US1761812A - Machine for washing, drying, and sterilizing dishes - Google Patents

Machine for washing, drying, and sterilizing dishes Download PDFInfo

- Publication number

- US1761812A US1761812A US81636A US8163626A US1761812A US 1761812 A US1761812 A US 1761812A US 81636 A US81636 A US 81636A US 8163626 A US8163626 A US 8163626A US 1761812 A US1761812 A US 1761812A

- Authority

- US

- United States

- Prior art keywords

- washing

- machine

- drying

- dishes

- compartment

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Expired - Lifetime

Links

- 238000005406 washing Methods 0.000 title description 25

- 238000001035 drying Methods 0.000 title description 21

- 230000001954 sterilising effect Effects 0.000 title description 7

- XLYOFNOQVPJJNP-UHFFFAOYSA-N water Substances O XLYOFNOQVPJJNP-UHFFFAOYSA-N 0.000 description 30

- 239000007921 spray Substances 0.000 description 3

- 238000004140 cleaning Methods 0.000 description 2

- 238000004891 communication Methods 0.000 description 2

- 230000000694 effects Effects 0.000 description 2

- 206010022000 influenza Diseases 0.000 description 2

- 238000012986 modification Methods 0.000 description 2

- 230000004048 modification Effects 0.000 description 2

- 239000003643 water by type Substances 0.000 description 2

- RIUAYUDQYSSIOM-UHFFFAOYSA-N 5,5-bis(4-methoxyphenyl)-3-(2-piperidin-1-ylethyl)imidazolidine-2,4-dione;hydrochloride Chemical compound Cl.C1=CC(OC)=CC=C1C1(C=2C=CC(OC)=CC=2)C(=O)N(CCN2CCCCC2)C(=O)N1 RIUAYUDQYSSIOM-UHFFFAOYSA-N 0.000 description 1

- 241000746181 Therates Species 0.000 description 1

- LZCDAPDGXCYOEH-UHFFFAOYSA-N adapalene Chemical compound C1=C(C(O)=O)C=CC2=CC(C3=CC=C(C(=C3)C34CC5CC(CC(C5)C3)C4)OC)=CC=C21 LZCDAPDGXCYOEH-UHFFFAOYSA-N 0.000 description 1

- 230000001112 coagulating effect Effects 0.000 description 1

- 238000010276 construction Methods 0.000 description 1

- 229940002658 differin Drugs 0.000 description 1

- 238000010981 drying operation Methods 0.000 description 1

- 239000007789 gas Substances 0.000 description 1

- 239000002184 metal Substances 0.000 description 1

- 230000002035 prolonged effect Effects 0.000 description 1

- 230000001105 regulatory effect Effects 0.000 description 1

- 230000013707 sensory perception of sound Effects 0.000 description 1

- 238000005507 spraying Methods 0.000 description 1

- 238000004659 sterilization and disinfection Methods 0.000 description 1

- 239000000126 substance Substances 0.000 description 1

- 239000002918 waste heat Substances 0.000 description 1

- 239000002699 waste material Substances 0.000 description 1

Images

Classifications

-

- A—HUMAN NECESSITIES

- A47—FURNITURE; DOMESTIC ARTICLES OR APPLIANCES; COFFEE MILLS; SPICE MILLS; SUCTION CLEANERS IN GENERAL

- A47L—DOMESTIC WASHING OR CLEANING; SUCTION CLEANERS IN GENERAL

- A47L15/00—Washing or rinsing machines for crockery or tableware

- A47L15/24—Washing or rinsing machines for crockery or tableware with movement of the crockery baskets by conveyors

- A47L15/241—Washing or rinsing machines for crockery or tableware with movement of the crockery baskets by conveyors the dishes moving in a horizontal plane

- A47L15/242—Washing or rinsing machines for crockery or tableware with movement of the crockery baskets by conveyors the dishes moving in a horizontal plane in a closed loop

- A47L15/243—Washing or rinsing machines for crockery or tableware with movement of the crockery baskets by conveyors the dishes moving in a horizontal plane in a closed loop with conveyors of the rotary table type

Definitions

- the present invention concerns improve .ments in machines for washing, drying and sterilizing dishes. It aims, more particular- 1y, to simplify and improve the construction and operation of machines in this class of the so-called continuous type of design.

- One of the objects of the invention is to provide an economical arrangement of heaters and fiues for accelerating thedrying of the dishes.

- Another object is to provide a hot water heater so arranged that the waste heat therefrom is used in the drying operation.

- Still-another object is to arrange the washing sprays so that they not only clean the dishes but at the same time impel them to move through the machine on suitably arranged carriages or conveyors at any chosen regulatable speed.

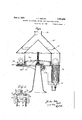

- ig. 1 is a'front view, partially in sect-ion of a complete machine of the straight-line ty e.- v Fig. 2 is anotherfront view of the same machine showing details of the outside casing.

- Fig. 3 is a transverse section through the machine shown in Fig. 1, taken through one of the wash-water reservoirs.

- Fig. 4 is another transversesection through the same machine andt-aken through the hot water heater.

- Fig. 5 is an end View of the chain driveshowing particularly the disposition of the gutters, and of the guards for protecting the chains.

- Fig. 6 is a section through another embodiment of the machine, which utilizes a revolv ing table.

- 7 is a top view of the machine shown in Fig. 6 with the top removed.

- Fig. 8 is a view of the machine illustrated in Fig; 6. showing the outside casing in posi- 2' tion.

- Fig 9 is partial section of the same mascreens leading to the the drawing.

- a motor direct-1y connected to centrifugal pump 2, and to a worm-andwheel drive 3 which actuatcs chain 4 to rotate sprocket-wheel 5 mounted on shaft 6.

- Shaft 6 is fitted with a; pair of sprockets 7 carrying ment of each basket is effected by the dishbaskets 12 mounted immediately behind it, which are in engagement with the drivechains 8.

- Chains 8 are protected from water and refuse falling from the baskets 12 by the sheet metal plates 16 which are arranged to leave a space 17 for the passage 'of fingers 15. Gutters 18 are placed beneath space 17 to intercept anything passing therethrough.

- sh baskets 12 are moved along the trackway 11 and enter a first washing compartment 23 where suitably arranged sprayers 21, 24 spray water fed to them by the pump 2 from wash water reservoir 25.

- the refuse from the dishes falls upon the inclined funnel-sha ed screens 26which empty into refuse basl ets 27.

- the baskets 12 proceed now into compartment 28 where the dishes are again rinsed by sprayers 29, 29 fed by pump 2 from wash water reservoir 30. Screens 31 are provided to catch refuse falling from the dishes toward reservoir 30.

- the dish baskets now are moved past Sprayers 32,32 which are supplied with clean, hot water coming directly from the coil (see Fig. 1) forming part of the hot water heater 33.

- the continued movement of the dishes brings them over hot water heater 33 the waste heatfrom which rises through flue 34 and effects their drying and sterilization.

- Water heater 34 is heated by .a convenient form of gas heater, as shown in Fig. 1.

- flue 34 and chimney 35 are provided immediately over washing compartments 23 and 28.

- Flue 34 is provided with a cen-v tral wall 36, and it is also provided with baflles 37 designed to deflect the wash waters from the sprayers back into their respective reservoirs.

- a valve 40 may be adjusted to dischargefoul water from reservoir 25 at any desired rate.

- wash waters projected from sprayers 24, 24 for effecting the first rinsing be not above in temperature in Order to avoid coagulating the 'albuminous substances adhering to the dishes.

- Means must therefore be provided for preventingan excessively rapid transfer of heat from hot water reservoir 30 to the cooler water in reservoir 25. vThis is accomplished by interpos ing a heat insulating wall 39 between the two reservoirs. The respective temperatures of the water in the two reservoirs may be followed by observing thermometers 41, 41 and p these respective temperatures may be regulated by changing the rate of feed or the'tem perature of the hot water fed to the machine or by manipulating therate of discharge.

- Spraying tubes 24, 24 29,29 and 32,32 are fastened to the casing of the machine by wing nuts 43 and maybe detached for cleaning by loosening these nuts.

- the dish embodiment of the invention move through a circular compartment, instead of through straight washing and drying compartments, and are delivered back to their starting point.

- the conveyor for the dishes consists of a revoluble table 100suitably supported by ball hearings on column 101 and by rollers 101.

- the table is divided by members 102 into compartments capable of receiving curved baskets 103. -Dishes are loaded onto the table at station A, move through washing compartment B, then through drying compartment washed and dried.

- the arrangement of wash water reservoirs and sprays is similar to that G and return to station A,

- Movement of the rotating table is obtained in this type of machine simply by inclining the wash water heads or sprayers so that the water strikes the dishes forcibly on one side.

- the slow movement of the table 30 obtained insures thorough washing and drying and eliminates the ne'cessity'for a

- a brake may be provided actuated by a governor connected motor drive.

- the gears 104 may, of course, be just as advantageously connected to a speedshaft of a fan arranged toexhaust the air and vaporsfrom flue 34

- a' somewhat difierent arrangement for removing the screens from the wash-water reservoirs is shown.

- the screens 105 are disposed here radially and are held in position in the manholes by doors 106 maintained closed by the screws 107. I the screens, screws 107 are loosened and doors 106 are swung on their pivots 108'out of the way. The screens may then be removed.

- the system of moving thedishes by means ofthe washing jets may be applied as well.

- a machine of the class described comprising in comb'nation a washing compartment, a rmsing head positioned in said washor to-the.

- a drying compartment communicating with the washing compartment, means for conveying articles to becleaned first into the washing and then into the drying compartment, a water heater positioned under the drying compartment and in communication therewith so as to discharge heated air into the latter, a flue mounted over the washing compartment,

- a chimney connected to said flu'e and positioned to draw the heated air from the water-heater through the drying compartment into the washing compartment in the direction opposite to that of the movement of the articles being cleaned and finally into the signature.

Landscapes

- Washing And Drying Of Tableware (AREA)

Description

J. L. BRETON June 3, 1930.

MACHINE FOR WASHING, DRYING, AND'STERILIZING DISHES,

Filed Jan. 16, 1926 7 Sheets-Shegt 1 W am June 3, 1930. J. BRETON 1,761,812

MACHINE FOR WASHING, DRYING, AND STERILIZING DISHES June 3, 1930.

J. L. BRETON 1,761,812 MACHINE FOR WASHING,- DRYING, AND S TERILIZING DISHES Filed Jan. 16, 1926 7 Sheets-Sheet 3 Fig.3 q

June 3, 1930.

J. BRETON 1,761,812 MACHINE FOR WASHING, DRYING, AND STERILIZING DISHES Filed Jan. 16, 1926 7 SIheets-Sheet 4 103 Q 1 I r c D mg 34'- 101 .701 C 104 d E Q C v I I o June 3, 1930.

J. L. BRETON MACHINE FOR WASHING, DRYING, AND STERILIZING DISHES Filed Jan. 16, 192s 7 Sheets-Sheet 5 June 3, 1930. J. L. BRETON 1,161;s12

MACHINE FOR WASHING, DRYING, AND STERILIZING DISHES be L J. L. BRETON June 3, 1930;

MACHINE FOR WASHING, DRYING, AND STERILIZING DISHES 7 Shgets-Sheet 7 Filed Jan. 16 1926 llll I l'li Patented June 3,1930

OFFICE JULES LOUIS BRETON, OF BELLEVUE, FRANCE MACHINE FOR WASHING, DRYING, AND STERILIZING DISHES Application filed January 16, 1926, Serial No. 81,636, and in France January 21, 1925.

, The present invention concerns improve .ments in machines for washing, drying and sterilizing dishes. It aims, more particular- 1y, to simplify and improve the construction and operation of machines in this class of the so-called continuous type of design.

One of the objects of the invention is to provide an economical arrangement of heaters and fiues for accelerating thedrying of the dishes.

Another object is to providea hot water heater so arranged that the waste heat therefrom is used in the drying operation.

Still-another object is to arrange the washing sprays so that they not only clean the dishes but at the same time impel them to move through the machine on suitably arranged carriages or conveyors at any chosen regulatable speed.

Other objects will appear in the course of the detailed description of preferred embodiments of the invention which follows, reference being made to the accompanying drawin s in which ig. 1 is a'front view, partially in sect-ion of a complete machine of the straight-line ty e.- v Fig. 2 is anotherfront view of the same machine showing details of the outside casing.

Fig. 3 is a transverse section through the machine shown in Fig. 1, taken through one of the wash-water reservoirs.

Fig. 4 is another transversesection through the same machine andt-aken through the hot water heater.

Fig. 5 is an end View of the chain driveshowing particularly the disposition of the gutters, and of the guards for protecting the chains.

Fig. 6 is a section through another embodiment of the machine, which utilizes a revolv ing table. 7 is a top view of the machine shown in Fig. 6 with the top removed. Fig. 8 is a view of the machine illustrated in Fig; 6. showing the outside casing in posi- 2' tion.

Fig 9 is partial section of the same mascreens leading to the the drawing,

chine, the section being taken through the pumps.

In each of the several views similar numerals indicate similar parts.

Referring now to the various figures of 1 is a motor direct-1y connected to centrifugal pump 2, and to a worm-andwheel drive 3 which actuatcs chain 4 to rotate sprocket-wheel 5 mounted on shaft 6. Shaft 6 is fitted with a; pair of sprockets 7 carrying ment of each basket is effected by the dishbaskets 12 mounted immediately behind it, which are in engagement with the drivechains 8. Chains 8 are protected from water and refuse falling from the baskets 12 by the sheet metal plates 16 which are arranged to leave a space 17 for the passage 'of fingers 15. Gutters 18 are placed beneath space 17 to intercept anything passing therethrough. When the baskets reach the opposite end of the trackwayll they may be removed through doors 19; but if they are 'not removed, they actuate plunger 21 to open switch 22 leading to the motor. The machine then comes to a stop. It is to be understood of course that trackway 11 may be prolonged beyond the casing of the machine, in which case the dishes may be removed. from the track after thgy emerge from the casing. i

In order to provide .for proper circulation of hot air overthe dishes, flue 34 and chimney 35 are provided immediately over washing compartments 23 and 28. The vigorous movement of air from flue 34 to flue 34* via the drying compartment, which communicates with and which connects both of these flues, acts to dry the dishes and to sweep the vapors in the washing compartments up into chimney 35. Flue 34 is provided with a cen-v tral wall 36, and it is also provided with baflles 37 designed to deflect the wash waters from the sprayers back into their respective reservoirs.

The course of the wash water through the machine is from sprayers 32, 32 to reservoir 30, through screen 38, thence through the pump to sprayers 29, 29 ervoir 3,0. Reservoir 30 overflows at 39 into reservoir 25 from which the wash water is drawn through screen 38 into the pump, whence it is elevated to sprayers 24 and 24 which deliver the water back to reservoir 25.

r Doors cess to the reservoir so that the-various screens A valve 40 may be adjusted to dischargefoul water from reservoir 25 at any desired rate.

It is necessary that the wash waters projected from sprayers 24, 24 for effecting the first rinsing be not above in temperature in Order to avoid coagulating the 'albuminous substances adhering to the dishes. Means must therefore be provided for preventingan excessively rapid transfer of heat from hot water reservoir 30 to the cooler water in reservoir 25. vThis is accomplished by interpos ing a heat insulating wall 39 between the two reservoirs. The respective temperatures of the water in the two reservoirs may be followed by observing thermometers 41, 41 and p these respective temperatures may be regulated by changing the rate of feed or the'tem perature of the hot water fed to the machine or by manipulating therate of discharge.

through valve 40.

42, 42 are provided for gaining acand refuse baskets may be removed and cleaned. Spraying tubes 24, 24 29,29 and 32,32 are fastened to the casing of the machine by wing nuts 43 and maybe detached for cleaning by loosening these nuts.

. Turning now'to the modification shown Figs'. 6'to 9. inclusive, there is baskets, in this 7 drying and back to resregulating clock work mechanism,

shown a machine differin mainly from the one already described in t e arrangement of the conveying mechanism. for the dishes. The dish embodiment of the invention, move through a circular compartment, instead of through straight washing and drying compartments, and are delivered back to their starting point. The conveyor for the dishes consists of a revoluble table 100suitably supported by ball hearings on column 101 and by rollers 101. The table is divided by members 102 into compartments capable of receiving curved baskets 103. -Dishes are loaded onto the table at station A, move through washing compartment B, then through drying compartment washed and dried. The arrangement of wash water reservoirs and sprays is similar to that G and return to station A,

in the machine already described. -Heat for the dishes is supplied here also as in the straight line type of machine by hot water heater 33. Draft'for drawing hot air from the heater over the dishes is supplied by circular flue 34 fitted with bafiies 37 and connected to chimney 35. I

Movement of the rotating table is obtained in this type of machine simply by inclining the wash water heads or sprayers so that the water strikes the dishes forcibly on one side. The slow movement of the table 30 obtained insures thorough washing and drying and eliminates the ne'cessity'for a In order that the slow movement of the table may be further assured, a brake may be provided actuated by a governor connected motor drive.

through the system of gears 104 to the rotat- 7 ing table. The gears 104 may, of course, be just as advantageously connected to a speedshaft of a fan arranged toexhaust the air and vaporsfrom flue 34 In this embodiment of the invention a' somewhat difierent arrangement for removing the screens from the wash-water reservoirs is shown. The screens 105 are disposed here radially and are held in position in the manholes by doors 106 maintained closed by the screws 107. I the screens, screws 107 are loosened and doors 106 are swung on their pivots 108'out of the way. The screens may then be removed.

The system of moving thedishes by means ofthe washing jets,.described in connection with this modification, may be applied as well.

to the'straight line type of machine. It is only necessary in using this system of propulsion with-the straight line machine to push the dish carriages into the washing compartments. The action of the washing jets then. effects their "continued motion through these eom'partments into the drying compartment.

-1 claim: R I

1. A machine of the class described comprising in comb'nation a washing compartment, a rmsing head positioned in said washor to-the.

When it is necessary to clean ing compartment and adapted to direct a jet of water on articles to be cleaned, a drying compartment communicating with the washing compartment, means for conveying articles to becleaned first into the washing and then into the drying compartment, a water heater positioned under the drying compartment and in communication therewith so as to discharge heated air into the latter, a flue mounted over the washing compartment,

a chimney connected to said flu'e and positioned to draw the heated air from the water-heater through the drying compartment into the washing compartment in the direction opposite to that of the movement of the articles being cleaned and finally into the signature.

flue, and a feed conduit extending from the water-heater to the rinsing head in the washing compartment.

2. A machine of the class describedcomprising in combination a washing compartment, a rinsing head ositioned in said washing compartment an adapted to direct a jet of water on articles to be cleaned, a drying compartment communicating with the wash ing compartment, means for conveying artcles to be cleaned first'into the washing and then into the drying compartment, a water heater positioned under the drying compartment and in communication therewith so as to deliver heated air to the latter, and means connected to the washing compartment and operative to draw the heated air from the water heater through the drying compartment into the washing com artment in a direction opposite tothat 0 the articles being cleaned, and a feed conduit extending from the water heater to the rinsinghead in the washing compartment. 1

-In testimony whereof I hereunto afiix my JULES LOUIS BRETON.

Applications Claiming Priority (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| FR1761812X | 1925-01-21 |

Publications (1)

| Publication Number | Publication Date |

|---|---|

| US1761812A true US1761812A (en) | 1930-06-03 |

Family

ID=9680843

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| US81636A Expired - Lifetime US1761812A (en) | 1925-01-21 | 1926-01-16 | Machine for washing, drying, and sterilizing dishes |

Country Status (1)

| Country | Link |

|---|---|

| US (1) | US1761812A (en) |

Cited By (9)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US2443091A (en) * | 1940-10-15 | 1948-06-08 | Metalwash Machinery Co | Cleaning apparatus having rotary conveyer and recirculating liquid systems |

| US2595838A (en) * | 1945-07-02 | 1952-05-06 | Winona Tool Mfg Company | Apparatus for cleaning parts and for separating suspended particles from liquids |

| US2608981A (en) * | 1944-02-03 | 1952-09-02 | Otto V Jackson | Dishwashing machine |

| US2619097A (en) * | 1945-09-04 | 1952-11-25 | Ingeniors N Adolph Von Bromsse | Dishwashing machine with water temperature regulating means |

| US2677368A (en) * | 1949-06-01 | 1954-05-04 | R C Mahon Company | Water heater |

| US2688407A (en) * | 1940-10-15 | 1954-09-07 | Metalwash Machinery Co | Rotary table conveyer for cleansing apparatus |

| US2800995A (en) * | 1940-10-15 | 1957-07-30 | Metalwash Machinery Co | Rotary table conveyors for cleansing apparatus |

| US3642012A (en) * | 1969-09-03 | 1972-02-15 | American Sterilizer Co | Sterilizing apparatus for continuously sterilizing articles by flames means |

| US3885987A (en) * | 1973-12-13 | 1975-05-27 | Flight Services Unlimited Inc | Process for cleaning and sanitizing ear sets |

-

1926

- 1926-01-16 US US81636A patent/US1761812A/en not_active Expired - Lifetime

Cited By (9)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US2443091A (en) * | 1940-10-15 | 1948-06-08 | Metalwash Machinery Co | Cleaning apparatus having rotary conveyer and recirculating liquid systems |

| US2688407A (en) * | 1940-10-15 | 1954-09-07 | Metalwash Machinery Co | Rotary table conveyer for cleansing apparatus |

| US2800995A (en) * | 1940-10-15 | 1957-07-30 | Metalwash Machinery Co | Rotary table conveyors for cleansing apparatus |

| US2608981A (en) * | 1944-02-03 | 1952-09-02 | Otto V Jackson | Dishwashing machine |

| US2595838A (en) * | 1945-07-02 | 1952-05-06 | Winona Tool Mfg Company | Apparatus for cleaning parts and for separating suspended particles from liquids |

| US2619097A (en) * | 1945-09-04 | 1952-11-25 | Ingeniors N Adolph Von Bromsse | Dishwashing machine with water temperature regulating means |

| US2677368A (en) * | 1949-06-01 | 1954-05-04 | R C Mahon Company | Water heater |

| US3642012A (en) * | 1969-09-03 | 1972-02-15 | American Sterilizer Co | Sterilizing apparatus for continuously sterilizing articles by flames means |

| US3885987A (en) * | 1973-12-13 | 1975-05-27 | Flight Services Unlimited Inc | Process for cleaning and sanitizing ear sets |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| US2651065A (en) | Tray washing and sterilizing machine | |

| US1761812A (en) | Machine for washing, drying, and sterilizing dishes | |

| US2250238A (en) | Industrial washing machine | |

| US4420854A (en) | Apparatus for cleaning trays | |

| US3263341A (en) | Car wash system | |

| BRPI1000418A2 (en) | bottle cleaning machine and bottle cleaning method | |

| US1144023A (en) | Bottle-washing machine. | |

| US3312230A (en) | Dish-washing machines | |

| US2392540A (en) | Fluid spraying device for dishwashing apparatus | |

| US1508495A (en) | Dishwasher | |

| US1045079A (en) | Dish-cleaner. | |

| CN211191232U (en) | Ultrasonic bottle washing machine | |

| US2681872A (en) | Bottle washer | |

| US3056414A (en) | Article washing machine | |

| US1972711A (en) | Apparatus for washing receptacles | |

| CN220992019U (en) | Cleaning device for remanufacturing automobile parts | |

| JPH1157634A (en) | Cleaning equipment | |

| US1018046A (en) | Method of cleaning bottles. | |

| US2774361A (en) | Bottle washer | |

| US1391141A (en) | Can-washing machine | |

| US1215107A (en) | Dish-washer. | |

| US1692812A (en) | Machine for washing and drying sheet-metal boxes or cans | |

| USRE25421E (en) | nolte | |

| US2253912A (en) | Bottle washer | |

| US2114893A (en) | Washing and drying machine |