US1391663A - Tank-car - Google Patents

Tank-car Download PDFInfo

- Publication number

- US1391663A US1391663A US1391663DA US1391663A US 1391663 A US1391663 A US 1391663A US 1391663D A US1391663D A US 1391663DA US 1391663 A US1391663 A US 1391663A

- Authority

- US

- United States

- Prior art keywords

- car

- tank

- heating elements

- steam

- heating

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Expired - Lifetime

Links

Images

Classifications

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B60—VEHICLES IN GENERAL

- B60C—VEHICLE TYRES; TYRE INFLATION; TYRE CHANGING; CONNECTING VALVES TO INFLATABLE ELASTIC BODIES IN GENERAL; DEVICES OR ARRANGEMENTS RELATED TO TYRES

- B60C15/00—Tyre beads, e.g. ply turn-up or overlap

- B60C15/0009—Tyre beads, e.g. ply turn-up or overlap features of the carcass terminal portion

- B60C15/0081—Tyre beads, e.g. ply turn-up or overlap features of the carcass terminal portion the carcass plies folded around or between more than one bead core

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B60—VEHICLES IN GENERAL

- B60C—VEHICLE TYRES; TYRE INFLATION; TYRE CHANGING; CONNECTING VALVES TO INFLATABLE ELASTIC BODIES IN GENERAL; DEVICES OR ARRANGEMENTS RELATED TO TYRES

- B60C9/00—Reinforcements or ply arrangement of pneumatic tyres

- B60C9/02—Carcasses

-

- Y—GENERAL TAGGING OF NEW TECHNOLOGICAL DEVELOPMENTS; GENERAL TAGGING OF CROSS-SECTIONAL TECHNOLOGIES SPANNING OVER SEVERAL SECTIONS OF THE IPC; TECHNICAL SUBJECTS COVERED BY FORMER USPC CROSS-REFERENCE ART COLLECTIONS [XRACs] AND DIGESTS

- Y10—TECHNICAL SUBJECTS COVERED BY FORMER USPC

- Y10T—TECHNICAL SUBJECTS COVERED BY FORMER US CLASSIFICATION

- Y10T152/00—Resilient tires and wheels

- Y10T152/10—Tires, resilient

- Y10T152/10495—Pneumatic tire or inner tube

- Y10T152/10819—Characterized by the structure of the bead portion of the tire

- Y10T152/10828—Chafer or sealing strips

-

- Y—GENERAL TAGGING OF NEW TECHNOLOGICAL DEVELOPMENTS; GENERAL TAGGING OF CROSS-SECTIONAL TECHNOLOGIES SPANNING OVER SEVERAL SECTIONS OF THE IPC; TECHNICAL SUBJECTS COVERED BY FORMER USPC CROSS-REFERENCE ART COLLECTIONS [XRACs] AND DIGESTS

- Y10—TECHNICAL SUBJECTS COVERED BY FORMER USPC

- Y10T—TECHNICAL SUBJECTS COVERED BY FORMER US CLASSIFICATION

- Y10T152/00—Resilient tires and wheels

- Y10T152/10—Tires, resilient

- Y10T152/10495—Pneumatic tire or inner tube

- Y10T152/10855—Characterized by the carcass, carcass material, or physical arrangement of the carcass materials

- Y10T152/10864—Sidewall stiffening or reinforcing means other than main carcass plies or foldups thereof about beads

Definitions

- My invention relates generally to improvements in tank cars, but relates more particularly to an improved construction for heating the contents of tank cars.

- Tank cars are used to a large extent for transporting liquids and semi-liquids such as refined oils, tars, asphalts, road oils, -tluX oils and the like.

- Such materials are usually placed in tank cars directly from the reiining processes and while they are sufficiently' hot to flow readily.

- the contents When such cars reach their destination, however, the contents have become congealed and in some instances, as asphalte, are in a solid state.

- Vhen such a car having ⁇ leaking ⁇ coils

- Another disadvantage is that the car cannot be returned promptly to the shipper because of the diiiiculty and delays of unloading. Often times the condition is so bad that the car contents can not be unloaded or used and must be returned to the shipper. This entails loss of freight, time, labor and prevents use of tank car on other service. Furthermore, most specifications are very rigid as to the amount of water permitted in the material. Therefore, leaking coils very often are the cause of the material being rejected and the car and contents returned to the shipper with consequent loss of time and money.

- rupture may be caused by discharging hot material from the stills or otherwise upon the relatively cold coils or upon certain parts thereof thus causing unequal expansion with the results before stated.

- One of the objects of my invention is to make the operation of tank car unloading more reliable and speedy and to reduce the expense thereof.

- Another object of my invention is to provide a heating apparatus which shall overcome the defects found in present means of heating tank cars.

- a further object is to facilitate the inspection, repair and maintenance of tank car heating systems and in particular to reduce breakage or rupturing in such systems and hence to eliminate the annoyance and expense which such defective condition entails.

- My invention consists generally in the form, arrangement, construction and coperation of the parts whereby the above named obj ects, together with others that will appear hereinafter, are attainable; and my invention will be more readily understood by reference to the accompanying drawings which illustrate what I consider, at the present time, to be the best embodiment thereof.

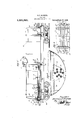

- Figure l is a View partly in section and partly in elevation of a tank car equipped with apparatus embodying my invention.

- Fig. 2 is an enlarged detail view substantially on the line 2 2 of Fig. 1.

- Fig. 3 is a detail sectional view on an enlarged scale taken substantially on the line 8 3 of Fig. 1.

- Fig. e is a fragmentary detail view substantially on the line 1 -4: of Fig. 1.

- F ig. 5 is an end view of the car, parts thereof being broken away better to disclose the interior construction.

- Fig. 6 is a sectional detail of one end of one of the heating elements.

- F 7 is a sectional view substantially on the line 7-7 of Fig. 6.

- Fig. 8 is a detail view of one end of the tank car.

- Fig. 9 is a detail view showing use of car without heating elements therein.

- rIhe car tank 2 is usually of cylindrical form and is closed at the ends by the headers 3 and 4, respectively.

- the tank 2 is ⁇ supported on the car sills 5 by means of cradles 6.

- the car is provided with a dome 7, which contains an opening 8 for ⁇ filling the tank.

- vSubstantially centrally of the car, and under the dome 7, is an outlet 9 which, in turn, is controlled by means of a valve 10 which, in turn, is provided with a long stem or rod 11, so that it may be conveniently manipulated by reaching into the dome 7.

- the nest of heating elements 10 is composed of nine elements, but this number may be varied as may be necessary or desired to secure the proper heating effect.

- the respective heating elements ⁇ ll are preferablv grouped so that the other series thereof will have their centers arranged in a circle.

- Each element, 11, as here shown, is composed of an outer tube,

- the outer tubes, 11, are permanently secured at one end in the wall, 14, of a housing, 15, which housing is bolted to a flange, 16, that is permanently secured to the end of the car.

- a gasket, 17, isy provided so. that when the bolts, 18, are tightlyv drawn a liquid tight joint will be formed.

- the outer end of the housing,A 16, is provided lwith a flange, 19, and to this is secured, as by means of bolts, 20, a header, 21.

- the header, 21, is provided with spaced inner and outer walls, 22 and 23, respectively, thereby forming the chamber, 24.

- the inner pipes, 12, of the heating elements are secured in the wall, 23, of the header, 21, and, as is well shown in Fig. 6, the Vopposite ends terminate short of the ends of the outer tubes 11.

- I provide the outer tube, 11, with a pointed cap, 25,which is preferably secured to the pipe or tube, 11, as by means of welding.

- the inner pipe, 12, is held in proper spaced relation to the outer pipe by means ofv one or more spiders, 26.

- Steam preferably under high pressure, is admitted toV the chamber, 24, by means of the steam supply pipe, 27, which, in turn, is provided with a suitable controlling valve 28.

- the chamber, 24, serves to distribute steam to all of the ⁇ tubes or pipes, 12, and being under high pressure, quickly finds its way to the opposite ends thereof where it issues against the pointed cap 25. Being under high pressure, high ,temperature is secured thereby keeping the point, 25, very hot.

- I thus secure a'thermic head which establishes and maintains a rapid and vigorous circulation thatyraises the temperature of the contents in the quickest time and with the least expenditure of heat.

- Another advantage which I secure by grouping the heating elements as I do, is that the cleaning of the car is facilitated since practically all of theI shell of the car is unobstructed and can be readily gotten at by Workmen. This is an important feature because tank cars are used for products of different kinds and require thorough cleaning at frequent intervals. This is a slow, laborious and tedious job, as heretofore carried out, since the workmen must work within the car where air and lighting conditions are poor.

- heating elements are individual in form, z'. e. they are not interconnected as is usual in tank car heating coils. heating element is free to expand and contract as 'the specific temperature conditions in that element demand, and not under the compulsion of the expansion or contraction in an adjacent coil or section as in tank car heating coils in general use. This is a feature of utmost importance for the eX- pensive and wasteful shipping and unloading of tank car products is in a large measure caused by defective and leaking steam coils for the reasons heretofore stated.

- the respective heating elements, 11, are held in proper spaced relation by being secured in the headers, but, as an additional spacing means, T prefer to provide a disk or plate, 30, which is secured to one of the elements as by means of a set screw.

- the various heating elements pass through openings properly spaced in the plate, 30.

- This plate, 30, being secured to one of the outer heating elements, is removed with the outer heating elements when they are Withdrawn.

- the respective heating elements are held in proper spaced relation for easy insertion and a removal from the car.

- they are additionally spaced and supported by means of spaced plates, 31, Whit-h depend from the cross channel members, 32, of the car.

- the channel members, 32 in addition to providing a support for the depending plates, 30, serve to act as splash plates and brace the car Walls.

- the pointed ends, 25, of the respective heating elements serve a purpose in addition to that already stated and that is in piloting or guiding the elements into the respective openings provided therefor in the depending plates, 81. Tt is not necessary, therefore, accurately to guide the nest of heating elements vvhen they are inserted for the reason that the points, 25, will readily find their openings. Thus, the heating elements can be very quickly and easily inserted through the respective spacing plates, 81.

- a device of the' class described embodying therein a steam inlet, a steam outlet, a heating element having communication with said steam inlet and outlet and being pointed at the end opposite from said steam inlet and'outlet, said heating elementl being free to expand and contract longitudinally.

- a device of the class described embodying therein a relatively long heating element, a steam inlet and .a steam outlet adjacent one end thereof, the opposite end of the heating element being closed and of pointed form, and means supporting said heating element and permitting the free longitudinal expansion and contraction thereof.

- a steam inlet a steam outlet, a plurality of heating elements, Vall free to expand and contract longitudinally and individually, and all of said heating elements having communication With said inlet and outlet, and each of said heating elements being pointed at one end.

- A. tank car embodying therein atank provided with an opening, aV relatively closely nested group of heating elements positioned through said opening and arranged centrally and longitudinally of the car.

- a tank car embodying therein a tank provided with a centrally arranged lading egress opening, a plurality of heating elements.l a steam inlet and outlet communicatino' with said heating elements, said heating elements being closed at the end opposite said steam inlet and outlet, and said heating elements being positioned so that the closed ends terminate adjacent said lading egress opening.

- a tank car embodying therein a tank having openings in both ends and having a lading egress opening on its underside, a nest of heating elements positioned through each of the respective end openings, extending longitudinally of the car, and terminating in closed ends which are positioned adjacent said lading egress opening.

- a tank car embodying therein a tank having an opening, a header secured to the tank and closing said opening, a plurality of steam supply pipes secured to the header and extending into said tank, a plurality of return pipes secured in said header, extending into said tank, and each return pipe surrounding one supply pipe, the ends o said supply pipes opposite from the header being open, the ends of said return pipe opposite the header being closed and being of pointed form, and steam inlet and outlet connections on said header.

- a heating element for tank cars being relatively long, steam inlet and outlet connections at one end thereof, and the opposite end thereof being closed by a pointed Wall.

- a devicey of the class described embodying therein means for the admission and discharge of steam, a heating element having communication With said means and being pointed at the end opposite from said steam admission and discharge means, said heating element being free to expand and contract longitudinally.

- a device of the class described embodying therein a relatively long heating element, means for the admission and discharge of steam adjacent one end thereof, the opposite end of the heating element being closed and of pointed form, and means supporting said heating element and permitting the free longitudinal expansion and contraction thereof.

- a tank car embodying therein a tank provided With a substantially centrally positioned lading egress opening, a plurality of heating elements, means for the* admission and discharge of steam, communicating With said heating elements, said heating elements being closed at the end opposite saidl steam admission and discharge means, and said heating elements being positioned so that the closed ends terminate adjacent said lading egress opening.

- a tank car the combination With a tank, the end Wall of which is formed with an aperture, inlet and outlet headers detachably secured to the end Wall of the tank for separate removal and in a position to close said aperture, a plurality of inflow pipes secured to the inlet header and a plurality of outflow pipes secured yto the outlet header, said outflow pipes surrounding said inflow pipes and all pipes being free to expand and contract.

Landscapes

- Engineering & Computer Science (AREA)

- Mechanical Engineering (AREA)

- Vehicle Cleaning, Maintenance, Repair, Refitting, And Outriggers (AREA)

- Tires In General (AREA)

Description

H. P. ANDRESEN.

TANK GAR.

APPLICATION HLED APR. 29. 1920.

1,391,663, Y PatentedSept. 27, 1921.,

3 SHEETS-SHEET l.

se, y venzvf t j Kerman P/nore A /5 QE aim gulf/I "14 v15 la H. P. ANDRESEN.

` TANK CAR. APPLICATION FILED APR- 29, 1920.

Patented Sept. 27, 1921.;

3 SHEtfITS-SHtEI 2- Ihnen/Z551' german PnareseW..

H. P. ANDRESEN.

TANK CAR.

APPLlCATlON FILED APR. 29, 1920.

1,391,663, A Patented Sept. 27, 1921..

3 SHEETS-SHEET 3.

Il' german .Dhdresem.

UNITED STATES PATENT oEEIcE.

HERMAN P. NDR-ESEN, 0F CHICAGO, ILLINOIS.

TANK-CAR.

Application filed April 29, 1920. Serial No. 377,656.

Il "0 all w from t may concern Be it known that T, HERMAN l?. ANDRE- sEN, a citizen of the United States, and a resident of Chicagmcounty of Cook, and State of Illinois, have invented certain new and useful Improvements in Tank-Cars, of which the following is a specitication.

My invention relates generally to improvements in tank cars, but relates more particularly to an improved construction for heating the contents of tank cars.

Tank cars are used to a large extent for transporting liquids and semi-liquids such as refined oils, tars, asphalts, road oils, -tluX oils and the like. Such materials are usually placed in tank cars directly from the reiining processes and while they are sufficiently' hot to flow readily. When such cars reach their destination, however, the contents have become congealed and in some instances, as asphalte, are in a solid state. Hence before the contents can be unloaded, it is necessary to heat it and this is usually accomplished by providing steam coils in the bottom of the tank car, and, which terminate in an outlet such that a steam pipe or hose can be connected thereto. Steam is admitted to the coils under high pressure, so that a ver;T high temperature is produced, the object being to heat the contents of the car as quickly as possible so that the car may be speedily unloaded. t is ditiicult to maintain heating coils in tank cars, as heretofore constructed, in proper working condition, and it is not at all uncommon to find defective and leaking heating coils in a large percentage of tank cars when unloading. This condition prevails in the face ot the fact that 4it is common practice before the car is loaded at the refinery, or other loading point, to inspect them. l/Vorkmen tirst test the coils with air and thereafter with high pressure steam. If the system leaks at any point it is repaired before the car is loaded. The inspection and repair of heating systems in tank cars is a slow, laborious and expensive operation as heretofore carried on for the workmen must work inside of the dirty greasy car under conditions which are not conducive to speedy, or accurate work. It is common practice to withdraw such cars from service to permit repairs to be made properly.

Vhen such a car, having` leaking` coils,

containing heavy residuums such as asphalte,

pulp oils or road oils, etc., is being unloaded the steam escaping from the coils forces its way up through the contents, expanding as it rises, and carries with it a quantity of the car contents.v This is forced through the opening in the dome and flows downwardly over the car and to the road bed. This material is not only lost to all practical purposes, but it also entails the labor of removal, as well as great loss of time and money to user of the car contents. This condition is referred to usually as foaming. The contents of cars with leaky heatmg systems becomes mixed with the water of condensation and must be removed before the contents can be used. This involves considerable expense to user and considerable loss of time and labor. Another disadvantage is that the car cannot be returned promptly to the shipper because of the diiiiculty and delays of unloading. Often times the condition is so bad that the car contents can not be unloaded or used and must be returned to the shipper. This entails loss of freight, time, labor and prevents use of tank car on other service. Furthermore, most specifications are very rigid as to the amount of water permitted in the material. Therefore, leaking coils very often are the cause of the material being rejected and the car and contents returned to the shipper with consequent loss of time and money.

The causes of leaking coils are many. For instance, when cold material arrives at destination, to heat same to temperature necessary to get it to flow requires the application of steam at from 125 to 150 pounds pressure for some materials. tice to admit full pressure at once. This results in subjecting part of the coils to high temperature While others are still cold. Obviously the highly heated pipes of the coil expand greatly whereas the pipes that are still cold have not expanded. This results in severe stresses being set up in some of the pipes and especially in the return bends to which the ends of pipes are connected. This very often results in rupture or cracking of pipe or return bends and is the prime cause of breakage and consequent leakage. rThis is further aggravated when the contents consist of solids or semi-solids such as asphalte which prevent the pipes from expanding uniformly. Again, in loading, after coils have been inspected and found or It is common prac-r placed in good condition, rupture may be caused by discharging hot material from the stills or otherwise upon the relatively cold coils or upon certain parts thereof thus causing unequal expansion with the results before stated.

One of the objects of my invention is to make the operation of tank car unloading more reliable and speedy and to reduce the expense thereof. l

Another object of my invention is to provide a heating apparatus which shall overcome the defects found in present means of heating tank cars.

A further object is to facilitate the inspection, repair and maintenance of tank car heating systems and in particular to reduce breakage or rupturing in such systems and hence to eliminate the annoyance and expense which such defective condition entails.

I aim also to provide means whereby the contents of the tank car can be more quickly and uniformly raised to desired temperature, as is necessary at times, when other products are to be shipped.

Again it is an object of my invention to provide a construction wherewith difiicultie's of washing out or cleaning tank cars are overcome.

My invention consists generally in the form, arrangement, construction and coperation of the parts whereby the above named obj ects, together with others that will appear hereinafter, are attainable; and my invention will be more readily understood by reference to the accompanying drawings which illustrate what I consider, at the present time, to be the best embodiment thereof.

In said drawings:

Figure l is a View partly in section and partly in elevation of a tank car equipped with apparatus embodying my invention.

Fig. 2 is an enlarged detail view substantially on the line 2 2 of Fig. 1.

Fig. 3 is a detail sectional view on an enlarged scale taken substantially on the line 8 3 of Fig. 1.

Fig. e is a fragmentary detail view substantially on the line 1 -4: of Fig. 1.

F ig. 5 is an end view of the car, parts thereof being broken away better to disclose the interior construction.

Fig. 6 is a sectional detail of one end of one of the heating elements.

F 7 is a sectional view substantially on the line 7-7 of Fig. 6.

Fig. 8 is a detail view of one end of the tank car; and

Fig. 9 is a detail view showing use of car without heating elements therein.

As stated in the opening of the 'specification, it is necessary to heat the contents of the car in order that it may flow out through the unloader outlet 9. It has heretofore been customary to place a steam coil in the bottom ofthe car extending from end to end thereof and covering a considerable part of the bottom of the car. Such apparatus, as heretofore provided and arranged, has been far from satisfactory for the reasons heretofore stated. My invention contemplates an improvement thereof whereby a reduction in the cost of the equipment and its installation, and whereby more rapid, satisfactory, and economical functioning 0f the apparatus is attained.

Instead of distributing the heating coils throughout a considerable part of the bottom of the car, I prefer to concentrate a nest of heating elements near the bottom of the ear and centrally thereof. As a matter of convenience in manufacturing, maintenance and repair, I also prefer to provide two groups or nests of such heating elements, and to provide means at each end for the insertion and removal of such heating elements. I prefer to so construct them that they shall operate to heat the entire contents of the car and in addition to provide particularly for a hot spot or zone -iust above the outlet. As will be better understood from the detailed description which will follow, by this arrangement I increase enormously the effective heating of the contents and facilitate in a remarkable manner the prompt unloading of the car. At the same time,`and what is probably of more importance, I provide a construction which, to a remarkable extent, eliminates breakage of the heating apparatus parts and the resultant destruction or loss of much of the contents of the car.

Inasmuch as the group or nest of heating elements at each end of the car is alike, a description of one will suffice for the both. In the present instance, the nest of heating elements 10 is composed of nine elements, but this number may be varied as may be necessary or desired to secure the proper heating effect. The respective heating elements` ll, are preferablv grouped so that the other series thereof will have their centers arranged in a circle. Each element, 11, as here shown, is composed of an outer tube,

11', and an inner tube, 12, the inner tubeV being smaller in size thus providing an annular chamber, 13, therebetween. The outer tubes, 11, are permanently secured at one end in the wall, 14, of a housing, 15, which housing is bolted to a flange, 16, that is permanently secured to the end of the car. A gasket, 17, isy provided so. that when the bolts, 18, are tightlyv drawn a liquid tight joint will be formed. @The outer end of the housing,A 16, is provided lwith a flange, 19, and to this is secured, as by means of bolts, 20, a header, 21. The header, 21, is provided with spaced inner and outer walls, 22 and 23, respectively, thereby forming the chamber, 24. The inner pipes, 12, of the heating elements are secured in the wall, 23, of the header, 21, and, as is well shown in Fig. 6, the Vopposite ends terminate short of the ends of the outer tubes 11. I provide the outer tube, 11, with a pointed cap, 25,which is preferably secured to the pipe or tube, 11, as by means of welding. The inner pipe, 12, is held in proper spaced relation to the outer pipe by means ofv one or more spiders, 26.

Steam, preferably under high pressure, is admitted toV the chamber, 24, by means of the steam supply pipe, 27, which, in turn, is provided with a suitable controlling valve 28. The chamber, 24, serves to distribute steam to all of the `tubes or pipes, 12, and being under high pressure, quickly finds its way to the opposite ends thereof where it issues against the pointed cap 25. Being under high pressure, high ,temperature is secured thereby keeping the point, 25, very hot. This is a distinct advantage because the heating elements in being raised from a cold state to the temperature required to heat the contents of the car must-expand a considerable-length, and, since these coils are often embedded in an almost solid substance, suoli as asphalt 0r heavy tar, thehot point will readily pierce the material and permit proper expansion without imposing undue strains upon the structure.

The steam issuing from` the end of the pipe, 12, returns through the annular chamber, 13, and the water of condensation and returning steam is finally discharged through the outlet pipe, 29.

By arranging the heating element, 11, in a central group or nest, I secure a circulation which is best adapted quickly to bring the contents of the car to the necessary temperature. This will probably be best understood by reference to Fig. 5 where the 'convection currents are indicated. by means of arrows. Naturally, directly over the concentrated nest of heating elements willbe found a vertical column of `liquid or semiliquid at a temperature considerably above that adjacent the wall of the tank,

I thus secure a'thermic head which establishes and maintains a rapid and vigorous circulation thatyraises the temperature of the contents in the quickest time and with the least expenditure of heat.

Another advantage which I secure by grouping the heating elements as I do, is that the cleaning of the car is facilitated since practically all of theI shell of the car is unobstructed and can be readily gotten at by Workmen. This is an important feature because tank cars are used for products of different kinds and require thorough cleaning at frequent intervals. This is a slow, laborious and tedious job, as heretofore carried out, since the workmen must work within the car where air and lighting conditions are poor.

It should be noted that my heating elements are individual in form, z'. e. they are not interconnected as is usual in tank car heating coils. heating element is free to expand and contract as 'the specific temperature conditions in that element demand, and not under the compulsion of the expansion or contraction in an adjacent coil or section as in tank car heating coils in general use. This is a feature of utmost importance for the eX- pensive and wasteful shipping and unloading of tank car products is in a large measure caused by defective and leaking steam coils for the reasons heretofore stated.

Another advantage inherent in my construction is that of maintenance and repair. If it is desired simply to inspect the inner tubes, 12, the bolts, 20, are loosened, at which time the header, 22, and all of the pipes, 12, can be bodily removed by simply pulling them out longitudinally of the car. If for any reason, it is desired to inspect the heating elements in their entirety, the bolts, 17, can be removed and the entire nest of heating elements and the inlet and outlet headers can be withdrawn. If it should be found that any of the elements need repair, instead of sending workmen into the car to repair them, as is now the customary practice, I prefer simply to insert a new or repaired nest of heating elements. The removed heating elements can then be repaired in a shop where suitable facilities are provided, thus eliminating the necessity of repairing the apparatus by workmen inside of the car where the conditions are poorly adapted for efficient workmanship.

IWith apparatus of this'construction', it is not necessary to withdraw the rar from service for the purpose of making repairs because the old heating elements can be removed and a new nest inserted in a very limited time.

At times tank cars are used for shipping F or this reason, each Fig. 9). This results in providing greater capacity in the car, and, What is probably of more importance, greatly facilitates the cleaning of thc interior of the car as may be necessary when the car is to be used for shipping a different product since there need be no heating coils to be cleaned.

The respective heating elements, 11, are held in proper spaced relation by being secured in the headers, but, as an additional spacing means, T prefer to provide a disk or plate, 30, which is secured to one of the elements as by means of a set screw. The various heating elements pass through openings properly spaced in the plate, 30. This plate, 30, being secured to one of the outer heating elements, is removed with the outer heating elements when they are Withdrawn. Thus the respective heating elements, are held in proper spaced relation for easy insertion and a removal from the car. When they are in the car they are additionally spaced and supported by means of spaced plates, 31, Whit-h depend from the cross channel members, 32, of the car. The channel members, 32, in addition to providing a support for the depending plates, 30, serve to act as splash plates and brace the car Walls.

The pointed ends, 25, of the respective heating elements serve a purpose in addition to that already stated and that is in piloting or guiding the elements into the respective openings provided therefor in the depending plates, 81. Tt is not necessary, therefore, accurately to guide the nest of heating elements vvhen they are inserted for the reason that the points, 25, will readily find their openings. Thus, the heating elements can be very quickly and easily inserted through the respective spacing plates, 81.

By reference to Figs. l and a, it will be noted that the ends of the heating elements terminate closely adjacent the outlet 9. These points, being extremely hot, serve to liquefy very readily the material adjacent the outlet. They also serve to bring this material to a slightly greatertemperature than the material remote from the outlet, and this facilitates the flow of heavy liquids through the outlet to such an extent that l rarely iind it necessary to steam jacket the outlet as is frequently done.

Another advantage of these hot point pilots is that they quickly heat the material adjacent the outlet opening, thus enabling the unloading of the car before the entire contents are properly heated. Y

The many advantages of my invention Will be understood by those skilled in this art without further comment, but inasmuch as this disclosure will suggest to others various modifications whereby the substantial obj ects of my invention must be attained, I do not Wish to be limited to the specific construction herein shoyvn and described except only as may be necessary by vlimitations in the hereunto appended claims.

I claim 1. A device of the' class described embodying therein a steam inlet, a steam outlet, a heating element having communication with said steam inlet and outlet and being pointed at the end opposite from said steam inlet and'outlet, said heating elementl being free to expand and contract longitudinally.

2. A device of the class described embodying therein a relatively long heating element, a steam inlet and .a steam outlet adjacent one end thereof, the opposite end of the heating element being closed and of pointed form, and means supporting said heating element and permitting the free longitudinal expansion and contraction thereof. Y

3. In a device of the class described, a steam inlet, a steam outlet, a plurality of heating elements, Vall free to expand and contract longitudinally and individually, and all of said heating elements having communication With said inlet and outlet, and each of said heating elements being pointed at one end. Y

ll. A. tank car embodying therein atank provided with an opening, aV relatively closely nested group of heating elements positioned through said opening and arranged centrally and longitudinally of the car.

5. A tank car embodying therein a tank provided with a centrally arranged lading egress opening, a plurality of heating elements.l a steam inlet and outlet communicatino' with said heating elements, said heating elements being closed at the end opposite said steam inlet and outlet, and said heating elements being positioned so that the closed ends terminate adjacent said lading egress opening. 'v

6. A tank car embodying therein a tank having openings in both ends and having a lading egress opening on its underside, a nest of heating elements positioned through each of the respective end openings, extending longitudinally of the car, and terminating in closed ends which are positioned adjacent said lading egress opening.

7 The improvements hereinvdescribed embodying therein a steam inlet, a steam outlet, a supply pipe extending away from the steam inlet and being open at the far end, a return pipe connected to the steam outlet, surrounding said supply pipe, and having a closed pointed end adjacent the open end of said supply pipe.

8. A tank car embodying therein a tank having an opening, a header secured to the tank and closing said opening, a plurality of steam supply pipes secured to the header and extending into said tank, a plurality of return pipes secured in said header, extending into said tank, and each return pipe surrounding one supply pipe, the ends o said supply pipes opposite from the header being open, the ends of said return pipe opposite the header being closed and being of pointed form, and steam inlet and outlet connections on said header.

9. A heating element for tank cars being relatively long, steam inlet and outlet connections at one end thereof, and the opposite end thereof being closed by a pointed Wall.

10. A devicey of the class described embodying therein means for the admission and discharge of steam, a heating element having communication With said means and being pointed at the end opposite from said steam admission and discharge means, said heating element being free to expand and contract longitudinally.

11. A device of the class described embodying therein a relatively long heating element, means for the admission and discharge of steam adjacent one end thereof, the opposite end of the heating element being closed and of pointed form, and means supporting said heating element and permitting the free longitudinal expansion and contraction thereof.

12. In a device of the class described, means for the admission and discharge of 30 steam, a plurality of heating elements, all

free to expand and contract longitudinally and individually, and all of said heating elements having communication with said steam admission and discharge means, and each of said heating elements being pointed at one end.

13. A tank car embodying therein a tank provided With a substantially centrally positioned lading egress opening, a plurality of heating elements, means for the* admission and discharge of steam, communicating With said heating elements, said heating elements being closed at the end opposite saidl steam admission and discharge means, and said heating elements being positioned so that the closed ends terminate adjacent said lading egress opening.

14. In a tank car, the combination With a tank, the end Wall of which is formed with an aperture, inlet and outlet headers detachably secured to the end Wall of the tank for separate removal and in a position to close said aperture, a plurality of inflow pipes secured to the inlet header and a plurality of outflow pipes secured yto the outlet header, said outflow pipes surrounding said inflow pipes and all pipes being free to expand and contract.

In testimony whereof, I have hereunto set my hand this 21st day of April, A. D. 1920. 60

HERMAN P. ANDRESEN.

Applications Claiming Priority (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| US106755A US1341663A (en) | 1916-06-30 | 1916-06-30 | Tire-casing |

Publications (1)

| Publication Number | Publication Date |

|---|---|

| US1391663A true US1391663A (en) | 1921-09-27 |

Family

ID=22313077

Family Applications (2)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| US1391663D Expired - Lifetime US1391663A (en) | 1916-06-30 | Tank-car | |

| US106755A Expired - Lifetime US1341663A (en) | 1916-06-30 | 1916-06-30 | Tire-casing |

Family Applications After (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| US106755A Expired - Lifetime US1341663A (en) | 1916-06-30 | 1916-06-30 | Tire-casing |

Country Status (1)

| Country | Link |

|---|---|

| US (2) | US1341663A (en) |

Cited By (2)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US2995343A (en) * | 1957-07-29 | 1961-08-08 | Griscom Russell Co | Heat exchanger construction |

| US4603733A (en) * | 1982-12-30 | 1986-08-05 | Richard Loevinger | Heated railroad tank car |

Families Citing this family (2)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US2501372A (en) * | 1947-06-27 | 1950-03-21 | Us Rubber Co | Wire fabric tire casing |

| GB854971A (en) * | 1957-03-12 | 1960-11-23 | Dunlop Rubber Co | Improvements in pneumatic tyres |

-

0

- US US1391663D patent/US1391663A/en not_active Expired - Lifetime

-

1916

- 1916-06-30 US US106755A patent/US1341663A/en not_active Expired - Lifetime

Cited By (2)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US2995343A (en) * | 1957-07-29 | 1961-08-08 | Griscom Russell Co | Heat exchanger construction |

| US4603733A (en) * | 1982-12-30 | 1986-08-05 | Richard Loevinger | Heated railroad tank car |

Also Published As

| Publication number | Publication date |

|---|---|

| US1341663A (en) | 1920-06-01 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| US2256882A (en) | Heat exchanger | |

| US1562991A (en) | Transportable tank | |

| US1391663A (en) | Tank-car | |

| US2640686A (en) | Heat exchange type of tank heater | |

| US1381669A (en) | Tank-car-heating apparatus | |

| US1817978A (en) | Liquid storage or tempering apparatus | |

| RU200705U1 (en) | RAILWAY TANK FOR TRANSPORTATION OF VISCOUS PETROLEUM PRODUCTS | |

| US2817499A (en) | Steam generator | |

| US2125972A (en) | Heat exchanger | |

| US2267695A (en) | Heat exchanger | |

| US1706084A (en) | Car-tank heater | |

| RU2698637C2 (en) | Railway tank car | |

| US1813057A (en) | Apparatus for heat exchanging | |

| US2081432A (en) | Milk heater | |

| US1602887A (en) | Heater for discharge outlets of fluid containers | |

| US2064901A (en) | Digester | |

| US1727694A (en) | Discharge outlet | |

| US2684762A (en) | Apparatus for separating immiscible liquids or liquids and insoluble solids | |

| US1738126A (en) | Refrigerating apparatus | |

| US2011640A (en) | Heat exchanger | |

| US162659A (en) | Improvement in refrigerating-tanks for ice-machines | |

| US2009837A (en) | Tubular heat exchanger for liquids | |

| US2387883A (en) | Heating apparatus | |

| US1435570A (en) | Storage heater | |

| US1436380A (en) | Oil heater |