US1856548A - Cover for sintering machines - Google Patents

Cover for sintering machines Download PDFInfo

- Publication number

- US1856548A US1856548A US383187A US38318729A US1856548A US 1856548 A US1856548 A US 1856548A US 383187 A US383187 A US 383187A US 38318729 A US38318729 A US 38318729A US 1856548 A US1856548 A US 1856548A

- Authority

- US

- United States

- Prior art keywords

- hood

- pallets

- air

- charge

- cover

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Expired - Lifetime

Links

- 238000005245 sintering Methods 0.000 title description 11

- 239000000463 material Substances 0.000 description 5

- NINIDFKCEFEMDL-UHFFFAOYSA-N Sulfur Chemical compound [S] NINIDFKCEFEMDL-UHFFFAOYSA-N 0.000 description 3

- 239000005864 Sulphur Substances 0.000 description 3

- 238000002485 combustion reaction Methods 0.000 description 3

- 238000001816 cooling Methods 0.000 description 3

- 101150095401 AURKA gene Proteins 0.000 description 1

- 238000003723 Smelting Methods 0.000 description 1

- 238000006243 chemical reaction Methods 0.000 description 1

- 238000010276 construction Methods 0.000 description 1

- 230000001276 controlling effect Effects 0.000 description 1

- 210000005069 ears Anatomy 0.000 description 1

- 230000004927 fusion Effects 0.000 description 1

- 239000007789 gas Substances 0.000 description 1

- 238000004519 manufacturing process Methods 0.000 description 1

- 239000002245 particle Substances 0.000 description 1

- 238000007670 refining Methods 0.000 description 1

- 230000001105 regulatory effect Effects 0.000 description 1

Images

Classifications

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F27—FURNACES; KILNS; OVENS; RETORTS

- F27B—FURNACES, KILNS, OVENS OR RETORTS IN GENERAL; OPEN SINTERING OR LIKE APPARATUS

- F27B21/00—Open or uncovered sintering apparatus; Other heat-treatment apparatus of like construction

- F27B21/06—Endless-strand sintering machines

Definitions

- This invention relates to metallurgical apparatus, and more particularly to sintering machines.

- the invention provides for preheating the air which is passed through the pallets of a sintering machine in order to prevent the surface 'ofthe charge from becomingcooled before the reaction has been completed. This is particularly applicable in cases where it is desired to reduce the sulphur content of an ore, since the cold air being drawn through the charge chills the surface before the sul- .phur has been burned to the desired extent. This is evidenced by the fact that the surface of such sinter cakev 'frequently contains ⁇ a substantially higher percentage of sulphur than the interior thereof.

- the present invention provides a hood for covering the surface of the pallets and which is heated by passage of the air therethrough.y

- the hood is so arranged, that before air enters the pallets it passes along the hot portion of tliehood and is preheated 'before it can come in contact with the charge.

- Suitable means are provided for'controlling the elevation of thehood with respect to the pallets and regulating the amount of air which passes therethrough.

- the Ainvention also consists in certain new and originalfeaturesvof construction and combinations of partshereinafter set forth and claimed.

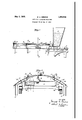

- the invention is shown as applied to a sinter ing machine including a plurality of pallets which are caused by any suitable means, such as driving wheel 11, to pass along trackway 12.

- Pallets 10 passing along trackway 12 are first brought under hopper 14 from which they receive the charge of ore and other material to be sintered, thence under mufiie 15 which ignites the combustible material at the surface of the charge.

- Pallets 10 are then passed under hood 16 and over a wind box (not shown) by means of which air is caused to be passed downwardly therethrough.

- the air in so passing supports the combustion of the combustible material contained in the charge in a manner well known in the sintering art, and causes an incipient fusion of the ore particles, whereby a porous sinter cake is produced.

- Hood 16 is positionedabove the pallets l0 by means of support 17 and is provided with an adjustable end member 18 which is secured thereto by any suitable means, such as bolts 19 cooperating with elongated slots 2O formed in ears 21 ywhich are secured to said hood in any convenient manner.

- End member 18 is adapted to be positioned closely adjacent the surface of the material ⁇ in pallets 10 and thereby prevent air from entering the end of the hood and cooling the upper surface of the charge.

- Air ducts are formed by plates 26 which are secured to hoodl as by studs 27. Said air ⁇ ducts are designed to receive air from thev outside of the machine and to supply said air to the'top of the pallets after which it is drawn through the charge by means of the wind box, not shown.

- the air in passing through ducts 25 is preheated by contact with the hot hood and is applied to the charge in a heated condition whereby the rapid cooling ofthe upper surface of the charge is prevented.

- One end of the cover is positioned adjacent kthe mulile, and the other end is provided with an adjustable vmember 18 vwhich should preferably come within one inch of the top of the charge forpreventing air from entering and cooling the. same.. ,Y Infoperation'it has been found that temperatures as high as 800 C. are obtained in the gases under the cover. It is accordingly essential to make the hood from" material i vwhich will stand this temperature.V

- the hood has been shownas formed of Ya #plurality of sections lsecured togetherby flanges and Vbolts 3 1. It is obvious that lthe hood could befmade of'any desired length for securing ⁇ ,the proper operation lof the sintering machine, but is particularly important at the portio'nadjacent the mufde where the top of the charge is being burned. Afterthe top has become ,burned the upper portion 1of the charge serves to preheat the air. and .thereby assist in the combustion of the lower portions. It is evident, therefore,

- Vhood extending over said'pallets from a point adjacent said mulfle, said hood beingarched and extending suiiciently close to thejsides of said pallets to restrict the passage of air therebetween, air Y ducts carried by said hood through vwhichthe incoming air is caused to fpass, said ducts directing saidinto contact with said hood whereby saidair is preheated before being applied .to the'charge in said pallets, and an adjustable end member mounted ,on saidy hood and adapted to be extended into close relationship. to said charge so that excessive lateral movement of air thereover is prevented.

- a hoody covering said pallets through a portion of their travel, means for guiding air underfsaid hood and in contact with the lower surface thereof so that said air becomes heated by heat transfer from said hood and meansfor limiting horizontal movement ofsaid heated air relatively tothe surface of the charge in said pallets.

- Sii In combination with asinteringmachine I i having a'fmuliie and movable pallets, a lowv h'oodextendin'g over said pallets from a point adjacent said muffle,-said hood bein'g'arched and extending suiciently closeto the sides of sald pallets to restrict the passage of air there.- between,V air. ducts carried by said hood.

Landscapes

- Engineering & Computer Science (AREA)

- Mechanical Engineering (AREA)

- General Engineering & Computer Science (AREA)

- Manufacture And Refinement Of Metals (AREA)

Description

May 3, 1932- E G. u. GREENE 1,856,548

COVER FOR SINTERING MACHINES original Filed Aug. 3, 1929 Patented May 3, 1932 UNITED i STATES PATENT OFFICE vG'rIEYlRALD U. GREENEKOF SALT LAKE CITY, UTAH, ASSIGNOR TO AMERICAN SMELTING vAND REFINING COMPANY, OF NEW YORK, N. Y., A CORPORATION OF NEW JERSEY COVER FOR SINTERING MACHINES yAppue'aticm ined-August 3, 1929, serien Ne. 383,187. Renewed June 17, 1931.

This invention relates to metallurgical apparatus, and more particularly to sintering machines.

The invention provides for preheating the air which is passed through the pallets of a sintering machine in order to prevent the surface 'ofthe charge from becomingcooled before the reaction has been completed. This is particularly applicable in cases where it is desired to reduce the sulphur content of an ore, since the cold air being drawn through the charge chills the surface before the sul- .phur has been burned to the desired extent. This is evidenced by the fact that the surface of such sinter cakev 'frequently contains `a substantially higher percentage of sulphur than the interior thereof.

The present invention provides a hood for covering the surface of the pallets and which is heated by passage of the air therethrough.y The hood is so arranged, that before air enters the pallets it passes along the hot portion of tliehood and is preheated 'before it can come in contact with the charge. Suitable means are provided for'controlling the elevation of thehood with respect to the pallets and regulating the amount of air which passes therethrough. A

l The Ainvention also consists in certain new and originalfeaturesvof construction and combinations of partshereinafter set forth and claimed.

lAlthough the novel features which are be- 'V lieved to be characteristic of this invention (LTL will be particularly pointed out in the claims vappended hereto, the invention itself, as to Like reference characters denote like yparts in the several figures of the drawings.

In the following description and in the claims parts will be identified by specic names for convenience, but they are intended to be as generic in their application to similar parts as the art will permit.

Referring to the drawings more in detail, the invention is shown as applied to a sinter ing machine including a plurality of pallets which are caused by any suitable means, such as driving wheel 11, to pass along trackway 12. Pallets 10 passing along trackway 12 are first brought under hopper 14 from which they receive the charge of ore and other material to be sintered, thence under mufiie 15 which ignites the combustible material at the surface of the charge. Pallets 10 are then passed under hood 16 and over a wind box (not shown) by means of which air is caused to be passed downwardly therethrough. The air in so passing supports the combustion of the combustible material contained in the charge in a manner well known in the sintering art, and causes an incipient fusion of the ore particles, whereby a porous sinter cake is produced.

Hood 16 is positionedabove the pallets l0 by means of support 17 and is provided with an adjustable end member 18 which is secured thereto by any suitable means, such as bolts 19 cooperating with elongated slots 2O formed in ears 21 ywhich are secured to said hood in any convenient manner.

- Air ducts are formed by plates 26 which are secured to hoodl as by studs 27. Said air` ducts are designed to receive air from thev outside of the machine and to supply said air to the'top of the pallets after which it is drawn through the charge by means of the wind box, not shown. The air in passing through ducts 25 is preheated by contact with the hot hood and is applied to the charge in a heated condition whereby the rapid cooling ofthe upper surface of the charge is prevented. Y f

"Ithas been found that the above described CTI.

apparatus not only provides a more complete `elimination of sulphur, but aids in the production of Va final sinter of more desirable physical characteristics. One end of the cover is positioned adjacent kthe mulile, and the other end is provided with an adjustable vmember 18 vwhich should preferably come within one inch of the top of the charge forpreventing air from entering and cooling the. same.. ,Y Infoperation'it has been found that temperatures as high as 800 C. are obtained in the gases under the cover. It is accordingly essential to make the hood from" material i vwhich will stand this temperature.V

The hood has been shownas formed of Ya #plurality of sections lsecured togetherby flanges and Vbolts 3 1. It is obvious that lthe hood could befmade of'any desired length for securing `,the proper operation lof the sintering machine, but is particularly important at the portio'nadjacent the mufde where the top of the charge is being burned. Afterthe top has become ,burned the upper portion 1of the charge serves to preheat the air. and .thereby assist in the combustion of the lower portions. It is evident, therefore,

:that the `exact dimension of the hood will 'be determined. by thethicknessof the charge f and the irate of combustion.

" f' v1. In combination witha sintering machine having a muffle, a low hood covering the `pallets'adj acent'said muiiie, said hood being provided withV air ducts at the sides thereof, the air pasing through said ducts being4 preheatedby contact with said hood beforerbeing applied to the surface of the charge; u i

' wherebythe entrance of air into the 2. 'In combination with a sintering machine having a muffle, a low hood coveringthe pallets'adjacent said muflie, said hood being provided with air ducts atthe sides thereof, the airk vpassing through( said 'ducts beingv preheated by contact with said hood before bej 'ing applied tothe surface ofzth'e charge, the

end Vof said hoodopp'osite4 said mufflebeing Vprovided Ywith an adjustable closure member endfOf `said hood may be controlled. i

Vhood extending over said'pallets from a point adjacent said mulfle, said hood beingarched and extending suiiciently close to thejsides of said pallets to restrict the passage of air therebetween, air Y ducts carried by said hood through vwhichthe incoming air is caused to fpass, said ducts directing saidinto contact with said hood whereby saidair is preheated before being applied .to the'charge in said pallets, and an adjustable end member mounted ,on saidy hood and adapted to be extended into close relationship. to said charge so that excessive lateral movement of air thereover is prevented. Y v l l Y 5. In a sintering machine having a plurality of movable pallets, a hood Vcovering said pallets through a portion of their travel, said hood extending laterallyv beyond said pallets and being spaced vertically from the Yedge-of said pallets to form air ducts between said ,hood and/said edges, whereby the y air drawnV through said. pallets is caused to lenter under the overhanging edges-of said hood and to become preheated by contact therewith'before being applied to the surface of the charge in saidpallets. Y Y

' 6. In afsintering machine having a pluralityY of movable pallets, a hoody covering said pallets through a portion of their travel, means for guiding air underfsaid hood and in contact with the lower surface thereof so that said air becomes heated by heat transfer from said hood and meansfor limiting horizontal movement ofsaid heated air relatively tothe surface of the charge in said pallets.

7. In a sinteringmachine havingy a pluralf ity of movable pallets, ,ahod covering said pallets through a portion of their travel and extending laterally beyond Vvsaid pallets and Vmeans for guiding air under said hood Vand in contact'with saidl lateral extensionso that said*k air is pre-heated by said'contactand means for limiting horizontal movement of said pre-heatedair relatively to the vsurface of the charge in said'pallets. v i

In. testimony'whereof I have hereiinto set my hand.

'GERALD fu, GREENE. i

1; Sii In combination with asinteringmachine I i having a'fmuliie and movable pallets, a lowv h'oodextendin'g over said pallets from a point adjacent said muffle,-said hood bein'g'arched and extending suiciently closeto the sides of sald pallets to restrict the passage of air there.- between,V air. ducts carried by said hood.

Priority Applications (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| US383187A US1856548A (en) | 1929-08-03 | 1929-08-03 | Cover for sintering machines |

Applications Claiming Priority (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| US383187A US1856548A (en) | 1929-08-03 | 1929-08-03 | Cover for sintering machines |

Publications (1)

| Publication Number | Publication Date |

|---|---|

| US1856548A true US1856548A (en) | 1932-05-03 |

Family

ID=23512080

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| US383187A Expired - Lifetime US1856548A (en) | 1929-08-03 | 1929-08-03 | Cover for sintering machines |

Country Status (1)

| Country | Link |

|---|---|

| US (1) | US1856548A (en) |

Cited By (3)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US3088723A (en) * | 1961-03-21 | 1963-05-07 | Reserve Mining Co | Air draft for pelletizing furnace |

| RU2432538C1 (en) * | 2010-04-26 | 2011-10-27 | Открытое акционерное общество "Научно-исследовательский институт металлургической теплотехники (ОАО "ВНИИМТ") | Device for supply of heat carrier into layer of sintered charge at sintering machine |

| RU2453785C1 (en) * | 2010-10-13 | 2012-06-20 | Открытое акционерное общество "Научно-исследовательский институт металлургической теплотехники (ОАО "ВНИИМТ") | Sintering method of sintering mix using dusty aspiration air |

-

1929

- 1929-08-03 US US383187A patent/US1856548A/en not_active Expired - Lifetime

Cited By (3)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US3088723A (en) * | 1961-03-21 | 1963-05-07 | Reserve Mining Co | Air draft for pelletizing furnace |

| RU2432538C1 (en) * | 2010-04-26 | 2011-10-27 | Открытое акционерное общество "Научно-исследовательский институт металлургической теплотехники (ОАО "ВНИИМТ") | Device for supply of heat carrier into layer of sintered charge at sintering machine |

| RU2453785C1 (en) * | 2010-10-13 | 2012-06-20 | Открытое акционерное общество "Научно-исследовательский институт металлургической теплотехники (ОАО "ВНИИМТ") | Sintering method of sintering mix using dusty aspiration air |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| US1856548A (en) | Cover for sintering machines | |

| US1885381A (en) | Process for the production of iron | |

| DE886390C (en) | Process for melting sulphide-containing raw materials | |

| US2030627A (en) | Process of making iron oxide and sulphur dioxide from iron sulphide ores | |

| US2157321A (en) | Method of and apparatus for treating cement raw material and similar substances | |

| US2015336A (en) | Coking of agglomerates | |

| US1920379A (en) | Producing and melting sponge iron | |

| US1800239A (en) | Manufacture of lead oxides | |

| US2030021A (en) | Method and apparatus for the production of sulphur dioxide | |

| US1567756A (en) | Method and apparatus for flattening and annealing sheet glass | |

| US1773779A (en) | Method of reducing zinc ore and the product obtained thereby | |

| US2056564A (en) | Apparatus for roasting ores | |

| US2053249A (en) | Process of treating zinc oxide | |

| US1992049A (en) | Roasting of plumbiferous pyrites | |

| US2035699A (en) | Method and apparatus for roasting ores | |

| US1115281A (en) | Method of oxidizing steel or iron sheets. | |

| US1703658A (en) | Apparatus for melting and casting | |

| DE568300C (en) | Tunnel furnace | |

| US1582496A (en) | Method and apparatus for annealing and cooling sheet glass | |

| US1289834A (en) | Metallizing process and apparatus. | |

| US735032A (en) | Process of separating precious metals. | |

| GB374486A (en) | Process of making iron oxide and sulphur dioxide from iron sulphide ores | |

| DE471271C (en) | Process for the refining of oolite kernels and similar fine ores or ore creeping obtained from minette | |

| US1141719A (en) | Method of oxidizing steel or iron sheets. | |

| US1188111A (en) | Method of operating reverberatory iron-melting furnaces. |