US3231663A - Electromagnetic shield having multiple electroconductive passages - Google Patents

Electromagnetic shield having multiple electroconductive passages Download PDFInfo

- Publication number

- US3231663A US3231663A US234631A US23463162A US3231663A US 3231663 A US3231663 A US 3231663A US 234631 A US234631 A US 234631A US 23463162 A US23463162 A US 23463162A US 3231663 A US3231663 A US 3231663A

- Authority

- US

- United States

- Prior art keywords

- core

- grille

- passages

- electrically conductive

- electromagnetic shield

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Expired - Lifetime

Links

- 239000004020 conductor Substances 0.000 claims description 7

- 239000000463 material Substances 0.000 claims description 6

- 239000002245 particle Substances 0.000 claims description 3

- 239000002184 metal Substances 0.000 description 7

- 229910052751 metal Inorganic materials 0.000 description 7

- OKTJSMMVPCPJKN-UHFFFAOYSA-N Carbon Chemical compound [C] OKTJSMMVPCPJKN-UHFFFAOYSA-N 0.000 description 6

- 238000000576 coating method Methods 0.000 description 6

- 239000011248 coating agent Substances 0.000 description 5

- 239000003973 paint Substances 0.000 description 5

- 230000005670 electromagnetic radiation Effects 0.000 description 4

- 229910052799 carbon Inorganic materials 0.000 description 3

- 229910002804 graphite Inorganic materials 0.000 description 3

- 239000010439 graphite Substances 0.000 description 3

- 238000004519 manufacturing process Methods 0.000 description 3

- 238000000034 method Methods 0.000 description 3

- 238000010137 moulding (plastic) Methods 0.000 description 3

- PPBRXRYQALVLMV-UHFFFAOYSA-N Styrene Chemical compound C=CC1=CC=CC=C1 PPBRXRYQALVLMV-UHFFFAOYSA-N 0.000 description 2

- 238000004378 air conditioning Methods 0.000 description 2

- 239000003086 colorant Substances 0.000 description 2

- 239000004922 lacquer Substances 0.000 description 2

- 238000005507 spraying Methods 0.000 description 2

- RYGMFSIKBFXOCR-UHFFFAOYSA-N Copper Chemical compound [Cu] RYGMFSIKBFXOCR-UHFFFAOYSA-N 0.000 description 1

- 239000004593 Epoxy Substances 0.000 description 1

- BQCADISMDOOEFD-UHFFFAOYSA-N Silver Chemical compound [Ag] BQCADISMDOOEFD-UHFFFAOYSA-N 0.000 description 1

- 235000003560 Valerianella locusta Nutrition 0.000 description 1

- 240000004668 Valerianella locusta Species 0.000 description 1

- NIXOWILDQLNWCW-UHFFFAOYSA-N acrylic acid group Chemical group C(C=C)(=O)O NIXOWILDQLNWCW-UHFFFAOYSA-N 0.000 description 1

- 230000005540 biological transmission Effects 0.000 description 1

- 230000000903 blocking effect Effects 0.000 description 1

- 238000010276 construction Methods 0.000 description 1

- 229910052802 copper Inorganic materials 0.000 description 1

- 239000010949 copper Substances 0.000 description 1

- 238000007598 dipping method Methods 0.000 description 1

- 238000009713 electroplating Methods 0.000 description 1

- 230000008030 elimination Effects 0.000 description 1

- 238000003379 elimination reaction Methods 0.000 description 1

- 125000003700 epoxy group Chemical group 0.000 description 1

- 238000001125 extrusion Methods 0.000 description 1

- 239000007888 film coating Substances 0.000 description 1

- 238000009501 film coating Methods 0.000 description 1

- PCHJSUWPFVWCPO-UHFFFAOYSA-N gold Chemical compound [Au] PCHJSUWPFVWCPO-UHFFFAOYSA-N 0.000 description 1

- 229910052737 gold Inorganic materials 0.000 description 1

- 239000010931 gold Substances 0.000 description 1

- 150000002734 metacrylic acid derivatives Chemical class 0.000 description 1

- 238000005555 metalworking Methods 0.000 description 1

- 238000012986 modification Methods 0.000 description 1

- 230000004048 modification Effects 0.000 description 1

- 239000012778 molding material Substances 0.000 description 1

- 238000010422 painting Methods 0.000 description 1

- 229920000647 polyepoxide Polymers 0.000 description 1

- 229920000728 polyester Polymers 0.000 description 1

- 230000009467 reduction Effects 0.000 description 1

- 229910052709 silver Inorganic materials 0.000 description 1

- 239000004332 silver Substances 0.000 description 1

- 238000001228 spectrum Methods 0.000 description 1

- 239000007858 starting material Substances 0.000 description 1

- 230000001629 suppression Effects 0.000 description 1

- 229920003002 synthetic resin Polymers 0.000 description 1

- 239000000057 synthetic resin Substances 0.000 description 1

- 229960004402 tiopronin Drugs 0.000 description 1

- 238000009423 ventilation Methods 0.000 description 1

Images

Classifications

-

- H—ELECTRICITY

- H05—ELECTRIC TECHNIQUES NOT OTHERWISE PROVIDED FOR

- H05K—PRINTED CIRCUITS; CASINGS OR CONSTRUCTIONAL DETAILS OF ELECTRIC APPARATUS; MANUFACTURE OF ASSEMBLAGES OF ELECTRICAL COMPONENTS

- H05K9/00—Screening of apparatus or components against electric or magnetic fields

- H05K9/0007—Casings

- H05K9/0041—Ventilation panels having provisions for screening

Definitions

- This invention relates to grilles or louver structures employed particularly for radio frequency shielding in fluorescent lighting fixtures, air conditioning ducts, and in other appliances and applications.

- a grille or louver structure for radio frequency shielding in which the structure has a core formed of plastic material such as styrene, acrylic, and other synthetic resins.

- the core is a one-piece member having rectangular, circular or hexagonal passages therethrough.

- the walls of the core are coated with thin metallic films to render them electrically conductive.

- Such a grille structure serves as an effective shield or filter to prevent the passage of undesired radio frequency emanations from a fluorescent lamp or other appliance, while permitting passage of light and air through the grille.

- the metallic films can be applied over lacquer coatings applied to the walls of the grilles.

- the metallic coated grilles can be painted white or in various colors.

- the grilles may be formed of plastic materials -such as epoxies, polyesters, methacrylates, etc.

- the plastic molding material may contain conductive materials such as powdered carbon, graphite or metal.

- the conductive materials will render the grille cores electrically conductive and effective as radio frequency shielding devices.

- the plastic cores may be formed by extrusion, or other well known plastic molding methods at low cost.

- Another object of the invention is to provide a grille structure having a plastic core with integrally joined walls coated with a metallic film.

- a further object is to provide a radio frequency shield in the form of a nonelectrically conductive grille core rendered electrically conductive by coating or impregnating the core with conductive material.

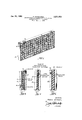

- FIG. l is a perspective view of a grille embodying the invention.

- FIG. 2 is a sectional view on an enlarged scale taken on line 2-2 of FIG. l.

- FIGS. 3 and 4 are sectional views similar to FIG. 2 illustrating other forms of the invention.

- a grille panel which may be rectangular in form or may have other geometrical shape.

- the panel is formed with a plurality of axially parallel passages P defined by opposing walls 12 of aplastic core.

- the passages are shown as'rectangular in the drawing, butthey could be cylindrical, triangular, hexagonal or have other geometrical shape.

- the Walls 1S of the core are coated on all sides with a thin coating 16 of lacquer which serves as a sealer and provides a smooth base for a coating of metallic film 18 which covers the coating 16.

- This film may be gold, silver, copper, etc., Vapplied byevaporation, electroplating, spraying, painting or other known metal film coating process.

- the metallic film can be painted with a thin layer 20 of white paint or paint of any desired color.

- the grille When the grille is to be used in a fluorescent lamp fixture, it is preferably painted white to pass and diffuse light more efficiently. At the same time the grille will serve as an efiicient shield to prevent passage of radio frequency, interference elimination, reduction or suppression of noise from the fluorescent lamps, ballast, starter and other parts of the fixture and also of the complete fixture.

- the passages in the grille serve as wave guide filters to block undesired electromagnetic radiations formed in the operating parts of the fixture. If the grille is to be used in an air conditioning or ventilation duct it may be painted any color or may be left unpainted. In such a duct, the grille will permit free passage of air while serving t0 block passage of undesired electromagnetic radiation.

- FIG. 3 shows another grille structure in which the plastic core 1lia is intermixed, formulated or impregnated with particles of conductive material such as carbon, graphite, metal and the like to render the core electrically conductive.

- This core may have all its walls 15eL coated with a thin non-conductive paint layer 20a.

- FIG. 4 shows another grille structure in which the plastic core 1-4b has all its walls 15b coated with electrically conductive paint Ztlb applied by spraying, dipping, etc.

- a plastic grille core which is rendered electrically conductive on all its external surfaces which can also be grounded or bonded so as to act as an efiicient electromagnetic shield in association with an appliance emitting electromagnetic radiation.

- the grille cores can be manufactured at low cost by mass production plastic molding machinery. rl ⁇ hey can be attractively painted in various colors as desired. For different requirements, the dimensions and shapes of the grille cores and passages will be different. Where metallic films or paints are applied to the grille cores they will be controlled in 4thickness so that they have high electrical conductivity.

- the grilles make efficient air and light transmission components while effectively blocking electromagnetic radiation of radio frequencies and other frequencies in the electromagnetic spectrum.

- the core may be made of papier mache cardboard and the like in addition to the plastic material.

- An electromagnetic shield comprising a rectangular grille panel, a core for said panel including a plurality of axially parallel passages extending therethrough and defined by opposing smooth walls, said core being formed of electrically nonconductive plastic material impregnated throughout with sufficient particles of electrically conductive material to render said core electrically conductive on all surfaces thereof, so that said passages constitute wave guide filters to prevent passage of electromagnetic waves E 4 of certain frequencies therethrough while freely passing 2,911,333 11/1959 Capen et al. 29-l55.5 air and light. 2,925,457 2/1960 Lindgren 174-35 2.

Landscapes

- Engineering & Computer Science (AREA)

- Microelectronics & Electronic Packaging (AREA)

- Shielding Devices Or Components To Electric Or Magnetic Fields (AREA)

Description

IN VEN TOR.

EDWARD SCHWARTZ BY gmt A 770.01757 Jan. 25, 1966 UnitedStates Patent O 35231563. ELECTRMAGNETIC SHIELD HAVING MULTIPLE ELECTROCGNDUCTIVE PASSAGES Edward Schwartz, 63 Avenue A.,Apt. 20H,

New York,-N.Y. 10009 Filed Nov..1,.1962, Ser. No. 234,631

` 3 Claims. (Cl. 174-35) This invention relates to grilles or louver structures employed particularly for radio frequency shielding in fluorescent lighting fixtures, air conditioning ducts, and in other appliances and applications.

It has been proposed heretofore to provide grilles formed of expanded sheet metal into honeycomb structure. It has also been proposed to form a panel of metal tubes welded together in axially parallel disposition. The tubes may be of rectangular, circular or hexagonal cross section. These prior grille structures have been costly to manufacture because of the large quantities of metal employed, the high labor cost in securing individual tubes together, and the large capital investment required for costly metal working machinery.

According to the present invention, it is proposed to provide a grille or louver structure for radio frequency shielding in which the structure has a core formed of plastic material such as styrene, acrylic, and other synthetic resins. The core is a one-piece member having rectangular, circular or hexagonal passages therethrough. The walls of the core are coated with thin metallic films to render them electrically conductive. Such a grille structure serves as an effective shield or filter to prevent the passage of undesired radio frequency emanations from a fluorescent lamp or other appliance, while permitting passage of light and air through the grille. The metallic films can be applied over lacquer coatings applied to the walls of the grilles. The metallic coated grilles can be painted white or in various colors.

It is also possible to form the grilles of plastic materials -such as epoxies, polyesters, methacrylates, etc. The plastic molding material may contain conductive materials such as powdered carbon, graphite or metal. The conductive materials will render the grille cores electrically conductive and effective as radio frequency shielding devices. The plastic cores may be formed by extrusion, or other well known plastic molding methods at low cost.

It is -therefore a principal object to provide a novel electromagnetic shield structure and novel method of manufacture of such a structure.

Another object of the invention is to provide a grille structure having a plastic core with integrally joined walls coated with a metallic film.

A further object is to provide a radio frequency shield in the form of a nonelectrically conductive grille core rendered electrically conductive by coating or impregnating the core with conductive material.

For further comprehension of the invention, and of the objects and advantages thereof, reference will be had to the following description and accompanying drawings, and to the appended claims in which the various novel features of the invention are more particularly set forth.

In the accompanying drawings forming a material part of this disclosure:

FIG. l is a perspective view of a grille embodying the invention.

FIG. 2 is a sectional view on an enlarged scale taken on line 2-2 of FIG. l.

FIGS. 3 and 4 are sectional views similar to FIG. 2 illustrating other forms of the invention.

Referring to the drawing, there is shown a grille panel which may be rectangular in form or may have other geometrical shape. The panel is formed with a plurality of axially parallel passages P defined by opposing walls 12 of aplastic core. The passages are shown as'rectangular in the drawing, butthey could be cylindrical, triangular, hexagonal or have other geometrical shape. The Walls 1S of the core are coated on all sides with a thin coating 16 of lacquer which serves as a sealer and provides a smooth base for a coating of metallic film 18 which covers the coating 16. This film may be gold, silver, copper, etc., Vapplied byevaporation, electroplating, spraying, painting or other known metal film coating process. The metallic film can be painted with a thin layer 20 of white paint or paint of any desired color. When the grille is to be used in a fluorescent lamp fixture, it is preferably painted white to pass and diffuse light more efficiently. At the same time the grille will serve as an efiicient shield to prevent passage of radio frequency, interference elimination, reduction or suppression of noise from the fluorescent lamps, ballast, starter and other parts of the fixture and also of the complete fixture. The passages in the grille serve as wave guide filters to block undesired electromagnetic radiations formed in the operating parts of the fixture. If the grille is to be used in an air conditioning or ventilation duct it may be painted any color or may be left unpainted. In such a duct, the grille will permit free passage of air while serving t0 block passage of undesired electromagnetic radiation.

FIG. 3 shows another grille structure in which the plastic core 1lia is intermixed, formulated or impregnated with particles of conductive material such as carbon, graphite, metal and the like to render the core electrically conductive. This core may have all its walls 15eL coated with a thin non-conductive paint layer 20a.

FIG. 4 shows another grille structure in which the plastic core 1-4b has all its walls 15b coated with electrically conductive paint Ztlb applied by spraying, dipping, etc.

In all forms of the invention, there is provided a plastic grille core which is rendered electrically conductive on all its external surfaces which can also be grounded or bonded so as to act as an efiicient electromagnetic shield in association with an appliance emitting electromagnetic radiation.

The grille cores can be manufactured at low cost by mass production plastic molding machinery. rl`hey can be attractively painted in various colors as desired. For different requirements, the dimensions and shapes of the grille cores and passages will be different. Where metallic films or paints are applied to the grille cores they will be controlled in 4thickness so that they have high electrical conductivity. The grilles make efficient air and light transmission components while effectively blocking electromagnetic radiation of radio frequencies and other frequencies in the electromagnetic spectrum.

It will be understood that the core may be made of papier mache cardboard and the like in addition to the plastic material.

While I have illustrated and described the preferred embodiments of my invention, it is to be understood that I do not limit myself to the precise constructions herein disclosed and that various changes and modifications may be made within the scope of the invention as defined in the appended claims.

Having thus described my invention, what I claim as new, and desire to secure by United States Letters Patent 1s:

1. An electromagnetic shield, comprising a rectangular grille panel, a core for said panel including a plurality of axially parallel passages extending therethrough and defined by opposing smooth walls, said core being formed of electrically nonconductive plastic material impregnated throughout with sufficient particles of electrically conductive material to render said core electrically conductive on all surfaces thereof, so that said passages constitute wave guide filters to prevent passage of electromagnetic waves E 4 of certain frequencies therethrough while freely passing 2,911,333 11/1959 Capen et al. 29-l55.5 air and light. 2,925,457 2/1960 Lindgren 174-35 2. An electromagnetic shield according to claim 1, fur- 2,971,083 2/1961 Phillips et aL 24,04639 X ther comprising a thin, non-conductive coating on all the 3 082 510 3/1963 Kelly et al 29 155 5 walls of the core.

3. An electromagnetic shield according to claim 1, 5 3112221 11/1963 Pn wherein said conductive material is selected from the FOREIGN PATENTS group consisting of carbon, graphite and metal.

References Cited by the Examiner 10 F. Pl'llary Exalnllef.

2,405,987 8/1946 Arnold 174-35 RlCHARD H. EANES, IR., JOHN P. WILDMAN, 2,840,811 6/1958 McMillan 343-872 X Examiners.

768,996 2/1957 Great Britain.

Claims (1)

1. AN ELECTROMAGNETIC SHIELD, COMPRISING A RECTANGULAR GRILLE PANEL, A CORE FOR SAID PANEL INCLUDING A PLURALITY OF AXIALLY PARALLEL PASSAGES EXTENDING THERETHROUGH AND DEFINED BY OPPOSING SMOOTH WALLS, SAID CORE BEING FORMED OF ELECTRICALLY NONCONDUCTIVE PLASTIC MATERIAL IMPREGNATED THROUGHOUT WITH SUFFICIENT PARTICLES OF ELECTRICALLY CONDUCTIVE MATERIAL TO RENDER SAID CORE ELECTRICALLY CONDUCTIVE ON ALL SURFACES THEREOF, SO THAT SAID PASSAGES CONSTITUTE WAVE GUIDE FILTERS TO PREVENT PASSAGE OF ELECTROMAGNETIC WAVES OF CERTAIN FREQUENCIES THERETHROUGH WHILE FREELY PASSING AIR AND LIGHT.

Priority Applications (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| US234631A US3231663A (en) | 1962-11-01 | 1962-11-01 | Electromagnetic shield having multiple electroconductive passages |

Applications Claiming Priority (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| US234631A US3231663A (en) | 1962-11-01 | 1962-11-01 | Electromagnetic shield having multiple electroconductive passages |

Publications (1)

| Publication Number | Publication Date |

|---|---|

| US3231663A true US3231663A (en) | 1966-01-25 |

Family

ID=22882158

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| US234631A Expired - Lifetime US3231663A (en) | 1962-11-01 | 1962-11-01 | Electromagnetic shield having multiple electroconductive passages |

Country Status (1)

| Country | Link |

|---|---|

| US (1) | US3231663A (en) |

Cited By (29)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US3406369A (en) * | 1966-07-08 | 1968-10-15 | John E. Taylor Jr. | Modular shielded patchord programming system |

| US3418621A (en) * | 1966-04-20 | 1968-12-24 | Cam Corp | Plugboard assembly |

| US3512946A (en) * | 1967-04-17 | 1970-05-19 | Lash Mfg Inc | Composite material for shielding electrical and magnetic energy |

| US3594490A (en) * | 1970-07-17 | 1971-07-20 | Ibm | Electronic grounding system |

| US3816836A (en) * | 1973-06-11 | 1974-06-11 | Gen Motors Corp | Shielded instrument panel for use with a windshield radio antenna |

| US3885150A (en) * | 1973-12-03 | 1975-05-20 | John Ott Lab | Shielded luminaire |

| US4004194A (en) * | 1972-09-27 | 1977-01-18 | Siemens Aktiengesellschaft | Module for supporting circuit boards |

| US4698197A (en) * | 1985-02-12 | 1987-10-06 | The United States Of America As Represented By The United States Department Of Energy | Magnetic shielding |

| US4833575A (en) * | 1988-06-15 | 1989-05-23 | Lam Lighting Systems | Brightness equalizing light filter system |

| US4896001A (en) * | 1986-01-27 | 1990-01-23 | Dennison Manufacturing Company | Anti-electric protection |

| US4978812A (en) * | 1987-12-25 | 1990-12-18 | Asahi Glass Company, Ltd. | Electromagnetic wave shielding transparent body |

| WO1995017083A1 (en) * | 1993-12-16 | 1995-06-22 | W.L. Gore & Associates, Inc. | Electromagnetic radiation shielding assembly |

| US5455117A (en) * | 1992-10-27 | 1995-10-03 | Kansai Paint Co., Ltd. | Electromagnetic wave reflection-preventing material and electromagnetic wave reflection-preventing method |

| WO1997032459A1 (en) * | 1996-02-28 | 1997-09-04 | The Whitaker Corporation | Shielding device for ventilation panels of electronic instruments and method for manufacture thereof |

| US5882227A (en) * | 1997-09-17 | 1999-03-16 | Intercon Systems, Inc. | Controlled impedance connector block |

| US6006419A (en) * | 1998-09-01 | 1999-12-28 | Millitech Corporation | Synthetic resin transreflector and method of making same |

| WO2003049521A1 (en) * | 2001-12-04 | 2003-06-12 | Laird Technologies, Inc. | Methods and apparatus for emi shielding |

| US6747607B1 (en) * | 1988-02-12 | 2004-06-08 | The Directv Group, Inc. | Radiation power limiter |

| US7277300B2 (en) * | 2005-03-01 | 2007-10-02 | Fujitsu Limited | Vent grid and electronic apparatus employing the same |

| US20110088940A1 (en) * | 2009-10-16 | 2011-04-21 | Emprimus, Inc. | Modular Electromagnetically Shielded Enclosure |

| US20120113317A1 (en) * | 2010-11-05 | 2012-05-10 | David Anderson | Electromagnetically Shielded Video Camera and Shielded Enclosure for Image Capture Devices |

| US8599576B2 (en) | 2010-10-29 | 2013-12-03 | Emprimus, Llc | Electromagnetically-protected electronic equipment |

| US8754980B2 (en) | 2010-11-05 | 2014-06-17 | Emprimus, Llc | Electromagnetically shielded camera and shielded enclosure for image capture devices |

| US8760859B2 (en) | 2010-05-03 | 2014-06-24 | Emprimus, Llc | Electromagnetically-shielded portable storage device |

| US8933393B2 (en) | 2011-04-06 | 2015-01-13 | Emprimus, Llc | Electromagnetically-shielded optical system having a waveguide beyond cutoff extending through a shielding surface of an electromagnetically shielding enclosure |

| EP2844054A3 (en) * | 2013-08-27 | 2015-05-06 | Parker Hannifin Corporation | Homogeneous EMI vent panel |

| US9093755B2 (en) | 2010-12-20 | 2015-07-28 | Emprimus, Llc | Lower power localized distributed radio frequency transmitter |

| US9420219B2 (en) | 2010-12-20 | 2016-08-16 | Emprimus, Llc | Integrated security video and electromagnetic pulse detector |

| US9642290B2 (en) | 2013-03-14 | 2017-05-02 | Emprimus, Llc | Electromagnetically protected electronic enclosure |

Citations (8)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US2405987A (en) * | 1941-11-18 | 1946-08-20 | Orlan M Arnold | High-frequency shielding |

| GB768996A (en) * | 1952-06-21 | 1957-02-27 | Siemens Ag | Improvements in or relating to electric screening of enclosed spaces |

| US2840811A (en) * | 1954-05-17 | 1958-06-24 | Edward B Mcmillan | Dielectric bodies for transmission of electromagnetic waves |

| US2911333A (en) * | 1954-11-24 | 1959-11-03 | Itt | Method for manufacturing a coaxial filter |

| US2925457A (en) * | 1955-03-23 | 1960-02-16 | Erik A Lindgren | Screen room air inlet and wave guard |

| US2971083A (en) * | 1958-11-14 | 1961-02-07 | Gen Electric | Low brightness louver |

| US3082510A (en) * | 1960-04-29 | 1963-03-26 | Goodyear Aircraft Corp | Method for making radar transparent flexible covering |

| US3112221A (en) * | 1960-07-06 | 1963-11-26 | Duracote Corp | Electro-magnetic wave reflecting laminate and method of making it |

-

1962

- 1962-11-01 US US234631A patent/US3231663A/en not_active Expired - Lifetime

Patent Citations (8)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US2405987A (en) * | 1941-11-18 | 1946-08-20 | Orlan M Arnold | High-frequency shielding |

| GB768996A (en) * | 1952-06-21 | 1957-02-27 | Siemens Ag | Improvements in or relating to electric screening of enclosed spaces |

| US2840811A (en) * | 1954-05-17 | 1958-06-24 | Edward B Mcmillan | Dielectric bodies for transmission of electromagnetic waves |

| US2911333A (en) * | 1954-11-24 | 1959-11-03 | Itt | Method for manufacturing a coaxial filter |

| US2925457A (en) * | 1955-03-23 | 1960-02-16 | Erik A Lindgren | Screen room air inlet and wave guard |

| US2971083A (en) * | 1958-11-14 | 1961-02-07 | Gen Electric | Low brightness louver |

| US3082510A (en) * | 1960-04-29 | 1963-03-26 | Goodyear Aircraft Corp | Method for making radar transparent flexible covering |

| US3112221A (en) * | 1960-07-06 | 1963-11-26 | Duracote Corp | Electro-magnetic wave reflecting laminate and method of making it |

Cited By (38)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US3418621A (en) * | 1966-04-20 | 1968-12-24 | Cam Corp | Plugboard assembly |

| US3406369A (en) * | 1966-07-08 | 1968-10-15 | John E. Taylor Jr. | Modular shielded patchord programming system |

| US3512946A (en) * | 1967-04-17 | 1970-05-19 | Lash Mfg Inc | Composite material for shielding electrical and magnetic energy |

| US3594490A (en) * | 1970-07-17 | 1971-07-20 | Ibm | Electronic grounding system |

| US4004194A (en) * | 1972-09-27 | 1977-01-18 | Siemens Aktiengesellschaft | Module for supporting circuit boards |

| US3816836A (en) * | 1973-06-11 | 1974-06-11 | Gen Motors Corp | Shielded instrument panel for use with a windshield radio antenna |

| US3885150A (en) * | 1973-12-03 | 1975-05-20 | John Ott Lab | Shielded luminaire |

| US4698197A (en) * | 1985-02-12 | 1987-10-06 | The United States Of America As Represented By The United States Department Of Energy | Magnetic shielding |

| US4896001A (en) * | 1986-01-27 | 1990-01-23 | Dennison Manufacturing Company | Anti-electric protection |

| US4978812A (en) * | 1987-12-25 | 1990-12-18 | Asahi Glass Company, Ltd. | Electromagnetic wave shielding transparent body |

| US6747607B1 (en) * | 1988-02-12 | 2004-06-08 | The Directv Group, Inc. | Radiation power limiter |

| US4833575A (en) * | 1988-06-15 | 1989-05-23 | Lam Lighting Systems | Brightness equalizing light filter system |

| US5455117A (en) * | 1992-10-27 | 1995-10-03 | Kansai Paint Co., Ltd. | Electromagnetic wave reflection-preventing material and electromagnetic wave reflection-preventing method |

| WO1995017083A1 (en) * | 1993-12-16 | 1995-06-22 | W.L. Gore & Associates, Inc. | Electromagnetic radiation shielding assembly |

| WO1997032459A1 (en) * | 1996-02-28 | 1997-09-04 | The Whitaker Corporation | Shielding device for ventilation panels of electronic instruments and method for manufacture thereof |

| US5882227A (en) * | 1997-09-17 | 1999-03-16 | Intercon Systems, Inc. | Controlled impedance connector block |

| US6006419A (en) * | 1998-09-01 | 1999-12-28 | Millitech Corporation | Synthetic resin transreflector and method of making same |

| US20030192715A1 (en) * | 2001-12-04 | 2003-10-16 | Laird Technologies, Inc. | Methods and apparatus for EMI shielding |

| USRE42512E1 (en) | 2001-12-04 | 2011-07-05 | Laird Technologies, Inc. | Methods and apparatus for EMI shielding |

| US6870092B2 (en) | 2001-12-04 | 2005-03-22 | Laird Technologies, Inc. | Methods and apparatus for EMI shielding |

| EP1799023A1 (en) * | 2001-12-04 | 2007-06-20 | Laird Technologies, Inc. | Methods and apparatus for EMI schielding |

| USRE41594E1 (en) | 2001-12-04 | 2010-08-31 | Laird Technologies, Inc. | Methods and apparatus for EMI shielding |

| WO2003049521A1 (en) * | 2001-12-04 | 2003-06-12 | Laird Technologies, Inc. | Methods and apparatus for emi shielding |

| US7277300B2 (en) * | 2005-03-01 | 2007-10-02 | Fujitsu Limited | Vent grid and electronic apparatus employing the same |

| US20110088940A1 (en) * | 2009-10-16 | 2011-04-21 | Emprimus, Inc. | Modular Electromagnetically Shielded Enclosure |

| US8642900B2 (en) | 2009-10-16 | 2014-02-04 | Emprimus, Llc | Modular electromagnetically shielded enclosure |

| US8760859B2 (en) | 2010-05-03 | 2014-06-24 | Emprimus, Llc | Electromagnetically-shielded portable storage device |

| US8599576B2 (en) | 2010-10-29 | 2013-12-03 | Emprimus, Llc | Electromagnetically-protected electronic equipment |

| US8643772B2 (en) * | 2010-11-05 | 2014-02-04 | Emprimus, Llc | Electromagnetically shielded video camera and shielded enclosure for image capture devices |

| US8754980B2 (en) | 2010-11-05 | 2014-06-17 | Emprimus, Llc | Electromagnetically shielded camera and shielded enclosure for image capture devices |

| US20120113317A1 (en) * | 2010-11-05 | 2012-05-10 | David Anderson | Electromagnetically Shielded Video Camera and Shielded Enclosure for Image Capture Devices |

| US9093755B2 (en) | 2010-12-20 | 2015-07-28 | Emprimus, Llc | Lower power localized distributed radio frequency transmitter |

| US9420219B2 (en) | 2010-12-20 | 2016-08-16 | Emprimus, Llc | Integrated security video and electromagnetic pulse detector |

| US8933393B2 (en) | 2011-04-06 | 2015-01-13 | Emprimus, Llc | Electromagnetically-shielded optical system having a waveguide beyond cutoff extending through a shielding surface of an electromagnetically shielding enclosure |

| US9642290B2 (en) | 2013-03-14 | 2017-05-02 | Emprimus, Llc | Electromagnetically protected electronic enclosure |

| US10136567B2 (en) | 2013-03-14 | 2018-11-20 | Emprimus, Llc | Electromagnetically protected electronic enclosure |

| US9370132B2 (en) | 2013-08-27 | 2016-06-14 | Parker-Hannifin Corporation | Homogeneous EMI vent panel and method for preparation thereof |

| EP2844054A3 (en) * | 2013-08-27 | 2015-05-06 | Parker Hannifin Corporation | Homogeneous EMI vent panel |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| US3231663A (en) | Electromagnetic shield having multiple electroconductive passages | |

| AU2008295181B2 (en) | A microwave oven door with a wake chokes system | |

| DE69601846T2 (en) | Shielding against electromagnetic impulses and manufacturing method | |

| JPH10256777A5 (en) | ||

| US5244708A (en) | Electromagnetic wave shielding interior material | |

| US20030015334A1 (en) | Electronics enclosure having an interior EMI shielding and cosmetic coating | |

| DE10231145A1 (en) | Shielding device for electronic assemblies on a printed circuit board | |

| EP2410831A2 (en) | Three-dimensional shapes with multiple parametric geometries and surfaces formed in electronics enclosures for providing electromagnetic interference (EMI) shielding | |

| EP3557121B1 (en) | Lighting assembly and method for constructing a lighting assembly | |

| WO2006076258A2 (en) | Three-dimensional configurations providing electromagnetic interference shielding for electronics enclosures | |

| SE8107157L (en) | MATERIAL FOR SHIELDING OF ELECTROMAGNETIC ENERGY | |

| KR101739977B1 (en) | Anti-electromagnetic waves aparatus and method for manufacturing the same | |

| DE102009029874A1 (en) | Lighting device with a plurality of light sources | |

| TW201345394A (en) | Heat sink | |

| KR20050082190A (en) | Shelter box for shielding electromagnetic waves | |

| DE19648544A1 (en) | Electromagnetic radiation screening arrangement e.g. for wireless telecommunication services | |

| DE10143418C1 (en) | Material for shielding electromagnetic radiation and / or for making electrical contact with electrically conductive components | |

| JPH0248159B2 (en) | ||

| CN206298988U (en) | Plug-in radiation proof wall | |

| KR19990046575A (en) | a matter for electromagnetic wave absorption and bacteria repression | |

| JPH025033B2 (en) | ||

| DE2441950A1 (en) | Loudspeaker box made of transparent plastics - is designed to appear smaller, and it may be coloured on the inside | |

| JPH023679Y2 (en) | ||

| JPS6018997A (en) | Electromagnetic shielding mold and method of producing same | |

| KR20050120435A (en) | Cover of electrical and electronic product with electromagnetic field shielding structure |