US1851788A - Tape moistening and pasting device - Google Patents

Tape moistening and pasting device Download PDFInfo

- Publication number

- US1851788A US1851788A US229370A US22937027A US1851788A US 1851788 A US1851788 A US 1851788A US 229370 A US229370 A US 229370A US 22937027 A US22937027 A US 22937027A US 1851788 A US1851788 A US 1851788A

- Authority

- US

- United States

- Prior art keywords

- tape

- wick

- cap

- water

- guide

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Expired - Lifetime

Links

- XLYOFNOQVPJJNP-UHFFFAOYSA-N water Substances O XLYOFNOQVPJJNP-UHFFFAOYSA-N 0.000 description 25

- 210000005069 ears Anatomy 0.000 description 8

- 230000001105 regulatory effect Effects 0.000 description 7

- 229920002160 Celluloid Polymers 0.000 description 2

- 241001108995 Messa Species 0.000 description 2

- 238000010276 construction Methods 0.000 description 2

- 239000003292 glue Substances 0.000 description 2

- 229920001875 Ebonite Polymers 0.000 description 1

- 235000017276 Salvia Nutrition 0.000 description 1

- 241001072909 Salvia Species 0.000 description 1

- 238000009825 accumulation Methods 0.000 description 1

- 239000002390 adhesive tape Substances 0.000 description 1

- 230000015572 biosynthetic process Effects 0.000 description 1

- 150000001768 cations Chemical class 0.000 description 1

- 230000000694 effects Effects 0.000 description 1

- 238000002386 leaching Methods 0.000 description 1

- 239000007788 liquid Substances 0.000 description 1

- 239000000463 material Substances 0.000 description 1

- 238000012856 packing Methods 0.000 description 1

- 238000007789 sealing Methods 0.000 description 1

- 239000012780 transparent material Substances 0.000 description 1

Images

Classifications

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B43—WRITING OR DRAWING IMPLEMENTS; BUREAU ACCESSORIES

- B43M—BUREAU ACCESSORIES NOT OTHERWISE PROVIDED FOR

- B43M11/00—Hand or desk devices of the office or personal type for applying liquid, other than ink, by contact to surfaces, e.g. for applying adhesive

Definitions

- the present invention relates to tape mois tening and pasting devices.

- the invention relates to tape moistening and pasting devices especial- 1y adapted for use in pasting telegra h mes sages received on tape or messa e lanks; for sealing package wrappers with adhesive tape, and like uses.

- Objects of the invention are to provide im- 10 proved and simplified tape moistening and pasting devices provided with a single body portion serving as a hand grip and container for water and into which the inner end of the Wick protrudes; to provide moistening and pasting devices arranged for minimum leakage when not in use which facilitate rapid, efiicient, and neat handling of the tape; and to provide such other objectsas may be attained by a utilization of the principles and arrangements hereinafter set forth and as de- 5 ing the guide slot formation.

- 1 designates a tubular body which is preferably formed of a transparent material in order that the liquid contained therein may be seen, and in the present instance is formed'of pyralin.

- the tubular body 1, as is clearly shown in Figure 3, is an open ended structure having one end thereof closed by means of a suitable plug 2 which is cemented therein and a rubber or pyralin protecting cap 2 embraces the end and the plug 2.

- the opposite end of the tubular body is internally threaded as indicated at 3 in Figure 3 which is adapted to receive the externally threaded end 4 of a removable cap 5', which may be of hard rubber or other suitable material, Cap 5 adjacent its threaded portion is provided with a shoulder portion 6 which is upwardly extended as indicated at 7, and provided with a guide recess or slot 8 ( Figure 5).

- Engaging the shoulder portion 6 is a metallic-washer 9 which is provided with a laterally turned lip 10 adapted to rest in said recess and further provided with upwardly extending projections 10' on either side of lip 10, and a suitable rubber washer or packing member 11 is interposed between the washer 9 and adjacent end of tube 1 to effect a water tight seal between the tubular body and cap 5.

- the metallic. washer 9 ma be eliminated in which instance only the ru ber washer 11 would be interposed between the cap 5' and the body to provide a leak proof connection.

- Cap 5 has rigidly embedded and secured therein, a unitary metallic member 12 providing a .Wick conduit 13 which, as shown in Figure 3 extends from the inner end of cap 5 and projects arcuately upward and outward from the opposite or outer end thereof as indicated at 14, the conduit 13 may be straight and extended upwardly and outwardly from a point adjacent the bottomof the body 1.

- the member 12 further provides a tape guide comprising a flanged extension 15 having secured to the base thereof the base portion of a flanged upwardly extending tape guiding members 16 and extending through the flanges of the extension 15 at the outer ends thereof is a shaft 17 on which is supported a tape guiding member or shoe 18.

- the wick conduit 13 is adapted to receive a suitable wick 19 which, as shown in Figure 3, has the inner end thereof projecting in-- wardly of the inner end of the cap into tubular body 1 and the outer end thereofis adapted to be' so positioned as to engage the tape when drawn thereon as indicated in Figure 2.

- the upper wall of the tape conduit is-provided with a groove as indicated in Figure 4 adapted to extend the full length of the conduit for the purpose of admitting air Without the necessity for very careful fitting of the Wicks necessary when such a groove is loo not provided.

- a suitable fine mesh screen .21 is positioned between the upper wall of cation of the wick with the groove through.

- a unitary tape guiding and pressure regulating mechanism 22 which in its construction comprises a longitudinally extending tape guide 23 having secured to the under surface thereof a pair of ar'cuate yieldable body engaging members 24 adapted to yieldably engage the body 1 to detachably secure the guide and pressure regulating mechanism thereto.

- the guide23 is provided with an internal channel 25 adapted to receive and guide the tape 26.

- the base of the guide 23 extends forwardly of the channelled portion as indicated at 27 and is provided with laterally extending ears 28 adapted to engage the rear sides of the projections 10' to hold the guide anecphalnism against forward movement on Piirtion 27 merges into a thickened angularly extending guide member 27' and rearwardly of the cars 28 the guide 23 is provided with a pair of cars 29 through which extends a pintle 30.

- a tape pressure regulating member 32 which, as shown in Figures 2 and 3, is provided at the forward end thereof with a slotted tubular tape engaging member 33 and at the rear end thereof is provided with an angular finger engaging member 34.

- the member 33 is normally held in engage- Operation I

- the wick 19 and screen 21 are introduced into conduit 13 of cap 5 and body 1 is filled with water after which the cap is screwed into the end of the body causing the inner end of the wick to project into the water in the body.

- the tape guiding and pressure regulating mechanism 22 is then applied to the body 1 by means of members 21 yieldably engaging the body and the ears 28 engaging the projections 10' which positions the guide member 27' substantially in alignment with the end of the wick as shown in Figure 2.

- water fills groove 20 establishing an air seal which prevents air from entering body 1 andaccordingly prevents water from continually dripping out. 1 i

- the tape'26 to be pasted is inserted into channel 25 and drawn therethrough either before or after the guide mechanism is positioned on the body.

- the tape will then pass over the end of the wick, the tape extending between guide 27' and member 33 passing over the end of the wick, guiding member 16, and under roller 18, as indicated in Figure 2.

- the location of the air groove 20 innnediatelv adjacent to the wick 19 serves a very useful purpose when the moistener is not in use and tape is not. being passed over the end of the wick as at the end of a line, and while the succeeding line is being started during which period air would continue toenter the water reservoir and water would drip continuously if the groove 20'were not positioned immediately adjacent to the wick.

- the screen 21 permits water to flow through it when the preventing any further flow of water.

- tape is again drawn over the end of the wick the water 1n groove 20 is drawn mto the wick, and the groove is thu automatically-freed of water and again acts as a vent permitting air to enter the water reservoir.

- the tape is lifted oil the end of the wick 19 through engagement therewith of the member 37 by presslng down on the member 34 which member- 34, together with the member 37 upon re- Y lease of the member 34 will automatically assume their original positions but due to a sufficient stifiness of the tape it will remain in the position acquired by the above operation and hence will remain out of contact with the wick until it is desired to again put the moistener into operation.

- a tape moistener comprising a transparent cylindrical water supporting body, said body internally threaded at one end thereof, a wick supporting cap externally threaded for detachable threaded connection in saidend of said body, tape guiding and tensioning means detachably supported by said body, and a tape guiding and tensioning means positioning washer interposed between said cap and said body.

- a tape moistener comprising a water supporting body, tape guiding and tensioning means detachably supported by said body, a wick supporting cap detachably connected to one end of said body, and tape guiding means carried by said cap for co-operation with said tape guiding and tensioning means;

- a tape moistener comprising abody adapted to receive water, tape guiding and tensioning means supported by said body: a

- cap detachably connected to said body, said cap provided with a wick supporting conduit.

- an extension integral with said conduit said extension being substantially U-shaped in crosssection, a tape guide secured to the base of said extension, and a tape guiding member supported on a shaft extending transversely of said extension in spaced relation to the base thereof.

- a tape-moistener comprising a cylindr cal water receiving body, unitary tape guiding and tensioning means detachably supported by said body, said means comprising an elongated guide provided with a pair of yieldable arcuate members detachably engaged with said cylindrical body.

- a tape moistener comprising an open ended transparent tubular member, a wick supporting cap detachably engaged with one of .said member, a plug secured to the opposite end of said member; and a cap embracing said plug and said opposite end of said member.

- a tape moistener comprising a tubular body adapted to receive water, tape guiding and tensioning means detachably supported by said body; a. cap detachably connected to one end of said body, a unitary member cm- This prevents leaching the glue off the bedded in said cap and providing a wick supporting conduit and a tape guide co-operating therewith, said cap provided with a re Dedextension, a yieldable washer interposed bctween said cap and said body, a metallic washer interposed between said cap and said yieldable washer, said metallic washer provided with a lip seated in said recess in said extension and upwardly extending projections on either side of said lip.

- said tape guiding and tensioning means comprises an elongated member adapted to rest between said upwardly extending projections and provided with laterally extending projections for limiting forward movement of said tape guiding and tensioning means relative to said body.

- a tape moistener comprising a water receiving body, a tape guiding and tensioning means detachably supported by said body,

- said means comprising an enclosed channel defined by inner and outer walls, said inner wall having an angular extension defining a tape guide, ears carried by said outer wall, and tensioning means pivotally supported by said ears, said tensioning means comprising a pressure regulating member, said member provided with a tape engaging portion for co-operation with said angular extension and tape lifting means which with said tape engaging portion defines a tape guide.

- a tape moistener comprising a body adapted to receive water, an elongated tape guide member detachably supported by said body, said guide member provided with a downwardly turned extension, laterally spaced ears supported by said guide member adjacent said downwardly turned extension, a tape pressureregulating member pivotally mounted on a pintle supported by said ears, a helical spring adj ustably mounted on said p'intle and adapted to yieldably urge said "pressure regulating member into-contact with the tape, said pressure re ulating member bein provided with a tubu ar tape engaging mem er for co-operation with said downwardly turned extension, and a tape lifting member of substantially U-shape having one leg thereof secured to said pressure regulating member and the other leg thereof in operative position disposed substantially in al1rati with said downwardly turned extension, said tubular tape engaging member and said other leg defining a guidefor the tape.

Landscapes

- Adhesive Tape Dispensing Devices (AREA)

Description

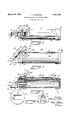

March 29, 1932. 4 c. J. WALBRAN 1,851,788

TAPE MOISTENING AND PASTING DEVICE Filed Oct. 28. 1927' Patented Mar; .29, 1932 UNITED STATES PATENT- OFFICE CHRISTOPHER JAMES WALBRAN, OF MONTCLAIR, NEW JERSEY, ASSIGNOR TO TELE- TYPE CORPORATION, OF CHICAGO, ILLINOIS, A CORPORATION OF DELAWARE TAPE MOISTENIN G AND PASTIN G DEVICE Application filed October 28, 1927. Serial No 229,870.

The present invention relates to tape mois tening and pasting devices.

More particularly the invention relates to tape moistening and pasting devices especial- 1y adapted for use in pasting telegra h mes sages received on tape or messa e lanks; for sealing package wrappers with adhesive tape, and like uses. v

Objects of the invention are to provide im- 10 proved and simplified tape moistening and pasting devices provided with a single body portion serving as a hand grip and container for water and into which the inner end of the Wick protrudes; to provide moistening and pasting devices arranged for minimum leakage when not in use which facilitate rapid, efiicient, and neat handling of the tape; and to provide such other objectsas may be attained by a utilization of the principles and arrangements hereinafter set forth and as de- 5 ing the guide slot formation.

Referring to the drawings by reference characters in which like characters designate like parts, 1 designates a tubular body which is preferably formed of a transparent material in order that the liquid contained therein may be seen, and in the present instance is formed'of pyralin. The tubular body 1, as is clearly shown in Figure 3, is an open ended structure having one end thereof closed by means of a suitable plug 2 which is cemented therein and a rubber or pyralin protecting cap 2 embraces the end and the plug 2. The opposite end of the tubular body is internally threaded as indicated at 3 in Figure 3 which is adapted to receive the externally threaded end 4 of a removable cap 5', which may be of hard rubber or other suitable material, Cap 5 adjacent its threaded portion is provided with a shoulder portion 6 which is upwardly extended as indicated at 7, and provided with a guide recess or slot 8 (Figure 5). Engaging the shoulder portion 6 is a metallic-washer 9 which is provided with a laterally turned lip 10 adapted to rest in said recess and further provided with upwardly extending projections 10' on either side of lip 10, and a suitable rubber washer or packing member 11 is interposed between the washer 9 and adjacent end of tube 1 to effect a water tight seal between the tubular body and cap 5. The metallic. washer 9 ma be eliminated in which instance only the ru ber washer 11 would be interposed between the cap 5' and the body to provide a leak proof connection.

The member 12 further provides a tape guide comprising a flanged extension 15 having secured to the base thereof the base portion of a flanged upwardly extending tape guiding members 16 and extending through the flanges of the extension 15 at the outer ends thereof is a shaft 17 on which is supported a tape guiding member or shoe 18.

The wick conduit 13 is adapted to receive a suitable wick 19 which, as shown in Figure 3, has the inner end thereof projecting in-- wardly of the inner end of the cap into tubular body 1 and the outer end thereofis adapted to be' so positioned as to engage the tape when drawn thereon as indicated in Figure 2.

The upper wall of the tape conduit is-provided with a groove as indicated in Figure 4 adapted to extend the full length of the conduit for the purpose of admitting air Without the necessity for very careful fitting of the Wicks necessary when such a groove is loo not provided. A suitable fine mesh screen .21 is positioned between the upper wall of cation of the wick with the groove through.

the mesh of the screen in pasting operations so that the-water in the groove may be absorbed by the wick permitting access of air to the interior of the container as will more fully hereinafter appear.

Detachably supported on tubular body 1 is p a unitary tape guiding and pressure regulating mechanism 22 which in its construction comprises a longitudinally extending tape guide 23 having secured to the under surface thereof a pair of ar'cuate yieldable body engaging members 24 adapted to yieldably engage the body 1 to detachably secure the guide and pressure regulating mechanism thereto. The guide23 is provided with an internal channel 25 adapted to receive and guide the tape 26. The base of the guide 23 extends forwardly of the channelled portion as indicated at 27 and is provided with laterally extending ears 28 adapted to engage the rear sides of the projections 10' to hold the guide anecphalnism against forward movement on Piirtion 27 merges into a thickened angularly extending guide member 27' and rearwardly of the cars 28 the guide 23 is provided with a pair of cars 29 through which extends a pintle 30. Mounted on pintle 30 between ears 29 are ears 31 of, a tape pressure regulating member 32 which, as shown in Figures 2 and 3, is provided at the forward end thereof with a slotted tubular tape engaging member 33 and at the rear end thereof is provided with an angular finger engaging member 34.

The member 33 is normally held in engage- Operation I In operation, the wick 19 and screen 21 are introduced into conduit 13 of cap 5 and body 1 is filled with water after which the cap is screwed into the end of the body causing the inner end of the wick to project into the water in the body. The tape guiding and pressure regulating mechanism 22 is then applied to the body 1 by means of members 21 yieldably engaging the body and the ears 28 engaging the projections 10' which positions the guide member 27' substantially in alignment with the end of the wick as shown in Figure 2. Initially, and also when the device is filled but not in use for pasting purposes water fills groove 20 establishing an air seal which prevents air from entering body 1 andaccordingly prevents water from continually dripping out. 1 i

The tape'26 to be pasted is inserted into channel 25 and drawn therethrough either before or after the guide mechanism is positioned on the body. The tape will then pass over the end of the wick, the tape extending between guide 27' and member 33 passing over the end of the wick, guiding member 16, and under roller 18, as indicated in Figure 2.

When the tape passes over the end of the wick, water is drawn from the wick which in 'turn obsorbs the water from groove 20 through screen 21 permitting air to enter body 1 through the groove allowing the water to pass freely by means of capillary attraction through the wick to be transferred to the gummcd surface of the tape. It will accordingly be seen the recess '20 in conduit 13 admits suflicient air into body 1 to avoid creation of a vacuum'and causmg the water to maintain a level, commensurate with the 7 beyond the shoe 18. The moistened surface is then pressed against the part to which it is to be pasted, such for example. as a message blank or over the edge of a package wrapper and the moistener is moved along.

This action draws the tape from the moistener allowing the tape to be pressed against the message blank or package either by hand or by means of some other ob ect. \Vhen a suflicient quantity of tape has been used it may be torn and the operation repeated. In this way strips of any desired length may be applied rapidly to the message blanks or the package and the tension of the tape may be varied by turning the pintle 30 and putting spring 35 under more or less tension.

The location of the air groove 20 innnediatelv adjacent to the wick 19 serves a very useful purpose when the moistener is not in use and tape is not. being passed over the end of the wick as at the end of a line, and while the succeeding line is being started during which period air would continue toenter the water reservoir and water would drip continuously if the groove 20'were not positioned immediately adjacent to the wick. By positioning the groove 20, as disclosd, the screen 21 permits water to flow through it when the preventing any further flow of water. When tape is again drawn over the end of the wick the water 1n groove 20 is drawn mto the wick, and the groove is thu automatically-freed of water and again acts as a vent permitting air to enter the water reservoir.-

VVhen the moistener is not in use, the tape is lifted oil the end of the wick 19 through engagement therewith of the member 37 by presslng down on the member 34 which member- 34, together with the member 37 upon re- Y lease of the member 34 will automatically assume their original positions but due to a sufficient stifiness of the tape it will remain in the position acquired by the above operation and hence will remain out of contact with the wick until it is desired to again put the moistener into operation.

small section of'tape which would rest on the end of the wick and prevents the choking of the wick due to an accumulation of glue.

It will accordingly be seen that a simple and etiicient moistener and tape paster has been provided which auton'iatically seals against leakage when not in use and lends itself to rapid and etli'cient pasting of tape for various purposes, and which when used for pasting telegraphic tape on messa e blanks permits satisfactory use without soiling of copies.

Having described a preferred embodiment of the invention, what is desired to be secured by Letters Patent and claimed as new is:

1. A tape moistener comprising a transparent cylindrical water supporting body, said body internally threaded at one end thereof, a wick supporting cap externally threaded for detachable threaded connection in saidend of said body, tape guiding and tensioning means detachably supported by said body, and a tape guiding and tensioning means positioning washer interposed between said cap and said body.

2. A tape moistener comprising a water supporting body, tape guiding and tensioning means detachably supported by said body, a wick supporting cap detachably connected to one end of said body, and tape guiding means carried by said cap for co-operation with said tape guiding and tensioning means;

3. A tape moistener comprising abody adapted to receive water, tape guiding and tensioning means supported by said body: a

cap detachably connected to said body, said cap provided with a wick supporting conduit. an extension integral with said conduit, said extension being substantially U-shaped in crosssection, a tape guide secured to the base of said extension, and a tape guiding member supported on a shaft extending transversely of said extension in spaced relation to the base thereof. I

4. A tape-moistener comprising a cylindr cal water receiving body, unitary tape guiding and tensioning means detachably supported by said body, said means comprising an elongated guide provided with a pair of yieldable arcuate members detachably engaged with said cylindrical body.

5. A tape moistener comprising an open ended transparent tubular member, a wick supporting cap detachably engaged with one of .said member, a plug secured to the opposite end of said member; and a cap embracing said plug and said opposite end of said member.

6. A tape moistener comprising a tubular body adapted to receive water, tape guiding and tensioning means detachably supported by said body; a. cap detachably connected to one end of said body, a unitary member cm- This prevents leaching the glue off the bedded in said cap and providing a wick supporting conduit and a tape guide co-operating therewith, said cap provided with a re cessedextension, a yieldable washer interposed bctween said cap and said body, a metallic washer interposed between said cap and said yieldable washer, said metallic washer provided with a lip seated in said recess in said extension and upwardly extending projections on either side of said lip.

7. The construction defined in claim 6 in which said tape guiding and tensioning means comprises an elongated member adapted to rest between said upwardly extending projections and provided with laterally extending projections for limiting forward movement of said tape guiding and tensioning means relative to said body.

8. A tape moistener comprising a water receiving body, a tape guiding and tensioning means detachably supported by said body,

said means comprising an enclosed channel defined by inner and outer walls, said inner wall having an angular extension defining a tape guide, ears carried by said outer wall, and tensioning means pivotally supported by said ears, said tensioning means comprising a pressure regulating member, said member provided with a tape engaging portion for co-operation with said angular extension and tape lifting means which with said tape engaging portion defines a tape guide.

9. A tape moistener comprising a body adapted to receive water, an elongated tape guide member detachably supported by said body, said guide member provided with a downwardly turned extension, laterally spaced ears supported by said guide member adjacent said downwardly turned extension, a tape pressureregulating member pivotally mounted on a pintle supported by said ears, a helical spring adj ustably mounted on said p'intle and adapted to yieldably urge said "pressure regulating member into-contact with the tape, said pressure re ulating member bein provided with a tubu ar tape engaging mem er for co-operation with said downwardly turned extension, and a tape lifting member of substantially U-shape having one leg thereof secured to said pressure regulating member and the other leg thereof in operative position disposed substantially in al1nement with said downwardly turned extension, said tubular tape engaging member and said other leg defining a guidefor the tape.

In testimony whereof I afiix my signature.

CHRIS. J. WALBRAN.

Priority Applications (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| US229370A US1851788A (en) | 1927-10-28 | 1927-10-28 | Tape moistening and pasting device |

Applications Claiming Priority (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| US229370A US1851788A (en) | 1927-10-28 | 1927-10-28 | Tape moistening and pasting device |

Publications (1)

| Publication Number | Publication Date |

|---|---|

| US1851788A true US1851788A (en) | 1932-03-29 |

Family

ID=22860926

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| US229370A Expired - Lifetime US1851788A (en) | 1927-10-28 | 1927-10-28 | Tape moistening and pasting device |

Country Status (1)

| Country | Link |

|---|---|

| US (1) | US1851788A (en) |

-

1927

- 1927-10-28 US US229370A patent/US1851788A/en not_active Expired - Lifetime

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| US2143712A (en) | Fountain brush | |

| US1926367A (en) | Liquid and semiliquid container | |

| US2243752A (en) | Liquid vaporizing and diffusing device | |

| US1851788A (en) | Tape moistening and pasting device | |

| US973375A (en) | Moistener. | |

| US2588548A (en) | Ink applicator for typewriter ribbons | |

| US2492377A (en) | Moistener for duplicating machines | |

| US1044190A (en) | Gummed-strip-serving apparatus. | |

| US1972661A (en) | Tape moistening device | |

| US1389003A (en) | Sealing-strip apparatus | |

| US1900121A (en) | Tape moistening and affixing device | |

| US3297510A (en) | Portable tape dispenser | |

| US2031597A (en) | Gummed strip moistener | |

| US2349564A (en) | Moistening device for gummed objects | |

| US2547803A (en) | Pen cap | |

| US2530037A (en) | Envelope moistener and sealer | |

| US2198519A (en) | Label, stamp, or strip applying device | |

| US530135A (en) | Stamp or envelope moistener | |

| US2101415A (en) | Sealing device | |

| US2028079A (en) | Floor oiler or waxer | |

| US549105A (en) | Device for moistening gummed surfaces | |

| US2077780A (en) | Envelope flap moistening device | |

| US2776077A (en) | Resilient spring envelope for collapsible tubes | |

| US1554568A (en) | Envelope sealer | |

| US1313056A (en) | And fred pearson |