US1663170A - Combing machine for textile fibers - Google Patents

Combing machine for textile fibers Download PDFInfo

- Publication number

- US1663170A US1663170A US209906A US20990627A US1663170A US 1663170 A US1663170 A US 1663170A US 209906 A US209906 A US 209906A US 20990627 A US20990627 A US 20990627A US 1663170 A US1663170 A US 1663170A

- Authority

- US

- United States

- Prior art keywords

- roller

- brush

- aspirator

- waste

- combing

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Expired - Lifetime

Links

- 239000000835 fiber Substances 0.000 title description 6

- 239000004753 textile Substances 0.000 title description 4

- 239000002699 waste material Substances 0.000 description 19

- 238000000034 method Methods 0.000 description 5

- 239000011435 rock Substances 0.000 description 2

- 241000612703 Augusta Species 0.000 description 1

- 206010053567 Coagulopathies Diseases 0.000 description 1

- 208000025814 Inflammatory myopathy with abundant macrophages Diseases 0.000 description 1

- 230000035602 clotting Effects 0.000 description 1

- 238000007689 inspection Methods 0.000 description 1

- 239000000463 material Substances 0.000 description 1

- 239000002245 particle Substances 0.000 description 1

Images

Classifications

-

- D—TEXTILES; PAPER

- D01—NATURAL OR MAN-MADE THREADS OR FIBRES; SPINNING

- D01G—PRELIMINARY TREATMENT OF FIBRES, e.g. FOR SPINNING

- D01G19/00—Combing machines

- D01G19/06—Details

- D01G19/28—Air draught or like pneumatic arrangements

Definitions

- rator'w Means are provided for thereof ,arou

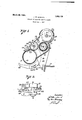

- Figure 2 i Referring of the usual ty then adjacent, to the aspia 1 aspirator 11 "and is then'carriedround to be removed,

- Eigurez is the usual YES

- brackets 22 may be formed as shown in Fig- Each bracket is extended with open bearings 23 for ure 1 at 28, these ends thus forming are ceptacle for thedoifing roller when the latter with its shaft is removed from its operative. position for access to the brush 6, say

- Each combing head of a combing machine roller shaft 9 may extend across one or more of such heads.

- a combing combing cylinder is cleared of waste by a brush for the su sequent removal of such a complete roller shaft maybe made inse'ctions, each section having 'mounted thereon two doffingroller's;

- means for rotating the said dolling roller comprising friction discs on the shaft of the said roller, which discs are in the surface of the aspirator.

- an aspirator including a rotary drum, arms mounted to rock about the axiso-f the aspirator drum, a dofling roller supported in bear-i positioned between ping roll supported inbearings in said arms in operative relation to the doffing roller i driven contact with comprising i roller shaft, the said bear tmgs being adjustable on a'circular path 120 5.

- the combination 6 In a combing machine, the combination 6.

- a combing cylinder for clearing Waste from aspirator including a r0 5 mounted to rock about the tor drum, a doifing roller ings in said arms and 7p supported the combination of a rotary brush said cylinder, an tary drum, arms axis of the aspirain bearositioned between the brush and aspirator drum, and means for rotating both the doffing and stripping rollers by the aspirator drum.

Landscapes

- Engineering & Computer Science (AREA)

- Textile Engineering (AREA)

- Preliminary Treatment Of Fibers (AREA)

Description

March 20, 1928.

J. W. NASMITH COMBING MACHINE FOR TEXTILE FIBERS Filed Aug: 1. 1927 .w m v mL n s M M Ma w Patented Mar. 20, 1928.

unrrsn srn JOHN wILLiAM NA COMBING1 IliHiGl-I Application filed Augusta,

These improveme machines for textile 'cally to such machines in. material collected by a 5 ing cylinder or the like is transferred from? the said brush to the surface of an aspl'ra tor-+that is,

cagethe. interior of wh tion with an exhaust, :f meanse and re haustingv "fibers and 1927; Serial 1v nt-s relate to, combing more 'sp'ecifi-r" which; the waste; brush from, the comb j -a rotating perforated or. like action of the said exhausting means] Direct remov waste; by the fa the aspirator is to the brush method in use,

bristles and, in

al from'the brush n exhaust to. the surface of diflic'ult as the I waste clings the brush runs at a" ane speed and throws the waste ofi 'centrifugally and rator. This he air current dr awsit on to the oasp1-e method however entails 'a high objectof these improvements to provlde means. for: allowing the brush an ordinary full efficiency o to be run at speed whilst still retaining the the improvement-s; wherein the combing Cyl-i f the aspiratory. method of waste collecting 7 According to L combing machine inderis stripped of waste fibers by a brush to be subsequentlyremoved by a dofiing roller 7 is interposed brush and aspirator, ing .teet-h whichpass the brush to which. teeth an .aspirator,

between the the doifing rollerf havclosepro xim ity to remove the waste therefrom and pass.

rator'w Means are provided for thereof ,arou

for r-otatably supporting The improvementsin a rangement a machine will .nowbeing had to which show provements.

nd to the aspirator s applie suflicient of such a doffingroller and the aspirator,

may be known Roth moval, and

Figure 2 i Referring of the usual ty then adjacent, to the aspia 1 aspirator 11 "and is then'carriedround to be removed,

rotating the bring the waste laden teeth andp 3 purpose? and also for keeping'the'various.

surface,

the said roller.

very "suitable are d to a Nasmith combing be described; reference on the accompanying drawings,

combing 1118.

chine to allow of explanationof'the imelevation partly in secthe brush the 'which latter pe as employed in the aspiratory system for waste re s a plan of part of to the drawings,,3

Eigurez is the usual YES;

the usual toothed segment 5'.

J tating in the directions" narrows. Adjacent to the brush 6 ismounted ich is in 'commiinicaFf l an or e ui al'ent ex-i taine d'thereon by the ing roller centre and brush of the" fiicient high 7 ffore, are cleared from 10 of the dofiingroller 8' v ofthe said roller, the" 1 d. it is the perforated on its surface as shown at 12 Figure 2' and has the i able inner damper 13. As 1n usual practice; f?

v vscrews .or the like imam rear Inn non TEXTILE: FIBERS.

,z'oaaoaam in ,Great Britain Apri1 6, 1926.

and having p The usual '1 'clearlng brush 6 mounted-joirthe jshaft makes clearing contact" with the" segment fneedlesa's usual; the cylinder andbrush'ro of their respective combingcylinder on its shaft 4 ing rollerro'tate in the direction; of-thefan-" v Waste fibers "collected row shown thereon. by the brush 6' from the cylinder 8, there-"' 7 and owingto the continued rotation waste is passed closely adjacent to the sur-"f 7 face of an aspirator'jll. "This'laspiratonisi75 stationary but adj :7 the interior of theaspirator communicates w th an exhaust fan to draw air ra'dially in-i 'wardly of the'aspirator through such 'p'er-' Y fi IIS as are not'obturatedby the damper 13 as theaspirator tube 11 rotates in the die ff rection'of its arrow. I j H I V It will be, seen therefore thatowing to the action o'f the air current induced by thefan, waste is d'epos'itedrfrom the teeth'i'l'O 'ofthef I dofling roller 8' upon the "surface l'2' of the I" members clear of particles of waste which 1nigl1t settle thereon vertical side plates 1 L are provided at eachsi'de of the combin gwg cylinder Sfon which'plat'es are cast the ribs f l5 and a sheetiiron cover16 'is provided; 1 supported by these plates 'and extending around thefvarious members as shown. The platesla arelsupportedi in any convenient manner, but they arefshown as secured'u'pon p the beam 17 For clearne'ss only one of the plates 14 is'illustratedin Figure 1 To an;

low of removal or adjustment of part cover 16, theplates vlav-are slotted"at18,set 1 19 engaging j in'fthe slots f j to maintain; this cover portion in desired po i thebrush b m g It will be obvious that any means of rotating the dolfing roller 8 may be adopted but a very convenient method is illustrated in the drawingswhich method allows of the easy and exact adjustment when required of the dofling roller in relation to the brush 6.

Upon the clotting roller shaft 9 are mounted by means of theirbosses the friction discs or bowls 29 of such diameter as to keep the doffer teeth justclear of the aspirator tube and which are in driving contact with the surface of the aspirator 11. The dofling roller 8 is therefore rotated by the'aspirator, as is also the stripping roller 27, and this drive is not affected by desired adjustment ofthe brackets 22, which the aspiratorv tube. I V

Upon the plates 14 at either side of the cylinder are formed suitable surfaces to receive the semicircular supports 22 and fitted with screws 20 which engage in slots 21 formed in, the semicircular supports 22.

These h'ave formed" at their upper ends the bifurcated bearings 23 forthe shaft 9 of the doifing roller. at 24 and formed the shaft 26 of 27.7 Adjustment of the supports 22 by the screws 20 will thus ensure that the do'fling roller'8 and brush 6 are always in the desired relation and'thisadjustment does not disturb the stripping roller 27 which remains in contact'with the aspirator 11 and in the requisite proximityto the teeth 10 of the dolfing roller 8, whilst the latter is easily removable when desired. The ends of the brackets 22 may be formed as shown in Fig- Each bracket is extended with open bearings 23 for ure 1 at 28, these ends thus forming are ceptacle for thedoifing roller when the latter with its shaft is removed from its operative. position for access to the brush 6, say

for inspection or readjustment of the latter,

In addition to the advantage of the savingof power in driving the brush 6, and also the saving of wear and tear thereon consetquent upon the decreasedcspeed thereof, it

as found that a very slight air current is suflicient to clear the doifing roller teeth '10,, with the'assistance of the stripping roller 27. The air currentmay therefore, be reducedconsiderably, and indeed may only'be maintained in a degree sutlicient to ensure that the fly shall be kept within the cover and prevented from getting out and settling on the exterml parts of the machine.

This reduction is further aided by the fact that where the doffing roller is introduced, nearly the whole of the waste is collected on the teeth thereof and does not obstruct the passage of air through the perforations exposed within the casing until it and they reach the stripping position. In the arrangement where the dofiing roller is absent, the wholeof the Waste is drawn on to the perforations immediately they are ex are concentric with "is fitted as above described, and the dofling the small stripping roller ings in said arms'and the brush and asplrator drum, and a stripforations and the fan speed, may be reduced by half andstill sufiice to strip the dofler and keep themachine clean.

Each combing head of a combing machine roller shaft 9 may extend across one or more of such heads.

For instance in comb ng apparatus, the dofling I claim 1. In a combing combing cylinder is cleared of waste by a brush for the su sequent removal ofsuch a complete roller shaft maybe made inse'ctions, each section having 'mounted thereon two doffingroller's;

machine in which the waste by means of an aspirator,*a dolfing roller interposed between the brush and,

aspirator the said roller having teeth which strip the brush bristles and'pass ,closelyadjacent to the aspirator surfaceyfmeans for rotating the dofling roller; and means supthat itmay be bod- I V porting the said roller so ily adjusted toward and from the brush. 2. In a combing machine havin a dofling roller arranged as claimed in cairnv 1, a

aspirator' close" proximity to the roller as and for'the stripping roller in contact with the surface and also in I teeth of the doffing purpose hereinbefore set forth.

In a combing machine having a doifing roller for stripping the cylinder clearing brusharranged as claimed in claim 1, means for rotating the said dolling roller, comprising friction discs on the shaft of the said roller, which discs are in the surface of the aspirator.

4; In a combing machine having adofiing roller for stripping the cylinder clearing 7 brush, arranged as claimed in claim 1, means for supporting the dofling roller, bearings for the around the longitudinal axis of the aspirator substantially as hereinbefore set forth.

with a combing cylinder, of a rotary brush for clearing waste from said cylinder, an aspirator including a rotary drum, arms mounted to rock about the axiso-f the aspirator drum, a dofling roller supported in bear-i positioned between ping roll supported inbearings in said arms in operative relation to the doffing roller i driven contact with comprising i roller shaft, the said bear tmgs being adjustable on a'circular path 120 5. In a combing machine, the combination 6. In a combing machine,

with a combing cylinder, for clearing Waste from aspirator including a r0 5 mounted to rock about the tor drum, a doifing roller ings in said arms and 7p supported the combination of a rotary brush said cylinder, an tary drum, arms axis of the aspirain bearositioned between the brush and aspirator drum, and means for rotating both the doffing and stripping rollers by the aspirator drum.

In testimony whereof I have hereunto set my hand.

JOHN WILLIAM NASMITH.

Applications Claiming Priority (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| GB1663170X | 1926-04-06 |

Publications (1)

| Publication Number | Publication Date |

|---|---|

| US1663170A true US1663170A (en) | 1928-03-20 |

Family

ID=10887905

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| US209906A Expired - Lifetime US1663170A (en) | 1926-04-06 | 1927-08-01 | Combing machine for textile fibers |

Country Status (1)

| Country | Link |

|---|---|

| US (1) | US1663170A (en) |

Cited By (3)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US3084400A (en) * | 1959-09-04 | 1963-04-09 | Sant Andrea Novara Ohg E Fonde | Dust removing device for combing frames |

| DE1151755B (en) * | 1959-09-04 | 1963-07-18 | Sant Andrea Novara Ohg E Fonde | Device for sucking off the dust and recovering the combing on a flat combing machine |

| US6226838B1 (en) * | 1998-11-03 | 2001-05-08 | W. Schlafhorst Ag & Co. | Device for opening slivers |

-

1927

- 1927-08-01 US US209906A patent/US1663170A/en not_active Expired - Lifetime

Cited By (3)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US3084400A (en) * | 1959-09-04 | 1963-04-09 | Sant Andrea Novara Ohg E Fonde | Dust removing device for combing frames |

| DE1151755B (en) * | 1959-09-04 | 1963-07-18 | Sant Andrea Novara Ohg E Fonde | Device for sucking off the dust and recovering the combing on a flat combing machine |

| US6226838B1 (en) * | 1998-11-03 | 2001-05-08 | W. Schlafhorst Ag & Co. | Device for opening slivers |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| US7779514B2 (en) | Method and apparatus for separating foreign matter from fibrous material | |

| US1663170A (en) | Combing machine for textile fibers | |

| JPH0348222Y2 (en) | ||

| US3251175A (en) | Traveling textile cleaning apparatus with filter cleaning means | |

| US2151273A (en) | Method of and device for collecting dust and fly, particularly in textile factories, as spinning mills | |

| US2284750A (en) | Delinting waste puller | |

| US2876500A (en) | Machine for fiber cleaning | |

| US2493849A (en) | Air cleaner | |

| US3205537A (en) | Lickerin for carding machines | |

| US1794058A (en) | Cleaner for paper driers | |

| US2332413A (en) | Cotton drying machine | |

| US1485401A (en) | Cleaner for cotton | |

| US1645745A (en) | Machine for cleaning, opening, and combing cotton, cotton waste, and like materials | |

| US2813306A (en) | Apparatus for removing dust and granular material from asbestos fibre | |

| US1231032A (en) | Cotton-gin. | |

| US966565A (en) | Doffer or knocking-off apparatus for the doffer-rollers of carding-machines. | |

| US1460228A (en) | Gin rib | |

| US2912720A (en) | Lint cotton cleaner | |

| US1915920A (en) | Mill | |

| US1666379A (en) | Waste-collecting device for combing and like machines | |

| US1930890A (en) | Revolving screen cotton cleaner and separator | |

| CN212640696U (en) | Carding machine body with dust removal function | |

| US3039149A (en) | Fiber condenser | |

| US1810675A (en) | Opening, mixing, blowing room, and like machinery used in cotton mills | |

| US3071823A (en) | Condenser |