US1852515A - Pipe and conduit bending machine - Google Patents

Pipe and conduit bending machine Download PDFInfo

- Publication number

- US1852515A US1852515A US543175A US54317531A US1852515A US 1852515 A US1852515 A US 1852515A US 543175 A US543175 A US 543175A US 54317531 A US54317531 A US 54317531A US 1852515 A US1852515 A US 1852515A

- Authority

- US

- United States

- Prior art keywords

- pipe

- former

- conduit

- spindle

- opening

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Expired - Lifetime

Links

- 238000005452 bending Methods 0.000 title description 17

- 230000015572 biosynthetic process Effects 0.000 description 3

- 241000276495 Melanogrammus aeglefinus Species 0.000 description 2

- 230000008878 coupling Effects 0.000 description 1

- 238000010168 coupling process Methods 0.000 description 1

- 238000005859 coupling reaction Methods 0.000 description 1

- 238000006073 displacement reaction Methods 0.000 description 1

- 230000000694 effects Effects 0.000 description 1

- 230000002441 reversible effect Effects 0.000 description 1

Images

Classifications

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B21—MECHANICAL METAL-WORKING WITHOUT ESSENTIALLY REMOVING MATERIAL; PUNCHING METAL

- B21D—WORKING OR PROCESSING OF SHEET METAL OR METAL TUBES, RODS OR PROFILES WITHOUT ESSENTIALLY REMOVING MATERIAL; PUNCHING METAL

- B21D7/00—Bending rods, profiles, or tubes

- B21D7/06—Bending rods, profiles, or tubes in press brakes or between rams and anvils or abutments; Pliers with forming dies

- B21D7/063—Pliers with forming dies

Definitions

- This invention relates to pipe and conduit bending machines, and has for one of its objects to provide a manually operable machine of this character through the medium of which a pipe or conduit may be easily and quickly provided with a U-bend or an angular bend of any desired or required degree.

- the invention comprehends the provision of a bending machine embodying rotatably connected disks between which the pipe or conduit to be bent is to be positioned, a former located between the disks and engaged with one of the disks and rotatable therewith with respect to the other disk, means carried by said other disk for holding the pipe or conduit inv contact with the former, a hook carried by the former for engagement with the conduit or pipe, and handles through the medium of which the disks may be rotated in opposite directions and thus effect the bending of the pipe or contact.

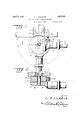

- Figure 1 is a view in side elevation of the bending machine with the pipe arranged therein.

- Figure 2 is a sectional view taken on the horizontal plane indicated by the line 22 of Figure 1.

- Figure 3 is a sectional view taken on the vertical plane indicated by the line 33 of Figure 1.

- Figure 4 is a view partly in elevation and partly in vertical section of the machine

- the bending machine comprises a rear disk 1, a front disk 2, and a former 3.

- the disk 1 is provided at its center with an opening a which is of rectangular formation in contour and tapers in the direction of the Serial No. 543,175.

- the opening 4 is provided for the reception of the head 5 of a spindle 6, the head being similar in contour and tapered similarly to the opening and having a drive fit therein.

- the spindle 6 is formed integrally with the head 5 and eX- tends forwardly therefrom and rotatably supports the disk 2 and former 3.

- the opening 4 is arranged with its respective diagonal axes disposed vertically and horizontally, and the spindle 6 is provided between its ends with a recess 7 facing the lower left hand wall of the opening.

- the disk 1 is provided at its upper end with a housing 8 which extends upwardly and forwardly therefrom.

- the housing 8 overlies the former 3 and is open at its lower side and ends.

- Pintles 9 extend forwardly and rearwardly through the housing 8 and journaled upon the pintles are rollers 10 having concave peripheries 10a.

- the disk 1 is provided with a socket 11 which extends downwardly and rearwardly therefrom and with which is screw threadedly engaged the upper end of a handle 12.

- the rollers 10 are located at opposite sides of the vertical center of the former 3, and the rollers extend transversely of the former.

- the former 3 has a concave periphery 3a, and is provided at its center with a circular opening 13 for the reception of the spindle 6.

- the former 3 is provided at opposite sides of the opening 13 with circular openings 14 and 15 for the reception of cylindrical pins 16 extending rearwardly from the disk 2.

- the openings 13 and 15 are connected by a slot 15a. That portion of a pipe or conduit 17 to be bent is positioned between the former 3 and the rollers 10, and is connected to the former through the medium of a hook 18, the hook being connected to the right hand edge of the former by a universal coupling 19.

- the disk 2 is provided at its center with a circular opening 20 for the reception of the front end portion of the spindle 6, and it is provided at its right hand edge with a socket 21. which extends laterally and forwardly therefrom and with which the inner end of a handle 22 is screw threadedly engaged.

- the disk 2, pin 16 and socket 21 are formed integrally.

- the handles 12 and 22 are preferably of tubular formation and may be of any desired or required length.

- the front disk 2 and the former 3 are removed from the spindle 6, to the end that the rear disk 1 may be readily applied to the pipe or conduit to be bent,

- the rear disk 1 is applied to the pipe or conduit by engaging the housing 8 with the pipe or conduit in such manner as to position the rollers 10 upon the conduit.

- the former 8 is then applied to the spindle 6 with its opening 15 receiving the spindle. As the opening 15 is located between the opening 13 and the pe riphery of the former 3, the former may be applied to the spindle 6 without contacting with the pipe or conduit.

- the former 3 is moved upwardly on the spindle 6 to position its periphery in contact with the lower side of the I 13601 conduit this movement of the p l a former being possible due to the provision of the former with the slot 15a and the provision of the spindle with the slot 7, and this movement of the former carrying the spindle into the central opening 13 of the former.

- the hook 18 is now engaged about the upper side of the pipe or conduit, and thereafter the front disk 2 is applied to the spindle 6 in such manner as to engage its pins 16 in the openings 14 and 1-5.

- the vaious parts of the device are so arranged that when it is engaged with the pipe or conduit the handles 12 and 22 are right angularly related with the handle 22 extending from the right hand side of the device.

- the handle 22 is moved with respect to the handle 12.. By moving the handle 22 through ninety degrees the pipe or conduit will be provided with a right angu lar bend, and by moving the handle 22 through one-hundred eighty degrees the pipe or conduit will be provided with a right hand U-bend.

- T adapt the device for providing the pipe or conduit with a left hand ri ht angular or U -bend

- the head is driven out of the opening a and reapplied to the opening in such manner as to position the recess 7 of the spindle 6 opposite the lower right hand Wall of the opening

- the former 3 is applied to the spindle in .a manner to arrange its hook 18 for engagement with the pipe or conduit at the left hand side of the device

- the front disk 2 is applied to the spindle 6 for engagement with the former with its handle 22 extending from the left hand side of the device.

- the rollers support the device from the pipe or conduit for movement in the direction thereof during the formation of the bend, the rollers also serving to guide the device along the pipe or conduit to the end that any lateral displacement thereof may be avoided.

- a pipe or conduit bending device comprising a member, means carried by said member for contact with one side of the pipe or conduit, a spindle carried by said member and provided in a side thereof with a recess, a former provided with an opening for the reception of the spindle, the former being provided at one side of said opening with another opening and with a slot establishing communication between the openings, means carried by the former for engagement with the pipe or conduit, and means by which the former may be rotated with relation to said member.

- a pipe or conduit bending device comprising a member, means carried by said member for contact with one side of the pipe or conduit, a spindle carried by said member and provided in one side thereof with a recess, a former having an opening for the re ception of the spindle, the former being provided with other openings at opposite sides of said first opening and with a slot connecting said first opening and one of said other openings, a second member rotatable on the spindle and provided with pins fitting in said other openings, and handles secured to said members.

- a pipe or conduit bending device comprising a member, means carried by said member for contact with one side of the pipe or conduit, a former rotatably mounted on said member for contact with the opposite side of the pipe or conduit, the former being provided with openings, means carried by the former for engagement with the pipe or conduit, a second member rotatably mounted on said first member and provided with pins engaging in said openings of the former,'and handles connected to said members.

- a pipe or conduit bending device comprising'a member, means carried by said member for contact with one side of the pipe or conduit, a spindle carried by said member and provided in a side thereof with a recess, the spindle being adjustable on said member to arrange said recess in facing relation to the lower left or lower right hand side of said member, a former provided at one side thereof with a hook for engagement with the pipe or conduit, the former being provided with spindle receiving openings and a slot communicating with the openings, one of said openings adapting the former for application to the spindle Without contacting with the pipe or conduit and the slot permitting the former to be moved on the spindle into contact with the opposite side of the pipe or conduit, the former being reversible to position its hook at either the right or left hand side of said member, means holding the former against accidental radial movement with relation to the spindle, and handles secured to said member and said means.

- a pipe or conduit bending device comprising a member, means carried by said member for contact with one side of the pipe or conduit, a spindle carried by said member, a former rotatable on the spindle for contact with the opposite side of the pipe or conduit,

- a pipe or conduit bending device comprising a member, means carried by said member, rollers carried by said member for rotation about axes having fixed positions With relation to the spindle and adapted to contact With one side of the pipe or conduit at points laterally beyond the spindle, a former rotatable on the spindle for contact with the opposite side of the pipe or conduit, means for rotating the former, and means connected to the former for engagement With the pipe or conduit for bending it in the di rection in Which the former is turned.

Landscapes

- Engineering & Computer Science (AREA)

- Mechanical Engineering (AREA)

- Bending Of Plates, Rods, And Pipes (AREA)

Description

April 5, 1932. HADDQCK 1,852,515

PIPE AND CONDUIT BENDING MACHINE Filed June 9, 1951 2 Sheets-Sheet l gm newton April 5, 1932. H i HADDOCK 1,852,515

PIPE AND CONDUIT BENDING MACHINE Filed June 9, 1931 2 Sheets-Sheet 2 gwuento o HITHQJ OC Patented Apr. 5, 1932 UNITED STATES HARVEY T. HADDOCK, OF CARROLLTON, ILLINOIS PII'E AND CONDUI'I IBENDIN G MACHINE Application filed June 9, 1931.

This invention relates to pipe and conduit bending machines, and has for one of its objects to provide a manually operable machine of this character through the medium of which a pipe or conduit may be easily and quickly provided with a U-bend or an angular bend of any desired or required degree.

To attain the foregoing and other objects, the nature of which will appear as the description proceeds, the invention comprehends the provision of a bending machine embodying rotatably connected disks between which the pipe or conduit to be bent is to be positioned, a former located between the disks and engaged with one of the disks and rotatable therewith with respect to the other disk, means carried by said other disk for holding the pipe or conduit inv contact with the former, a hook carried by the former for engagement with the conduit or pipe, and handles through the medium of which the disks may be rotated in opposite directions and thus effect the bending of the pipe or contact.

The invention is hereinafter more fully described and claimed, and illustrated in the accompanying drawings, wherein Figure 1 is a view in side elevation of the bending machine with the pipe arranged therein.

Figure 2 is a sectional view taken on the horizontal plane indicated by the line 22 of Figure 1.

Figure 3 is a sectional view taken on the vertical plane indicated by the line 33 of Figure 1.

Figure 4 is a view partly in elevation and partly in vertical section of the machine, the

. front disk of the machine being omitted from this view.

the machine.

The bending machine comprises a rear disk 1, a front disk 2, and a former 3. The disk 1 is provided at its center with an opening a which is of rectangular formation in contour and tapers in the direction of the Serial No. 543,175.

front side of the disk. The opening 4: is provided for the reception of the head 5 of a spindle 6, the head being similar in contour and tapered similarly to the opening and having a drive fit therein. The spindle 6 is formed integrally with the head 5 and eX- tends forwardly therefrom and rotatably supports the disk 2 and former 3. The opening 4 is arranged with its respective diagonal axes disposed vertically and horizontally, and the spindle 6 is provided between its ends with a recess 7 facing the lower left hand wall of the opening.

The disk 1 is provided at its upper end with a housing 8 which extends upwardly and forwardly therefrom. The housing 8 overlies the former 3 and is open at its lower side and ends. Pintles 9 extend forwardly and rearwardly through the housing 8 and journaled upon the pintles are rollers 10 having concave peripheries 10a. The disk 1 is provided with a socket 11 which extends downwardly and rearwardly therefrom and with which is screw threadedly engaged the upper end of a handle 12.

The rollers 10 are located at opposite sides of the vertical center of the former 3, and the rollers extend transversely of the former. The former 3 has a concave periphery 3a, and is provided at its center with a circular opening 13 for the reception of the spindle 6. The former 3 is provided at opposite sides of the opening 13 with circular openings 14 and 15 for the reception of cylindrical pins 16 extending rearwardly from the disk 2. The openings 13 and 15 are connected by a slot 15a. That portion of a pipe or conduit 17 to be bent is positioned between the former 3 and the rollers 10, and is connected to the former through the medium of a hook 18, the hook being connected to the right hand edge of the former by a universal coupling 19.

The disk 2 is provided at its center with a circular opening 20 for the reception of the front end portion of the spindle 6, and it is provided at its right hand edge with a socket 21. which extends laterally and forwardly therefrom and with which the inner end of a handle 22 is screw threadedly engaged. The disk 2, pin 16 and socket 21 are formed integrally. The handles 12 and 22 are preferably of tubular formation and may be of any desired or required length.

In practice, the front disk 2 and the former 3 are removed from the spindle 6, to the end that the rear disk 1 may be readily applied to the pipe or conduit to be bent, The rear disk 1 is applied to the pipe or conduit by engaging the housing 8 with the pipe or conduit in such manner as to position the rollers 10 upon the conduit. The former 8 is then applied to the spindle 6 with its opening 15 receiving the spindle. As the opening 15 is located between the opening 13 and the pe riphery of the former 3, the former may be applied to the spindle 6 without contacting with the pipe or conduit.

After it has been applied, the former 3 is moved upwardly on the spindle 6 to position its periphery in contact with the lower side of the I 13601 conduit this movement of the p l a former being possible due to the provision of the former with the slot 15a and the provision of the spindle with the slot 7, and this movement of the former carrying the spindle into the central opening 13 of the former.

The hook 18 is now engaged about the upper side of the pipe or conduit, and thereafter the front disk 2 is applied to the spindle 6 in such manner as to engage its pins 16 in the openings 14 and 1-5. The vaious parts of the device are so arranged that when it is engaged with the pipe or conduit the handles 12 and 22 are right angularly related with the handle 22 extending from the right hand side of the device. During the bending of the pipe or conduit the handle 22 is moved with respect to the handle 12.. By moving the handle 22 through ninety degrees the pipe or conduit will be provided with a right angu lar bend, and by moving the handle 22 through one-hundred eighty degrees the pipe or conduit will be provided with a right hand U-bend. T adapt the device for providing the pipe or conduit with a left hand ri ht angular or U -bend, the head is driven out of the opening a and reapplied to the opening in such manner as to position the recess 7 of the spindle 6 opposite the lower right hand Wall of the opening, the former 3 is applied to the spindle in .a manner to arrange its hook 18 for engagement with the pipe or conduit at the left hand side of the device, and the front disk 2 is applied to the spindle 6 for engagement with the former with its handle 22 extending from the left hand side of the device.

During the operation of the device, the

pipe or conduit is bent about the former 3 v to which it is connected 'by the hook 18, and

the rollers support the device from the pipe or conduit for movement in the direction thereof during the formation of the bend, the rollers also serving to guide the device along the pipe or conduit to the end that any lateral displacement thereof may be avoided.

While I have described the principle of the invention, together with the structure which i now consider the preferred embodiment thereof, it is to be understood that the structure shown is merely illustrative and that such changes may be made, when desired, as fall Within the scope of the invention as claimed.

hat is claimed is 1. A pipe or conduit bending device, comprising a member, means carried by said member for contact with one side of the pipe or conduit, a spindle carried by said member and provided in a side thereof with a recess, a former provided with an opening for the reception of the spindle, the former being provided at one side of said opening with another opening and with a slot establishing communication between the openings, means carried by the former for engagement with the pipe or conduit, and means by which the former may be rotated with relation to said member.

2. A pipe or conduit bending device, comprising a member, means carried by said member for contact with one side of the pipe or conduit, a spindle carried by said member and provided in one side thereof with a recess, a former having an opening for the re ception of the spindle, the former being provided with other openings at opposite sides of said first opening and with a slot connecting said first opening and one of said other openings, a second member rotatable on the spindle and provided with pins fitting in said other openings, and handles secured to said members.

3. A pipe or conduit bending device, comprising a member, means carried by said member for contact with one side of the pipe or conduit, a former rotatably mounted on said member for contact with the opposite side of the pipe or conduit, the former being provided with openings, means carried by the former for engagement with the pipe or conduit, a second member rotatably mounted on said first member and provided with pins engaging in said openings of the former,'and handles connected to said members.

4. A pipe or conduit bending device, comprising'a member, means carried by said member for contact with one side of the pipe or conduit, a spindle carried by said member and provided in a side thereof with a recess, the spindle being adjustable on said member to arrange said recess in facing relation to the lower left or lower right hand side of said member, a former provided at one side thereof with a hook for engagement with the pipe or conduit, the former being provided with spindle receiving openings and a slot communicating with the openings, one of said openings adapting the former for application to the spindle Without contacting with the pipe or conduit and the slot permitting the former to be moved on the spindle into contact with the opposite side of the pipe or conduit, the former being reversible to position its hook at either the right or left hand side of said member, means holding the former against accidental radial movement with relation to the spindle, and handles secured to said member and said means.

5. A pipe or conduit bending device, comprising a member, means carried by said member for contact with one side of the pipe or conduit, a spindle carried by said member, a former rotatable on the spindle for contact with the opposite side of the pipe or conduit,

means for rotating the former, and means a connected to the former for engagement With the pipe or conduit for bending it in the direction in Which the former is turned.

6. A pipe or conduit bending device comprising a member, means carried by said member, rollers carried by said member for rotation about axes having fixed positions With relation to the spindle and adapted to contact With one side of the pipe or conduit at points laterally beyond the spindle, a former rotatable on the spindle for contact with the opposite side of the pipe or conduit, means for rotating the former, and means connected to the former for engagement With the pipe or conduit for bending it in the di rection in Which the former is turned.

In testimony whereof I hereunto aflix my signature.

HARVEY T. HADDOCK.

Priority Applications (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| US543175A US1852515A (en) | 1931-06-09 | 1931-06-09 | Pipe and conduit bending machine |

Applications Claiming Priority (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| US543175A US1852515A (en) | 1931-06-09 | 1931-06-09 | Pipe and conduit bending machine |

Publications (1)

| Publication Number | Publication Date |

|---|---|

| US1852515A true US1852515A (en) | 1932-04-05 |

Family

ID=24166896

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| US543175A Expired - Lifetime US1852515A (en) | 1931-06-09 | 1931-06-09 | Pipe and conduit bending machine |

Country Status (1)

| Country | Link |

|---|---|

| US (1) | US1852515A (en) |

Cited By (8)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US2464800A (en) * | 1944-07-15 | 1949-03-22 | Imp Brass Mfg Co | Portable tube bending tool |

| US2623425A (en) * | 1948-10-29 | 1952-12-30 | Arthur J Shiley | Lever actuated tube bending hand tool |

| US2709382A (en) * | 1953-03-16 | 1955-05-31 | Powers Regulator Co | Portable pivoted tube bender |

| US2719561A (en) * | 1954-01-18 | 1955-10-04 | Parker Appliance Co | Bench supported, hand operated tube bender |

| US2839957A (en) * | 1955-04-15 | 1958-06-24 | Jacob S Buckwalter | Pawl and ratchet actuated roller type tube bender |

| US2908193A (en) * | 1957-11-07 | 1959-10-13 | Imp Brass Mfg Co | Manual tube bender |

| US3448602A (en) * | 1965-10-24 | 1969-06-10 | Parker Hannifin Corp | Hand held tube bender |

| FR2347117A1 (en) * | 1976-04-07 | 1977-11-04 | Schuler Jacob | MANUAL TOOL FOR BENDING TUBES |

-

1931

- 1931-06-09 US US543175A patent/US1852515A/en not_active Expired - Lifetime

Cited By (8)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US2464800A (en) * | 1944-07-15 | 1949-03-22 | Imp Brass Mfg Co | Portable tube bending tool |

| US2623425A (en) * | 1948-10-29 | 1952-12-30 | Arthur J Shiley | Lever actuated tube bending hand tool |

| US2709382A (en) * | 1953-03-16 | 1955-05-31 | Powers Regulator Co | Portable pivoted tube bender |

| US2719561A (en) * | 1954-01-18 | 1955-10-04 | Parker Appliance Co | Bench supported, hand operated tube bender |

| US2839957A (en) * | 1955-04-15 | 1958-06-24 | Jacob S Buckwalter | Pawl and ratchet actuated roller type tube bender |

| US2908193A (en) * | 1957-11-07 | 1959-10-13 | Imp Brass Mfg Co | Manual tube bender |

| US3448602A (en) * | 1965-10-24 | 1969-06-10 | Parker Hannifin Corp | Hand held tube bender |

| FR2347117A1 (en) * | 1976-04-07 | 1977-11-04 | Schuler Jacob | MANUAL TOOL FOR BENDING TUBES |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| US1852515A (en) | Pipe and conduit bending machine | |

| JP2018175863A5 (en) | ||

| US1713513A (en) | Surfacer | |

| US2422353A (en) | Swinging hose guide | |

| JPS6031625B2 (en) | cutting device | |

| US1189754A (en) | Extensible bracket. | |

| US1837938A (en) | Dental polishing cup and other point | |

| US1555129A (en) | Door holder | |

| US2185519A (en) | Disk sharpener | |

| US1192416A (en) | Holder for sharpening gravers and other tools. | |

| US2146949A (en) | Edge bending device | |

| US1495911A (en) | Gyroscope | |

| US2108291A (en) | Tractor wheel scraper | |

| US1533136A (en) | Holder | |

| FR2322282A1 (en) | Pump for motor with spherical working chamber - has wedge shaped pistons contacting inside surface and mounted on drive spindle extending through side | |

| US2383693A (en) | Grain drill | |

| US1285987A (en) | Pipe-bending apparatus. | |

| FR2380099A1 (en) | HELICOIDAL MILLING DEVICE FOR UNIVERSAL MILLING MACHINE | |

| US1591469A (en) | Rotary disk sharpener | |

| US3394571A (en) | Conduit-bending machines | |

| US2188585A (en) | Optical lens groover | |

| US1289943A (en) | Camera attachment. | |

| US952866A (en) | Emery-wheel stand. | |

| US1077338A (en) | Double-disk grain-drill. | |

| US1975287A (en) | Advertising device |