KR860001881B1 - Light weight joint compound - Google Patents

Light weight joint compound Download PDFInfo

- Publication number

- KR860001881B1 KR860001881B1 KR1019830005835A KR830005835A KR860001881B1 KR 860001881 B1 KR860001881 B1 KR 860001881B1 KR 1019830005835 A KR1019830005835 A KR 1019830005835A KR 830005835 A KR830005835 A KR 830005835A KR 860001881 B1 KR860001881 B1 KR 860001881B1

- Authority

- KR

- South Korea

- Prior art keywords

- binder

- light

- filler

- dry weight

- weight

- Prior art date

Links

Classifications

-

- C—CHEMISTRY; METALLURGY

- C09—DYES; PAINTS; POLISHES; NATURAL RESINS; ADHESIVES; COMPOSITIONS NOT OTHERWISE PROVIDED FOR; APPLICATIONS OF MATERIALS NOT OTHERWISE PROVIDED FOR

- C09K—MATERIALS FOR MISCELLANEOUS APPLICATIONS, NOT PROVIDED FOR ELSEWHERE

- C09K3/00—Materials not provided for elsewhere

- C09K3/10—Materials in mouldable or extrudable form for sealing or packing joints or covers

-

- C—CHEMISTRY; METALLURGY

- C04—CEMENTS; CONCRETE; ARTIFICIAL STONE; CERAMICS; REFRACTORIES

- C04B—LIME, MAGNESIA; SLAG; CEMENTS; COMPOSITIONS THEREOF, e.g. MORTARS, CONCRETE OR LIKE BUILDING MATERIALS; ARTIFICIAL STONE; CERAMICS; REFRACTORIES; TREATMENT OF NATURAL STONE

- C04B26/00—Compositions of mortars, concrete or artificial stone, containing only organic binders, e.g. polymer or resin concrete

- C04B26/02—Macromolecular compounds

- C04B26/04—Macromolecular compounds obtained by reactions only involving carbon-to-carbon unsaturated bonds

-

- C—CHEMISTRY; METALLURGY

- C09—DYES; PAINTS; POLISHES; NATURAL RESINS; ADHESIVES; COMPOSITIONS NOT OTHERWISE PROVIDED FOR; APPLICATIONS OF MATERIALS NOT OTHERWISE PROVIDED FOR

- C09K—MATERIALS FOR MISCELLANEOUS APPLICATIONS, NOT PROVIDED FOR ELSEWHERE

- C09K3/00—Materials not provided for elsewhere

- C09K3/10—Materials in mouldable or extrudable form for sealing or packing joints or covers

- C09K3/1006—Materials in mouldable or extrudable form for sealing or packing joints or covers characterised by the chemical nature of one of its constituents

- C09K3/1015—Polysaccharides or derivatives thereof

-

- C—CHEMISTRY; METALLURGY

- C09—DYES; PAINTS; POLISHES; NATURAL RESINS; ADHESIVES; COMPOSITIONS NOT OTHERWISE PROVIDED FOR; APPLICATIONS OF MATERIALS NOT OTHERWISE PROVIDED FOR

- C09K—MATERIALS FOR MISCELLANEOUS APPLICATIONS, NOT PROVIDED FOR ELSEWHERE

- C09K2200/00—Chemical nature of materials in mouldable or extrudable form for sealing or packing joints or covers

- C09K2200/02—Inorganic compounds

- C09K2200/0217—Salts

- C09K2200/023—Sulfur-containing compounds

-

- C—CHEMISTRY; METALLURGY

- C09—DYES; PAINTS; POLISHES; NATURAL RESINS; ADHESIVES; COMPOSITIONS NOT OTHERWISE PROVIDED FOR; APPLICATIONS OF MATERIALS NOT OTHERWISE PROVIDED FOR

- C09K—MATERIALS FOR MISCELLANEOUS APPLICATIONS, NOT PROVIDED FOR ELSEWHERE

- C09K2200/00—Chemical nature of materials in mouldable or extrudable form for sealing or packing joints or covers

- C09K2200/02—Inorganic compounds

- C09K2200/0239—Oxides, hydroxides, carbonates

-

- C—CHEMISTRY; METALLURGY

- C09—DYES; PAINTS; POLISHES; NATURAL RESINS; ADHESIVES; COMPOSITIONS NOT OTHERWISE PROVIDED FOR; APPLICATIONS OF MATERIALS NOT OTHERWISE PROVIDED FOR

- C09K—MATERIALS FOR MISCELLANEOUS APPLICATIONS, NOT PROVIDED FOR ELSEWHERE

- C09K2200/00—Chemical nature of materials in mouldable or extrudable form for sealing or packing joints or covers

- C09K2200/02—Inorganic compounds

- C09K2200/0243—Silica-rich compounds, e.g. silicates, cement, glass

-

- C—CHEMISTRY; METALLURGY

- C09—DYES; PAINTS; POLISHES; NATURAL RESINS; ADHESIVES; COMPOSITIONS NOT OTHERWISE PROVIDED FOR; APPLICATIONS OF MATERIALS NOT OTHERWISE PROVIDED FOR

- C09K—MATERIALS FOR MISCELLANEOUS APPLICATIONS, NOT PROVIDED FOR ELSEWHERE

- C09K2200/00—Chemical nature of materials in mouldable or extrudable form for sealing or packing joints or covers

- C09K2200/02—Inorganic compounds

- C09K2200/0243—Silica-rich compounds, e.g. silicates, cement, glass

- C09K2200/0252—Clays

-

- C—CHEMISTRY; METALLURGY

- C09—DYES; PAINTS; POLISHES; NATURAL RESINS; ADHESIVES; COMPOSITIONS NOT OTHERWISE PROVIDED FOR; APPLICATIONS OF MATERIALS NOT OTHERWISE PROVIDED FOR

- C09K—MATERIALS FOR MISCELLANEOUS APPLICATIONS, NOT PROVIDED FOR ELSEWHERE

- C09K2200/00—Chemical nature of materials in mouldable or extrudable form for sealing or packing joints or covers

- C09K2200/06—Macromolecular organic compounds, e.g. prepolymers

- C09K2200/0615—Macromolecular organic compounds, e.g. prepolymers obtained by reactions only involving carbon-to-carbon unsaturated bonds

- C09K2200/0622—Polyvinylalcohols, polyvinylacetates

-

- C—CHEMISTRY; METALLURGY

- C09—DYES; PAINTS; POLISHES; NATURAL RESINS; ADHESIVES; COMPOSITIONS NOT OTHERWISE PROVIDED FOR; APPLICATIONS OF MATERIALS NOT OTHERWISE PROVIDED FOR

- C09K—MATERIALS FOR MISCELLANEOUS APPLICATIONS, NOT PROVIDED FOR ELSEWHERE

- C09K2200/00—Chemical nature of materials in mouldable or extrudable form for sealing or packing joints or covers

- C09K2200/06—Macromolecular organic compounds, e.g. prepolymers

- C09K2200/068—Containing also other elements than carbon, oxygen or nitrogen in the polymer main chain

- C09K2200/0685—Containing silicon

Abstract

Description

본 발명은 인접한 석고벽판(gypsum wallboard)사이의 이음매(joint)를 메우고 도포하는데 사용하기 위한 결합제에 관한 것으로, 특히 통상의 결합제보다 중량이 가벼우며 모래치기(sandability) 에 보다 좋고 운송비용이 절감되고 콘테이너조작 및 도구이용이 용이하며 마지막 모래질(sanding) 및 벽판이음매의 마무리에 용이한 결합제에 관한 것이다.FIELD OF THE INVENTION The present invention relates to a binder for use in filling and applying joints between adjacent gypsum wallboards, and in particular, is lighter in weight than conventional binders, better sandability and reduced transportation costs. It relates to a binder that is easy to operate and tool and is easy to finish sanding and finishing of wallboard joints.

빌딩건축에 있어서, 가장 보편적인 요소의 하나는 벽 및/혹은 천정공사에 사용되는 통상적으로 "건조벽(dry wall)"이라고 알려져 있는 석고벽판이다.In building construction, one of the most common elements is gypsum wallboard, commonly known as a "dry wall" used for walls and / or ceilings.

석고벽판으로 만들어진 벽은 통상적으로 패널을 샛기둥이나 이음매에 붙이고 "결합제(joint compoumd)" 라고 불리우는 특별히 제조된 접착제로써 이음매를 채우고, 도포하므로써 이루어진다. 이 공정은 대개 다음 형태로 진행한다.Walls made of gypsum wallboard are usually made by attaching panels to a jaw or seam and filling and applying the seams with a specially prepared adhesive called "joint compoumd". This process usually proceeds in the following form.

즉, 테이핑결합도의(taping grade)결합제를 벽판의 인접 가장자리에 의해 형성된 이음매내부에 놓고, 액체투과가능한 테이프를 테이핑결합제 내부에 채운다.That is, a tapping grade binder is placed inside the seam formed by the adjacent edges of the wallboard, and the liquid permeable tape is filled inside the taper binder.

건조되면(혹은 응결되면), 토핑 결합도의(topping grade)결합제를 포함하는 2차도포가 이음새위에 행하여진다. 가볍게 모래질이 된뒤 3차도포가 행하여지며 통상적방법으로 마무리 된다.Once dried (or condensed), a secondary coating containing a topping grade binder is made on the seam. After being lightly sanded, tertiary application is carried out and finished in the usual way.

다른 결합도의(Grade) 결합제는 테이프 매립(embedding)및 마무리도포로써 사용되는 문자그대로 다목적의 것이다. 몇몇 경우에 있어, 무늬효과가 마무리된 벽에 주어지면 다목적 결합제와 합하여 그결과 질감있는 마무리(textured finish)를 제공한다. 과거에 있어서 결합제의 여러결합도(grade)사이의 일차적인 차이는 성분요소의 조성비의 차이에 있었다.Other grade binders are literally versatile, used as tape embedding and finishing applications. In some cases, when a patterning effect is given to a finished wall, it combines with a multipurpose binder to provide a textured finish. In the past, the primary difference between the different grades of binders was the difference in the composition ratio of the components.

어떠한 결합도에 있어서도 결합제는 항상 충진재와 접착재를 포함한다. 테이핑 결합도에서는 토핑 결합도에서보다 더많은 접합제가 사용된다. 전형적인 충진재는 탄산칼슘, 칼슘 설페이트 헤미하이드레이트 혹은 칼슘설페이트 디 하이드레이트이다.In any bond, the binder always includes filler and adhesive. In the taping bond more binder is used than in the topping bond. Typical fillers are calcium carbonate, calcium sulfate hemihydrate or calcium sulfate dihydrate.

명백한 선택은 결합제가 건조에 의해 견고해지느냐 아니면 응결에 의해 견고해지느냐에 따라 결정된다. 응결형 결합제의 예는 미국특허 제3297601호에 나와있다. 미국특허 제Re29753호에서의 결합제는 석면이 제기되고 석면섬유의 사용에 의해 미리 얻어진 비평준성(non-leveling properties)을 제공하기 위하여 점토(attapulgus clay)를 사용하는 것으로 알려져 있다. 점토(attapulgus clay)를 사용한 혹은 사용하지 않은 종래의 결합제는 성능면에서는 우수하나 이들은 중량이 매우 무거우며 운송비가 많이든다. 또한 이들은 건조될때 단단한 질감을 가지며 매끈한 표면을 가진 이음새처리를 제공하기 위한 모래질이 어려운 것이다. 따라서 종래의 결합제보다 가볍고, 건조시 매끈한 표면을 제공하기 위하여 모래질이 쉽게되는 결합제가 요구되는 것이다.The obvious choice depends on whether the binder is hardened by drying or by condensation. Examples of coagulating binders are found in US Pat. No. 3297601. The binder in US Pat. No. Re29753 is known to use clay to provide asbestos and to provide non-leveling properties previously obtained by the use of asbestos fibers. Conventional binders with or without clay clay are excellent in performance but they are very heavy and expensive to transport. They are also difficult to sand to provide seams with a smooth texture and smooth surface when dried. Therefore, there is a need for a binder that is lighter than a conventional binder and that is easily sanded in order to provide a smooth surface when dried.

본 발명의 목적은 석면이 제외된 결합제를 제공하는 것이다. 또한 일반적으로 결합제에 요구되는 비평준성, 비균열성(non-cracking) 및 양호한 접착성 같은 뛰어난 성질을 가진 결합제를 제공하는데 있다. 또 다른 본 발명의 목적은 종래의 결합제보다 중량이 가볍고 저렴한 가격으로 운반가능한 결합제를 제공하는데 있다. 또한 건조후 매끈한 마무리를 위하여 쉽게 모래질되는 형태의 결합제를 제공하는데 있다.It is an object of the present invention to provide a binder without asbestos. It is also to provide a binder having excellent properties such as non-leveling, non-cracking and good adhesion generally required for the binder. Another object of the present invention is to provide a binder that is lighter in weight than the conventional binder and can be transported at a lower price. It is also to provide a binder of the easily sanded form for a smooth finish after drying.

비균열성 및 뛰어난 접착성을 제공하는 것은 부가적인 목적이다. 본 발명의 제목적 및 장점들은 다음 기술을 참고로 명백하게 될 것이다. 본 발명에 따라서, 탄산칼슘, 칼슘 설페이트 디하이드레이트 또는 칼슘설페이트 헤미하이드레이트와 같은 충진재, 폴리비닐아세테이트와 같은 접합재, 점토(attapulgus clay)와 같은 비평준화 및 슬립제공물질, 하이드록시프로필메틸셀룰로우즈와 같은 보수제 또는 농조화제 및 특수처리된 팽창퍼얼라이트(expanded perlite)를 포함하는 조성을 조형화함에 의하여 석면이 필요없는, 매우 가벼운 중량의 신규결합제가 제공된다.Providing non-crackability and good adhesion is an additional object. The title and advantages of the present invention will become apparent with reference to the following description. According to the present invention, fillers such as calcium carbonate, calcium sulfate dihydrate or calcium sulfate hemihydrate, binders such as polyvinylacetate, non-leveling and slip-providing materials such as claypulgus clay, and hydroxypropylmethylcellulose By formulating a composition comprising a repair or thickening agent and a specially treated expanded perlite, asbestos-free new binders are provided that are asbestos free.

퍼얼라이트의 존재는 실제적으로 결합제의 밀도를 줄이며 운송비용을 절감케한다. 나아가 물과 혼합시 그 구성은 뛰어난 성질을 가진, 건조시 쉽게 모래질되어 매끈한 마무리를 가지는 결합제를 제공한다. 본발명 경량 결합제의 제1성분은 팽창된, 특수처리된 퍼얼라이트이다. 퍼얼라이트는 흑요석(黑曜石)과 비슷한 유리질암석형태이다. 일반적으로 이는 65-75% SiO2, 10-20% Al2O3, 2-5% H2O 및 소량의 소오다, 포타시(potash) 및 석회로 이루어져 있다. 퍼얼라이트가 연화점까지 가열되면, 이는 창팽하여 부석(浮石)과 비슷한 가벼운 솜털모양의 부풀은 물질을 형성한다.The presence of pearlite actually reduces the density of the binder and saves transportation costs. Furthermore, when mixed with water, the composition provides a binder having excellent properties, which is easily sanded upon drying and has a smooth finish. The first component of the lightweight binder of the present invention is an expanded, specially treated pearlite. Pearlite is a glassy rock form similar to obsidian. Generally it consists of 65-75% SiO 2 , 10-20% Al 2 O 3 , 2-5% H 2 O and small amounts of soda, potash and lime. When the pearlite is heated to a softening point, it expands and forms a light, fluffy, swelling material that resembles pumice.

본 발명에 사용하기 위한 퍼얼라이트제조에 있어 이것은 우선 크기가 -200메쉬(mesh)보다 미세하게 연마분쇄된다. 분쇄된 퍼얼라이트는 그 다음 약 1500℉의 온도로 가열된다. 이 공정은 퍼얼라이트 팽창기내에서 우선 공기를 1500℉까지 가열하므로써 행하여진다. 미세하게 연마된 퍼얼라이트는 그 다음 가열공기속으로 도입된다. 가열공기에 의해 운반되면서 이는 가열되고 팝콘같이 튀겨진다. 팽창 퍼얼라이트는 아주 가벼운 물질이다. 그러나 이것은 많은 미세한 홈 및 갈라진 틈이있다. 그리고 물에 닿게되면 물이 이 홈및 갈라진 틈으로 침투해들어가서 퍼얼라이트의 공기로 가득찬 공동(空洞)으로 들어간다. 따라서, 팽창 퍼얼라이트를 결합제로 만드는데 사용하기 이전에 이것은 우선 물에 영양받지 않도록 처리되어야 한다. 이는 여러가지 방법중 한가지로 행할수가 있다. 바람직한 방법은 팽창 된 퍼얼라이트를 균열이나 틈새를 막는 실리콘화합물로 처리하는 것이다.In the production of pearlite for use in the present invention, it is first ground to a finer size than -200 mesh. The pulverized pearlite is then heated to a temperature of about 1500 ° F. This process is done by first heating the air to 1500 ° F. in the pearlite expander. Finely ground pearlite is then introduced into the heated air. Transported by heated air, it is heated and fried like popcorn. Expanded pearlite is a very light substance. But this has many fine grooves and cracks. When it comes in contact with water, it penetrates into these grooves and cracks and enters the cavity filled with the air of the pearlite. Therefore, prior to use to make expanded pearlite into a binder, it must first be treated in a water-free manner. This can be done in one of several ways. The preferred method is to treat the expanded pearlite with a silicone compound that prevents cracks and crevices.

바람직한 실리콘 화합물은 물로희석가능한 폴리디메틸 실록산(poly dimethyl siloxane)의 에멀젼이다. 이 실리콘 화합물은 분무 또는 침지에 의해 팽창 퍼얼라이트에 사용된다. 이 실리콘 화합물은 약 300℉에서 약 5분간 처리된다.Preferred silicone compounds are emulsions of poly dimethyl siloxane dilutable with water. This silicone compound is used in expanded pearlite by spraying or dipping. This silicone compound is treated for about 5 minutes at about 300 ° F.

설비작동에 있어서, 실리콘 화합물은 처리실에 있을때 및 뜨거운 상태에서 팽창된 퍼얼라이트에 사용될 수 있다. 그리고 나서 실리콘 화합물은 상승온도의 결과로써 고온 처리된다. 물에 영향받지 않은 퍼얼라이트가 되게하는 다른 방법은 미국특허3658564에 나타나 있는데, 이에 의하면 퍼얼라이트는 나트륨이나 포타슘실리게이트로 처리하므로써 물에 영향받지 않게된다.In plant operation, silicone compounds can be used in expanded pearlite when in a process chamber and in a hot state. The silicon compound is then hot treated as a result of the elevated temperature. Another method for making water unaffected perlite is shown in US Patent 3658564, whereby the pearlite is not affected by water by treatment with sodium or potassium silicate.

본 발명의 두번째 성분은 충진재(filler)이다. 이분야에서 알려진 어떠한 통상적인충진재도 사용가능하다. 바람직한 충진재는 잘게 분쇄된 탄산칼슘이다. 사용가능한 다른 충진재는 칼슘 설페이트 디하이레이트 및 칼슘설페이트 헤미 하이드레이트이다. 덧붙여서 운모, 활석, 피로필라이트(pyrophylite), 견운모, 규조토 및 고령토 같은 점토를 앞서의 충진재와 함께 사용할 수 있다.The second component of the invention is a filler. Any conventional filler known in the art may be used. Preferred fillers are finely ground calcium carbonate. Other fillers that can be used are calcium sulfate dihydrate and calcium sulfate hemi hydrate. In addition, clays such as mica, talc, pyrophylite, biotite, diatomaceous earth, and kaolin can be used with the preceding fillers.

본 발명의 세번째성분은 비평준화제(non-leveling agent)이다. 바람직한 비평준화제는 점토(attapulgusclay)이다. 그밖의 다른 비평준화제는 아미로팩틴전분(amylopectin starch)을 여러가지 질점토와 개중량비로 5 : 1로 혼합한 혼합체이다. 또 다른 사용가능한 비평준화제는 여러종류의 벤토 나이트이다. 비평준화제는 결합제에 요변성(thixotropicity)같은 일종의 유동적인 성질을 부여한다.The third component of the present invention is a non-leveling agent. Preferred leveling agents are clays (attapulgusclay). Another leveling agent is a mixture of amylopectin starch 5: 1 in various weight clays and weight ratios. Another usable leveling agent is various types of bentonite. Leveling agents impart a kind of fluidity property such as thixotropicity to the binder.

나아가 팽창 퍼얼라이트자체도 상당한 정도로까지 바람직한 유동학적인 성질이 기여한다는 것이 발견되었다. 결합제에 있어서 요구되는 다른 물질은 농조화제이다. 통상의 농조화제는 하이드록시프로필 메틸 셀룰로우즈, 하이드록시 에틸셀룰로우즈, 하이드록시에틸메틸 셀룰로우즈 및 소디움카복시메틸 셀룰로우즈등이다. 농조화제는 단독으로 사용될 수 있고 혹은 상호 연합하여 사용될 수도 있다.Furthermore, it has been found that the expanded pearlite itself contributes to a considerable extent desirable rheological properties. Another material required for the binder is a thickening agent. Typical thickening agents are hydroxypropyl methyl cellulose, hydroxy ethyl cellulose, hydroxyethylmethyl cellulose and sodium carboxymethyl cellulose and the like. Thickening agents may be used alone or in combination with each other.

결합제에 요구되는 다른 성분은, 특히 건조화합물인 경우, 접합재(Binde)이다. 바람직한 접합재는 폴리비닐아세테이트이다. 사용가능한 다른 접합재는 폴리비닐알콜, 에틸렌 비닐 아세테이트공중합체, 비닐 아크릴 공중합체, 스티렌-부타디엔 공중합체, 다른 아크릴 중합체 및 전분이다. 결합제에 일반적으로 사용되는 부가성분은 방부제, 습윤제, 탈거품제 및 가소제이다.Another component required for the binder is a binder, especially when it is a dry compound. Preferred bonding material is polyvinylacetate. Other binders that can be used are polyvinyl alcohol, ethylene vinyl acetate copolymers, vinyl acrylic copolymers, styrene-butadiene copolymers, other acrylic polymers, and starches. Additives commonly used in binders are preservatives, wetting agents, stripping agents and plasticizers.

[실시예 1-6]Example 1-6

하기 도표 1에는 실시예 1-6에서 제조되는 결합제의 여러가지 조성비(formulation)가 나타나 있다.Table 1 below shows the different formulations of the binder prepared in Examples 1-6.

실시예 1-6의 결합제는 실험실규모로서 제조되었다. 결합제를 제조하는데 있어 접합재 및 방부제가 먼저 혼합보울(bowl)에서 물과 함께혼합된다. 그리고나서 건조 분말성분이 추가된다.The binder of Examples 1-6 was prepared on a laboratory scale. In preparing the binder, the binder and preservative are first mixed with water in a mixing bowl. Then dry powder component is added.

이 성분들은 짧은 시간동안 손으로써 일차 혼합된 다음 호바르트 N-50부억용믹서기(Hobart N-50 Kitchen mixer)에 넣어진다. 이 조성물들은 5분동안 함께 혼합되고, 보울을 닦고, 그리고 나서 추가로 10분동안 혼합된다. 이에 소망 정도를 맞추기 위해 물을 첨가한다. 이 물질은 그뒤 공기를 제거하기 위하여 약 4분동안 15인치의 한란계(merury)에서 처리된후 점도를 조정하여 측정한다. 제조된 결합제는 결합제로써 요구되는 여러가지 성질에 대하여 검사되었다.These ingredients are first mixed by hand for a short time and then placed in a Hobart N-50 Kitchen mixer. These compositions are mixed together for 5 minutes, wipe the bowl, and then for an additional 10 minutes. Add water to meet your wishes. This material is then measured by adjusting the viscosity after treatment in a 15 inch merry for about 4 minutes to remove the air. The binders prepared were tested for various properties required as binders.

상기표 1에서 표시된 물질중 "코산(cosan 158)"은 코산화학(주)(Cosan Chemical Company)에서 살균제로 제조판매되는 것이고, "트로이산(Troysan)174"는 트로이 화학(주)(Troy Chemical Company)에서 방부제로 제조판매되며 결합재가 선적된 컨테이너를 보존하기 위하여 사용하는 것이다.Among the substances shown in Table 1, "cosan (158)" is manufactured and sold as a disinfectant from Cosan Chemical Company (Cosan Chemical Company), "Troysan (174)" is Troy Chemical (Troy Chemical) The company manufactures and sells them as preservatives and is used to preserve containers in which binders are shipped.

실시예 1-6에서 제조된 모든 결합제는 이들이 과연 상업적인 사용에 적당한가에 대하여 결정하는데 이용되는 통상적인 테스트를 받는다. 테스트의 대상은 흙손실시의 용이성(ease of trowel application) 손모래치기성(hand sanding properties), 균열저항성, 액체투과테이프에의 접착, 모서리 이탈성, 습한조건하에서의 퇴화저항성, 기계적모래치기(mechanical sanding), 방치수명(shelf life), 해빙안정성등이다.All binders prepared in Examples 1-6 are subjected to conventional tests used to determine whether they are suitable for commercial use. Test subjects include: ease of trowel application, hand sanding properties, crack resistance, adhesion to liquid permeable tapes, edge detachment, degradation resistance under wet conditions, and mechanical sanding. ), Shelf life, sea ice stability.

실시예 1-6의 결합제는 모든 테스트에서 뛰어난 성질을 나타냈다. 사실상 실시예 1-6에서 제조된 결합제는 뛰어난 접착 및 균열 저항성을 가지기 때문에 통상의 결합제에서 균열을 막기위해 요구되며 최종결합제의 단가를 높이는 운모를 사용할 필요가 없는 것이다.The binder of Examples 1-6 showed excellent properties in all tests. In fact, the binders prepared in Examples 1-6 have excellent adhesion and crack resistance and therefore are required to prevent cracking in conventional binders and do not require the use of mica to increase the cost of the final binder.

[실시예 7]Example 7

결합제는 공장규모로 공장 설비장치를 사용하여 제조하였다. 결합제를 생성하기 위한 설비조작은 실시예 1-6에 의해 서술된 실험실제조에 사용된 것과 흡사하다. 다만 큰 설비가 사용되며 각 성분들이 다량으로 사용된다는 점이 다르다. 공정 진행에 있어서, 우선 물이 큰 혼합기에 채워진다. 그리고 나서 접착제 및 방부제가 추가되어 함께 혼합된다. 혼합기는 그뒤 작동을 하게되고 점토, 탄산칼슘, 퍼얼라이트등 다른 고체물은 혼합기의 윗부분으로 주입된다. 이들 성분은 약 15-20분간 함께 혼합된다. 이 시간의 막바지에 물이 추가로 주입되며 결합제의 점도를 맞추기위해 구성물과 혼합된다. 이 물질은 그뒤 수송을 위해 컨테이너에 적재된다. 결합제의 구성은 아래 도표 Ⅱ에 나타나 있다.The binder was prepared using plant equipment on a factory scale. The plant operation to produce the binder is similar to that used in the laboratory manufacture described in Examples 1-6. The difference is that large equipment is used and each component is used in large quantities. In the course of the process, water is first filled in a large mixer. Then adhesive and preservative are added and mixed together. The mixer is then activated and other solids such as clay, calcium carbonate and pearlite are injected into the top of the mixer. These ingredients are mixed together for about 15-20 minutes. At the end of this time additional water is injected and mixed with the composition to match the viscosity of the binder. This material is then loaded into a container for transportation. The composition of the binder is shown in Table II below.

위에서와 같이 제조된 결합제는 실시예 1-6에 대하여 위에 열거한 모든 테스트를 받았으며, 이결합제는 모든 테스트에서 뛰어난 성질을 갖는 것으로 밝혀졌다.The binder prepared as above was subjected to all the tests listed above for Examples 1-6, and the binder was found to have excellent properties in all tests.

비록운모가 사용되지 않았다하더라고 접착 및 비균열성이 매우좋다. 이 실험의 결과는 본 발명의 결합제, 특히 실시예 7에서 제조된 결합제가 상업용으로 탁월하게 적당하다는 것을 나타낸다.Although mica is not used, the adhesion and non-cracking properties are very good. The results of this experiment indicate that the binder of the present invention, especially the binder prepared in Example 7, is excellently commercially suitable.

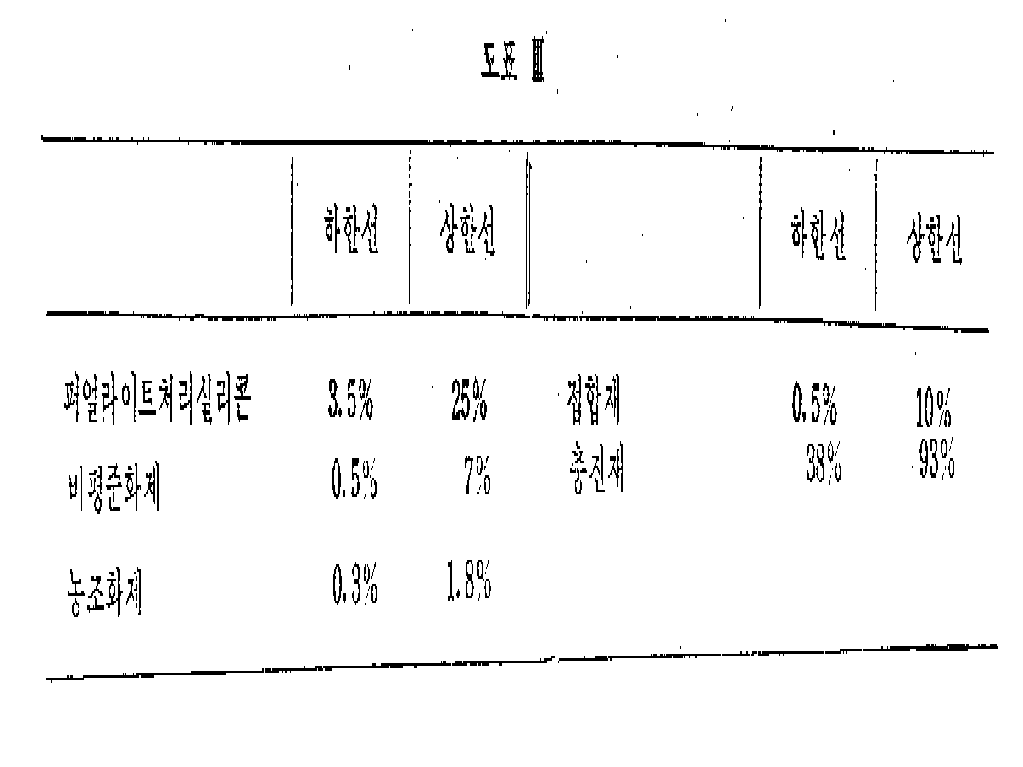

아래도표 Ⅲ은 본 발명에 따라 유용한 경량결합제를 생산하는데 사용되는 여러가지 성분들간의 상, 하한선을 나타낸다. 이 물질들은 조성비에서 건조성분이 중량퍼센트로 기재되어 있다. 공급된 에멀젼 접합재 또는 다른 성분들은 그 퍼센트에서 수분을 포함시키지 않았으며 단지 에멀젼의 고체용량이나 활성부분만을 기술하였다.Table III below shows the upper and lower limits between the various components used to produce useful light binders in accordance with the present invention. These materials are listed by weight percentage of dry ingredients in the composition ratio. The emulsion binder or other ingredients supplied contained no moisture at that percentage and only described the solid dose or active portion of the emulsion.

본 발명의 경량 결합제는 선행기술에서 알려진 결합제보다 많은 잇점을 가지고 있다.The lightweight binder of the present invention has many advantages over the binders known in the prior art.

가장 큰 잇점은 물질의 중량이 종래의 결합제보다 가볍다는 것이다. 결과적으로운반비가 절감되는 것이다. 덧붙여서 이러한 중량의 가벼움 때문에, 결합제는 양동이(Bucket), 흙손(trowel) 혹은 바쥬카(bazooka)로 쉽게 옮겨지며 근로자가 쉽게 일을 할 수 있는 것이다.The biggest advantage is that the weight of the material is lighter than conventional binders. As a result, the transportation cost is reduced. In addition, because of this light weight, the binder is easily transferred to a bucket, trowel or bazooka and is easy for the worker to work with.

결합제가 가해지고 건조된 후,이는 종래의 결합제보다 모래치기가 훨씬 쉬우며모래치기후 매끈하게 처리된 벽이 얻어진다.After the binder has been applied and dried, it is much easier to sand than conventional binders and a smoothly treated wall is obtained after sanding.

본 발명의 결합제는 또한 수축율이 낮다는 점에서 통상의 결합제보다 큰 잇점이 있다.The binder of the present invention also has an advantage over conventional binders in that the shrinkage rate is low.

이러한 성질로 인하여, 균열을 피하기위해 통상의 결합제에 사용하는 성분인 활석이나 운모를 사용할 필요가 없다.Due to this property, it is not necessary to use talc or mica, which is a component used in conventional binders, to avoid cracking.

본 발명의 결합제는 뛰어난 접착성 및 뛰어난 도포성을 가진다. 사실상 석고판금속코너비드(beads)를 덮기위하여 종래의 결합제에서 주로 요구되는 통상적인 3번의 도포를 2번도포로 줄일 수 있다는것이 발견되었으며 이로인하여 인력및 재료비 절감이 되는 것이다.The binder of the present invention has excellent adhesion and excellent applicability. In fact, it has been found that the typical three applications required for conventional binders to cover gypsum sheet metal beads are reduced to two coatings, thereby reducing manpower and material costs.

Claims (30)

Applications Claiming Priority (2)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| US06/450,823 US4454267A (en) | 1982-12-20 | 1982-12-20 | Lightweight joint compound |

| US450823 | 1999-11-29 |

Publications (2)

| Publication Number | Publication Date |

|---|---|

| KR840006959A KR840006959A (en) | 1984-12-04 |

| KR860001881B1 true KR860001881B1 (en) | 1986-10-24 |

Family

ID=23789631

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| KR1019830005835A KR860001881B1 (en) | 1982-12-20 | 1983-12-09 | Light weight joint compound |

Country Status (15)

| Country | Link |

|---|---|

| US (1) | US4454267A (en) |

| EP (1) | EP0128157B1 (en) |

| JP (1) | JPS60500134A (en) |

| KR (1) | KR860001881B1 (en) |

| AU (1) | AU571473B2 (en) |

| CA (1) | CA1190342A (en) |

| DE (1) | DE3372373D1 (en) |

| DK (1) | DK164111C (en) |

| ES (1) | ES8605017A1 (en) |

| FI (1) | FI76101C (en) |

| GB (1) | GB2132185B (en) |

| IE (1) | IE56439B1 (en) |

| MX (1) | MX164897B (en) |

| NZ (1) | NZ206023A (en) |

| WO (1) | WO1984002531A1 (en) |

Families Citing this family (78)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US4657594A (en) * | 1985-07-05 | 1987-04-14 | Usg Corporation | Lightweight joint compound |

| US4686253A (en) * | 1986-02-20 | 1987-08-11 | United States Gypsum Company | Lightweight joint compound having improved paintability |

| EP0245718B1 (en) * | 1986-05-12 | 1991-12-27 | National Starch and Chemical Investment Holding Corporation | Tape joint compounds utilizing starch stabilized emulsions as binders |

| AU585444B2 (en) * | 1986-06-20 | 1989-06-15 | Minnesota Mining And Manufacturing Company | Shrinkage tape joint composition |

| US4743475A (en) * | 1987-02-09 | 1988-05-10 | United States Gypsum Company | Drywall coating composition |

| US4876142A (en) * | 1987-04-17 | 1989-10-24 | Magic Stuff, Inc. | Fluid resistant coating composition |

| US4845144A (en) * | 1987-04-17 | 1989-07-04 | Magic Stuff, Inc. | Fluid resistant coating composition |

| DE3814078A1 (en) * | 1988-04-26 | 1989-11-09 | Henkel Kgaa | USE OF NONTIONAL CELLULOSE ETHERS IN JOINT DENSITY AND / OR COATING MATERIALS |

| US5039341A (en) * | 1988-12-19 | 1991-08-13 | The Dow Chemical Company | Binder composition comprises a blend of a high viscosity and low viscosity hydroxypropyl methylcellulose ether, and a tape joint composition containing such binder |

| US4972013A (en) * | 1989-02-28 | 1990-11-20 | Air Products And Chemicals, Inc. | Emulsion binders for joint compounds |

| US5811113A (en) * | 1989-04-27 | 1998-09-22 | Cancer Technologies, Inc. | Method and composition for deactivating HIV infected blood and for deactivating and decolorizing anticancer drugs |

| US5112400A (en) * | 1990-03-06 | 1992-05-12 | Rheox, Inc. | Clay thickener for use in water-based systems and joint compounds containing such compositions |

| CA2065231A1 (en) * | 1990-09-17 | 1992-03-18 | Peter M. Attard | Clay-free, asbestos-free and glass microbubble-free joint compounds |

| CH684944A5 (en) * | 1993-03-30 | 1995-02-15 | Warmoctro Bv | Concealed Mass for interiors. |

| US5334243A (en) * | 1993-05-04 | 1994-08-02 | The Dow Chemical Company | Crack inhibitor for tape joint compositions |

| CA2139373C (en) * | 1994-05-12 | 2002-06-25 | Therese A. Espinoza | Ready-mixed, setting type joint compound |

| US7208225B2 (en) * | 1995-06-30 | 2007-04-24 | Lafarge Platres | Prefabricated plaster board |

| US5661211A (en) * | 1995-11-30 | 1997-08-26 | Todd; Ronald L. | Patch material for patching holes and cracks in drywall, wood, block, and cement and the like, and method of making and dispensing the patch material |

| US5671321A (en) * | 1996-04-24 | 1997-09-23 | Bagnuolo; Donald J. | Air heater gun for joint compound with fan-shaped attachment |

| US5653797A (en) * | 1996-04-26 | 1997-08-05 | National Gypsum Company | Ready mixed setting-type joint compound and method of making same |

| AT403277B (en) * | 1996-06-28 | 1997-12-29 | Tulln Zuckerforschung Gmbh | BUILDING MATERIAL ADDITIVES |

| US5922447A (en) * | 1996-09-16 | 1999-07-13 | United States Gypsum Company | Lightweight gypsum board |

| US5964934A (en) * | 1997-12-18 | 1999-10-12 | Usg Interiors, Inc. | Acoustical tile containing treated perlite |

| US6295794B1 (en) | 1998-01-09 | 2001-10-02 | Universal Forest Products, Inc. | Joint compound including recycled constituents and method and system for making the same |

| US6358309B1 (en) * | 1998-12-10 | 2002-03-19 | 3M Innovative Properties Company | Low dust wall repair compound |

| US6429257B1 (en) | 1999-06-24 | 2002-08-06 | Weyerhaeuser Company | Polyurethane casting system and method |

| US6673144B2 (en) | 2000-02-11 | 2004-01-06 | United States Gypsum Company | Joint compound providing low dusting and good gloss retention |

| JP2004506107A (en) * | 2000-08-04 | 2004-02-26 | ラファルジュ プラトル | Method, assembly and additional coating for the construction of indoor works |

| US20040154264A1 (en) * | 2000-08-04 | 2004-08-12 | Colbert Elizabeth A. | Coated gypsum board products and method of manufacture |

| US6476099B1 (en) | 2000-11-28 | 2002-11-05 | United States Gypsum Company | Joint compound additive for reduction of cracking, cratering and shrinkage |

| US6676746B2 (en) | 2001-06-01 | 2004-01-13 | 3M Innovative Properties Company | Low dust wall repair compound |

| US7141284B2 (en) | 2002-03-20 | 2006-11-28 | Saint-Gobain Technical Fabrics Canada, Ltd. | Drywall tape and joint |

| US7311964B2 (en) * | 2002-07-30 | 2007-12-25 | Saint-Gobain Technical Fabrics Canada, Ltd. | Inorganic matrix-fabric system and method |

| FR2846961B1 (en) * | 2002-11-08 | 2005-02-11 | Lafarge Platres | COMPOSITION FOR JOINT COATING FOR BUILDING ELEMENTS AND METHOD OF MAKING A WORK |

| US6936099B2 (en) * | 2003-03-19 | 2005-08-30 | National Gypsum Properties, Llc | Lightweight joint compound containing stable air pockets |

| US6902614B2 (en) * | 2003-03-21 | 2005-06-07 | Slawomir Ratomski | Perlited Portland cement plaster joint compound additive with lime |

| US7469510B2 (en) * | 2004-04-14 | 2008-12-30 | Lafarge Platres | System using a drywall board and a jointing compound |

| US20050246993A1 (en) * | 2004-04-13 | 2005-11-10 | Elizabeth Colbert | System using a drywall board and a jointing compound |

| US7214411B2 (en) * | 2004-04-13 | 2007-05-08 | Lafarge Platres | Coating spray apparatus and method of using same |

| US7414085B2 (en) * | 2004-04-14 | 2008-08-19 | Lafarge Platres | Coating for wall construction |

| US20050252128A1 (en) * | 2004-04-13 | 2005-11-17 | Elizabeth Colbert | Coating for wall construction |

| US20100083879A1 (en) * | 2008-10-08 | 2010-04-08 | Georgia-Pacific Gypsum Llc | Low voc joint composition |

| US10669215B2 (en) * | 2009-01-14 | 2020-06-02 | United States Gypsum Company | Snap-set, ready-mix joint compound |

| US8343272B2 (en) * | 2009-04-29 | 2013-01-01 | Christine L. Rada, legal representative | Lightweight construction material and methods and device for fabrication thereof |

| EP2475627A4 (en) * | 2009-09-11 | 2013-10-30 | Nat Gypsum Properties Llc | Low dust joint compound and method of making the same |

| US9174881B2 (en) | 2009-11-05 | 2015-11-03 | United States Gypsum Company | Ready mixed setting type joint compound and set initiator in chambered pouch |

| CN102712536B (en) | 2010-02-04 | 2016-04-27 | 美国石膏公司 | Snap-set, ready-mix joint compound |

| US8822566B2 (en) | 2010-12-23 | 2014-09-02 | United States Gypsum Company | Non-homogeneous ready-mix joint compound |

| US8038790B1 (en) | 2010-12-23 | 2011-10-18 | United States Gypsum Company | High performance non-combustible gypsum-cement compositions with enhanced water durability and thermal stability for reinforced cementitious lightweight structural cement panels |

| US8668087B2 (en) | 2011-12-22 | 2014-03-11 | United States Gypsum Company | Two-phase packaging of ready mix joint compound |

| JP2013209253A (en) * | 2012-03-30 | 2013-10-10 | Daiken Corp | Inorganic foam and method for producing the same |

| FR3005976B1 (en) * | 2013-05-24 | 2017-02-24 | Romain Garcin | METHOD FOR MAKING A JOINT BETWEEN TWO PLASTER PLATES |

| CN103497562B (en) * | 2013-08-29 | 2015-09-30 | 王传福 | Putty powder for exterior wall true stone paint |

| CN103497560B (en) * | 2013-08-29 | 2015-09-16 | 王传福 | Formaldehyde-free putty paste for interior wall latex paint |

| EP3080213A4 (en) * | 2013-12-11 | 2017-11-22 | Henry Company LLC | Water-resistant products using a wax emulsion |

| US9828504B2 (en) | 2013-12-11 | 2017-11-28 | Henry Company, Llc | Water-resistant products using a wax emulsion |

| WO2016069583A1 (en) * | 2014-10-27 | 2016-05-06 | Henry Company, Llc | Water-resistant exterior joint compounds |

| AU2015255229B2 (en) * | 2014-11-11 | 2020-02-06 | Csr Building Products Limited | Jointing Compound |

| EP3230227A4 (en) * | 2014-12-11 | 2018-12-05 | Henry Company LLC | Water-resistant products using a wax emulsion |

| US10801217B2 (en) | 2015-06-29 | 2020-10-13 | Henry Company, Llc | Low-dust products using a wax emulsion |

| US10099961B2 (en) | 2015-08-12 | 2018-10-16 | United States Gypsum Company | Fluorescent building product and related detection method |

| CA2998884A1 (en) | 2015-09-24 | 2017-03-30 | Henry Company, Llc | Low-dust products using microcrystalline wax emulsion |

| WO2017106289A1 (en) | 2015-12-14 | 2017-06-22 | Henry Company, Llc | Dust control formulations |

| WO2017142927A1 (en) | 2016-02-15 | 2017-08-24 | Henry Company, Llc | Low dust additives for joint compounds and joint compounds thereof |

| CA3015669A1 (en) | 2016-03-23 | 2017-09-28 | Henry Company, Llc | Low dust additives comprising emulsified powder for joint compounds and joint compounds thereof |

| WO2017218793A1 (en) | 2016-06-15 | 2017-12-21 | Henry Company, Llc | Low dusting additive for joint compound |

| US10781139B2 (en) | 2017-06-07 | 2020-09-22 | United States Gypsum Company | Joint compound with sulfonated starch |

| US11453613B2 (en) | 2017-11-07 | 2022-09-27 | United States Gypsum Company | Joint compounds, activators and methods for setting a joint compound and preventing seed setting |

| US10800706B2 (en) | 2018-04-23 | 2020-10-13 | United States Gypsum Company | Vesicle dedusting agents for joint compounds |

| US11040910B2 (en) | 2018-06-06 | 2021-06-22 | United States Gypsum Company | Phospholipid dedusting agents for joint compounds |

| US20200261864A1 (en) | 2019-02-15 | 2020-08-20 | United States Gypsum Company | System and method for continuous manufacture of joint compound |

| US20210017082A1 (en) | 2019-07-19 | 2021-01-21 | United States Gypsum Company | Plasticizer dedusting agents for joint compounds |

| US20210147703A1 (en) * | 2019-11-14 | 2021-05-20 | National Gypsum Properties, Llc | Lightweight Joint Compound Composition |

| US11760692B2 (en) | 2020-01-28 | 2023-09-19 | United States Gypsum Company | Setting type joint compound compositions with reduced plaster |

| EP3943466A1 (en) * | 2020-07-21 | 2022-01-26 | Saint-Gobain Placo | A filler compound and use of a filler compound |

| WO2022175865A1 (en) | 2021-02-19 | 2022-08-25 | Knauf Gips Kg | High solids, sprayable setting type joint compound |

| WO2022253469A1 (en) | 2021-06-04 | 2022-12-08 | Knauf Gips Kg | Ready-mixed drying-type joint compounds containing ph buffer systems |

| WO2024073313A1 (en) | 2022-09-28 | 2024-04-04 | United States Gypsum Company | Method of making a sprayable setting type compound |

Family Cites Families (11)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US29753A (en) * | 1860-08-28 | bacon | ||

| US2690594A (en) * | 1952-03-17 | 1954-10-05 | Dant & Russell | Acoustical tile and method of manufacture |

| US3321410A (en) * | 1965-02-17 | 1967-05-23 | Central Mfg Distr | Expanded perlite and method for the formation thereof |

| US3386223A (en) * | 1966-02-01 | 1968-06-04 | Minnesota Mining & Mfg | Method of joining drywall panels |

| US3565851A (en) * | 1967-04-17 | 1971-02-23 | Stauffer Wacker Silicone Corp | Organopolysiloxane coatings |

| US3867335A (en) * | 1968-07-09 | 1975-02-18 | Union Carbide Corp | Tape joint cement additive |

| GB1303632A (en) * | 1969-04-11 | 1973-01-17 | ||

| US3658564A (en) * | 1970-06-01 | 1972-04-25 | Du Pont | Water-insensitive bonded perlite structures |

| US3907725A (en) * | 1973-02-26 | 1975-09-23 | Nat Gypsum Co | Asbestos-free drywall joint compound utilizing attapulgite clay as asbestos substitute |

| US3891453A (en) | 1973-07-26 | 1975-06-24 | United States Gypsum Co | Asbestos-free joint compounds |

| US4287103A (en) * | 1980-02-11 | 1981-09-01 | Georgia-Pacific Corporation | Joint composition including starch |

-

1982

- 1982-12-20 US US06/450,823 patent/US4454267A/en not_active Expired - Fee Related

-

1983

- 1983-10-13 CA CA000438953A patent/CA1190342A/en not_active Expired

- 1983-10-17 EP EP83903691A patent/EP0128157B1/en not_active Expired

- 1983-10-17 AU AU22026/83A patent/AU571473B2/en not_active Ceased

- 1983-10-17 JP JP58503564A patent/JPS60500134A/en active Granted

- 1983-10-17 WO PCT/US1983/001625 patent/WO1984002531A1/en active IP Right Grant

- 1983-10-17 DE DE8383903691T patent/DE3372373D1/en not_active Expired

- 1983-10-20 NZ NZ206023A patent/NZ206023A/en unknown

- 1983-11-09 MX MX199342A patent/MX164897B/en unknown

- 1983-12-07 GB GB08332700A patent/GB2132185B/en not_active Expired

- 1983-12-09 KR KR1019830005835A patent/KR860001881B1/en active Pre-grant Review Request

- 1983-12-19 ES ES528149A patent/ES8605017A1/en not_active Expired

- 1983-12-19 IE IE2992/83A patent/IE56439B1/en not_active IP Right Cessation

-

1984

- 1984-07-27 FI FI843006A patent/FI76101C/en not_active IP Right Cessation

- 1984-08-17 DK DK394884A patent/DK164111C/en not_active IP Right Cessation

Also Published As

| Publication number | Publication date |

|---|---|

| FI76101B (en) | 1988-05-31 |

| JPH0480958B2 (en) | 1992-12-21 |

| AU571473B2 (en) | 1988-04-21 |

| IE56439B1 (en) | 1991-07-31 |

| DK394884A (en) | 1984-08-17 |

| EP0128157A4 (en) | 1985-07-30 |

| EP0128157B1 (en) | 1987-07-08 |

| MX164897B (en) | 1992-09-30 |

| FI843006A (en) | 1984-07-27 |

| WO1984002531A1 (en) | 1984-07-05 |

| GB2132185B (en) | 1986-09-10 |

| GB2132185A (en) | 1984-07-04 |

| EP0128157A1 (en) | 1984-12-19 |

| JPS60500134A (en) | 1985-01-31 |

| AU2202683A (en) | 1984-07-17 |

| FI76101C (en) | 1988-09-09 |

| IE832992L (en) | 1984-06-20 |

| ES528149A0 (en) | 1986-02-16 |

| CA1190342A (en) | 1985-07-09 |

| GB8332700D0 (en) | 1984-01-11 |

| DK394884D0 (en) | 1984-08-17 |

| DE3372373D1 (en) | 1987-08-13 |

| US4454267A (en) | 1984-06-12 |

| NZ206023A (en) | 1986-07-11 |

| ES8605017A1 (en) | 1986-02-16 |

| DK164111C (en) | 1992-10-05 |

| FI843006A0 (en) | 1984-07-27 |

| DK164111B (en) | 1992-05-11 |

| KR840006959A (en) | 1984-12-04 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| KR860001881B1 (en) | Light weight joint compound | |

| FI85461B (en) | LAETT FOGKITT MED FOERBAETTRAD MAOLBARHET. | |

| CA1244170A (en) | Lightweight joint compound | |

| US5336318A (en) | Clay-free, asbestos-free and glass microbubble-free drying type joint compounds | |

| US6238476B1 (en) | Method of curing drywall compound | |

| JPH0860139A (en) | Premixed curing joining composition | |

| NO115522B (en) | ||

| US20190345365A1 (en) | Composition and method of using perlite | |

| AU2019280232A1 (en) | Phospholipid dedusting agents for joint compounds | |

| US3366502A (en) | Densifier and waterproofing agents for mortar and concrete and method of making same | |

| AU2019204874B1 (en) | A light weight adhesive composition | |

| NO152176B (en) | MEDICINE FOR COLORING HAIR AND WOOL | |

| US6569497B2 (en) | Method of finishing a drywall and a compound therefor | |

| US2095614A (en) | Nonhardening cement | |

| NO159730B (en) | LIGHT WEIGHT SUBMISSION. |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| G160 | Decision to publish patent application | ||

| O035 | Opposition [patent]: request for opposition |

Free format text: OPPOSITION NUMBER: 001986002074; OPPOSITION DATE: 19861223 |

|

| J2X1 | Appeal (before the patent court) |

Free format text: APPEAL AGAINST DECISION TO DECLINE REFUSAL Free format text: TRIAL NUMBER: 1988201001114; APPEAL AGAINST DECISION TO DECLINE REFUSAL |