US1854680A - Door for furnace coal hoppers - Google Patents

Door for furnace coal hoppers Download PDFInfo

- Publication number

- US1854680A US1854680A US516128A US51612831A US1854680A US 1854680 A US1854680 A US 1854680A US 516128 A US516128 A US 516128A US 51612831 A US51612831 A US 51612831A US 1854680 A US1854680 A US 1854680A

- Authority

- US

- United States

- Prior art keywords

- door

- frame

- caps

- hopper

- latch

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Expired - Lifetime

Links

- 239000003245 coal Substances 0.000 title description 13

- 230000006835 compression Effects 0.000 description 3

- 238000007906 compression Methods 0.000 description 3

- 239000000779 smoke Substances 0.000 description 3

- 229910052782 aluminium Inorganic materials 0.000 description 1

- XAGFODPZIPBFFR-UHFFFAOYSA-N aluminium Chemical compound [Al] XAGFODPZIPBFFR-UHFFFAOYSA-N 0.000 description 1

- 101150066916 capV gene Proteins 0.000 description 1

- 230000007423 decrease Effects 0.000 description 1

- 239000000463 material Substances 0.000 description 1

- 229910052751 metal Inorganic materials 0.000 description 1

- 239000002184 metal Substances 0.000 description 1

Images

Classifications

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F23—COMBUSTION APPARATUS; COMBUSTION PROCESSES

- F23K—FEEDING FUEL TO COMBUSTION APPARATUS

- F23K3/00—Feeding or distributing of lump or pulverulent fuel to combustion apparatus

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F23—COMBUSTION APPARATUS; COMBUSTION PROCESSES

- F23K—FEEDING FUEL TO COMBUSTION APPARATUS

- F23K2203/00—Feeding arrangements

- F23K2203/002—Feeding devices for steam boilers, e.g. in locomotives

Definitions

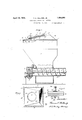

- Fig. 1 is a sectional view partly 1n elevation showing the manner of connecting the im- 0 proved door to a coal hopper, the said hopper being shown in connection with the coal feeding screw conveyor of a mechanical stoker. ⁇

- Fig. 2 is a plan view-fenlarged-of the door and frame.

- Fig. 3 is a central vertical sectional view of Fig. 2.

- Fig. 4 is a sectional view through one of the hinges, on the line 4.-4 of Fig. 2.

- Fig. 5 is a bottom plan view of one of the hinge bearing caps.

- Fig. 6 is a front view of a portion of the door and frame, showing the curved projection on the frame, which is engaged by the door latch, thereby to clamp the door against theV frame, and

- Fig. 7 is a plan view of the hood which is secured to the hoppers and to which the door frame is secured.

- the numeral 1 designates a coal hopper

- a screw conveyor which is supported beneath the hopper within a tube 2A to receive coal from the hopper and supply the same to a furnace--not shown.

- the conveyor shaft has secured thereon a worm gear Y 3 in mesh with an operating worm pinion 4 by which rotation is imparted to theconveyor.

- the hopper is provided at its upper end,

- This cap is of a shape to conform to the shape of the hopper, which,

- the capV comprises a marginal flange 6 which is riveted to the hopper flange V5, a felt or other suitable gasket 7 being interposed between the flanges to make a tight connection; and

- a cover plate 8 which inclines upward at a slight angle from the front edge of the cap to a point near the back edge thereof and also decreases in width, as shown in Fig ure 7 thus forming inclined side and back walls 9 and 10 respectively.

- the cover plate 8 is provided with a central hole 11, which is about fourteen inches in diameter, and is surrounded by a circular row of bolt holes 12.

- a circular ring-like frame B is bolted to the cover plate, by bolts 13 which pass through holes 14 in the frame and through the holes 12 in the cover plate,

- a circ-ular door C of slightlyY less diameter than the frame B is hinged thereto in the following manner:

- the door is formed on its rear edge with spaced lugs 22 vwhich are outwardly curved and terminate in oppositely projecting alined trunnions or hinge pins 23, which extend through the hinge bearings on the frame, the caps 19 being first removed to permit the pins to lie in the blocks 18.

- Saddle blocks 24 rest upon the pins, their underfaces ⁇ beingV formed with.

- coil springs 25 are interposed between the tops of the saddle blocks and the ⁇ end walls of the sockets in the caps, as shown in Figure-4, and when the caps are screwed down upon the blocks the springs 25 are compressed, thus forcing the saddle blocks down against the hinge pins.

- Thev under side ofthe door is provided with a circular flat surface26, which rests upon the rim 16 of the frame, and the surface 26 and rim 16 are ground so as toV make a tight connection.

- a depending lug 27 On the under side ofthe front portion of the door is formed a depending lug 27 having an axialr hole 28, which extends out through the top of the door.

- a latch pin 29 passes through the hole 28, and is formed with .a shoulder 30 which rests upon a flat raisedportion 31 on the top of the door.

- the pinI extends a short distancey below the end of the lug 27, the extended portion being square and reduced in diameter as. shown at 32, and a latch 33, in the form of a short ilat bar havinga square central hole, is placed on thev reduced end 32y and clamped against the shoulder of the pin, formed by the reduced end, by a nut 34.

- a handle 35 is formed on an upwardly eX- tending portion of the pin 29.

- the latch 33 engages a curvedy projection 36. on the lower edge 17 of the Aframe Bf, as shownv in Figures 3, and 6, and as'the latch engages and passes under the said projection, the door is drawn down tightly'against the rim 16v ofthe frame at this point, while, at the same time, the

- Ysprings 25, in the hinge caps exert a downward pressure on the saddle blocks, which in turn are forced. down upon the hinge trunnions, thus acting in cooperation with thev latch, in seating the door firmly upon the rim of the door frame.- As the engaging faces of the door and rim are ground, a tight joint is formed 'which preventsy the escap-e of smoke which may ⁇ be forced back through the conveyor tube 2A and into the coal hopper. As the latch 33 is a double ended latch, itA will engage the ⁇ curved projection 36,V when given a quarter turn in either direction.

- the door is formed with a slightly raised central cir-V cular boss 37 which is intended for use as a name plate.

- the oblong bearing holes 21 in the hinge blocks and caps permit the door to freely engage the rim 16 under the pressure of the springs 25, as the hinge trunnions do not Contact with either the upper or lower ends of the said bearing holes, as will be seen by reference to Figure 1.

- the saddle blocks 24 are aluminum, and under the pressure of the springsy 25 engage the hinge pins with suflicient frictional pressure to hold the door open at any angle to which it may be swung.

- the door is closed and clamped to its frame, as above described, and need not be opened again, until the hopper requires replenishing, thus preventing either the escape of smoke into the furnace room or the entrance of air into the furnace through the screw conveyor.

- a door for the hoppers of furnaces having mechanical stokers the combination with a hopper, of a cap thereon having a circular opening therein, a ring-like frame surrounding said opening and secured to said cap and having an upwardly projecting ground rim, bearings on said frame having socketed caps, a door on said frame having a ground surface which is adapted to restupon said rim, and oppositely extending hinge pins which pass loosely through saidbearings, saddle blocks in said caps which rest upon the hinge pins, and springs under compression between the saddle blocks and top walls of the caps, a latch rotatably mounted in the door and having a latch bar thereon, and a projection on the under edge of the frame having a cam face 'adapted to be engaged by the latch bar and thus cooperate with saidfsprings in forcibly closing said door upon the rim of the frame.

- a ring like frame having hinge bearings with holes which are oblong on their vertical diameters, said bearings including socketed caps, a door on said frame having hinge pins which extend loosely through said bearings, soft metal saddle blocks in said caps which rest upon said hinge pins, and coil springs interposed between the saddle blocksV and the end walls of the cap sockets, a latch on said door for engaging the frame, thereby to cooperate with the springs in forcibly closing the door upon the frame, said hinge blocks engaging the hinge pins with suicient rctional pressure to hold the door open at any angle to which it may be swung.

Landscapes

- Engineering & Computer Science (AREA)

- Chemical & Material Sciences (AREA)

- Combustion & Propulsion (AREA)

- Mechanical Engineering (AREA)

- General Engineering & Computer Science (AREA)

- Special Wing (AREA)

Description

1931 2 Sheets-Sheet l T. C. WALKER, JR

DOOR FOR FURNACE COAL HOPPERS Filed Feb. 16,

April 19, 1932.

April 19, 1932; T, C, WALKER, JR 1,854,680

DooR FOR FURNAGE COAL HoPPERs Filed Feb. 16, 1951 2 Sheets-Sheet, '2

Patented Apr. 19, 1932 UNITED STATES llrn'nslrr OFFICE `THOMAS C. WALKER, JR., OF DENVER, COLORADO, ASSIGNOR TO THE W. AND M. STOKER COMPANY, OF DENVER, COLORADO, A CORPORATIONOF COLORADO DOOR FOR FURNACE COAL HOPPERS Application led February 16, 1931. Serial No. 516,128.

pers of furnaces having mechanical stokers,

such as shown and described in my` pending application, Serial No. 444,552, liled April 15, 1930.

Further, to provide a combined door and frame having a spring pressure hinge connection, said door having a latch for clamping it in closed relation with respect to the frame; said spring pressure hinge cooperating with said latch in clamping the door against the frame with a uniform pressure,

Vthereby to make a tight joint between the parts, the engaging surfaces of the door and frame being ground for that purpose, whereby, when the frame is affixed to a coal hopper,

0 and the door is latched in closed relation, it

will prevent smoke from entering the furnace room, due to back pressure of air through the coal hopper, or air passing into the furnace through the hopper.

These objects are 'accomplished by the' -mechanism illustrated in the accompanying drawings in which:

Fig. 1 is a sectional view partly 1n elevation showing the manner of connecting the im- 0 proved door to a coal hopper, the said hopper being shown in connection with the coal feeding screw conveyor of a mechanical stoker.`

Fig. 2 is a plan view-fenlarged-of the door and frame.

Fig. 3 is a central vertical sectional view of Fig. 2.

Fig. 4 is a sectional view through one of the hinges, on the line 4.-4 of Fig. 2.

Fig. 5 is a bottom plan view of one of the hinge bearing caps.

Fig. 6 is a front view of a portion of the door and frame, showing the curved projection on the frame, which is engaged by the door latch, thereby to clamp the door against theV frame, and

\ Fig. 7 is a plan view of the hood which is secured to the hoppers and to which the door frame is secured.

Referring to the accompanying drawings:

The numeral 1 designates a coal hopper, and

2 a screw conveyor which is supported beneath the hopper within a tube 2A to receive coal from the hopper and supply the same to a furnace--not shown. 1 The conveyor shaft has secured thereon a worm gear Y 3 in mesh with an operating worm pinion 4 by which rotation is imparted to theconveyor. These parts are shown and described in the pending application above referred to, and are embodied inthe present application simply to show the -relation between the hopper and a mechanical Stoker, and to make clear the purpose of the improved coal door on the hopper.

The hopper is provided at its upper end,

with an introverted ange 5, to which is secured a hood or cap A of the character shown in Figures 1 and 7. This cap is of a shape to conform to the shape of the hopper, which,

in the present instance is square. The capV comprises a marginal flange 6 which is riveted to the hopper flange V5, a felt or other suitable gasket 7 being interposed between the flanges to make a tight connection; and

a cover plate 8, which inclines upward at a slight angle from the front edge of the cap to a point near the back edge thereof and also decreases in width, as shown in Fig ure 7 thus forming inclined side and back walls 9 and 10 respectively.

The cover plate 8 is provided with a central hole 11, which is about fourteen inches in diameter, and is surrounded by a circular row of bolt holes 12. A circular ring-like frame B is bolted to the cover plate, by bolts 13 which pass through holes 14 in the frame and through the holes 12 in the cover plate,

- a gasket 15 of suitable material being interblocks 18 having socketed caps 19 which are CII secured to the blocks by screws 20, the blocks and caps having matching semicircular recesses, which together form bearing holes 21, which are oblong in vertical diameter, as shown in Figure 1.

A circ-ular door C of slightlyY less diameter than the frame B is hinged thereto in the following manner: The door is formed on its rear edge with spaced lugs 22 vwhich are outwardly curved and terminate in oppositely projecting alined trunnions or hinge pins 23, which extend through the hinge bearings on the frame, the caps 19 being first removed to permit the pins to lie in the blocks 18. Saddle blocks 24 rest upon the pins, their underfaces` beingV formed with. seniicircul-arv recesses for that purpose, and coil springs 25 are interposed between the tops of the saddle blocks and the `end walls of the sockets in the caps, as shown in Figure-4, and when the caps are screwed down upon the blocks the springs 25 are compressed, thus forcing the saddle blocks down against the hinge pins.

Thev under side ofthe door is provided with a circular flat surface26, which rests upon the rim 16 of the frame, and the surface 26 and rim 16 are ground so as toV make a tight connection. On the under side ofthe front portion of the door is formed a depending lug 27 having an axialr hole 28, which extends out through the top of the door. A latch pin 29 passes through the hole 28, and is formed with .a shoulder 30 which rests upon a flat raisedportion 31 on the top of the door. The pinI extends a short distancey below the end of the lug 27, the extended portion being square and reduced in diameter as. shown at 32, and a latch 33, in the form of a short ilat bar havinga square central hole, is placed on thev reduced end 32y and clamped against the shoulder of the pin, formed by the reduced end, by a nut 34.

A handle 35 is formed on an upwardly eX- tending portion of the pin 29. The latch 33 engages a curvedy projection 36. on the lower edge 17 of the Aframe Bf, as shownv in Figures 3, and 6, and as'the latch engages and passes under the said projection, the door is drawn down tightly'against the rim 16v ofthe frame at this point, while, at the same time, the

Ysprings 25, in the hinge caps, exert a downward pressure on the saddle blocks, which in turn are forced. down upon the hinge trunnions, thus acting in cooperation with thev latch, in seating the door firmly upon the rim of the door frame.- As the engaging faces of the door and rim are ground, a tight joint is formed 'which preventsy the escap-e of smoke which may `be forced back through the conveyor tube 2A and into the coal hopper. As the latch 33 is a double ended latch, itA will engage the `curved projection 36,V when given a quarter turn in either direction. The door is formed with a slightly raised central cir-V cular boss 37 which is intended for use as a name plate. The oblong bearing holes 21 in the hinge blocks and caps, permit the door to freely engage the rim 16 under the pressure of the springs 25, as the hinge trunnions do not Contact with either the upper or lower ends of the said bearing holes, as will be seen by reference to Figure 1. The saddle blocks 24 are aluminum, and under the pressure of the springsy 25 engage the hinge pins with suflicient frictional pressure to hold the door open at any angle to which it may be swung.

After the hopper is filled with coal, the door is closed and clamped to its frame, as above described, and need not be opened again, until the hopper requires replenishing, thus preventing either the escape of smoke into the furnace room or the entrance of air into the furnace through the screw conveyor.

Having described my invention, what I claim as new, and desire to secure by Letters Patent is 1. In a device of the character described, the combination with a hopper, of a cap thereon having a circular opening, a ringlike frame surrounding sai-d opening and secured to said cap, bearings on said frame having socketed caps, a door on said frame having hinge kpins which extend loosely through said bearings, saddle blocks in said caps which rest on said hinge pins, and springs under compression between the saddl'e blocks and the top walls of the caps, a curved projection on the under edge of the frame and a rotatable latch in said door having a member to engage said curved projection, and thus cooperate with said springs in forcibly closing said door upon said frame.

2. In a door for the hoppers of furnaces having mechanical stokers, the combination with a hopper, of a cap thereon having a circular opening therein, a ring-like frame surrounding said opening and secured to said cap and having an upwardly projecting ground rim, bearings on said frame having socketed caps, a door on said frame having a ground surface which is adapted to restupon said rim, and oppositely extending hinge pins which pass loosely through saidbearings, saddle blocks in said caps which rest upon the hinge pins, and springs under compression between the saddle blocks and top walls of the caps, a latch rotatably mounted in the door and having a latch bar thereon, and a projection on the under edge of the frame having a cam face 'adapted to be engaged by the latch bar and thus cooperate with saidfsprings in forcibly closing said door upon the rim of the frame.

3. The combination with a ring-like frame bearings, saddle blocks in said caps which lll) rest upon said hinge pins, and coil springs Y under compression between said saddle blocks and the top walls of the caps, a latch rotatably mounted in said door and having a latch bar on its lower end, and a projection on the lower side of said frame having a cam face adapted to be engaged by said latch bar, thereby to cooperate with said springs in forcibly closing the door upon the rim of the frame.

4. In a door of the character described, a ring like frame having hinge bearings with holes which are oblong on their vertical diameters, said bearings including socketed caps, a door on said frame having hinge pins which extend loosely through said bearings, soft metal saddle blocks in said caps which rest upon said hinge pins, and coil springs interposed between the saddle blocksV and the end walls of the cap sockets, a latch on said door for engaging the frame, thereby to cooperate with the springs in forcibly closing the door upon the frame, said hinge blocks engaging the hinge pins with suicient rctional pressure to hold the door open at any angle to which it may be swung.

lon testimony whereof, I affix my signature.

THOMAS C. WALKER, JB;

Priority Applications (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| US516128A US1854680A (en) | 1931-02-16 | 1931-02-16 | Door for furnace coal hoppers |

Applications Claiming Priority (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| US516128A US1854680A (en) | 1931-02-16 | 1931-02-16 | Door for furnace coal hoppers |

Publications (1)

| Publication Number | Publication Date |

|---|---|

| US1854680A true US1854680A (en) | 1932-04-19 |

Family

ID=24054243

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| US516128A Expired - Lifetime US1854680A (en) | 1931-02-16 | 1931-02-16 | Door for furnace coal hoppers |

Country Status (1)

| Country | Link |

|---|---|

| US (1) | US1854680A (en) |

Cited By (3)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US2420411A (en) * | 1945-04-12 | 1947-05-13 | Sr Eugene Augustus Blount | Retort, tank, or like container |

| US2546760A (en) * | 1944-09-20 | 1951-03-27 | Harry F Joesting | Fastener for pressure doors |

| US3246313A (en) * | 1962-09-27 | 1966-04-12 | Walter L Weaklend | Grain tank extension and signal device |

-

1931

- 1931-02-16 US US516128A patent/US1854680A/en not_active Expired - Lifetime

Cited By (3)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US2546760A (en) * | 1944-09-20 | 1951-03-27 | Harry F Joesting | Fastener for pressure doors |

| US2420411A (en) * | 1945-04-12 | 1947-05-13 | Sr Eugene Augustus Blount | Retort, tank, or like container |

| US3246313A (en) * | 1962-09-27 | 1966-04-12 | Walter L Weaklend | Grain tank extension and signal device |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| US3081009A (en) | Solids flow system | |

| US1854680A (en) | Door for furnace coal hoppers | |

| US1966454A (en) | Well equipment | |

| US3127852A (en) | Sliding gates and operating assembly for railway hopper cars | |

| US1317028A (en) | Evrnace-hopper | |

| US2252425A (en) | Dsaft control device | |

| US1880370A (en) | Feed hopper for incinerator flues | |

| US1597314A (en) | Charging apparatus for gas generators | |

| US2251514A (en) | Valve | |

| US1928962A (en) | Hopper for stokers | |

| US418159A (en) | Albert p | |

| US1631427A (en) | Revolving grate | |

| GB342058A (en) | Improvements in and relating to sliding doors | |

| KR101329712B1 (en) | Drop prevention device of remnant coal for coke making inner feeder cone | |

| US1187878A (en) | Segregating-feeder for nut-cracking machines. | |

| USRE4147E (en) | Improvement in coal-hods | |

| US2716951A (en) | Rubbish burner | |

| US949017A (en) | Locomotive ash-pan. | |

| US758935A (en) | Closure for gas-retorts. | |

| US449971A (en) | Cremation-closet | |

| US2081114A (en) | Stoker | |

| US1133940A (en) | Fuel-holder. | |

| DE340287C (en) | Grate loading device with fuel feed device and throwing shovel | |

| US1350768A (en) | Stove-door | |

| US1130344A (en) | Stove-grate. |