US1857041A - Sewing machine - Google Patents

Sewing machine Download PDFInfo

- Publication number

- US1857041A US1857041A US101985A US10198526A US1857041A US 1857041 A US1857041 A US 1857041A US 101985 A US101985 A US 101985A US 10198526 A US10198526 A US 10198526A US 1857041 A US1857041 A US 1857041A

- Authority

- US

- United States

- Prior art keywords

- arm

- looper

- eccentric

- shaft

- work supporting

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Expired - Lifetime

Links

- 238000009958 sewing Methods 0.000 title description 17

- 230000033001 locomotion Effects 0.000 description 17

- 238000010276 construction Methods 0.000 description 2

- OYFJQPXVCSSHAI-QFPUQLAESA-N enalapril maleate Chemical compound OC(=O)\C=C/C(O)=O.C([C@@H](C(=O)OCC)N[C@@H](C)C(=O)N1[C@@H](CCC1)C(O)=O)CC1=CC=CC=C1 OYFJQPXVCSSHAI-QFPUQLAESA-N 0.000 description 1

- 230000010355 oscillation Effects 0.000 description 1

- 238000006467 substitution reaction Methods 0.000 description 1

Images

Classifications

-

- D—TEXTILES; PAPER

- D05—SEWING; EMBROIDERING; TUFTING

- D05B—SEWING

- D05B15/00—Machines for sewing leather goods

- D05B15/02—Shoe sewing machines

-

- D—TEXTILES; PAPER

- D05—SEWING; EMBROIDERING; TUFTING

- D05B—SEWING

- D05B73/00—Casings

- D05B73/005—Doors or covers for accessing inner parts of the machine; Security devices therefor

Definitions

- the invention relates'to new and useful improvements in sewing machlnes, and more particularly to a'sewing machine, having a" cylindrical work supporting arm on which tubular .articlesare stltched.

- An object of'the invention is to provide a sewing machine of the abovetype having a four-motion feed dog and a four-motion looper, with actuatmg devlces therefor wherein all of the movements imparted to the feed dog and the looper are der ved from two eccentrlcs and a crank on the mam shaft.

- a further object of the invention is to wherein the parts actuated by the eccentrics and the crank may be detached therefrom, after which the entire worksupporting arm with the remainder of the feedinglm echanism and looper mechanism assembledthere- I T in may be removed, and .a different arm with a feeding mechanism including a differential feed dog and a looper mechanism substituted therefor.

- V v I A further object of the invention is'to pro-f vide a sewing machine of the above type wherein the feeding mechanism includes de vices wherein the feed dog may be leveled or tilted as desired, or the Working position thereof ralsed andlowered.

- a still further obgect of the invention is to provide a'sewing machine of the above type 1 wherein the feed bar is supported at the rear end thereof by two independent rocking arms,

- rocking arms are positively connected so as to maintain the work supporting arm and the parts of the frame on which said arm is mounterhare provided with suitably covered openings through which access maybe readily had tov adjustable parts in the looper actuating mechanism, for adjusting and for initially assembling.

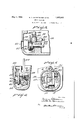

- Fig. 3 is a;detail' in section on the line 3 3 of Fig.2, I v

- Fig. 4 is a detail in sectionon the line 44; of Fig.

- Fig. 5 is a detailin section on the line 5+5.

- Fig. 1 is a View of a portion of the front of the detachable arm and showingthe uncovered openings through whichaccess may be had 'to certain of the actuating parts

- F ig. 7 is a plan view of a cover plate for closing the openings in the work supporting arm.

- Theinvention is directed broadly to a sewing machine having a suspended work supa porting arm, and preferably a machineof the: type I shown in the Patent No. 1,74i1,095,, granted Messrs. Christensen and LeVesconte, December 24, 1929.

- I 1

- the machine of the present application includes a supporting base .or frame, which is provided with an overhanging portionat the upper end to which the main frame 1 of: the machine is integrally attached.

- a main actuating shaft 2 which is. driven .by a suit-v able belt'wheel at the opposite end ofthe shaftfrom that shown inFig. 1.

- This main frame of the machine has an integral depending portion .3. This depending portion is open at its lower-end.

- Detachably mounted on the depending portion is a work supportting arm A.”

- the work s'upporting'arm closes. the lower. end ofthe depending portion, and. said arm projects laterally from said depend ing portion, thus forming a suspended substantially cylindrical .work' supporting arm on which tubular articles may be stitched and 1 formed.

- the worksupporting arm is secured to the depending portion by screws 5.

- the lever 12 is mounted on a fulcrum pin 13.

- This fulcrum pin 13 has an eccentric portion on which the lever swings as a fulcrum, and the pin is capable of being adjusted in differentrset positions for raisingorlowering the fulcrum point of the lever.

- the'links 8 are raised or lowered and thus it is that the working position of the feed dog is raised or lowered.

- the feed bar at the rear end thereof is mounted so as to slide on a pin 14.

- This pin 14 is mounted in the upper end of swinging arms 15 and 16. f

- These'arms 15 v and 16 are'mounted on an eccentricportion of the pin 17, whichpin is mounted in lugs in the work supporting arm and capable of being adjustedtherein and set in different ad- 'justed positions. This eccentric pin permits the swinging arms tobe'raised or lowered.

- a link 21 is pivoted at 22 to the feed. bar 6.

- This link 21 is pivoted at 23 to a lug which is adjustable in a segmental slot 24 formed in the swingingv arm 16. As noted above, the feed bar slides back and forth on the pin 14, and the pin 14 can move back and forth in the forked end of the feed bar.

- a looper shaft 25 Also mounted in the work supporting arm is a looper shaft 25.

- This looper shaft 25 is mountedso as to oscillate in suitable bearporting arm.

- the link 20 oscillates the swinging arms 15 and 16, and

- the needles are carried by a needle bar 28 and the material is held on the work support by a presser foot 29 carried by a presser bar 30.. Asnoted above, the feed dog is moved back and forth and up and down,

- eccentrics 31 and 32 Mounted on the main shaft 2 are two eccentrics 31 and 32.

- An eccentric strap 33 cooperates with the eccentric 32 and isconnected to a ball stud 34 on the inner end of the lever 12. As the eccentric 32 rotates, it

- an eccentric strap 35 Cooperating with the eccentric 31 is an eccentric strap 35.' This eccentric strap'at its lower end is connected to a ball stud 36 mounted on an arm 37.

- the arm 37- is formed integral with a sleeve 38.

- the sleeve 38 is mounted on a bearing pin 39 mounted in lugs formed as a part of the detachable work supporting arm 4.

- the sleeve 38 is provided with an upwardly projecting arm 40.

- Thelink 20 is pivoted at 41 to this upwardly projecting arm. As the sleeve 38 is oscillated, this arm 40, through the link 20, will oscillate the arms 15 and 16, and through the link 21, will impart an endwise movement to the feed bar.

- a depend ing arm 42 is mounted on the sleeve 38.

- This depending arm 42 is provided with a slot 43.

- the looper shaft2-5 is provided with spaced collars 44, 44, which are rigidly secured to the looper shaft.

- a short sleeve 45 which is loose on the looper shaft so'that theloop'e'r shaft may oscillate in this short sleeve 45.

- the sleeve 45 has a pin 46 projecting radially therefrom, and a link 47 is connected to this pin 46.

- a pin 48 is mounted in the slot 43 of the arm 42, and is capable of being adjusted to diflerent posi tions in said slot, and rigidly clamped in said positions.

- this pin 48 Mounted on this pin 48 is a bearing sleeve 49.

- the link 47 engages this bearing sleeve. As the sleeve 38 oscillates, it will swing the arm 42 back and forth, and through the link 47, will move the looper shaft endwise. By adjusting the position of the pin 48, the amount of endwise movement im'part-- ed to the looper shaft may be varied,and

- crank carrying a ball stud 51 On the end of the looper supporting shaft 25 there is a crank carrying a ball stud 51 (see Fig. 2).

- a collar 52 On the end of the main shaft 2 is a collar 52 which is fixed to the shaft by a clamping screw.

- This collar 52 carries a crank 53 in the form of a ball stud.

- a link 54 engages the crank 53 and also en-. gages the ball stud 51 on the crank .50 attached to the end'of the loopersupporting shaft. As the main shaft rotates, the link 54 will be moved endwise, and said link will oscillate the looper supporting shaft.

- the main shaft with two eccentrics and a crank, and devices are provided which are actuated thereby for imparting four motions to the feed dog, and four motions to the looper.

- the only parts of the feeding mechanism and the looper mechanism which extend up into the depending member of theframe are the eccentric rods 33 and 35 and the link 54. These parts may bereadily disthe work supporting arm 4 may be readily disconnected from the depending member and removed from the machine.

- Another arm can be readily substituted for the one taken off, in which a differential feeding mechanism is located, that is,a feeding mechanism not only having a main feed dog, but an auxiliary feed dog. By this, substitution, the machine may be quickly changed over to a machine which is ready to operate on knit material, so far as the feeding mechanism and looper mechanism are concerned.

- the work supporting arm is provided with an opening 56 through which the pin .46 is readily accessible.

- the work supporting arm is also provided with an opening'55 through which the pin 41 is readily accessible.

- the work supporting'arm is provided with an opening 57 through which the pin 48 is accessible, so that it can be adjusted in the slot 43.

- the work supporting arm is provided with a dove-tailed recess'58.

- a cover plate 59 is adapted to be inserted in said dove-tailed recess, and covers all three of the openings 55, 56 and 57.

- A' sewing machine including a main.

- a sewing-machine including a main frame having a depending-member open at its lower end, a detachable pro ecting work supportmg arm connected to and closmgthe lower end of said depending member, a feed- 7 ing mechanism located'in said work supporting arm including a feed dog, a looper mechanism'located'in said work supporting arm I including a looper, a main shaft in said frame extending over said depending member, an

- a sewing machine including a main" frame having a depending'member open at its "lower end, adetachable projecting work supporting-arm connected-to and closing the lowerend'of said depending member, affeedextending over said depending member,- an Y eccentric on said main shaft, devices actuated by said eccentric for raising and lowering the feed dog of said feeding mechanism, a second eccentric on said main shaft, devices actuated by said second, eccentric for imparting back andforth movements to the feed dog and for imparting needle avoiding movements to the looper, a crank on said main shaft, and devices actuated by said crank for oscillating said looper, all-of the devices foractuating the feed dog and the looper being mounted for operation in-Lthe work supporting arm, whereby when said devices are disconnected from the eccentrics and the crank on the main shaft, said work supporting arm may be de-' tached from the machine.

- a sewing machine including a main frame having a depending member open at its lower end, a detachable projecting work supporting arm connected to and closing the lower end of said depending member, a feeding mechanism and a looper mechanism mounted in said work supporting arm, said feeding mechanism including a feed bar, and a feed dog carried thereby, said looper mechanism including a looper shaft and a 'looper carried thereby, a pin extending across said I work supporting arm beneath said depending 35 member, a sleeve mounted on said pin, a main shaft in the frame extending over said depending member, an eccentric on said main shaft, an eccentric rod cooperating therewith V and connected to said sleeve for oscillating the same, an arm projecting upwardly from said sleeve, devices connected to said arm for moving said feed bar backand forth, an arm projecting downwardly from said sleeve, and devices connected to said downwardly projecting arm for moving said looper shaft endwise.

- a sewing machine including in combination, amain frame having a depending member open at its lower end, a work supporting arm' connected to .said depending member and adapted to close the lower end thereof, a looper mechanism and a feeding mechanism located in said work supporting arm, driving connections extending from said depending member for actuating said feeding mechanism and said looper mechanism, said work supporting arm having independent openings inrthe side face thereof through which access may be had to certain of the parts of the feeding mechanism and looper mechanism and the devicesfor actuating the same, and a single cover plate for closing said openings.

- a sewing machine including in combination, a main shaft, alooper having an os-" V ifs 59,041

- a feed dog having an up and down and a back and forth movement

- means for actuating the looper and feed dog including three eccentric members on said main shaft, and devices connecting one of said members to the feed dog for raising and lowering the same, devices for connecting a second of said eccentric members to the looper for oscillating the same, and devices for connecting the third eccentric to the feed dog and the looper for simultaneously imparting back and forth or feeding movements to the feed dog, and needle avoiding movements to the loop-er.

- A'sewing machine including in combination, a'main frame, having a depending member, a work supporting arm connected to said dependingmember and suspended thereby, a feeddog in said work supporting arm having an up and down and a back and forth movement, a looper in said work supporting arm having an oscillating and a needle avoiding'movem-ent, a main shaft in said frame, three eccentric members on said main shaft, devices for connecting oneof said eccentric members to the feed dog for raising and lowering the same, devices, connecting a second eccentric member to the looper for oscillating the same, and devices connecting the third eccentric member to the looper and the feed dog for simultaneously imparting feeding movements to thefeed dog and needle avoiding movements to the looper.

- a sewing machine including a work supporting arm, a feed bar extending lengthwise of said arm, a feed dog carried thereby, swinging arms for supporting the inner end of the feed bar, said armshaving inter-engaging parts for rigidly connecting said arms, whereby said arms swing together, a main shaft, a rocking, member oscillated thereby, a link connected to the rocking memberand moved endwise thereby, said link being pivoted to said swinging arms for rocking said arms, and devices connecting one of said arms to the feed bar for moving the feed bar back and forth, said arms having a pin for slidingly supporting the feed bar whereby the feed bar'may be given an en'dwise movement relative to said pin.

Landscapes

- Engineering & Computer Science (AREA)

- Textile Engineering (AREA)

- Sewing Machines And Sewing (AREA)

Description

May 3, 193 N. v. CHRISTENSEN ET AL SEWING MACHINE Filed pril 14. 1926 5 Sheets-Sheet, l

mute 0S Y MM May 3, 1932. N. v. CHRISTENSEN r'r AL 7,

SEWING MACHINE Filed April 14, 1926 s Sheets-Sheet 2 y 1932- N. v CHRISTENSEN ET AL 1,357,041

SEWING MACHINE Filed April 14. 1926 5 Sheets-Sheet 5 Patented May 3, 1932 3 UNITED? s'r r-Es nommiv v. onnrs'rmvsniv WALTER M. nAnNE An-orcmcAGo LLrNois, As- SIGNOR-S TO umonsrncmt MACHINE eomrnnm or cnIcAeo rumors, A con- POBATION or ILLINOIS snwme Macar ni; i

Application filedApril '14,

The invention'relates'to new and useful improvements in sewing machlnes, and more particularly to a'sewing machine, having a" cylindrical work supporting arm on which tubular .articlesare stltched.

An object of'the invention is to provide a sewing machine of the abovetype having a four-motion feed dog and a four-motion looper, with actuatmg devlces therefor wherein all of the movements imparted to the feed dog and the looper are der ved from two eccentrlcs and a crank on the mam shaft.

A further object of the inventionis to wherein the parts actuated by the eccentrics and the crank may be detached therefrom, after which the entire worksupporting arm with the remainder of the feedinglm echanism and looper mechanism assembledthere- I T in may be removed, and .a different arm with a feeding mechanism including a differential feed dog and a looper mechanism substituted therefor. V v I A further object of the invention is'to pro-f vide a sewing machine of the above type wherein the feeding mechanism includes de vices wherein the feed dog may be leveled or tilted as desired, or the Working position thereof ralsed andlowered.

.A still further obgect of the invention is to provide a'sewing machine of the above type 1 wherein the feed bar is supported at the rear end thereof by two independent rocking arms,

one at each side thereof, which rocking arms are positively connected so as to maintain the work supporting arm and the parts of the frame on which said arm is mounterhare provided with suitably covered openings through which access maybe readily had tov adjustable parts in the looper actuating mechanism, for adjusting and for initially assembling.

These and other objects will in part be ob vious and will in part be hereinafter more' fully disclosed.

In the drawings which show by way of illustration one embodiment 't1on-' V 1926. serial 101,985. I

of the inven in plan'on the line 2-2 of Fig.1, the cover plate and end cap of the arm being removed and parts broken away;

, Fig. 3 is a;detail' in section on the line 3 3 of Fig.2, I v

Fig. 4 is a detail in sectionon the line 44; of Fig.

Fig. 5 is a detailin section on the line 5+5.

of Fig.1; Fig. 6 is a View of a portion of the front of the detachable arm and showingthe uncovered openings through whichaccess may be had 'to certain of the actuating parts F ig. 7 isa plan view of a cover plate for closing the openings in the work supporting arm. J

Theinvention is directed broadly to a sewing machine having a suspended work supa porting arm, and preferably a machineof the: type I shown in the Patent No. 1,74i1,095,, granted Messrs. Christensen and LeVesconte, December 24, 1929. I 1

The machine of the present application includes a supporting base .or frame, which is provided with an overhanging portionat the upper end to which the main frame 1 of: the machine is integrally attached. Located inthis main. supporting frame is a main actuating shaft 2 which is. driven .by a suit-v able belt'wheel at the opposite end ofthe shaftfrom that shown inFig. 1. This main frame of the machine has an integral depending portion .3. This depending portion is open at its lower-end. Detachably mounted on the depending portion is a work supportting arm A." The work s'upporting'arm closes. the lower. end ofthe depending portion, and. said arm projects laterally from said depend ing portion, thus forming a suspended substantially cylindrical .work' supporting arm on which tubular articles may be stitched and 1 formed. The worksupporting arm is secured to the depending portion by screws 5.

60 "ings formed integral with .the work sup- In the preferred form of the invention, the

material is wrapped around the arm and is fed off from the end of the arm as it is stitched.

work supporting arm. It is mounted adj acent the outer end thereof on supporting links 8. These links are pivoted to the feed bar at 9 and are also pivoted at 10 to a lever 12.

The lever 12 is mounted on a fulcrum pin 13.

This fulcrum pin 13 has an eccentric portion on which the lever swings as a fulcrum, and the pin is capable of being adjusted in differentrset positions for raisingorlowering the fulcrum point of the lever. By raising or lowering the fulcrum point of the lever 12,

the'links 8 are raised or lowered and thus it is that the working position of the feed dog is raised or lowered. The feed bar at the rear end thereof is mounted so as to slide on a pin 14. This pin 14 is mounted in the upper end of swinging arms 15 and 16. f These'arms 15 v and 16 are'mounted on an eccentricportion of the pin 17, whichpin is mounted in lugs in the work supporting arm and capable of being adjustedtherein and set in different ad- 'justed positions. This eccentric pin permits the swinging arms tobe'raised or lowered.

This willraise or lower the rear end of the feedbar. Thus it is that the feed dog may be tilted or leveled as desired. The construction of the feed bar and the mounting of the same thus far described, is similar to that shown in our Patent No. 1,763,952, granted June 17, 1930., These swingingarms 15 and 16 in the'present embodiment of the invention are provided with positive means for connecting the same. The hub of the arm 15. is provided with radial'grooves 18, while These arms are swungback and forth on" the hub of the arm 16 isprovided with radial projections 19.] These projections fit in the grooves and lock the two arms together, so that they are bodily oscillated together.

their, pivot pins by means of a link 20. A link 21 is pivoted at 22 to the feed. bar 6. This link 21 is pivoted at 23 to a lug which is adjustable in a segmental slot 24 formed in the swingingv arm 16. As noted above, the feed bar slides back and forth on the pin 14, and the pin 14 can move back and forth in the forked end of the feed bar.

the arm 16, through the link 21, will move the feed bar back and forth.

Also mounted in the work supporting arm is a looper shaft 25. This looper shaft 25 is mountedso as to oscillate in suitable bearporting arm. On the forward end of the the reason that two needles 27,27 are shown,

The link 20. oscillates the swinging arms 15 and 16, and

and of course, there is a looper for each ne'edle when making independent lines of stitches. The needles are carried by a needle bar 28 and the material is held on the work support by a presser foot 29 carried by a presser bar 30.. Asnoted above, the feed dog is moved back and forth and up and down,

isoscillated by an oscillation of the looper shaft, and thexlooper is moved laterally by an endwise movement ofthe looper shaft.

Mounted on the main shaft 2 are two eccentrics 31 and 32. An eccentric strap 33 cooperates with the eccentric 32 and isconnected to a ball stud 34 on the inner end of the lever 12. As the eccentric 32 rotates, it

will, through the eccentric strap 33, oscillatethe lever 12and thus raise and lower the outer end of the feed bar.

Cooperating with the eccentric 31 is an eccentric strap 35.' This eccentric strap'at its lower end is connected to a ball stud 36 mounted on an arm 37. The arm 37- is formed integral with a sleeve 38. The sleeve 38 is mounted on a bearing pin 39 mounted in lugs formed as a part of the detachable work supporting arm 4. When the eccentric rotates, the arm 37 will be raised and lowered through the eccentric strap connection therewith, and this will oscillate the sleeve 38'. The sleeve 38 is provided with an upwardly projecting arm 40. Thelink 20 is pivoted at 41 to this upwardly projecting arm. As the sleeve 38 is oscillated, this arm 40, through the link 20, will oscillate the arms 15 and 16, and through the link 21, will impart an endwise movement to the feed bar.

Also mounted on the sleeve 38 is a depend ing arm 42. This depending arm 42 is provided with a slot 43. The looper shaft2-5 is provided with spaced collars 44, 44, which are rigidly secured to the looper shaft. Located between these spaced collars is a short sleeve 45 which is loose on the looper shaft so'that theloop'e'r shaft may oscillate in this short sleeve 45. The sleeve 45 has a pin 46 projecting radially therefrom, and a link 47 is connected to this pin 46. A pin 48 is mounted in the slot 43 of the arm 42, and is capable of being adjusted to diflerent posi tions in said slot, and rigidly clamped in said positions. Mounted on this pin 48 is a bearing sleeve 49. The link 47 engages this bearing sleeve. As the sleeve 38 oscillates, it will swing the arm 42 back and forth, and through the link 47, will move the looper shaft endwise. By adjusting the position of the pin 48, the amount of endwise movement im'part-- ed to the looper shaft may be varied,and

thus the amount of needle avoiding move: ment given to the looper varied. From the above it will be apparent that the eccentric 31 which oscillates the sleeve'38 performs two functions. It not only moves the looper shaft endwise, but it also moves thefeed bar endwise. in the work supporting arm 4 so as to provide a substantially straight line drive tothe feed bar and to the looper shaft.

On the end of the looper supporting shaft 25 there is a crank carrying a ball stud 51 (see Fig. 2). On the end of the main shaft 2 is a collar 52 which is fixed to the shaft by a clamping screw. This collar 52 carries a crank 53 in the form of a ball stud. A link 54 engages the crank 53 and also en-. gages the ball stud 51 on the crank .50 attached to the end'of the loopersupporting shaft. As the main shaft rotates, the link 54 will be moved endwise, and said link will oscillate the looper supporting shaft.

It will be noted from the above that we have provided the main shaft with two eccentrics and a crank, and devices are provided which are actuated thereby for imparting four motions to the feed dog, and four motions to the looper. Furthermore, it will be noted that the only parts of the feeding mechanism and the looper mechanism which extend up into the depending member of theframe are the eccentric rods 33 and 35 and the link 54. These parts may bereadily disthe work supporting arm 4 may be readily disconnected from the depending member and removed from the machine. Another arm can be readily substituted for the one taken off, in which a differential feeding mechanism is located, that is,a feeding mechanism not only having a main feed dog, but an auxiliary feed dog. By this, substitution, the machine may be quickly changed over to a machine which is ready to operate on knit material, so far as the feeding mechanism and looper mechanism are concerned.

The work supporting arm is provided with an opening 56 through which the pin .46 is readily accessible. The work supporting arm is also provided with an opening'55 through which the pin 41 is readily accessible.

Again, the work supporting'arm is provided with an opening 57 through which the pin 48 is accessible, so that it can be adjusted in the slot 43. The work supporting arm is provided with a dove-tailed recess'58. A cover plate 59 is adapted to be inserted in said dove-tailed recess, and covers all three of the openings 55, 56 and 57. In the right-hand end of the work supporting arm, as viewed in Fig. 1, there is an opening 60, which The pin 39 is set sufliciently-low' cilita-tes thev insertionof the looper supporting shaft in setting up the machine This openingisclosedby a cover plate61.

It is obvious that minor changes in the details of construction and the arrangement of the parts may be made without-departs.

ing .from'the spirit of the. invention as set forth in the appended claims.

Ha'vingthus described'the invention, what we claim as new and desire to secure by Letters-Patent, Is-

1.,A' sewing machine including a main.

frame having a depending member open at its lower'end, a detachable work supporting arm connected to and closing the lowerend of said depending member, a. feed bar extending lengthwise of said work supporting arm,-

a'feed dog carried thereby, a looper shaft extending lengthwise of said work supports ingarm, a looper carried thereby, a main arm projecting laterally fromsaid sleeve, an

eccentric rod cooperating with said second eccentric and connected to saidarm for. oscillating said sleeve, a second arm'mounted onv said sleeve, and devices connecting said second arm to said feed bar for moving said feed bar endwise, a third arm mounted on said sleeve, and devices connected to said third arm and to the looper shaft for moving the'looper shaftendwise, a crank on said main shaft, and devices actuated-by said cgazglfi: for oscillatingsaidlooper supporting s a 2; A sewing-machine including a main frame having a depending-member open at its lower end, a detachable pro ecting work supportmg arm connected to and closmgthe lower end of said depending member, a feed- 7 ing mechanism located'in said work supporting arm including a feed dog, a looper mechanism'located'in said work supporting arm I including a looper, a main shaft in said frame extending over said depending member, an

eccentric onsaid main shaft, devices actuated by said eccentric for raising and lowering the feed dogof said feeding mechanism, a second a '3. A sewing machine including a main" frame having a depending'member open at its "lower end, adetachable projecting work supporting-arm connected-to and closing the lowerend'of said depending member, affeedextending over said depending member,- an Y eccentric on said main shaft, devices actuated by said eccentric for raising and lowering the feed dog of said feeding mechanism, a second eccentric on said main shaft, devices actuated by said second, eccentric for imparting back andforth movements to the feed dog and for imparting needle avoiding movements to the looper, a crank on said main shaft, and devices actuated by said crank for oscillating said looper, all-of the devices foractuating the feed dog and the looper being mounted for operation in-Lthe work supporting arm, whereby when said devices are disconnected from the eccentrics and the crank on the main shaft, said work supporting arm may be de-' tached from the machine. 4; A sewing machine including a main frame having a depending member open at its lower end, a detachable projecting work supporting arm connected to and closing the lower end of said depending member, a feeding mechanism and a looper mechanism mounted in said work supporting arm, said feeding mechanism including a feed bar, and a feed dog carried thereby, said looper mechanism including a looper shaft and a 'looper carried thereby, a pin extending across said I work supporting arm beneath said depending 35 member, a sleeve mounted on said pin, a main shaft in the frame extending over said depending member, an eccentric on said main shaft, an eccentric rod cooperating therewith V and connected to said sleeve for oscillating the same, an arm projecting upwardly from said sleeve, devices connected to said arm for moving said feed bar backand forth, an arm projecting downwardly from said sleeve, and devices connected to said downwardly projecting arm for moving said looper shaft endwise. 7 5. A sewing machine including in combination, amain frame having a depending member open at its lower end, a work supporting arm' connected to .said depending member and adapted to close the lower end thereof, a looper mechanism and a feeding mechanism located in said work supporting arm, driving connections extending from said depending member for actuating said feeding mechanism and said looper mechanism, said work supporting arm having independent openings inrthe side face thereof through which access may be had to certain of the parts of the feeding mechanism and looper mechanism and the devicesfor actuating the same, and a single cover plate for closing said openings.

6. A sewing machine including in combination, a main shaft, alooper having an os-" V ifs 59,041

cill'ating and'a 'needle'avoiding movement, a feed dog having an up and down and a back and forth movement, means for actuating the looper and feed dog including three eccentric members on said main shaft, and devices connecting one of said members to the feed dog for raising and lowering the same, devices for connecting a second of said eccentric members to the looper for oscillating the same, and devices for connecting the third eccentric to the feed dog and the looper for simultaneously imparting back and forth or feeding movements to the feed dog, and needle avoiding movements to the loop-er.

7. A'sewing machine including in combination,a'main frame, having a depending member, a work supporting arm connected to said dependingmember and suspended thereby, a feeddog in said work supporting arm having an up and down and a back and forth movement, a looper in said work supporting arm having an oscillating and a needle avoiding'movem-ent, a main shaft in said frame, three eccentric members on said main shaft, devices for connecting oneof said eccentric members to the feed dog for raising and lowering the same, devices, connecting a second eccentric member to the looper for oscillating the same, and devices connecting the third eccentric member to the looper and the feed dog for simultaneously imparting feeding movements to thefeed dog and needle avoiding movements to the looper.

8. A sewing machine including a work supporting arm, a feed bar extending lengthwise of said arm, a feed dog carried thereby, swinging arms for supporting the inner end of the feed bar, said armshaving inter-engaging parts for rigidly connecting said arms, whereby said arms swing together, a main shaft, a rocking, member oscillated thereby, a link connected to the rocking memberand moved endwise thereby, said link being pivoted to said swinging arms for rocking said arms, and devices connecting one of said arms to the feed bar for moving the feed bar back and forth, said arms having a pin for slidingly supporting the feed bar whereby the feed bar'may be given an en'dwise movement relative to said pin.

In testimony whereof, we affix our signatures.

NORMAN. V. CHRISTENSEN. /VALTER (M. HANNEMAN.

Priority Applications (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| US101985A US1857041A (en) | 1926-04-14 | 1926-04-14 | Sewing machine |

Applications Claiming Priority (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| US101985A US1857041A (en) | 1926-04-14 | 1926-04-14 | Sewing machine |

Publications (1)

| Publication Number | Publication Date |

|---|---|

| US1857041A true US1857041A (en) | 1932-05-03 |

Family

ID=22287506

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| US101985A Expired - Lifetime US1857041A (en) | 1926-04-14 | 1926-04-14 | Sewing machine |

Country Status (1)

| Country | Link |

|---|---|

| US (1) | US1857041A (en) |

Cited By (2)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US2623484A (en) * | 1948-03-19 | 1952-12-30 | Singer Mfg Co | Feed-off-the-arm sewing machine |

| US2712805A (en) * | 1952-07-22 | 1955-07-12 | Union Special Machine Co | Feed-off-the-arm sewing machine |

-

1926

- 1926-04-14 US US101985A patent/US1857041A/en not_active Expired - Lifetime

Cited By (2)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US2623484A (en) * | 1948-03-19 | 1952-12-30 | Singer Mfg Co | Feed-off-the-arm sewing machine |

| US2712805A (en) * | 1952-07-22 | 1955-07-12 | Union Special Machine Co | Feed-off-the-arm sewing machine |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| US2623484A (en) | Feed-off-the-arm sewing machine | |

| US1857041A (en) | Sewing machine | |

| US1731221A (en) | Hat-sewing machine | |

| US2024434A (en) | Feeding mechanism for sewing machines | |

| US2329681A (en) | Needle-vibrating mechanism for sewing machines | |

| US1613605A (en) | Looper mechanism for sewing machines | |

| US1663490A (en) | Feeding mechanism for sewing machines | |

| US1741096A (en) | Feed-off-the arm sewing machine | |

| US2336368A (en) | Loop-taker mechanism for sewing machines | |

| US2561310A (en) | Feeding mechanism for sewing machines | |

| US2058635A (en) | Sewing machine | |

| US2322207A (en) | Feeding mechanism for sewing machines | |

| US1830126A (en) | Zigzag-stitch sewing machine | |

| US1843197A (en) | Feeding mechanism for sewing machines | |

| US1763952A (en) | Feeding mechanism for sewing machines | |

| US2415383A (en) | Sewing machine | |

| US1311880A (en) | Planooraph co | |

| US1729994A (en) | Feeding mechanism for sewing machines | |

| US2308465A (en) | Ornamental seam sewing machine | |

| US2156525A (en) | Feed mechanism for sewing machines and the like | |

| US1144797A (en) | Feeding mechanism for sewing-machines. | |

| US2236308A (en) | Ruffling and stitching machine | |

| US1295074A (en) | Sewing-machine. | |

| US1861540A (en) | Looper operating mechanism for sewing machines | |

| US1952534A (en) | Chain stitch sewing machine |