KR20160016632A - Tablet supplying apparatus, tablet supplying method, and recording medium thereof - Google Patents

Tablet supplying apparatus, tablet supplying method, and recording medium thereof Download PDFInfo

- Publication number

- KR20160016632A KR20160016632A KR1020150106415A KR20150106415A KR20160016632A KR 20160016632 A KR20160016632 A KR 20160016632A KR 1020150106415 A KR1020150106415 A KR 1020150106415A KR 20150106415 A KR20150106415 A KR 20150106415A KR 20160016632 A KR20160016632 A KR 20160016632A

- Authority

- KR

- South Korea

- Prior art keywords

- tablet

- prescription data

- sheet

- taking

- information included

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Withdrawn

Links

- 238000000034 method Methods 0.000 title claims description 67

- 239000003814 drug Substances 0.000 claims abstract description 73

- XLYOFNOQVPJJNP-UHFFFAOYSA-N water Chemical compound O XLYOFNOQVPJJNP-UHFFFAOYSA-N 0.000 claims abstract description 66

- 239000008213 purified water Substances 0.000 claims abstract description 62

- 238000003860 storage Methods 0.000 claims description 29

- 229940079593 drug Drugs 0.000 claims description 26

- 238000007599 discharging Methods 0.000 claims description 16

- 238000000605 extraction Methods 0.000 claims description 12

- 238000001802 infusion Methods 0.000 claims 3

- 238000012545 processing Methods 0.000 description 57

- 238000009826 distribution Methods 0.000 description 42

- 238000004806 packaging method and process Methods 0.000 description 29

- 238000001514 detection method Methods 0.000 description 24

- 238000010586 diagram Methods 0.000 description 22

- 230000010365 information processing Effects 0.000 description 18

- 230000006870 function Effects 0.000 description 17

- 238000001125 extrusion Methods 0.000 description 16

- 238000012546 transfer Methods 0.000 description 12

- 238000011068 loading method Methods 0.000 description 7

- 238000004891 communication Methods 0.000 description 6

- 238000012856 packing Methods 0.000 description 3

- 239000000843 powder Substances 0.000 description 3

- 230000004308 accommodation Effects 0.000 description 2

- 239000002775 capsule Substances 0.000 description 2

- 238000000746 purification Methods 0.000 description 2

- 238000007789 sealing Methods 0.000 description 2

- 238000005507 spraying Methods 0.000 description 2

- 229910052782 aluminium Inorganic materials 0.000 description 1

- XAGFODPZIPBFFR-UHFFFAOYSA-N aluminium Chemical compound [Al] XAGFODPZIPBFFR-UHFFFAOYSA-N 0.000 description 1

- 235000021152 breakfast Nutrition 0.000 description 1

- 238000004590 computer program Methods 0.000 description 1

- 230000000994 depressogenic effect Effects 0.000 description 1

- 230000035622 drinking Effects 0.000 description 1

- 239000000284 extract Substances 0.000 description 1

- 239000011888 foil Substances 0.000 description 1

- 230000005484 gravity Effects 0.000 description 1

- 238000005259 measurement Methods 0.000 description 1

- 229910052751 metal Inorganic materials 0.000 description 1

- 239000002184 metal Substances 0.000 description 1

- 238000002360 preparation method Methods 0.000 description 1

- 238000003825 pressing Methods 0.000 description 1

- 238000003892 spreading Methods 0.000 description 1

Images

Classifications

-

- A—HUMAN NECESSITIES

- A61—MEDICAL OR VETERINARY SCIENCE; HYGIENE

- A61J—CONTAINERS SPECIALLY ADAPTED FOR MEDICAL OR PHARMACEUTICAL PURPOSES; DEVICES OR METHODS SPECIALLY ADAPTED FOR BRINGING PHARMACEUTICAL PRODUCTS INTO PARTICULAR PHYSICAL OR ADMINISTERING FORMS; DEVICES FOR ADMINISTERING FOOD OR MEDICINES ORALLY; BABY COMFORTERS; DEVICES FOR RECEIVING SPITTLE

- A61J7/00—Devices for administering medicines orally, e.g. spoons; Pill counting devices; Arrangements for time indication or reminder for taking medicine

- A61J7/0076—Medicament distribution means

- A61J7/0084—Medicament distribution means for multiple medicaments

Landscapes

- Medical Preparation Storing Or Oral Administration Devices (AREA)

- Control And Other Processes For Unpacking Of Materials (AREA)

- Basic Packing Technique (AREA)

- Health & Medical Sciences (AREA)

- Life Sciences & Earth Sciences (AREA)

- Animal Behavior & Ethology (AREA)

- General Health & Medical Sciences (AREA)

- Public Health (AREA)

- Veterinary Medicine (AREA)

Abstract

본 발명의 과제는, 효율적으로 정제 시트의 정제 수용부로부터 정제를 취출하기 위한 구조를 제공하는 것이다.

제1 처방 데이터에 포함되는 약제 정보와 제2 처방 데이터에 포함되는 약제 정보가 동일하지 않은 경우에는, 제1 처방 데이터에 포함되는 정제수의 정제를 취출하는 취출 동작이 행해지고 나서부터, 제2 처방 데이터에 포함되는 정제수의 정제를 취출하는 취출 동작이 행해질 때까지의 동안에, 반송 경로 내에 남아있는 정제 시트를, 배출로에 배출하도록 반송 수단을 제어하고, 한편, 제1 처방 데이터에 포함되는 약제 정보와 제2 처방 데이터에 포함되는 약제 정보가 동일한 경우에는, 제1 처방 데이터에 포함되는 정제수의 정제를 취출하는 취출 동작이 행해지고 나서부터, 제2 처방 데이터에 포함되는 정제수의 정제를 취출하는 취출 동작이 행해질 때까지의 동안에, 반송 경로 내에 남아있는 정제 시트를, 배출로에 배출하지 않도록 반송 수단을 제어하는 것을 특징으로 한다.It is an object of the present invention to provide a structure for efficiently extracting a tablet from a tablet accommodating portion of a tablet sheet.

When the medicine information included in the first prescription data and the medicine information included in the second prescription data are not the same, after the taking out operation for taking out the purified water contained in the first prescription data is performed, the second prescription data The control means controls the conveying means to discharge the tablet sheet remaining in the conveying path to the discharge passage while taking out the tablet of the purified water contained in the first prescription data, When the medicine information included in the second prescription data is the same, a taking-out operation for taking out the purified water contained in the second prescription data from the taking-out operation for taking out the purified water contained in the first prescription data The control means controls the conveying means so as not to discharge the tablet sheet remaining in the conveying path to the discharge passage And that is characterized.

Description

본 발명은, 정제 공급 장치, 정제 공급 방법 및 그 기록 매체에 관한 것으로, 특히 효율적으로 정제 시트의 정제 수용부로부터 정제를 취출하기 위한 기술에 관한 것이다.TECHNICAL FIELD The present invention relates to a tablet supplying device, a tablet supplying method, and a recording medium therefor, and more particularly, to a technique for efficiently taking tablets from a tablet accommodating portion of a tablet sheet.

종래, 조제 업무에 있어서, PTP 시트로 제공되고 있는 정제(약)의 1포화를 행하기 위해서는, 사람의 손에 의해 PTP 시트로부터 정제를 1회분의 정제수씩 취출하고, 분포기에 세트시킬 필요가 있어, 작업이 번잡하였다.Conventionally, in order to perform 1 saturation of the tablets (approximately) provided in the PTP sheet in the preparation work, it is necessary to take tablets from the PTP sheet one by one by hand and set them in the distributor , The work was complicated.

상기 과제를 해결하기 위해서, 특허문헌 1에서는, 정제 시트로부터 정제를 제포하고, 정제를 1회 음용분씩 플라스틱제 작은 병 등의 적절한 용기에 넣어서 투여하는 정제 제포 장치가 제안되고 있다.In order to solve the above problems,

특허문헌 1은, 구체적으로는, 정제 시트로부터 정제를 취출하는 정제 제포 장치를 복수대 준비하고, 복수대의 정제 제포 장치로 취출된 정제를, 하방의 집합부에서 모아 작은 병 등의 용기에 넣는 것이 기재되어 있다.

일반적으로, 처방전(처방 데이터)마다, PTP 시트로부터 정제를 취출해서 분포를 행하게 된다.Generally, tablets are taken out from the PTP sheet for each prescription (prescription data) and distributed.

예를 들어, 2개의 처방전(유저 A, 유저 B의 처방전)의 내용이 동일한 경우, PTP 시트로부터 정제를 취출하는 정제 취출 장치는, 먼저, 첫번째 처방전에 나타나는 수만큼 PTP 시트로부터 정제를 취출한다. 이 정제가 취출된 PTP 시트에는, 아직, 정제의 취출 동작이 행해지지 않고 있는 정제 수용부가 있는(정제가 남아있는) 것도 있다. 그러나, 다음의 분포에서, 잘못해서 상이한 정제를 분포하는 것을 미연에 방지하기 위해서, 이러한 PTP 시트는 배출로에 배출되어버린다.For example, when contents of two prescriptions (prescription of user A and user B) are the same, the tablet taking out apparatus for taking out the tablet from the PTP sheet first extracts the tablets from the PTP sheet as many as appear in the first prescription. The PTP sheet from which the tablet is taken out may have a tablet accommodating portion (tablets remain) which has not yet been taken out of the tablet. However, in the following distribution, such a PTP sheet is discharged to the discharge passage in order to prevent in advance the distribution of different tablets by mistake.

그로 인해, 두번째의 처방전에 대한 분포 처리를 행하는 경우에는, 투입구에 투입되어 있는 새로운 PTP 시트를 정제 취출 위치까지 반송하여, 두번째 처방전에 나타나는 수만큼, 당해 PTP 시트로부터 정제를 취출하게 된다.Therefore, in the case of performing distribution processing for the second prescription, the new PTP sheet put in the inlet is transported to the tablet extraction position, and the tablets are taken out from the PTP sheet for the number indicated in the second prescription.

이와 같이, 예를 들어 처방전이 연속해서 동일하고, 동일한 PTP 시트로부터 정제를 취출할 필요가 있는 경우에도, 1개의 처방전분의 정제 취출을 행할 때마다, PTP 시트는 배출로에 배출되는 것이 된다(투입구에 세트된 PTP 시트도 안전 때문에 모두 배출로에 배출되어버림). 그로 인해, 사용중인 PTP 시트(정제의 취출 동작이 행해지지 않고 있는 정제 수용부가 있는(정제가 남아있는) PTP 시트)가 증가해버린다. 이러한 사용중인 PTP 시트는 변형 등을 하고 있으므로 반송하는 것은 어렵고, 정제 취출 장치로의 정제 취출이 어렵다. 그로 인해, 종래, 효율적으로 정제 시트로부터 정제를 취출할 수 없었다.Thus, for example, even when the prescriptions are continuously the same and the tablets need to be taken out from the same PTP sheet, the PTP sheet is discharged to the discharge path every time one prescription powder is taken out for purification PTP sheets set in the inlet port are all discharged to the discharge port because of safety). As a result, the PTP sheet in use (the PTP sheet having the tablet accommodating portion (tablets remaining) in which the tablets are not taken out is increased). Since the PTP sheet in use is deformed or the like, it is difficult to carry it, and it is difficult to take out the tablet to the tablet removal device. Therefore, conventionally, tablets can not be efficiently taken out from the tablet sheet.

또한, 투입구에 세트된 PTP 시트도 안전 때문에 모두 배출로에 배출되어버리므로, 약사 등의 유저는, 다시, 동일한 PTP 시트를 투입구에 세트하지 않으면 안되어, 번잡한 조작을 행할 필요가 있었다.In addition, since the PTP sheets set in the loading port are all discharged to the discharge path for safety, a user such as a pharmacist must again set the same PTP sheet in the loading port, and it is necessary to perform complicated operations.

또한, 이러한 방법에서는, 두번째의 처방전에 나타나는 수의 정제를 PTP 시트로부터 취출하기 위해서, 투입구에 투입되어 있는 새로운 PTP 시트를 정제 취출 위치까지 반송하게 되므로, 반송 시간이 오래 걸려버리고, 결과적으로, 분포하기 위한 시간이 오래 걸려버려서, 효율적으로 PTP 시트로부터 정제를 취출할 수 없었다.Further, in this method, since the new PTP sheet put in the inlet is conveyed to the tablet taking-out position in order to take out the number of tablets appearing in the second prescription from the PTP sheet, the conveying time takes a long time, It took a long time to take the tablets from the PTP sheet efficiently.

본 발명은, 효율적으로 정제 시트의 정제 수용부로부터 정제를 취출하기 위한 구조를 제공하는 것을 목적으로 한다.It is an object of the present invention to provide a structure for efficiently taking tablets from a tablet accommodating portion of a tablet sheet.

본 발명은, 정제의 취출 동작을 행하는 정제 시트의 약제를 나타내는 약제 정보와 정제의 취출 동작을 행하는 정제수를 포함하는 처방 데이터를 복수 기억하는 기억 수단과, 정제 시트를 보유 지지하는 시트 보유 지지부와, 상기 정제 시트를 반송하는 반송 수단과, 상기 반송 수단에 의해 상기 시트 보유 지지부로부터 정제의 취출 위치에 반송된 정제 시트로부터, 상기 기억 수단에 기억된 처방 데이터에 포함되는 정제수의 정제를 취출하는 취출 동작을 행하는 정제 취출 수단과, 상기 반송 수단에 의해 상기 정제 시트가 배출되는 배출로와, 상기 기억 수단에 기억된 제1 처방 데이터이며 상기 정제 취출 수단으로 정제의 취출 동작이 행해지는 상기 제1 처방 데이터에 포함되는 약제 정보와, 상기 기억 수단에 기억된 제2 처방 데이터이며 상기 제1 처방 데이터의 다음에 상기 정제 취출 수단으로 정제의 취출 동작을 행하는 상기 제2 처방 데이터에 포함되는 약제 정보가 동일한지 여부를 판정하는 판정 수단과, 상기 판정 수단에 의해, 상기 제1 처방 데이터에 포함되는 약제 정보와 상기 제2 처방 데이터에 포함되는 약제 정보가 동일하지 않다고 판정된 경우에는, 상기 제1 처방 데이터에 포함되는 정제수의 정제를 취출하는 취출 동작이 행해지고 나서, 상기 제2 처방 데이터에 포함되는 정제수의 정제를 취출하는 취출 동작이 행해질 때까지의 동안에, 상기 반송 수단에 의한 반송 경로 내에 남아있는 정제 시트이며 상기 정제 취출 동작이 행해지지 않고 있는 정제 수용부를 포함하는 정제 시트를, 상기 배출로에 배출하도록 상기 반송 수단을 제어하고, 한편, 상기 판정 수단에 의해, 상기 제1 처방 데이터에 포함되는 약제 정보와 상기 제2 처방 데이터에 포함되는 약제 정보가 동일하다고 판정되는 경우에는, 상기 제1 처방 데이터에 포함되는 정제수의 정제를 취출하는 취출 동작이 행해지고 나서, 상기 제2 처방 데이터에 포함되는 정제수의 정제를 취출하는 취출 동작이 행해질 때까지의 동안에, 상기 반송 수단에 의한 반송 경로 내에 남아있는 정제 시트이며 상기 정제 취출 동작이 행해지지 않고 있는 정제 수용부를 포함하는 정제 시트를, 상기 배출로에 배출하지 않도록 상기 반송 수단을 제어하는 제어 수단을 구비하는 것을 특징으로 한다.The present invention relates to a tablet apparatus comprising: storage means for storing a plurality of prescription data including tablet information for indicating a medicine of a tablet sheet for taking out a tablet and purifying water for taking out tablets; a sheet holding section for holding the tablet sheet; A takeout operation for taking out a tablet of purified water contained in the prescription data stored in the storage means from the tablet sheet transported from the sheet holding section to the take-out position of the tablet by the transporting means; A tablet discharge means for discharging the tablet sheet by the transfer means, and a control means for controlling the tablet discharge means to discharge the tablet sheet by using the first prescription data stored in the storage means and the first prescription data The second prescription data stored in the storage means, and the first prescription data Determining means for determining whether drug information included in the second prescription data to be used for taking out tablets next to the tablet take-out means is the same or not; and determination means for determining whether drug information included in the first prescription data Wherein when it is determined that the medicine information and the medicine information included in the second prescription data are not the same, a take-out operation for taking out the purified water contained in the first prescription data is performed, A tablet sheet including a tablet accommodating portion remaining in the conveying path by the conveying means and not subjected to the tablet taking-out operation during a period until a taking-out operation for taking out the purified water of the purified water is performed, And the control means controls the conveying means to discharge the first prescription data And when it is determined that the medicament information included in the second prescription data is the same as the medicament information included in the first prescription data, extracting the tablets of the purified water contained in the first prescription data is performed and then included in the second prescription data The tablet sheet including the tablet accommodating portion remaining in the conveying path by the conveying means and not being subjected to the tablet ejecting operation until the ejecting operation for ejecting the tablets of the purified water is performed, And a control unit for controlling the conveying unit so as not to discharge it to the outside.

본 발명에 따르면, 효율적으로 정제 시트의 정제 수용부로부터 정제를 취출할 수 있다.INDUSTRIAL APPLICABILITY According to the present invention, the tablets can be efficiently taken out from the tablet accommodating portion of the tablet sheet.

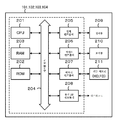

도 1은, 본 발명의 실시 형태에 따른 분포 시스템의 구성을 도시하는 도면이다.

도 2는, 본 발명의 실시 형태에서의 정제 공급 장치(101), 정제 취출 장치(102), 포장 장치(103), 정보 처리 장치(104)의 하드웨어 구성의 일부의 일례를 도시하는 도면이다.

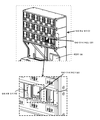

도 3은, 도 1에 도시한 정제 공급 장치(101)의 확대도이다.

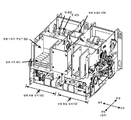

도 4는, 정제 취출 장치(102)의 내부 구조를 설명하기 위한 정제 취출 장치(102)의 경사도이다.

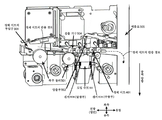

도 5는, 분포 장치의 정면에서 보고 우측에서 본 정제 취출 장치(102)의 내부 구조(단면)를 도시하는 도면의 일례이다.

도 6은, 처방 데이터에 따라, 정제 시트의 정제 수용부로부터 정제를 취출하여, 배출부(106)에 정제 시트를 배출하는 일련의 처리의 일례를 나타내는 흐름도이다.

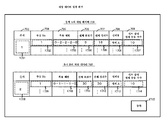

도 7은, 외부 메모리(1807)에 등록된 처방 데이터(701, 702)의 데이터의 일례를 나타내는 도면이다.

도 8은, 처방 데이터에 따라, 정제 시트의 정제 수용부로부터 정제를 취출하여, 배출부(106)에 정제 시트를 배출하는 일련의 처리의 일례를 나타내는 흐름도이다.

도 9는, 정제 공급 장치(101)가, 포장 장치(103)로부터 수신한 처방 데이터이며, 외부 메모리(211) 등의 기억부에 기억된 처방 데이터(701, 702)의 데이터의 일례를 나타내는 도면이다.

도 10은, 처방 데이터에 따라, 정제 시트의 정제 수용부로부터 정제를 취출하여, 배출부(106)에 정제 시트를 배출하는 일련의 처리의 일례를 나타내는 흐름도이다.

도 11은, 정제 공급 장치(101)가, 포장 장치(103)로부터 수신한 처방 데이터이며, 외부 메모리(211) 등의 기억부에 기억된 처방 데이터(701, 702, 710)의 데이터의 일례를 나타내는 도면이다.

도 12는, 유저에 의한, 미처리의 처방 데이터를 편집할지 여부의 선택을 접수하는 선택 화면의 일례를 도시하는 도면이다.

도 13은, 처방 데이터 편집 화면의 일례를 도시하는 도면이다.

도 14는, 처방 데이터의 편집을 접수한 처방 데이터 편집 화면의 일례를 도시하는 도면이다.

도 15는, 스텝 S604의 상세 처리를 나타내는 흐름도의 일례를 나타내는 도면이다.

도 16은, 정제 시트가 반송되어 정제가 취출된 정제 시트(401) 및 압출부(502)의 관계를 도시하는 도면이다.

도 17은, 처방 데이터 입력 화면의 일례를 도시하는 도면이다.

도 18은, 본 발명의 실시 형태에 있어서의 본 발명의 실시 형태에서의 정제 공급 장치(101), 포장 장치(103) 및 정보 처리 장치(104)를 포함하는 분포 시스템의 하드웨어 구성의 일례를 도시하는 도면이다.

도 19는, 정제 취출 장치(102)가 구비하는 PTP 시트 검출 센서(1902)를 설명하기 위한 정제 취출 장치(102)의 단면 경사도이다.

도 20은, 정제 취출 장치(102)에 있어서의, PTP 시트가 투입되어 있는 투입구(301)를 위에서 본 도면이다.1 is a diagram showing a configuration of a distribution system according to an embodiment of the present invention.

2 is a diagram showing an example of a part of the hardware configuration of the tablet supply device 101, the

3 is an enlarged view of the tablet feeder 101 shown in Fig.

4 is an inclined view of the tablet take-out

5 is an example of a diagram showing the internal structure (cross section) of the

6 is a flowchart showing an example of a series of processes for extracting tablets from the tablet accommodating portion of the tablet sheet and discharging the tablet sheet to the discharging portion 106 according to the prescription data.

7 is a diagram showing an example of data of the prescription data 701 and 702 registered in the

8 is a flowchart showing an example of a series of processes for extracting tablets from the tablet accommodating portion of the tablet sheet and discharging the tablet sheet to the discharging portion 106 according to the prescription data.

9 is a diagram showing an example of data of the prescription data 701 and 702 stored in the storage unit such as the

10 is a flowchart showing an example of a series of processes for extracting tablets from the tablet accommodating portion of the tablet sheet and discharging the tablet sheet to the discharging portion 106 according to the prescription data.

11 shows an example of the data of the prescription data 701, 702, and 710 stored in the storage unit such as the

12 is a diagram showing an example of a selection screen for accepting a selection of whether to edit the unprocessed prescription data by the user.

13 is a diagram showing an example of a prescription data editing screen.

14 is a diagram showing an example of a prescription data edit screen in which editing of prescription data is received.

Fig. 15 is a diagram showing an example of a flowchart showing the detailed processing in step S604.

16 is a diagram showing the relationship between the

17 is a diagram showing an example of a prescription data input screen.

18 shows an example of the hardware configuration of the distribution system including the tablet supply device 101, the packaging device 103 and the information processing device 104 in the embodiment of the present invention in the embodiment of the present invention. FIG.

19 is a sectioned gradient view of the tablet take-out

Fig. 20 is a top view of the inlet 301 into which the PTP sheet is inserted in the

이하, 도면을 참조하여, 본 발명의 실시 형태를 상세하게 설명한다.Hereinafter, embodiments of the present invention will be described in detail with reference to the drawings.

이하, 본 발명을 적용한 적합한 실시 형태를, 첨부 도면을 참조하면서 상세하게 설명한다.Best Mode for Carrying Out the Invention Hereinafter, preferred embodiments to which the present invention is applied will be described in detail with reference to the accompanying drawings.

<제1 실시 형태>≪ First Embodiment >

이하, 도면을 사용하여, 본 발명에 따른 제1 실시 형태에 대해서 설명한다.Hereinafter, a first embodiment according to the present invention will be described with reference to the drawings.

도 1은, 본 발명의 실시 형태에 따른 분포 시스템의 구성을 도시하는 도면이다.1 is a diagram showing a configuration of a distribution system according to an embodiment of the present invention.

먼저, 도 1에 대해서 설명한다.First, Fig. 1 will be described.

도 1은, 정제 공급 장치(101)와 포장 장치(103)를 구비하는 분포 장치와, 정보 처리 장치(104)를 포함하는 분포 시스템의 일례를 도시하는 도면이다.1 is a view showing an example of a distribution system including a distribution apparatus having a tablet supply apparatus 101 and a packaging apparatus 103 and an information processing apparatus 104. Fig.

포장 장치(103)와 정보 처리 장치(104)는, 네트워크(105)를 통해서 서로 통신 가능하게 접속되어 있다.The packaging apparatus 103 and the information processing apparatus 104 are connected to each other so as to be able to communicate with each other via the network 105. [

정제 공급 장치(101)는, 복수의 정제 취출 장치(102)를 구비하고 있다.The tablet supply apparatus 101 includes a plurality of tablet take-

정제 취출 장치(102)(정제 취출 수단)는, 정제 공급 장치(101)의 폭 방향(좌우 방향)에 6개가 배열되고, 이 6개의 정제 취출 장치(102)를 포함하는 세트가 상하에 3단으로 배치되어 있다.Six tablet removal devices 102 (tablet removal means) are arranged in the width direction (left and right direction) of the tablet supply device 101, and a set including the six

정제 공급 장치(101)는, 복수의 정제 취출 장치(102)를 구비하고 있는데, 정제 취출 장치의 수는 1개이어도 된다.The tablet supply device 101 includes a plurality of

정제 취출 장치(102)는, 정제 시트의 정제 수용부(간단히 수용부라고도 함)에 수용된 정제를 취출하는 취출 동작을 행하고, 당해 수용부로부터 정제를 취출하는 장치이다.The

정제 취출 장치(102)는, 1장의 정제 시트의 복수의 수용부에 각각 수용된 정제를, 1개씩 당해 수용부로부터 취출하는 취출 동작을 행하고, 정제를 1개씩 포장 장치(103)에 공급한다.The

정제 시트는, 일반적으로 PTP 시트라고 불리고 있으며, 정제 시트를 PTP 시트라고도 한다.The tablet sheet is generally called a PTP sheet, and the tablet sheet is also called a PTP sheet.

도 3은, 도 1에 도시한 정제 공급 장치(101)의 확대도이다.3 is an enlarged view of the tablet feeder 101 shown in Fig.

도 1, 도 3에 도시한 바와 같이, 정제 공급 장치(101)는, 유저에 의해 투입구(301)에 투입되는 정제 시트의 복수의 정제 수용부로부터 순차 각각 정제를 취출하여, 당해 취출된 정제를 포장 장치(103)에 공급하고, 정제 시트의 배출로(505)(도 5를 참조)에, 당해 정제가 취출된 정제 시트를 배출하는 정제 공급 장치이다.As shown in Figs. 1 and 3, the tablet feeder 101 takes out the tablets sequentially from a plurality of tablet accommodating portions of the tablet sheet put into the inlet 301 by the user, To the packaging device 103 and discharges the tablet sheet from which the tablets are taken out to the discharge path 505 (see Fig. 5) of the tablet sheet.

투입구(301)는, 정제 시트를 보유 지지하는 본 발명의 시트 보유 지지부의 적용예이다.The input port 301 is an application example of the sheet holding portion of the present invention for holding the tablet sheet.

도 1, 도 3에 도시한 배출부(106)는, 배출로(505)와 도통하고 있고, 배출로(505)를 거쳐서 정제 시트가 배출되는 박스이다.The discharge portion 106 shown in Figs. 1 and 3 is a box which is in communication with the discharge path 505 and through which the tablet sheet is discharged via the discharge path 505. [

정제 공급 장치(101)는, 정제 취출 장치(102)에 의해 정제 시트(PTP 시트)로부터 정제를 취출하여, 당해 정제를, 정제 공급 장치(101)의 공급 경로(도 5에 도시한 도입 슈트(503)를 거쳐서 포장 장치(103)에 공급한다.The tablet supply apparatus 101 takes out the tablet from the tablet sheet (PTP sheet) by the

포장 장치(103)는, 정제 공급 장치(101)의 정제 취출 장치(102)로부터 공급된 정제를 처방 데이터에 따라서 1포씩 포장하는 장치이다.The packaging device 103 is a device for packing tablets supplied from the

도 2는, 본 발명의 실시 형태에서의 정제 공급 장치(101), 정제 취출 장치(102), 포장 장치(103), 정보 처리 장치(104)의 하드웨어 구성의 일부의 일례를 도시하는 도면이다.2 is a diagram showing an example of a part of the hardware configuration of the tablet supply device 101, the

CPU(201)는, 시스템 버스(204)에 접속되는 각 디바이스나 컨트롤러를 통괄적으로 제어하는 제어부이다.The

또한, ROM(202) 또는 외부 메모리(211)에는, CPU(201)의 제어 프로그램인 BIOS(Basic Input/Output System)나 오퍼레이팅 시스템 프로그램(이하, OS)이나, 각 서버 또는 각 PC의 실행하는 기능을 실현하기 위해서 필요한 후술하는 각종 프로그램 등이 기억되어 있다. RAM(203)은, CPU(201)의 주메모리, 워크에리어 등으로서 기능한다.In addition, the

CPU(201)는, 처리의 실행 시에 필요한 프로그램 등을 RAM(203)에 로드하여, 프로그램을 실행함으로써 각종 동작을 실현하는 것이다.The

또한, 입력 컨트롤러(입력 C)(205)는, 버튼이나 키보드 등의 입력부(209)나 도시하지 않은 마우스 등의 포인팅 디바이스로부터의 입력을 제어한다.The input controller (input C) 205 also controls input from a pointing device such as an

비디오 컨트롤러(VC)(206)는, 디스플레이 등의 표시부(210)에의 표시를 제어한다.The video controller (VC) 206 controls display on a

메모리 컨트롤러(MC)(207)는, 부트 프로그램, 브라우저 소프트웨어, 각종 애플리케이션, 폰트 데이터, 유저 파일, 편집 파일, 각종 데이터 등을 기억하는 하드 디스크(HD) 등의 외부 메모리(211)에의 액세스를 제어한다.The memory controller (MC) 207 controls access to the

통신 I/F 컨트롤러(통신 I/FC)(208)는, 네트워크를 통하여, 외부 기기와 접속·통신하는 것이며, 네트워크에서의 통신 제어 처리를 실행한다. 예를 들어, TCP/IP를 사용한 인터넷 통신 등이 가능하다.The communication I / F controller (communication I / FC) 208 connects and communicates with an external device via a network, and executes communication control processing in the network. For example, Internet communication using TCP / IP is possible.

또한, CPU(201)는, 예를 들어 RAM(203) 내의 표시 정보용 영역에 아웃라인 폰트의 전개(rasterize) 처리를 실행함으로써, 표시부(210) 상에서의 표시를 가능하게 하고 있다. 또한, CPU(201)는, 표시부(210) 상의 도시하지 않은 마우스 커서 등으로의 유저 지시를 가능하게 한다.The

본 발명을 실현하기 위한 프로그램은, 외부 메모리(211)에 기록되어 있고, 필요에 따라 RAM(203)에 로드됨으로써 CPU(201)에 의해 실행되는 것이다. 또한, 본 발명에 관한 프로그램이 사용하는 모든 데이터는 외부 메모리(211)에 저장되어 있다.The program for realizing the present invention is stored in the

이어서, 도 18을 사용하여, 본 발명의 실시 형태에서의 정제 공급 장치(101), 포장 장치(103) 및 정보 처리 장치(104)를 포함하는 분포 시스템의 하드웨어 구성에 대해서 설명한다.Next, the hardware configuration of the distribution system including the tablet supply device 101, the packaging device 103, and the information processing device 104 in the embodiment of the present invention will be described with reference to Fig.

도 18은, 본 발명의 실시 형태에 있어서의 본 발명의 실시 형태에서의 정제 공급 장치(101), 포장 장치(103) 및 정보 처리 장치(104)를 포함하는 분포 시스템의 하드웨어 구성의 일례를 도시하는 도면이다.18 shows an example of the hardware configuration of the distribution system including the tablet supply device 101, the packaging device 103 and the information processing device 104 in the embodiment of the present invention in the embodiment of the present invention. FIG.

여기에서는, 정보 처리 장치(104)의 CPU(1801)와, 포장 장치(103)의 CPU(1809)와, 정제 공급 장치(101)의 CPU(1817)(본 발명의 판정 수단 및 제어 수단)가 각각 연휴하여, 포장 장치(103)가 제어하는 각 장치(각 유닛) 및 정제 공급 장치(101)가 제어하는 각 장치(각 유닛)의 각종 동작을 제어하고 있는 일례를 도시하고 있다.Here, the

그러나, 1개의 CPU가, 도 1에 도시한 분포 시스템의 모든 각 장치를 제어하는 구성이어도 상관없다.However, a single CPU may be configured to control all the devices of the distribution system shown in Fig.

또한, 여기서는, 정제 공급 장치(101)에 CPU가 1개 설치되어 있는 하드웨어 구성에 대해서 도시하고 있지만, 정제 취출 장치(102)마다 CPU를 설치해도 되고, 정제 취출 장치(102)의 단마다 CPU를 설치해도 된다.Although a hardware configuration in which one CPU is provided in the tablet supply device 101 is shown here, a CPU may be provided for each tablet take-out

먼저, 정보 처리 장치(104)의 하드웨어 구성에 대해서 설명한다.First, the hardware configuration of the information processing apparatus 104 will be described.

정보 처리 장치(104)의 CPU(1801)는, 시스템 버스에 접속되는 각 디바이스나 컨트롤러를 통괄적으로 제어할 수 있다.The

도 18에 도시한 정보 처리 장치(104)의 CPU(1801)는, 도 2의 CPU(201)에 상당하는 것이다.The

또한, ROM(1802) 또는 외부 메모리(1807)에는, CPU(1801)의 제어 프로그램인 BIOS(Basic Input/Output System)나 오퍼레이팅 시스템 프로그램(이하, OS)이나, 각 서버 또는 각 PC가 실행하는 기능을 실현하기 위해서 필요한 후술하는 각종 프로그램 등이 기억되어 있다.The

도 18에 도시한 ROM(1802)은, 도 2에 도시한 ROM(202)에 상당하고, 도 18에 도시한 외부 메모리(1807)는, 도 2에 도시한 외부 메모리(211)에 상당한다.The

도 18에 도시한 RAM(1804)은, CPU(1801)의 주메모리, 워크에리어 등으로서 기능한다.The

도 18에 도시한 RAM(1804)은, 도 2에 도시한 RAM(203)에 상당하는 것이다.The

CPU(1801)는, 처리의 실행 시에 필요한 프로그램 등을 RAM(1804)에 로드하여, 프로그램을 실행함으로써 각종 동작을 실현하는 것이다.The

또한, CPU(1801)는, 키보드나 도시하지 않은 마우스 등의 입력 단말기(1806)로부터의 입력을 제어한다.Further, the

도 18에 도시한 입력 단말기(1806)는, 도 2에 도시한 입력부(209)에 상당하는 것이다.The

또한, CPU(1801)는, 디스플레이(1805) 등의 표시부에의 표시를 제어할 수 있다.Further, the

도 18에 도시한 디스플레이(1805)는, 도 2에 도시한 표시부(210)에 상당하는 것이다.The

또한, CPU(1801)는, 각종 애플리케이션, 각 처방 데이터 등을 기억하는 하드 디스크(HD) 메모리 등의 외부 메모리(1807)에의 액세스를 제어할 수도 있다.The

또한, I/F(320)는, 네트워크를 통해서 외부 기기와 접속·통신하는 것이며, 본 실시 형태에 있어서는, 포장 장치(103)의 I/F(1808)와 통신 가능하게 접속되어 있다.The I / F 320 is connected to and communicates with an external device via a network. In the present embodiment, the I / F 320 is connected to the I /

도 18에 도시한 I/F(320), I/F(1808)는, 도 2에 도시한 통신 I/F 컨트롤러(208)에 상당하는 것이다.The I / F 320 and the I /

이어서, 포장 장치(103)의 하드웨어 구성에 대해서 설명한다.Next, the hardware configuration of the packaging apparatus 103 will be described.

포장 장치(103)의 CPU(1809)는, 버스에 접속되어 있는 각 디바이스를 통괄적으로 제어할 수 있다.The

도 18에 도시한 CPU(1809)는, 도 2의 CPU(201)에 상당하는 것이다.The

ROM(1801)에는, CPU(1809)의 제어 프로그램이나 각종 제어 프로그램이 기억되어 있다.In the

도 18에 도시한 ROM(1801)은, 도 2에 도시한 ROM(202)에 상당하는 것이다.The

RAM(1811)은, CPU(1809)가 동작하기 위한 시스템 워크 메모리로서 기능한다.The

도 18에 도시한 RAM(1811)은, 도 2에 도시한 RAM(203)에 상당하는 것이다.The

CPU(1809)는, 터치 패널식의 디스플레이(1813) 등의 표시부에 대하여 표시 제어하거나, 디스플레이(1813)의 터치 패널 기능을 입력 단말기(1814)로서 유저로부터 정보의 입력을 접수하거나, 프린터(1815)에 인쇄 지시를 내리거나 할 수도 있다.The

도 18에 도시한 디스플레이(1813)는, 도 2에 도시한 표시부(210)에 상당하는 것이다.The

도 18에 도시한 입력 단말기(1814)는, 도 2에 도시한 입력부(209)에 상당하는 것이다.The

또한, CPU(1809)는, 처방 데이터에 따라, 정제 취출 장치(102)로부터 공급된 정제를 1포로 분포하는 분포 수단(1816)의 동작을 제어할 수 있다.In addition, the

분포 수단(1816)은, 정제 취출 장치(102)가 정제 시트로부터 취출된 정제나, 포장 장치(103)의 도시하지 않은 가루약 투입부로부터 투입된 가루약이나, 유저로부터 손으로 뿌려진 정제를, 1포마다 분포하는 수단이다.The distribution means 1816 is a means for distributing the tablet taken out from the tablet sheet by the tablet take-out

또한, 포장 장치(103)와 정제 공급 장치(101)는, 포장 장치(103)의 I/O(1812)와 정제 공급 장치(101)의 I/O(1818)로 통신 가능하게 접속되어 있다.The packaging apparatus 103 and the tablet supply apparatus 101 are communicably connected to the I /

이어서, 정제 공급 장치(101)의 하드웨어 구성에 대해서 설명한다.Next, the hardware configuration of the tablet feeder 101 will be described.

정제 공급 장치(101)의 CPU(1817)는, 버스에 접속되어 있는 각 디바이스를 통괄적으로 제어할 수 있다.The

도 18에 도시한 CPU(1817)는, 도 2에 도시한 CPU(201)에 상당하는 것이다.The

ROM(1820)에는, CPU(1817)의 제어 프로그램이나 각종 제어 프로그램이 기억되어 있다.In the

도 18에 도시한 ROM(1820)은, 도 2에 도시한 ROM(202)에 상당하는 것이다.The

RAM(1819)은, CPU(1817)가 동작하기 위한 시스템 워크 메모리로서 기능한다.The

도 18에 도시한 RAM(1819)은, 도 2에 도시한 RAM(203)에 상당하는 것이다.The

CPU(1817)는, 또한, 1개 또는 복수의 정제 취출 장치(102)에서의 취출 동작을 제어한다.The

이러한, 하드웨어 구성에 있어서는, 이하와 같이 정제 취출을 행하도록 제어할 수 있다.In such a hardware configuration, it is possible to perform control such that tablet extraction is performed as follows.

먼저, 포장 장치(103)의 CPU(1809)가, 정제 공급 장치(101)의 CPU(1817)에 대하여 정제의 취출 동작 명령을 송신한다.First, the

그리고, 정제 공급 장치(101)의 CPU(1817)가, 당해 취출 동작 명령에 따라, 정제 취출 장치(102)를 제어하여, 정제의 취출 동작을 행하게 할 수 있다.Then, the

또한, 정제 공급 장치(101)의 CPU(1817)는, 포장 장치(103)의 CPU(1808)에 대하여, 정제의 취출 동작의 상황을 나타내는 동작 정보를 송신할 수도 있다.The

또한, 여기서는, 정제 공급 장치(101)의 CPU(1817)가, 정제 취출 장치(102)의 동작을 제어한다고 설명했지만, 정제 취출 장치(102)가 CPU를 구비하고, 그 CPU가 정제 취출 장치(102)의 동작을 제어할 수도 있다.Although the

CPU(1817)는, 터치 패널식의 디스플레이(1821) 등의 표시부에 대하여 표시 제어하거나, 디스플레이(1821)의 터치 패널 기능을 입력 단말기(1822)로서 유저로부터 정보의 입력을 접수하거나 할 수도 있다.The

도 18에 도시한 디스플레이(1821)는, 도 2에 도시한 표시부(210)에 상당하는 것이다.The

도 18에 도시한 입력 단말기(1822)는, 도 2에 도시한 입력부(209)에 상당하는 것이다.The

이어서, 도 4를 사용하여, 정제 취출 장치(102)의 내부 구조에 대해서 설명한다.Next, the internal structure of the tablet take-out

도 4는, 정제 취출 장치(102)의 내부 구조를 설명하기 위한 정제 취출 장치(102)의 경사도이다.4 is an inclined view of the tablet take-out

또한, 도 4는, 정제 취출 장치(102)가, 2개 나열되어 있는 도면을 도시하고 있다.Fig. 4 shows two tablets take-out

정제 시트(401)는, 정제를 수용하는 정제 수용부를 갖는 시트 본체의 하면에, 알루미늄 등을 포함하는 금속박 등을 사용한 밀봉 시트를 설치함으로써 정제가 정제 수용부에 밀봉된 것이다.The

정제 시트(401)는, 시트부 상에 볼록 형상의 정제 수용부가 폭 방향에 간격을 두고 2열로 배열된 형태이다. 각 열을 이루는 복수의 정제 수용부는 정제 시트(401)의 길이 방향을 따라서 나열되어 있다.The

또한, 정제 시트(401)로서는, 시트부 상에 정제 수용부가 2열로 나열된 형태의 것에 한하지 않고, 정제 수용부가 정제 시트(401)의 길이 방향에 1열로 나열된 형태나, 정제 수용부가 폭 방향에 간격을 두고 3열 이상의 복수열로 나열된 형태이어도 된다.The

도 4에 도시한 바와 같이, 정제 시트의 투입구(301)는, 복수의 정제 시트(401)가 복수매 겹쳐져서 세트할 수 있는 형상으로 되어 있다.As shown in Fig. 4, the inlet 301 of the tablet sheet has a shape that can be set by overlapping a plurality of

또한, 404는, 정제 도입로이며, 후술하는 도입 슈트(503)로부터 낙하해 온 정제를 포장 장치(103)에 공급하는 공급 경로이다.Reference numeral 404 denotes a supply path for supplying the tablets dropped from the introduction chute 503, which will be described later, to the packaging device 103 as a tablet introduction path.

또한, 캠(402), 캠(403)은, 캠(402), 캠(403)이 회전함으로써, 후술하는 압출부(502)를 중력 방향으로 상하로 반복해서 이동시키는 부재이다.The cam 402 and the cam 403 are members that move the extruded portion 502 to be described later repeatedly up and down in the gravity direction as the cam 402 and the cam 403 rotate.

압출부(502)는, 반송 수단에 의해 시트 보유 지지부로부터 정제의 취출 위치에 반송된 정제 시트로부터, 기억 수단에 기억된 처방 데이터에 포함되는 정제수의 정제를 취출하는 취출 동작을 행하는 본 발명의 정제 취출 수단의 적용예이다.The pushing-out portion 502 is a tablet of the present invention which performs a taking-out operation for taking out the purified water contained in the prescription data stored in the storage means from the tablet sheet transported from the sheet holding portion to the take- Is an application example of the take-out means.

그리고, 압출부(502)가 정제 시트의 정제 수용부를 압출하여, 정제 수용부 내의 정제를 정제 수용부로부터 취출할 수 있다.Then, the pushing-out portion 502 extrudes the tablet accommodating portion of the tablet sheet, and the tablets in the tablet accommodating portion can be taken out from the tablet accommodating portion.

이어서, 도 5를 사용하여, 정제 취출 장치(102)의 내부 구조에 대해서 더욱 상세하게 설명한다.Next, the internal structure of the tablet take-out

도 5는, 분포 장치의 정면에서 보고 우측에서 본 정제 취출 장치(102)의 내부 구조(단면)를 도시하는 도면의 일례이다.5 is an example of a diagram showing the internal structure (cross section) of the

도 5는, 정제 시트의 투입구(301)에 PTP 시트를 세트하고, PTP 시트를 제포 위치(정제의 취출 위치)까지 반송했을 때의 도면이다.5 is a view showing a case where the PTP sheet is set in the inlet 301 of the tablet sheet and the PTP sheet is conveyed to the position of the tablet (tablets take-out position).

501은, 하부 롤러이다.Reference numeral 501 denotes a lower roller.

하부 롤러(501)는, 정제 시트(401)를 반송하는 반송 수단의 적용예이다.The lower roller 501 is an application example of a conveying means for conveying the

반송 수단은, 정제 시트(401)를 진행 방향을 향해서 반송하는 것이며, 진행 방향에 서로 간격을 두고 설치된 하부 롤러(501)와, 진행 방향에 서로 간격을 두고 설치된 상부 롤러를 구비하고 있다.The conveying means conveys the

검출 기구(504)는, 광에 의해 정제 수용부를 검출하는 광 센서이다.The detection mechanism 504 is a photosensor that detects the tablet accommodating portion by light.

검출 기구(504)는, 광을 발하는 발광부와, 당해 광을 수광하는 수광부를 구비한다.The detection mechanism 504 includes a light emitting portion for emitting light and a light receiving portion for receiving the light.

검출 기구(504)는, 발광부로부터 광이 발해지고 있는 위치를, 정제 시트의 정제 수용부가 통과하면, 광이 당해 정제 수용부에 의해 차단되고, 수광부가 광을 수광할 수 없게 되므로, 정제 수용부를 검출할 수 있다.When the tablet accommodating portion of the tablet sheet passes through the position where the light is emitted from the light emitting portion, the detecting mechanism 504 blocks the light by the tablet accommodating portion and the light receiving portion can not receive light, Can be detected.

정제 공급 장치는, 반송 수단에 의해 PTP 시트를 반송하여, 당해 PTP 시트의 정제 수용부를 검출 기구(504)에 의해 검출하면, 반송 수단에 의해, 소정 거리, PTP 시트를 반송하여, 당해 정제 수용부가 가압되는 소정의 위치까지 PTP 시트를 반송한다. 여기서, 소정 거리란, 후술하는 스텝 S1510에서 산출된 반송 거리이다.When the tablet accommodating portion of the PTP sheet is detected by the detecting mechanism 504, the tablet supplying device conveys the PTP sheet by the conveying means a predetermined distance to the tablet accommodating portion, The PTP sheet is conveyed to a predetermined position where it is pressed. Here, the predetermined distance is the conveyance distance calculated in step S1510 described later.

압출부(502)는, 정제 시트의 정제 수용부를 압출하는 부이다.The extrusion portion 502 is a portion for extruding the tablet accommodating portion of the tablet sheet.

정제 취출 장치(102)는, 도시하지 않은 구동 모터가 캠(402, 403)을 회전 구동시킴으로써, 압출하는 부(502)를 상하로 반복하여 이동시킴으로써, 정제 시트의 정제 수용부를 압출하는 압출 동작(취출 동작)을 행한다.The

이에 의해 정제 수용부로부터 취출된 정제는, 도입 슈트(503)(공급 경로)에 낙하하여, 또한, 도입 슈트(503)에 도통하고 있는 정제 도입로(404)(공급 경로)에 낙하하여, 공급 경로를 거쳐서 포장 장치(103)에 공급된다.As a result, the tablets taken out from the tablet accommodating portion drop on the introduction chute 503 (supply path), fall on the tablet introducing path 404 (supply path) communicating with the introduction chute 503, And is supplied to the packaging apparatus 103 via the path.

도입 슈트(503) 내에는, 낙하한 정제(낙하물)를 검출하는 센서(506)가 설치되어 있고, 센서(506)에 의해, 정제 수용부로부터 취출된 정제, 및 그 정제수를 검출할 수 있다.In the introduction chute 503, a sensor 506 for detecting dropped tablets (falling objects) is provided, and the tablet taken out from the tablet accommodating portion and the purified water can be detected by the sensor 506.

센서(506)는, 광을 발하는 발광부와, 당해 광을 수광하는 수광부를 구비하고 있다.The sensor 506 includes a light emitting portion for emitting light and a light receiving portion for receiving the light.

정제 수용부로부터 취출된 정제(낙하물)가 낙하하면, 발광부로부터의 광이 당해 정제(낙하물)에 의해 차단되고, 수광부가 광을 수광할 수 없게 되므로, 취출된 정제를 검출하여, 차단 횟수로부터 그 정제수를 검출할 수 있다.When the tablets (falling objects) taken out from the tablet accommodating portion drop, the light from the light emitting portion is blocked by the refill (falling object), and the light receiving portion can not receive light. Therefore, the taken tablets are detected, The purified water can be detected.

505는, 배출로이다.Reference numeral 505 denotes a discharge passage.

배출로(505)는, 반송 수단에 의해 정제 시트가 배출되는 본 발명의 배출로의 적용예이다.The discharge path 505 is an application example of the discharge path of the present invention in which the tablet sheet is discharged by the conveying means.

반송 수단에 의해 반송된 정제 시트는, 배출로(505)에 배출된다. 그리고, 배출로(505)에 배출된 정제 시트는, 배출부(106)에 배출된다.The tablet sheet conveyed by the conveying means is discharged to the discharge path (505). The tablet sheet discharged into the discharge path 505 is discharged to the discharge portion 106. [

도 5에 도시한 바와 같이, 정제 취출 장치(102)는, 정제 시트(401)를 반송하는 반송 수단(도 5에 도시한 하부 롤러(501), 도시하지 않은 상부 롤러)과, 반송 수단에 의해 반송된 정제 시트(401)의 정제 수용부를 가압해서 정제를 취출하는 압출부(502)를 갖고 있다.5, the tablet take-out

반송 수단에 의해, 투입구(301)로부터, 배출로(505)에, 정제 시트가 반출될 때까지의 경로를 반송 경로라고 한다.The path from the loading port 301 to the discharge path 505 until the tablet sheet is taken out by the transfer means is referred to as a transfer path.

도 6은, 처방 데이터에 따라, 정제 시트의 정제 수용부로부터 정제를 취출하여, 배출부(106)에 정제 시트를 배출하는 일련의 처리의 일례를 나타내는 흐름도이다.6 is a flowchart showing an example of a series of processes for extracting tablets from the tablet accommodating portion of the tablet sheet and discharging the tablet sheet to the discharging portion 106 according to the prescription data.

도 6에 나타낸 각 스텝에 나타내는 처리·동작은, 분포 시스템의 CPU(제어부)가 분포 시스템의 각 장치의 동작을 제어함으로써 실현된다.The processing / operation shown in each step shown in Fig. 6 is realized by the CPU (control unit) of the distribution system controlling the operation of each apparatus in the distribution system.

여기에서는, 정제 공급 장치(101)의 CPU(제어부)가, 도 6에 나타낸 각 스텝에 나타내는 처리·동작을 실현하는 것으로서 설명한다.Here, it is assumed that the CPU (control unit) of the tablet feeder 101 realizes the processing / operation shown in each step shown in Fig.

먼저, 정보 처리 장치(104)는, 도 17에 도시한 처방 데이터 입력 화면을, 디스플레이(1805)에 표시한다.First, the information processing apparatus 104 displays the prescription data input screen shown in Fig. 17 on the

도 17은, 처방 데이터 입력 화면의 일례를 도시하는 도면이다.17 is a diagram showing an example of a prescription data input screen.

그리고, 정보 처리 장치(104)는, 유저의 조작에 의해, 도 17에 도시한 처방 데이터 입력 화면을 통하여, 처방 데이터(701, 702)의 입력을 접수한다.Then, the information processing apparatus 104 accepts input of the prescription data 701 and 702 through the prescription data input screen shown in Fig. 17 by the user's operation.

도 17에 도시한 처방 데이터 입력 화면은, 유저에 의해, 처방 데이터(701, 702)의 입력을 접수하는 화면이다.The prescription data input screen shown in Fig. 17 is a screen for accepting input of prescription data 701 and 702 by the user.

도 17에 도시한 처방 데이터 입력 화면의 처방 데이터(701)는, 유저 A(고객:환자)의 처방 데이터의 일례이다.The prescription data 701 of the prescription data input screen shown in Fig. 17 is an example of prescription data of the user A (customer: patient).

또한, 도 17에 도시한 처방 데이터 입력 화면의 처방 데이터(702)는, 유저 A와는 상이한 유저 B(고객:환자)의 처방 데이터의 일례이다.The prescription data 702 of the prescription data input screen shown in Fig. 17 is an example of prescription data of user B (customer: patient) different from user A.

도 17에 도시한 처방 데이터 입력 화면의 처방 데이터(701)에는, 순서(703), 유닛 No.(704), 복용 패턴(705), 전체 분포수(706), 전체 정제수(707), 정제명(708), 시트 상의 정제 수용 부수(709)의 항목으로 구성되어 있다.The

703은, 분포의 동작 처리를 행하는 순서(우선 순위)를 나타내고 있으며, 값이 작은 쪽이, 값이 큰 쪽보다도 우선으로 실행된다.

그로 인해, 도 17의 예에서는, 701의 처방 데이터에 따라, 분포의 동작 처리를 행한 후에, 702의 처방 데이터에 따라, 분포의 동작 처리를 행하는 것을 도시하고 있다.Therefore, in the example shown in Fig. 17, distribution operation processing is performed according to prescription data 701, and then distribution processing is performed according to prescription data 702. Fig.

또한, 도 17의 704는, 유닛 No.(정제 취출 장치(102)를 식별하는 번호)이다.In addition,

또한, 도 17의 705은, 복용 패턴이다. 도 17의 처방 데이터(701)의 예에서는, 아침 점심 저녁 2정씩 복용하는 것을 나타낸다.In Fig. 17,

도 17의 706은, 분포되는 수(전체 분포수)이다.In Fig. 17,

도 17의 707은, 분포되는 정제의 모든 수(전체 정제수)이다.In Fig. 17,

도 17의 예에서는, 아침 점심 저녁 2정씩 9포분 정제를 취출하므로, 취출하는 전체 정제수는 18정이 된다.In the example of Fig. 17, since the tablets for nine-pack are taken out by two tablets for breakfast lunch and dinner, the total number of purified tablets to be taken out is 18 tablets.

도 17의 708은, 정제명이며, 정제나 약제를 포함하는 약품의 명칭이나, 당해 약품의 PTP 시트의 명칭이 등록된다.In FIG. 17,

도 17의 709는, 708로 등록되어 있는 정제명의 1장의 PTP 시트의 모든 정제 수용 부수를 나타내고 있다.In Fig. 17, numeral 709 denotes the number of tablets to be accommodated in one PTP sheet of the tablets name registered as 708.

도 17에 도시한 순서(703), 유닛 No.(704), 복용 패턴(705), 전체 분포수(706), 전체 정제수(707), 정제명(708)의 각 항목의 입력란은, 각각, 1701, 1702, 1703, 1704, 1705, 1706이다.The input fields of the

유저는, 순서(703), 유닛 No.(704), 복용 패턴(705), 전체 분포수(706), 전체 정제수(707), 정제명(708)의 각 항목의 입력란(1701, 1702, 1703, 1704, 1705, 1706)에 각각, 유저 A의 처방 데이터(701)를 입력한다.The user can input

정보 처리 장치(104)는, 입력란(1706)에서 정제명이 입력된 경우, 정제명과, 당해 정제명의 1장의 PTP 시트의 모든 정제 수용 부수가 관련지어져서, 정보 처리 장치(104)의 외부 메모리(1807)에 기억되어 있는 테이블로부터, 당해 입력된 정제명의 1장의 PTP 시트의 모든 정제 수용 부수를 취득하여, 자동으로 1704의 표시란에 표시한다.When the tablet name is inputted in the

도 17의 처방 데이터(701)는, 유닛 No.가 1인 정제 취출 장치(102)에 의해, 정제 A가 정제 수용부에 수용되어 있는 정제 시트로부터, 1703, 1704, 1705에 나타나는 수만큼, 정제를 취출할 필요가 있는 것을 나타내고 있다.The prescription data 701 shown in Fig. 17 is obtained by the tablets taking out

즉, 포장 장치(103)가, 아침, 점심, 저녁 각각의 1포에 2정을 분포하고, 합계 9포(3일분)를 분포하기 위해서, 유닛 No.가 1인 정제 취출 장치(102)가, 정제 A가 정제 수용부에 수용되어 있는 정제 시트로부터, 18정을 취출하는 것을 나타내고 있다.That is, the packing apparatus 103 has two

또한, 마찬가지로, 도 17의 처방 데이터(702)에 대해서도, 순서, 유닛 No., 복용 패턴, 전체 분포수, 전체 정제수, 정제명의 각 항목의 입력란(1708, 1709, 1710, 1711, 1712, 1713)에 각각, 유저 B의 처방 데이터(702)를 입력한다.179, 1710, 1711, 1712, and 1713 for each item of the order, the unit number, the taking pattern, the total number of distributions, the total number of refills, and the refinement name are stored in the

정보 처리 장치(104)는, 입력란(1713)에서 정제명이 입력된 경우, 마찬가지로, 테이블로부터, 당해 입력된 정제명의 1장의 PTP 시트의 모든 정제 수용 부수를 취득하여, 자동으로 1714의 표시란에 표시한다.When the tablet name is input in the

도 17의 처방 데이터(702)는, 처방 데이터(701)의 전체 정제수(1705)에 나타나는 수만큼, 정제를 취출한 후에, 유닛 No.가 1인 정제 취출 장치(102)에 의해, 정제 A가 정제 수용부에 수용되어 있는 정제 시트로부터, 처방 데이터(702)의 전체 정제수(1712)에 나타나는 수만큼, 정제를 취출할 필요가 있는 것을 나타내고 있다.The prescription data 702 shown in Fig. 17 is obtained by extracting the tablets by the number indicated in the total number of purified

도 17의 처방 데이터 입력 화면에서는, 2개의 처방 데이터를 입력하는 예에 대해서 설명했지만, 3개 이상의 처방 데이터를 입력하는 것도 가능하다. 그 경우에는, 3개 이상의 처방 데이터의 입력란이 표시되는 것으로 한다.In the prescription data input screen of Fig. 17, an example of inputting two prescription data is described, but it is also possible to input three or more prescription data. In this case, it is assumed that three or more prescription data input fields are displayed.

그리고, 정보 처리 장치(104)는, 유저에 의해 등록 버튼(1715)이 눌러지면, 입력된 처방 데이터(701, 702)를 외부 메모리(1807)에 등록한다.The information processing apparatus 104 then registers the entered prescription data 701 and 702 in the

도 7은, 외부 메모리(1807)에 등록된 처방 데이터(701, 702)의 데이터의 일례를 나타내는 도면이다.7 is a diagram showing an example of data of the prescription data 701 and 702 registered in the

그리고, 정보 처리 장치(104)는, 유저의 조작에 의해 입력을 접수하고, 등록된 도 7에 나타낸 처방 데이터(701, 702)를, 포장 장치(103)에 송신한다.The information processing apparatus 104 receives the input by the user's operation and transmits the registered prescription data 701 and 702 shown in Fig. 7 to the packaging apparatus 103. [

그리고, 포장 장치(103)는, 당해 처방 데이터(701, 702)를 수신하면, 당해 처방 데이터(701, 702)를 정제 공급 장치(101)에 송신한다.The packing apparatus 103 receives the prescription data 701 and 702 and transmits the prescription data 701 and 702 to the tablet supply apparatus 101. [

정제 공급 장치(101)는, 도 7에 나타낸 처방 데이터(701, 702)를 수신함으로써, 복수의 처방 데이터의 입력을 접수한다(스텝 S601). 그리고, 정제 공급 장치(101)는, 접수한 도 7에 나타낸 복수의 처방 데이터(처방 데이터(701, 702))를 외부 메모리(211) 등의 기억부에 기억한다.The tablet supply device 101 receives the prescription data 701 and 702 shown in Fig. 7, thereby accepting input of a plurality of prescription data (step S601). The tablet supply device 101 stores a plurality of received prescription data (prescription data 701 and 702) shown in Fig. 7 in a storage unit such as the

여기서, 외부 메모리(211) 등의 기억부는, 처방 데이터를 복수 기억하는 본 발명의 기억 수단의 적용예이다.Here, the storage unit such as the

또한, 도 7에 나타낸 복수의 처방 데이터는, 정제의 취출 동작을 행하는 정제 시트의 약제를 나타내는 약제 정보로서의 정제명(708)과, 정제의 취출 동작을 행하는 전체 정제수(707)를 포함하고 있다.The plurality of prescription data shown in Fig. 7 includes a

그리고, 정제 공급 장치(101)는, 유저에 의해, 종료 지시를 접수했는지 여부를 판정한다(스텝 S602). 그리고, 종료 지시를 접수했다고 판정된 경우에는, 처리를 종료한다.Then, the tablet supply device 101 determines whether or not the user has accepted a termination instruction (step S602). If it is determined that the end instruction has been received, the process is terminated.

한편, 종료 지시를 접수하고 있지 않다고 판정된 경우에는, 처리를 스텝 S603에 이행하여, 유저로부터의 분포 처리의 개시 지시의 접수를 기다린다.On the other hand, if it is determined that the end instruction has not been received, the process advances to step S603 to wait for acceptance of the start instruction of the distribution process from the user.

정제 공급 장치(101)는, 유저로부터의 분포 처리의 개시 지시를 접수하면, 도 7의 처방 데이터(701, 702)의 「순서」로, 분포 처리를 개시한다.Upon reception of an instruction to start the distribution process from the user, the tablet supply device 101 starts the distribution process in the " order " of the prescription data 701 and 702 in Fig.

여기에서는, 도 7의 처방 데이터(701, 702)의 「순서」로 개시한다고 설명했지만, 여기서, 유저에 의해 선택된 처방 데이터에 따른 분포 처리를 우선으로 실행할 수도 있다.Here, it is described that the procedure data 701 and 702 of Fig. 7 are started in the " order ", but the distribution process according to the prescription data selected by the user may be executed first.

정제 공급 장치(101)는, 유저로부터의 분포 처리의 개시 지시를 접수하면, 순서값이 다음으로 높은 미처리의 처방 데이터(701)를 처리 대상의 처방 데이터로 설정해서(스텝 S603), 투입구(301)에 투입된 정제 시트를, 반송 수단에 의해, 당해 정제 시트의 정제 수용부를, 압출부(502)에 의해 밀어낼 수 있는 위치(압출 위치)에 반송한다(스텝 S604).Upon receiving an instruction to start the distribution process from the user, the tablet supply device 101 sets the prescription data 701, which is the next highest in the order value, as the processing target prescription data (step S603) (Step S604). The tablet accommodating portion of the tablet sheet is conveyed by the conveying means to a position (extruded position) where the tablet accommodating portion can be pushed out by the extruding portion 502 (Step S604).

스텝 S604의 상세 처리는, 도 15를 사용하여 후술한다.The detailed processing of step S604 will be described later with reference to Fig.

그리고, 정제 공급 장치(101)는, 압출부(502)에 의해 정제 수용부를 가압하여 정제를 취출하는 동작을 행한다(스텝 S605).Then, the tablet supply device 101 presses the tablet accommodating portion by the push-out portion 502 to take out the tablet (Step S605).

그리고, 정제 공급 장치(101)는, 정제의 취출 동작을 행하면, 정제 수용부로부터 취출된 정제(낙하물)를 센서(506)가 검출한다. 그리고, 처리를 스텝 S606에 이행한다.When the tablets are taken out from the tablet supply device 101, the sensor 506 detects the tablets (falling objects) taken out from the tablet accommodating portion. Then, the process proceeds to step S606.

스텝 S606에서는, 현재 처리 대상의 처방 데이터와, 정제 취출 동작 횟수에 기초하여, 처방 데이터에 나타나는 수(예를 들어, 처방 데이터 701의 경우라면, 18개(전체 정제수))의 정제를 취출했는지 여부를 판정하고, 취출했다고 판정한 경우에는, 처리를 스텝 S607에 이행한다. 한편, 처방분(예를 들어, 처방 데이터 701의 경우라면, 18개(전체 정제수))의 정제를 취출하고 있지 않다고 판정된 경우에는, 처리를 스텝 S604에 이행하여, 다시, 정제 시트의 정제 수용부로부터 정제의 취출 동작을 행한다.In step S606, it is determined whether or not tablets of 18 (total purified water) in the case of prescription data 701 have been taken out based on the prescription data and the number of times of tablets take-out operation, And if it is determined that it has been taken out, the process proceeds to step S607. On the other hand, when it is judged that the tablets of the prescription amount (for example, 18 (total purified water) in the case of the prescription data 701) have not been taken out, the process proceeds to step S604, The operation of taking out the tablet is performed.

여기서, 도 16을 사용하여, 정제 시트가 반송되어 정제가 취출된 정제 시트(401) 및 압출부(502)와의 관계에 대해서 설명한다.Here, with reference to Fig. 16, the relationship between the

도 16은, 정제 시트가 반송되어 정제가 취출된 정제 시트(401) 및 압출부(502)와의 관계를 도시하는 도면이다.16 is a diagram showing the relationship between the

도 16에 나타낸 1601은, 정제 수용부이며, 1602는, 당해 정제 수용부에 수용되어 있는 정제이다.16,

도 16의 (a)는, 투입구에 투입된 정제 시트(401)가 압출부(502)(502-1, 502-2)의 방향으로 반송되는 모습을 도시하고 있다.16 (a) shows a state in which the

압출부(502)는, 좌우에 2개의 정제 수용부(1601)를 각각 개별적으로 취출 동작을 행하기 위해서, 좌우에 2개의 압출부(502-1), 압출부(502-2)를 구비하고 있다.The extruding portion 502 includes two extruding portions 502-1 and 502-2 on the left and right in order to individually take out the two

도 16의 (b)는, 압출부(502)의 방향으로 반송되어, 2정의 정제가 취출된 정제 시트(401)의 모습을 도시하고 있다. 압출하는 순서는, 압출부(502-1)가 압출한 후에, 압출부(502-2)로 압출한다. 즉, 좌측, 우측의 순서로 압출한다.16 (b) shows the state of the

그리고, 정제 시트로부터 5정의 정제가 취출되면, 도 16의 (c)에 도시한 상태가 된다.When the five-tablet is taken out from the tablet sheet, the state shown in Fig. 16 (c) is obtained.

스텝 S606에서는, 현재 처리 대상의 처방 데이터와, 정제 취출 동작 횟수에 기초하여, 처방 데이터에 나타나는 수(예를 들어, 처방 데이터 701의 경우라면, 18(전체 정제수))의 정제를 취출했는지 여부를 판정한다고 설명했지만, 다음으로 설명하는 별도의 방법이어도 된다.In step S606, it is determined whether or not the number of tablets in the prescription data (for example, 18 (total number of tablets) in the case of the prescription data 701) is taken out based on the prescription data to be processed and the number of tablets However, it may be a separate method described below.

예를 들어, 도입 슈트(503)에, 정제 시트로부터 취출된 정제를 검출하는 검출 수단(예를 들어, 센서(506))을 구비하고, 현재 처리 대상의 처방 데이터에 나타나는 수(예를 들어, 처방 데이터 701의 경우라면, 18개(전체 정제수))만큼, 당해 검출 수단으로 정제를 검출할 수 있었는지를 판정함으로써, 현재 처리 대상의 처방 데이터에 나타나는 수(예를 들어, 처방 데이터 701의 경우라면, 18개(전체 정제수))의 정제를 취출했는지 여부를 판정할 수도 있다.For example, the introduction chute 503 may be provided with detection means (for example, a sensor 506) for detecting the tablet taken out from the tablet sheet, and a number (for example, (In the case of the prescription data 701), 18 (the total number of purified water)), it is determined whether or not the detection means has detected the tablet, , It is possible to judge whether or not the tablets of 18 (total purified water) have been taken out.

이어서, 정제 공급 장치(101)는, 스텝 S606에서, 현재 처리 대상의 처방 데이터에 나타나는 수(예를 들어, 처방 데이터 701의 경우라면, 18개(전체 정제수))의 정제를 취출했다고 판정된 경우에는, 처리를 스텝 S607에 이행한다.Subsequently, when it is determined in step S606 that the number of tablets of the present processing target (for example, 18 tablets in the case of the prescription data 701 (total number of tablets)) has been taken out , The process proceeds to step S607.

정제 공급 장치(101)는, 스텝 S601에서 입력된 복수의 처방 데이터 중, 아직, 분포의 동작 처리(S604, S605의 동작 처리를 포함함)를 행하고 있지 않는 미처리의 처방 데이터가 있는지를 판정한다.The tablet supply device 101 determines whether any of the plurality of prescription data input in step S601 contains unprocessed prescription data that is not yet subjected to the distribution operation processing (including the operation processing of S604 and S605).

그리고, 정제 공급 장치(101)는, 아직, 분포의 동작 처리(S604, S605의 동작 처리를 포함함)를 행하고 있지 않는 미처리의 처방 데이터가 있다고 판정된 경우에는, 동일한 정제 취출 장치(102)에 있어서, 당해 미처리의 처방 데이터이며 「순서」의 값이 현재 처리 대상의 처방 데이터의 「순서」의 값보다도 다음으로 높은 미처리의 처방 데이터에 나타나는 정제명(약제)이, 현재 처리 대상으로 되어 있는 처방 데이터에 나타나는 정제명(약제)과 상이한지 여부를 판정한다(스텝 S607).Then, when it is determined that there is unprocessed prescription data that is not yet subjected to the distribution operation process (including the operation process of S604 and S605), the tablet supply device 101 is connected to the same tablet removal device 102 (Pharmaceutical) in which the value of the " order " is the unprocessed prescription data and the value of the " order " appears in the unprocessed prescription data next to the value of the " order " of the current processing target prescription data is the prescription data (Medicament) appearing at step S607 (step S607).

스텝 S607은, 기억 수단에 기억된 제1 처방 데이터(예를 들어, 처방 데이터 701)이며 정제 취출 수단으로 정제의 취출 동작이 행해지는 제1 처방 데이터에 포함되는 약제 정보와, 기억 수단에 기억된 제2 처방 데이터(예를 들어, 처방 데이터 702)이며 제1 처방 데이터의 다음에 정제 취출 수단으로 정제의 취출 동작을 행하는 제2 처방 데이터에 포함되는 약제 정보가 동일한지 여부를 판정하는 판정 수단의 본 발명의 적용예이다.Step S607 is a step of acquiring drug information included in the first prescription data (for example, prescription data 701) stored in the storage means and contained in the first prescription data in which tablets are taken out by the tablet extraction means, The second prescription data (e.g., prescription data 702) and the second prescription data for performing the tablets take-out operation by the tablet extraction means next to the first prescription data are the same Is an application example of the present invention.

구체적으로는, 정제 공급 장치(101)는, 스텝 S601에서 입력된 복수의 처방 데이터 중, 미처리의 처방 데이터가 있을지를 판정하고, 미처리의 처방 데이터가 있다고 판정된 경우에는, 스텝 S601에서 입력된 복수의 처방 데이터 중, 현재 처리 대상의 처방 데이터(예를 들어, 처방 데이터 701)의 유닛 No.가 동일하고, 또한, 정제명이 동일한 다음의 미처리의 처방 데이터(이 처방 데이터는, 「순서」의 값이 현재 처리 대상의 처방 데이터의 「순서」의 값보다도 다음으로 높은 미처리의 처방 데이터이며, 예를 들어 처방 데이터 702임)가 있는지 여부를 판정하고(스텝 S607), 현재 처리 대상의 처방 데이터의 유닛 No.가 동일하고, 또한, 정제명이 동일한 다음의 미처리의 처방 데이터가 있다고 판정된 경우에는(스텝 S607: YES), 처리를 스텝 S602에 이행한다. 한편, 스텝 S601에서 입력된 복수의 처방 데이터 중, 미처리의 처방 데이터가 없다고 판정된 경우에는, 처리를 스텝 S608에 이행한다.Specifically, the tablet supply device 101 determines whether there is unprocessed prescription data among the plurality of prescription data input in step S601. If it is determined that there is unprocessed prescription data, Of the prescription data (for example, prescription data 701) of the current processing target, and the next unprocessed prescription data having the same refinement name (this prescription data is the value of the " order " (Step S607). If it is determined that there is any unprocessed prescription data (for example, prescription data 702) that is higher than the value of the " order " If it is determined that there is the next unprocessed prescription data having the same number and the same refinement name (step S607: YES), the process proceeds to step S602. On the other hand, if it is determined that there is no unprocessed prescription data among the plurality of prescription data inputted in step S601, the process proceeds to step S608.

또한, 정제 공급 장치(101)는, 스텝 S607에서, 스텝 S601에서 입력된 복수의 처방 데이터에, 「순서」의 값이 현재 처리 대상의 처방 데이터의 「순서」의 값보다도 다음으로 높은 미처리의 처방 데이터이며, 현재 처리 대상의 처방 데이터의 「유닛 No.」의 값이 동일하지 않은 처방 데이터가 없다고 판정된 경우, 또는, 스텝 S607에서, 스텝 S601에서 입력된 복수의 처방 데이터에, 「순서」의 값이 현재 처리 대상의 처방 데이터의 「순서」의 값보다도 낮은 미처리의 처방 데이터이며, 현재 처리 대상의 처방 데이터의 「유닛 No.」의 값이 동일한 처방 데이터이며, 당해 「유닛 No.」의 값이 동일한 처방 데이터의 「정제명」이 동일하지 않은 처방 데이터가 있다고 판정된 경우에는(스텝 S607: "NO"), 처리를 스텝 S608에 이행한다.In step S607, the tablet supply device 101 supplies the plurality of prescription data input in step S601 to the prescription data in which the value of " order " is set to the next highest value of the " order " Unit data " of the prescription data to be processed is not the same, or in the case where it is determined in step S607 that there is no prescription data for which the value of the " unit number "Quot; is smaller than the value of the " order " of the presently processed process data, and the value of the " unit number " of the presently processed process prescription data is the same, (Step S607: "NO"), the process proceeds to step S608.

스텝 S607에서 "NO"라고 판정되어, 처리를 스텝 S608에 이행하는 제어는, 스텝 S607에서, 제1 처방 데이터에 포함되는 약제 정보와 제2 처방 데이터에 포함되는 약제 정보가 동일하다고 판정되는 경우에는, 제1 처방 데이터에 포함되는 정제수의 정제를 취출하는 취출 동작이 행해지고 나서부터, 제2 처방 데이터에 포함되는 정제수의 정제를 취출하는 취출 동작이 행해질 때까지의 동안에, 반송 수단에 의한 반송 경로 내에 남아있는 정제 시트이며 정제 취출 동작이 행해지지 않고 있는 정제 수용부를 포함하는 정제 시트와, 상기 시트 보유 지지부에 보유 지지된 모든 정제 시트를, 배출로(505)에 배출하지 않도록 반송 수단을 제어하는 제어 수단의 본 발명의 적용예이다.If it is determined in step S607 that the medication information included in the first prescription data is the same as the medication information included in the second prescription data in step S607 , And until the take-out operation for taking out the purified water contained in the second prescription data is performed after the take-out operation for taking out the purified water contained in the first prescription data is carried out, within the conveyance path by the conveying means A tablet sheet including a remaining tablet sheet and a tablet accommodating portion in which a tablet removing operation is not performed, and a control for controlling the conveying means so as not to discharge all the tablet sheets held in the sheet holding portion to the discharge path (505) Lt; / RTI > of the present invention.

스텝 S607은, 정제 취출 수단에 의한 정제의 취출 동작을 행하는 다음의 처방 데이터에, 현재 처리 대상의 처방 데이터와 동일한 정제 시트의 약제를 나타내는 정보가 포함되어 있는지 여부를 판정하는 본 발명의 판정 수단의 적용예이다.Step S607 is a step S607 of judging means of the present invention for judging whether or not the next prescription data for performing tablet taking-out operation by the tablet taking-out means includes information indicating the medicine of the same tablet sheet as the prescription data currently being processed This is an application example.

상술한 바와 같이, 정제 공급 장치(101)는, 스텝 S607에 있어서, 예를 들어 동일한 정제 취출 장치(102)(동일한 유닛 No.)에 있어서, 처방 데이터(701)와 처방 데이터(702)의 정제명이 상이한지 여부를 판정한다.As described above, the tablet supply apparatus 101 determines whether or not the tablets of the prescription data 701 and the prescription data 702 in the tablet removal apparatus 102 (the same unit No.) It is determined whether or not this difference exists.

또한, 상술한 바와 같이, 정제 공급 장치(101)는, 스텝 S607에 있어서, 아직, 분포의 동작 처리(S604, S605의 동작 처리를 포함함)를 행하고 있지 않는 미처리의 처방 데이터(「순서」의 값이 현재 처리 대상의 처방 데이터의 「순서」의 값보다도 낮은 미처리의 처방 데이터)에 나타나는 정제명(약제)이, 현재 처리 대상의 처방 데이터의 약제(정제명)와 동일한 약제(처방 데이터(701)와 처방 데이터(702)의 정제명이 동일함)라고 판정된 경우에는(스텝 S607: "NO"), 스텝 S608, S609의 동작 처리를 행하지 않고, 처리를 스텝 S602에 복귀한다. 즉, 이 경우에는, 정제 취출 장치(102)의 반송 경로(투입구(301)와 배출로(505)의 사이의 정제 시트의 반송 경로)에 정제 시트를 남긴 채로 한다.As described above, in step S607, the tablet supply device 101 determines whether or not the unprocessed prescription data (of the " order ") that is not yet subjected to the distribution operation processing (including the operation processing of S604 and S605) (Prescription data) having the same value as that of the prescription data (prescription name) of the presently-processed prescription data (prescription data 701 and prescription data 702) (Step S607: "NO"), the process returns to step S602 without performing the processings of steps S608 and S609. That is, in this case, the tablet sheet is left on the conveying path of the tablet take-out apparatus 102 (the conveying path of the tablet sheet between the inlet port 301 and the discharge path 505).

정제 공급 장치(101)는, 스텝 S608에 있어서, 현재, 정제 취출 장치(102)의 반송 경로 내(투입구(301)와 배출로(505)의 사이의 정제 시트의 반송 경로 내)에 있는 정제 시트를, 반송 수단에 의해 배출로(505)에 반송한다.The tablets supply device 101 supplies the tablets in the transport path of the tablet take-out device 102 (in the transport path of the tablet sheet between the feed port 301 and the discharge path 505) at step S608, Is conveyed to the discharge path (505) by the conveying means.

스텝 S608은, 스텝 S607에서, 제1 처방 데이터에 포함되는 약제 정보와 제2 처방 데이터에 포함되는 약제 정보가 동일하지 않다고 판정된 경우에는, 제1 처방 데이터에 포함되는 정제수의 정제를 취출하는 취출 동작이 행해지고 나서부터, 제2 처방 데이터에 포함되는 정제수의 정제를 취출하는 취출 동작이 행해질 때까지의 동안에, 반송 수단에 의한 반송 경로 내에 남아있는 정제 시트이며 정제 취출 동작이 행해지지 않고 있는 정제 수용부를 포함하는 정제 시트를, 배출로(505)에 배출하도록 반송 수단을 제어하는 본 발명의 제어 수단의 적용예이다.If it is determined in step S607 that the drug information included in the first prescription data is not the same as the drug information included in the second prescription data, The tablet sheet remaining in the conveying path by the conveying means and not being subjected to the tablet taking-out operation during the period from when the operation is performed until the take-out operation for taking out the tablet of the purified water contained in the second prescription data is performed, In which the conveying means is controlled so as to discharge the tablet sheet including the sheet to the discharge path (505).

그리고, 정제 공급 장치(101)는, 정제 취출 장치(102)의 반송 경로 내의 정제 시트를 배출로(505)에 반송하면, 투입구(301)에 세트되어 있는 모든 정제 시트를 1장씩, 반송 수단에 의해, 정제 취출 장치(102)의 반송 경로(투입구(301)와 배출로(505)의 사이의 정제 시트의 반송 경로)에 반송하고, 또한, 반송 수단에 의해, 배출로(505)에 반송한다(스텝 S609).When the tablet sheet in the conveying path of the tablet take-out

스텝 S609는, 시트 보유 지지부에 보유 지지된 모든 정제 시트를, 배출로에 배출하지 않도록 반송 수단을 제어하는 본 발명의 제어 수단의 적용예이다.Step S609 is an application example of the control means of the present invention for controlling the conveying means so as not to discharge all the tablet sheets held in the sheet holding portion to the discharge passage.

그리고, 정제 공급 장치(101)는, 처리를 스텝 S602에 이행한다. 본 발명에서는, 스텝 S608, 스텝 S609의 처리를 실행하는 것을 설명했지만, 스텝 S609의 처리를 행하지 않고, 스텝 S608의 처리를 행하도록 해도 된다.Then, the tablet feeder 101 shifts the processing to step S602. In the present invention, the processing of steps S608 and S609 is described. However, the processing of step S608 may be performed without performing the processing of step S609.

스텝 S607에서 "NO"라고 판정되고, 또는, 스텝 S609의 동작 처리 후에, 처리를 스텝 S602에 이행하는 경우에는, 「순서」의 값이 현재 처리 대상의 처방 데이터의 「순서」의 값보다도 낮은 미처리의 처방 데이터를 스텝 S603에서 처리 대상으로 하여, 스텝 S604 이후의 처리를 실행한다.If it is determined to be "NO" in the step S607, or if the processing is shifted to the step S602 after the operation processing in the step S609, the value of the " order " The process goes to step S604 and the subsequent steps.

이와 같이, 본 실시 형태에서의 정제 공급 장치(101)는, 상술한 도 6과 같이 처리를 행하기 위해서, 예를 들어 동일한 정제 취출 장치(102)에 있어서, 예를 들어 도 9에 나타낸 처방 데이터와 같이, 처방 데이터(701)의 정제명이 정제 A이고, 처방 데이터(702)의 정제명이 정제 B인 경우에는, 스텝 S608, 스텝 S609의 처리를 실행하게 된다. 이와 같이, 처방 데이터마다, 투입구(301)나 반송 경로 내의 정제를 모두 배출부(106)에 배출하므로, 다음의 분포에서, 잘못해서 상이한 정제를 분포하는 것을 미연에 방지할 수 있다.As described above, in order to perform the processing as shown in Fig. 6 described above, the tablet supply apparatus 101 according to the present embodiment is configured so that, for example, in the same tablet take-out

도 9는, 정제 공급 장치(101)가, 포장 장치(103)로부터 수신한 처방 데이터이며, 외부 메모리(211) 등의 기억부에 기억된 처방 데이터(701, 702)의 데이터 일례를 나타내는 도면이다.9 is a diagram showing an example of data of the prescription data 701 and 702 stored in a storage unit such as the

도 9는, 도 7에 나타난 처방 데이터(702)의 「정제명」을 「정제 A」가 아니라 「정제 B」로 한 경우의 처방 데이터의 일례이다.9 is an example of prescription data in the case where the "refinement name" of the prescription data 702 shown in FIG. 7 is set to "refinement B" instead of "refinement A".

한편, 도 7에 나타낸 처방 데이터와 같이, 처방 데이터(701)의 정제명이 정제 A이고, 처방 데이터(702)의 정제명이 정제 A인 경우에는, 스텝 S608, 스텝 S609의 처리를 행하지 않으므로, 처방 데이터(701)에 따라, 정제의 취출 동작을 행한 후, 스텝 S608, 스텝 S609의 처리를 행하지 않고, 계속해서, 다음의 미처리의 처방 데이터(702)에 따라, 정제의 취출 동작을 행할 수 있고, 분포 동작 처리 및 정제 취출 동작 처리를 효율적으로 실행할 수 있다. 즉, 효율적으로 정제 시트의 정제 수용부로부터 정제를 취출할 수 있다.On the other hand, in the case where the refinement name of the prescription data 701 is the refinement A and the refinement name of the prescription data 702 is the refinement A as in the prescription data shown in Fig. 7, the processes of the steps S608 and S609 are not performed, The tablets can be taken out in accordance with the next unprocessed prescription data 702 without performing the processes of steps S608 and S609 after the tablets are taken out according to the prescription data 701, It is possible to efficiently perform the operation processing and the tablet extraction operation processing. That is, the tablets can be efficiently taken out from the tablet accommodating portion of the tablet sheet.

또한, 약사 등의 유저가, 처방 데이터마다, 정제 시트를 투입구에 세트하는 부하를 경감시킬 수도 있다.It is also possible for a user such as a pharmacist to reduce the load for setting the tablet sheet at the loading port for each prescribed data.

이와 같이, 스텝 S607은, 스텝 S607의 판정 결과에 따라, 정제 취출 수단에 의해, 현재 처리 대상의 처방 데이터에 따라, 당해 처방 데이터에 나타나는 수의 정제를 취출한 후의 정제 시트를, 반송 수단에 의해, 배출로에 반송할지 여부를 결정한다.In this manner, in step S607, the tablet sheet obtained by removing the tablets of the number indicated by the prescribed data according to the prescription data of the current processing target is read by the tablet retrieving unit by the conveying unit in accordance with the determination result of step S607 , And determines whether or not to return to the discharge passage.

이어서, 도 15를 사용하여, 스텝 S604의 상세 처리에 대해서 설명한다.Next, with reference to Fig. 15, the detailed processing in step S604 will be described.

도 15은, 스텝 S604의 상세 처리를 나타내는 흐름도의 일례를 나타내는 도면이다.Fig. 15 is a diagram showing an example of a flowchart showing the detailed processing in step S604.

도 15에 나타낸 각 스텝에 나타내는 처리·동작은, 분포 시스템의 CPU(제어부)가 분포 시스템의 각 장치의 동작을 제어함으로써 실현된다.The processing / operation shown in each step shown in Fig. 15 is realized by the CPU (control unit) of the distribution system controlling the operation of each apparatus in the distribution system.

여기에서는, 정제 공급 장치(101)의 CPU(제어부)가, 도 15에 나타낸 각 스텝에 나타내는 처리·동작을 실현하는 것으로서 설명한다.Here, it is assumed that the CPU (control unit) of the tablet feeder 101 realizes the processing / operation shown in each step shown in Fig.

먼저, 정제 공급 장치(101)는, 정제 취출 장치(102)의 반송 경로 내의 정제 시트에, 정제가 남아있는지 여부를 판정한다(스텝 S1501). 즉, 정제 공급 장치(101)는, 정제 취출 장치(102)가, 반송 경로 내의 정제 시트의 모든 정제 수용부에 대하여, 스텝 S605의 정제 취출 동작을 행했는지 여부를 판정한다.First, the tablet supply device 101 judges whether or not the tablets remain in the tablet sheet in the conveying path of the tablet take-out device 102 (step S1501). That is, the tablet supply device 101 determines whether or not the

구체적으로는, 스텝 S605의 취출 동작을 행한 정제 수용부의 수(1장의 정제 시트 단위의 수), 또는 센서(506)에 의해 검출한 정제수(1장의 정제 시트 단위의 수)가, 현재 처리 대상의 처방 데이터의 「시트 상의 정제 수용 부수(709)」의 값보다도 작은 값인지 여부를 판정하고, 작은 값이라고 판정된 경우에는, 반송 경로 내의 정제 시트의 모든 정제 수용부에 대하여, 스텝 S605의 정제 취출 동작을 행하고 있지 않다고 판정한다.Specifically, the number of tablet accommodating portions (the number of sheets of one tablet sheet) or the number of purified water (the number of sheets of one tablet sheet) detected by the sensor 506 in the step S605 is calculated Is smaller than the value of the " number of tablets received on the

한편, 스텝 S605의 취출 동작을 행한 정제 수용부의 수(1장의 정제 시트 단위의 수), 또는 센서(506)에 의해 검출한 정제수(1장의 정제 시트 단위의 수)가, 현재 처리 대상의 처방 데이터의 「시트 상의 정제 수용 부수(709)」의 값과 동일한 값이라고 판정된 경우에는, 반송 경로 내의 정제 시트의 모든 정제 수용부에 대하여, 스텝 S605의 정제 취출 동작을 행했다고 판정한다.On the other hand, the number of tablet accommodating portions (the number of sheets of one tablet sheet) or the number of purified water (the number of sheets of one tablet sheet) detected by the sensor 506 in the step S605 is set as the present prescription data , It is determined that the tablet extracting operation in step S605 has been performed on all the tablet accommodating portions of the tablet sheet in the conveying path.

정제 공급 장치(101)는, 스텝 S1501에서, 정제 취출 장치(102)의 반송 경로 내의 정제 시트에, 정제가 남아있는지 여부를 판정하는 방법의 다른 예에 대해서 설명한다.The tablet supply device 101 will explain another example of a method for determining whether or not the tablets are left on the tablet sheet in the conveying path of the tablet take-out

예를 들어, 정제 공급 장치(101)는, 검출 기구(504)가 정제 수용부를 검출함으로써 정제 수용부간의 간격(거리)을 검출하고, 당해 정제 수용부간의 간격(거리) 이상을 반송 수단이 반송해도, 검출 기구(504)가 정제 수용부를 검출할 수 없는 경우에는, 반송 경로 내의 정제 시트에, 정제가 남아있지 않다고 판정하고, 검출 기구(504)가 정제 수용부를 검출할 수 있는 경우에는, 반송 경로 내의 정제 시트에, 정제가 남아있다고 판정할 수도 있다.For example, the tablet supply device 101 detects the interval (distance) between the tablet accommodating portions by detecting the tablet accommodating portion by the detecting mechanism 504, and conveys more than the interval (distance) between the tablet accommodating portions When the detecting mechanism 504 can not detect the tablet accommodating portion, it is determined that no tablets remain on the tablet sheet in the conveying path. When the detecting mechanism 504 can detect the tablet accommodating portion, It may be determined that tablets remain on the tablet sheet in the path.

정제 공급 장치(101)는, 정제 취출 장치(102)가, 반송 경로 내의 정제 시트의 모든 정제 수용부에 대하여, 스텝 S605의 정제 취출 동작을 행했다고 판정된 경우에는(스텝 S1501: "NO"), 반송 수단을 동작시켜, 당해 반송 경로 내의 정제 시트를, 배출로(505)에 배출한다(스텝 S1503). 이에 의해, 당해 정제 시트는, 배출부(106)에 배출된다.When it is determined that the

그리고, 정제 공급 장치(101)는, 반송 수단을 동작시켜, 투입구(301)에 투입되어 있는 정제 시트를, 1장, 반송 경로 내에 반송한다(스텝 S1504). 그리고, 정제 공급 장치(101)는, 반송 수단을 동작시켜서, 반송 경로 내에 반송된 정제 시트를, 압출부(502)의 압출 위치의 방향으로 반송한다(스텝 S1505).Then, the tablet feeder 101 operates the conveying means to convey the tablet sheet put in the inlet 301 into the conveying path (Step S1504). Then, the tablet supply device 101 operates the conveying means to convey the tablet sheet conveyed in the conveying path in the direction of the extrusion position of the extrusion portion 502 (step S1505).

정제 공급 장치(101)는, 스텝 S1501에 있어서, 정제 취출 장치(102)가, 반송 경로 내의 정제 시트의 모든 정제 수용부에 대하여, 스텝 S605의 정제 취출 동작을 행하고 있지 않다고 판정된 경우에는("YES"), 예를 들어 도 16의 (c)와 같이, 당해 반송 경로 내의 정제 시트의 정제 수용부이며, 압출부(502)의 압출 위치에 위치한 정제 수용부에, 정제가 있는지 여부를 판정한다(스텝 S1502).When the

구체적으로는, 정제 공급 장치(101)는, 스텝 S605의 취출 동작을 행한 정제 수용부의 수(1장의 정제 시트 단위의 수), 또는 센서(506)에 의해 검출한 정제수(1장의 정제 시트 단위의 수)가, 홀수인 경우에는, 정제 시트의 좌우에 2개 있는 정제 수용부 중 우측의 정제 수용부에 대해서는, 정제의 취출 동작을 행하고 있지 않아, 정제가 있다고 판정한다.Specifically, the tablet supply device 101 determines whether or not the number of tablets accommodated in the step S605 (the number of tablets in one tablet sheet) or the number of tablets Is an odd number, it is judged that the tablets are not taken out for the right tablet reservoir among the two tablet reservoirs on the right and left sides of the tablet sheet.

이 경우, 정제 공급 장치(101)는, 예를 들어 도 16의 (c)와 같이, 당해 반송 경로 내의 정제 시트의 정제 수용부이며, 압출부(502)의 압출 위치에 위치한 정제 수용부에, 정제가 있다고 판정한다(스텝 S1502: "YES").In this case, as shown in Fig. 16C, for example, the tablet supply device 101 is a tablet accommodating portion of the tablet sheet in the conveying path, and the tablet accommodating portion located at the extruding position of the extruding portion 502, It is determined that there is a tablet (step S1502: YES).

그리고, 정제 공급 장치(101)는, 압출 위치에 위치한 정제 수용부에 정제가 있다고 판정된 경우에는(스텝 S1502: "YES"), 처리를 스텝 S605로 복귀하여, 반송 수단에 의한 정제 시트의 반송은 행하지 않고, 정제가 남아있는 정제 수용부에 대하여 정제의 취출 동작을 행한다.When it is determined that there is a tablet in the tablet accommodating portion located at the extrusion position (step S1502: YES), the processing returns to step S605, and the tablet sheet is conveyed by the conveying means The tablets are taken out to the tablet accommodating portion in which tablets remain.

정제 공급 장치(101)는, 스텝 S605의 취출 동작을 행한 정제 수용부의 수(1장의 정제 시트 단위의 수), 또는 센서(506)에 의해 검출한 정제수(1장의 정제 시트 단위의 수)가, 짝수인 경우에는, 예를 들어 도 16의 (b)와 같이, 압출 위치에 위치한 정제 수용부에 정제는 없다고 판정하고(스텝 S1502: "NO"), 처리를 스텝 S1505에 이행한다. 그리고, 정제 공급 장치(101)는, 스텝 S1505에 있어서, 반송 수단을 동작시켜서, 반송 경로 내의 정제 시트를, 압출부(502)의 압출 위치의 방향으로 반송한다.The tablet supply device 101 determines whether the number of tablet accommodating portions (the number of tablets in one tablet sheet) or the number of tablets (one tablet sheet) detected by the sensor 506 in step S605, If it is an even number, for example, as shown in Fig. 16B, it is determined that there is no tablet in the tablet accommodating portion located at the extruded position (step S1502: NO), and the process proceeds to step S1505. Then, in step S1505, the tablet supply device 101 operates the conveying means to convey the tablet sheet in the conveying path in the direction of the extrusion position of the extrusion portion 502. [

이어서, 정제 공급 장치(101)는, 스텝 S1505에서, 반송 경로 내의 정제 시트를, 압출부(502)의 압출 위치의 방향으로 반송하고 있는 동안에, 검출 기구(504)가 정제 수용부를 검출했는지 여부를 판정한다(스텝 S1506).Subsequently, in step S1505, while the tablet sheet in the conveying path is being conveyed in the direction of the extruded position of the extruding section 502, the tablet feeder 101 determines whether or not the detection mechanism 504 has detected the tablet accommodating section (Step S1506).

정제 공급 장치(101)는, 검출 기구(504)가 정제 수용부를 검출하고 있지 않다고 판단된 경우에는(스텝 S1506: "NO"), 계속해서, 반송 경로 내의 정제 시트를 압출 위치의 방향으로 반송하고(스텝 S1505), 검출 기구(504)가 정제 수용부를 검출했다고 판정한 경우에는(스텝 S1506: "YES"), 정제 수용부의 길이의 계측을 시작한다(스텝 S1507).When it is determined that the detection mechanism 504 does not detect the tablet accommodating portion (step S1506: "NO"), the tablet supply device 101 subsequently conveys the tablet sheet in the conveying path in the direction of the extrusion position (Step S1505). If it is determined that the detection mechanism 504 has detected the tablet accommodating portion (step S1506: YES), measurement of the length of the tablet accommodating portion is started (step S1507).

구체적으로는, 정제 공급 장치(101)는, 스텝 S1507에서는, 스텝 S1509에서 정제 수용부를 검출하기 시작하여, 스텝 S1509에서 정제 수용부를 검출하지 않게 될 때까지 정제 시트를 반송하는 하부 롤러(501) 및/또는 상부 롤러의 회전 거리(반송 거리), 또는, 하부 롤러(501) 및/또는 상부 롤러의 회전 시간(반송 시간)을 계측한다.Specifically, in step S1507, the tablet supply device 101 starts to detect the tablet accommodating part in step S1509, and transfers the tablet sheet until the tablet accommodating part is not detected in step S1509. (Transport distance) of the upper roller, or the rotation time (transport time) of the lower roller 501 and / or the upper roller.

정제 공급 장치(101)는, 스텝 S1508에 있어서, 계속해서, 반송 수단을 동작시켜서, 반송 경로 내의 정제 시트를 압출 위치의 방향으로 반송하여, 검출 기구(504)가 정제 수용부를 계속해서 검출한다.In step S1508, the tablet supply device 101 continues to operate the conveying means to convey the tablet sheet in the conveying path in the direction of the extrusion position, and the detection mechanism 504 continues to detect the tablet accommodating portion.

그리고, 정제 공급 장치(101)는, 검출 기구(504)가 당해 정제 수용부를 검출 하고 있는지 여부를 판정하고(스텝 S1509), 검출하고 있지 않다고 판단된 경우에는(스텝 S1509: "NO"), 처리를 스텝 S1507에 이행한다.Then, the tablet supply device 101 determines whether or not the detection mechanism 504 detects the tablet accommodating portion (step S1509). When it is determined that the detection mechanism 504 does not detect the tablet accommodating portion (step S1509: "NO & The process proceeds to step S1507.

정제 공급 장치(101)는, 검출 기구(504)가 당해 정제 수용부를 검출하고 있지 않다고 판단되면(스텝 S1509: "YES"), 처리를 스텝 S1510에 이행한다.When it is determined that the detection mechanism 504 has not detected the tablet accommodating portion (step S1509: "YES"), the tablet supply device 101 proceeds to step S1510.

이와 같이, 정제 공급 장치(101)는, 정제 시트의 당해 정제 수용부를 검출하지 않게 될 때까지, 반복적으로, 스텝 S1507, S1508의 처리를 실행한다.Thus, the tablet supply device 101 repeatedly performs the processes of steps S1507 and S1508 until it does not detect the tablet accommodating portion of the tablet sheet.

정제 공급 장치(101)는, 스텝 S1507에서 계측된 하부 롤러(501) 및/또는 상부 롤러의 회전 거리(반송 거리), 또는, 하부 롤러(501) 및/또는 상부 롤러의 회전 시간(반송 시간)으로부터, 정제 수용부의 반경(절반)의 길이를 산출한다(스텝 S1510).The tablets supply device 101 may determine whether the rotation distance (conveyance distance) of the lower roller 501 and / or the upper roller measured in step S1507 or the rotation time (conveyance time) of the lower roller 501 and / The length of the radius (half) of the tablet accommodating portion is calculated (step S1510).

정제 공급 장치(101)는, 스텝 S1510에 있어서, 계측된 회전 거리(반송 거리)를 2로 나눔으로써, 정제 수용부의 반경(절반)의 길이를 산출한다.In step S1510, the tablet supply device 101 calculates the length of the radius (half) of the tablet accommodating portion by dividing the measured rotation distance (transfer distance) by two.

또는, 정제 공급 장치(101)는, 스텝 S1510에 있어서, 소정 시간(예를 들어 1초)당의 반송 거리(예를 들어 1mm)의 값(「반송 거리/소정 시간」의 값)을 기억하고 있고, 이 값(「반송 거리/소정 시간」의 값)을, 계측된 회전 시간(반송 시간)에 곱함으로써, 반송 거리를 산출하고, 당해 산출된 반송 거리를 2로 나눔으로써, 정제 수용부의 반경(절반)의 길이를 산출한다.Alternatively, the tablet feeder 101 stores the value (the value of the "conveying distance / predetermined time") of the conveying distance (for example, 1 mm) per a predetermined time (for example, one second) in step S1510 , The conveyance distance is calculated by multiplying the measured rotation time (conveyance time) by this value (the value of the conveyance distance / predetermined time), and the calculated conveyance distance is divided by 2 to calculate the radius Half).

그리고, 정제 공급 장치(101)는, 당해 산출된 정제의 반경(예를 들어, 1mm)과, 검출 기구(504)부터 압출부(502)에 의한 압출 위치까지의 소정 거리(예를 들어, 25mm)의 차(예를 들어, 24mm)를, 스텝 S1509에서 "YES"라고 판정된 시점의 정제 시트의 반송 경로 내의 위치부터, 압출부(502)에 의한 압출 위치까지의 반송 거리로서 산출한다(스텝 S1510).The tablets supply device 101 is arranged at a predetermined distance (for example, 25 mm) from the radius (for example, 1 mm) of the tablets thus calculated to the extrusion position by the detection mechanism 504 to the extrusion portion 502 (For example, 24 mm) from the position in the conveying path of the tablet sheet at the time when it is judged as "YES " in the step S1509 as the conveyance distance from the extrusion portion 502 to the extrusion position S1510).

그리고, 정제 공급 장치(101)는, 반송 수단을 동작시켜서, 스텝 S1510에서 산출된 반송 거리만큼, 당해 정제 시트를 반송해서(스텝 S1511), 당해 정제 시트를 압출 위치에 배치시킨다.Then, the tablet supply device 101 operates the conveying means to convey the tablet sheet by the conveyance distance calculated in step S1510 (step S1511), and places the tablet sheet at the extrusion position.

그리고, 정제 공급 장치(101)는, 스텝 S1511의 처리를 실행하면, 처리를 스텝 S605로 복귀시킨다.Then, the tablet supply device 101 returns the process to step S605 when executing the process of step S1511.

<제2 실시 형태>≪ Second Embodiment >

이어서, 도 8을 사용하여, 본 발명에 따른 제2 실시 형태에 대해서 설명한다.Next, a second embodiment according to the present invention will be described with reference to Fig.

도 8은, 처방 데이터에 따라, 정제 시트의 정제 수용부로부터 정제를 취출하여, 배출부(106)에 정제 시트를 배출하는 일련의 처리의 일례를 나타내는 흐름도이다.8 is a flowchart showing an example of a series of processes for extracting tablets from the tablet accommodating portion of the tablet sheet and discharging the tablet sheet to the discharging portion 106 according to the prescription data.

도 8에 나타낸 각 스텝에 나타내는 처리·동작은, 분포 시스템의 CPU(제어부)가 분포 시스템의 각 장치의 동작을 제어함으로써 실현된다.The processing / operation shown in each step shown in Fig. 8 is realized by the CPU (control unit) of the distribution system controlling the operation of each device of the distribution system.

여기에서는, 정제 공급 장치(101)의 CPU(제어부)가, 도 8에 나타낸 각 스텝에 나타내는 처리·동작을 실현하는 것으로서 설명한다.Here, it is assumed that the CPU (control unit) of the tablet feeder 101 realizes the processing / operation shown in each step shown in Fig.

도 8에 나타낸 흐름도는, 도 6의 흐름도에, 스텝 S801, S802, S804를 추가한 흐름도이다.The flowchart shown in Fig. 8 is a flowchart in which steps S801, S802, and S804 are added to the flowchart of Fig.

즉, 도 8에 나타낸 흐름도의 각 스텝 중, 스텝 S801, S802, S804 이외의 스텝의 처리는, 도 6에 나타낸 처리와 동일하므로, 여기서는, 그 처리의 설명에 대해서는 생략한다.In other words, among the steps of the flowchart shown in Fig. 8, the processing of steps other than steps S801, S802, and S804 is the same as the processing shown in Fig. 6, and therefore the description of the processing is omitted here.

도 8에 나타낸 처리에 있어서, 도 6에 나타낸 처리와 동일한 처리에 대해서는, 동일한 부호를 붙이고 있다.In the process shown in Fig. 8, the same processes as those shown in Fig. 6 are denoted by the same reference numerals.

정제 공급 장치(101)는, 현재 처리 대상의 처방 데이터에 나타나는 전체 정제수(예를 들어, 처방 데이터 701의 경우라면, 18개(전체 정제수))의 정제를 취출했다고 판정된 경우에는(스텝 S606: "YES"), 정제 취출 장치(102)의 반송 경로 내의 정제 시트에, 정제가 남아있는지 여부를 판정한다(스텝 S801).When it is determined that the tablets are taken out of the total number of purified water (for example, 18 (total purified water) in the case of the prescription data 701) (step S606: YES), it is judged whether or not the tablets remain in the tablet sheet in the conveying path of the tablet take-out device 102 (step S801).

스텝 S801은, 반송 경로 내에 남아있는 정제 시트에, 정제 취출 동작이 행해지지 않고 있는 정제 수용부가 포함되어 있는지 여부를 판정하는 본 발명의 수용부 판정 수단의 적용예이다.Step S801 is an application example of the accommodating portion determining means of the present invention for determining whether or not the tablet sheet remaining in the conveying path includes a tablet accommodating portion that is not subjected to the tablet removing operation.