WO2010001497A1 - Semiconductor die pickup apparatus and semiconductor die pickup method - Google Patents

Semiconductor die pickup apparatus and semiconductor die pickup method Download PDFInfo

- Publication number

- WO2010001497A1 WO2010001497A1 PCT/JP2008/064516 JP2008064516W WO2010001497A1 WO 2010001497 A1 WO2010001497 A1 WO 2010001497A1 JP 2008064516 W JP2008064516 W JP 2008064516W WO 2010001497 A1 WO2010001497 A1 WO 2010001497A1

- Authority

- WO

- WIPO (PCT)

- Prior art keywords

- semiconductor die

- lid

- holding sheet

- stage

- contact surface

- Prior art date

Links

Images

Classifications

-

- H—ELECTRICITY

- H01—ELECTRIC ELEMENTS

- H01L—SEMICONDUCTOR DEVICES NOT COVERED BY CLASS H10

- H01L21/00—Processes or apparatus adapted for the manufacture or treatment of semiconductor or solid state devices or of parts thereof

- H01L21/67—Apparatus specially adapted for handling semiconductor or electric solid state devices during manufacture or treatment thereof; Apparatus specially adapted for handling wafers during manufacture or treatment of semiconductor or electric solid state devices or components ; Apparatus not specifically provided for elsewhere

- H01L21/683—Apparatus specially adapted for handling semiconductor or electric solid state devices during manufacture or treatment thereof; Apparatus specially adapted for handling wafers during manufacture or treatment of semiconductor or electric solid state devices or components ; Apparatus not specifically provided for elsewhere for supporting or gripping

- H01L21/6835—Apparatus specially adapted for handling semiconductor or electric solid state devices during manufacture or treatment thereof; Apparatus specially adapted for handling wafers during manufacture or treatment of semiconductor or electric solid state devices or components ; Apparatus not specifically provided for elsewhere for supporting or gripping using temporarily an auxiliary support

-

- H—ELECTRICITY

- H01—ELECTRIC ELEMENTS

- H01L—SEMICONDUCTOR DEVICES NOT COVERED BY CLASS H10

- H01L21/00—Processes or apparatus adapted for the manufacture or treatment of semiconductor or solid state devices or of parts thereof

- H01L21/67—Apparatus specially adapted for handling semiconductor or electric solid state devices during manufacture or treatment thereof; Apparatus specially adapted for handling wafers during manufacture or treatment of semiconductor or electric solid state devices or components ; Apparatus not specifically provided for elsewhere

- H01L21/67005—Apparatus not specifically provided for elsewhere

- H01L21/67011—Apparatus for manufacture or treatment

- H01L21/67132—Apparatus for placing on an insulating substrate, e.g. tape

-

- H—ELECTRICITY

- H01—ELECTRIC ELEMENTS

- H01L—SEMICONDUCTOR DEVICES NOT COVERED BY CLASS H10

- H01L21/00—Processes or apparatus adapted for the manufacture or treatment of semiconductor or solid state devices or of parts thereof

- H01L21/67—Apparatus specially adapted for handling semiconductor or electric solid state devices during manufacture or treatment thereof; Apparatus specially adapted for handling wafers during manufacture or treatment of semiconductor or electric solid state devices or components ; Apparatus not specifically provided for elsewhere

- H01L21/683—Apparatus specially adapted for handling semiconductor or electric solid state devices during manufacture or treatment thereof; Apparatus specially adapted for handling wafers during manufacture or treatment of semiconductor or electric solid state devices or components ; Apparatus not specifically provided for elsewhere for supporting or gripping

- H01L21/6835—Apparatus specially adapted for handling semiconductor or electric solid state devices during manufacture or treatment thereof; Apparatus specially adapted for handling wafers during manufacture or treatment of semiconductor or electric solid state devices or components ; Apparatus not specifically provided for elsewhere for supporting or gripping using temporarily an auxiliary support

- H01L21/6836—Wafer tapes, e.g. grinding or dicing support tapes

-

- H—ELECTRICITY

- H01—ELECTRIC ELEMENTS

- H01L—SEMICONDUCTOR DEVICES NOT COVERED BY CLASS H10

- H01L2221/00—Processes or apparatus adapted for the manufacture or treatment of semiconductor or solid state devices or of parts thereof covered by H01L21/00

- H01L2221/67—Apparatus for handling semiconductor or electric solid state devices during manufacture or treatment thereof; Apparatus for handling wafers during manufacture or treatment of semiconductor or electric solid state devices or components; Apparatus not specifically provided for elsewhere

- H01L2221/683—Apparatus for handling semiconductor or electric solid state devices during manufacture or treatment thereof; Apparatus for handling wafers during manufacture or treatment of semiconductor or electric solid state devices or components; Apparatus not specifically provided for elsewhere for supporting or gripping

- H01L2221/68304—Apparatus for handling semiconductor or electric solid state devices during manufacture or treatment thereof; Apparatus for handling wafers during manufacture or treatment of semiconductor or electric solid state devices or components; Apparatus not specifically provided for elsewhere for supporting or gripping using temporarily an auxiliary support

- H01L2221/68318—Auxiliary support including means facilitating the separation of a device or wafer from the auxiliary support

- H01L2221/68322—Auxiliary support including means facilitating the selective separation of some of a plurality of devices from the auxiliary support

-

- H—ELECTRICITY

- H01—ELECTRIC ELEMENTS

- H01L—SEMICONDUCTOR DEVICES NOT COVERED BY CLASS H10

- H01L2221/00—Processes or apparatus adapted for the manufacture or treatment of semiconductor or solid state devices or of parts thereof covered by H01L21/00

- H01L2221/67—Apparatus for handling semiconductor or electric solid state devices during manufacture or treatment thereof; Apparatus for handling wafers during manufacture or treatment of semiconductor or electric solid state devices or components; Apparatus not specifically provided for elsewhere

- H01L2221/683—Apparatus for handling semiconductor or electric solid state devices during manufacture or treatment thereof; Apparatus for handling wafers during manufacture or treatment of semiconductor or electric solid state devices or components; Apparatus not specifically provided for elsewhere for supporting or gripping

- H01L2221/68304—Apparatus for handling semiconductor or electric solid state devices during manufacture or treatment thereof; Apparatus for handling wafers during manufacture or treatment of semiconductor or electric solid state devices or components; Apparatus not specifically provided for elsewhere for supporting or gripping using temporarily an auxiliary support

- H01L2221/68327—Apparatus for handling semiconductor or electric solid state devices during manufacture or treatment thereof; Apparatus for handling wafers during manufacture or treatment of semiconductor or electric solid state devices or components; Apparatus not specifically provided for elsewhere for supporting or gripping using temporarily an auxiliary support used during dicing or grinding

-

- H—ELECTRICITY

- H01—ELECTRIC ELEMENTS

- H01L—SEMICONDUCTOR DEVICES NOT COVERED BY CLASS H10

- H01L2221/00—Processes or apparatus adapted for the manufacture or treatment of semiconductor or solid state devices or of parts thereof covered by H01L21/00

- H01L2221/67—Apparatus for handling semiconductor or electric solid state devices during manufacture or treatment thereof; Apparatus for handling wafers during manufacture or treatment of semiconductor or electric solid state devices or components; Apparatus not specifically provided for elsewhere

- H01L2221/683—Apparatus for handling semiconductor or electric solid state devices during manufacture or treatment thereof; Apparatus for handling wafers during manufacture or treatment of semiconductor or electric solid state devices or components; Apparatus not specifically provided for elsewhere for supporting or gripping

- H01L2221/68304—Apparatus for handling semiconductor or electric solid state devices during manufacture or treatment thereof; Apparatus for handling wafers during manufacture or treatment of semiconductor or electric solid state devices or components; Apparatus not specifically provided for elsewhere for supporting or gripping using temporarily an auxiliary support

- H01L2221/68327—Apparatus for handling semiconductor or electric solid state devices during manufacture or treatment thereof; Apparatus for handling wafers during manufacture or treatment of semiconductor or electric solid state devices or components; Apparatus not specifically provided for elsewhere for supporting or gripping using temporarily an auxiliary support used during dicing or grinding

- H01L2221/68336—Apparatus for handling semiconductor or electric solid state devices during manufacture or treatment thereof; Apparatus for handling wafers during manufacture or treatment of semiconductor or electric solid state devices or components; Apparatus not specifically provided for elsewhere for supporting or gripping using temporarily an auxiliary support used during dicing or grinding involving stretching of the auxiliary support post dicing

Definitions

- the present invention relates to a structure of a pickup device for a semiconductor die and a pickup method.

- the semiconductor die is manufactured by cutting a wafer having a size of 6 inches or 8 inches into a predetermined size. At the time of cutting, an adhesive holding tape is attached to the back surface so that the cut semiconductor dies do not fall apart, and the wafer is cut from the front side with a dicing saw or the like. At this time, the holding tape attached to the back surface is slightly cut, but is not cut and holds each semiconductor die. Each cut semiconductor die is picked up from the holding tape one by one and sent to the next process such as die bonding.

- this method using the push-up needle has a problem that the semiconductor die is broken by the push-up when the thickness of the semiconductor die is reduced, and it has become difficult to use it for the pickup of a thin semiconductor die in recent years. .

- Patent Document 1 a semiconductor die to be picked up is placed on a suction hole of a stage having a plurality of suction holes, and the suction hole is held in a vacuum while the semiconductor die is sucked and held on a collet. The sheet is sucked into each suction hole, deformed, the part of the holding sheet corresponding to the suction hole is peeled off from the semiconductor die, and then the stage is moved or rotated to hold the remaining part without being peeled off. There has been proposed a method of peeling a sheet from a semiconductor die (see FIGS. 1 to 4 of Patent Document 1).

- Patent Document 1 a protrusion having a narrower width than the semiconductor die to be picked up is provided on the surface of the stage, a suction hole is provided in the stage surface around the protrusion, and the semiconductor die is picked up.

- the semiconductor die to be picked up on the projecting part is placed so as to protrude from the projecting part, and is sucked and held by a collet, and the holding sheet of the part protruding from the projecting part is vacuum-sucked by the suction hole and the semiconductor sheet is held out of the projecting part.

- Patent Document 1 The method described in Patent Document 1 is a method in which the suction hole is evacuated, the holding tape is sucked into the suction hole, and the holding tape is peeled off from the semiconductor die. Since the surface is covered, air cannot be sucked from the portion around the suction hole after the holding tape just above the suction hole is peeled off. For this reason, the holding sheet directly above the suction hole can be peeled off by suction, but the portion around the suction hole cannot be peeled off by vacuum suction of the suction hole and remains in a state of being adhered to the semiconductor die. (See FIGS. 1 and 2 of Patent Document 1).

- the stage when the stage is moved to separate the peeled remaining portion of the holding sheet, the smaller the area of the remaining portion, the less the force applied to the semiconductor die, and the damage to the semiconductor die can be suppressed.

- the suction hole in order to reduce the remaining portion to be peeled off by the suction hole, it is necessary to make the suction hole large in accordance with the size of the semiconductor to be picked up. If the holding sheet is sucked at once by such a large suction hole, a large force may be applied to the semiconductor die when the adhesive force of the holding sheet is large.

- recent semiconductor dies are thin and low in strength, and this force may cause cracking or deformation.

- Patent Document 1 Another method described in Patent Document 1 is to evacuate a small suction hole arranged only around the protruding portion to peel off the portion of the semiconductor die holding sheet protruding from the protruding portion, Because the holding sheet of the semiconductor die is peeled off by the tensile force applied to the holding sheet, it is necessary to increase the height of the protruding part in order to reliably peel off the holding sheet. If there is a semiconductor die adjacent in the direction, the protrusion may hit the semiconductor die and damage the semiconductor die, so the height of the protrusion is limited and the holding sheet cannot be peeled off reliably. There was a problem.

- an object of the present invention is to easily pick up a semiconductor die while suppressing a force applied to the semiconductor die when the holding sheet is peeled off in a semiconductor die pickup apparatus.

- the semiconductor die pick-up device of the present invention is a semiconductor die pick-up device for picking up a semiconductor die attached to a holding sheet, and is in close contact with the surface of the holding sheet opposite to the surface to which the semiconductor die is attached.

- a cylindrical stage including a close contact surface, a suction opening provided on the close contact surface and extending in a straight line from the inner periphery side to the outer periphery side of the stage with substantially the same width as the semiconductor die to be picked up, and the width of the suction opening It is provided on the stage so that the tip on the side that closes the suction opening can move forward from the contact surface with approximately the same width, slide along the contact surface to open and close the suction opening, and let the tip of the lid advance from the contact surface

- the surface that pushes up the holding sheet of the lid is inclined downward from the front end side of the lid toward the rear end side of the lid opening side, and is recessed from the contact surface by the thickness of the lid.

- the inclination angle of the inclined surface with respect to the contact surface is preferably larger than the inclination angle with respect to the contact surface of the surface opposite to the surface that pushes up the holding sheet of the lid, A step portion extending from the inclined surface to the outer peripheral surface of the stage along the contact surface is provided. It is also preferable that the inclination angle is larger than the inclination angle of the contact surface, and the inclination surface is also preferably a plane substantially perpendicular to the contact surface.

- a pin is provided that extends in the width direction of the suction opening, and includes a slider that slides in the direction in which the suction opening extends by a slider drive mechanism provided inside the stage and moves forward and backward with respect to the contact surface. It is also preferable that the lid includes an arm projecting from the tip to the side of closing the suction opening and is rotatably attached to the slider pin via the arm.

- the semiconductor die pick-up method of the present invention is a semiconductor die pick-up method for picking up a semiconductor die attached to a holding sheet, wherein the semiconductor die of the holding sheet to which the semiconductor die to be picked up is attached is attached.

- a cylindrical stage including a contact surface that is in close contact with the surface opposite to the surface on which it is located, and a linear surface extending from the inner periphery side of the stage toward the outer periphery side with the same width as the semiconductor die to be picked up, provided on the contact surface

- the suction opening and the width of the suction opening are substantially the same width, provided on the stage so that the tip of the suction opening closing side can be advanced from the contact surface, slide along the contact surface to open and close the suction opening, When the front end of the lid is advanced from the contact surface, the surface that pushes up the holding sheet of the lid is inclined downward from the front end side of the lid toward the rear end side of the lid opening side.

- a semiconductor die pick-up device comprising a collet for adsorbing the die is prepared, one end of the semiconductor die to be picked up is aligned with the tip of the closed lid, and the width direction position of the lid and the width direction position of the semiconductor die are Alignment process, the tip of the lid is advanced from the contact surface, the holding sheet and the semiconductor die are pushed up, and the surface on the opposite side of the lid from which the holding sheet is pushed up is inclined with the bottom surface of the slide groove Slide the lid from one end to the other end of the semiconductor die to be picked up while making contact with the edge with the surface to open the suction openings sequentially, and pick up the open suction opening from one end of the semiconductor die to the other end.

- the holding sheet is sequentially sucked toward and picked up from the semiconductor die to be picked up sequentially, and the semiconductor die is sequentially adsorbed from one end side to the other end side on the collet waiting immediately above the semiconductor die to be picked up, A pickup step of picking up a semiconductor die.

- the present invention provides an effect that a semiconductor die can be easily picked up while suppressing a force applied to the semiconductor die when the holding sheet is peeled off in the semiconductor die pick-up device.

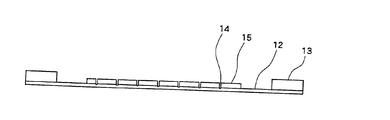

- an adhesive holding sheet 12 is attached to the back surface of the wafer 11, and the holding sheet 12 is attached to a metal ring 13.

- the wafer 11 is handled in such a state that it is attached to the metal ring 13 via the holding sheet 12 in this way.

- the wafer 11 is cut by a dicing saw or the like from the surface side into a semiconductor die 15 in the cutting process.

- a notch gap 14 formed during dicing is formed between the semiconductor dies 15. The depth of the cut gap 14 reaches from the semiconductor die 15 to a part of the holding sheet 12, but the holding sheet 12 is not cut and each semiconductor die 15 is held by the holding sheet 12.

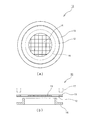

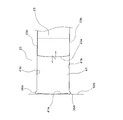

- the wafer holder 10 includes an annular expand ring 16 having a flange portion and a ring presser 17 for fixing the ring 13 on the flange of the expand ring 16.

- the ring retainer 17 is driven in a direction to advance and retract toward the flange of the expand ring 16 by a ring retainer drive unit (not shown).

- the inner diameter of the expand ring 16 is larger than the diameter of the wafer on which the semiconductor die 15 is arranged, the expand ring 16 has a predetermined thickness, and the flange is outside the expand ring 16 and is separated from the holding sheet 12.

- the wafer holder 10 is configured to be movable in a direction along the surface of the holding sheet 12 by a wafer holder horizontal direction drive unit (not shown).

- the holding sheet 12 to which the semiconductor die 15 is attached is in a substantially planar state before being set on the expanding ring 16.

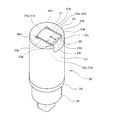

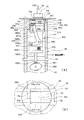

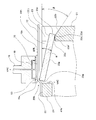

- FIG. 4 is a diagram showing a configuration of the semiconductor die pick-up apparatus 100, and FIG. 4 shows a state in which the semiconductor die 15 attached to the holding sheet 12 is set in the semiconductor die pick-up apparatus 100.

- the ring presser 17 is lowered on the ring 13, and the ring 13 is sandwiched between the flanges of the expand ring 16. Since there is a step between the upper surface where the holding sheet 12 of the expand ring 16 contacts and the flange surface, when the ring 13 is pressed against the flange surface, the holding sheet 12 is the same as the step between the upper surface of the expand ring 16 and the flange surface.

- the expansion ring 16 is stretched along the curved surface.

- the holding sheet 12 fixed on the expand ring 16 is subjected to a pulling force from the center of the holding sheet toward the periphery.

- a gap between the semiconductor dies 15 attached on the holding sheet 12 is widened.

- the wafer holder 10 is attached with a wafer holder horizontal direction driving unit 72 that moves the wafer holder 10 along a surface along the holding sheet 12.

- the wafer holder horizontal direction driving unit 72 may be, for example, a unit that drives the wafer holder 10 in the horizontal direction by a motor and a gear provided inside, or along a guide by a driving source such as a motor provided outside.

- the wafer holder 10 may be moved in the XY direction.

- a collet 18 for attracting and moving the semiconductor die 15 is provided on the wafer holder 10.

- the collet 18 includes suction holes 19 for sucking the semiconductor die 15 on the suction surface, and each suction hole 19 is connected to a vacuum device 71.

- a stage 20 is provided below the wafer holder 10, and the stage 20 is driven in a vertical direction that is an advancing / retreating direction with respect to the holding sheet 12 by a stage vertical direction driving mechanism 73.

- the stage vertical direction drive mechanism 73 may be, for example, a mechanism that drives the stage 20 in the vertical direction by a motor and a gear provided inside, or is vertically moved along a guide by a drive source such as a motor provided outside.

- the stage 20 may be moved in the direction.

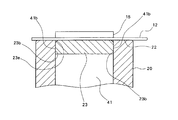

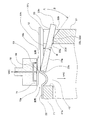

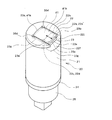

- the stage 20 has a cylindrical casing 21 having a close contact surface 22 in close contact with the holding sheet 12 on the upper surface thereof, and a base portion 24 provided on the opposite side of the close contact surface 22 of the casing 21. And a drive unit 25 that is attached to the base unit 24 and drives a slider drive mechanism 300 attached to the inside of the housing 21.

- the base portion 24 of the stage 20 is attached to a stage fixing portion (not shown).

- the suction opening 41 is provided in the contact surface 22, is substantially the same width as the semiconductor die 15 to be picked up shown in FIG. 4, and is longer than the semiconductor die 15, from the inner peripheral side of the stage 20 toward the outer peripheral side. It extends in a straight line.

- a lid 23 that slides along the direction in which the suction opening 41 extends and opens and closes the suction opening 41 is attached to the suction opening 41.

- the side of the lid 23 that closes the suction opening 41 along the sliding direction is the front end 23a, and the end on the side where the lid 23 opens is the rear end 23c.

- the side surface 23b of the lid 23 and the side surface 41b of the suction opening 41 constitute a slide surface. If the suction opening 41 has substantially the same width as the semiconductor die 15 to be picked up on the contact surface 22, a step is provided inside, and a slit communicating with the stage 20 is provided in the step portion. May be.

- the tip 23a of the lid 23 is a curved surface that is convex toward the side of closing the suction opening 41, and the end surface 41 a of the suction opening against which the tip 23 a of the lid 23 is pressed has a curved surface along the curved surface of the tip 23 a of the lid 23.

- the curved surface may be a cylindrical surface, a combination of cylindrical surfaces having a plurality of radii, or a curved surface having another shape.

- a longitudinal groove 364 that extends in the direction and sucks the holding sheet 12 is provided.

- the vertical groove 364 is configured by a fan-shaped cylindrical surface of approximately 270 degrees connected to the suction opening 41, and the tangent line 500 that contacts the cylindrical surface of each vertical groove 364 at both corners of the suction opening 41 is the cylindrical surface of the end surface 41a. It protrudes from the end face 41a in the direction in which the lid 23 is closed to a position that becomes a tangent.

- a vertical groove 364 having a fan-shaped cylindrical surface of approximately 270 degrees communicates the contact surface 22 and the inside of the housing 21.

- 7B when the one end 15a of the semiconductor die 15 is aligned with the end face 41a of the suction opening 41 or the tip 23a of the lid 23, a part of the semiconductor die 15 is part of the tip of the lid 23.

- the fan-shaped hatched portion that protrudes from 23 a and is approximately 90 degrees is located above the vertical groove 364.

- the surface on the holding sheet 12 side becomes substantially flush with the contact surface 22.

- a chamfered portion 23 e is provided around the surface of the lid 23, and when the lid 23 closes the suction opening 41, a small V-shaped groove is formed between the contact surface 22 and the lid 23.

- the width of the suction opening 41, the width of the lid 23, and the width of the semiconductor die 15 are substantially the same, and the side surfaces 41b of the suction opening 41 and the side surfaces 23b of the lid 23 slide. It touches.

- the stage 20 is recessed from the contact surface 22 by the thickness of the lid 23, and is substantially the same width as the lid 23 from the end of the suction opening 41 on the side where the lid 23 opens to the outer peripheral side of the stage 20.

- An extending slide groove 22a and an inclined surface 22b following the bottom surface 22a 'of the slide groove 22a are provided.

- the side surface 22h of the slide groove 22a is the same surface as the side surface 41b of the suction opening 41, and the side surface 23b of the lid 23 and the side surface 22h of the slide groove 22a constitute a slide surface.

- the bottom surface 22 a ′ of the slide groove 22 a is substantially parallel to the contact surface 22 and does not cover the cylindrical surface of the outer periphery of the stage 20, and is more than the position of the rear end 23 c of the lid 23 when the lid 23 closes the suction opening 41. It extends to the end 22c located at the stage inner peripheral side.

- the end 22c is linear, and the rear end 23c of the lid 23 projects slightly toward the outer periphery of the stage 20 from the end 22c of the slide groove 22a with the lid 23 closed.

- the inclined surface 22b is inclined downward from the end 22c of the sliding groove 22a in the direction opposite to the contact surface 22. Side surfaces 22j that are flush with the side surface 22h of the sliding groove 22a extend on both sides of the inclined surface 22b.

- the side surface 22j and the side surface 23b of the lid 23 constitute a slide surface.

- a line of intersection between the inclined surface 22b and the bottom surface 22a 'of the slide groove 22a forms a linear ridge line edge 22d extending in a direction perpendicular to the slide direction of the lid 23.

- the rear end 23c of the lid 23 protrudes to the outer peripheral side of the stage 20 from the end 22c of the slide groove 22a and the edge 22d in a state where the lid 23 closes the suction opening 41.

- the lower surface 23g which is the surface opposite to the surface to be pushed up, is supported by the edge 22d.

- a slider drive mechanism 300 for sliding a slider 332 to which a lid 23 is rotatably attached is provided inside the stage 20.

- the slider drive mechanism 300 is slidably attached to the first link 326 driven in the forward and backward direction with respect to the contact surface 22 by the drive unit 25 attached to the base portion 24 of the stage 20 and the housing 21 of the stage 20.

- a piston 370 that moves forward and backward with respect to the contact surface 22; a stopper 321a that is provided inside the housing 21 and that engages with a flange 371 of the piston 370 to limit the movement of the piston 370 in the forward / backward direction; A spring 373 that connects one link 326 and the piston 370 in a direction that advances and retreats with respect to the contact surface 22; a guide rail 331 that is attached to the piston 370 and extends substantially parallel to the contact surface 22 and extends in the direction of the suction opening 41; A slider 332 slidably attached to the guide rail 331 and a piston 370 can be freely rotated by a pin 328.

- a cylindrical pin 330 extending in the width direction of the suction opening 41 is attached to the slider 332, and an inverted U-shape provided on an arm 23 f that protrudes from the tip 23 a of the lid 23 toward the closing side of the suction opening 41.

- the mold notch is rotatably engaged.

- casing 21 is connected to the vacuum apparatus 71, and is comprised so that an inside can be made into a vacuum.

- the pin 327 provided at one end enters the engagement groove 326a of the first link 326, and the engagement groove 329a provided at the other end sandwiches the pin 330a of the slider 332, whereby the first link 326 and the first link 326 are engaged with the first link 326.

- a link 326 is connected.

- a motor 381 for operating the slider drive mechanism 300 is attached inside the drive unit 25, and a cam that contacts a roller 326 c provided at the tip of the shaft 326 b of the first link 326 on the rotating shaft of the motor 381. 383 is attached.

- the slider drive mechanism 300 changes the operation of the first link 326 that moves in the forward and backward direction toward the contact surface 22 to the operation in the direction in which the slider 332 is moved in parallel with the contact surface 22 by the L-shaped second link 329. Since it is converted, the structure can be made compact, and the mechanism can be stored inside the cylindrical casing 21.

- a semiconductor die pick-up device 100 includes a control unit 70 which is a computer including a CPU and the like, and includes a driving unit 25, a vacuum device 71, a collet 18, a wafer holder horizontal driving unit 72, a stage.

- the vertical drive mechanism 73 is connected to each other, and the drive unit 25, vacuum device 71, collet 18 and wafer holder horizontal drive unit 72, and stage vertical drive mechanism 73 are configured to be driven by commands output from the control unit 70.

- a one-dot chain line indicates a signal line that connects the control unit 70, the drive unit 25, the vacuum device 71, the collet 18, the wafer holder horizontal direction drive unit 72, and the stage vertical direction drive mechanism 73.

- FIGS. 1 to 8 The portions described with reference to FIGS. 1 to 8 are denoted by the same reference numerals, and description thereof is omitted.

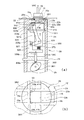

- the control unit 70 starts the alignment process between the lid 23 and the semiconductor die 15 with the lid 23 closed. Since the lid 23 is in a position where the suction opening 41 is closed, the tip 23a of the lid 23 is in contact with the end surface 41a of the suction opening 41, and the lower surface of the rear end 23c of the lid 23 is the surface of the slide groove 22a. And is supported by the slide groove 22a. Further, the surface of the lid 23 and the contact surface 22 are substantially the same surface.

- the controller 70 moves the wafer holder 10 horizontally above the standby position of the stage 20 by the wafer holder horizontal direction driving unit 72 shown in FIG.

- the controller 70 once stops the horizontal movement of the wafer holder 10, and the stage 20 is brought into close contact with the stage vertical drive mechanism 73.

- the stage 20 is raised until the surface 22 and the surface of the lid 23 are in close contact with the lower surface of the holding sheet 12.

- the control unit 70 stops raising the stage 20.

- the control unit 70 again aligns the one end 15a of the semiconductor die 15 to be picked up with the tip 23a of the lid 23 in the closed state by the wafer holder horizontal direction driving unit 72, and the position in the width direction of the lid 23 and the position of the semiconductor die 15

- the width direction position is adjusted and adjusted so that the side surface of the semiconductor die 15 matches the side surface 23 b of the lid 23. Since the width of the lid 23 is substantially the same as that of the semiconductor die 15 to be picked up, the position of each side surface of the semiconductor die 15 and each side surface 23b of the lid 23 when the one side surface 23b is aligned with the side surface of the semiconductor die 15. Can be combined.

- the holding sheet 12 receives a tensile force by the expanding ring 16 of the wafer holder 10.

- FIG. 9B is a plan view of the contact surface 22 of the stage 20 and the surface of the lid 23.

- the holding sheet 12 and the semiconductor die 15 placed thereon are indicated by a one-dot chain line so that the positional relationship can be understood.

- the lid 23 is shown slightly larger than the semiconductor die 15 in order to distinguish between the semiconductor die 15 and the lid 23 having substantially the same width.

- FIGS. 10B and 12B As shown in FIG. 9 (b), when the positions of the lid 23 and the semiconductor die 15 are aligned, the approximately 90-degree fan-shaped hatched portion of the semiconductor die 15 is located on the vertical groove 364.

- the control unit 70 ends the alignment process. Then, the control unit 70 moves to the position immediately above the semiconductor die 15 from which the collet 18 is to be picked up, and holds the collet 18 at a height with a slight gap. When the movement of the collet 18 is finished, the control unit 70 starts sucking air from the suction hole 19 by the vacuum device 71, and puts the collet 18 in a suction standby state of the semiconductor die 15.

- the control unit 70 starts the holding sheet peeling process.

- the control unit 70 evacuates the inside of the casing 21 of the stage 20 using the vacuum device 71.

- the vertical groove 364 communicating with the inside of the housing 21 shown in FIG. 10B is also evacuated, and the holding sheet 12 is attracted to the contact surface 22.

- the holding sheet 12 is pulled downward by the vacuum, but in this state, the holding sheet 12 is not yet peeled from the semiconductor die 15.

- the V-shaped groove between the chamfered portion 23e provided on the surface of the lid 23 shown in FIG. 8 and the suction opening 41 air flows from the outer peripheral side of the stage 20 toward the vertical groove 364 that becomes a vacuum. Flowing.

- the pressure in the V-shaped groove is lower than the atmospheric pressure, but the holding sheet 12 is not peeled off at this negative pressure.

- the cam 383 attached to the shaft of the motor 381 is rotated.

- the cam 383 has an elliptical shape, and the cam surface is in contact with the roller 326c attached to the tip of the shaft 326b of the first link 326.

- the cam surface of the cam 383 becomes the roller 326c. Is pushed up toward the contact surface 22.

- the shaft 326 b rises and the entire first link 326 rises toward the contact surface 22.

- the tip 23 a of the lid 23 advances upward from the contact surface 22, the tip 23 a of the lid 23 pushes up the holding sheet 12 and one end 15 a of the semiconductor die 15. Then, since the tip 23 a receives a downward force from the holding sheet 12, the lid 23 rotates clockwise about the pin 330.

- the lower surface 23g which is the surface opposite to the surface that pushes up the holding sheet 12 of the lid 23, is supported by an edge 22d between the slide groove 22a and the inclined surface 22b, and the surface of the rear end 23c on the holding sheet 12 side is in close contact. Since the surface is substantially flush with the surface 22, the surface of the lid 23 that pushes up the holding sheet 12 is inclined downward from the front end 23a side of the lid 23 toward the rear end 23c side.

- the inclination angle is an angle ⁇ with respect to the contact surface 22.

- the inclined surface 22b is inclined with respect to the contact surface 22 by an angle ⁇ larger than the angle ⁇ . For this reason, the inclined surface 22b does not hinder the movement of the rear end 23c of the lid 23, and the lower surface 23g of the lid 23 is always in line contact with the edge 22d.

- the lid 23 pushes up the semiconductor die 15 and the holding sheet 12 to be picked up.

- the holding sheets 12 at both corners of the semiconductor die 15 located on the vertical grooves 364 that have become vacuum are sucked and fixed to the contact surface 22.

- the holding sheet 12 attached to the semiconductor die 15 to be picked up is pulled obliquely downward toward the contact surface 22, and the diagonal downward pulling force causes the holding sheet 12 to be placed on the vertical groove 364.

- the holding sheet 12 begins to peel from both corners of the semiconductor die 15 positioned, and the approximately 90-degree fan-shaped holding sheet 12 positioned on the longitudinal groove 364 is peeled off.

- the holding sheet 12 of the substantially triangular portion of the semiconductor die 15 that protrudes from the tip 23 a of the lid 23 to the contact surface 22 is pulled obliquely downward toward the contact surface 22.

- the semiconductor die 15 is peeled from both sides in the width direction toward the center in the width direction.

- the peeling line 53 is formed at a position slightly closer to the sliding direction of the lid 23 than the one end 15 a of the semiconductor die 15.

- the portion of the semiconductor die 15 from which the holding sheet 12 is peeled loses the force drawn toward the contact surface 22 by the holding sheet 12.

- the pressure on the surface of the semiconductor die 15 on the collet 18 side is reduced by approaching the adsorption surface of the collet 18 by the upward movement of the tip 23a of the lid 23.

- the pressure of the surface of the semiconductor die 15 on the holding sheet 12 side becomes higher than the pressure on the collet 18 side, and the portion of the semiconductor die 15 peeled off from the holding sheet 12 is adsorbed by the collet 18.

- a portion of the semiconductor die 15 on the rear end 23c side of the lid 23 from the peeling line 53 where the holding sheet 12 has not yet been peeled is left with a slight gap between the semiconductor die 15 and the collet 18. Since the pressure difference between the holding sheet 12 side and the collet 18 side is not so large and there is a pulling force by the holding sheet 12, it is not yet adsorbed by the collet 18. For this reason, the semiconductor die 15 undergoes minute bending deformation between a portion adsorbed by the collet 18 and a portion not adsorbed by the collet 18.

- the peeling line 53 is a line extending from the side surface in the width direction of the semiconductor die 15 to the side surface along the tip 23 a of the lid 23, and in the portion along the side surface 23 b of the lid 23.

- the peeling line 53 does not extend.

- each side surface 23b of the lid 23 is in contact with each side surface 41b of the suction opening 41. It has become a state.

- the lower surface of the rear end 23c of the lid 23 is in contact with the surface of the slide groove 22a.

- the holding sheet 12 peeled off from the semiconductor die 15 is covered on the vertical groove 364. For this reason, since almost no air flows from the outside of the housing 21 toward the inside of the housing 21, the inside of the housing 21 is kept in a vacuum.

- the spring 373 of the slider drive mechanism 300 has such a stiffness that it hardly bends when the tip 23 a of the lid 23 is pushed up from the contact surface 22, the tip 23 a of the lid 23 has a predetermined advance height from the contact surface 22. Even if pushed up, the distance between the piston 370 and the first link 326 hardly changes. For this reason, the lid 23 only protrudes from the contact surface 22 by the rising of the first link 326 and does not slide.

- the pin 328 of the piston 370 does not rise with respect to the contact surface 22, and only the pin 327 of the second link 329 entering the engagement groove 326 a of the first link 326 rises in the direction of the contact surface 22. Then, the second link 329 starts to rotate around the pin 328. By this rotation operation, the engaging groove 329a at the other end of the second link 329 moves toward the outer periphery of the stage 20, and the slider 332 and the pin of the slider 332 to which the pin 330a in the engaging groove 329a is fixed.

- the lid 23 that is rotatably engaged with the 330 via the arm 23 f starts to slide toward the outer peripheral side of the stage 20.

- the tip 23a of the lid 23 is separated from the end face 41a of the suction opening 41, and the suction opening 41 is opened to have an opening having substantially the same width as the semiconductor die 15 to be picked up.

- An opening 42 is formed. Since the inside of the housing 21 of the stage 20 is in a vacuum state by the vacuum device 71, the opening opening 42 sucks the holding sheet 12 therein. Then, the holding sheet 12 is drawn into the opening portion 42 as the lid 23 slides, and is peeled off from the semiconductor die 15.

- the center in the width direction of the lid 23 from the adhesion surface 22 is a ridge line that rises in a mountain shape.

- each side surface 23 b side of the lid 23 is a line inclined toward the sliding direction from the center portion. For this reason, the holding sheet 12 on each side of the semiconductor die 15 is peeled off before the holding sheet 12 at the center portion in the width direction of the semiconductor die 15.

- the peeling line 53 is inclined with respect to the ends 15a and 15b of the semiconductor die 15 or with respect to the sliding direction in the plane along the contact surface 22, the portion adsorbed by the collet 18 and the collet The stress generated by a minute bending deformation between the portion not adsorbed by 18 is relieved, and damage to the semiconductor die 15 can be effectively suppressed.

- the opening portion 42 increases toward the outer peripheral side of the stage 20, and the peeling line 53 sequentially moves in parallel to the outer peripheral side of the stage 20.

- the holding sheet 12 is sequentially peeled from the one end 15 a to the other end 15 b of the semiconductor die 15 along the peeling line 53, and is sequentially sucked into the opening opening 42.

- the lower surface 23g opposite to the surface pushing up the holding sheet 12 of the lid 23 slides in contact with the edge 22d.

- the tangent line of the lower surface 23g of 23 is a seal line that separates the outside of the casing 21 at atmospheric pressure from the inside of the casing 21 in a vacuum state.

- the side surface 23b of the lid 23, the side surface 22j of the slide groove 22a, and the side surfaces 22h on both sides of the lid 23 and the inclined surface 22b constitute a slide surface.

- the opening portion 42 is covered by the peeled holding sheet 12, but the holding sheet 12 is sucked into the opening portion 42, and the tip 23 a of the lid 23 faces the portion where the holding sheet 12 is not peeled off. Therefore, the suction of the holding sheet 12 by the opening 42 is not stopped, and the entire holding sheet 12 is sequentially sucked from the one end 15a of the semiconductor die 15 to the other end 15b by the opening 42. It can be peeled off and the remaining part of the peeling can be prevented.

- the semiconductor die 15 is entirely adsorbed by the collet 18 and picked up by the collet 18.

- the cam 383 of the slider drive mechanism 300 After the semiconductor die 15 is picked up, when the cam 383 of the slider drive mechanism 300 further rotates according to a command from the control unit 70, the shaft 326b of the first link 326 is lowered due to the rotation of the cam 383.

- the lid 23 closes the suction opening 41 when the tip 23a is in contact with the end face 41a, sliding in the direction toward the end face 41a of the suction opening 41. Then, the compression force of the spring 373 is released.

- the cam 383 further rotates and the shaft 326b is lowered, the piston 370, the first link 326, and the second link 329 are both lowered, and the tip 23a of the lid 23 is lowered to substantially the same position as the surface of the contact surface 22. To return to the initial position.

- the lid 23 is slid in a state in which the tip 23a of the lid 23 is advanced upward from the contact surface 22, and substantially the same width as that of the semiconductor die 15 appearing immediately below the semiconductor die 15.

- the holding sheet 12 is sequentially pulled into the opening portion 42 of the suction opening 41 to sequentially peel off the holding sheet 12, and the semiconductor die 15 is sequentially placed on the collet 18 waiting immediately above the semiconductor die 15. Since the adsorption is performed, the semiconductor die 15 can be easily picked up while suppressing the force applied to the semiconductor die 15 when the holding sheet 12 is peeled off.

- the tip 23a of the lid 23 is advanced upward from the contact surface 22 in a state where the vertical groove 364 is evacuated, and the semiconductor die 15 is pushed up and picked up by the downward pulling force generated in the holding sheet 12. Since a trigger for peeling is created by peeling off the holding sheets 12 at both corners of the one end 15a of the semiconductor die 15, and then the lid 23 is slid to suck the holding sheet 12 into the opening 42, There is an effect that the holding sheet 12 can be peeled off more easily.

- the lid 23 is slid from the one end 15a side to the other end 15b side of the semiconductor die 15, and the holding sheet 12 is sequentially sucked into the opening opening 42 to peel off the holding sheet 12. Even if the opening portion 42 is covered by the holding sheet 12 sucked into the opening portion 42, the lid 23 slides toward the portion where the holding sheet 12 is not peeled, so that the entire holding sheet 12 is sequentially opened. The opening 42 can be sucked and peeled off, and the entire holding sheet 12 can be easily peeled off.

- the tip 23 a of the lid 23 is a curved surface

- the peeling line 53 is inclined with respect to the ends 15 a and 15 b of the semiconductor die 15 or with respect to the sliding direction within the plane along the contact surface 22.

- the part that advances upward from the contact surface 22 is a part of the vicinity of the tip 23a of the lid 23, and the rear end 23c of the lid 23 does not advance upward from the contact surface 22, so that the lid 23 is slid.

- the rear end 23c of the lid 23 does not collide with the adjacent semiconductor die 15, and the adjacent semiconductor die 15 is not damaged by the sliding of the lid 23. Therefore, even when there are adjacent semiconductor dies 15 around The semiconductor die 15 can be picked up.

- the stage 20 includes only a vertical movement in the advancing and retreating direction with respect to the holding sheet 12 by the stage vertical driving mechanism 73, and a moving mechanism with respect to the horizontal direction that is along the holding sheet 12. Therefore, there is no backlash of the mechanism in the horizontal direction, and the position stability in the direction along the holding sheet 12 is good. Further, since the alignment of the semiconductor die 15 to be picked up and the lid 23 in the direction along the surface of the holding sheet 12 is performed by the wafer holder horizontal direction driving unit 72, the horizontal position of the stage 20 is adjusted during the horizontal alignment. Is stable, and it is possible to reduce the occurrence of misalignment during alignment between the lid 23 of the stage 20 and the semiconductor die 15 attached to the holding sheet 12.

- FIGS. 1 to 13 Parts similar to those of the embodiment described with reference to FIGS. 1 to 13 are denoted by the same reference numerals and description thereof is omitted.

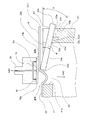

- the stage 20 is recessed from the contact surface 22 by the thickness of the lid 23, from the end of the suction opening 41 on the side where the lid 23 opens with substantially the same width as the lid 23 toward the outer peripheral side of the stage 20.

- the bottom surface 22a 'of the slide groove 22a a flat surface 22e substantially perpendicular to the contact surface 22 and a step portion 22f are provided.

- the side surface 22h of the slide groove 22a is the same surface as the side surface 41b of the suction opening 41, and the side surface 23b of the lid 23 and the side surface 22h of the slide groove 22a constitute a slide surface.

- the bottom surface 22a ′ of the slide groove 22a is substantially parallel to the contact surface 22 and does not cover the cylindrical surface on the outer periphery of the stage 20, and from the position of the rear end 23c of the lid 23 with the lid 23 closing the suction opening 41. Also extends to the end 22c at the position on the inner periphery side of the stage.

- the end 22c is linear, and the rear end 23c of the lid 23 protrudes slightly to the outer peripheral side of the stage 20 from the end 22c of the slide groove 22a with the lid 23 closed.

- the flat surface 22e extends vertically from the end 22c of the slide groove 22a in the direction opposite to the contact surface 22 and downward in the longitudinal direction of the housing 21.

- An intersection line between the flat surface 22e and the bottom surface 22a 'of the slide groove 22a forms an edge 22d of a linear ridge line extending in a direction perpendicular to the sliding direction of the lid 23.

- the flat surface 22e continues to a step 22f extending from the flat surface 22e to the outer peripheral surface of the housing 21 substantially in parallel with the contact surface 22. Since the step 22 f extends to the outer peripheral surface of the cylindrical casing 21, the outer peripheral end 22 g is an arc along the cylinder of the casing 21.

- Side surfaces 22j that are flush with the side surface 22h of the slide groove 22a extend on both sides of the step 22f.

- the side surface 22j and the side surface 23b of the lid 23 constitute a slide surface.

- the rear end 23c of the lid 23 protrudes to the outer peripheral side of the stage 20 from the end 22c of the slide groove 22a and the edge 22d in a state where the lid 23 closes the suction opening 41.

- the lower surface 23g which is the surface opposite to the surface to be pushed up, is supported by the edge 22d.

- the angle of the surface including the edge 22d and the outer peripheral side end 22g of the step portion 22f with respect to the contact surface 22 is an angle ⁇ , and the contact surface of the lower surface 23g of the lid 23 when the lid 23 slides.

- the inclination angle with respect to 22 is ⁇ . Since the angle ⁇ is always larger than the angle ⁇ with respect to the contact surface 22 of the lower surface 23g of the lid 23 even when the lid 23 is slid, the outer peripheral side end 22g of the step 22f does not interfere with the rear end 23c of the lid 23. While the lid 23 is sliding, the lower surface 23g of the lid 23 is always in line contact with the edge 22d.

- the lower surface 23g of the lid 23 opposite to the surface pushing up the holding sheet 12 slides in contact with the edge 22d, so the tangent between the edge 22d and the lower surface 23g of the lid 23 Is a seal line that separates the outside of the casing 21 at atmospheric pressure from the inside of the casing 21 in a vacuum state.

- the side surface 23b of the lid 23, the side surface 22j of the slide groove 22a, and the side surfaces 22h of the lid 23 and both sides of the step portion 22f constitute a slide surface.

- the step portion 22f has been described as extending from the flat surface 22e substantially perpendicular to the contact surface 22 toward the outer peripheral side of the stage 20, but as shown in FIG.

- an inclined surface 22 b is provided following the bottom surface 22 a ′ of the sliding groove 22 a, and the stepped portion 22 f may extend from the inclined surface 22 b toward the outer peripheral side of the stage 20.

- the angle of the inclined surface 22b with respect to the contact surface 22 is larger than the angle ⁇ with respect to the contact surface 22 of the surface including the edge 22d and the outer peripheral end 22g of the step portion 22f.

Abstract

A semiconductor die pickup apparatus is provided with a stage (20) including an adhering surface (22) to be adhered to a holding sheet (12); a suction opening (41) arranged on the adhering surface (22); a cover (23) which slides along the adhering surface (22) and opens/closes the suction opening (41); and a collet (18) for sucking a semiconductor die (15). At the time of picking up the semiconductor die (15), a leading end (23a) of the cover (23) is advanced from the adhering surface (22), and the cover (23) is slid while pressing up the holding sheet (12) and the semiconductor die (15) to successively open the suction hole (41). The holding sheet (12) is successively sucked by the opened suction opening (41) to successively pull and remove the holding sheet (12) from the semiconductor die (15), and at the same time, a collet (18) waiting directly above the semiconductor (15) is made to successively suck the semiconductor dies (15) to pickup the semiconductor dies (15). Thus, the semiconductor die pickup device easily picks up the semiconductor die while suppressing a force applied to the semiconductor die at the time of pulling and removing the holding sheet.

Description

本発明は、半導体ダイのピックアップ装置の構造及びピックアップ方法に関する。

The present invention relates to a structure of a pickup device for a semiconductor die and a pickup method.

半導体ダイは、6インチや8インチの大きさのウェーハを所定の大きさに切断して製造される。切断の際には切断した半導体ダイがバラバラにならないように、裏面に粘着性の保持テープを貼り付け、表面側からダイシングソーなどによってウェーハを切断する。この際、裏面に貼り付けられた保持テープは若干切り込まれるが切断されないで各半導体ダイを保持した状態となっている。そして切断された各半導体ダイは一つずつ保持テープからピックアップされてダイボンディング等の次の工程に送られる。

The semiconductor die is manufactured by cutting a wafer having a size of 6 inches or 8 inches into a predetermined size. At the time of cutting, an adhesive holding tape is attached to the back surface so that the cut semiconductor dies do not fall apart, and the wafer is cut from the front side with a dicing saw or the like. At this time, the holding tape attached to the back surface is slightly cut, but is not cut and holds each semiconductor die. Each cut semiconductor die is picked up from the holding tape one by one and sent to the next process such as die bonding.

従来、粘着性の保持テープから半導体ダイをピックアップする方法としては、突き上げ針による方法が多く用いられている(例えば、特許文献1の図15参照)。これは、コレットで半導体ダイを吸引した状態で、周囲に向かって引っ張り力が掛けられている保持シートの下側から突き上げ針によって半導体ダイの中央を突き上げ、保持シートに掛かっている引張り力によって半導体ダイから粘着性の保持シートを引き剥がし、コレットで半導体ダイをピックアップする方法である。

Conventionally, as a method of picking up a semiconductor die from an adhesive holding tape, a method using a push-up needle is often used (see, for example, FIG. 15 of Patent Document 1). This is because the semiconductor die is sucked by the collet and the center of the semiconductor die is pushed up from the lower side of the holding sheet on which the tensile force is applied toward the periphery by the push-up needle, and the semiconductor is pulled by the tensile force applied to the holding sheet. In this method, the adhesive holding sheet is peeled off from the die and the semiconductor die is picked up by a collet.

しかし、この突き上げ針による方法は半導体ダイの厚さが薄くなってくると突き上げによって半導体ダイが割れてしまうという問題があり、近年の薄型半導体ダイのピックアップには用いることが困難となってきている。

However, this method using the push-up needle has a problem that the semiconductor die is broken by the push-up when the thickness of the semiconductor die is reduced, and it has become difficult to use it for the pickup of a thin semiconductor die in recent years. .

そこで、突き上げ針を用いずに半導体ダイを粘着性の保持シートから分離、ピックアップする方法が提案されている。たとえば、特許文献1には、複数の吸引孔を備えるステージの吸引孔の上にピックアップしようとする半導体ダイを載せ、コレットにその半導体ダイを吸着保持させた状態で、吸引孔を真空にして保持シートを各吸引孔の中に吸い込んで変形させ、吸引孔に対応する部分の保持シートを半導体ダイから引き剥がした後、ステージを水平に移動または回転させることにより引き剥がされずに残った部分の保持シートを半導体ダイから引き剥がす方法が提案されている(特許文献1の図1から図4参照)。

Therefore, a method for separating and picking up a semiconductor die from an adhesive holding sheet without using a push-up needle has been proposed. For example, in Patent Document 1, a semiconductor die to be picked up is placed on a suction hole of a stage having a plurality of suction holes, and the suction hole is held in a vacuum while the semiconductor die is sucked and held on a collet. The sheet is sucked into each suction hole, deformed, the part of the holding sheet corresponding to the suction hole is peeled off from the semiconductor die, and then the stage is moved or rotated to hold the remaining part without being peeled off. There has been proposed a method of peeling a sheet from a semiconductor die (see FIGS. 1 to 4 of Patent Document 1).

また、特許文献1には、ステージの表面にピックアップしようとする半導体ダイよりも幅の狭い突出部を設け、突出部の周辺のステージ表面には吸引孔を設け、半導体ダイをピックアップする際には、突出部の上にピックアップしようとする半導体ダイを突出部からはみ出すように載せてコレットによって吸着保持し、吸引孔で保持シートを下方に真空吸引して突出部分からはみ出した部分の保持シートを半導体ダイより引き剥がし、その後、半導体ダイをコレットで吸着したまま突出部をステージ表面に対して水平に移動させて半導体ダイの残りの部分の保持シートを引き剥がす他の方法が提案されている(特許文献1の図9から図10参照)。

Further, in Patent Document 1, a protrusion having a narrower width than the semiconductor die to be picked up is provided on the surface of the stage, a suction hole is provided in the stage surface around the protrusion, and the semiconductor die is picked up. The semiconductor die to be picked up on the projecting part is placed so as to protrude from the projecting part, and is sucked and held by a collet, and the holding sheet of the part protruding from the projecting part is vacuum-sucked by the suction hole and the semiconductor sheet is held out of the projecting part. Another method has been proposed in which the semiconductor die is peeled off from the die, and then the protrusion is moved horizontally with respect to the stage surface while the semiconductor die is attracted by the collet to peel off the remaining sheet of the semiconductor die (patent) (See FIGS. 9 to 10 of Document 1).

特許文献1に記載された方法は、吸引孔を真空にして保持テープを吸引孔に吸い込み、保持テープを半導体ダイから引き剥がす方法であるが、保持テープは半導体ダイから引き剥がされると吸引孔の表面を覆ってしまうため、吸引孔の真上にある保持テープを引き剥がした後は吸引孔の周囲の部分から空気を吸い込むことができなくなる。このため、吸引孔の真上にある保持シートは吸引によって引き剥がすことができるが、吸引孔の周囲の部分は吸引孔の真空吸引によって引き剥がすことができず、半導体ダイと接着した状態が残ってしまう(特許文献1の図1、図2参照)。一方、ステージを移動させて、この引き剥がし残り部分の保持シートの分離を行う場合には、残り部分の面積が少ないほうが半導体ダイに加わる力が少なくなり半導体ダイの損傷を抑制することができる。しかし、吸引孔による引き剥がし残り部分を少なくしようとすると、吸引孔をピックアップする半導体の大きさにあわせた大きなものとすることが必要となる。この様に大きな吸引孔によって保持シートを一度に吸引すると保持シートの接着力が大きい場合には半導体ダイに大きな力がかかる場合がある。特に近年の半導体ダイは薄く強度が低いため、この力によって割れや変形が生じる場合がある。このように、特許文献に記載された方法は、大きな吸引孔を用いると吸引の際に半導体ダイに大きな力が加わってしまい、小さな吸引孔を用いるとステージの移動の際に半導体ダイに大きな力がかかってしまうので、保持シートの引き剥がしの際に半導体ダイにかかる力を抑制できず、半導体ダイの損傷を招く場合があるという問題があった。

The method described in Patent Document 1 is a method in which the suction hole is evacuated, the holding tape is sucked into the suction hole, and the holding tape is peeled off from the semiconductor die. Since the surface is covered, air cannot be sucked from the portion around the suction hole after the holding tape just above the suction hole is peeled off. For this reason, the holding sheet directly above the suction hole can be peeled off by suction, but the portion around the suction hole cannot be peeled off by vacuum suction of the suction hole and remains in a state of being adhered to the semiconductor die. (See FIGS. 1 and 2 of Patent Document 1). On the other hand, when the stage is moved to separate the peeled remaining portion of the holding sheet, the smaller the area of the remaining portion, the less the force applied to the semiconductor die, and the damage to the semiconductor die can be suppressed. However, in order to reduce the remaining portion to be peeled off by the suction hole, it is necessary to make the suction hole large in accordance with the size of the semiconductor to be picked up. If the holding sheet is sucked at once by such a large suction hole, a large force may be applied to the semiconductor die when the adhesive force of the holding sheet is large. In particular, recent semiconductor dies are thin and low in strength, and this force may cause cracking or deformation. As described above, in the method described in the patent document, if a large suction hole is used, a large force is applied to the semiconductor die during suction, and if a small suction hole is used, a large force is applied to the semiconductor die during the stage movement. Therefore, there is a problem that the force applied to the semiconductor die when the holding sheet is peeled off cannot be suppressed, and the semiconductor die may be damaged.

また、特許文献1に記載された他の方法は、突出部の周辺にのみ配置された小さな吸引孔を真空にすることによって突出部からはみ出た部分の半導体ダイの保持シートを引き剥がし、残りの部分の半導体ダイの保持シートの引き剥がしを保持シートにかかっている引張り力によって行うため、確実に保持シートの引き剥がしを行うためには突出部高さを高くする必要があり、突出部の移動方向に隣接する半導体ダイがある場合にはその半導体ダイに突出部が当たって半導体ダイを損傷させる場合があるので、突出部の高さが制限され、保持シートを確実に引き剥がすことができないという問題があった。

Another method described in Patent Document 1 is to evacuate a small suction hole arranged only around the protruding portion to peel off the portion of the semiconductor die holding sheet protruding from the protruding portion, Because the holding sheet of the semiconductor die is peeled off by the tensile force applied to the holding sheet, it is necessary to increase the height of the protruding part in order to reliably peel off the holding sheet. If there is a semiconductor die adjacent in the direction, the protrusion may hit the semiconductor die and damage the semiconductor die, so the height of the protrusion is limited and the holding sheet cannot be peeled off reliably. There was a problem.

そこで、本発明は、半導体ダイのピックアップ装置において、保持シートの引き剥がしの際に半導体ダイに加わる力を抑制しつつ半導体ダイを容易にピックアップすることを目的とする。

Therefore, an object of the present invention is to easily pick up a semiconductor die while suppressing a force applied to the semiconductor die when the holding sheet is peeled off in a semiconductor die pickup apparatus.

本発明の半導体ダイのピックアップ装置は、保持シートに貼り付けられた半導体ダイをピックアップする半導体ダイのピックアップ装置であって、保持シートの半導体ダイが貼り付けられている面と反対側の面に密着する密着面を含む円筒形のステージと、密着面に設けられ、ピックアップする半導体ダイと略同一幅でステージの内周側から外周側に向かって直線状に延びる吸引開口と、吸引開口の幅と略同一幅で、吸引開口を閉じる側の先端が密着面から進出自在となるようにステージに設けられ、密着面に沿ってスライドして吸引開口を開閉し、蓋の先端を密着面から進出させた際に、蓋の保持シートを押し上げる面が蓋の先端側から蓋が開く側の後端側に向かって下向きに傾斜する蓋と、密着面から蓋の厚さだけ凹み、蓋と略同一幅で、蓋が開く側の吸引開口の端から、ステージ外周の円筒面にかからない位置で蓋が吸引開口を閉じた状態での蓋の後端の位置よりもステージ内周側の位置まで、ステージ外周面に向かって延びるスライド用溝と、ステージ外周側端のスライド用溝の底面から密着面と反対側に向かって延びる傾斜面と、半導体ダイを吸着するコレットと、を備え、半導体ダイをピックアップする際に、蓋の先端を密着面から進出させ、保持シートと半導体ダイとを押し上げると共に、蓋の保持シートを押し上げる面と反対側の面をスライド用溝の底面と傾斜面とのエッジに接触させながら蓋をスライドさせて吸引開口を順次開き、開いた吸引開口に保持シートを順次吸引させてピックアップする半導体ダイから保持シートを順次引き剥がすと共にピックアップする半導体ダイの直上で待機しているコレットに半導体ダイを順次吸着させること、を特徴とする。

The semiconductor die pick-up device of the present invention is a semiconductor die pick-up device for picking up a semiconductor die attached to a holding sheet, and is in close contact with the surface of the holding sheet opposite to the surface to which the semiconductor die is attached. A cylindrical stage including a close contact surface, a suction opening provided on the close contact surface and extending in a straight line from the inner periphery side to the outer periphery side of the stage with substantially the same width as the semiconductor die to be picked up, and the width of the suction opening It is provided on the stage so that the tip on the side that closes the suction opening can move forward from the contact surface with approximately the same width, slide along the contact surface to open and close the suction opening, and let the tip of the lid advance from the contact surface When the cover is pressed, the surface that pushes up the holding sheet of the lid is inclined downward from the front end side of the lid toward the rear end side of the lid opening side, and is recessed from the contact surface by the thickness of the lid. The outer peripheral surface of the stage from the end of the suction opening on the opening side of the lid to the position on the inner peripheral side of the stage rather than the position of the rear end of the lid in a state where the lid closes the suction opening at a position that does not cover the cylindrical surface of the outer periphery of the stage When picking up a semiconductor die, a slide groove extending toward the surface, an inclined surface extending from the bottom surface of the slide groove on the outer periphery side of the stage toward the opposite side of the contact surface, and a collet that adsorbs the semiconductor die In addition, the front end of the lid is advanced from the contact surface, and the holding sheet and the semiconductor die are pushed up, and the surface opposite to the side of the lid that pushes up the holding sheet is brought into contact with the edge of the bottom surface of the slide groove and the inclined surface. Slide the lid to open the suction openings one after the other, pull the holding sheets sequentially from the semiconductor die to be picked up by sequentially sucking the holding sheets into the opened suction openings and pick up. Be sequentially adsorb semiconductor die collet waiting immediately above the semiconductor die to be, characterized by.

本発明の半導体ダイのピックアップ装置において、傾斜面の密着面に対する傾斜角度は、蓋の保持シートを押し上げる面と反対側の面の密着面に対する傾斜角度よりも大きいこと、としても好適であるし、傾斜面から密着面に沿ってステージ外周面まで延びる段部を備え、エッジと段部のステージ外周側端とを含む面の密着面に対する角度は、蓋の保持シートを押し上げる面と反対側の面の密着面に対する傾斜角度よりも大きいこと、としても好適であるし、傾斜面は、密着面に対して略直角な平面としても好適である。

In the semiconductor die pick-up device of the present invention, the inclination angle of the inclined surface with respect to the contact surface is preferably larger than the inclination angle with respect to the contact surface of the surface opposite to the surface that pushes up the holding sheet of the lid, A step portion extending from the inclined surface to the outer peripheral surface of the stage along the contact surface is provided. It is also preferable that the inclination angle is larger than the inclination angle of the contact surface, and the inclination surface is also preferably a plane substantially perpendicular to the contact surface.

本発明の半導体ダイのピックアップ装置において、吸引開口の幅方向に延びるピンが取り付けられ、ステージ内部に設けられるスライダ駆動機構によって吸引開口の延びる方向にスライドするとともに密着面に対して進退するスライダを備え、蓋は、先端から吸引開口を閉じる側に張り出したアームを備え、アームを介してスライダのピンに回転自在に取り付けられていること、としても好適である。

In the semiconductor die pick-up device of the present invention, a pin is provided that extends in the width direction of the suction opening, and includes a slider that slides in the direction in which the suction opening extends by a slider drive mechanism provided inside the stage and moves forward and backward with respect to the contact surface. It is also preferable that the lid includes an arm projecting from the tip to the side of closing the suction opening and is rotatably attached to the slider pin via the arm.

本発明の半導体ダイのピックアップ方法は、保持シートに貼り付けられた半導体ダイをピックアップする半導体ダイのピックアップ方法であって、ピックアップする半導体ダイが貼り付けられた保持シートの半導体ダイが貼り付けられている面と反対側の面に密着する密着面を含む円筒形のステージと、密着面に設けられ、ピックアップする半導体ダイと略同一幅でステージの内周側から外周側に向かって直線状に延びる吸引開口と、吸引開口の幅と略同一幅で、吸引開口を閉じる側の先端が密着面から進出自在となるようにステージに設けられ、密着面に沿ってスライドして吸引開口を開閉し、蓋の先端を密着面から進出させた際に、蓋の保持シートを押し上げる面が蓋の先端側から蓋が開く側の後端側に向かって下向きに傾斜する蓋と、密着面から蓋の厚さだけ凹み、蓋と略同一幅で、蓋が開く側の吸引開口の端から、ステージ外周の円筒面にかからない位置で蓋が吸引開口を閉じた状態での蓋の後端の位置よりもステージ内周側の位置まで、ステージ外周面に向かって延びるスライド用溝と、ステージ外周側端のスライド用溝の底面から密着面と反対側に向かって延びる傾斜面と、半導体ダイを吸着するコレットと、を備える半導体ダイのピックアップ装置を用意し、閉じている状態の蓋の先端にピックアップする半導体ダイの一端を合わせ、蓋の幅方向位置と半導体ダイの幅方向位置とを合わせる位置合わせ工程と、蓋の先端を密着面から進出させ、保持シートと半導体ダイとを押し上げると共に、蓋の保持シートを押し上げる面と反対側の面をスライド用溝の底面と傾斜面とのエッジに接触させながらピックアップする半導体ダイの一端側から他端側に向かって蓋をスライドさせて吸引開口を順次開き、開いた吸引開口にピックアップする半導体ダイの一端側から他端側に向かって保持シートを順次吸引させてピックアップする半導体ダイから保持シートを順次引き剥がすと共にピックアップする半導体ダイの直上で待機しているコレットに半導体ダイを一端側から他端側に向かって順次吸着させ、半導体ダイをピックアップするピックアップ工程と、を有することを特徴とする。

The semiconductor die pick-up method of the present invention is a semiconductor die pick-up method for picking up a semiconductor die attached to a holding sheet, wherein the semiconductor die of the holding sheet to which the semiconductor die to be picked up is attached is attached. A cylindrical stage including a contact surface that is in close contact with the surface opposite to the surface on which it is located, and a linear surface extending from the inner periphery side of the stage toward the outer periphery side with the same width as the semiconductor die to be picked up, provided on the contact surface The suction opening and the width of the suction opening are substantially the same width, provided on the stage so that the tip of the suction opening closing side can be advanced from the contact surface, slide along the contact surface to open and close the suction opening, When the front end of the lid is advanced from the contact surface, the surface that pushes up the holding sheet of the lid is inclined downward from the front end side of the lid toward the rear end side of the lid opening side. After the lid with the lid closed with the suction opening at a position that is recessed from the contact surface by the thickness of the lid, is approximately the same width as the lid, and does not cover the cylindrical surface on the outer periphery of the stage from the end of the suction opening on the side where the lid opens. A slide groove extending toward the outer peripheral surface of the stage from the end position to a position on the inner peripheral side of the stage, an inclined surface extending from the bottom surface of the slide groove on the outer peripheral side of the stage toward the side opposite to the contact surface, and a semiconductor A semiconductor die pick-up device comprising a collet for adsorbing the die is prepared, one end of the semiconductor die to be picked up is aligned with the tip of the closed lid, and the width direction position of the lid and the width direction position of the semiconductor die are Alignment process, the tip of the lid is advanced from the contact surface, the holding sheet and the semiconductor die are pushed up, and the surface on the opposite side of the lid from which the holding sheet is pushed up is inclined with the bottom surface of the slide groove Slide the lid from one end to the other end of the semiconductor die to be picked up while making contact with the edge with the surface to open the suction openings sequentially, and pick up the open suction opening from one end of the semiconductor die to the other end. The holding sheet is sequentially sucked toward and picked up from the semiconductor die to be picked up sequentially, and the semiconductor die is sequentially adsorbed from one end side to the other end side on the collet waiting immediately above the semiconductor die to be picked up, A pickup step of picking up a semiconductor die.

本発明は、半導体ダイのピックアップ装置において、保持シートの引き剥がしの際に半導体ダイに加わる力を抑制しつつ半導体ダイを容易にピックアップすることができるという効果を奏する。

The present invention provides an effect that a semiconductor die can be easily picked up while suppressing a force applied to the semiconductor die when the holding sheet is peeled off in the semiconductor die pick-up device.

10 ウェーハホルダ、11 ウェーハ、12 保持シート、13 リング、14 切り込み隙間、15 半導体ダイ、15a 一端、15b 他端、16 エキスパンドリング、17 リング押さえ、18 コレット、19 吸着孔、20 ステージ、21 筐体、22 密着面、22a スライド用溝、22a’ 底面、22b 傾斜面、22c 端部、22d エッジ、22e 平面、22f 段部、22g 外周側端、22h,22j 側面、23 蓋、23a 先端、23b 側面、23c 後端、23e 面取り部分、23f アーム、23g 下面、24 基体部、25 駆動部、41 吸引開口、41a 端面、41b 側面、42 開口開き部、53 剥離線、70 制御部、71 真空装置、72 ウェーハホルダ水平方向駆動部、73 ステージ上下方向駆動機構、100 半導体ダイのピックアップ装置、300 スライダ駆動機構、321a ストッパ、326 第1リンク、326a,329a 係合溝、326b シャフト、326c ローラ、327,328,330,330a ピン、329 第2リンク、331 ガイドレール、332 スライダ、364 縦溝、370 ピストン、371 フランジ、373 ばね、381 モータ、383 カム、500 接線、α,β,γ 角度。

10 wafer holder, 11 wafer, 12 holding sheet, 13 ring, 14 notch gap, 15 semiconductor die, 15a one end, 15b other end, 16 expanding ring, 17 ring presser, 18 collet, 19 suction hole, 20 stage, 21 housing 22 contact surface, 22a slide groove, 22a 'bottom surface, 22b inclined surface, 22c edge, 22d edge, 22e flat surface, 22f step, 22g outer peripheral side end, 22h, 22j side surface, 23 lid, 23a front end, 23b side surface , 23c rear end, 23e chamfered part, 23f arm, 23g lower surface, 24 base part, 25 drive part, 41 suction opening, 41a end face, 41b side face, 42 opening side part, 53 peeling line, 70 control part, 71 vacuum device, 72 Wafer holder water Direction drive unit, 73 stage vertical drive mechanism, 100 semiconductor die pickup device, 300 slider drive mechanism, 321a stopper, 326 first link, 326a, 329a engagement groove, 326b shaft, 326c roller, 327, 328, 330, 330a pin, 329 second link, 331 guide rail, 332 slider, 364 vertical groove, 370 piston, 371 flange, 373 spring, 381 motor, 383 cam, 500 tangent, α, β, γ angles.

以下、本発明の好適な実施形態について図面を参照しながら説明する。本発明の半導体ダイのピックアップ装置について説明する前にウェーハとウェーハホルダについて説明する。

Hereinafter, preferred embodiments of the present invention will be described with reference to the drawings. Before describing the semiconductor die pick-up apparatus of the present invention, the wafer and the wafer holder will be described.

図1に示すように、ウェーハ11は裏面に粘着性の保持シート12が貼り付けられており、保持シート12は金属製のリング13に取付けられている。ウェーハ11はこのように保持シート12を介して金属製のリング13に取付けられた状態でハンドリングされる。そして、図2に示すように、ウェーハ11は切断工程で表面側からダイシングソーなどによって切断されて各半導体ダイ15となる。各半導体ダイ15の間にはダイシングの際に出来た切り込み隙間14が出来る。切り込み隙間14の深さは半導体ダイ15から保持シート12の一部にまで達しているが、保持シート12は切断されておらず、各半導体ダイ15は保持シート12によって保持されている。

As shown in FIG. 1, an adhesive holding sheet 12 is attached to the back surface of the wafer 11, and the holding sheet 12 is attached to a metal ring 13. The wafer 11 is handled in such a state that it is attached to the metal ring 13 via the holding sheet 12 in this way. As shown in FIG. 2, the wafer 11 is cut by a dicing saw or the like from the surface side into a semiconductor die 15 in the cutting process. A notch gap 14 formed during dicing is formed between the semiconductor dies 15. The depth of the cut gap 14 reaches from the semiconductor die 15 to a part of the holding sheet 12, but the holding sheet 12 is not cut and each semiconductor die 15 is held by the holding sheet 12.

このように、保持シート12とリング13とが取付けられた半導体ダイ15は図3に示すように、ウェーハホルダ10に取付けられる。ウェーハホルダ10は、フランジ部を持つ円環状のエキスパンドリング16とエキスパンドリング16のフランジの上にリング13を固定するリング押さえ17とを備えている。リング押さえ17は図示しないリング押さえ駆動部によってエキスパンドリング16のフランジに向かって進退する方向に駆動される。エキスパンドリング16の内径は半導体ダイ15が配置されているウェーハの径よりも大きく、エキスパンドリング16は所定の厚さを備えており、フランジはエキスパンドリング16の外側にあって、保持シート12から離れた方向の端面側に外側に突出するように取付けられている。また、エキスパンドリング16の保持シート12側の外周は保持シート12をエキスパンドリング16に取付ける際に、保持シート12をスムーズに引き伸ばすことができるように曲面構成となっている。また、ウェーハホルダ10は図示しないウェーハホルダ水平方向駆動部によって保持シート12の面に沿った方向に移動することができるように構成されている。

As described above, the semiconductor die 15 to which the holding sheet 12 and the ring 13 are attached is attached to the wafer holder 10 as shown in FIG. The wafer holder 10 includes an annular expand ring 16 having a flange portion and a ring presser 17 for fixing the ring 13 on the flange of the expand ring 16. The ring retainer 17 is driven in a direction to advance and retract toward the flange of the expand ring 16 by a ring retainer drive unit (not shown). The inner diameter of the expand ring 16 is larger than the diameter of the wafer on which the semiconductor die 15 is arranged, the expand ring 16 has a predetermined thickness, and the flange is outside the expand ring 16 and is separated from the holding sheet 12. It is attached so as to protrude outward on the end face side in the direction. Further, the outer periphery of the expanding ring 16 on the holding sheet 12 side has a curved surface configuration so that the holding sheet 12 can be smoothly stretched when the holding sheet 12 is attached to the expanding ring 16. Further, the wafer holder 10 is configured to be movable in a direction along the surface of the holding sheet 12 by a wafer holder horizontal direction drive unit (not shown).

図3(b)に示すように、半導体ダイ15が貼り付けられた保持シート12はエキスパンドリング16にセットされる前は略平面状態となっている。

As shown in FIG. 3B, the holding sheet 12 to which the semiconductor die 15 is attached is in a substantially planar state before being set on the expanding ring 16.

図4は半導体ダイのピックアップ装置100の構成を示す図であり、また図4は半導体ダイのピックアップ装置100に保持シート12に貼り付けられた半導体ダイ15をセットした状態を示している。この状態では、リング13の上にリング押さえ17が降下し、リング13をエキスパンドリング16のフランジとの間に挟み込んでいる。エキスパンドリング16の保持シート12の当たる上面とフランジ面との間には段差があるので、リング13がフランジ面に押し付けられると、保持シート12はエキスパンドリング16の上面とフランジ面との段差分だけエキスパンドリング16上部の曲面に沿って引き伸ばされる。このため、エキスパンドリング16の上に固定された保持シート12には保持シートの中心から周囲に向かう引っ張り力が働いている。また、この引っ張り力によって保持シート12が延びるので、保持シート12の上に貼り付けられた各半導体ダイ15間の隙間が広がっている。

FIG. 4 is a diagram showing a configuration of the semiconductor die pick-up apparatus 100, and FIG. 4 shows a state in which the semiconductor die 15 attached to the holding sheet 12 is set in the semiconductor die pick-up apparatus 100. In this state, the ring presser 17 is lowered on the ring 13, and the ring 13 is sandwiched between the flanges of the expand ring 16. Since there is a step between the upper surface where the holding sheet 12 of the expand ring 16 contacts and the flange surface, when the ring 13 is pressed against the flange surface, the holding sheet 12 is the same as the step between the upper surface of the expand ring 16 and the flange surface. The expansion ring 16 is stretched along the curved surface. For this reason, the holding sheet 12 fixed on the expand ring 16 is subjected to a pulling force from the center of the holding sheet toward the periphery. In addition, since the holding sheet 12 is extended by the pulling force, a gap between the semiconductor dies 15 attached on the holding sheet 12 is widened.