US1854622A - Variable speed gearing - Google Patents

Variable speed gearing Download PDFInfo

- Publication number

- US1854622A US1854622A US451808A US45180830A US1854622A US 1854622 A US1854622 A US 1854622A US 451808 A US451808 A US 451808A US 45180830 A US45180830 A US 45180830A US 1854622 A US1854622 A US 1854622A

- Authority

- US

- United States

- Prior art keywords

- shaft

- clutch

- pinion

- gear

- casing

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Expired - Lifetime

Links

- 230000002093 peripheral effect Effects 0.000 description 4

- 238000010276 construction Methods 0.000 description 3

- 230000008859 change Effects 0.000 description 2

- 230000008878 coupling Effects 0.000 description 2

- 238000010168 coupling process Methods 0.000 description 2

- 238000005859 coupling reaction Methods 0.000 description 2

- 230000007935 neutral effect Effects 0.000 description 2

- 208000027418 Wounds and injury Diseases 0.000 description 1

- 239000000470 constituent Substances 0.000 description 1

- 230000006378 damage Effects 0.000 description 1

- 230000000994 depressogenic effect Effects 0.000 description 1

- 239000004519 grease Substances 0.000 description 1

- 208000014674 injury Diseases 0.000 description 1

- 238000005461 lubrication Methods 0.000 description 1

- 238000004519 manufacturing process Methods 0.000 description 1

- 235000019640 taste Nutrition 0.000 description 1

Images

Classifications

-

- A—HUMAN NECESSITIES

- A61—MEDICAL OR VETERINARY SCIENCE; HYGIENE

- A61H—PHYSICAL THERAPY APPARATUS, e.g. DEVICES FOR LOCATING OR STIMULATING REFLEX POINTS IN THE BODY; ARTIFICIAL RESPIRATION; MASSAGE; BATHING DEVICES FOR SPECIAL THERAPEUTIC OR HYGIENIC PURPOSES OR SPECIFIC PARTS OF THE BODY

- A61H11/00—Belts, strips or combs for massage purposes

- A61H11/02—Massage devices with strips oscillating lengthwise

-

- Y—GENERAL TAGGING OF NEW TECHNOLOGICAL DEVELOPMENTS; GENERAL TAGGING OF CROSS-SECTIONAL TECHNOLOGIES SPANNING OVER SEVERAL SECTIONS OF THE IPC; TECHNICAL SUBJECTS COVERED BY FORMER USPC CROSS-REFERENCE ART COLLECTIONS [XRACs] AND DIGESTS

- Y10—TECHNICAL SUBJECTS COVERED BY FORMER USPC

- Y10T—TECHNICAL SUBJECTS COVERED BY FORMER US CLASSIFICATION

- Y10T74/00—Machine element or mechanism

- Y10T74/19—Gearing

- Y10T74/19219—Interchangeably locked

- Y10T74/19242—Combined gear and clutch

-

- Y—GENERAL TAGGING OF NEW TECHNOLOGICAL DEVELOPMENTS; GENERAL TAGGING OF CROSS-SECTIONAL TECHNOLOGIES SPANNING OVER SEVERAL SECTIONS OF THE IPC; TECHNICAL SUBJECTS COVERED BY FORMER USPC CROSS-REFERENCE ART COLLECTIONS [XRACs] AND DIGESTS

- Y10—TECHNICAL SUBJECTS COVERED BY FORMER USPC

- Y10T—TECHNICAL SUBJECTS COVERED BY FORMER US CLASSIFICATION

- Y10T74/00—Machine element or mechanism

- Y10T74/19—Gearing

- Y10T74/19219—Interchangeably locked

- Y10T74/19377—Slidable keys or clutches

- Y10T74/19414—Single clutch shaft

- Y10T74/1947—Selective

- Y10T74/19474—Multiple key

- Y10T74/19479—Spur gears

Definitions

- the invention relates to variable speed gearing, and more particularly to speedk changing mechanism forming anv integral part of an exercising and massaging ma- Exercising and massaging machines ⁇ in common use include a strap applicator, or other form of massaging appliance, for inassaging and exercising body parts by imparti ing a massaging or rubbing movement to the strap through the medium of pins eccentrically mounted on Va rotating shaft, the ends of the strap applicator being connected With the pins.

- the strap applicator engages the portion of the body desired to be massaged, and the eccentric pin shaft is rotated, thereby imparting a massaging movement to the body part.

- an unenclosed running belt presents a serious hazard', and in orderV that safe operation of such massaging machines can be had, the belts and cone pulleys must be enclosed', thus increasing the difficulty with Which the belt may bey changed to change the speed of operation of the machine.

- anV object of ther present invention to provide a variablel speed.l exercising machine Withvvhich the speed. of rotation may be changed by the most unskilled operator or user, according tothe requirement of that person, by merely moving a lever.

- a further obj ect of theinvention is top-rovide a variable ⁇ speed exercising machine which is safe in operation, no mechanical hazards being presented by the speed changing operating mechanism.

- a further ob'ectof the invention is toprovide a variable speed gearing speed changing device-having a very simplified andl inexpen.- sive constructionv and having aV centralized visible control readily operableby the average person.

- an object of the present invention is to provide a speed changing mechanism in connection Wth an exercising machine, Which has a relatively fewv number of constituents parts, each of Which have a very simplified and standard design Whichv may accordingly ber manufactured at a very low cost so that a variable speed exerciservvill be available for use by the average person.

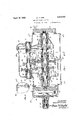

- Figure 1 is a longitudinal section through the gear box of the improved massaging machine variable speed gearing, on the line 11, Fig. 2;

- Fig. 2 is a cross section through the gear box, taken on the line 2 2, Fig. 1 and showing a fragmentary portion of the massaging machine drive motor in elevation;

- Fig. 3 is a front elevation of the gear box looking toward the centralized internal cam control disk

- Fig. 4 is a fragmentary elevation view showing the manner in which a ieXible shaft Ibnay be operatively connected with the gear Similar numerals refer to corresponding parts throughout the various gures of the drawings.

- the massaging machine includes the motor, shown in broken lines at 10, having a rotatable motor shaft 11 journaled in bearings 12 and 13 carried respectively by the gearing casing sections 14 and 15.

- the main eccentric pin shaft 16 is provided at either end with disks 17, which have eccentric pins 18 thereon, and the shaft 16 is j ournaled adjacent its end portions in bearings 19 carried by the casing section 14.

- the shaft 16 is provided with a peripheral flange portion 2O intermediate its ends and a master gear bearing 21, a second bearing 22, and a third bearing 23 are mounted on the shaft 16.

- the master bearing 21 is held in seated relation with the flanged peripheral portion 20, by the collar 24 and set screw 25.

- a washer 26 is interposed between the third bearing 23 and the end bearing 19; and the collar 27 with its set screw 28 holds the third bearing 23 in seated relation against the washer 26.

- a counter shaft 29 is mounted in bearings 30 in the upper portion of the casing 14, and the bearings 30 and counter shaft 29 are held in position by the bearing caps 31.

- the motor shaft 11 is provided preferably with an integral worm 32 which meshes with a worm gear 33 rotatably mounted on the master bearing 21.

- a master gear 34 is preferably bolted at 34a to the worm gear 33, and is accordingly similarly rotatably mounted on the master bearing 21.

- the master pinion 35 is pinned to the counter shaft 29 and arranged to mesh with the master gear 34; and the master pinion 35 has mounted thereon the second idler gear 36 which meshes with the second idler pinion 37 fixedly mounted on the second bearing 22 which is rotatably mounted on the eccentric shaft 16.

- rlhe counter shaft 29 also has a third idler gear 38 pinned thereon which meshes with the third idler pinion 39 fiXedly mounted ori the third bearing 23 which is rotatably mounted on the eccentric shaft 16.

- a main clutch 40 is slidably keyed at 41 to the shaft 16 and is provided with a master clutch jaw 42 and a third clutch jaw 43 for selective engagement with the worm gear clutch jaw 44 and the third pinion clutch jaw 45 respectively.

- a collar 46 having clutch aws 47 is pinned to the shaft 16 and spaced from the left hand bearing 19 by the washer 48; and the jaws 47 are adapted for engagement with the clutch jaws 49 provided on the second idler pinion 37.

- a disk plate 50 provided with an operating handle 51 is rotatably journaled at 52 on the front of the casing member 15, and the disk 50 is provided with the internal slow-fast cam slot indicated generally at 53 and the medium cam slot generally indicated at 54.

- a slow-fast bell crank lever shaft 55 is rotatably journaled in the bearing 56 carried by the casing section 15, and its outer lever arm 57 carries a roller 58 which rides in the cam slot 53, while its clutch lever arm 59 carries a clutch operating pin 60 which rides in the peripheral groove 61 of the main Clutch 40.

- a medium bell crank lever shaft 62 is rotatably journaled in the bearing 63 carried in the casing section 15, and its outer lever arm 64 carries a roll-er 65 which rides in the cam slot 54, while its clutch lever arm 66 carries a. clutch operating pin 67 which rides in the peripheral groove 68 of the combined second gear and clutch 37-49.

- the operating disk 60 is adapted to be shifted to three different positions, shown in Fig. 3 as slow, medium, and fast, at which times the spring pressed ball 69 is seated in one of the recesses 70 provided in the face plate 71 of the casing section 15.

- the operation of the device is as follows TWhen the motor 10 is operating to drive the shaft 16 at slow speed, which may preferably be some 200 R. l). M., the various parts are in the positions shown in full lines in the various figures of the drawings, and the worm 32 on the motor shaft 11, drives the worm gear 33, and clutch 40 through the medium of the clutch jaws 42 and 44, and rotary motion is transmitted from the clutch 40 to the shaft 16 through the key 41.

- the'operating ⁇ disk 5() is-rotated-clockwise so'tliat the spring pressed ball'69moves toward the medium recess I worm gear 33.

- roller 654V rides along. the cani slot portion 54a, through thezone A of the cam slot 54, as shown in Fig. 3.

- the roller 65 rides into the depressed portion 54?) of the Cam slot 54 within the Zone B', and the roller v58 rides along the portion 53?) of the cam slot 53 within the zone B.

- the rotating motor shaft 11 through its worm 32 drives the worm gear 33, and the drive continues through the bolts 34a, to the master gear 34, master pinion 35, second idler gear 36, second idler pinion 37, clutch jaws 49-47, and to the shaft 16 through its keyed collar 46.

- the operating disk 50 is rotated clockwise from medium position so that the spring pressed ball 69 moves toward the fast recess 70.

- the roller 58 rides along the cam slot portion 53?) and into the cam slot portion 530, through the zones marked B and C of the cam slot 53, rotating the shaft 55 in a counter-clockwise direction to move the clutch 40 from neutral position into engagement with the clutch jaws 45 of the third idler pinion 39.

- the shaft-16 may operate at slow, medium, or fast speeds. of from some 20G to 700 R. I?. M., todrive the disks 17 and eccentric pins 18 carriedk thereby.V Any desirable strap applicator, or other massaging appliance may be connected with the ⁇ pins18 for massaging body parts in the usual manner.

- the shaft 16 and counter shaft 29 may be insertedv lengthwise into-the endr bearing openings of thecasing section 14, while the various gears, clutches, bearings, etc., may be strung along the shaftl by inserting the same throughl the front opening 14 of the'casing section 14.

- the casingsectio'n 14 has an auxiliary member 14a arranged to cover up all parts of the mechanism excepting the rotating disks 17.

- Theauxiliary casportion 14 may be provided with feet ⁇ r 1

- the casing 14 is preferably partially filled with grease for insuring a' smooth and'n quiet operation and complete lubrication of the various moving parts.

- anv exercising or massaging machine which may be runl atV any one'of several desired predetermined speeds, andthe speed cha-nge device may be readily operated by the most inexperienced user by merelyr moving a lever.

- the machine is very quiet inv operation, and all moving parts are completely covered excepting only the disks car rying the eccentric pins.

- a coupling member v Provided on the end of a flexible shaft casing 81 journalling ai flanged plate 82 may be connected by means ofV a bayonet joint indicatedv at 83, with the auxiliary casing 14a.

- the coupling member 80 the flanged' plate 82 engages onev of the ec'- centric pins 18 ⁇ for transferring rotary motion from the shaft 16 to the flexible drive shaft 84.

- a variable speed mechanism including a casing, a drive shaft journaled in the casing, means for ro:- tating the driveshat, a driven; shaft. journailed in the 'casing having eccentric pins mounted thereon, a worm on the drive shaft, a worm gear meshing Vwith the worm rotatably mounted on the driven shaft, a master gear associated with the worm gear rotatably mounted on the driven shaft, a countershaft ournaled in the casing, a master pinion meshing with the master gear keyed to the countershaft, a second gear keyed to the counter-shaft, a third gear keyed to the countershaft, a second pinion meshing with the second gear slidably and rotatably mounted on the driven shaft, a third pinion meshing with the third gear rotatably mounted on the driven shaft, the worm gear, second pinion and third pinion being provided with clutch aws, a main clutch

- a variable speed mechanism including a casing, a drive shaft journaled in the casing, meansvfor rotating the drive shaft, a driven shaft journaled in the casing having eccentric pins mounted thereon, a worm on the drive shaft, a worm gear meshing with the worm rotatably mounted on the driven shaft, a master gear associated with the worm gear rotatably mounted on the driven shaft, a countersha-ft ournaled in the casing, a master pinion meshing with the master gear keyed to the countershaft, a second gear keyed to the countershaft, a third gear keyed to the countershaft, a second pinion meshing with the second gear slidably and rotatably mounted on the driven shaft, a third pinion meshing with the third gear rotatably mounted on the driven shaft, the worm gear, second pinion and third pinion being provided with clutch jaws, a.

- main clutch slidably keyed to the driven shaft having clutch jaws for selective engagement with either the worm gear or the third pinion clutch jaws, a collar keyed to the driven shaft having clutch jaws for alternate engagement with the second pinion clutch jaws, centralized operating means for slidably shifting the main clutch and second pinion on the driven Shaft including a slow-fast bell crank lever journaled on the casing engaging the main clutch, a medium bell crank lever journaled on the casing engaging the second pinion, and a cam disk mounted for rotary movement exteriorly of the casing engaging the levers, and means for rotating the cam disk to diiferent positions for simultaneously shifting the levers for engaging the main clutch jaws and worm gear clutch jaws at one position, the second pinion clutch jaws and collar clutch aws at another position, or the main clutch jaws and third pinion clutch jaws at another position for changing the speed of rotation of the driven shaft.

Landscapes

- Health & Medical Sciences (AREA)

- Epidemiology (AREA)

- Pain & Pain Management (AREA)

- Physical Education & Sports Medicine (AREA)

- Rehabilitation Therapy (AREA)

- Life Sciences & Earth Sciences (AREA)

- Animal Behavior & Ethology (AREA)

- General Health & Medical Sciences (AREA)

- Public Health (AREA)

- Veterinary Medicine (AREA)

- Transmission Devices (AREA)

Description

April 19, 1.932. W. V, @RR 1,854,622

VARIABLE SPEED GEARING Filed May l2, 1930 2 Sheets-Sheet l t wir au April '19, W v ORR- K VARIABLE SPEED GEARING Filed May lz, 1930 :2 Sheets-Sheet 2 Arron/yew,

Patented Apr. 19, 1932 'UNTED STA PATENT lili-[6151v WIILLIAM V. ORE, OF CLEVELAND HEIGHTS, OHIO; THE CLEVELND TRUST" COMPAJIY AND' ADELE lfAR- f OIR-R EXECUTORS 0F SAID VIILLA'M.' V. OER, DECEASED VARIALE SPEEIVD` GEARING Application filed May 12,

The invention relates to variable speed gearing, and more particularly to speedk changing mechanism forming anv integral part of an exercising and massaging ma- Exercising and massaging machines` in common use include a strap applicator, or other form of massaging appliance, for inassaging and exercising body parts by imparti ing a massaging or rubbing movement to the strap through the medium of pins eccentrically mounted on Va rotating shaft, the ends of the strap applicator being connected With the pins.

In use, the strap applicator engages the portion of the body desired to be massaged, and the eccentric pin shaft is rotated, thereby imparting a massaging movement to the body part. l

In order to meet the tastes and requirements of different persons, to comply with physical characteristics of the body parts being massaged, and to prevent physical damageto particular persons utilizing the exerciser, it isv desirable if not necessary to rotate the eccentric pin shaft at different speeds of from 200 to 7 00 R. P'. M., for varying the rate of massage movement of the strapapplicat-or.

Prior devices are known in Which the speed ofthe eccentric pin shaft may be retarded or advanced by utilizing cone pulleys operatively connected by a belt. However', difiiculties are encountered in changing the beltr When such a` construction is used in the home of ordinary persons Who knowlittle of the manner in Which belts should be changed. Consequently, such belts are never changed by the users When they should be changed; and physical injury has often resulted, due to the use of improper speeds When massaging certain body parts.

Moreover, an unenclosed running belt presents a serious hazard', and in orderV that safe operation of such massaging machines can be had, the belts and cone pulleys must be enclosed', thus increasing the difficulty with Which the belt may bey changed to change the speed of operation of the machine.

Moreover, enclosed cone pulleys and belt variable speedexercisers are so expensiveto 1930'. Serial No. 451,808.

manufacture that itis commercially impractical to produce the same for common use-by the ordinary person. i

Accordingly, it isk anV object of ther present invention to provide a variablel speed.l exercising machine Withvvhich the speed. of rotation may be changed by the most unskilled operator or user, according tothe requirement of that person, by merely moving a lever.

A further obj ect of theinvention is top-rovide a variable` speed exercising machine which is safe in operation, no mechanical hazards being presented by the speed changing operating mechanism. l

A further ob'ectof the invention is toprovide a variable speed gearing speed changing device-having a very simplified andl inexpen.- sive constructionv and having aV centralized visible control readily operableby the average person.

Moreover, an object of the present invention is to providea speed changing mechanism in connection Wth an exercising machine, Which has a relatively fewv number of constituents parts, each of Which have a very simplified and standard design Whichv may accordingly ber manufactured at a very low cost so that a variable speed exerciservvill be available for use by the average person.

It is often desirable to use massagingI appliances Which can only be attached tothe massaging machine through the medium of a flexible drive shaft..

Itis therefore a further object of the pres.- ent invention to provide means for connectingv a flexible drive shaft With the eccentric crank pin'ofthe exercising machine for transferring rot-ary motion from the exercising machine rotatable shaft to the flexible shaft.

These and other objects-maybe obtained by utilizing a construction Which may be stated in general terms as including in connection With a motor, a' drive shaft, al driven shaft carrying eccentric pins, means interposed betvveen the drive shaft andthe driven shaft including clutches and gearing for drivingthe driven shaft atgdiriferent speeds, and centralized operati-ng means for the clutches including bell crank levers cooperating with the clutches and a rotatable internal cam disk operating the levers for changing the speed of rotation of the eccentric pin shaft.

The preferred embodiment of the improved device is illustrated in the accompanying drawings forming part hereof, in which Figure 1 is a longitudinal section through the gear box of the improved massaging machine variable speed gearing, on the line 11, Fig. 2;

Fig. 2 is a cross section through the gear box, taken on the line 2 2, Fig. 1 and showing a fragmentary portion of the massaging machine drive motor in elevation;

Fig. 3 is a front elevation of the gear box looking toward the centralized internal cam control disk; and

Fig. 4 is a fragmentary elevation view showing the manner in which a ieXible shaft Ibnay be operatively connected with the gear Similar numerals refer to corresponding parts throughout the various gures of the drawings.

The massaging machine includes the motor, shown in broken lines at 10, having a rotatable motor shaft 11 journaled in bearings 12 and 13 carried respectively by the gearing casing sections 14 and 15.

The main eccentric pin shaft 16 is provided at either end with disks 17, which have eccentric pins 18 thereon, and the shaft 16 is j ournaled adjacent its end portions in bearings 19 carried by the casing section 14.

The shaft 16 is provided with a peripheral flange portion 2O intermediate its ends and a master gear bearing 21, a second bearing 22, and a third bearing 23 are mounted on the shaft 16. The master bearing 21 is held in seated relation with the flanged peripheral portion 20, by the collar 24 and set screw 25. A washer 26 is interposed between the third bearing 23 and the end bearing 19; and the collar 27 with its set screw 28 holds the third bearing 23 in seated relation against the washer 26.

A counter shaft 29 is mounted in bearings 30 in the upper portion of the casing 14, and the bearings 30 and counter shaft 29 are held in position by the bearing caps 31.

The motor shaft 11 is provided preferably with an integral worm 32 which meshes with a worm gear 33 rotatably mounted on the master bearing 21.

A master gear 34 is preferably bolted at 34a to the worm gear 33, and is accordingly similarly rotatably mounted on the master bearing 21. The master pinion 35 is pinned to the counter shaft 29 and arranged to mesh with the master gear 34; and the master pinion 35 has mounted thereon the second idler gear 36 which meshes with the second idler pinion 37 fixedly mounted on the second bearing 22 which is rotatably mounted on the eccentric shaft 16.

A main clutch 40 is slidably keyed at 41 to the shaft 16 and is provided with a master clutch jaw 42 and a third clutch jaw 43 for selective engagement with the worm gear clutch jaw 44 and the third pinion clutch jaw 45 respectively.

A collar 46 having clutch aws 47 is pinned to the shaft 16 and spaced from the left hand bearing 19 by the washer 48; and the jaws 47 are adapted for engagement with the clutch jaws 49 provided on the second idler pinion 37.

A disk plate 50 provided with an operating handle 51 is rotatably journaled at 52 on the front of the casing member 15, and the disk 50 is provided with the internal slow-fast cam slot indicated generally at 53 and the medium cam slot generally indicated at 54.

A slow-fast bell crank lever shaft 55 is rotatably journaled in the bearing 56 carried by the casing section 15, and its outer lever arm 57 carries a roller 58 which rides in the cam slot 53, while its clutch lever arm 59 carries a clutch operating pin 60 which rides in the peripheral groove 61 of the main Clutch 40.

A medium bell crank lever shaft 62 is rotatably journaled in the bearing 63 carried in the casing section 15, and its outer lever arm 64 carries a roll-er 65 which rides in the cam slot 54, while its clutch lever arm 66 carries a. clutch operating pin 67 which rides in the peripheral groove 68 of the combined second gear and clutch 37-49.

Although the sectional plane of Fig. 1 is taken beyond the clutch operating levers 59 and 66, for convenience in explanation, the location of the levers 59 and 66, is shown in dot-dash lines in Fig. 1 of the drawings.

The operating disk 60 is adapted to be shifted to three different positions, shown in Fig. 3 as slow, medium, and fast, at which times the spring pressed ball 69 is seated in one of the recesses 70 provided in the face plate 71 of the casing section 15.

The operation of the device is as follows TWhen the motor 10 is operating to drive the shaft 16 at slow speed, which may preferably be some 200 R. l). M., the various parts are in the positions shown in full lines in the various figures of the drawings, and the worm 32 on the motor shaft 11, drives the worm gear 33, and clutch 40 through the medium of the clutch jaws 42 and 44, and rotary motion is transmitted from the clutch 40 to the shaft 16 through the key 41.

If it is desired to drive the shaft 16 at medium or second speed, which is preferably at ige-54,622

orabout 350 R. M., the'operating` disk 5() is-rotated-clockwise so'tliat the spring pressed ball'69moves toward the medium recess I worm gear 33.

Meanwhile, the roller 654V rides along. the cani slot portion 54a, through thezone A of the cam slot 54, as shown in Fig. 3. Upon further rotation ofthe operating disk 5() toward mediumy position, the roller 65 rides into the depressed portion 54?) of the Cam slot 54 within the Zone B', and the roller v58 rides along the portion 53?) of the cam slot 53 within the zone B. i

Thus the shaft 62 is rotated in a counterclockwise direction to shift the second pinion 37 axially of the shaft 16, so that its clutch jaws 49 engage the clutch jaws 47 of the Collar 46; and the clutch 4() is held in neutral position.

' With the parts in the positions last described, the spring pressed ball 69 moves into engagement with the medium recess 70 and the device will operate at medium or second speed, the drive being transmitted as follows:

The rotating motor shaft 11 through its worm 32 drives the worm gear 33, and the drive continues through the bolts 34a, to the master gear 34, master pinion 35, second idler gear 36, second idler pinion 37, clutch jaws 49-47, and to the shaft 16 through its keyed collar 46.

If it is desired to drive the shaft 16 at fast or third speed, which is preferably at or about 700 R. P. M. the operating disk 50 is rotated clockwise from medium position so that the spring pressed ball 69 moves toward the fast recess 70. During rotation of the disk, the roller 58 rides along the cam slot portion 53?) and into the cam slot portion 530, through the zones marked B and C of the cam slot 53, rotating the shaft 55 in a counter-clockwise direction to move the clutch 40 from neutral position into engagement with the clutch jaws 45 of the third idler pinion 39.

Meanwhile, the rollers ride out of the cam slot portion 545 into the cam slot portion -540 through the Zones marked B and C of the cam slot 54, as shown in Fig. 3, so that the shaft 62 is rotated in a clockwise direction to shift the second pinion 37' axially of the shaft 16 to disengage its clutch jaws 49 from engagement with the clutch jaws 47 of the collar 46.

lith the parts in the last described position, the spring pressed ball 69 moves into engagement with the fast recess 7 0 and thev drive from the motor 10 is as follows:

The'rotating motor'shaft 11, throughthe' worm 32, drives the Worm: gear 33, andY thev drive continues through thebolts 34a to the-v master gear' 34, master pinion 35, third idler gear 38, third idler pinion139, clutch pins 454-43, and to the shaft 16 through: th clutch 40 and its key 41.

Accordingly, the shaft-16 may operate at slow, medium, or fast speeds. of from some 20G to 700 R. I?. M., todrive the disks 17 and eccentric pins 18 carriedk thereby.V Any desirable strap applicator, or other massaging appliance may be connected with the` pins18 for massaging body parts in the usual manner.

In assembling the device"7 the shaft 16 and counter shaft 29 may be insertedv lengthwise into-the endr bearing openings of thecasing section 14, while the various gears, clutches, bearings, etc., may be strung along the shaftl by inserting the same throughl the front opening 14 of the'casing section 14.-

- The casing section 15 with its operating. disk assembly thereon may then -be placed in^ assembled relation with theV casing section 14 and so held by bolts 15.

It is pointed out that the casingsectio'n 14: has an auxiliary member 14a arranged to cover up all parts of the mechanism excepting the rotating disks 17. Theauxiliary casportion 14 may be provided with feet`r 1 The casing 14 ispreferably partially filled with grease for insuring a' smooth and'n quiet operation and complete lubrication of the various moving parts.

Accordingly, anv exercising or massaging machine is provided which may be runl atV any one'of several desired predetermined speeds, andthe speed cha-nge device may be readily operated by the most inexperienced user by merelyr moving a lever.

Moreover, the machine is very quiet inv operation, and all moving parts are completely covered excepting only the disks car rying the eccentric pins.

And iinally, all` of the parts are of an extremely simple design and construction andi can be manufactured at a very low cost.

When it may bef desired totransm-it rotaryy motion to a flexible shaft, a coupling member vprovided on the end of a flexible shaft casing 81 journalling ai flanged plate 82 may be connected by means ofV a bayonet joint indicatedv at 83, with the auxiliary casing 14a. In so connecting the coupling member 80, the flanged' plate 82 engages onev of the ec'- centric pins 18 `for transferring rotary motion from the shaft 16 to the flexible drive shaft 84.

I claim: p

1`. In a massaging appliance, a variable speed mechanism including a casing, a drive shaft journaled in the casing, means for ro:- tating the driveshat, a driven; shaft. journailed in the 'casing having eccentric pins mounted thereon, a worm on the drive shaft, a worm gear meshing Vwith the worm rotatably mounted on the driven shaft, a master gear associated with the worm gear rotatably mounted on the driven shaft, a countershaft ournaled in the casing, a master pinion meshing with the master gear keyed to the countershaft, a second gear keyed to the counter-shaft, a third gear keyed to the countershaft, a second pinion meshing with the second gear slidably and rotatably mounted on the driven shaft, a third pinion meshing with the third gear rotatably mounted on the driven shaft, the worm gear, second pinion and third pinion being provided with clutch aws, a main clutch slidably keyed to the driven shaft having clutch jaws for selective engagement with either the worm gear or the third pinion clutch jaws, a collar keyed to the driven shaft having clutch jaws for alternate engagement with the second pinion clutch jaws, centralized operating means. for slidably shifting the main clutch and second pinion on the driven shaft including bell crank levers journaled on the casing engaging the main clutch and second pinion, and an internal cam mounted for rotary movement exteriorly of the casing engaging the levers, and means for rotating the cam disk to different positions for simultaneously shifting the levers to selectively engage certain of the clutch jaws for changing the speed of rotation of the driven shaft.

2. In a massaging appliance, a variable speed mechanism including a casing, a drive shaft journaled in the casing, meansvfor rotating the drive shaft, a driven shaft journaled in the casing having eccentric pins mounted thereon, a worm on the drive shaft, a worm gear meshing with the worm rotatably mounted on the driven shaft, a master gear associated with the worm gear rotatably mounted on the driven shaft, a countersha-ft ournaled in the casing, a master pinion meshing with the master gear keyed to the countershaft, a second gear keyed to the countershaft, a third gear keyed to the countershaft, a second pinion meshing with the second gear slidably and rotatably mounted on the driven shaft, a third pinion meshing with the third gear rotatably mounted on the driven shaft, the worm gear, second pinion and third pinion being provided with clutch jaws, a. main clutch slidably keyed to the driven shaft having clutch jaws for selective engagement with either the worm gear or the third pinion clutch jaws, a collar keyed to the driven shaft having clutch jaws for alternate engagement with the second pinion clutch jaws, centralized operating means for slidably shifting the main clutch and second pinion on the driven Shaft including a slow-fast bell crank lever journaled on the casing engaging the main clutch, a medium bell crank lever journaled on the casing engaging the second pinion, and a cam disk mounted for rotary movement exteriorly of the casing engaging the levers, and means for rotating the cam disk to diiferent positions for simultaneously shifting the levers for engaging the main clutch jaws and worm gear clutch jaws at one position, the second pinion clutch jaws and collar clutch aws at another position, or the main clutch jaws and third pinion clutch jaws at another position for changing the speed of rotation of the driven shaft.

In testimony that l claim the above, I have hereunto subscribed m name.

VILL' M V. OBR.

Priority Applications (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| US451808A US1854622A (en) | 1930-05-12 | 1930-05-12 | Variable speed gearing |

Applications Claiming Priority (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| US451808A US1854622A (en) | 1930-05-12 | 1930-05-12 | Variable speed gearing |

Publications (1)

| Publication Number | Publication Date |

|---|---|

| US1854622A true US1854622A (en) | 1932-04-19 |

Family

ID=23793776

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| US451808A Expired - Lifetime US1854622A (en) | 1930-05-12 | 1930-05-12 | Variable speed gearing |

Country Status (1)

| Country | Link |

|---|---|

| US (1) | US1854622A (en) |

-

1930

- 1930-05-12 US US451808A patent/US1854622A/en not_active Expired - Lifetime

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| US1854622A (en) | Variable speed gearing | |

| US1804138A (en) | Reversing gear mechanism | |

| US2020992A (en) | Exercising machine | |

| US1465796A (en) | Variable-speed-transmitting mechanism | |

| US2285534A (en) | Mechanical movement | |

| US1811624A (en) | Intermittent drive | |

| US2314981A (en) | Vibrator attachment for washing machines | |

| US2116624A (en) | Adjusting mechanism for transmissions | |

| US2014954A (en) | Speed variator | |

| US1070924A (en) | Abdominal exerciser. | |

| US1715778A (en) | Variable-speed transmission | |

| GB1007784A (en) | Improvements in and relating to mechanisms for imparting a rotary and wobbling motion to a body | |

| US1367544A (en) | Body-treatment machine | |

| US2424120A (en) | Foot massaging machine | |

| US1456200A (en) | Reduction gear | |

| US1797982A (en) | Power-transmitting and speed-changing mechanism | |

| GB246644A (en) | A new or improved variable speed gear | |

| US2016499A (en) | Driving mechanism for churns | |

| US321278A (en) | clarke | |

| USRE5481E (en) | Improvement in mechanical movements forsewing-machines,gc | |

| US1676344A (en) | Hoisting apparatus | |

| US1125282A (en) | Two-speed-transmission mechanism for motor-cycles. | |

| US1922965A (en) | Transmission gear | |

| US2287860A (en) | Winding machine | |

| US2555413A (en) | Torque distributing drive |