US1855034A - Gas producing apparatus - Google Patents

Gas producing apparatus Download PDFInfo

- Publication number

- US1855034A US1855034A US305003A US30500328A US1855034A US 1855034 A US1855034 A US 1855034A US 305003 A US305003 A US 305003A US 30500328 A US30500328 A US 30500328A US 1855034 A US1855034 A US 1855034A

- Authority

- US

- United States

- Prior art keywords

- coal

- retort

- gas

- pipe

- hopper

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Expired - Lifetime

Links

- 239000007789 gas Substances 0.000 description 35

- 239000003245 coal Substances 0.000 description 33

- XLYOFNOQVPJJNP-UHFFFAOYSA-N water Substances O XLYOFNOQVPJJNP-UHFFFAOYSA-N 0.000 description 11

- OKTJSMMVPCPJKN-UHFFFAOYSA-N Carbon Chemical compound [C] OKTJSMMVPCPJKN-UHFFFAOYSA-N 0.000 description 9

- 229910052799 carbon Inorganic materials 0.000 description 9

- 238000004519 manufacturing process Methods 0.000 description 9

- 238000010276 construction Methods 0.000 description 8

- 239000000446 fuel Substances 0.000 description 7

- 238000000034 method Methods 0.000 description 7

- 239000000571 coke Substances 0.000 description 5

- 238000005422 blasting Methods 0.000 description 4

- 239000000463 material Substances 0.000 description 4

- 239000002699 waste material Substances 0.000 description 4

- 239000002802 bituminous coal Substances 0.000 description 3

- 239000000470 constituent Substances 0.000 description 3

- 239000003077 lignite Substances 0.000 description 3

- IJGRMHOSHXDMSA-UHFFFAOYSA-N Atomic nitrogen Chemical compound N#N IJGRMHOSHXDMSA-UHFFFAOYSA-N 0.000 description 2

- CURLTUGMZLYLDI-UHFFFAOYSA-N Carbon dioxide Chemical compound O=C=O CURLTUGMZLYLDI-UHFFFAOYSA-N 0.000 description 2

- UGFAIRIUMAVXCW-UHFFFAOYSA-N Carbon monoxide Chemical compound [O+]#[C-] UGFAIRIUMAVXCW-UHFFFAOYSA-N 0.000 description 2

- QVGXLLKOCUKJST-UHFFFAOYSA-N atomic oxygen Chemical compound [O] QVGXLLKOCUKJST-UHFFFAOYSA-N 0.000 description 2

- 208000027697 autoimmune lymphoproliferative syndrome due to CTLA4 haploinsuffiency Diseases 0.000 description 2

- 238000002485 combustion reaction Methods 0.000 description 2

- 239000000428 dust Substances 0.000 description 2

- 230000008030 elimination Effects 0.000 description 2

- 238000003379 elimination reaction Methods 0.000 description 2

- 238000010438 heat treatment Methods 0.000 description 2

- 239000001301 oxygen Substances 0.000 description 2

- 229910052760 oxygen Inorganic materials 0.000 description 2

- 238000005303 weighing Methods 0.000 description 2

- 241000196324 Embryophyta Species 0.000 description 1

- 229910000831 Steel Inorganic materials 0.000 description 1

- 240000006365 Vitis vinifera Species 0.000 description 1

- 229910002092 carbon dioxide Inorganic materials 0.000 description 1

- 239000001569 carbon dioxide Substances 0.000 description 1

- 229910002091 carbon monoxide Inorganic materials 0.000 description 1

- 229940000425 combination drug Drugs 0.000 description 1

- 229910052500 inorganic mineral Inorganic materials 0.000 description 1

- 239000011707 mineral Substances 0.000 description 1

- 239000000203 mixture Substances 0.000 description 1

- 229910052757 nitrogen Inorganic materials 0.000 description 1

- 238000010298 pulverizing process Methods 0.000 description 1

- 239000002994 raw material Substances 0.000 description 1

- 239000011819 refractory material Substances 0.000 description 1

- 230000000284 resting effect Effects 0.000 description 1

- 239000011435 rock Substances 0.000 description 1

- 239000010454 slate Substances 0.000 description 1

- 239000010959 steel Substances 0.000 description 1

- 230000008093 supporting effect Effects 0.000 description 1

- 239000002918 waste heat Substances 0.000 description 1

Images

Classifications

-

- C—CHEMISTRY; METALLURGY

- C10—PETROLEUM, GAS OR COKE INDUSTRIES; TECHNICAL GASES CONTAINING CARBON MONOXIDE; FUELS; LUBRICANTS; PEAT

- C10J—PRODUCTION OF PRODUCER GAS, WATER-GAS, SYNTHESIS GAS FROM SOLID CARBONACEOUS MATERIAL, OR MIXTURES CONTAINING THESE GASES; CARBURETTING AIR OR OTHER GASES

- C10J3/00—Production of combustible gases containing carbon monoxide from solid carbonaceous fuels

Definitions

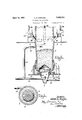

- Fig. l is a partial vertical section'and lside 1o present invention to produce gas from coal, elevation of the essential elements ofthe ap- 6 particularly the inferior grades of coal, utiparatus which I have devised.

- v lizing and extracting all of the heat produc- Fig.Vv 2 is a fragmentary ⁇ enlarged vertical ing elements of the coal and separating the section through the lower part of the retort same from the mineral matter, ash and the of the apparatus,fand

- This invention relates to gas production gasoil now used for carbureting'what is X5 like.

- Fig. 3 is a horizontal section substantially 66 signed that many grades of soft or bitum1 on the plane of line 3;-3 of Fig. 2.

- Y While coal, not now suitable for gas produc- Like reference characters refer tolike tion, may be used with a consequent greater parts in the different figures of the drawings.

- a retort shell also the waste coal at the mines, which is now l, preferably of steel, suitably lined at its 70 universally thrown away, may be utilized inner side with refractory material, is proeven though it many times contains a very vided, the upper section of which tapers uphigh percentage of slate, rock and the like. wardly and the lower section Zof which ta"- Furthermore, brown lignite may be used by pers downwardly, as shown. In practice the my process and with the apparatus which I retort may be betweenl 80 and 90 ⁇ feet in 75 have invented in the same manner.

- a hopper 6 into which the transportation now required in many the ash drops as it is passed through the grate, places for the proper grades of bituminous the lower end of which is equipped with a 90 coal necessarily'used.

- Y suitable outlet closure 7 which may be ropened It is also contemplated with my invention to deliver the ash from the hopper.

- the lowthat the apparatus ⁇ may be installed at or ader end of thel retort is not lined with refracjacent a mine and the gaseous fuel produced tory material but is surrounded by a hollow Y thereby piped over a large area with a total ring or drum 8 vin which'water is carried, said 95. elimination of freight costs.

- a further object of my invention is to prothe surrounding suppor-ting wall 9, as shown. vide an apparatus and operate the same Vin It is to be understood that the apparatus is accordance with a novel process thereby obmounted upon a suitable fioor l0, the hopper y, taining an elimination of the use of so-called 6 extending therethrough and that the retort do may extend upwardly through other oors of a building, one of which is indicated at 11.

- a pipe 12 leads into one side of the ash collecting hopper 6 below the grate 4 in the length of which is a blower 13 to force air to below the grate.

- a branch pipe 14 extends from the pipe 12 upwardly and is then turned horizontally, its end passing through the side of the retort in substantially tangential relation thereto.

- a control damper 15 is mounted in the pipe 14, the purpose of whichw-ill later appear.

- a branch vpipe 18 having a closing Vvalve or damper 19 therein.

- the pipe 18 At its outer end'the pipe 18 is formed Vwith a-vertical extension, the upper part 2O of which has an open upper end with a closure 21 therefor, while the downwardly extending part 22 enters the upper end of a wash box 23, connecting with a sleeve' 22a which, at its lower end, enters intoand extends below the level of the water in the box.

- An outlet pipe 24 leads away from the wash box to a gas relief holder (not shown) at a vpoint above the level of the water.

- a pipe 25 connects to the vertical extension at the end ofthe outlet pipe 18 and is then ycarried downwardly to adjacent the iioor 10,

- a by-pass pipe28around the suction exhaust y126 connects the pipes 2'5 and 27, 'as shown, in which is a valve 29 tov open and close said bypass pipe.

- valves 30 are located inthe pipe 27, one ⁇ at each side of the point of connection of the vby-pass 28 therewith.

- a bin or hopper ⁇ 34for holding coal for the ⁇ blasting charges islocated to oiie'side of and near the upper end of the retort having an outlet pipe i 35 with vertical branches B6 which are disposed around the retort at spaced apart t intervals and which deliver coal to ⁇ suitable automatic weighing andcharging machines ⁇ 37v which serve to deliver the coal carried Athereto to inletY chutes 38 to the lower part of against the grate.

- coal pulverizing unit of course, will be associated with the retort but as it in itself is not new and Yforms no part of the present invention it is notshown ordescribed.A

- the closure 21 is moved to a closed position, the damper is closed, the blower 13 stopped, and the exhauster at 26 is started in operation.

- the screw conveyer at 40 which is motor driven, is started and pulverized coal is fed continuously in at the top of the heated retort and evenly' distributed therein.

- the valve or damper at 19 is closed during this step of operation. The gas passes outwardly through the pipe 24: to the relief holder therefor.

- the fixed carbon or coke deposited upon the ignited fuel bed is heated to a very high degree but is not consumed due to the absence of oxygen.

- the various valves at may be closed, steam which has been produced in the jacket 8 is introduced through the pipe 16 into the hopper 6 and forces itself upwardly through the incondescent mass.

- This passage of steam may be later reversed; that is, steam is entered through the pipe 17 into the upper part of the retort, the valve 19 is closed, the blower 13 stopped from operation, the first valve 30 opened, whereupon the steam forces downwardly through the mass of incandescent material and blue Water gas produced which by-passes the eXhauster through pipe 28 and passes outwardly through the wash box asis evident.

- the reversal of the passage of the steam serves to withdraw additional heat from the walls of the retort and to completely consume the upper portion of the incandescent coke, it being apparent that on the upward passage of steam through the mass of incandescent material, the lower portion thereof is consumed and combined with the water for the production of water gas first and becomes coke while the upper portion remains Y in'an incandescent state.

- producer gas alone may be desired, in which case air is blown upwardly by the blower 13 through the incandescent coke combining therewith for the production of producer gas alone. This completes the cycle of operations. The succeeding cycles are identical with that described.

- the air blasting step of the process takes from 4; to 5 minutes and in some cases a little longer dependingV upon the grade of coal used, while the gas making step, as previously stated, requires approximately from 10 to 12 minutes.

- gas generating apparatus comprising a vertical retort, a grate located at the lower end of saidretort, an outlet conduit lat the upper end of the retort, means to close said outlet, a pipe leading from said outlet conduit downwardly and opening into the retort below the grate, and means for delivering fuel into the retort at a point above said grate and below theoutlet conduit.

- An apparatus for making gas comprising, an elongated verticalretort having an. outlet conduit adjacent its upper end, ⁇ said conduit terminating in a vertical section open at both ends, a removable closure for closing the upper end of said section, a wash box attached to the lower portion fordsaid seotion, a pipe leading fromA said section between the upper and lower ends thereof, la valve in said outlet conduit for opening and closing the same, a grate at the lower end of the retort, a closed hopper below said grate, an air carrying conduit entering said hopper, means for forcing lair therethrough, a branch conduit extending Jfrom said air conduit into said hopper at a side thereof a distance above its lower end, a damper for closing the branch conduit, an exhauster c0nnected in said pipe between the ends thereof, said pipe leadingat its lower end into said hopper, means for delivering V,fuel into the-retort at a point adjacent the entrance of said branch conduit thereinto, and additional means for entering fuel into

Landscapes

- Chemical & Material Sciences (AREA)

- Engineering & Computer Science (AREA)

- Combustion & Propulsion (AREA)

- Oil, Petroleum & Natural Gas (AREA)

- Organic Chemistry (AREA)

- Solid Fuels And Fuel-Associated Substances (AREA)

Description

April 19, 1932. A. R. STRYKER GAS PRODUCING APPARATUS Filed Sept. lO, 1928 2 Sheets-Sheet l t .l m om n n .u 3 www im b 1 a L Z m e? 1 9 Q o 2 f /m l \l f Z 3 3 7. MW l 2. n0 4 9N 0 Mmm... um) afw/ uw .u. L `.I.....I.......,H...J Q .U 7 0u 7 E n ad l mau n n M lil d 9 f 0 d f. i1 l n l Q l April 19, 1932. A R, STRYKER 1,855,034

GAS PRODUC ING APPARATUS Filed Sept. l0, 1928 2. Sheets-Sheet 2 3b l 3b lnocmor (Slben' 1i @azz/g Patented Apr. 19, 1932 l 1,855,034

UNITED STATES PATENT OFFICE-4L l ALBERT R. STRYKER, F ST. JOSEPH, MISSOURI GAS IPRODUCNG APPARATUS Application filed September 10, 1928. Serial No. 305,003.

and is primarily concerned with a novel apknown as blue or water gas. Y g paratus for converting the entire Volatile With these objects in view I'have devised and fixed carbon constituents of coal, irrethe 4apparatus for carrying out the process of spective of its grade, into gas which by the my invention, all ofV which -will appear fully 55 use of my apparatus and process may be of and in detail in thel following description, different characters, such as illuminating gas, taken fin connection 'with the accompanying gas for heating purposes and the like. drawings, in which, v

It is a primary object and purpose of the Fig. l is a partial vertical section'and lside 1o present invention to produce gas from coal, elevation of the essential elements ofthe ap- 6 particularly the inferior grades of coal, utiparatus which I have devised.v lizing and extracting all of the heat produc- Fig.Vv 2 is a fragmentary `enlarged vertical ing elements of the coal and separating the section through the lower part of the retort same from the mineral matter, ash and the of the apparatus,fand

This invention relates to gas production gasoil now used for carbureting'what is X5 like. By this process and apparatus it is de- Fig. 3 is a horizontal section substantially 66 signed that many grades of soft or bitum1 on the plane of line 3;-3 of Fig. 2. Y nous coal, not now suitable for gas produc- Like reference characters refer tolike tion, may be used with a consequent greater parts in the different figures of the drawings. reduction in the cost of production; and that In the construction illustrated a retort shell also the waste coal at the mines, which is now l, preferably of steel, suitably lined at its 70 universally thrown away, may be utilized inner side with refractory material, is proeven though it many times contains a very vided, the upper section of which tapers uphigh percentage of slate, rock and the like. wardly and the lower section Zof which ta"- Furthermore, brown lignite may be used by pers downwardly, as shown. In practice the my process and with the apparatus which I retort may be betweenl 80 and 90` feet in 75 have invented in the same manner. height and 11 feet in diameter at thebottom, By utilizing the inferior grades of softv or tapering to 4 feet in diameter at its top, bituminous coal, lignite or the like, or waste, though, ofcourse, these dimensions lare not which now is a source of loss, trouble and necessarily the only dimensions which may annoyance, not only is the raw material rebe used. The retort at its bottom rests upon 30 quired for gas production greatly reduced in a suitable support 3 within which an eccencost but it is not necessary to ship higher trically located androtatably mounted grate grades of gas producing coal long distances 4 is positioned -which'may be driven at any to the places where they are used; for in pracsuitable speedthrough the worm and tangent tically all sections of the United States there construction illustrated at 5, it being u'nder- 85 can be found bituminous coal lor lignite or stood that vthe worm 5 ,is driven from any the like and the transportation thereof to anyl suitable `source of power. given place is relatively short compared to Below the -grate is a hopper 6 into which the transportation now required in many the ash drops as it is passed through the grate, places for the proper grades of bituminous the lower end of which is equipped with a 90 coal necessarily'used. Y suitable outlet closure 7 which may be ropened It is also contemplated with my invention to deliver the ash from the hopper. The lowthat the apparatus `may be installed at or ader end of thel retort is not lined with refracjacent a mine and the gaseous fuel produced tory material but is surrounded by a hollow Y thereby piped over a large area with a total ring or drum 8 vin which'water is carried, said 95. elimination of freight costs. Y drum resting upon the member 3 and upon A further object of my invention is to prothe surrounding suppor-ting wall 9, as shown. vide an apparatus and operate the same Vin It is to be understood that the apparatus is accordance with a novel process thereby obmounted upon a suitable fioor l0, the hopper y, taining an elimination of the use of so-called 6 extending therethrough and that the retort do may extend upwardly through other oors of a building, one of which is indicated at 11.

A pipe 12 leads into one side of the ash collecting hopper 6 below the grate 4 in the length of which is a blower 13 to force air to below the grate. A branch pipe 14 extends from the pipe 12 upwardly and is then turned horizontally, its end passing through the side of the retort in substantially tangential relation thereto. A control damper 15 is mounted in the pipe 14, the purpose of whichw-ill later appear. lA steam carrying pipe 16 at one end passes through a side of the hopper` and connects with the inner end of the pipe 12,v and in practice this pipe 16 may also connect" with the upper pipe 17 leading into the upper end of the retort, it being understood that steam generated in the shell'8 may be carried through said pipes to either the upper or lower end ofthe retort, as shown.

Near the upper end .of the retort is a branch vpipe 18 having a closing Vvalve or damper 19 therein. At its outer end'the pipe 18 is formed Vwith a-vertical extension, the upper part 2O of which has an open upper end with a closure 21 therefor, while the downwardly extending part 22 enters the upper end of a wash box 23, connecting with a sleeve' 22a which, at its lower end, enters intoand extends below the level of the water in the box. ,An outlet pipe 24 leads away from the wash box to a gas relief holder (not shown) at a vpoint above the level of the water. Y c

A pipe 25 connects to the vertical extension at the end ofthe outlet pipe 18 and is then ycarried downwardly to adjacent the iioor 10,

there being equipped with a power driven l vexhaust or suction apparatus 26, and after it has passed through the floor 10 it is extended as a horizontal pipe 27l to the hopper 6 with which it connects and into which it leads. A by-pass pipe28around the suction exhaust y126 connects the pipes 2'5 and 27, 'as shown, in which is a valve 29 tov open and close said bypass pipe. Likewise/two valves 30 are located inthe pipe 27, one `at each side of the point of connection of the vby-pass 28 therewith.

HOver the upper end of the vertical member 2O is a` dust collecting apparatus including the various elements 31, 82 and 33which not be -ing in themselves of novel construction are not specifically illustrated or described. Such dust collecting `apparatus is old and well known and its use in conjunction with the Aapparatus which I have devised willlater appear.

A bin or hopper` 34for holding coal for the `blasting charges islocated to oiie'side of and near the upper end of the retort having an outlet pipe i 35 with vertical branches B6 which are disposed around the retort at spaced apart t intervals and which deliver coal to` suitable automatic weighing andcharging machines `37v which serve to deliver the coal carried Athereto to inletY chutes 38 to the lower part of against the grate.

well known and used commercially. The coal pulverizing unit, of course, will be associated with the retort but as it in itself is not new and Yforms no part of the present invention it is notshown ordescribed.A

Operation: in the use and operation of the apparatus described a chai-ge of coal is entered into the retort from the bin or hopper 34, known a's the blasting chai-ge. This coal 1enters* the lower part of the retort and rests It is ignited and airis forced by the blower '13 through the coal to burn the saine. The damper at 15 is opened anda part of the air passes `into the retort above the coal.

The air which enters through thepipe l2 below the grate is forced upwardly through the coal and its oxygen combines therewith with a resultant production of producer gas which ordinarily contains, roughly, 20% carbon monoxide and 480% nitrogen. Vrl"he producer @as is acted uponby the air abore'tlie coal which enters through the branchv pipe 14 and the carbon,k monoxide istburned so that a completereduction of the carbon in the coal to carbon dioxide is obtained with the resultant production of. high'heat. The tangential entrance Vof air 'into the retort through the pipe 14 causes a spira-l upward movement of the products of combustion and lthe heat produced by the consumption of the coal is absorbed by Lthe refractory walls of the retort so that the retort` isheated to 'a very high degree Aof temperature.

contemplated that utilization of this waste 5 if heat may be had forrdry-ing the pnlverized coal, or it vmay be used for the production of steaiiiv as desired. The .utilization of waste heat in itself is not new and the details of mechanism or apparatusv which may be required therefor is not shownv in the present application.

rllhe air blasting step of the process iscon-Lk tinued until the temperature at the inner sides of the walls of the retort reaches vfrom 1500 to 1800o F. Of course, it 'is not essential that all of the blasting charge be consumed forif any ofthe carbon of thev coal Yisl left unconsuined it can very readily lbe utilized with additional coal in*4 the' succeeding gas The i Vproducts vof combustion from the blasty pass icc 'i making step of the operation. In fact it is contemplated that a predetermined amount of coal, sutlicient to maintain a proper fire level, shall be charged into the retort in small amounts at set intervals by the weighing and charging machines.

In the succeeding step of the operation the closure 21 is moved to a closed position, the damper is closed, the blower 13 stopped, and the exhauster at 26 is started in operation. Simultaneously the screw conveyer at 40, which is motor driven, is started and pulverized coal is fed continuously in at the top of the heated retort and evenly' distributed therein. As the coal passes down the heat of the walls of the retort acts thereupon to drive olf the volatile gases, which are drawn downwardly7 and carried through the pipes 27 and 25 and thence downwardly from the downward extension 22 to and through the wash box 23. It is to be understood that the valve or damper at 19 is closed during this step of operation. The gas passes outwardly through the pipe 24: to the relief holder therefor.

The operation continues until there is insuficient heat left in the walls of the retort to drive off volatile material.y There will be deposited on t-he ignited fuel bed at the bottom of the retort the residue of the coal, namely, the ash and the fixed carbon which ordinarily is known as gas coke.V This operation continues from 10 to 12 minutes and between 2,000 and 3,000 pounds of coal may be treated in this period of time.

The fixed carbon or coke deposited upon the ignited fuel bed is heated to a very high degree but is not consumed due to the absence of oxygen. After the volatile constituents of the coal are driven off the exhauster at 26 is stopped from operation, the various valves at may be closed, steam which has been produced in the jacket 8 is introduced through the pipe 16 into the hopper 6 and forces itself upwardly through the incondescent mass. This passage of steam may be later reversed; that is, steam is entered through the pipe 17 into the upper part of the retort, the valve 19 is closed, the blower 13 stopped from operation, the first valve 30 opened, whereupon the steam forces downwardly through the mass of incandescent material and blue Water gas produced which by-passes the eXhauster through pipe 28 and passes outwardly through the wash box asis evident.

The reversal of the passage of the steam serves to withdraw additional heat from the walls of the retort and to completely consume the upper portion of the incandescent coke, it being apparent that on the upward passage of steam through the mass of incandescent material, the lower portion thereof is consumed and combined with the water for the production of water gas first and becomes coke while the upper portion remains Y in'an incandescent state. Of course, it is possible and many times desirable to produce other types of gas than the water gas. For instance, producer gas alone may be desired, in which case air is blown upwardly by the blower 13 through the incandescent coke combining therewith for the production of producer gas alone. This completes the cycle of operations. The succeeding cycles are identical with that described. After a charge of coal has been .treated first to drive ofl the volatile or gaseous lconstituents thereof and then to convert the carbon into either producer or water gas, a new fuel charge is admitted into the retort and the cycle. of operations repeated. It is, of course, apparent lthat many gas making combinations are possible in that producer gas may be made for a short period and after that the water or blue gas and any desired mixture of gases for the attainment of a proper and desired heating .value of the gas obtained. f

The air blasting step of the process takes from 4; to 5 minutes and in some cases a little longer dependingV upon the grade of coal used, while the gas making step, as previously stated, requires approximately from 10 to 12 minutes. v

With this construction soft or bituminous coal of any and all grades may be used for gas making. Also waste vwhich contains a Vlarge percentage of carbon may be used. The

ash from the coal is taken care of readily by the apparatus. All of the volatile constituents of the coal are Vdriven off by heat i and all of the fixed carbon which will not distill into gas is consumed in the production of either producer or water gas. The apparatus is very practical and eflicient. It is to be understood that the various controls Y for the valves, the blower andthe exhauster,

are of well known and standard construction and are operative from a central control boa-rd in the plant. AThe invention is defined in the appended claims and is to be considered comprehensive of all forms of structure coming within their scope.

I claim:

1. gas generating apparatus comprising a vertical retort, a grate located at the lower end of saidretort, an outlet conduit lat the upper end of the retort, means to close said outlet, a pipe leading from said outlet conduit downwardly and opening into the retort below the grate, and means for delivering fuel into the retort at a point above said grate and below theoutlet conduit.

2. An apparatus for making gas comprising, an elongated verticalretort having an. outlet conduit adjacent its upper end, `said conduit terminating in a vertical section open at both ends, a removable closure for closing the upper end of said section, a wash box attached to the lower portion fordsaid seotion, a pipe leading fromA said section between the upper and lower ends thereof, la valve in said outlet conduit for opening and closing the same, a grate at the lower end of the retort, a closed hopper below said grate, an air carrying conduit entering said hopper, means for forcing lair therethrough, a branch conduit extending Jfrom said air conduit into said hopper at a side thereof a distance above its lower end, a damper for closing the branch conduit, an exhauster c0nnected in said pipe between the ends thereof, said pipe leadingat its lower end into said hopper, means for delivering V,fuel into the-retort at a point adjacent the entrance of said branch conduit thereinto, and additional means for entering fuel into lthe retort at the upper vend thereof.

3. A construction containing the elements -in combination defined in claim 2, combined 'with a bypass pipe connectedvwith the first mentioned pipe and-passing around said eX K hauster, saidr by-pass pipehaving a valve AP therein to open and close the same, and said irstmentioned pipe ,having two Valves there in, one at each side of where theby-pass pipe connects therewith.

4. A construction containing the elements in combination defined in claim 2, ycombined with meansfor admitting steam into said hopper below the grate.

5. A construction containing the elements in combi-nation defined in claim 2, combined with means for admitting steam into the re tort adjacent the vupper end thereof.

In testimony whereof I affix my si nature.

ALBERT n. s'rnY En, f

Priority Applications (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| US305003A US1855034A (en) | 1928-09-10 | 1928-09-10 | Gas producing apparatus |

Applications Claiming Priority (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| US305003A US1855034A (en) | 1928-09-10 | 1928-09-10 | Gas producing apparatus |

Publications (1)

| Publication Number | Publication Date |

|---|---|

| US1855034A true US1855034A (en) | 1932-04-19 |

Family

ID=23178879

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| US305003A Expired - Lifetime US1855034A (en) | 1928-09-10 | 1928-09-10 | Gas producing apparatus |

Country Status (1)

| Country | Link |

|---|---|

| US (1) | US1855034A (en) |

Cited By (2)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US2689786A (en) * | 1949-01-20 | 1954-09-21 | Hubmann Otto | Process for the gasification of solid fuels |

| US4352676A (en) * | 1980-05-08 | 1982-10-05 | Szloboda David Tibor | Apparatus for converting garbage into a fuel gas |

-

1928

- 1928-09-10 US US305003A patent/US1855034A/en not_active Expired - Lifetime

Cited By (2)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US2689786A (en) * | 1949-01-20 | 1954-09-21 | Hubmann Otto | Process for the gasification of solid fuels |

| US4352676A (en) * | 1980-05-08 | 1982-10-05 | Szloboda David Tibor | Apparatus for converting garbage into a fuel gas |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| US3655518A (en) | Retort system for oil shales and the like | |

| US1509667A (en) | Method and apparatus for distillation of carbonaceous material | |

| US3201329A (en) | Carbonizing process and apparatus | |

| US1855034A (en) | Gas producing apparatus | |

| US1671448A (en) | Retort for carbonizing bituminous fuels | |

| US2249410A (en) | Method and apparatus for reducing ore | |

| US1929880A (en) | Process of incinerating and equipment therefor | |

| US1932830A (en) | Apparatus for heating coal or the like | |

| US1533572A (en) | Furnace | |

| US1713032A (en) | Apparatus for use in drying and distilling lignite, peat, noncoking coals, and othersimilar carbonaceous matter | |

| US1833964A (en) | Process of making producer gas | |

| US1089110A (en) | Apparatus for treating alunite. | |

| US1204789A (en) | Method and apparatus for low-temperature distillation of coal. | |

| US1792632A (en) | Gasification process | |

| US1585892A (en) | Blast furnace | |

| US1055334A (en) | Process of making gas. | |

| US2216792A (en) | Gas making apparatus | |

| US1836005A (en) | Process for the heat treatment and reduction of ores | |

| US1657371A (en) | Method of making producer gas | |

| US551113A (en) | Nils karl herman ekeltjnd | |

| US860058A (en) | Method of distilling organic matters. | |

| GB338153A (en) | Improvements in and apparatus for the manufacture and production of fuel gases of high calorific power from bituminous coals | |

| US1481428A (en) | Ginia | |

| US1530493A (en) | Apparatus for producing aluminum chloride | |

| US360222A (en) | herrick |