US1852845A - Lighter of instantaneous type - Google Patents

Lighter of instantaneous type Download PDFInfo

- Publication number

- US1852845A US1852845A US280092A US28009228A US1852845A US 1852845 A US1852845 A US 1852845A US 280092 A US280092 A US 280092A US 28009228 A US28009228 A US 28009228A US 1852845 A US1852845 A US 1852845A

- Authority

- US

- United States

- Prior art keywords

- fuel

- tube

- burner

- container

- vaporizing

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Expired - Lifetime

Links

Images

Classifications

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F23—COMBUSTION APPARATUS; COMBUSTION PROCESSES

- F23D—BURNERS

- F23D11/00—Burners using a direct spraying action of liquid droplets or vaporised liquid into the combustion space

- F23D11/36—Details

- F23D11/44—Preheating devices; Vaporising devices

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F23—COMBUSTION APPARATUS; COMBUSTION PROCESSES

- F23D—BURNERS

- F23D2900/00—Special features of, or arrangements for burners using fluid fuels or solid fuels suspended in a carrier gas

- F23D2900/31021—Vaporisers with devices for controlling the feeding of the fuel

Definitions

- This invention relates to a stove of the stype using a vaporizing liquid hydrocarbon fuel.

- Cooking and heating stoves using a Volatile hydrocarbon fuel such as gasoline are now quite extensively used. In most of these stoves it is necessary to have some priming means for starting the same, or some means separate from the stove for initially heating and starting the same. Such means have heretofore comprised priming cups and separate starting torches.

- Patent Number 1,729,652 filed May 19, 1926, a form of torchless starter was illustrated, but in this it was necessary to hold a match under the small vaporizing tube of the starting burner.

- It is a further object of this invention as shown in the embodiment illustrated to provide a liquid hydrocarbon stove comprising a main burner, a vaporizing member, an auxiliary burner for heating the vaporizing member, and means connected with the main fuel tank comprising a separate fuel container adapted to receive fuel and air from the main fuel tank and furnish a combustible mixture to the starting burner, whereby the same can be started with an ordinary match.

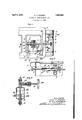

- Fig. 1 is a plan view of a portion of the stove having the invention applied thereto;

- Fig. 2 is a vertical section taken on line -2d2 of Fig. 1, as indicated by the arrows;

- Fig. 3 is a section taken on line 3-3 of Fig.

- Figs. 2 and 3 being shown on an enlarged scale.

- a stove comprising a frame 5 to one end of which is connected a main fuel tank 6, the same being shown as secured by straps 7 attached to said frame.

- the stove comprises a mixing chamher 8, which is attached by suitable conduits to the main burners, one of which is shown as 9.

- the vaporizing tube 10 supplies the fuel to the mixing chamber 8, said tube being shown as passing over the burner 9, whereby it is heated for the purpose of vaporizing the fuel.

- the vaporizing tube 10 is controlled by a valve 11 and is supplied with fuel by a tube or conduit 12 extending into the tank 6 to a point adjacent the bottom thereof.

- a pressure gauge 13a is shown as connected to the body of valve 13, for indito a bracket 16 which is in turn secured to the a frame 5 as shown in Fig. 2.

- the bracket 16 also constitutes a valve body and contains the valve forming stem 17 equipped with the operating wheel 17 a.

- a tube or conduit 18 extends from member 16 to the burner 14, the same being alined with and terminating substantially at the opening 140 in burner 14 and leaving a small space for air to enter burner 14 about tube 18.

- An auxiliary fuel container 19 is provided, and this container, whichis of comparatively small size, is connected at its bottom by the coupling 20 to a conduit 21 which extends to and is connected to the valve body 16.

- a tube 22 is also connected to coupling 20 and ex-.

- Tube 22 has a small hole 22a therein adjacent the bottom of container 19.

- the container 19 has a valve body 23 se- I also connected to fuel tank 6 and having its end disposed adjacent the top of said tank so as to be in the air space in said tank.

- a tube or conduit 26 also connects the container .19 with the conduit '12, said conduits 12 and 26 communicating with a fitting 27.

- valve 13 In operation, when it is desired to light the burner, the valve 13 will be opened, thus turned ofi by closin the valve 11. The stove is thenagain in con ition to be relighted.

- This gasoline will be forced therein by the air pressure in tank 6 and will pass into member 19 through tube 26.

- This flow of gasoline into member 19 will be stopped at a certain period when the pressure of the air in member 19 balances the pressure of air in the tank 6.

- the gasoline in member 19 flows into the tube 22 through the small orifice 22a.

- the valves 17 and 24 are now opened and the pressure of air in member 19 will force the gasoline in tube 22 through tube 21 to the valve body 16, through tube 18 and into the mixing chamber 14.

- the air moving with the gasoline through tube 22 and through the tube 21 vaporizes a sufiicient amount of the gasoline to make a combustible mixture and this combustible mixtures issues through the opening 14?) and can be lighted at once.

- valve 24 is closed, shutting off the air supply.

- chamber 19 will be filled with gasoline so that by the time the air contained in chamber 19 has been all forced through the conduit 21 to burner 14, tube 18 will be sufficiently heated to vaporize the gasoline and burner 14 will continue to burn as long as desired, or until vaporizing tube 10 is sufiiciently hot to vaporize the gasoline for the balance of the burners.

- Valve 11 is then opened and burner 9 lighted, after which valve 17 may be closed, leaving chamber 19 filled with gasoline ready for operation the next time the stove is to be lighted.

- gasoline level will be lowered in chamber 19 to outlet 26, leaving gasoline to produce vapor for supplying urner 14 until vaporizing tube 18 is hot enough to convert the raw gasoline into vapor.

- the main burners 9 will, of course, be kept in operation as long as desired and then ⁇ to be very successful and efficient.

- a heating device adapted to burn liquid vaporizing fuel having a vaporizing member and main fuel tank, a burner positioned to heat said vaporizing member, an auxiliary fuel container, a valve controlled conduit connecting the top of said container to the top of said tank and communicating with the air space therein, a conduit connected adjacent the bottom of said container and connected to said tank to communicate with the fuel in said tank, a tube upstanding in said container having an open upper end adjacent the top of said container and having a small orifice therein adjacent the bottom of said container and a conduit leading from said tube for conveying a combustible mixture of air and vaporized fuel for said burner.

- a heating device adapted to burn liquid vaporizing fuel and having a main burner.

- a vaporizing member and a fuel tank for holding fuel under pressure

- an auxiliary burner for heating said vaporizing member to start said stove

- an auxiliary fuel container connected at its lower portion to the fuel containing portion of said tank and connected at its top to the air containing portion of said tank

- a member upstanding in said container having an open upper end adjacent the top of said container and having a small orifice thereinto adjacent the bottom of said container and a conduit connecting said member and said auxiliary burner.

- a heating device adapted to burn liquid vaporizing fuel and having a fuel tank adapted to hold said liquid fuel under air pressure and a vaporizing member, a burner for heating said vaporizing member, an auxiliary fuel container, a conduit connecting the lower portion of said container to the fuel containing portion of said tank, a conduit connecting the top of said container to the lit air containing portion of said tank, a valve for opening and closing the last mentioned conduit, a member disposed in said container having an open upper end adjacent the top thereof and having a small orifice leading thereinto adjacent the bottom of said container and a conduit leading from said member for supplying a combustible mixture of vaporized fuel and air for said burner.

Landscapes

- Engineering & Computer Science (AREA)

- Chemical & Material Sciences (AREA)

- Combustion & Propulsion (AREA)

- Mechanical Engineering (AREA)

- General Engineering & Computer Science (AREA)

- Feeding And Controlling Fuel (AREA)

Description

April 1932- H.'C. HANSQN 1,852,845-

LIGHTER OF INSTANTANEOUS TYPE Filed May 23. 1928 Patented Apr. 5, 1932 UNITED STATES PATENT OFFICE HANS C. HANSON, OF ALBERT LEA, MINNESOTA, ASSIGNOR TO AMERICAN GAS'.

MACHINE COMPANY, OF ALBERT LEA, MINNESOTA, A CORPORATION OF MINNESOTA LIGHTER or ms'ranrmons 'rvrn Application filed Kay 2a, 1928. Serial no. 280,092.

This invention relates to a stove of the stype using a vaporizing liquid hydrocarbon fuel. Cooking and heating stoves using a Volatile hydrocarbon fuel such as gasoline, are now quite extensively used. In most of these stoves it is necessary to have some priming means for starting the same, or some means separate from the stove for initially heating and starting the same. Such means have heretofore comprised priming cups and separate starting torches. In applicants co-pending application, Patent Number 1,729,652, filed May 19, 1926, a form of torchless starter was illustrated, but in this it was necessary to hold a match under the small vaporizing tube of the starting burner.

It is an object of this invention, therefore, to provide a liquid hydrocarbon stove which can be lighted immediately, with the usual match, without heating any vaporizing mem her with the match.

It is another object of the invention to provide a liquid hydrocarbon stove having a vaporizing member, a burner for heating the vaporizing tube connected to the main burners, which starting burner can be immediately lighted with an ordinary match.

It is a further object of this invention as shown in the embodiment illustrated to provide a liquid hydrocarbon stove comprising a main burner, a vaporizing member, an auxiliary burner for heating the vaporizing member, and means connected with the main fuel tank comprising a separate fuel container adapted to receive fuel and air from the main fuel tank and furnish a combustible mixture to the starting burner, whereby the same can be started with an ordinary match.

These and other objects and advantages of the invention will be fully set forth in the following description made in connection with the accompanying drawings, in which like reference characters refer to similar parts throughout the several views and in which Fig. 1 is a plan view of a portion of the stove having the invention applied thereto;

Fig. 2 is a vertical section taken on line -2d2 of Fig. 1, as indicated by the arrows; an

Fig. 3 is a section taken on line 3-3 of Fig.

1, as indicated by the arrows, Figs. 2 and 3 being shown on an enlarged scale.

Referring to the drawings, a stove is shown comprising a frame 5 to one end of which is connected a main fuel tank 6, the same being shown as secured by straps 7 attached to said frame. The stove comprises a mixing chamher 8, which is attached by suitable conduits to the main burners, one of which is shown as 9. The vaporizing tube 10 supplies the fuel to the mixing chamber 8, said tube being shown as passing over the burner 9, whereby it is heated for the purpose of vaporizing the fuel. The vaporizing tube 10 is controlled by a valve 11 and is supplied with fuel by a tube or conduit 12 extending into the tank 6 to a point adjacent the bottom thereof. The

flow of gasoline to tube 12 is controlled by.

a valve 13. A pressure gauge 13a is shown as connected to the body of valve 13, for indito a bracket 16 which is in turn secured to the a frame 5 as shown in Fig. 2. The bracket 16 also constitutes a valve body and contains the valve forming stem 17 equipped with the operating wheel 17 a. A tube or conduit 18 extends from member 16 to the burner 14, the same being alined with and terminating substantially at the opening 140 in burner 14 and leaving a small space for air to enter burner 14 about tube 18.

An auxiliary fuel container 19 is provided, and this container, whichis of comparatively small size, is connected at its bottom by the coupling 20 to a conduit 21 which extends to and is connected to the valve body 16. A tube 22 is also connected to coupling 20 and ex-.

of said container, Tube 22 has a small hole 22a therein adjacent the bottom of container 19. The container 19 has a valve body 23 se- I also connected to fuel tank 6 and having its end disposed adjacent the top of said tank so as to be in the air space in said tank. A tube or conduit 26 also connects the container .19 with the conduit '12, said conduits 12 and 26 communicating with a fitting 27.

In operation, when it is desired to light the burner, the valve 13 will be opened, thus turned ofi by closin the valve 11. The stove is thenagain in con ition to be relighted.

From the above description it is seen that applicant has provided a simple and efficient lighting device for a hydrocarbon stove and one by means of which the stove-can be instantly lighted with an ordinary match, without any preliminary priming or heating of the vaporizing member. The device necessitates the addition of very few parts to the regular stove and is easily and conveniently manipulated. The same has been amply allowing fuel to be forced into the tube or demonstrated in actual practice and found conduit 12. It will be understood that the fuel in tank 6 is under pressure, air being pumped into said tank. The fuel can flow through conduit 12 and through conduit 21, but as long as valve 11 is closed, it cannot flow throu h vaporizing tube 10. There will normally be some gasoline in the member 19. This gasoline will be forced therein by the air pressure in tank 6 and will pass into member 19 through tube 26. This flow of gasoline into member 19 will be stopped at a certain period when the pressure of the air in member 19 balances the pressure of air in the tank 6. The gasoline in member 19 flows into the tube 22 through the small orifice 22a. The valves 17 and 24 are now opened and the pressure of air in member 19 will force the gasoline in tube 22 through tube 21 to the valve body 16, through tube 18 and into the mixing chamber 14. The air moving with the gasoline through tube 22 and through the tube 21 vaporizes a sufiicient amount of the gasoline to make a combustible mixture and this combustible mixtures issues through the opening 14?) and can be lighted at once. There is enough of this combustible mixture formed to heat the tube 18 so that the burner continues to function with gasoline supplied from container 19. As soon as the burner 14 has been lighted, valve 24 is closed, shutting off the air supply. Then chamber 19 will be filled with gasoline so that by the time the air contained in chamber 19 has been all forced through the conduit 21 to burner 14, tube 18 will be sufficiently heated to vaporize the gasoline and burner 14 will continue to burn as long as desired, or until vaporizing tube 10 is sufiiciently hot to vaporize the gasoline for the balance of the burners. Valve 11 is then opened and burner 9 lighted, after which valve 17 may be closed, leaving chamber 19 filled with gasoline ready for operation the next time the stove is to be lighted. In lighting the stove, immediately upon opening valve 24, gasoline level will be lowered in chamber 19 to outlet 26, leaving gasoline to produce vapor for supplying urner 14 until vaporizing tube 18 is hot enough to convert the raw gasoline into vapor. The main burners 9 will, of course, be kept in operation as long as desired and then \to be very successful and efficient.

It will, of course, be understood that various changes may be made in the form, details, arrangement and proportions of the parts, without departing from the scope of the applicants invention, which, generally stated, consists in a device capable of carrying out the objects above set forth, in the novel parts and combinations of parts disclosed and defined in the appended claims.

What is claimed is 1. In a heating device adapted to burn liquid vaporizing fuel having a vaporizing member and main fuel tank, a burner positioned to heat said vaporizing member, an auxiliary fuel container, a valve controlled conduit connecting the top of said container to the top of said tank and communicating with the air space therein, a conduit connected adjacent the bottom of said container and connected to said tank to communicate with the fuel in said tank, a tube upstanding in said container having an open upper end adjacent the top of said container and having a small orifice therein adjacent the bottom of said container and a conduit leading from said tube for conveying a combustible mixture of air and vaporized fuel for said burner.

2. In a heating device adapted to burn liquid vaporizing fuel and having a main burner. a vaporizing member and a fuel tank for holding fuel under pressure, an auxiliary burner for heating said vaporizing member to start said stove, an auxiliary fuel container connected at its lower portion to the fuel containing portion of said tank and connected at its top to the air containing portion of said tank, a member upstanding in said container having an open upper end adjacent the top of said container and having a small orifice thereinto adjacent the bottom of said container and a conduit connecting said member and said auxiliary burner.

3. In a heating device adapted to burn liquid vaporizing fuel and having a fuel tank adapted to hold said liquid fuel under air pressure and a vaporizing member, a burner for heating said vaporizing member, an auxiliary fuel container, a conduit connecting the lower portion of said container to the fuel containing portion of said tank, a conduit connecting the top of said container to the lit air containing portion of said tank, a valve for opening and closing the last mentioned conduit, a member disposed in said container having an open upper end adjacent the top thereof and having a small orifice leading thereinto adjacent the bottom of said container and a conduit leading from said member for supplying a combustible mixture of vaporized fuel and air for said burner.

In testimony whereof I aflix my signature.

HANS C. HANSON.

Priority Applications (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| US280092A US1852845A (en) | 1928-05-23 | 1928-05-23 | Lighter of instantaneous type |

Applications Claiming Priority (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| US280092A US1852845A (en) | 1928-05-23 | 1928-05-23 | Lighter of instantaneous type |

Publications (1)

| Publication Number | Publication Date |

|---|---|

| US1852845A true US1852845A (en) | 1932-04-05 |

Family

ID=23071630

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| US280092A Expired - Lifetime US1852845A (en) | 1928-05-23 | 1928-05-23 | Lighter of instantaneous type |

Country Status (1)

| Country | Link |

|---|---|

| US (1) | US1852845A (en) |

Cited By (1)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US5417565A (en) * | 1994-10-17 | 1995-05-23 | The Coleman Company, Inc. | Automatic instant lighting system for liquid fuel burner |

-

1928

- 1928-05-23 US US280092A patent/US1852845A/en not_active Expired - Lifetime

Cited By (1)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US5417565A (en) * | 1994-10-17 | 1995-05-23 | The Coleman Company, Inc. | Automatic instant lighting system for liquid fuel burner |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| US1852845A (en) | Lighter of instantaneous type | |

| US3057399A (en) | Self-pressurizing gasoline stove | |

| US2321034A (en) | Liquid fuel stove | |

| US1711965A (en) | Oil burner | |

| US1718473A (en) | Oil-burning device | |

| US2003363A (en) | Carburetor | |

| US1378675A (en) | Automatic asphalt-smoothing iron | |

| US1613060A (en) | Hydrocarbon burner | |

| US1886420A (en) | Carbureting device for lighting stoves | |

| US1832503A (en) | Carbureting apparatus for lighters | |

| US1852846A (en) | Valve for carbureting and starting | |

| US1633175A (en) | Hydrocarbon burner | |

| US1796767A (en) | Vapor stove | |

| US2402871A (en) | Apparatus for heating and vaporizing liquid | |

| US1914393A (en) | Valve and generator assembly | |

| US1436038A (en) | Priming device for heating systems | |

| US2256305A (en) | Burner construction | |

| US2103328A (en) | Fuel feeding system with thermostatic air control | |

| US1858264A (en) | Device for burning liquid fuels | |

| US1671238A (en) | Apparatus for mixing and burning oil | |

| US1586489A (en) | Liquid-fuel burner | |

| GB298221A (en) | Method of and apparatus for controlling the flow of fluids of different specific gravities, especially in hydrocarbon fuel burning apparatus | |

| US1429598A (en) | Oil burner | |

| US1450530A (en) | Oil burner | |

| US1340038A (en) | Vapor oil-burner |