US1856729A - Fiber shipping case - Google Patents

Fiber shipping case Download PDFInfo

- Publication number

- US1856729A US1856729A US486564A US48656430A US1856729A US 1856729 A US1856729 A US 1856729A US 486564 A US486564 A US 486564A US 48656430 A US48656430 A US 48656430A US 1856729 A US1856729 A US 1856729A

- Authority

- US

- United States

- Prior art keywords

- flaps

- box

- fiber

- extending

- shipping case

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Expired - Lifetime

Links

- 239000000835 fiber Substances 0.000 title description 9

- 238000010276 construction Methods 0.000 description 4

- 238000007789 sealing Methods 0.000 description 3

- 230000003014 reinforcing effect Effects 0.000 description 2

- 239000000428 dust Substances 0.000 description 1

- 239000011094 fiberboard Substances 0.000 description 1

- 238000004519 manufacturing process Methods 0.000 description 1

- 239000000463 material Substances 0.000 description 1

- 239000000123 paper Substances 0.000 description 1

Images

Classifications

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B65—CONVEYING; PACKING; STORING; HANDLING THIN OR FILAMENTARY MATERIAL

- B65D—CONTAINERS FOR STORAGE OR TRANSPORT OF ARTICLES OR MATERIALS, e.g. BAGS, BARRELS, BOTTLES, BOXES, CANS, CARTONS, CRATES, DRUMS, JARS, TANKS, HOPPERS, FORWARDING CONTAINERS; ACCESSORIES, CLOSURES, OR FITTINGS THEREFOR; PACKAGING ELEMENTS; PACKAGES

- B65D5/00—Rigid or semi-rigid containers of polygonal cross-section, e.g. boxes, cartons or trays, formed by folding or erecting one or more blanks made of paper

- B65D5/42—Details of containers or of foldable or erectable container blanks

- B65D5/44—Integral, inserted or attached portions forming internal or external fittings

- B65D5/46—Handles

- B65D5/46072—Handles integral with the container

- B65D5/4608—Handgrip holes

-

- Y—GENERAL TAGGING OF NEW TECHNOLOGICAL DEVELOPMENTS; GENERAL TAGGING OF CROSS-SECTIONAL TECHNOLOGIES SPANNING OVER SEVERAL SECTIONS OF THE IPC; TECHNICAL SUBJECTS COVERED BY FORMER USPC CROSS-REFERENCE ART COLLECTIONS [XRACs] AND DIGESTS

- Y10—TECHNICAL SUBJECTS COVERED BY FORMER USPC

- Y10S—TECHNICAL SUBJECTS COVERED BY FORMER USPC CROSS-REFERENCE ART COLLECTIONS [XRACs] AND DIGESTS

- Y10S229/00—Envelopes, wrappers, and paperboard boxes

- Y10S229/915—Stacking feature

Definitions

- This invention relates to paper boxes, or rather the larger and heavier variety known as fiber shipping cases, and it has as its objects an improved box of this sort which is easy to manufacture and will provide specially reinforced hand gripping flaps on the packed box, also such a construction which will not prevent the boxes from being stacked but which will in fact aid in aligning the boxes one upon another.

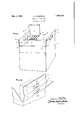

- Fig. l is a perspective view of any improved box filled with merchandise and with a portion of one closing flap broken and lifted to show the relation of the parts.

- Fig. 2 is an enlarged perspective View of a portion of the box showing-one of the hand grip flaps unfolded to show the manner of its scoring.

- my box comprises a '7 sheet of fiber board 1 either plain or corrugated as may be desired, cut, folded and Joined in the well known manner to produce a rectangular body 1 with four free flaps 2, 2, 3, 3 extending from the upper edges of its walls. Ordinarily such flaps are simply glued down in overlapping arrangement to close and seal the box over whatever commodity 4 the box is filled with.

- All four flaps are scored at their juncture with the vertical walls of the box to fold, andthe flaps 3, 3 lying at right angles to flaps 2, 2 are scored in two more places, one being at 5 to fold inwardly and the other at 6 to fold outwardly so that when the flaps may bedoubled from the line 5 to form an outer layer 3 and an inner layer 3 and a marginal layer 3", while extending through both layers 3 and 3'.

- are elongated apertures 10, 10' adapted to coincide when the flaps are folded to make a single hand grip 111 eachup- 2, and to which margins the closing flaps are usually pasted when the box is sealed, and in addition a strip of gummed tape 7 is run along over the abutting edges of the main closing flaps to complete the closure.

- the marginal portions 3" of the gripping flaps will be properly supported from below, but if the nature of the goods afi'ords no such support a heavy sheet of cardboard is usually laid on the goods under marginal pieces 3" to give a flat support, though of course this is optional.

- main flaps 2, 2 maybe made of a height to overlap to any desired extent when closed, also that a reinforcing strip of any suitable material may be inserted between the layers of the folded handle as at 11.

- a fiber box having a rectangular body with flaps extending from the upper edges i the box,

- a fiber box having a rectangular bodyof its side walls, two of said flaps arranged to fold toward one another over the top of the box, the other two projecting above the box in spaced relation for nesting a similar box therebetween and being doubled downward upon themselves and provided with hand grip openings, and marginal portions extending under the two closing flaps and coextensive therewith.

- a fiber box having a rectangular body with fla sv extending from the upper edges of its si e walls, twoof said flaps arranged to fold toward one another over the top of the other two projecting above the box and bein doubled downward upon openings, and a reinforcing strip extending between the layers of the doubled flaps above the hand grip openings.

- a pasteboard box having a rectangular body provided with handle flaps extending upwardly at opposite edges, said handle flaps of pasteboard stock doubled over and apertured for hand grips, and with free ends ex- Y tending downward into the box, and a pair of flaps connected to the other two edges of the box arranged to fold inwardly for sealing the box.

- a pasteboard box having a rectangular body provided with handle aps extending upwardly at opposite edges, said handle .flaps of pasteboard stock doubled. over and apertured forhand grips, and with free ends extending downward into the box, and a pair of flaps connected to the other two edges of the box arranged to fold inwardly for sealing the box formed'of a length to lie tightly between said handle flaps to hold same in upward extension.

- hand grip fiber box having a rectangular body with flaps extending from the upper edges of its side walls, two of said flaps arranged

Landscapes

- Engineering & Computer Science (AREA)

- Mechanical Engineering (AREA)

- Cartons (AREA)

Description

3, 1932- J. F. ROBINSON 1,356,729

FIBER SHIPPING CASE Filed Oct. 6, 1950 INVENT OR. JOJEPH ff Roam/.50

ATTORNEYS.

rg Z hu a I Patented May 3, 1932 UNITEli STATES PATENT OFFICE JOSEPH F. ROBINSON, OF SAN FRANCISCO, CALIFORNIA, ASSIGNOR TO SCHMIDT IIITHO" GRAPH COMPANY, OF SAN FRANCISCO,

FORNIA CALIFORNIA, A CORPORATION OF CALI- FIBER SHIPPING CASE Application filed October 6, 1930. Serial No. 486,564.

This invention relates to paper boxes, or rather the larger and heavier variety known as fiber shipping cases, and it has as its objects an improved box of this sort which is easy to manufacture and will provide specially reinforced hand gripping flaps on the packed box, also such a construction which will not prevent the boxes from being stacked but which will in fact aid in aligning the boxes one upon another.

My improved construction is shown in the drawings accompanying this application and in which drawings Fig. l is a perspective view of any improved box filled with merchandise and with a portion of one closing flap broken and lifted to show the relation of the parts. I

Fig. 2 is an enlarged perspective View of a portion of the box showing-one of the hand grip flaps unfolded to show the manner of its scoring.

In further detail my box comprises a '7 sheet of fiber board 1 either plain or corrugated as may be desired, cut, folded and Joined in the well known manner to produce a rectangular body 1 with four free flaps 2, 2, 3, 3 extending from the upper edges of its walls. Ordinarily such flaps are simply glued down in overlapping arrangement to close and seal the box over whatever commodity 4 the box is filled with. I

In my improved construction, however, I make two of the flaps 2, 2 of a length substantially equal to the width X of the box and of a height so that when both are folded down their long edges will just meet to close the box.

All four flaps are scored at their juncture with the vertical walls of the box to fold, andthe flaps 3, 3 lying at right angles to flaps 2, 2 are scored in two more places, one being at 5 to fold inwardly and the other at 6 to fold outwardly so that when the flaps may bedoubled from the line 5 to form an outer layer 3 and an inner layer 3 and a marginal layer 3", while extending through both layers 3 and 3'. are elongated apertures 10, 10' adapted to coincide when the flaps are folded to make a single hand grip 111 eachup- 2, and to which margins the closing flaps are usually pasted when the box is sealed, and in addition a strip of gummed tape 7 is run along over the abutting edges of the main closing flaps to complete the closure.

If-the box is filled-evenly with goods as indicated in Fig. 1 or if it is filled with carton goods which present a relatively flat upper surface, the marginal portions 3" of the gripping flaps will be properly supported from below, but if the nature of the goods afi'ords no such support a heavy sheet of cardboard is usually laid on the goods under marginal pieces 3" to give a flat support, though of course this is optional. 1

When the box as described is filled and sealed the hand flaps with the hand grips are held in vertical position as shown so that they are always ready for lifting thebox cent score lines, with a result also that a slight wall is produced at 9 which aids in sealing'the end joint of the main flaps and prevents the ingress of dirt and dust at this point.

It is of course evident that if desired the main flaps 2, 2 maybe made of a height to overlap to any desired extent when closed, also that a reinforcing strip of any suitable material may be inserted between the layers of the folded handle as at 11.

By the construction described it will be seen to be adapted for use with shipping cases of relatively large dimensions filled with heavy goods such as canned goods and and to make the like which in ordinary fiber cases are very hard to handle, whereas with the doubled over gripping flaps substantial handles are provided, and with the margins 3" extending under the main closing flaps 2 all glued in place a structure is secured which will easily support the load and be in good shape at the end of long shipments.

I therefore claim I i 1. A fiber box having a rectangular body with flaps extending from the upper edges i the box,

of its side walls, two of said flaps arranged to fold toward one another over the top of the box, and the other two projecting above the box substantially in the planes of the side walls respectively from which they extend and being doubled downward upon themselves and provided with hand grip openings, the two projecting flaps spaced to permit nesting of a similar size box therebetween when the boxes are piled.

2. A fiber box having a rectangular bodyof its side walls, two of said flaps arranged to fold toward one another over the top of the box, the other two projecting above the box in spaced relation for nesting a similar box therebetween and being doubled downward upon themselves and provided with hand grip openings, and marginal portions extending under the two closing flaps and coextensive therewith.

4. A fiber box having a rectangular body with fla sv extending from the upper edges of its si e walls, twoof said flaps arranged to fold toward one another over the top of the other two projecting above the box and bein doubled downward upon openings, and a reinforcing strip extending between the layers of the doubled flaps above the hand grip openings.

6. A pasteboard box having a rectangular body provided with handle flaps extending upwardly at opposite edges, said handle flaps of pasteboard stock doubled over and apertured for hand grips, and with free ends ex- Y tending downward into the box, and a pair of flaps connected to the other two edges of the box arranged to fold inwardly for sealing the box.

" 7. A pasteboard box having a rectangular body provided with handle aps extending upwardly at opposite edges, said handle .flaps of pasteboard stock doubled. over and apertured forhand grips, and with free ends extending downward into the box, and a pair of flaps connected to the other two edges of the box arranged to fold inwardly for sealing the box formed'of a length to lie tightly between said handle flaps to hold same in upward extension.

JOSEPH F. ROBINSON.

themselves an provided with hand grip I openings, and marginal portions extending under the two closing flaps coextensive with the length of the side walls from which they extend, said hand grip openings spaced away from the foldingllnes of the flaps providing an abutting wall for the ends of the closing flaps.

to fold toward one another over the top of the box, the other two projecting above the box and being doubled downward upon themselves and provided with hand grip fiber box having a rectangular body with flaps extending from the upper edges of its side walls, two of said flaps arranged

Priority Applications (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| US486564A US1856729A (en) | 1930-10-06 | 1930-10-06 | Fiber shipping case |

Applications Claiming Priority (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| US486564A US1856729A (en) | 1930-10-06 | 1930-10-06 | Fiber shipping case |

Publications (1)

| Publication Number | Publication Date |

|---|---|

| US1856729A true US1856729A (en) | 1932-05-03 |

Family

ID=23932384

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| US486564A Expired - Lifetime US1856729A (en) | 1930-10-06 | 1930-10-06 | Fiber shipping case |

Country Status (1)

| Country | Link |

|---|---|

| US (1) | US1856729A (en) |

Cited By (6)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US2772044A (en) * | 1954-08-17 | 1956-11-27 | Inland Container Corp | Handled carton |

| US3521741A (en) * | 1968-06-04 | 1970-07-28 | Int Paper Co | Plant container |

| US3815809A (en) * | 1972-06-21 | 1974-06-11 | Interstate Folding Box Co | Carton with integral reinforced handle |

| US4471870A (en) * | 1982-07-14 | 1984-09-18 | Owens-Illinois, Inc. | Package for holding a plurality of discrete container assemblies |

| US4981254A (en) * | 1990-05-01 | 1991-01-01 | Inland Container Corporation | Top structure for a collapsible carton |

| US6247593B1 (en) * | 1999-03-17 | 2001-06-19 | Ashland Inc. | Carton having integrally formed alignment retainer tabs |

-

1930

- 1930-10-06 US US486564A patent/US1856729A/en not_active Expired - Lifetime

Cited By (6)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US2772044A (en) * | 1954-08-17 | 1956-11-27 | Inland Container Corp | Handled carton |

| US3521741A (en) * | 1968-06-04 | 1970-07-28 | Int Paper Co | Plant container |

| US3815809A (en) * | 1972-06-21 | 1974-06-11 | Interstate Folding Box Co | Carton with integral reinforced handle |

| US4471870A (en) * | 1982-07-14 | 1984-09-18 | Owens-Illinois, Inc. | Package for holding a plurality of discrete container assemblies |

| US4981254A (en) * | 1990-05-01 | 1991-01-01 | Inland Container Corporation | Top structure for a collapsible carton |

| US6247593B1 (en) * | 1999-03-17 | 2001-06-19 | Ashland Inc. | Carton having integrally formed alignment retainer tabs |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| US2151472A (en) | Carton | |

| US1150105A (en) | Carton. | |

| US2114052A (en) | Container | |

| US2312598A (en) | Container | |

| US2347422A (en) | Octagonal box | |

| US959261A (en) | Folding box. | |

| US1953885A (en) | Container | |

| US2111376A (en) | Box structure | |

| US1550646A (en) | Shipping box | |

| US2216299A (en) | Box | |

| US1624439A (en) | Box | |

| US2336655A (en) | Carton | |

| US2311857A (en) | Reinforcing means for folding boxes | |

| US1856729A (en) | Fiber shipping case | |

| US3291370A (en) | Two opposed recessed end panel carton with closure flaps | |

| US1925298A (en) | Box | |

| US2013227A (en) | Carton | |

| US2309134A (en) | Receptacle | |

| US2597289A (en) | Paper box | |

| US1987461A (en) | Box | |

| US2614745A (en) | Divisible carton | |

| US2665050A (en) | Shipping container | |

| US886058A (en) | Paper vessel. | |

| US2364829A (en) | Box | |

| US3929273A (en) | Tray for strawberries and the like |