RU2558191C1 - Unground whole oat grain product ready for consumption and such product manufacture method - Google Patents

Unground whole oat grain product ready for consumption and such product manufacture method Download PDFInfo

- Publication number

- RU2558191C1 RU2558191C1 RU2014121748/13A RU2014121748A RU2558191C1 RU 2558191 C1 RU2558191 C1 RU 2558191C1 RU 2014121748/13 A RU2014121748/13 A RU 2014121748/13A RU 2014121748 A RU2014121748 A RU 2014121748A RU 2558191 C1 RU2558191 C1 RU 2558191C1

- Authority

- RU

- Russia

- Prior art keywords

- grains

- whole

- suspension

- oat

- water

- Prior art date

Links

Classifications

-

- A—HUMAN NECESSITIES

- A23—FOODS OR FOODSTUFFS; TREATMENT THEREOF, NOT COVERED BY OTHER CLASSES

- A23L—FOODS, FOODSTUFFS, OR NON-ALCOHOLIC BEVERAGES, NOT COVERED BY SUBCLASSES A21D OR A23B-A23J; THEIR PREPARATION OR TREATMENT, e.g. COOKING, MODIFICATION OF NUTRITIVE QUALITIES, PHYSICAL TREATMENT; PRESERVATION OF FOODS OR FOODSTUFFS, IN GENERAL

- A23L7/00—Cereal-derived products; Malt products; Preparation or treatment thereof

- A23L7/10—Cereal-derived products

- A23L7/143—Cereal granules or flakes to be cooked and eaten hot, e.g. oatmeal; Reformed rice products

- A23L7/148—Cereal granules or flakes to be cooked and eaten hot, e.g. oatmeal; Reformed rice products made from wholegrain or grain pieces without preparation of meal or dough

-

- A—HUMAN NECESSITIES

- A23—FOODS OR FOODSTUFFS; TREATMENT THEREOF, NOT COVERED BY OTHER CLASSES

- A23L—FOODS, FOODSTUFFS, OR NON-ALCOHOLIC BEVERAGES, NOT COVERED BY SUBCLASSES A21D OR A23B-A23J; THEIR PREPARATION OR TREATMENT, e.g. COOKING, MODIFICATION OF NUTRITIVE QUALITIES, PHYSICAL TREATMENT; PRESERVATION OF FOODS OR FOODSTUFFS, IN GENERAL

- A23L7/00—Cereal-derived products; Malt products; Preparation or treatment thereof

- A23L7/10—Cereal-derived products

- A23L7/104—Fermentation of farinaceous cereal or cereal material; Addition of enzymes or microorganisms

Landscapes

- Life Sciences & Earth Sciences (AREA)

- Engineering & Computer Science (AREA)

- Health & Medical Sciences (AREA)

- Nutrition Science (AREA)

- Chemical & Material Sciences (AREA)

- Food Science & Technology (AREA)

- Polymers & Plastics (AREA)

- Biotechnology (AREA)

- Microbiology (AREA)

- Cereal-Derived Products (AREA)

Abstract

Description

ОБЛАСТЬ ТЕХНИКИFIELD OF TECHNOLOGY

Группа изобретений относится к пищевой промышленности, а именно к готовому к употреблению продукту на основе целых цельных зерен овса, равномерно распределенных в пищевой суспензии, ферментированных живыми лакто- и бифидобактериями, и способу его получения.The group of inventions relates to the food industry, namely, a ready-to-eat product based on whole whole oat grains uniformly distributed in a food suspension, fermented with live lacto and bifidobacteria, and a method for its preparation.

УРОВЕНЬ ТЕХНИКИBACKGROUND

Питание является важным фактором обеспечения и поддержания здоровья. Злаки являются главным источником пищевых веществ во всем мире. Цельные зерна овса имеют большую пищевую ценность и более высокое содержание пищевых волокон, чем резаные зерна овса, овсяные хлопья и овсяная мука. Цельные злаки овса содержат высокое содержание липидов от 3-х до 11% и высокую ферментную активность, вследствие чего подвергаются разной степени окисления в процессе хранения в нативном виде.Nutrition is an important factor in ensuring and maintaining health. Cereals are the main source of nutrients worldwide. Whole grains of oats have greater nutritional value and a higher content of dietary fiber than chopped oats, oatmeal and oatmeal. Whole oat cereals contain a high lipid content of 3 to 11% and high enzyme activity, as a result of which they undergo different degrees of oxidation during storage in their native form.

Следует отметить, что для здоровья потребителей целесообразно использовать в рационе цельные злаки овса, готовые к употреблению, так как именно они в наибольшей степени сохраняют аромат овса, привкус, текстуру, при обеспечении во время приготовления продукта из цельных злаков минимальных потерь пищевых веществ. Ферментация является наиболее простым и экономным путем улучшения пищевой ценности, сенсорных и функциональных свойств продуктов. Продукты, произведенные на основе различных злаков или их смесей, ферментированные лактобактериями и другими культурами, в результате этого процесса становятся более полезными для здоровья.It should be noted that for the health of consumers it is advisable to use whole oat cereals in the diet that are ready to eat, since it is they that most retain the aroma of oats, taste, texture, while ensuring the minimum loss of nutrients during the preparation of a product from whole grains. Fermentation is the easiest and most economical way to improve nutritional value, sensory and functional properties of products. Products made on the basis of various cereals or their mixtures, fermented by lactobacilli and other cultures, as a result of this process become more healthy.

В настоящем изобретении используется следующая принятая в данной области терминология.The following terminology is used in the present invention.

Цельный овес - это овес или его производные, в которых зерновые компоненты: крахмальный эндосперм, зародыш и отруби присутствуют в тех же пропорциях, как и в оригинальном составе зерновки злака овса.Whole oats are oats or their derivatives, in which the grain components: starch endosperm, germ and bran are present in the same proportions as in the original composition of the oat cereal grains.

Целое цельное зерно - это зерно овса, сохранившее свою целостность с мелкопористой поверхностью зерна овса и, возможно, незначительными трещинами внешней оболочки.Whole whole grain is oat grain, which has retained its integrity with the finely porous surface of the oat grain and, possibly, minor cracks in the outer shell.

Принудительная сила трения - это процесс эффективного трения зерен друг о друга при соотношении воды и зерен овса по весу воды к зерну 3:1 с применением циркуляции суспензии по циклу: танк-насос-система трубопроводов комбинированных диаметров для создания эффективного трения.Forced friction force is the process of effective friction of grains against each other at a ratio of water and oat grains by weight of water to grain of 3: 1 using suspension circulation in a cycle: tank-pump-piping system of combined diameters to create effective friction.

Желатинизация крахмалов - это процесс, в результате которого внутренняя структура кристаллической крахмальной гранулы подвержена набуханию в воде и под действием тепла разрушена для наиболее полного усвоения овса пищеварительными энзимами человека. Известны средние значения температур желатинизации злаков 70-75°C, обуславливающие факт желатинизации крахмалов [Determination of the gelatinizationtemperature of starch presented inmaize floursd. f. Corall, P. Pineda-Go′mez 1, 2, A. Rosales-Riveral and M.E. Rodriguez - Garcia 31 Laboratorio de Magnetismo у MaterialesAvanzados, Facultad de CienciasExactasyNaturales, Universidad Nacional de Colombia, Manizales, Caldas, Colombia et al.].Starch gelatinization is a process whereby the internal structure of a crystalline starch granule is subject to swelling in water and is destroyed by heat for the most complete absorption of oats by human digestive enzymes. The average values of cereal gelatinization temperatures of 70-75 ° C are known, which determine the fact of gelatinization of starches [Determination of the gelatinization temperature of starch presented inmaize floursd. f. Corall, P. Pineda-Go′mez 1, 2, A. Rosales-Riveral and M.E. Rodriguez - Garcia 31 Laboratorio de Magnetismo by MaterialesAvanzados, Facultad de CienciasExactasy Naturales, Universidad Nacional de Colombia, Manizales, Caldas, Colombia et al.].

Прежелатинизация крахмалов на 85% - это неполный процесс желатинизации крахмалов, который определяется под микроскопом путем подсчета гранул крахмалов в процентах с оставшимися «крестиками» в поле зрения на 1 см2 или определения степени желатинизации путем йодной пробы.Pregelatinization of starches by 85% is an incomplete process of gelatinization of starches, which is determined under the microscope by counting the granules of starches in percent with the remaining “crosses” in the field of view per 1 cm 2 or determining the degree of gelatinization by iodine test.

Готовый к употреблению продукт - это продукт, прошедший достаточную обработку пищевых веществ цельного овса водой и теплом, пригодного для непосредственного употребления в пищу, то есть при полной доступности к усвоению энзимами человека с минимальными потерями пищевых веществ в процессе обработки.A ready-to-eat product is a product that has undergone sufficient processing of whole oat nutrients with water and heat, suitable for direct consumption, that is, with complete accessibility to assimilation by human enzymes with minimal loss of nutrients during processing.

Из уровня известны ферментированные пищевые продукты, приготовленные с использованием обработанных зерен овса, и способы их производства.Fermented foods prepared using processed oat grains and methods for their production are known from the level.

Известен пищевой продукт [WO 9117672], полученный ферментацией водной смеси отрубей злаков (овес, ячмень, пшеница, рис, просо) молочнокислыми микроорганизмами. Пищевой продукт, описанный в WO 9117672, не обладает стабильно вязкой консистенцией, поэтому может расслаиваться в процессе хранения, что свидетельствует о несовершенной коллоидной системе продукта, а значит, и неоднозначном уровне его пищевой и биологической ценности. Согласно изобретению в конечном продукте цельные целые зерна не используются.Known food product [WO 9117672], obtained by fermentation of an aqueous mixture of bran of cereals (oats, barley, wheat, rice, millet) by lactic microorganisms. The food product described in WO 9117672 does not have a stably viscous consistency, therefore, it can be stratified during storage, which indicates an imperfect colloidal system of the product, and, therefore, an ambiguous level of its nutritional and biological value. According to the invention, whole grains are not used in the final product.

Известен биоовсяный пищевой продукт, ферментированный лактобактериями [RU 2332113], полученный методом двойной ферментации, овес и его производные после нескольких этапов переработки превращаются в суспензию, которая пастеризуется и ферментируется дрожжами и молочнокислыми бактериями. Согласно изобретению ферментируют измельченные и предварительно обработанные разными процессами производные овса, при этом ферментация цельного зерна не предусматривается.Known bio-oat food product, fermented by lactobacilli [RU 2332113], obtained by double fermentation, oats and its derivatives after several stages of processing turn into a suspension, which is pasteurized and fermented by yeast and lactic acid bacteria. According to the invention, oat derivatives are ground and pre-processed by different processes, and no whole grain fermentation is envisaged.

Биоовсяный продукт, описанный в патенте RU 2332113, является наиболее близким к предлагаемому готовому продукту по методу ферментации содержащей злаки суспензии и составу лакто и бифидобактерий.The bio-oat product described in patent RU 2332113 is the closest to the proposed finished product by the method of fermentation of cereal-containing suspension and the composition of lacto and bifidobacteria.

Известен способ приготовления биологически активного пищевого продукта [RU 2189153], заключающийся в подготовке зерен пищевых злаков, включая овес, и последующей их ферментации молочнокислыми микроорганизмами. Способ предусматривает трудоемкий процесс подготовки сквашиваемой основы с длительной последующей ферментацией (от одного до трех дней), что является недостатком этого способа.A known method of preparing a biologically active food product [RU 2189153], which consists in the preparation of grains of cereals, including oats, and their subsequent fermentation by lactic acid microorganisms. The method involves a time-consuming process of preparing a sour base with a long subsequent fermentation (from one to three days), which is a disadvantage of this method.

Известен способ ферментативной обработки зерновых [RU 2323590], предусматривающий получение зерна, суспендирование зерна в жидкости с получением суспензии, добавление к суспензии одной или более карбогидраз и/или одной или более амилаз и инкубирование при 55-70°C, подвергание суспензии первой стадии инактивации при температуре выше 80°C, добавление одной или нескольких амилаз и инкубирование при 60-70°C и подвергание суспензии второй стадии инактивации при температуре выше 80°C с получением зерновой жидкости, содержащей модифицированный крахмал.A known method of enzymatic processing of grain [RU 2323590], which includes obtaining grain, suspending grain in a liquid to obtain a suspension, adding one or more carbohydrases and / or one or more amylases to the suspension and incubating at 55-70 ° C, exposing the suspension to the first stage of inactivation at temperatures above 80 ° C, adding one or more amylases and incubating at 60-70 ° C and exposing the suspension to a second stage of inactivation at temperatures above 80 ° C to obtain a grain liquid containing modified starch.

Известен способ получения готовой к употреблению овсяной крупы, включающий в себя варку овсяных злаков под давлением, вымешивание злаковых зерен, формирование пластичного сваренного овсяного теста, формирование хлопьев и сушку до влажности 2-10% по весу, конечный продукт сухой [US 3345183].A known method of producing ready-to-eat oatmeal includes cooking oatmeal under pressure, kneading cereal grains, forming a plastic cooked oatmeal, forming flakes and drying to a moisture content of 2-10% by weight, the final product is dry [US 3345183].

Известен способ производства сваренных злаковых зерен, включающих высокий уровень цельного овса для измельченных готовых к употреблению злаков в котором цельные злаки сначала измельчаются для высвобождения муки, далее смешиваются с водой и варятся, при этом конечный продукт, представляющий собой измельченную слоеную массу, высушивают [WO 2009/045991].A known method for the production of cooked cereal grains, including a high level of whole oats for chopped ready-to-eat cereals in which whole grains are first crushed to release flour, then mixed with water and cooked, while the final product, which is a crushed puff mass, is dried [WO 2009 / 045991].

Известен способ приготовления быстроваримого овса в целой форме [US 4413018]. Согласно изобретению процесс начинается кондиционированием зерна овса паром с одновременным высушиванием, далее используют темперирование непрямым паром или кипящей водой, а затем высушивание и обжарка зерна до влажности 5-8%.A known method of preparing instant oats in whole form [US 4413018]. According to the invention, the process begins by conditioning oat grains with steam while drying, then using tempering with indirect steam or boiling water, and then drying and roasting the grain to a moisture content of 5-8%.

Известные из уровня техники способы использования зерен овса для приготовления пищевых продуктов предусматривают разную степень предварительной обработки: инактивации ферментной активности и достижения кулинарной готовности зерен. При этом для обеспечения во время приготовления продукта из цельных злаков минимальных потерь пищевых веществ технология их приготовления намного сложнее, чем из резаных овсяных зерен, овсяных хлопьев или муки. В случае использования при приготовлении продукта из цельных зерен овса обычной варки требуется очень эффективная их обработка теплом.Known from the prior art, methods of using oat grains for preparing food products provide for a different degree of pre-treatment: inactivation of enzyme activity and achieving culinary readiness of grains. At the same time, to ensure during the preparation of the product from whole grains the minimum loss of nutrients, the technology for their preparation is much more complicated than from chopped oat grains, oatmeal or flour. In the case of using conventional cooking when preparing a product from whole grains of oats, their very effective heat treatment is required.

Наиболее близким к предлагаемому способу является способ приготовления смесей из разных цельных злаков [US6287626], а также продуктов из них. Согласно описанию известный способ приготовления пищевого продукта предусматривает:Closest to the proposed method is a method of preparing mixtures of different whole grains [US6287626], as well as products from them. According to the description, a known method of preparing a food product provides:

- варку цельных зерен до достижения уровня влажности от 40 до 80% при соотношении по весу воды к зерну от 2:1 до 10:1 при температуре воды от 80 до 150°C в течение периода от 5 до 90 минут до влажности содержания ядер от 60 до 80%, при этом зерна выбраны из группы состоящей из мягких зерен, твердых зерен и/или их смеси; при этом варку производят до полной или частичной желатинизации крахмалов при атмосферном давлении или под давлением до 3-х атмосфер;- boiling whole grains until a moisture level of from 40 to 80% is reached with a ratio by weight of water to grain from 2: 1 to 10: 1 at a water temperature of 80 to 150 ° C for a period of 5 to 90 minutes to a moisture content of kernels from 60 to 80%, while the grains are selected from the group consisting of soft grains, hard grains and / or mixtures thereof; at the same time, cooking is carried out until the starches are fully or partially gelled at atmospheric pressure or under pressure up to 3 atmospheres;

- ополаскивание сваренных зерен водой с температурой менее 20° и в течение достаточного количества времени производится, чтобы смыть избыточный крахмал, который вытек из зерен, и охладить зерна до температуры менее 60°C, при этом смывочная вода подвергается дренажу - удалению с поверхности зерен и из процесса;- rinsing the cooked grains with water with a temperature of less than 20 ° and for a sufficient amount of time is carried out to wash off excess starch that has leaked from the grains and cool the grains to a temperature of less than 60 ° C, while the wash water is subjected to drainage - removal from the surface of the grains and from the process;

- сушку зерен от 5 до 20 минут при температуре от 185 до 235°C, чтобы получить сухие зерна;- drying the grains from 5 to 20 minutes at a temperature of from 185 to 235 ° C to obtain dry grains;

- или замораживание зерна;- or freezing grain;

- хранение их при температуре от -18°C до -30°C.- storing them at temperatures from -18 ° C to -30 ° C.

Цельные злаки по патенту US 6287626 могут быть использованы в виде готовых к употреблению снеков, злаков или, после дополнительной переработки, как ингредиент для других пищевых продуктов.Whole grains according to the patent US 6287626 can be used in the form of ready-to-eat snacks, cereals or, after additional processing, as an ingredient for other food products.

К недостаткам описанного в патенте US 6287626 способа, предусматривающего подачу сырого зерна сразу в горячую воду с температурой 80-93°C, следует отнести:The disadvantages of the method described in patent US 6287626, providing for the supply of raw grain directly to hot water with a temperature of 80-93 ° C, include:

- очень жесткие режимы варки (со старта), при которых однородность текстуры сваренных зерен будет нестабильна в готовом продукте: так как за время, пока будет вариться сердцевина зерна, внешние слои уже претерпевают пережелатинизацию (температура начала желатинизации крахмалов овса составляет 62°C), при которой крахмал начинает вытекать из клеток;- very strict cooking modes (from the start), in which the uniformity of the texture of the cooked grains will be unstable in the finished product: since during the time the grain core is cooked, the outer layers already undergo gelatinization (the temperature of the start of gelatinization of oat starch is 62 ° C), in which starch begins to flow out of the cells;

- в процессе варки риск пережелатинизации внешних слоев крахмала цельного зерна затрудняет проникновение воды вовнутрь зерен через коллоидный слой желатинизированного крахмала в них;- during cooking, the risk of gelatinization of the outer layers of whole grain starch makes it difficult for water to penetrate into the grains through the colloidal layer of gelatinized starch in them;

- для смывания вытекающего крахмала в способе предусмотрено ополаскивание зерен холодной водой, вовремя которого вытекший из зерен крахмал удаляют, из-за чего соотношение пищевых веществ цельного зерна уже не будет соответствовать требованиям нативного соотношения эндосперма, отрубей и зародышей, т.е. требованиям определения цельного зерна;- in order to wash the starch out of the way, the method provides for rinsing the grains with cold water, during which the starch leaked from the grains is removed, due to which the ratio of whole grain nutrients will no longer meet the requirements of the native ratio of endosperm, bran and germ, i.e. requirements for the determination of whole grains;

- процесс производства конечного продукта характеризуется прерывистостью, что не позволяет начать немедленное употребление продукта в пищу, потому что цельные зерна согласно способу помимо соединения с другими ингредиентами необходимо сушить, дробить, молоть и/или регидратировать.- the process of production of the final product is characterized by discontinuity, which does not allow to start the immediate use of the product in food, because whole grains according to the method, in addition to combining with other ingredients, must be dried, crushed, ground and / or rehydrated.

Таким образом, способ, описанный в патенте US 6287626, предусматривающий начало варки цельных зерен при температуре от 80°C до 93°C и далее нагрев до 122°C и преимущественно варку при температурах от 90°C до 105°C, без предварительного замачивания, в действительности приводит к перегреву верхних слоев зерновок, в результате чего происходит вытекание крахмалов, что способствует неизбежной потере части пищевой ценности и потере соответствия цельным зернам.Thus, the method described in US patent 6287626, involving the start of cooking whole grains at a temperature of from 80 ° C to 93 ° C and then heating to 122 ° C and mainly cooking at temperatures from 90 ° C to 105 ° C, without pre-soaking , in fact, leads to overheating of the upper layers of the grains, resulting in leakage of starches, which contributes to the inevitable loss of part of the nutritional value and loss of compliance with whole grains.

Изобретение решает задачу создания предлагаемым способом готового к употреблению продукта на основе целых цельных зерен овса, в котором зерна овса сохранены целыми и цельными и обработаны бактериями и их ферментами во время ферментации. Цельные целые зерна овса равномерно распределены в пищевой суспензии готового продукта.The invention solves the problem of creating a ready-to-use product based on whole whole oat grains in the proposed method, in which oat grains are kept whole and whole and processed by bacteria and their enzymes during fermentation. Whole whole oat grains are evenly distributed in the food suspension of the finished product.

Технический результат заключается в получении готового к употреблению продукта на основе целых цельных зерен овса в непрерывном процессе, в котором ферментированные лакто- и бифидобактериями и равномерно распределенные в пищевой суспензии цельные зерна овса сохранены целыми за счет получения микропористой поверхности цельных зерен предлагаемым способом, включающим холодное замачивание цельного зерна овса, проведение циркуляции смеси зерен овса, последующую поэтапную обработку его водой, тепловую обработку согласно выбранным режимам до уровня желатинизации крахмала 100%.The technical result consists in obtaining a ready-to-eat product based on whole whole oat grains in a continuous process in which whole oat grains fermented by lacto- and bifidobacteria and whole oats uniformly distributed in the food suspension are kept intact due to the microporous surface of whole grains of the proposed method, including cold soaking whole oat grain, circulating a mixture of oat grains, subsequent stage-by-stage treatment with water, heat treatment according to the selected mode am to the level of gelatinization of starch 100%.

При разработке предлагаемого способа во время многочисленных экспериментов, касающихся последовательности действий и режимов их проведения, было установлено, что целое цельное зерно овса сохраняет свою форму в момент достижения полной кулинарной готовности, а именно при достижении 100% желатинизации крахмалов.When developing the proposed method during numerous experiments concerning the sequence of actions and the modes of their implementation, it was found that the whole whole oat grain retains its shape at the time of complete culinary readiness, namely when 100% gelatinization of starches is achieved.

В продукте зерно овса остается целым путем применения поэтапной обработки зерен овса выбранными режимами, включая режимы циркуляции в воде при выбранном соотношении зерна и воды для получения на поверхности целого зерна микротрещин защитного слоя отрубей-перикарпа.In the product, oat grain remains the whole way through the step-by-step processing of oat grains with the selected modes, including circulation modes in water at a selected ratio of grain to water to obtain a protective layer of pericarp bran on the whole grain surface of microcracks.

Это создает условия повышенной доступности проникновения воды внутрь зерновки овса уже на стадии замачивания в холодной воде и далее их обработку ферментами живых бактерий во время ферментации для придания целым цельным зернам всех свойств ферментированного злакового продукта.This creates conditions for increased accessibility of water penetration into the oat grains already at the stage of soaking in cold water and then their treatment with live bacteria enzymes during fermentation to give whole whole grains all the properties of the fermented cereal product.

РАСКРЫТИЕ ИЗОБРЕТЕНИЯSUMMARY OF THE INVENTION

Для решения поставленной задачи и достижения указанного технического результата предложена группа изобретений, объединенных общим изобретательским замыслом.To solve the problem and achieve the technical result, a group of inventions is proposed, united by a common inventive concept.

Одним из аспектов предлагаемой группы изобретений является способ получения готового к употреблению продукта на основе целого и цельного зерна овса, включающий увлажнение зерна водой и варку, характеризующийся тем, что осуществляют следующие стадии:One of the aspects of the proposed group of inventions is a method for producing a ready-to-eat product based on whole and whole oat grains, including moistening the grain with water and cooking, characterized in that the following stages are carried out:

- промывание зерна холодной водой;- washing the grain with cold water;

- поэтапное замачивание в воде с температурой от 20°C до 62°C и при атмосферном давлении с предварительным проведением циркуляции смеси зерен овса и воды до образования микротрещин на внешней оболочке цельного зерна и влажности зерна овса от 33 до 38%;- stepwise soaking in water with a temperature of from 20 ° C to 62 ° C and at atmospheric pressure with preliminary circulating a mixture of oat and water grains until microcracks form on the outer shell of the whole grain and the moisture content of oat grain is from 33 to 38%;

- темперирование цельных зерен овса проводят в воде с температурой 80°C и при атмосферном давлении;- tempering of whole oat grains is carried out in water with a temperature of 80 ° C and at atmospheric pressure;

- смешивание с предварительно подготовленной пищевой вкусовой и/или нутриционной суспензией;- mixing with a pre-prepared food flavoring and / or nutritional suspension;

при этом варку цельных зерен овса в суспензии проводят до желатинизации крахмалов 100%;while cooking whole oat grains in suspension is carried out until gelatinization of starches 100%;

- пастеризацию цельных зерен овса в суспензии до полного уничтожения вегетативной микрофлоры;- pasteurization of whole oat grains in suspension until the complete destruction of the vegetative microflora;

- охлаждение пастеризованной суспензии проводят до температуры ферментации;- cooling the pasteurized suspension is carried out to a fermentation temperature;

- инокулирование охлажденной суспензии закваской, содержащей живые бактерии;- inoculation of the cooled suspension with a starter culture containing live bacteria;

- ферментацию лакто- и бифидобактериями до значений pH от 3.8 до 4.4;- fermentation of lactobacilli and bifidobacteria to pH values from 3.8 to 4.4;

- охлаждение ферментированного продукта.- cooling the fermented product.

В дополнительном аспекте способ характеризуется тем, что цельные зерна овса промывают холодной водой с температурой ниже 20°C до полного отсутствия мучели, цветочных пленок и достижения уровня влажности зерна овса от 25 до 27%.In an additional aspect, the method is characterized in that whole oat grains are washed with cold water at a temperature below 20 ° C until there is no flour, flower films and the moisture content of oats is reached from 25 to 27%.

В дополнительном аспекте способ характеризуется тем, циркуляцию смеси зерен овса и воды проводят в воде с температурой 20-25°C при соотношении по весу зерна к воде 1:3 и воздействии принудительной силы трения зерен друг о друга до образования микротрещин на внешней оболочке цельного зерна путем прохождения зерна по замкнутой системе, включающей танк с мешалкой рамочного типа, насос кулачковый и трубопровод комбинированный с диаметрами, соответствующими 5.08-3.81-5.08 см в течение 25-35 минут.In an additional aspect, the method is characterized in that the mixture of oat and water grains is circulated in water at a temperature of 20-25 ° C with a grain to water ratio of 1: 3 and the coercive force of friction of the grains against each other until microcracks form on the outer shell of the whole grain by passing grain through a closed system, including a tank with a frame type mixer, a cam pump and a combined pipeline with diameters corresponding to 5.08-3.81-5.08 cm for 25-35 minutes.

В дополнительном аспекте способ характеризуется тем, что темперирование цельных зерен овса проводят в воде с температурой 80°C и при атмосферном давлении в течение 25-35 минут при соотношении по весу зерна к воде от 1:4 до 1:5 до состояния прежелатинизации крахмалов зерна овса на 85% и конечной влажности зерна овса от 52 до 56%.In an additional aspect, the method is characterized in that the tempering of whole oat grains is carried out in water at a temperature of 80 ° C and at atmospheric pressure for 25-35 minutes with a ratio by weight of grain to water from 1: 4 to 1: 5 to the state of gelatinization of grain starches oats by 85% and final moisture content of oats from 52 to 56%.

В дополнительном аспекте способ характеризуется тем, что цельные зерна овса с конечной влажностью от 52 до 56% и температурой 80°C смешивают с предварительно подготовленной пищевой вкусовой и/или нутриционной суспензией с температурой 20-22°C.In an additional aspect, the method is characterized in that whole oat grains with a final moisture content of 52 to 56% and a temperature of 80 ° C are mixed with a pre-prepared food flavoring and / or nutritional suspension with a temperature of 20-22 ° C.

В дополнительном аспекте способ характеризуется тем, что варку цельных зерен овса проводят до желатинизации крахмалов 100% в составе суспензии при соотношении по весу зерна к воде от 1:4,5 до 1:5,5 при температуре от 85 до 96°C.In an additional aspect, the method is characterized in that the cooking of whole oat grains is carried out until gelatinization of the starches 100% in the suspension at a ratio by weight of grain to water from 1: 4.5 to 1: 5.5 at a temperature of from 85 to 96 ° C.

В дополнительном аспекте способ характеризуется тем, что пастеризацию цельных зерен овса в суспензии проводят до полного уничтожения вегетативной микрофлоры при температуре 96°C в течение 10-15 минут.In an additional aspect, the method is characterized in that the pasteurization of whole oat grains in suspension is carried out until the complete destruction of the vegetative microflora at a temperature of 96 ° C for 10-15 minutes.

В дополнительном аспекте способ характеризуется тем, что охлаждение пастеризованной суспензии проводят до температуры ферментации от 38 до 40°C в течение 40-50 минут.In an additional aspect, the method is characterized in that the pasteurized suspension is cooled to a fermentation temperature from 38 to 40 ° C for 40-50 minutes.

В дополнительном аспекте изобретение характеризуется тем, что охлажденную пастеризованную суспензию инокулируют закваской, содержащей живые бактерии, выбираемые из группы: В. animalis - ВВ-12 - пробиотическая закваска; В. infantis; В. lactis; Lactobacillus spp.; L. fermentum L. bulgaricus; L. Rhamnosus or GG; L. Acidophilus La-5 - пробиотическая закваска; L. reuteri L. plantarum; L. Delbrueckii sub sp. Bulgaricus; L. lactis L. thamnosus; L. casei shirota Propionibacterium freudenreichii Lactoccus lactis sub sp.; lactis and cremoris; Enterococcus faecium Enterococcus faecalis; Streptococcus diacetilactis Streptococcus salivarius sub sp.; Streptococcus thermophilus; Streptococcus cremoris Streptococcus faecium; Streptococcus lactis Streptococcus equines в количестве 0,01%.In an additional aspect, the invention is characterized in that the cooled pasteurized suspension is inoculated with a starter culture containing live bacteria selected from the group: B. animalis — BB-12 — probiotic starter culture; B. infantis; B. lactis; Lactobacillus spp .; L. fermentum L. bulgaricus; L. Rhamnosus or GG; L. Acidophilus La-5 - probiotic sourdough; L. reuteri L. plantarum; L. Delbrueckii sub sp. Bulgaricus; L. lactis L. thamnosus; L. casei shirota Propionibacterium freudenreichii Lactoccus lactis sub sp .; lactis and cremoris; Enterococcus faecium Enterococcus faecalis; Streptococcus diacetilactis Streptococcus salivarius sub sp .; Streptococcus thermophilus; Streptococcus cremoris Streptococcus faecium; Streptococcus lactis Streptococcus equines in an amount of 0.01%.

В дополнительном аспекте изобретение характеризуется тем, что охлаждение ферментированного продукта проводят до температуры от 10 до 15°C.In an additional aspect, the invention is characterized in that the cooling of the fermented product is carried out to a temperature of from 10 to 15 ° C.

В дополнительном аспекте изобретение характеризуется тем, что продукт расфасовывают в стерильные порционные емкости и выдерживают в холодильной камере в течение 24 часов.In an additional aspect, the invention is characterized in that the product is packaged in sterile portioned containers and kept in a refrigerator for 24 hours.

Другим аспектом предлагаемой группы изобретений является готовый к употреблению продукт на основе целого и цельного зерна овса, полученный предлагаемым способом и характеризующийся тем, что представляет собой пищевую суспензию, в которой равномерно по всей массе распределены целые цельные зерна овса, ферментированные лакто- и бифидобактериями, имеющую pH от 3.8 до 4.4 и следующие физико-химические и микробиологические характеристики:Another aspect of the proposed group of inventions is a ready-to-eat product based on whole and whole oat grains, obtained by the proposed method and characterized in that it is a food suspension in which whole whole oats grains fermented with lacto and bifidobacteria are uniformly distributed over the whole mass, having pH from 3.8 to 4.4 and the following physicochemical and microbiological characteristics:

В дополнительном аспекте изобретение характеризуется тем, что продукт дополнительно содержит вкусовые и нутриционные наполнители.In an additional aspect, the invention is characterized in that the product further comprises flavoring and nutritional excipients.

В отличие от прототипа, предусматривающего немедленную варку и кипение сухого овса в течение не менее 28-30 минут без предварительного замачивания, на практике приводит к тому, что в центре зерна овса могут частично оставаться еще жесткими, а наружные слои могут частично развариться до пастообразного состояния. Предлагаемый способ предусматривает получение продукта на основе целого и цельного зерна овса одним непрерывным циклом от момента промывания овса до созревания продукта в холодильной камере без сушки, замораживания и других промежуточных процессов и продуктов, снижающих пищевую ценность конечного продукта. Кроме того, полученный предлагаемым способом готовый к употреблению продукт содержит целые цельные зерна овса без затрат на их отдельное приготовление, фасовку, хранение и транспортировку.In contrast to the prototype, which provides for the immediate cooking and boiling of dry oats for at least 28-30 minutes without preliminary soaking, in practice, in the center, the oat grains can partially remain still rigid, and the outer layers can partially boil to a pasty state . The proposed method involves obtaining a product based on whole and whole oat grains in one continuous cycle from the moment of washing the oats until the product ripens in the refrigerator without drying, freezing and other intermediate processes and products that reduce the nutritional value of the final product. In addition, the ready-to-eat product obtained by the proposed method contains whole whole oat grains without the cost of their separate preparation, packaging, storage and transportation.

При этом важно отметить, что в предлагаемом способе диапазоны температуры поэтапного замачивания в воде с температурой от 20°C до 62°C подобраны таким образом, чтобы максимально увеличить влажность зерна овса холодной и теплой водой до температуры начала желатинизации крахмалов, составляющей для зерен овса в среднем 62°C. В этом процессе влага постепенно проникает в межклеточные и клеточные структуры без изменения природного состояния крахмалов, белков, жиров и витаминов. Крахмалы зерен овса постепенно набухают и облегчают дальнейшую обработку зерен теплом и водой без подрыва внутренних слоев и без нарушения целостности зерен овса. Общее время процесса поэтапного замачивания, включая время циркуляции, составляет 40-60 минут. Конечная влажность зерна овса составляет в конце процесса поэтапного замачивания от 33 до 38%.It is important to note that in the proposed method, the temperature ranges of stepwise soaking in water with a temperature of from 20 ° C to 62 ° C are selected in such a way as to maximize the moisture content of oat grains with cold and warm water to the temperature of the start of gelatinization of starches, which constitutes for oat grains in average 62 ° C. In this process, moisture gradually penetrates into the intercellular and cellular structures without changing the natural state of starches, proteins, fats and vitamins. Oat grain starches gradually swell and facilitate further processing of the grains with heat and water without undermining the inner layers and without violating the integrity of the oat grains. The total time of the stepwise soaking process, including the circulation time, is 40-60 minutes. The final moisture content of oat grains is at the end of the stepwise soaking process from 33 to 38%.

При циркуляции зерна в заданном количестве холодной воды в начале процесса замачивания создается естественная сила трения зерна о зерно овса, которая позволяет нанести на поверхность цельного целого овса незначительное количество микропор - микротрещин защитного слоя отрубей (перикарпа), которые уже при холодном замачивании создают благоприятные условия повышения доступности проникновения воды внутрь до центра зерновки овса.When grain is circulated in a predetermined amount of cold water, at the beginning of the soaking process, the natural friction force of the grain against the oat grain is created, which allows applying a small amount of micropores to the surface of the whole whole oat - microcracks of the bran protective layer (pericarp), which already create favorable conditions for increasing the accessibility of water penetration inward to the center of the oat grain.

Темперирование цельных целых зерен овса начинается при температуре 80°C, когда все зерна уже максимально увлажнены, максимально набухли и дальнейшая обработка теплом уже не приводит к разрушениям цельного целого овса.Tempering of whole whole oat grains begins at a temperature of 80 ° C, when all the grains are already moistened as much as possible, swollen as much as possible, and further heat treatment no longer leads to destruction of the whole whole oat.

Описанная выше поэтапная обработка зерен овса и подобранные режимы его обработки позволяют достичь того, что продукт имеет в своем составе не просто готовые к употреблению целые цельные злаки овса, а злаки, ферментированные в непрерывном процессе лакто- и бифидобактериями. Состояние проницаемости цельных зерен овса перед ферментацией позволяет получить равномерно ферментированную консистенцию цельных целых зерен овса в суспензии премикса, чему способствует микропористость внешнего слоя цельных целых зерен овса.The step-by-step processing of oat grains described above and the selected modes of its processing allow us to achieve the fact that the product includes not just whole whole oats ready to eat, but cereals fermented in a continuous process by lactobacilli and bifidobacteria. The permeability state of whole oat grains before fermentation allows to obtain a uniformly fermented consistency of whole oat grains in a premix suspension, which is facilitated by the microporosity of the outer layer of whole oat grains.

При этом процесс происходит непрерывно, без промежуточных продуктов - полуфабрикатов и предусматривает поэтапное увлажнения зерна овса и поэтапную обработку температурой, что позволяет получить готовый к употреблению продукт, в котором зерно овса сохраняется целым до его употребления; цельные зерна овса ферментированы в непрерывном процессе. Это наиболее полно сохраняет полезные свойства овса, клеточные структуры и пищевые вещества не претерпевают таких стрессовых режимов дополнительной обработки прерывистого процесса прототипа: давления, высоких температур промежуточной сушки, дробления, помола и т.д.At the same time, the process takes place continuously, without intermediate products - semi-finished products and provides for stage-by-stage moistening of oat grain and stage-by-stage temperature treatment, which makes it possible to obtain a ready-to-eat product in which the oat grain is kept whole until it is consumed; whole oat grains are fermented in a continuous process. This most fully preserves the useful properties of oats, cellular structures and food substances do not undergo such stressful regimes of additional processing of the intermittent prototype process: pressure, high temperatures of intermediate drying, crushing, grinding, etc.

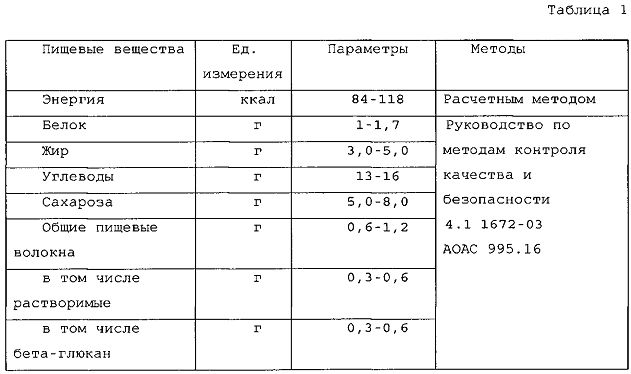

Изобретение иллюстрируется таблицами 1, 2, 3 и 4, в которых представлены показатели и характеристики готового к употреблению пищевого продукта, полученного предлагаемым способом.The invention is illustrated in tables 1, 2, 3 and 4, which presents the indicators and characteristics of the ready-to-eat food product obtained by the proposed method.

В Таблице 1 представлены показатели пищевой ценности готового к употреблению продукта на основе целых цельных зерен овса.Table 1 shows the nutritional values of a ready-to-eat product based on whole whole oat grains.

В Таблице 2 представлены показатели пищевой ценности готового к употреблению продукта на основе целых цельных зерен овса и содержащего вкусовые и нутриционные наполнители.Table 2 presents the nutritional values of a ready-to-eat product based on whole whole oat grains and containing flavoring and nutritional supplements.

В Таблице 3 представлены физико-химические и микробиологические характеристики готового к употреблению продукта на основе целых цельных зерен овса.Table 3 shows the physicochemical and microbiological characteristics of a ready-to-eat product based on whole whole oat grains.

В Таблице 4 представлены органолептические характеристики полученного предлагаемым способом готового к употреблению продукта на основе целых цельных зерен овса.Table 4 presents the organoleptic characteristics of the ready-to-eat product obtained by the proposed method based on whole whole oat grains obtained by the proposed method.

Изобретение иллюстрируется примерами получения предлагаемым способом готового к употреблению продукта на основе целых цельных зерен овса, равномерно распределенных в пищевой суспензии и ферментированных лакто- и бифидобактериями (примеры 1, 2).The invention is illustrated by examples of the preparation of a ready-to-eat product based on whole whole oat grains uniformly distributed in a food suspension and fermented by lacto and bifidobacteria by the proposed method (examples 1, 2).

Необходимо отметить, что процесс производится только при атмосферном давлении, при этом процесс является непрерывным от промывания овса до созревания продукта в холодильной камере.It should be noted that the process is carried out only at atmospheric pressure, while the process is continuous from washing the oats to ripening the product in the refrigerator.

Пример 1. Получение готового пищевого продуктаExample 1. Obtaining the finished food product

Способ осуществляют следующим образом. Вначале 27 кг цельных целых зерен овса промывают их проточной водой с температурой менее 20°C до полного удаления мучели и цветочных пленок. Сливают воду. Влажность зерен овса достигает 25-27%. После чего добавляют к промытому овсу 81 кг воды. Нагревают массу от 20 до 25°C.The method is as follows. First, 27 kg of whole whole oat grains are washed with running water with a temperature of less than 20 ° C until the flour and flower films are completely removed. Drain the water. The moisture content of oat grains reaches 25-27%. Then add 81 kg of water to the washed oats. Heat the mass from 20 to 25 ° C.

Проводят поэтапное замачивание в воде с температурой от 20°C до 62°C и при атмосферном давлении, включающее в себя проведение циркуляции промытого овса и воздействие принудительной силы трения зерен друг о друга до образования микротрещин на внешней оболочке цельного зерна.Phased soaking is carried out in water with a temperature from 20 ° C to 62 ° C and at atmospheric pressure, which includes circulating the washed oats and the effect of forced friction of the grains against each other until microcracks form on the outer shell of the whole grain.

Поэтапное замачивание начинают с проведения циркуляции промытого овса в воде с температурой 20-25°C при соотношении по весу зерна к воде 1:3 и воздействии принудительной силы трения зерен друг о друга путем прохождения зерна по замкнутой системе, включающей танк с мешалкой рамочного типа, насос кулачковый и трубопровод комбинированный с диаметрами, соответствующими 5.08-3.81-5.08 см, в течение 25-35 минут. Общее время поэтапного замачивания составляет 40-60 минут. По завершении процесса поэтапного замачивания влажность целого зерна овса достигает 33-38%. После чего добавляют 27 кг воды.Phased soaking begins with the circulation of washed oats in water with a temperature of 20-25 ° C with a ratio of grain to water weight 1: 3 and the effect of forced friction of grains against each other by passing grain through a closed system, including a tank with a frame type mixer, cam pump and piping combined with diameters corresponding to 5.08-3.81-5.08 cm, for 25-35 minutes. The total phased soaking time is 40-60 minutes. Upon completion of the stepwise soaking process, the moisture content of whole oat grains reaches 33-38%. Then add 27 kg of water.

Проводят темперирование цельных зерен овса в воде с температурой 80°C и при атмосферном давлении в течение 25-35 минут до состояния прежелатинизации крахмалов зерна овса на 85% и конечной влажности зерен овса от 52 до 56%.Whole oat grains are tempered in water at a temperature of 80 ° C and at atmospheric pressure for 25-35 minutes until the pre-gelatinization of oat grain starches by 85% and a final moisture content of oat grains from 52 to 56%.

Приготавливают премикс из злаковых цельных хлопьев из ячменя, пшеницы, ржи и овсяной муки весом - 12 кг. Добавляют сахар, фруктозу, натуральный крахмал, растительное масло, натуральную арому, соль, корицу, ваниль - 37,3 кг. Добавляют к сухой смеси премикса - 215 кг воды с температурой менее 20°C. Замачивают полученную суспензию в течение 30 минут. Смешивают цельные зерна овса с температурой 80°C с водной суспензией премикса с температурой 20°C.Prepare a premix of whole cereal from barley, wheat, rye and oat flour weighing 12 kg. Add sugar, fructose, natural starch, vegetable oil, natural aroma, salt, cinnamon, vanilla - 37.3 kg. Add to the dry premix mix - 215 kg of water with a temperature of less than 20 ° C. Soak the resulting suspension for 30 minutes. Mix whole oat grains with a temperature of 80 ° C with an aqueous suspension of premix with a temperature of 20 ° C.

Варят цельные зерна овса с водной суспензией премикса при температуре 85°C-96°C в течение 10-15 минут. Пастеризуют суспензию при температуре 96°C в течение 10-15 минут. Охлаждают суспензию с применением системы трубчатого теплообменника и непрямым охлаждающим агентом - ледяная вода с температурой 4°C до температуры 38°C-40°C. Инокулируют суспензию смесью лакто и бифидобактерий в количестве 0,01%. Выдерживают полученный продукт в ферментаторе 7-8 часов до рН от 3,8 до 4,4.Whole oat grains are cooked with an aqueous premix suspension at a temperature of 85 ° C-96 ° C for 10-15 minutes. Pasteurize the suspension at a temperature of 96 ° C for 10-15 minutes. The suspension is cooled using a tubular heat exchanger system and indirect cooling agent is ice water with a temperature of 4 ° C to a temperature of 38 ° C-40 ° C. Inoculate the suspension with a mixture of lacto and bifidobacteria in an amount of 0.01%. Maintain the resulting product in the fermenter for 7-8 hours to a pH of from 3.8 to 4.4.

Охлаждают полученный продукт до температуры 10°C-15°C.Cool the resulting product to a temperature of 10 ° C-15 ° C.

Готовый продукт фасуют в асептических условиях в стерильные контейнеры. Продукт помещают в холодильную камеру для созревания в течение 24 часов.The finished product is Packed under aseptic conditions in sterile containers. The product is placed in a refrigerator for maturation for 24 hours.

Показатели пищевой ценности полученного продукта представлены в Таблице 1.Indicators of nutritional value of the resulting product are presented in Table 1.

Пример 2. Получение готового пищевого продукта, содержащего вкусовые и нутриционные наполнителиExample 2. Obtaining a finished food product containing flavoring and nutritional excipients

Продукт готовят аналогично Примеру 1, при этом перед процессом фасовки продукта в асептических условиях в стерильные контейнеры проводят смешивание с используемыми в пищевой промышленности наполнителями (пищевыми наполнителями), такими как пюре фруктовые и/или овощные (уваренные или уваренные с сахаром и другими вкусовыми добавками), и/или концентрированные фруктово-ягодные соки, или жидкие экстракты лечебных трав и т.д.The product is prepared similarly to Example 1, and before the process of filling the product under aseptic conditions in sterile containers, they are mixed with excipients (food excipients) used in the food industry, such as fruit and / or vegetable purees (boiled or boiled with sugar and other flavoring additives) , and / or concentrated fruit and berry juices, or liquid extracts of medicinal herbs, etc.

При этом количество пищевого наполнителя может определяться, например, в следующем соотношении:The amount of food filler can be determined, for example, in the following ratio:

- пюре фруктовые и/или овощные 7-20 мас.%;- fruit and / or vegetable puree 7-20 wt.%;

- концентрированные фруктово-ягодные соки 7-15 мас.%;- concentrated fruit and berry juices 7-15 wt.%;

- жидкие экстракты лечебных трав 3-7 мас.%.- liquid extracts of herbs 3-7 wt.%.

Показатели пищевой ценности полученного продукта, содержащего вкусовые и нутриционные наполнители, представлены в Таблице 2.Indicators of nutritional value of the obtained product containing flavoring and nutritional excipients are presented in Table 2.

Продукт, полученный предлагаемым способом, характеризуется показателями, представленными в таблицах 3 и 4.The product obtained by the proposed method is characterized by the indicators presented in tables 3 and 4.

В результате осуществления предлагаемого способа получают готовый к употреблению продукт, содержащий цельный овес, ферментированный живыми лакто- и бифидобактериями и обработанный их метаболитами. При этом конечная влажность зерен овса составляет 50-80%, преимущественно 70-75% по весу; цельный овес сохраняет целостность зерен на 80-95%, преимущественно не менее чем 80% зерен овса по влажной массе; массовая доля цельных целых зерен овса в готовом продукте составляет не менее 35% по весу.As a result of the implementation of the proposed method, a ready-to-eat product is obtained containing whole oats, fermented with live lacto and bifidobacteria and processed with their metabolites. In this case, the final moisture content of oat grains is 50-80%, mainly 70-75% by weight; whole oats maintain grain integrity by 80-95%, mainly not less than 80% of oat grains by wet weight; the mass fraction of whole oat grains in the finished product is at least 35% by weight.

Приведенные примеры подтверждают достижение технического результата, поскольку в готовом к употреблению продукте зерно овса остается целым путем применения поэтапной обработки промытых зерен овса водой и теплом выбранными режимами, включая режимы циркуляции в воде при выбранном соотношении зерна и воды для нанесения на поверхность целого зерна микротрещин природного защитного слоя отрубей-перикарпа. Это создает условия повышенной доступности проникновения воды внутрь зерновки овса уже на стадии замачивания в холодной воде и далее их обработку ферментами для придания целым цельным зернам овса всех свойств ферментированного злакового продукта.The given examples confirm the achievement of the technical result, since the oat grain in the ready-to-eat product remains the whole by applying the stepwise treatment of washed oat grains with water and heat in the selected modes, including the modes of circulation in water at the selected ratio of grain to water for applying natural protective microcracks to the surface of the whole grain pericarp bran layer. This creates conditions for increased accessibility of water penetration into the oat grains already at the stage of soaking in cold water and then their processing with enzymes to give whole whole oat grains all the properties of the fermented cereal product.

Claims (13)

- промывание зерна холодной водой;

- поэтапное замачивание в воде с температурой от 20°C до 62°C и при атмосферном давлении с предварительным проведением циркуляции смеси зерен овса и воды до образования микротрещин на внешней оболочке цельного зерна и влажности зерна овса от 33 до 38%;

- темперирование цельных зерен овса проводят в воде с температурой 80°C и при атмосферном давлении;

- смешивание с предварительно подготовленной пищевой вкусовой и/или нутриционной суспензией;

- при этом варку цельных зерен овса в суспензии проводят до уровня желатинизации крахмалов 100%;

- пастеризацию цельных зерен овса в суспензии до полного уничтожения вегетативной микрофлоры;

- охлаждение пастеризованной суспензии проводят до температуры ферментации;

- инокулирование охлажденной суспензии закваской, содержащей живые бактерии;

- ферментацию лакто- и бифидобактериями до значений pH от 3,8 до 4,4;

- охлаждение ферментированного продукта.1. A method of obtaining a ready-to-eat product based on whole and whole oat grains, comprising wetting the grain with water and cooking, characterized in that the following stages are carried out:

- washing the grain with cold water;

- stepwise soaking in water with a temperature of from 20 ° C to 62 ° C and at atmospheric pressure with preliminary circulating a mixture of oat and water grains until microcracks form on the outer shell of the whole grain and the moisture content of oat grain is from 33 to 38%;

- tempering of whole oat grains is carried out in water with a temperature of 80 ° C and at atmospheric pressure;

- mixing with a pre-prepared food flavoring and / or nutritional suspension;

- while cooking whole oat grains in suspension is carried out to a level of gelatinization of starches 100%;

- pasteurization of whole oat grains in suspension until the complete destruction of the vegetative microflora;

- cooling the pasteurized suspension is carried out to a fermentation temperature;

- inoculation of the cooled suspension with a starter culture containing live bacteria;

- fermentation of lactobacilli and bifidobacteria to pH values from 3.8 to 4.4;

- cooling the fermented product.

Priority Applications (2)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| RU2014121748/13A RU2558191C1 (en) | 2014-05-28 | 2014-05-28 | Unground whole oat grain product ready for consumption and such product manufacture method |

| PCT/RU2015/000335 WO2015183138A1 (en) | 2014-05-28 | 2015-05-27 | Integral whole oat grain based ready-to-eat product and a method for producing the same |

Applications Claiming Priority (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| RU2014121748/13A RU2558191C1 (en) | 2014-05-28 | 2014-05-28 | Unground whole oat grain product ready for consumption and such product manufacture method |

Publications (1)

| Publication Number | Publication Date |

|---|---|

| RU2558191C1 true RU2558191C1 (en) | 2015-07-27 |

Family

ID=53484119

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| RU2014121748/13A RU2558191C1 (en) | 2014-05-28 | 2014-05-28 | Unground whole oat grain product ready for consumption and such product manufacture method |

Country Status (2)

| Country | Link |

|---|---|

| RU (1) | RU2558191C1 (en) |

| WO (1) | WO2015183138A1 (en) |

Cited By (4)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| RU2630294C1 (en) * | 2016-12-28 | 2017-09-06 | Вячеслав Анатольевич Криви | Method for production of cultured milk product |

| RU2734461C2 (en) * | 2017-06-13 | 2020-10-16 | Наталья Ивановна Светогорова | Oat product of functional purpose (versions) |

| RU2790676C1 (en) * | 2021-09-17 | 2023-02-28 | Общество С Ограниченной Ответственностью "Пробиодукты" | Plant-based probiotic composition and method for its obtaining |

| WO2023043340A1 (en) | 2021-09-17 | 2023-03-23 | Общество С Ограниченной Ответственностью "Пробиодукты" | Plant-based probiotic composition and method of producing same |

Families Citing this family (4)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| NL2016115B1 (en) * | 2016-01-18 | 2017-07-25 | Innoso B V | Food composition with fermented starch. |

| US20180327792A1 (en) * | 2017-05-10 | 2018-11-15 | The Quaker Oats Company | Fermented Hydrolyzed Plant-Origin Material |

| CN116210767B (en) * | 2021-12-06 | 2024-06-25 | 内蒙古蒙牛乳业(集团)股份有限公司 | Oat granule treatment method for beverage, oat milk and preparation method |

| CN114304487A (en) * | 2022-01-13 | 2022-04-12 | 兰州工业研究院 | Processing method of instant oat sweet fermented grains |

Citations (4)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| WO1991017672A1 (en) * | 1990-05-18 | 1991-11-28 | Hannu Salovaara | Food product containing dietary fiber and method of making said product |

| US6287626B1 (en) * | 1997-10-10 | 2001-09-11 | Joseph R. Fox | Method of processing multiple whole grain mixtures and products therefrom |

| RU2348178C1 (en) * | 2007-12-10 | 2009-03-10 | Государственное образовательное учреждение высшего профессионального образования "Орловский государственный технический университет (ОрелГТУ) | Method of manufacturing of food products from grain |

| RU2395212C2 (en) * | 2005-04-29 | 2010-07-27 | КРАФТ ФУДЗ ГЛОБАЛ БРЭНДС ЭлЭлСи | Production of crushed whole grains products |

Family Cites Families (8)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US3345183A (en) | 1964-05-18 | 1967-10-03 | Quaker Oats Co | Process for producing ready-to-eat oat cereals |

| US4413018A (en) | 1981-06-01 | 1983-11-01 | The Quaker Oats Company | Method for preparing whole grain oat product |

| RU2189153C2 (en) | 2000-01-11 | 2002-09-20 | Щинов Андрей Иванович | Method of preparing biologically active product |

| AU2002233258A1 (en) * | 2000-12-15 | 2002-06-24 | Societe Des Produits Nestle S.A. | Method for producing a composition having a fruity taste |

| SE0200735D0 (en) | 2002-03-13 | 2002-03-13 | Raisio Group Plc | Food and feed composition and process |

| RU2332113C1 (en) | 2006-12-25 | 2008-08-27 | Веллеоутс Лимитед | Bio-oat drinkable food product |

| AU2008308899B2 (en) | 2007-09-30 | 2013-07-11 | Kellanova | Shredded ready-to-eat cereal with oats |

| MX2013012618A (en) * | 2012-10-26 | 2016-05-26 | María Del Carmen Cadena Garcia | Method of manufacturing a fermented product. |

-

2014

- 2014-05-28 RU RU2014121748/13A patent/RU2558191C1/en active

-

2015

- 2015-05-27 WO PCT/RU2015/000335 patent/WO2015183138A1/en active Application Filing

Patent Citations (4)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| WO1991017672A1 (en) * | 1990-05-18 | 1991-11-28 | Hannu Salovaara | Food product containing dietary fiber and method of making said product |

| US6287626B1 (en) * | 1997-10-10 | 2001-09-11 | Joseph R. Fox | Method of processing multiple whole grain mixtures and products therefrom |

| RU2395212C2 (en) * | 2005-04-29 | 2010-07-27 | КРАФТ ФУДЗ ГЛОБАЛ БРЭНДС ЭлЭлСи | Production of crushed whole grains products |

| RU2348178C1 (en) * | 2007-12-10 | 2009-03-10 | Государственное образовательное учреждение высшего профессионального образования "Орловский государственный технический университет (ОрелГТУ) | Method of manufacturing of food products from grain |

Cited By (4)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| RU2630294C1 (en) * | 2016-12-28 | 2017-09-06 | Вячеслав Анатольевич Криви | Method for production of cultured milk product |

| RU2734461C2 (en) * | 2017-06-13 | 2020-10-16 | Наталья Ивановна Светогорова | Oat product of functional purpose (versions) |

| RU2790676C1 (en) * | 2021-09-17 | 2023-02-28 | Общество С Ограниченной Ответственностью "Пробиодукты" | Plant-based probiotic composition and method for its obtaining |

| WO2023043340A1 (en) | 2021-09-17 | 2023-03-23 | Общество С Ограниченной Ответственностью "Пробиодукты" | Plant-based probiotic composition and method of producing same |

Also Published As

| Publication number | Publication date |

|---|---|

| WO2015183138A1 (en) | 2015-12-03 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| RU2558191C1 (en) | Unground whole oat grain product ready for consumption and such product manufacture method | |

| Capriles et al. | Novel approaches in gluten‐free breadmaking: interface between food science, nutrition, and health | |

| ES2335783T3 (en) | FERMENTED PRODUCT WITHOUT LACTOSE FROM DRY FRUIT SHAKE WITHOUT VEGETABLES AND / OR HORCHATA. | |

| AU2007338362B2 (en) | A probiotic oat-based food product and process for making the same | |

| US20160192682A1 (en) | Formulation and process for making fermented probiotic food and beverage products | |

| Kumari et al. | Development of a rice incorporated synbiotic yogurt with low retrogradation properties. | |

| KR20160134202A (en) | Rice bread and rice fermented composition having superior effect of aging-retardation and manufacturing method thereof | |

| KR102062196B1 (en) | Manufacturing method for cheese baguette bread and cheese baguette bread manufactured by the same | |

| WO2020031143A1 (en) | Food preparations based on whole grain gluten-free cereals and method for preparation thereof | |

| JP2011092119A (en) | Layered dough containing soy protein fermentation liquor | |

| CN104886334A (en) | Probiotic glutinous rice skin ice cream and a preparation method thereof | |

| CN103948043A (en) | Food mixed with bacillus natto, food powder bag and preparation method thereof | |

| CN105851879A (en) | Oat-based probiotic food with effects of clearing heat, maintaining beauty and promoting appetite and preparation method thereof | |

| JP2011182750A (en) | Grain powder-processed product, and method for producing grain powder-processed product | |

| CN108887385A (en) | A kind of production method of the fine prebiotic Yoghourt of the height of unique flavor | |

| RU2332113C1 (en) | Bio-oat drinkable food product | |

| KR101260205B1 (en) | Steamed bread comprising sprouting grains and manufacturing method thereof | |

| CN106213180A (en) | A kind of heat clearing away skin care appetizing Herba bromi japonici probiotic food and preparation method thereof | |

| CN106418176A (en) | Pumpkin seed oil instant sliced noodles | |

| CN106213181A (en) | A kind of heat clearing away appetizing Herba bromi japonici anti-aging food and preparation method thereof | |

| EP3476221B1 (en) | Method for preparing a food product from oat flour and product thus obtained | |

| CN105145720A (en) | Foodstuff starter, preparation method thereof and application method thereof | |

| KR102475685B1 (en) | Restorative rice and manufacturing method thereof | |

| RU2728408C1 (en) | Method of preparation for storage and consumption of fermented and non-fermented grain components | |

| Arslan et al. | Probiotic cereal-based fermented functional foods |