US1663111A - Lavatory - Google Patents

Lavatory Download PDFInfo

- Publication number

- US1663111A US1663111A US5235725A US1663111A US 1663111 A US1663111 A US 1663111A US 5235725 A US5235725 A US 5235725A US 1663111 A US1663111 A US 1663111A

- Authority

- US

- United States

- Prior art keywords

- bowl

- valve

- pipe

- seat

- discharge pipe

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Expired - Lifetime

Links

Images

Classifications

-

- E—FIXED CONSTRUCTIONS

- E03—WATER SUPPLY; SEWERAGE

- E03D—WATER-CLOSETS OR URINALS WITH FLUSHING DEVICES; FLUSHING VALVES THEREFOR

- E03D9/00—Sanitary or other accessories for lavatories ; Devices for cleaning or disinfecting the toilet room or the toilet bowl; Devices for eliminating smells

- E03D9/08—Devices in the bowl producing upwardly-directed sprays; Modifications of the bowl for use with such devices ; Bidets; Combinations of bowls with urinals or bidets; Hot-air or other devices mounted in or on the bowl, urinal or bidet for cleaning or disinfecting

-

- Y—GENERAL TAGGING OF NEW TECHNOLOGICAL DEVELOPMENTS; GENERAL TAGGING OF CROSS-SECTIONAL TECHNOLOGIES SPANNING OVER SEVERAL SECTIONS OF THE IPC; TECHNICAL SUBJECTS COVERED BY FORMER USPC CROSS-REFERENCE ART COLLECTIONS [XRACs] AND DIGESTS

- Y10—TECHNICAL SUBJECTS COVERED BY FORMER USPC

- Y10T—TECHNICAL SUBJECTS COVERED BY FORMER US CLASSIFICATION

- Y10T137/00—Fluid handling

- Y10T137/8593—Systems

- Y10T137/86493—Multi-way valve unit

- Y10T137/86863—Rotary valve unit

- Y10T137/86871—Plug

Definitions

- I employ a device for delivering water or other cleansing fluid to a centrailydispos'ed position, and which is normally maintained in a non use position out of the way, adjacent the rimfof the bowl, but. may be movedv into. position for use in which the discharge end of the device assumes a position approximately in the centei" ot" the bowl and at a predetermined height.

- the invention alsoconteni plates suitable devices for'shittingthe delivery 'device to and from its'posit'ion for u'se and for Supplying the necessary liquid for the intended purposes, as will be he'reiiiafter more particularly described.

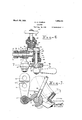

- FIG. 1 is a'se'c'tional elevation of a toilet bowl showing an attachment embodying a form ot m ypresent invention.

- Fig. 2 is a plan of the same. f 3

- Fig. 3' is a central longitudinal sectional elevation of the form of attachment shown in Figs. 1 andQ. v

- Fig. i is a sectional plan on line 1-4; Fig. 3.

- I p I Fig. 5 is a plan 'of the valve body showing the valve stem in section.

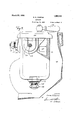

- Fig. 61 s a sectional elevation showing another form of the invention.

- Fig. 7 is a section on line 7-7 Fig. 6.

- v Fig. 8 is a sectional plan showing another storm of the invention.

- Fig. 9 is a sectional elevation illustrating thestructure shown in Fig. 8.

- FIG. 1 The toilet bowl is indicated at 10.

- this toilet bowl is of the usual construction and includes a base 11 and a: rim 12 in which there is a passage 13 through; which the water flows "from any suitable source of supply and is caused to enter the bowlv in'any customary manner in flushing the same.

- the strap'15 is provided withfariextension 15 and in this extension ther'eis mounted ahanger or' support bracket 17;

- this support bracket 17 in cludes a stud bolt 18 which passesthrou'gh an opening in the extension 15 andis' fitted with washers 19 and 20 and is lined to'the extension by a nut 21. turned to place on the bolt 18.

- the support bracket 17 also in cludes a head22 in which there is a transverse bore.

- the attachment proper in this form of the invent on comprises a suitable valve tor making and breaking communication with the source'ot supply, and a discharge pipe by which when the valve is opened the neces sary water is availabletor the intended purposes.

- This valve as illustrated, comprises a-body member 29. Extending from one ide-of the body member, is a tapped boss 30. This boss is formed to it Withina recess 31 provided for this purpose in thehead-QQ'of the support 17 and-the screw threaded end of the pipe fitting 23 is adapted'to turn down in the boss 30 so as to secure the pa'r'ts in their associated relationsl'iip.

- the body member of the valve is provided with a" tapered valve seat, and at one side of th'ebody member there is an inlet port'32, and at the opposite side there is a discharge or drain p0rt33; Also in this side of -the body member there is a drain passage. 33.

- At-the upper or outer end of the valve body there is a recess portion making-provisio at the end thereof-for stops 3 1 and 3 1,

- the same is exteriorly screw threaded, as indicated at 35, and the opposite end of this body member is also exteriorly screw threaded as in dicated at 36.

- the valve body In a position, preferably opposite the boss 30, the valve body is provided with a boss 37, which is tapped, and.

- valve stem 39 Associated with the valve body, there is a valve stem 39. At the inner end of this valve stem, the surface thereof is tapered to fit the tapered valve seat in the body member. Interiorly the valve stem is provided with a chamber or passage 40. In the wall of the valve stem there is an inlet port 41 adapted to register the inlet port 32, and in an otfsetpo-sition, oppositely disposed to the inlet port 41 there is an outlet or discharge port 42. lnteriorly the valve sten'i is reinforced as indicated at 43 in order to provide for a tap to receive a. stop bolt or pin 44. This stop pin 44 is placed in such a position that it may be made to contact with the stop 34 when the inlet port 41 is in register with the inlet port 32 and to contact with the stop 34 when the outlet 42 is in register with the outlet port 33.

- the inner or lower end of the valve stem is tapped as indicated at 45, and is thus adapted to receive the screw threaded shank 46 of a plug 47, adapted to close the inner end of the chamber in the valve stem, and to co-act with other parts in maintaining the valve stem in its proper position, longitudinally in the body member.

- these parts include a washer 48 fitting over the plug 47, a washer 49, a screw 50 and a spring washer 51.

- the washer 48 bears against the inner end of the body member, the washer 49 is adapted to fit over the shank of the screw 50, the spring washer 59, extends between the washers 48 and 4.9, and therefore, as will be understood, the spring washer. tends to yieldingly maintain the valve stem in an operative position in the body member.

- a base cap 52 Connected 'to thelower or inner end of the body member, is a base cap 52 which. encloses the washers 48, 49, the spring washer 51 and the head of the screw 50, and provides a chamber 53,'the purposes of which will be hereinafter indicated.

- This base cap, as illustrated is connected. to the body member by being turned down on the screw threaded portion 36 thereof.

- gland nut 54 At the other end of the body member. there is a gland nut 54, turned down and 7 thus secured in position on the screw threaded portion 35 thereof; this gland nut 54 is provided with an internal flange 55 through which the valve stem passes. and which acts as a. bearing to maintain the valve stem in its proper position.

- the outer portion of the gland nut 54 is exteriorly screw threaded, asindicated at 56, and on this screw threaded end portion of the; gland nut there is a packing nut 57, which by means of a gland 58, and a suitable packing 59 a water tight joint is made between the valve stem and the gland nut 54.

- the outer end of the valve stem is preferably of reduceddiameter and may be flat sided to receive the end of portion 60 of a handle 61, which is secured to the valve stem by means of a washer 62 and a bolt 63 or otherwise.

- the valve stem may be turned by the handle from one to the other of the limits of the revoluble movement thereof as determined by the pin 44 and. the stops 34 and 34 At the outer end, exteriorly of the nut 57, s

- valve stem is provided with a tapped opening 64. This opening is adapted to re ceive the end of the discharge pipe 65,. and to put the interior thereof into coi'i'nnunication with the chamber 40 in the valve stem.

- the parts are so placed, and the diameter of the discharge pipe 65 is such that it will pass freely through the space between the upper edge or rim of the closet bowl, and the under face of the seat when the same is in position or use.

- Thedischarge pipe therefore includes the portion 66', which extends across the top of the rim of the bowl, a portion ()7 which extends downwardly into the bowl, and a portion 68 which extends in a direction in a plane substantially parallel to the plane of the portion 66 of the discharge pipe.

- the discharge pipe is fitted with a nozzle 69.

- valve member is so placed that i the handle will assume a position in which it is readily available, and in their normal positions, as indicated in Figs. 1 and 2 of the drawing, the upright portion 67 of the discharge pipe lies adjacent the vertical edge of the rim of the bowl, and the nozzle 69, preferably lies against the surface of the bowl and beneath the rim, so that all of the parts are normally in such a position, as not to interfere with the usual and customary use of the toilet. In this.

- the inlet port 41 is out of registry with'the inlet port 32, so that the supply of water is cut oil; Furthermore in thispo'sition the discharge port 42 is in 'registry'with the discharge port 33, so that any water which may leak into the chamber 40 will passvicide with the Fig. 2 to its operative, or useful'position, as shown in dotted lines.

- This turning movement of the valve stem also causes the inlet port 41 to register with the inlet port 32, and to move the outlet port 12 out of register with the outlet port 33whereby the chamber 40 in the valve stem is placed in communication with the source of supply and the water flows directly to the discharge pipe and is delivered through the nozzle 69.

- the primary object of this attachment is for hygienically cleaning the anus, making it possible to disunsanitary use of paper for this purpose.

- the attachment may be used for other similar purposes, for example in takingene'mas or in douche baths, or similar purposes, and that these and other uses may be made possible by the employment of simple attachments, such as for example, catheterv tubes, adapted forthe particular purpose for which at any time it is desired or necessary toiemploy the apparatus.

- the supply pipe may be fitted with a suitable mixing valve, by

- valve body In'this device the valve body is indicated at 70. In a suitable position the valve body is provided with an inlet connection 71. To support the attachment this inlet connection passes through an opening provided therefor in the head 72 of a support bracket 17, which is fixed in position at the end 15 of the strap 15, and is secured in place at the rear of the bowl by the bracket bolts in the same manner as that hereinbefore described in connection with the other form of the invention.

- the valve body is secured in place by a nut 73 turned down against the outer face of the head'72, so as to force the inner face against the shoulder 74 at the base of the inlet connection 71.

- a supply pipe 75 leading'from any suitable source of supply extends into the inlet connection 71, and a water tight joint is made between them by means of a nut 76 and a gasket or packing 77 or otherwise.

- the extension 15 and the washers associated therewith are provided with a tongue 78 which'acts as a stop, as will be hereinafter described.

- valve 80 Interiorly the body of the valve is provided with a valve seat 79 against which a valve 80 is adapted to hear when the valve is closed.

- the valve 80 is connected in the usual manner with a drum 81 adapted to turn in the head 82 of the valve body, the drum 81 having a. stem 83'passing .through a cap nut 84: and-adapted to be turned by a disk 85 or otherwise.

- the valve body 70 is also provided with a discharge connection 86. This is fitted with a 'pipe87 which is maintained in position by a nut and suitable packing rings 89 and 90, whereby the pipe 87' is revoluble within the discharge connection and a water tight joint is made between these parts.

- the pipe 87 is provided with a head 91 and a handle 92.

- the head 91 is recessed as indicated at 93, and the recessed portion is so placed that the faces defining the ends of the recess, act as stops by coming into contact with the tongue 78.

- the pipe 87 leads to a chamber 94; in the head 91, and the head 91 is provided With an opening 95 adapted to receive the end of the discharge pipe 96.

- valve 80 is normally closed and the handle 92 in the position in which the discharge pipe 96 lies adjacent the back of the boWl and preferably with the nozzle end thereof beneath the rim of the bowl. In this position the parts of the attachment do not interfere in. any Way, with the usual and normal use of the toilet. It will be apparent, however, that by swinging the handle 92 from the full line position, as shown in Fig.

- the discharge pipe will have imparted thereto a corresponding swinging movement, so as to assume a positionas shown in dotted lines in which the nozzle end of the discharge pipe will be in position for use, irrespective of what the particular use may be; then, as will be equally apparent, the disk 85 may be turned and the valve 80 opened to make communication between the inlet pipe 75 and its source of supply, and the pipe 87 and thence to the discharge pipe 96.

- the attachments for toilet bowl as hereinbefore described are only illustrative of the invention, inasmuch as various other forms may be employed without departing from the nature and spirit of the invention. While I preferto mount the discharge pipe so as to swing from a nonuse position to a position for use within the bowl, in some forms of the invention the discharge pipe maybe in a fixed position either interiorly of the bowl or lavatory, or i so as to deliver a predetermined stream of water at a substantially central position within the toilet bowl or lavatory.

- liquid supply may be taken directly from the usual service pipes, or indirectly from a flush tank or flush valve or other apparatus, and that in any event the temperature of the water supply may be controlled by a suitable mixing valve in the supply pipe or a heater or other apparatus.

- toilet bowls and other similar structures may be manufactured to have my improvement directly connected thereto.

- the discharge pipe carried into or through a slot or recess made in the wall or rim of the bowl, for this purpose, or otherwise, as may be required for any particular construction, as shown in Figs. 8 and 9.

- the boss to which reference has just been made preferably comprises a wall 97 integral with the wall 98 of the bowl which as is customary is provided with an internal rim or flange 99 at the top thereof.

- the wall of the bowl there is an aperture 100 making communication between the interior of the bowl and a pocket 101 formed within the wall 97 comprising the boss.

- the fixture parts employed in this structure are located in this pocket 101 and consist of a valve and connections similar to those shown in Figures 6 and 7.

- the valve body is designated by 102.

- This is provided with an extension 103 adapted to pass through a slot 104 provided in the wall of the boss and to be secured in position by means of a nut 105 or otherwise.

- a supply pipe 106 is connected to the extension 103 by means of a clamp nut 107 or otherwise.

- This valve body also includesan extension 108, in this instance leading laterally therefrom and containing the valve structure, the valve stem 109 of which extends through a slot 110 in the wall of the boss and exterior-1y thereof is provided with a handle 111 by which the valve is operated to turn on and shut off the supply of water or other liquid employed.

- the valve body is also provided with an extension 112 in which the discharge pipe 113 is connected in a manner similar to that shown and described in the form of the invention as shown in Figures 6 and 7. In this instance, however, the discharge pipe 113 extends through the aperture 100 in the wall of the body of the bowl and is turned from its initial or inoperative position to its operative position by means of a handle 11 1 or otherwise.

- the aperture 100 in the wall of the bowl extends between the points indicated at 115 and 116 so that when the discharge pipe is in its normal inoperative position the nozzle end thereof lies entirely beneath the rim or flange 99 of the bowl and is adjacentthe end 115 of the aperture, whereas in its operative position the discharge pipe 113 assumes a position in which the nozzle end thereof lies approximately in a central position in the bowl and the discharge pipe vis then adjacent the end 116 of the slot or aperture 100.

- the attachment is neatly housed andis so mounted as to be unseen whenin its normal position and also in-such a manner that it will in no wise interfere with the normal use of the closet bowl.

- the boss may be provided in its lower end thereof with an opening 117 in which a discharge pipe 118 may be fitted and provided with a cap 119 so that any leakage may be drained from the pocket 101, and that in any event,'should the leakage become suflicient to reach the height of the opening 100, it will pass by way of the same to the interior of the bowl. Still furthermore, as illustrated, the boss may be provided with asuitable cover 120 by means of which normally-the pocket 101 therein and the fittings placed in the pocket are closed. 7 V

- valve bodyrand the fittings associated therewith are. connected to the walls forming the pocket in the bowl.

- the valve in this structure maybe mountedin a manner equivalent to that shown and described in connection with the other forms of the invention.

- a closet bowl having a seat attachment flange at the rear thereof, a support member, means for attaching the support member to'the seat attachment flange at the rear of the bowl, a valve carried in'the said support member, a delivery pipe connected to the said valve to extend into the said bowl to be movable horizontally at the top of the same from aposition in which the free end of the delivery pipe lies beneath the rim of the bowl to a position for use in which the free end of the delivery pipe lies approximately centrally of the bowl, and means for moving the delivery pipe from its non-use position to its position for use and vice versa.

- a closet bowl having a seat attachment flangeat the rear thereof, a support member, means for attaching the support member to the seat attachment flange at the rear of the bowl, a valve carried in the said support member, a delivery pipe connected to the said valve to extend into the said bowl to be movable horizontally at the top of the same from a position in which the free end of the delivery pipe lies beneath'the rim of the bowl to a position for use in which the free end of the delivery pipe lies approximately centrally of the bowl, means for mov ing the delivery pipe from its non-use position to its position for use and vice versa, and means for determining the extent of the movement of the said delivery pipe.

- a closet bowl a seat therefor, a support memtber, a fluid supply device carried by the support member, a delivery pipe connected to the fluid supply device and adapted to be moved into and out of operative'position in the bowl, and means for simultaneously connecting the support member and the seat to the said bowl.

- a closet bowl having a seat attachment flange therefor, a support member, means for attaching the support member to the seat attachment flange of the bowl, a fluid supply device carried by the support member, a delivery pipe connected to the said fluid supply member, and means for actuating the said delivery pipe to move the same to and from an inoperative position in which the end of the delivery pipe lies beneath the rim of the bowl and an operative position in which the end of the delivery pipe assumes a position substantially centrally of the bowl.

- a closet bowl having a seat attachment flange thereon, a closet seat, a support mem v ber, means for connecting the support member and the closet seat to the seat attachment flange thereon, a closet seat, a support member, means for connecting the support member and the closet seat to the seat attachment flange of the bowl, a valve carried by the support member, a delivery pipe connected to the said valve to extend into the bowl and to be movable horizontally at the top of the bowl from a position in which the free end of the delivery pipe lies beneath the rim of the bowl to a position for use in which the free end of the delivery pipe lies approximately, centrally of the bowl and. in a plane immediately below the rim thereof, and means for moving the delivery pipe from its non-use to its position for use and vice versa.

Landscapes

- Health & Medical Sciences (AREA)

- Public Health (AREA)

- Molecular Biology (AREA)

- Epidemiology (AREA)

- Life Sciences & Earth Sciences (AREA)

- Engineering & Computer Science (AREA)

- Hydrology & Water Resources (AREA)

- Water Supply & Treatment (AREA)

- Sanitary Device For Flush Toilet (AREA)

Description

March 20, 1928.

C. C. CAMPUS LAVATORY Filed Aug. 25, 1925 e Sheets-Sheet 1 INVENTOR.

6 5 74: 6. ampus C. C. CAMPUS Match 20, 1928.

LAVATORY Filed Aug. 25. 1925 6 Sheets-Sheet 2 INVENTOR' CEMRE 6.6mm:

H S A 'I'TORNEYS c. c. CAMPUS March 20, 1928.

LAVATORY Filed Aug. 25, 1925 6 Sheets-Sheet 3 q M IN VEN TOR.

Czsfiks 6, 64) P as NM V March 20, 1928.

C. C. CAMPUS LAVATORY Fild Aug. 25. 1925 6 Sheets- Sheet 4 March 20, 1928.

C. C. CAMPUS LAVATORY Filed Aug. 25, 1925 6 Sheets-Sheet 5 v INVENTOR. CESEAE C.6,7MP

. By r f 7 ATTO March 20, 1928. 1,663,111

C. C- CAMPUS LAVATORY Filed Aug. 25, 1925 e Sheets-Sheet s I N VEN TOR. C Asa/1": 664M Pus Ms A' RNEYS Patented Mar. 20, 1928.

CESARE CAMIPUSpOF SANTA MONICA, CALIFORNIA;

IJAVATORY.

eiip'iic'atin"fileirmgusma; 1925'. Serial at. 52,357.

In'carrying outmy invention, I employ a device for delivering water or other cleansing fluid to a centrailydispos'ed position, and which is normally maintained in a non use position out of the way, adjacent the rimfof the bowl, but. may be movedv into. position for use in which the discharge end of the device assumes a position approximately in the centei" ot" the bowl and at a predetermined height. The invention alsoconteni plates suitable devices for'shittingthe delivery 'device to and from its'posit'ion for u'se and for Supplying the necessary liquid for the intended purposes, as will be he'reiiiafter more particularly described.

In the drawing. Fig. 1 is a'se'c'tional elevation of a toilet bowl showing an attachment embodying a form ot m ypresent invention.

Fig. 2 is a plan of the same. f 3

Fig. 3' is a central longitudinal sectional elevation of the form of attachment shown in Figs. 1 andQ. v

Fig. i is a sectional plan on line 1-4; Fig. 3. I p I Fig. 5 is a plan 'of the valve body showing the valve stem in section.

Fig. 61s a sectional elevation showing another form of the invention.

Fig. 7 is a section on line 7-7 Fig. 6. v Fig. 8 isa sectional plan showing another storm of the invention, and

Fig. 9 is a sectional elevation illustrating thestructure shown in Fig. 8.

Referring. to the drawings and particular ly to Figs. 1 to 5 inclusive, it will be seen that I have herein illustrated my present invention as applied to a toilet bowl. The toilet bowl is indicated at 10. As illustrated, this toilet bowl is of the usual construction and includes a base 11 and a: rim 12 in which there is a passage 13 through; which the water flows "from any suitable source of supply and is caused to enter the bowlv in'any customary manner in flushing the same.

' Also, as is customary the upper portion ot 1s provided with a the bowl, at the rear,

flange or boss, it, by which, and by suitable brackets or otherwise, the seat and cover are hinged to the bowl. The flange 14-.iS pro 'vided with holes 16 through which the bracket- 'bolts pass in securing the seat and the cover in their respective-positions.

In attaching my invention to toilet bowls which are already set in place, it is necessary to employ a suitable support therefor. As shown in these figures of the drawing, this support may include a'st'rap or'bracket in which there are holes spaced'to correspond and register with the'hjoles' in"tl 1"e"fiange'14= so that the bracket bolts by' which these'a'tand cover are attached tofthe bowl may also be employed to fix this strap 15' in'pla'ce". At one end the strap'15, is provided withfariextension 15 and in this extension ther'eis mounted ahanger or' support bracket 17; As illustrated this support bracket 17in cludes a stud bolt 18 which passesthrou'gh an opening in the extension 15 andis' fitted with washers 19 and 20 and is lined to'the extension by a nut 21. turned to place on the bolt 18. The support bracket 17 also in cludes a head22 in which there is a transverse bore. I

Passing through the bore in the head'.22 I employ a supply pipe 'titt-ing 23; adjacent one end'this fitting'23' is providedwith a'nut head'Qt at the extremity of which there is'a'. screw threaded portion 25. 'lheopening at this end of the fittingfispre'ferably of slight- .iy enlarged diametenand is adaptedto'receive the end portion of asupply pipe 26 leading from the serv'ice pipes or any suitable" source of supply. As illustrated a watertight joint' is made with the supply pipe 26 bymeans of a nut 27' and a suitable packing 28 or otherwise.

The attachment proper in this form of the invent on comprises a suitable valve tor making and breaking communication with the source'ot supply, and a discharge pipe by which when the valve is opened the neces sary water is availabletor the intended purposes. This valve, as illustrated, comprises a-body member 29. Extending from one ide-of the body member, is a tapped boss 30. This boss is formed to it Withina recess 31 provided for this purpose in thehead-QQ'of the support 17 and-the screw threaded end of the pipe fitting 23 is adapted'to turn down in the boss 30 so as to secure the pa'r'ts in their associated relationsl'iip. The body member of the valve is provided with a" tapered valve seat, and at one side of th'ebody member there is an inlet port'32, and at the opposite side there is a discharge or drain p0rt33; Also in this side of -the body member there is a drain passage. 33. At-the upper or outer end of the valve body, there is a recess portion making-provisio at the end thereof-for stops 3 1 and 3 1, At the outer end of the body member the same is exteriorly screw threaded, as indicated at 35, and the opposite end of this body member is also exteriorly screw threaded as in dicated at 36. In a position, preferably opposite the boss 30, the valve body is provided with a boss 37, which is tapped, and.

thus adapted to receive a plug 38.

Associated with the valve body, there is a valve stem 39. At the inner end of this valve stem, the surface thereof is tapered to fit the tapered valve seat in the body member. Interiorly the valve stem is provided with a chamber or passage 40. In the wall of the valve stem there is an inlet port 41 adapted to register the inlet port 32, and in an otfsetpo-sition, oppositely disposed to the inlet port 41 there is an outlet or discharge port 42. lnteriorly the valve sten'i is reinforced as indicated at 43 in order to provide for a tap to receive a. stop bolt or pin 44. This stop pin 44 is placed in such a position that it may be made to contact with the stop 34 when the inlet port 41 is in register with the inlet port 32 and to contact with the stop 34 when the outlet 42 is in register with the outlet port 33.

The inner or lower end of the valve stem is tapped as indicated at 45, and is thus adapted to receive the screw threaded shank 46 of a plug 47, adapted to close the inner end of the chamber in the valve stem, and to co-act with other parts in maintaining the valve stem in its proper position, longitudinally in the body member. As illustrated, these parts include a washer 48 fitting over the plug 47, a washer 49, a screw 50 and a spring washer 51. The washer 48 bears against the inner end of the body member, the washer 49 is adapted to fit over the shank of the screw 50, the spring washer 59, extends between the washers 48 and 4.9, and therefore, as will be understood, the spring washer. tends to yieldingly maintain the valve stem in an operative position in the body member. Connected 'to thelower or inner end of the body member, is a base cap 52 which. encloses the washers 48, 49, the spring washer 51 and the head of the screw 50, and provides a chamber 53,'the purposes of which will be hereinafter indicated. This base cap, as illustrated is connected. to the body member by being turned down on the screw threaded portion 36 thereof.

At the other end of the body member. there is a gland nut 54, turned down and 7 thus secured in position on the screw threaded portion 35 thereof; this gland nut 54 is provided with an internal flange 55 through which the valve stem passes. and which acts as a. bearing to maintain the valve stem in its proper position. The outer portion of the gland nut 54, is exteriorly screw threaded, asindicated at 56, and on this screw threaded end portion of the; gland nut there is a packing nut 57, which by means of a gland 58, and a suitable packing 59 a water tight joint is made between the valve stem and the gland nut 54. y

The outer end of the valve stem is preferably of reduceddiameter and may be flat sided to receive the end of portion 60 of a handle 61, which is secured to the valve stem by means of a washer 62 and a bolt 63 or otherwise. The valve stem may be turned by the handle from one to the other of the limits of the revoluble movement thereof as determined by the pin 44 and. the stops 34 and 34 At the outer end, exteriorly of the nut 57, s

the valve stem is provided with a tapped opening 64. This opening is adapted to re ceive the end of the discharge pipe 65,. and to put the interior thereof into coi'i'nnunication with the chamber 40 in the valve stem.

In the form of the invention, as illustrated, the parts are so placed, and the diameter of the discharge pipe 65 is such that it will pass freely through the space between the upper edge or rim of the closet bowl, and the under face of the seat when the same is in position or use. Thedischarge pipe therefore includes the portion 66', which extends across the top of the rim of the bowl, a portion ()7 which extends downwardly into the bowl, and a portion 68 which extends in a direction in a plane substantially parallel to the plane of the portion 66 of the discharge pipe. At its extremity and within the bowl, the discharge pipe is fitted with a nozzle 69.

In the use of the device hereinbefore described, the valve member is so placed that i the handle will assume a position in which it is readily available, and in their normal positions, as indicated in Figs. 1 and 2 of the drawing, the upright portion 67 of the discharge pipe lies adjacent the vertical edge of the rim of the bowl, and the nozzle 69, preferably lies against the surface of the bowl and beneath the rim, so that all of the parts are normally in such a position, as not to interfere with the usual and customary use of the toilet. In this. position, the inlet port 41 is out of registry with'the inlet port 32, so that the supply of water is cut oil; Furthermore in thispo'sition the discharge port 42 is in 'registry'with the discharge port 33, so that any water which may leak into the chamber 40 will passv pense with the Fig. 2 to its operative, or useful'position, as shown in dotted lines. This turning movement of the valve stem also causes the inlet port 41 to register with the inlet port 32, and to move the outlet port 12 out of register with the outlet port 33whereby the chamber 40 in the valve stem is placed in communication with the source of supply and the water flows directly to the discharge pipe and is delivered through the nozzle 69. As hereinbefore stated, the primary object of this attachment is for hygienically cleaning the anus, making it possible to disunsanitary use of paper for this purpose. It will be evident that the attachment may be used for other similar purposes, for example in takingene'mas or in douche baths, or similar purposes, and that these and other uses may be made possible by the employment of simple attachments, such as for example, catheterv tubes, adapted forthe particular purpose for which at any time it is desired or necessary toiemploy the apparatus. It will be furthermore understood that the supply pipe may be fitted with a suitable mixing valve, by

means of which hot or cold water, or Water at'any intermediate temperature may be obtained for use with the attachment.

In Figs. 6 and7 I have illustrated the invention as applied to a faucet valve construction. In'this device the valve body is indicated at 70. In a suitable position the valve body is provided with an inlet connection 71. To support the attachment this inlet connection passes through an opening provided therefor in the head 72 of a support bracket 17, which is fixed in position at the end 15 of the strap 15, and is secured in place at the rear of the bowl by the bracket bolts in the same manner as that hereinbefore described in connection with the other form of the invention. The valve body is secured in place by a nut 73 turned down against the outer face of the head'72, so as to force the inner face against the shoulder 74 at the base of the inlet connection 71. A supply pipe 75 leading'from any suitable source of supply extends into the inlet connection 71, and a water tight joint is made between them by means of a nut 76 and a gasket or packing 77 or otherwise. In this structure, the extension 15 and the washers associated therewith are provided with a tongue 78 which'acts as a stop, as will be hereinafter described. I I

Interiorly the body of the valve is provided with a valve seat 79 against which a valve 80 is adapted to hear when the valve is closed. The valve 80 is connected in the usual manner with a drum 81 adapted to turn in the head 82 of the valve body, the drum 81 having a. stem 83'passing .through a cap nut 84: and-adapted to be turned by a disk 85 or otherwise.

The valve body 70 is also provided with a discharge connection 86. This is fitted with a 'pipe87 which is maintained in position by a nut and suitable packing rings 89 and 90, whereby the pipe 87' is revoluble within the discharge connection and a water tight joint is made between these parts. The pipe 87 is provided with a head 91 and a handle 92. The head 91 is recessed as indicated at 93, and the recessed portion is so placed that the faces defining the ends of the recess, act as stops by coming into contact with the tongue 78. The pipe 87 leads to a chamber 94; in the head 91, and the head 91 is provided With an opening 95 adapted to receive the end of the discharge pipe 96.

In the use of thedevice, shown in Figs. 6 and 7, the valve 80 is normally closed and the handle 92 in the position in which the discharge pipe 96 lies adjacent the back of the boWl and preferably with the nozzle end thereof beneath the rim of the bowl. In this position the parts of the attachment do not interfere in. any Way, with the usual and normal use of the toilet. It will be apparent, however, that by swinging the handle 92 from the full line position, as shown in Fig. 7 to the dotted line position, the discharge pipe will have imparted thereto a corresponding swinging movement, so as to assume a positionas shown in dotted lines in which the nozzle end of the discharge pipe will be in position for use, irrespective of what the particular use may be; then, as will be equally apparent, the disk 85 may be turned and the valve 80 opened to make communication between the inlet pipe 75 and its source of supply, and the pipe 87 and thence to the discharge pipe 96.

It will be understood that the attachments for toilet bowl as hereinbefore described are only illustrative of the invention, inasmuch as various other forms may be employed without departing from the nature and spirit of the invention. While I preferto mount the discharge pipe so as to swing from a nonuse position to a position for use within the bowl, in some forms of the invention the discharge pipe maybe in a fixed position either interiorly of the bowl or lavatory, or i so as to deliver a predetermined stream of water at a substantially central position within the toilet bowl or lavatory. It will also be understood that the invention is entirely independent of any source of liquid supply, that is to say: The liquid supply may be taken directly from the usual service pipes, or indirectly from a flush tank or flush valve or other apparatus, and that in any event the temperature of the water supply may be controlled by a suitable mixing valve in the supply pipe or a heater or other apparatus.

It will furthermore be understood that while in the foregoing description I have referred specifically to the use of water, that the apparatus may be employed for administering other liquids or even fluids forcertain purposes for which the attachment may be utilized. Still furthermore it will be understood that toilet bowls and other similar structures may be manufactured to have my improvement directly connected thereto. In such structures aboss maybe provided for the attachment of the improvement, and the discharge pipe carried into or through a slot or recess made in the wall or rim of the bowl, for this purpose, or otherwise, as may be required for any particular construction, as shown in Figs. 8 and 9.

As illustrated in Figure 9, the boss to which reference has just been made preferably comprises a wall 97 integral with the wall 98 of the bowl which as is customary is provided with an internal rim or flange 99 at the top thereof. Inthe wall of the bowl there is an aperture 100 making communication between the interior of the bowl and a pocket 101 formed within the wall 97 comprising the boss. I

The fixture parts employed in this structure are located in this pocket 101 and consist of a valve and connections similar to those shown in Figures 6 and 7. In Figures 8 and 9 the valve body is designated by 102. This is provided with an extension 103 adapted to pass through a slot 104 provided in the wall of the boss and to be secured in position by means of a nut 105 or otherwise. A supply pipe 106 is connected to the extension 103 by means of a clamp nut 107 or otherwise. This valve body also includesan extension 108, in this instance leading laterally therefrom and containing the valve structure, the valve stem 109 of which extends through a slot 110 in the wall of the boss and exterior-1y thereof is provided with a handle 111 by which the valve is operated to turn on and shut off the supply of water or other liquid employed.

The valve body is also provided with an extension 112 in which the discharge pipe 113 is connected in a manner similar to that shown and described in the form of the invention as shown in Figures 6 and 7. In this instance, however, the discharge pipe 113 extends through the aperture 100 in the wall of the body of the bowl and is turned from its initial or inoperative position to its operative position by means of a handle 11 1 or otherwise. The aperture 100 in the wall of the bowl extends between the points indicated at 115 and 116 so that when the discharge pipe is in its normal inoperative position the nozzle end thereof lies entirely beneath the rim or flange 99 of the bowl and is adjacentthe end 115 of the aperture, whereas in its operative position the discharge pipe 113 assumes a position in which the nozzle end thereof lies approximately in a central position in the bowl and the discharge pipe vis then adjacent the end 116 of the slot or aperture 100. In this structure as will be understood, the attachment is neatly housed andis so mounted as to be unseen whenin its normal position and also in-such a manner that it will in no wise interfere with the normal use of the closet bowl. It will also be understood that the boss may be provided in its lower end thereof with an opening 117 in which a discharge pipe 118 may be fitted and provided with a cap 119 so that any leakage may be drained from the pocket 101, and that in any event,'should the leakage become suflicient to reach the height of the opening 100, it will pass by way of the same to the interior of the bowl. Still furthermore, as illustrated, the boss may be provided with asuitable cover 120 by means of which normally-the pocket 101 therein and the fittings placed in the pocket are closed. 7 V

In the structure shown in Figures 8 and 9, the valve bodyrand the fittings associated therewith are. connected to the walls forming the pocket in the bowl. Obviously, however, the valve in this structure maybe mountedin a manner equivalent to that shown and described in connection with the other forms of the invention."

I claim as nay invention:

1. In an apparatus of the class described, a closet bowl having a seat attachment flange at the rear thereof, a support member, means for attaching the support member to'the seat attachment flange at the rear of the bowl, a valve carried in'the said support member, a delivery pipe connected to the said valve to extend into the said bowl to be movable horizontally at the top of the same from aposition in which the free end of the delivery pipe lies beneath the rim of the bowl to a position for use in which the free end of the delivery pipe lies approximately centrally of the bowl, and means for moving the delivery pipe from its non-use position to its position for use and vice versa.

2. In an apparatus of the class described, a closet bowlhaving a seat attachment flangeat the rear thereof, a support member, means for attaching the support member to the seat attachment flange at the rear of the bowl, a valve carried in the said support member, a delivery pipe connected to the said valve to extend into the said bowl to be movable horizontally at the top of the same from a position in which the free end of the delivery pipe lies beneath'the rim of the bowl to a position for use in which the free end of the delivery pipe lies approximately centrally of the bowl, means for mov ing the delivery pipe from its non-use position to its position for use and vice versa, and means for determining the extent of the movement of the said delivery pipe.

3. In an apparatus of the class described,

a closet bowl, a seat therefor, a support memtber, a fluid supply device carried by the support member, a delivery pipe connected to the fluid supply device and adapted to be moved into and out of operative'position in the bowl, and means for simultaneously connecting the support member and the seat to the said bowl.

4. In an apparatus of the class described, a closet bowl having a seat attachment flange therefor, a support member, means for attaching the support member to the seat attachment flange of the bowl, a fluid supply device carried by the support member, a delivery pipe connected to the said fluid supply member, and means for actuating the said delivery pipe to move the same to and from an inoperative position in which the end of the delivery pipe lies beneath the rim of the bowl and an operative position in which the end of the delivery pipe assumes a position substantially centrally of the bowl.

5. In an apparatus of the class described,

a closet bowl having a seat attachment flange thereon, a closet seat, a support mem v ber, means for connecting the support member and the closet seat to the seat attachment flange thereon, a closet seat, a support member, means for connecting the support member and the closet seat to the seat attachment flange of the bowl, a valve carried by the support member, a delivery pipe connected to the said valve to extend into the bowl and to be movable horizontally at the top of the bowl from a position in which the free end of the delivery pipe lies beneath the rim of the bowl to a position for use in which the free end of the delivery pipe lies approximately, centrally of the bowl and. in a plane immediately below the rim thereof, and means for moving the delivery pipe from its non-use to its position for use and vice versa.

7. In an apparatus of the class described,

approximately centrally of the bowl and in a plane immediately below the rim thereof, means for moving the delivery pipe from its non-use to its position for use and vice versa, and means for determining the extent of the movement of the delivery pipe.

Signed by me this 20th day of August, 1925.

' CESABE o. CAMPUS.

Priority Applications (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| US5235725 US1663111A (en) | 1925-08-25 | 1925-08-25 | Lavatory |

Applications Claiming Priority (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| US5235725 US1663111A (en) | 1925-08-25 | 1925-08-25 | Lavatory |

Publications (1)

| Publication Number | Publication Date |

|---|---|

| US1663111A true US1663111A (en) | 1928-03-20 |

Family

ID=21977085

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| US5235725 Expired - Lifetime US1663111A (en) | 1925-08-25 | 1925-08-25 | Lavatory |

Country Status (1)

| Country | Link |

|---|---|

| US (1) | US1663111A (en) |

Cited By (8)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US2722014A (en) * | 1953-04-08 | 1955-11-01 | Bonomolo Matthew | Rectum washer |

| US2852782A (en) * | 1956-05-09 | 1958-09-23 | Sundberg Gottfrid | Sanitary spray attachment for toilet bowl |

| US2957180A (en) * | 1959-08-13 | 1960-10-25 | Mcmullen Kenneth Donald | Bidet |

| US2999249A (en) * | 1959-12-28 | 1961-09-12 | Logan Emergency Showers Inc | Retractable emergency wash facility |

| US4926509A (en) * | 1988-07-21 | 1990-05-22 | Bass Joyce H | Bidet |

| US4953238A (en) * | 1989-04-24 | 1990-09-04 | Shifferly John P | Sanitizing spray seat for toilet |

| EP0566409A1 (en) * | 1992-04-16 | 1993-10-20 | Inax Corporation | Toilet seat mounting box |

| US5566402A (en) * | 1995-03-14 | 1996-10-22 | Rim Innovation And Marketing Consultants Inc. | Bidet apparatus for toilets |

-

1925

- 1925-08-25 US US5235725 patent/US1663111A/en not_active Expired - Lifetime

Cited By (10)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US2722014A (en) * | 1953-04-08 | 1955-11-01 | Bonomolo Matthew | Rectum washer |

| US2852782A (en) * | 1956-05-09 | 1958-09-23 | Sundberg Gottfrid | Sanitary spray attachment for toilet bowl |

| US2957180A (en) * | 1959-08-13 | 1960-10-25 | Mcmullen Kenneth Donald | Bidet |

| US2999249A (en) * | 1959-12-28 | 1961-09-12 | Logan Emergency Showers Inc | Retractable emergency wash facility |

| US4926509A (en) * | 1988-07-21 | 1990-05-22 | Bass Joyce H | Bidet |

| WO1991017693A1 (en) * | 1988-07-21 | 1991-11-28 | Joyce Hillin Bass | Bidet |

| US4953238A (en) * | 1989-04-24 | 1990-09-04 | Shifferly John P | Sanitizing spray seat for toilet |

| EP0566409A1 (en) * | 1992-04-16 | 1993-10-20 | Inax Corporation | Toilet seat mounting box |

| US5369817A (en) * | 1992-04-16 | 1994-12-06 | Inax Corporation | Toilet seat box |

| US5566402A (en) * | 1995-03-14 | 1996-10-22 | Rim Innovation And Marketing Consultants Inc. | Bidet apparatus for toilets |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| US1663111A (en) | Lavatory | |

| US2826761A (en) | Sanitary equipment adapted to be associated with a lavatory pedestal | |

| US1736803A (en) | Shower | |

| US988504A (en) | Faucet. | |

| US1896950A (en) | Flush valve | |

| US1960839A (en) | Bidet | |

| US1346252A (en) | Combination closet-seat and bidet | |

| US1091499A (en) | Bidet. | |

| US1145221A (en) | Liquid-dispenser. | |

| US1333826A (en) | And arthur i | |

| US1809567A (en) | Transfer valve | |

| US1740156A (en) | And tobias j | |

| US1821959A (en) | Bathtub | |

| US1532433A (en) | Water-supply fixture | |

| US1683063A (en) | Water-closet fitting | |

| US1632806A (en) | Device for supplying soapy water | |

| US1424250A (en) | Lavatory | |

| US1875283A (en) | Combination fatjcet and drinking fountain | |

| US276261A (en) | Urinal | |

| US1721786A (en) | Faucet fitting | |

| US1101749A (en) | Drinking-fountain. | |

| US1728577A (en) | Automatic air valve for hydropneumatic tanks | |

| US1604782A (en) | Ball cock | |

| US1369283A (en) | Bidet | |

| US1763562A (en) | Drain-pipe fitting |