantitatively detecting the conductivity of the washing liquid, the amount of dirt such as sweat attached to the laundry can be estimated.

この様に、光センサ41や電極センサ42により、衣類等の洗濯物の汚れの度合いが推定される。具体的には、例えば、光センサ41と電極センサ42との各々の出力の時間変化を検出し、ある期間の差分を取るなどの演算を行うことにより汚れ度合いを推定する。あるいは、光センサ41と電極センサ42との両者の出力結果を組み合わせることにより、汚れ度合いを推定する。この推定した洗濯物の汚れ度合いに応じて、洗濯ステップや濯ぎステップの運転制御が行われる。つまり、洗濯物の汚れが少ない場合には、洗いステップの時間が短縮される。あるいは、洗いステップや濯ぎステップで使用する水量が低減される。これにより、節水、省電力、運転時間の短縮化が行われる。

In this manner, the degree of dirt on the laundry such as clothes is estimated by the optical sensor 41 and the electrode sensor 42. Specifically, for example, the degree of contamination is estimated by detecting a temporal change in the outputs of the optical sensor 41 and the electrode sensor 42 and performing a calculation such as taking a difference between certain periods. Alternatively, the degree of contamination is estimated by combining the output results of both the optical sensor 41 and the electrode sensor 42. Operation control of the washing step and the rinsing step is performed according to the estimated degree of dirt on the laundry. That is, when there is little dirt on the laundry, the time for the washing step is shortened. Alternatively, the amount of water used in the washing step and rinsing step is reduced. Thereby, water saving, power saving, and shortening of operation time are performed.

ここで、洗濯液の濁り度合いは、洗濯液に含まれる洗剤によっても変化する。また、洗濯液の導電率は、洗濯液に含まれる洗剤の成分によっても増加する場合がある。このため、給水直後など、洗濯液状態検出部40により検出するタイミングによっては、洗剤の種類や量を見分けることが可能である。このように、洗濯液状態検出部40は、洗濯液の濁り度合いや導電率に基づき、洗濯液の汚れ度合いだけでなく、含まれる洗剤の種類や量などの洗濯液の状態を検出することもできる。

Here, the degree of turbidity of the washing liquid varies depending on the detergent contained in the washing liquid. In addition, the conductivity of the washing liquid may increase depending on the components of the detergent contained in the washing liquid. For this reason, depending on the timing detected by the washing liquid state detection unit 40, such as immediately after water supply, it is possible to distinguish the type and amount of detergent. As described above, the washing liquid state detection unit 40 may detect not only the degree of contamination of the washing liquid but also the state of the washing liquid such as the type and amount of the detergent included based on the degree of turbidity and conductivity of the washing liquid. it can.

洗濯液状態検出部40による検出結果と、衣類に付着している汚れ量との相関を高めるためには、検出値の絶対値や、検出値の変化率など、判定アルゴリズムの工夫が必要である。本実施の形態においては、循環経路37の内部に洗濯液状態検出部40が設けられるため、光センサ41や電極センサ42等への汚れの付着を防止する構成、あるいは洗濯液の撹拌の影響を受けにくい構成とすることができる。したがって、いかなる判定アルゴリズムであっても、その検出精度の向上に寄与するため、判定アルゴリズムは限定されない。例えば、洗濯液の汚れ度合いを、洗濯物の汚れ度合いと仮定して判定することができ、この場合は、洗濯液の汚れ度合いに応じて、洗濯機の洗いステップやすすぎステップでの運転時間や水量が制御される。

In order to increase the correlation between the detection result by the washing liquid state detection unit 40 and the amount of dirt adhering to clothing, it is necessary to devise a determination algorithm such as the absolute value of the detection value and the change rate of the detection value. . In the present embodiment, since the washing liquid state detection unit 40 is provided in the circulation path 37, the structure that prevents the dirt from adhering to the optical sensor 41, the electrode sensor 42, or the like, or the influence of stirring of the washing liquid is affected. It can be configured to be difficult to receive. Therefore, any determination algorithm contributes to the improvement of detection accuracy, and the determination algorithm is not limited. For example, the degree of stain of the washing liquid can be determined on the assumption that the degree of dirt on the laundry, and in this case, depending on the degree of dirt of the laundry liquid, the operation time in the washing step and the rinsing step of the washing machine The amount of water is controlled.

なお、洗濯液状態検出部40として、光センサ41および電極センサ42を用いて説明したが、いずれか一方であっても、洗濯液の汚れ度合いを検出することができる。また、洗濯液の濁度や導電率を測定するために、光センサ41や電極センサ42を用いた場合を説明したが、他のセンサを用いることができる。

In addition, although it demonstrated using the optical sensor 41 and the electrode sensor 42 as the washing | cleaning liquid state detection part 40, even if it is any one, the stain | pollution | contamination degree of a washing | cleaning liquid is detectable. Moreover, although the case where the optical sensor 41 and the electrode sensor 42 were used in order to measure the turbidity and electrical conductivity of a washing liquid was demonstrated, another sensor can be used.

光センサ41の受光素子44は、外部からの光の影響を受けないように、遮光することが望ましい。しかしながら、光センサ41として赤外線を用いる場合は、遮光が不要となり、構成を簡素化することができる。

It is desirable to shield the light receiving element 44 of the optical sensor 41 so as not to be affected by external light. However, when infrared rays are used as the optical sensor 41, light shielding is unnecessary, and the configuration can be simplified.

循環経路37を循環する洗濯液は、泡や砂等の粒子を含む。泡は水より軽いため循環経路37の内部の上方に集まり、砂等の粒子は重いため循環経路37の内部の下方に集まる。したがって、発光素子43と受光素子44とを、循環経路37の中央付近を挟んで略水平方向に設けると検出精度が高まる。しかしながら、特にこの構成に限らず、発光素子43と受光素子44とを、上下方向、斜め方向、あるいは循環経路37の片側に設けた場合でもあっても、洗濯液の濁り度合いの検出は可能である。

The washing liquid that circulates in the circulation path 37 includes particles such as foam and sand. Since bubbles are lighter than water, they gather above the inside of the circulation path 37, and particles such as sand gather below the inside of the circulation path 37 because they are heavy. Therefore, if the light emitting element 43 and the light receiving element 44 are provided in a substantially horizontal direction across the vicinity of the center of the circulation path 37, the detection accuracy is improved. However, the present invention is not limited to this configuration, and it is possible to detect the degree of turbidity of the washing liquid even when the light emitting element 43 and the light receiving element 44 are provided in the vertical direction, the oblique direction, or one side of the circulation path 37. is there.

電極センサ42も同様に、電極45aおよび電極45bを循環経路37の垂直方向の中央付近に設けることにより、泡の影響が低減され、より高精度で導電率が検出される。なお、特にこの構成に限らず、電極45aおよび電極45bを、循環経路37を挟んで上下方向や斜め方向に対向して設けた場合であっても、洗濯液の導電率の検出は可能である。

Similarly, by providing the electrode 45a and the electrode 45b in the vicinity of the center in the vertical direction of the circulation path 37, the influence of bubbles is reduced and the conductivity is detected with higher accuracy. Note that the present invention is not limited to this configuration, and the conductivity of the washing liquid can be detected even when the electrode 45a and the electrode 45b are provided facing each other in the vertical direction or the diagonal direction with the circulation path 37 interposed therebetween. .

循環ポンプ39を駆動することにより、外槽24に溜まった洗濯液が、取水口33から吸い込まれ、洗濯液状態検出部40と排水フィルタ34とを通って、吐出口38から内槽25の内部に向けて噴射される。洗濯液は洗濯物の汚れを落とし、再び取水口33から吸い込まれる。この様に、外槽24に溜まった洗濯液を循環させることにより、洗濯液の汚れ濃度が、より均一になる。つまり、洗濯液状態検出部40が検出する洗濯液の汚れ度合いと、外槽24の洗濯液の汚れ度合いとが、ほぼ同じになる。このため、循環経路37に洗濯液状態検出部40を設けることにより、洗濯液の汚れ度合いをより高い精度で、しかも素早く検出することができる。つまり、早期に汚れを判定することができる。また、循環した洗濯液を衣類に噴射することにより、洗いステップ開始後に衣類を素早く濡らすことができる。また、洗濯液の噴射による機械的な力が作用することにより、洗浄力が高まる。

By driving the circulation pump 39, the washing liquid accumulated in the outer tub 24 is sucked from the water intake port 33, passes through the washing liquid state detection unit 40 and the drainage filter 34, and is discharged from the discharge port 38 to the inside of the inner tub 25. It is injected toward The washing liquid cleans the laundry and is sucked again from the water intake 33. Thus, by circulating the washing liquid accumulated in the outer tub 24, the dirt concentration of the washing liquid becomes more uniform. That is, the degree of dirt of the washing liquid detected by the washing liquid state detection unit 40 and the degree of dirt of the washing liquid in the outer tub 24 are substantially the same. For this reason, by providing the washing liquid state detection unit 40 in the circulation path 37, the degree of contamination of the washing liquid can be detected more accurately and quickly. That is, it is possible to determine the contamination at an early stage. In addition, by spraying the circulated washing liquid onto the clothes, the clothes can be quickly wetted after the start of the washing step. Further, the cleaning power is increased by the mechanical force due to the spraying of the washing liquid.

上記の構成により、洗濯液の循環は、循環ポンプ39により強制的に行われる。したがって、洗濯液の循環は、衣類を撹拌するための撹拌部である内槽25の回転とは無関係に行われる。つまり、内槽25の回転速度が低い場合であっても、洗濯液の循環を充分に行うことができる。また、撹拌部の運転の影響を受けないような、洗濯液の循環量や循環のタイミングなどを任意に設定することができる。このため、洗浄力を損なうことなく、洗濯液の汚れ度合いの検出精度を高める制御を行うことができる。また、洗濯液の循環量を多くすることにより、洗濯液状態検出部40への汚れの付着を防止することができる。

With the above configuration, the circulation of the washing liquid is forcibly performed by the circulation pump 39. Therefore, the circulation of the washing liquid is performed regardless of the rotation of the inner tub 25 that is a stirring unit for stirring clothes. That is, even when the rotational speed of the inner tub 25 is low, the washing liquid can be sufficiently circulated. In addition, it is possible to arbitrarily set the circulation amount and the circulation timing of the washing liquid so as not to be affected by the operation of the stirring unit. For this reason, it is possible to perform control to increase the detection accuracy of the degree of contamination of the washing liquid without impairing the cleaning power. Further, by increasing the circulation amount of the washing liquid, it is possible to prevent the dirt from adhering to the washing liquid state detection unit 40.

さらに、濯ぎステップにおいても、循環ポンプ39を駆動させることにより、汚れ成分の少ない洗濯液が洗濯液状態検出部40を循環する。これにより、汚れ成分の少ない洗濯液が洗濯液状態検出部40を洗浄する。つまり、洗いステップで付着した洗剤成分や汚れが除去され、洗濯液状態検出部40の検出性能の低下が抑制される。

Furthermore, also in the rinsing step, by driving the circulation pump 39, the washing liquid with less dirt components circulates through the washing liquid state detection unit 40. As a result, the washing liquid with a small amount of dirt components cleans the washing liquid state detection unit 40. That is, the detergent component and dirt adhering at the washing step are removed, and the deterioration of the detection performance of the washing liquid state detection unit 40 is suppressed.

なお、循環経路37の吐出口38は、外槽24の下方の1箇所に設けた構成を説明したが、循環経路37を分岐し、吐出口38を複数個所に設け、内槽25に向かって同時に洗濯液を噴射する構成でもよい。また、循環経路37を複数に分岐した一部から、内槽25と外槽24との間に噴射する吐出口38を構成してもよい。

In addition, although the discharge port 38 of the circulation path 37 demonstrated the structure provided in one place under the outer tank 24, the circulation path 37 is branched, the discharge port 38 is provided in several places, and it goes to the inner tank 25. The structure which injects washing liquid simultaneously may be sufficient. Moreover, you may comprise the discharge port 38 which injects between the inner tank 25 and the outer tank 24 from the part which branched the circulation path 37 into plurality.

また、循環ポンプ39は、洗いステップ時および濯ぎステップ時に、駆動と停止を繰り返す間欠運転される。循環ポンプ39の駆動時は、泡や汚れの粒子が洗濯液に混ざって循環されるため、汚れ度合いは大きいと検出され、しかも検出値のバラツキが大きい。このため、洗濯液状態検出部40は、循環ポンプ39を停止させた状態で、洗濯液の状態を検出することにより、安定した、精度の高い検出を行う。したがって、汚れの推定精度が向上する。また、循環ポンプ39の停止後も、泡の影響などにより、検出値はしばらくは安定しない。このため、循環ポンプ39を所定時間停止させた後に検出を行う。または、検出された濁度の変化幅が所定以下になったときに、検出値として採用することにより、検出の精度が向上する。また、複数の検出値を平均化するなどの演算を行うことにより、さらに誤差を排除し、検出精度が高まる。また、洗濯液状態検出部40としては1秒間隔など、常に計測を行い、必要な情報のみを使用することができる。

In addition, the circulation pump 39 is intermittently operated repeatedly during driving and stopping during the washing step and the rinsing step. When the circulation pump 39 is driven, bubbles and dirt particles are mixed and circulated in the washing liquid, so that the degree of dirt is detected to be large, and the detection value varies greatly. For this reason, the washing liquid state detection unit 40 performs stable and highly accurate detection by detecting the state of the washing liquid while the circulation pump 39 is stopped. Therefore, the estimation accuracy of dirt is improved. Further, even after the circulation pump 39 is stopped, the detected value is not stable for a while due to the influence of bubbles or the like. For this reason, the detection is performed after the circulation pump 39 is stopped for a predetermined time. Alternatively, when the detected turbidity change width becomes equal to or less than a predetermined value, the detection accuracy is improved by adopting it as a detection value. Further, by performing an operation such as averaging a plurality of detection values, errors are further eliminated and detection accuracy is increased. Further, the washing liquid state detection unit 40 can always perform measurement such as 1 second intervals and use only necessary information.

また、電極センサ42に関しても光センサ41と同様であり、循環ポンプ39の停止時に計測することにより、検出の精度が向上する。なお、光センサ41による濁度の検出と、電極センサ42による導電率の検出とは、同じタイミングで行う必要はなく、各々の特徴に応じたタイミングで行えばよい。また、精度に問題がなければ、循環ポンプ39の駆動中に洗濯液の汚れ度合いを検出し、洗濯物の汚れ度合いを推定してもよい。

Also, the electrode sensor 42 is the same as the optical sensor 41, and the measurement accuracy is improved by measuring when the circulation pump 39 is stopped. Note that the turbidity detection by the optical sensor 41 and the conductivity detection by the electrode sensor 42 do not have to be performed at the same timing, and may be performed at a timing according to each feature. If there is no problem in accuracy, the degree of dirt on the laundry may be detected by detecting the degree of dirt on the laundry while the circulation pump 39 is being driven.

また、循環経路37への洗濯液の循環は、撹拌部である内槽25の回転により行うのではなく、循環ポンプ39により行うため、洗浄を行う撹拌部の駆動を停止させることなく、洗濯液の循環を停止させることができる。このため、洗浄力は確保しつつ、かつ、高い検出精度を得ることができる。さらに、循環ポンプ39の回転速度を、洗いステップや濯ぎのステップの進行に応じて変化させることにより、衣類への洗濯液の浸透や、泡立ち度合いなどを勘案した、より高い検出精度を得ることができる。

In addition, the circulation of the washing liquid to the circulation path 37 is not performed by the rotation of the inner tub 25 that is the agitation unit, but is performed by the circulation pump 39. The circulation of can be stopped. For this reason, high detection accuracy can be obtained while ensuring cleaning power. Furthermore, by changing the rotational speed of the circulation pump 39 according to the progress of the washing step and the rinsing step, higher detection accuracy can be obtained in consideration of the penetration of the washing liquid into the clothes, the degree of foaming, and the like. it can.

また、外槽24の洗濯液は、撹拌部である内槽25の回転によって撹拌される。このため、内槽25の回転は、洗濯液状態検出部40の検出に影響を与え、検出誤差を生じさせる。循環ポンプ39の運転と駆動モータ26の運転(つまり内槽25の回転)とを同期させることにより、この検出誤差が低減される。つまり、制御部46は、循環ポンプ39の駆動および停止と、駆動モータ26の正方向への駆動(以下、正転と言う)、停止および正方向とは逆方向への駆動(以下、反転と言う)とを同期させる。これにより、一定の条件で、洗濯液状態検出部40による検出が行われる。具体的には、例えば、制御部46は、循環ポンプ39を1分間駆動し、その後1分間停止する動作を繰り返す。この2分間を1サイクルとする。この場合、制御部46は、1サイクル中に駆動モータ26を、30秒間正転させ、その後30秒間反転させる動作を2回繰り返す。この様に、循環ポンプ39と駆動モータ26との運転を同期させる。なお、上記の同期の取り方は一例であり、駆動時間と停止時間、あるいは正転時間と反転時間は同一である必要はない。また、循環ポンプ39の回転速度を途中で変更しても良い。さらに、洗いステップの途中で同期の取り方を変更しても良い。

Further, the washing liquid in the outer tub 24 is stirred by the rotation of the inner tub 25 that is a stirring portion. For this reason, the rotation of the inner tub 25 affects the detection of the washing liquid state detection unit 40 and causes a detection error. This detection error is reduced by synchronizing the operation of the circulation pump 39 and the operation of the drive motor 26 (that is, the rotation of the inner tank 25). That is, the control unit 46 drives and stops the circulation pump 39, drives the drive motor 26 in the forward direction (hereinafter referred to as forward rotation), and stops and drives in the direction opposite to the forward direction (hereinafter referred to as inversion). Say). Thereby, the detection by the washing liquid state detection unit 40 is performed under a certain condition. Specifically, for example, the controller 46 repeats the operation of driving the circulation pump 39 for 1 minute and then stopping for 1 minute. This 2 minutes is one cycle. In this case, the control unit 46 repeats the operation of rotating the drive motor 26 normally for 30 seconds and then reversing for 30 seconds in one cycle twice. In this way, the operations of the circulation pump 39 and the drive motor 26 are synchronized. Note that the above-described method of synchronization is an example, and the drive time and the stop time, or the forward rotation time and the inversion time are not necessarily the same. Moreover, you may change the rotational speed of the circulation pump 39 in the middle. Further, the synchronization method may be changed during the washing step.

また、制御部46が、循環ポンプ39が停止した所定時間後に、駆動モータ26を停止させて、内槽25の回転を止めると、循環ポンプ39および駆動モータ26の両方が停止した状態となる。この時点あるいはこの時点の前後での、洗濯液状態検出部40による検出を行うことにより、誤差が少なくなる。なおこの場合、駆動モータ26の停止は、正転と反転との間にわずかに設けるだけでも効果を有する。

Further, when the control unit 46 stops the drive motor 26 and stops the rotation of the inner tank 25 after a predetermined time after the circulation pump 39 is stopped, both the circulation pump 39 and the drive motor 26 are stopped. By performing the detection by the washing liquid state detection unit 40 at this time or before and after this time, the error is reduced. In this case, the stop of the drive motor 26 is effective even if it is provided only slightly between the forward rotation and the reverse rotation.

ここで、循環経路37の吐出口38は、図2に示すように、外槽24と内槽25との隙間から内槽25の内部に向けて、洗濯液を噴射するように設けられる。この構成により、循環した洗濯液が衣類等の洗濯物に当たり、洗濯物の濡れが促進されるなど、洗濯機の洗浄力が向上する。

Here, as shown in FIG. 2, the discharge port 38 of the circulation path 37 is provided so as to inject the washing liquid from the gap between the outer tub 24 and the inner tub 25 toward the inside of the inner tub 25. With this configuration, the washing power of the washing machine is improved, for example, the circulated washing liquid hits the laundry such as clothes, and the wetting of the laundry is promoted.

また、循環ポンプ39の回転速度が所定の回転速度以上であれば、図2のBに示すように、洗濯液は、内槽25の内部へ噴射され、外槽24と内槽25との間で循環する。一方、循環ポンプ39の回転速度が所定の回転速度以下であれば、図6のDに示すように、洗濯液は、外槽24の内部を循環する。つまり、循環ポンプ39の回転速度を制御することにより、洗濯液が、内槽25の内部へ直接入らない状態と、内槽25の内外の両方に噴射される状態とを、必要に応じて切り換えることができる。これによる、洗濯液状態検出部40の検出精度の向上について以下に説明する。

If the rotation speed of the circulation pump 39 is equal to or higher than the predetermined rotation speed, the washing liquid is injected into the inner tub 25 as shown in FIG. Circulate with. On the other hand, if the rotational speed of the circulation pump 39 is equal to or lower than the predetermined rotational speed, the washing liquid circulates inside the outer tub 24 as shown in FIG. That is, by controlling the rotational speed of the circulation pump 39, the washing liquid is switched between a state where the washing liquid does not enter the inside of the inner tub 25 and a state where the washing liquid is sprayed both inside and outside the inner tub 25 as necessary. be able to. The improvement of the detection accuracy of the washing liquid state detection unit 40 will be described below.

洗濯機の運転開始後に、給水弁30が開かれ、給水とともに洗剤投入部31に投入された洗剤は外槽24に流入する。この給水の段階で、循環ポンプ39を所定の回転速度以上で駆動させると、洗剤濃度の高い洗濯液が、吐出口38から内槽25の内部に噴射される。この場合、洗剤濃度の高い洗濯液が衣類等に吸収されると、外槽24に溜まった洗濯液の洗剤濃度は低下する。給水開始直後の洗濯液は、ほぼ洗剤のみが溶けた状態である。この状態の洗濯液を洗濯液状態検出部40により検出し、洗剤の種類が粉末洗剤か液体洗剤かを見分けることができる。また、この検出結果を洗いステップ開始前の洗濯液の初期値として利用することができる。しかしながら、この状態の洗濯液を内槽25の内部に大量に噴射すると、上記の様な、洗剤の種類の見分けや、洗濯液の初期値としての利用ができない。そこで、洗濯開始直後の給水中においては、循環ポンプ39の回転速度を所定の回転速度以下とし、洗濯液を、吐出口38から内槽25の内部へ噴射させず、外槽24の下方に落下させる。これにより、洗剤の種類の見分けや、洗いステップ開始前の洗濯液の初期状態の検出精度が向上する。なお、洗濯液を衣類へ噴射させないために、循環ポンプ39による洗濯液の循環を止めた場合は、洗濯液状態検出部40に溜まった洗濯液と外槽24に溜まった洗濯液との均一化が行われないため、検出精度が悪化する。つまり、上記の通り、洗濯液を吐出口38から外槽24の下方に落下させ、外槽24の内部で循環させることにより、洗剤の溶解が促進され、洗濯液が均一化される。その後、洗いステップの途中からは、洗濯液を洗濯物に対して噴射することにより、洗浄効果が高まるとともに、洗濯物からの汚れの溶け出しが早くなり、早い段階で汚れ量を推定することができる。このように、循環ポンプ39の回転速度を制御することにより、1個の循環ポンプ39および循環経路37を用いて精度の高い汚れ判定を行うことができる。