US1856833A - Derrick finger attachment - Google Patents

Derrick finger attachment Download PDFInfo

- Publication number

- US1856833A US1856833A US441414A US44141430A US1856833A US 1856833 A US1856833 A US 1856833A US 441414 A US441414 A US 441414A US 44141430 A US44141430 A US 44141430A US 1856833 A US1856833 A US 1856833A

- Authority

- US

- United States

- Prior art keywords

- derrick

- finger

- attachment

- well

- slots

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Expired - Lifetime

Links

- 241000282472 Canis lupus familiaris Species 0.000 description 22

- 229910000746 Structural steel Inorganic materials 0.000 description 7

- 230000000284 resting effect Effects 0.000 description 4

- 230000005484 gravity Effects 0.000 description 3

- 241000282693 Cercopithecidae Species 0.000 description 2

- 238000005553 drilling Methods 0.000 description 2

- 238000010008 shearing Methods 0.000 description 2

- 241000947840 Alteromonadales Species 0.000 description 1

- 238000010276 construction Methods 0.000 description 1

- 230000008878 coupling Effects 0.000 description 1

- 238000010168 coupling process Methods 0.000 description 1

- 238000005859 coupling reaction Methods 0.000 description 1

- 239000003129 oil well Substances 0.000 description 1

Images

Classifications

-

- E—FIXED CONSTRUCTIONS

- E21—EARTH OR ROCK DRILLING; MINING

- E21B—EARTH OR ROCK DRILLING; OBTAINING OIL, GAS, WATER, SOLUBLE OR MELTABLE MATERIALS OR A SLURRY OF MINERALS FROM WELLS

- E21B19/00—Handling rods, casings, tubes or the like outside the borehole, e.g. in the derrick; Apparatus for feeding the rods or cables

- E21B19/14—Racks, ramps, troughs or bins, for holding the lengths of rod singly or connected; Handling between storage place and borehole

Definitions

- the invention relates particularly to a new and novel finger attachment for use in connection with' oil well derricks and casingV secy. tions associated therewith.

- the invention relates to a device for safely and conveniently positioning and holding an individual well casing section within a well derrick relative to lthe means for lowering Such casing sections into the well.

- An object of the invention is to safeguard workmen engaged in drilling wells fromthe present danger of falling from elevated portions of the derrick whiler engaged in positioned well casing sections preparatory to lowering the casing sections into the Well.

- Another object is to provide more eflicient means for controlling the movements of the casing sections as they are delivered one at a time, from a compact group standing on end in the usual arrangement, to the apparatus for lowering them into the well.

- Another object is to provide a very simple and inexpensive arrangement of the character stated, and one which may readily be attached to well drilling equipment now in general use.

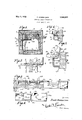

- Figure 1 ⁇ is a transverse section of a well derrick equipped with my inventionshowing a group of upstanding well casing sections in position prior to being individually positioned for lowering into the well.

- a casing section is more cr less fragmentally and dia- Vgrammatically illustrated in position to be received by the lowering means.

- Fig. 3 is a fragmental view on enlarged section showing my novel finger attachment 1930. Serial No. 441,414.

- Fig. 4 is a fragmentalv detail on the same scale as Fig. 3 showing the pivotal connection of my attachment tothe derrick finger. The View is ⁇ taken on the same plane as viewed in Fig. 2, and from the upper side of Fig. 3.

- Fig. 5 is a transverse section on a larger scale and taken'on line 5 5, Fig. 3.

- Fig. 6 isa transverse section analogous to the section illustrated in Fig. 5, but showing spring means for maintaining the resting means in operative or inoperative positions. Dot and dash lines indicate the positioning means in inoperative position.

- the well derrick comprises the usual angle-iron corner postsV 7 l which are united by angle iron bars 8, the frame work thus formed supporting the usual walk .9 which extends around the derrick at a considerable distance n from the ground.

- a slotted finger 15 overlies and is adjustably attached to said forble board 10 by bolts 16 which pass through the slot 17 thereof.

- Said finger 15 Y extends at substantially a right angle with 8o relation to said forble board 10A and as viewed in Fig. 1 ithe right hand portion .thereof is reinforced by means of a brace 18 .inorder Y to withstand the lateral pressurey of a .group of well casings yor tubingy or drill pipe 19 which lean against said finger 15.

- the bolts 16 maybe inserted through any of the paired holes 165 in ⁇ forble board 10 to attach the finger 15 upon the forble board V10 at the desired point.

- the finger 15 is provided at its free end with 'an attachment 20 which is mounted in the outer end of slot 17 thereof.

- Said attachment 2O is the device wherein lies my invention and is pivotallyvsecured to the linger 15 95 by means of a horizontally extending pin 20a, and is held in extended position by the shearing pin 20?) which will give way when too heavy downward pressure is applied to the; attachment' 20, thus safeguarding the finger 100 as a whole from collapsing under an excessive strain as when a joint coupling on the well casing would engage the attachment 20.

- ribs or short flanges 50 and 51 between which is fitted the open side of a channel-iron member 22 which is secured to body A by a series of bolts 23 having nuts 24. These bolts are preferably located at the mid-width of the body A and member 22, as shown in Fig, 5-

- Said channel iron member 22 is provided with a series of internally projecting apertured lugs 25 which are desirably cast integral therewith.

- lugs are arranged to support a pivot bar 27 that extends from end to end of member 22 and is held therein by cotter keys 52.

- Dog members 26 are pivoted to bar 27 at the aperture in lugs 25 and are adapted to swing to operative Vand non-operative positions therein.

- the lugs are located .within the upper corner portion of the channel iron member 22, and between each yof vthese pairs of lugs the channel iron is provided in its corner portion with a slot 30 within which said lugs swing, the lower .edge 3l of said slot forming .a stop shoulder to limit the downward swing of each finger 26.

- each finger 26 When in its down position yeach finger 26 extends in a substantially horizontal direction, and in the up position rests upon the rib 5() of body A at a slight backward inclination so as to be out of the way of the casing members as they are moved past the finger and attachment.

- Each of said fingers is desirably bent upwardly at its free end as at 35 thus .adapting it more positively to maintain its upward position as shown in Fig. 5, by causing its center of gravity to be to one side of its pivotal connection with bar 27, yand to adapt it to be out of; the way when not in use. f

- the usual monkey-board 37 is mounted in its usual manner in the well .derrick so as to provide an inside platform adjacent the group of' casing sections or well-tubing 19 from which casings are supplied one at a time to be lowered into the well.

- This group of tubing is placed in an upstanding position, but is slightlyy inclined so as to rest against both the forble board 10 and the transversely extending finger 15.

- a well tube 19a is shown as it apears after the workmen have removed it from the main group and, after throwing the dog 26.?) toits operative position, causing said tube 19a to lean against said dog 266 in a convenient position for being engaged by the clamp means preparatory to being lower-ed into the well.

- the workmen standing on the monkey board may use a stick or rod to move said dogs into and out of operative position.

- the shearing pin 20?) may be a thirty penny nail or the like ,and if the attachment is engaged by the casing members or block on the lowering means with a suiiicient upward or downward pressure the pins 20?) will be sheared ofiE thereby preventing breakage of the entire finger and providing for easy readjustment.

- the workman may easily and quickly move the desired f dog into operative position and remove the other ydogs out of the way where they are instantly available for further use.

- Such spring means 75 may comprise a iiat spring member 76 operating against the end 55 of dog 26 when moved to operative position or against the upper side 56 of dog 26 when the same is moved to inoperative position.

- a derrick a finger supported by said derrick in an elevated position, said finger extending transversely with respect to said derrick; an attachment at one end of said finger; and a plurality of dogs pivotally mounted upon said attachment and adapted to be individually moved to and from a position for intercepting the movement of Vwell casing supported by said finger.

- a derrick a linger supported by said derrick in an elevated position, said finger comprising a bar which eX- tends in a generally horizontal direction; an attachment pivotally connected to said finger; and a plurality of arresting elements mounted at diiierent points with respect to the length of said attachment, said elements being movable individually to and from a position for arresting individual tubing in said derrick.

- a derrick having a platform adapted to support a group of tubing resting endwise thereon, a transversely extending finger mounted upon said derrick at a distance above said platform and in position to form a lateral rest for said group of tubing; a finger attachment connected to said finger; and a plurality of arresting elements mounted on said attachment at different points with respect to the length thereof, said elements being movable individually to and from a position for arresting lateral los movement along said linger of tubing being fed from said group.

- a derrick having a platform adapted to support a group of tubing resting endwise thereon; a transversely extending finger mounted upon said derrick at a distance above said platform and in position to form a lateral rest for said group of tubing; and a plurality of arresting pivoted dogs connected to said finger at dierent points with respect to the length of said finger, said fingers being movable individually to and from a position for arresting lateral movement along said finger of tubing being fed from said stack, said fingers being mounted to swing in a vertical plane and being constructed andV arranged to maintain themselves by gravity in adjusted operative and non-operative positions.

- a derrick linger attachment comprising a body; a channel iron member; means to secure said member alongside of said body with its open side contacting therewith; said member being provided with slots; and dog members pivotally mounted to swing in said slots from an operative to an inoperative position and vice-versa.

- a derrick finger attachment comprising an elongated member adapted to be mounted in a horizontal position in a derrick frame, said member having a corner portion provided with slots cut thereinto; and dogs pivotally mounted in said slots, said dogs being adapted for adjustment to, and to maintain themselves by gravity in, either upright or horizontal position.

- An attachment for derrick fingers com- Y prising a member provided with slots; a bar connected to said member and extending across said slots; and dogs mounted in said slots and pivotally connected to said bar.

- An attachment for derrick fingers comprising a member provided with slots;.a bar connected to said member extending across said slots; and dogs mounted in said slots and pivotally connected to said bar ,said dogs being bent upwardly at their free ends.

- An attachment for derrick fingers comprising a member provided with slots; a bar connected to said member and extending across said slots; and dogs mounted in said slots and pivotally connected to said bar, said dogs being bent upwardly at their free ends, one end of each of said slots forming a stop for positioning in operative position, the dogs which are mounted in the slots.

Landscapes

- Engineering & Computer Science (AREA)

- Life Sciences & Earth Sciences (AREA)

- Geology (AREA)

- Mining & Mineral Resources (AREA)

- Mechanical Engineering (AREA)

- Physics & Mathematics (AREA)

- Environmental & Geological Engineering (AREA)

- Fluid Mechanics (AREA)

- General Life Sciences & Earth Sciences (AREA)

- Geochemistry & Mineralogy (AREA)

- Earth Drilling (AREA)

Description

May 3, 1932- I F. HAMMERSON 1,856,833

DERRICK FINGER ATTACHMENT Filed April 3, 1950 Patented May 3, 1932 PATENT ori-#ice FRANK HVAMMERSON, OF MAYWOOD, CALIFORNIA DERRIGK FINGER ATTACHMENT Application filed April 3,

The invention relates particularly to a new and novel finger attachment for use in connection with' oil well derricks and casingV secy. tions associated therewith.

'5 rThe invention relates to a device for safely and conveniently positioning and holding an individual well casing section within a well derrick relative to lthe means for lowering Such casing sections into the well.

An object of the invention is to safeguard workmen engaged in drilling wells fromthe present danger of falling from elevated portions of the derrick whiler engaged in positioned well casing sections preparatory to lowering the casing sections into the Well.

Another object is to provide more eflicient means for controlling the movements of the casing sections as they are delivered one at a time, from a compact group standing on end in the usual arrangement, to the apparatus for lowering them into the well.

Another object is to provide a very simple and inexpensive arrangement of the character stated, and one which may readily be attached to well drilling equipment now in general use.

Other objects, advantages and features of invention may appear from the accompanying drawings, the -subjoined detail description and the appended claims.

The accompanying drawings illustrate the irvention in a form I at present deem prefera le.

Figure 1` is a transverse section of a well derrick equipped with my inventionshowing a group of upstanding well casing sections in position prior to being individually positioned for lowering into the well. A casing section is more cr less fragmentally and dia- Vgrammatically illustrated in position to be received by the lowering means.

Fig. 2 is a fragmental section on line 2 2, Fig. 1. This view illustrates how my device arrests a casing section asit is moved into position preparatory to lowering the same into the well.

Fig. 3 is a fragmental view on enlarged section showing my novel finger attachment 1930. Serial No. 441,414.

construction in accordance with this invention.

Fig. 4 is a fragmentalv detail on the same scale as Fig. 3 showing the pivotal connection of my attachment tothe derrick finger. The View is `taken on the same plane as viewed in Fig. 2, and from the upper side of Fig. 3.

Fig. 5 is a transverse section on a larger scale and taken'on line 5 5, Fig. 3.

Fig. 6 isa transverse section analogous to the section illustrated in Fig. 5, but showing spring means for maintaining the resting means in operative or inoperative positions. Dot and dash lines indicate the positioning means in inoperative position. p

Referring in detail to the drawings, the well derrick comprises the usual angle-iron corner postsV 7 l which are united by angle iron bars 8, the frame work thus formed supporting the usual walk .9 which extends around the derrick at a considerable distance n from the ground.

Across the quadrangular space inclosed by Y said walk, near one side thereof, extends the forble board 10 having its ends resting upon and supported by said bars 8'. A slotted finger 15 overlies and is adjustably attached to said forble board 10 by bolts 16 which pass through the slot 17 thereof. n Said finger 15 Y extends at substantially a right angle with 8o relation to said forble board 10A and as viewed in Fig. 1 ithe right hand portion .thereof is reinforced by means of a brace 18 .inorder Y to withstand the lateral pressurey of a .group of well casings yor tubingy or drill pipe 19 which lean against said finger 15. The bolts 16 maybe inserted through any of the paired holes 165 in `forble board 10 to attach the finger 15 upon the forble board V10 at the desired point. f

:The finger 15 is provided at its free end with 'an attachment 20 which is mounted in the outer end of slot 17 thereof. Said attachment 2O is the device wherein lies my invention and is pivotallyvsecured to the linger 15 95 by means of a horizontally extending pin 20a, and is held in extended position by the shearing pin 20?) which will give way when too heavy downward pressure is applied to the; attachment' 20, thus safeguarding the finger 100 as a whole from collapsing under an excessive strain as when a joint coupling on the well casing would engage the attachment 20.

At opposite sides of one face of the body A of attachment 20 is provided the ribs or short flanges 50 and 51 between which is fitted the open side of a channel-iron member 22 which is secured to body A by a series of bolts 23 having nuts 24. These bolts are preferably located at the mid-width of the body A and member 22, as shown in Fig, 5-

Said channel iron member 22 is provided with a series of internally projecting apertured lugs 25 which are desirably cast integral therewith.

These lugs are arranged to support a pivot bar 27 that extends from end to end of member 22 and is held therein by cotter keys 52. Dog members 26 are pivoted to bar 27 at the aperture in lugs 25 and are adapted to swing to operative Vand non-operative positions therein.

The lugs are located .within the upper corner portion of the channel iron member 22, and between each yof vthese pairs of lugs the channel iron is provided in its corner portion with a slot 30 within which said lugs swing, the lower .edge 3l of said slot forming .a stop shoulder to limit the downward swing of each finger 26. When in its down position yeach finger 26 extends in a substantially horizontal direction, and in the up position rests upon the rib 5() of body A at a slight backward inclination so as to be out of the way of the casing members as they are moved past the finger and attachment. Each of said fingers is desirably bent upwardly at its free end as at 35 thus .adapting it more positively to maintain its upward position as shown in Fig. 5, by causing its center of gravity to be to one side of its pivotal connection with bar 27, yand to adapt it to be out of; the way when not in use. f

The usual monkey-board 37 is mounted in its usual manner in the well .derrick so as to provide an inside platform adjacent the group of' casing sections or well-tubing 19 from which casings are supplied one at a time to be lowered into the well. This group of tubing is placed in an upstanding position, but is slightlyy inclined so as to rest against both the forble board 10 and the transversely extending finger 15.

In Fig. 1 a well tube 19a is shown as it apears after the workmen have removed it from the main group and, after throwing the dog 26.?) toits operative position, causing said tube 19a to lean against said dog 266 in a convenient position for being engaged by the clamp means preparatory to being lower-ed into the well. The workmen standing on the monkey board may use a stick or rod to move said dogs into and out of operative position. Owing to a series of the dogs Or pawls 26 being provided along my attachment the particular tubular or casing section which is to be deflected from the main group need not be swung far from its base at any stage of the work, for, when the portion of the group of tubes 19 which is nearest to the monkey board has been used up, a dog 26 which is nearer to the main group of tubes will be used to arrest each tube 19a when it is withdrawn from the group.

The shearing pin 20?) may be a thirty penny nail or the like ,and if the attachment is engaged by the casing members or block on the lowering means with a suiiicient upward or downward pressure the pins 20?) will be sheared ofiE thereby preventing breakage of the entire finger and providing for easy readjustment.

By having a series of dogs 26 the workman may easily and quickly move the desired f dog into operative position and remove the other ydogs out of the way where they are instantly available for further use.

It will be apparent that without departing Jfrom the spirit of my invention, I may provide suitable spring means 75 for maintaining the dogs 26 in either operative or nonoperative positions. Such spring means may comprise a iiat spring member 76 operating against the end 55 of dog 26 when moved to operative position or against the upper side 56 of dog 26 when the same is moved to inoperative position.

I claim:

l. In combination, a derrick, a finger supported by said derrick in an elevated position, said finger extending transversely with respect to said derrick; an attachment at one end of said finger; and a plurality of dogs pivotally mounted upon said attachment and adapted to be individually moved to and from a position for intercepting the movement of Vwell casing supported by said finger.

2. In combination, a derrick; a linger supported by said derrick in an elevated position, said finger comprising a bar which eX- tends in a generally horizontal direction; an attachment pivotally connected to said finger; and a plurality of arresting elements mounted at diiierent points with respect to the length of said attachment, said elements being movable individually to and from a position for arresting individual tubing in said derrick.

3. In combination, a derrick having a platform adapted to support a group of tubing resting endwise thereon, a transversely extending finger mounted upon said derrick at a distance above said platform and in position to form a lateral rest for said group of tubing; a finger attachment connected to said finger; and a plurality of arresting elements mounted on said attachment at different points with respect to the length thereof, said elements being movable individually to and from a position for arresting lateral los movement along said linger of tubing being fed from said group.

4. In combination, a derrick having a platform adapted to support a group of tubing resting endwise thereon; a transversely extending finger mounted upon said derrick at a distance above said platform and in position to form a lateral rest for said group of tubing; and a plurality of arresting pivoted dogs connected to said finger at dierent points with respect to the length of said finger, said fingers being movable individually to and from a position for arresting lateral movement along said finger of tubing being fed from said stack, said fingers being mounted to swing in a vertical plane and being constructed andV arranged to maintain themselves by gravity in adjusted operative and non-operative positions.

5. A derrick linger attachment comprising a body; a channel iron member; means to secure said member alongside of said body with its open side contacting therewith; said member being provided with slots; and dog members pivotally mounted to swing in said slots from an operative to an inoperative position and vice-versa.

6. A derrick finger attachment comprising an elongated member adapted to be mounted in a horizontal position in a derrick frame, said member having a corner portion provided with slots cut thereinto; and dogs pivotally mounted in said slots, said dogs being adapted for adjustment to, and to maintain themselves by gravity in, either upright or horizontal position.

7. An attachment for derrick fingers com- Y prising a member provided with slots; a bar connected to said member and extending across said slots; and dogs mounted in said slots and pivotally connected to said bar.

8. An attachment for derrick fingers comprising a member provided with slots;.a bar connected to said member extending across said slots; and dogs mounted in said slots and pivotally connected to said bar ,said dogs being bent upwardly at their free ends.

9. An attachment for derrick fingers comprising a member provided with slots; a bar connected to said member and extending across said slots; and dogs mounted in said slots and pivotally connected to said bar, said dogs being bent upwardly at their free ends, one end of each of said slots forming a stop for positioning in operative position, the dogs which are mounted in the slots.

In testimony whereof, I have hereunto set my hand at Los Angeles, California, this 27 th day of March, 1930.

FRANK HAMMERSON.

Priority Applications (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| US441414A US1856833A (en) | 1930-04-03 | 1930-04-03 | Derrick finger attachment |

Applications Claiming Priority (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| US441414A US1856833A (en) | 1930-04-03 | 1930-04-03 | Derrick finger attachment |

Publications (1)

| Publication Number | Publication Date |

|---|---|

| US1856833A true US1856833A (en) | 1932-05-03 |

Family

ID=23752779

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| US441414A Expired - Lifetime US1856833A (en) | 1930-04-03 | 1930-04-03 | Derrick finger attachment |

Country Status (1)

| Country | Link |

|---|---|

| US (1) | US1856833A (en) |

-

1930

- 1930-04-03 US US441414A patent/US1856833A/en not_active Expired - Lifetime

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| US4359089A (en) | Carrier for blowout preventer | |

| US1754132A (en) | Scaffold jack | |

| US2331558A (en) | Portable derrick | |

| US1829879A (en) | Pipe handling apparatus | |

| US1838151A (en) | Barricade structure | |

| US3029607A (en) | Device for preventing cave-ins | |

| US1856833A (en) | Derrick finger attachment | |

| US2582528A (en) | Sheetsxsheet i | |

| US1799160A (en) | Samson post | |

| US1643730A (en) | Well drill | |

| US2425302A (en) | Safety adjustable pipe stabbing board | |

| US2695081A (en) | Portable well drilling apparatus | |

| US2326052A (en) | Pipe handling and racking platform | |

| US2148058A (en) | Lazy board | |

| US2840198A (en) | Apparatus and method for multiple well drilling | |

| US2291251A (en) | Drill pipe protector remover | |

| US2661711A (en) | Anchor davit | |

| US2413297A (en) | Pipe holder | |

| US1040721A (en) | Tile-setter. | |

| US2991852A (en) | Drilling rig and method of extending an upper section of the mast thereof | |

| US1887901A (en) | Pipe stacking appliance for oil wells | |

| US1716559A (en) | Well-derrick device | |

| US1971609A (en) | Tubing and drill pipe rack | |

| US2470983A (en) | Support and guide for drill stems | |

| US2645454A (en) | Auxiliary jack for oil wells |