JP6289199B2 - Mounting device for latch - Google Patents

Mounting device for latch Download PDFInfo

- Publication number

- JP6289199B2 JP6289199B2 JP2014064270A JP2014064270A JP6289199B2 JP 6289199 B2 JP6289199 B2 JP 6289199B2 JP 2014064270 A JP2014064270 A JP 2014064270A JP 2014064270 A JP2014064270 A JP 2014064270A JP 6289199 B2 JP6289199 B2 JP 6289199B2

- Authority

- JP

- Japan

- Prior art keywords

- caulking

- hook body

- locking claw

- backing plate

- claw

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Active

Links

Images

Landscapes

- Slide Fasteners, Snap Fasteners, And Hook Fasteners (AREA)

- Connection Of Plates (AREA)

Description

本発明は、掛止金具用取付装置に関し、更に詳しくは、ズボンのウエスト部分等の生地に掛止金具を取り付けるための装置に関する。 More particularly, the present invention relates to an apparatus for attaching a latch to a cloth such as a waist portion of a trouser.

掛止金具(掛止金具はフックアンドアイと呼ぶこともある)は、ズボンのウエスト部分等に一般的に取り付けられている。フックアンドアイは、一般に二本の係止爪を有するフック体と、二つの爪孔を有する裏当て板とから構成され、フック体及び裏当て板は共に金属製である。フック体を生地に取り付ける場合、一般に、フック体を上方ダイに、裏当て板を下方ダイにそれぞれ保持させ、裏当て板上に生地を配置した後、上方ダイを下方ダイに向かって降下させる。これにより、フック体の係止爪が生地を貫通し、次いで裏当て板の爪孔を通った後、下方ダイによって加締められる。これにより、フック体が生地の表側に固定される。裏当て板は、通常、フック体が固定された生地と、別の裏生地との間に挟まれる。 A latch (the latch is sometimes referred to as a hook and eye) is generally attached to a waist portion of trousers or the like. The hook and eye is generally composed of a hook body having two locking claws and a backing plate having two claw holes, and both the hook body and the backing plate are made of metal. When attaching the hook body to the fabric, generally, the hook body is held by the upper die and the backing plate is held by the lower die, the fabric is placed on the backing plate, and then the upper die is lowered toward the lower die. As a result, the hooking claw of the hook body penetrates the fabric and then passes through the claw hole of the backing plate, and is then crimped by the lower die. Thereby, a hook body is fixed to the front side of cloth. The backing plate is usually sandwiched between a fabric to which the hook body is fixed and another backing fabric.

従来の掛止金具用取付装置の一例が実公平3−24572号公報に開示されている。この掛止金具用取付装置は、フック体P1を保持した上方ダイ7が降下すると、フック体P1の二本の係止爪が生地Cを貫通し次いで裏当て板P2の爪孔を通った後、下方ダイの二つのカーリング部材6によって二本の係止爪が互いに近付く方向に曲げられ、これにより、フック体P1が生地Cに固定される。カーリング部材6は、軸5を中心に回動可能であり、上方ダイ7の降下に伴って押し下げられる際、上下方向に移動しない加締めダイ1の上部に突き当たることにより、カーリング部材6の自由端部が上方に変位するように回動する。この回動時に係止爪は加締められる。

An example of a conventional mounting device for a latch is disclosed in Japanese Utility Model Publication No. 3-24572. When the upper die 7 holding the hook body P1 is lowered, the hook metal fitting attachment device is configured such that after the two locking claws of the hook body P1 pass through the cloth C and then pass through the claw holes of the backing plate P2. The two locking claws are bent in the direction in which the two locking claws approach each other by the two curling members 6 of the lower die, whereby the hook body P1 is fixed to the fabric C. The curling member 6 is rotatable about the

裏当て板の爪孔は、従前、矩形の開口であった。この場合、フック体の係止爪が生地を貫通し次いで爪孔を通る際、生地が爪孔に巻き込まれ易く、例えば生地に皺が生じるといった問題があった。これを回避するため、爪孔を開口ではなく金属製の薄肉部とした裏当て板が知られている。この薄肉部は、フック板の生地への取り付け時に係止爪によって突き破られるように設計される。しかしながら、金属製の薄肉部を係止爪が突き破ることによって、薄肉部が突き破られる方向に沿って突出するような、いわゆるバリが発生し、このバリが上記裏生地を損傷したり、あるいは裏生地から突き出て、ユーザの皮膚を傷付けるといった弊害が生じ得る。 Conventionally, the nail holes of the backing plate were rectangular openings. In this case, when the hook claw of the hook body passes through the cloth and then passes through the nail hole, the cloth is easily caught in the nail hole, and there is a problem that wrinkles are generated in the cloth, for example. In order to avoid this, a backing plate is known in which the claw hole is not an opening but a metal thin portion. This thin portion is designed to be pierced by the locking claw when the hook plate is attached to the fabric. However, when the locking claw breaks through the thin metal portion, a so-called burr that protrudes along the direction in which the thin portion is broken is generated, and this burr damages the back fabric or There may be a negative effect of sticking out of the fabric and damaging the user's skin.

本発明は、上記問題点に鑑みてなされたもので、フック体の係止爪が裏当て板の薄肉部を突き破ることによって生じるバリの弊害を防ぐことができる掛止金具用取付装置を提供することを目的とする。 The present invention has been made in view of the above-described problems, and provides a mounting device for a latch that can prevent the adverse effects of burrs caused by the locking claws of the hook body breaking through the thin portion of the backing plate. For the purpose.

上記課題を解決するため、本発明によれば、係止爪を有するフック体を、係止爪によって突き破られる薄肉部を有する裏当て板を用いて生地に取り付けるための掛止金具用取付装置であって、前記薄肉部を突き破った係止爪を加締めるための加締め部材を備え、前記加締め部材は、係止爪を加締めるための加締め面を有し、係止爪が薄肉部を突き破ることによって、前記薄肉部の一部が、前記フック体と反対側に突出して生じ得るバリに対し、バリを潰すために、前記加締め面に対して立ち上がる潰し部を含むことを特徴とする掛止金具用取付装置が提供される。 In order to solve the above-described problems, according to the present invention, a hook fitting mounting apparatus for mounting a hook body having a locking claw to a fabric using a backing plate having a thin wall portion to be pierced by the locking claw. And a crimping member for crimping the latching claw that has broken through the thin-walled portion, the crimping member having a crimping surface for crimping the latching claw, and the latching claw is thin A portion of the thin wall portion includes a crushing portion that rises with respect to the caulking surface in order to crush the burr against a burr that may be caused by protruding through the portion and projecting to the opposite side of the hook body. An attachment device for a latching metal is provided.

本発明に係る掛止金具用取付装置では、フック体の係止爪を生地に貫通させ、次いで裏当て板の薄肉部を突き破らせた後、係止爪を加締め部材の加締め面により加締めることにより、フック体が裏当て板と共に生地に取り付けられる。フック体の係止爪が裏当て板の薄肉部を突き破ることによってフック体と反対側に突出して生じるバリは、加締め部材の潰し部によって潰される。 In the latch mounting apparatus according to the present invention, the hooking claw of the hook body is passed through the cloth, and then the thin portion of the backing plate is pierced, and then the locking claw is moved by the crimping surface of the crimping member. By hooking, the hook body is attached to the fabric together with the backing plate. The burr produced by the hooking pawls of the hook body protruding through the thin wall portion of the backing plate and projecting to the opposite side of the hook body is crushed by the crushed portion of the caulking member.

本発明において、掛止金具用取付装置は、フック体の生地への取り付け時に裏当て板を保持する側のダイ自体又はその一部として構成することができる。フック体及び裏当て板は、アルミニウム合金、銅合金、ニッケル合金等の金属製である。 In the present invention, the attaching device for the latch metal can be configured as a die itself or a part of the die that holds the backing plate when the hook body is attached to the cloth. The hook body and the backing plate are made of a metal such as an aluminum alloy, a copper alloy, or a nickel alloy.

本発明の一実施形態において、前記加締め部材は、初期位置と加締め完了位置の間を軸部を中心に回動可能である。この場合、加締め部材は初期位置から加締め完了位置へと回動しつつフック体の係止爪を加締める。加締め部材の回動機構は、例えば実公平3−24572号公報に開示されているような、移動中の加締め部材の自由端部が静止状態の部材等に突き当たることによって回動するような機構を挙げることができるが、これに限定されるものではない。 In one embodiment of the present invention, the caulking member is rotatable about an axis portion between an initial position and a caulking completion position. In this case, the caulking member caulks the locking claws of the hook body while rotating from the initial position to the caulking completion position. The swaging mechanism of the swaging member is swung by the free end of the swaging member that is moving, for example, as disclosed in Japanese Utility Model Publication No. 3-24572, by striking against a stationary member or the like. Although a mechanism can be mentioned, it is not limited to this.

本発明の一実施形態において、前記潰し部は前記加締め面の両側において立ち上がってなる。ここで、「加締め面の両側」とは、加締め面の、係止爪が加締められるすなわち曲げられる方向に垂直な方向における両側をいう。この点について、後述する本発明の一実施形態において、図5を参照して、係止爪14が加締められる方向は図5の紙面手前から奥であり、加締め面34の、係止爪14が加締められる方向に垂直な方向は図5の紙面左右である。そのため、潰し部(側壁)35は、加締め面34の図5紙面左右両側から立ち上がる。

In one embodiment of the present invention, the crushing portion rises on both sides of the caulking surface. Here, “both sides of the crimping surface” refers to both sides of the crimping surface in a direction perpendicular to the direction in which the locking claws are crimped, that is, bent. With regard to this point, in one embodiment of the present invention to be described later, referring to FIG. 5, the direction in which the

本発明の一実施形態において、前記加締め面は前記軸部の軸線を含む一つの平面に平行であり、前記潰し部は前記加締め面に対し前記軸線に沿う方向の両側において立ち上がる。この場合、加締め面は、加締め部材の回動の中心である軸部の軸線を含む無数の平面のうちの一つの平面に対して平行となるように設定される。また、潰し部は、前記軸線を含む一つの平面に平行な加締め面に対し、前記軸線に沿う方向(軸方向)の両側において立ち上がる。 In one embodiment of the present invention, the caulking surface is parallel to one plane including the axis of the shaft portion, and the crushing portion rises on both sides of the caulking surface along the axis. In this case, the caulking surface is set to be parallel to one of the infinite number of planes including the axis of the shaft portion that is the center of rotation of the caulking member. The crushing portion rises on both sides in the direction along the axis (axial direction) with respect to the crimped surface parallel to one plane including the axis.

本発明の一実施形態において、前記フック体は二つの係止爪を有し、前記裏当て板は前記二つの係止爪にてそれぞれ突き破られる二つの薄肉部を有し、前記掛止金具用取付装置は前記加締め部材を二つ備える。 In one embodiment of the present invention, the hook body has two locking claws, and the backing plate has two thin portions that are pierced by the two locking claws, respectively. The mounting apparatus includes two caulking members.

本発明では、加締め部材に潰し部を設けたことにより、フック体の係止爪が裏当て板の薄肉部を突き破ることによって生じるバリを潰し部により潰すことができるため、バリが裏生地を損傷したり、裏生地から突き出てユーザの皮膚を傷付けるといった弊害を防止することができる。 In the present invention, since the crushing portion is provided in the caulking member, the burr generated by the hooking claw of the hook body breaking through the thin portion of the backing plate can be crushed by the crushing portion. It is possible to prevent adverse effects such as damage or damage to the user's skin protruding from the back fabric.

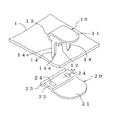

以下、本発明の好適な実施形態を図面を参照しつつ説明するが、本発明はそのような実施形態に限定されるものではなく、特許請求の範囲及び均等の範囲内で変更等がなされ得る。図1及び2は、生地1に取り付ける直前のフック体10と裏当て板20の配置状態を示す斜視図及び一部断面側面図である。以下の説明において、上下は図2〜7の紙面に基づく。また、前後及び左右は参照している図面に基づき、図2については、図2の紙面右側を前方、左側を後方という。フック体10と裏当て板20は掛止金具の構成部品であり、いずれも金属製である。フック体10は、前端が円弧状の表板部11と、表板部11と平行な裏板部12と、表板部11の後端と裏板部12の後端とを断面C字状に湾曲しつつ連結する連結部13と、裏板部12の左右両側から下方(表板部11とは反対側)に延びる二本の係止爪14とを備える。裏板部12は連結部13から前端までの長さが表板部11に比べ短く、裏板部12の前端は左右方向に沿う直線状である。各係止爪14は、水平断面が矩形の爪胴部14bと、爪胴部14bの下端から先細る尖った先端部(下端部)14aとを有する。爪胴部14bは前後方向の厚さが左右方向の厚さに比べ大きい。

DESCRIPTION OF EXEMPLARY EMBODIMENTS Hereinafter, preferred embodiments of the invention will be described with reference to the drawings. However, the invention is not limited to the embodiments, and modifications and the like can be made within the scope of the claims and the equivalent scope thereof. . 1 and 2 are a perspective view and a partial cross-sectional side view showing an arrangement state of the

裏当て板20は、前端が円弧状の前板部21と、前板部21の後端から上方に若干隆起し、次いで後方へと前板部21と平行(すなわち水平)に延びた後、下方に落ち込む隆起部22と、隆起部22の後端から後方に若干延びる後端部23とを備える。隆起部22は、裏当て板20の左右全長にわたる。また、隆起部22は、前板部21の後端から上方に隆起する部分である前側部22aと、後端部23の前端から上方に隆起する部分である後側部22bとを含む。図2から分かるように、前側部22aは後方へと上方に傾斜し、後側部22bは前方へと上方に傾斜する。また、後端部23も後方へと上方に傾斜するが、その角度は前側部22aに比べ若干小さい。隆起部22は、フック体10の生地1への取り付け時に係止爪14を通す二つの薄肉部24を有する。薄肉部24は、係止爪14の水平断面を包含する領域として設定され、左右方向よりも前後方向に厚い係止爪14に対応して左右方向よりも前後方向に長方形を有する。薄肉部24はフック体10における他の部分に比べて板厚が薄くされる。薄肉部24の厚さは、フック体10の生地1への取り付け時に係止爪14が突き破ることができる程度に設定される。薄肉部24を設けずに、薄肉部24に対応する部分を開口とする場合、フック体10の生地1への取り付け時に係止爪14によって生地が前記開口から裏当て板20の下方へと巻き込まれる量が増える。このような生地1の巻き込みを減らすにために薄肉部24が設けられている。各薄肉部24は、隆起部22の下面から上方に窪むように形成され、薄肉部24の上面は隆起部22の上面と共通である。

The

フック体10を生地1に取り付けるに当たり、図示はしないが、フック体10は上方ダイに、裏当て板20は下方ダイにそれぞれ保持され、また、裏当て板20上に生地1が配置される。次いで、本実施形態では上方ダイが下方ダイに向かって降下することにより、フック体10の係止爪14が生地を貫通し、次いで裏当て板20の薄肉部24を突き破った後、後述する回動ダイ(加締め部材)30によって左右二本の係止爪14が互いに近付く方向に加締められることにより、生地1にフック体10が取り付けられる。両係止爪14は、互いに近付く方向に曲がり易いように、図2紙面前後方向よりも左右方向に薄くされるともいえる。なお、下方ダイが上方ダイに対して上昇する場合等もあり得る。本発明に係る掛止金具用取付装置は下方ダイ自体又はその一部に相当する。

When attaching the

図3〜7は、フック体10を生地1に取り付ける工程の説明図である。図3は、フック体10の係止爪14が生地1に近接している時点を示し、ここに示す裏当て板20の薄肉部24は、図1の左右一方の薄肉部24のA線矢視断面である。以下、図3に示される薄肉部24及びこの薄肉部24に対応する係止爪14を右側の薄肉部24及び係止爪14とする。本発明に係る掛止金具用取付装置すなわち下方ダイは、フック体10の左右二本の係止爪14をそれぞれ加締めるための左右二つの加締め部材としての回動ダイ30を備える。回動ダイ30は実公平3−24572号公報に記載されたカーリング部材6に対応する。回動ダイ30は、図3等において右側の回動ダイ30のみが示される。回動ダイ30は、軸部31を中心に回動可能な回動体32を備える。図5及び図6は図3のB線矢視断面である。これらの図から分かるように、回動体32は、その上方側面(以下「上面」という)に係止爪14を加締めるための加締め面34と、加締め面34の図5及び6の紙面左右(軸部31の軸方向)両側において上方に立ち上がる、後述するバリ24aを潰すための潰し部としての側壁35とを有する。ここで、「加締め面の両側」とは、加締め面の、係止爪が加締められるすなわち曲げられる方向に垂直な方向における両側をいう。ここで、前記加締め面34は前記軸部31の軸線を含む一つの平面に平行であり、前記潰し部35は前記加締め面34に対し前記軸線に沿う方向(軸方向)の両側において立ち上がる。この点について、図5を参照して、係止爪14が加締められる方向は図5の紙面手前から奥であり、加締め面34の、係止爪14が加締められる方向に垂直な方向は図5の紙面左右である。そのため、潰し部(側壁)35は、加締め面34の図5紙面左右両側から立ち上げる。加締め面34は、軸部31の軸線を含む一つの平面に平行な平坦面であり、側壁35は加締め面34と平行な上面35aを有する。なお、加締め面34は、加締め部材30の回動の中心である軸部31の軸線を含む無数の平面のうちの一つの平面に対して平行となるように設定される。

3-7 is explanatory drawing of the process of attaching the

回動ダイ30は、図3に示す傾斜する初期位置から図7に示すほぼ水平な加締め完了位置まで軸部31を中心に時計回り方向に回動することができる。この回動ダイ30の回動は、例えば、降下する上方ダイに保持されたフック体10の係止爪14が生地1に接した後、更に降下する上方ダイが生地1等を介して下方ダイの回動ダイ30を下方に押し下げる際、下方ダイの静止部分が回動体32の自由端部32bに突き当たり、これにより、回動体32の自由端部32bが相対的に上方に持ち上げられて回動ダイ30が回動するような構成とすることができる。

The rotating die 30 can be rotated clockwise about the shaft portion 31 from the inclined initial position shown in FIG. 3 to the substantially horizontal crimping completion position shown in FIG. The rotation of the

次に、フック体10を生地1に取り付ける工程を説明する。図3の時点から更にフック体10が降下すると、フック体10の係止爪14が生地1を貫通し、次いで、図4及び5に示すように裏当て板20の薄肉部24を下方へと突き破る。この際、突き破られた薄肉部24には下方に捲られたバリ24aが発生する。バリ24aは、フック体10と反対側に突出して裏当て板20の矩形の薄肉部24の図2紙面左右両側及び前後両側で発生し、図4には左右両側に生じたバリ24aが、図5には前後両側に生じたバリ24aが表される。なお、係止爪14は、厚さが左右方向に薄く、前後方向に厚いため、左右両側のバリ24a(図4)よりも前後両側のバリ24a(図5)が大きくなる。左右両側のバリ24a(図4)は小さく、裏当て板20の隆起部22の下面より下方にほとんど突き出ないため、後述する潰し部(側壁)35によって潰す対象とはしない。

Next, the process of attaching the

回動ダイ30はほぼ図4の時点から回動を開始する。図5は、フック体10の右側の係止爪14の先端部14aが回動ダイ30の回動体32の加締め面34に接した時点を示す。この時点において係止爪14は上方ダイによって下方に押されると共に、図4の状態から時計回り方向に回動中の回動ダイ30の回動体32の加締め面34によって上方に押される。これにより右側の係止爪14は回動体32の加締め面34上を滑りながら図示しない左側の係止爪14に向かって曲げられる。つまり、加締め面34が係止爪14に接触し、さらに回動体32が回転することで、加締め面34が上方へ移動し、これによって係止爪14に圧力がかかり、その圧力が係止爪14を折り曲げるように変形させる。係止爪14が折り曲がる方向は、係止爪14の爪胴部14bが前後方向の厚さが左右方向の厚さに比べ大きいことから、左右方向に変形しやすく、かつ回動体32の回動前の初期位置の加締め面34が、軸部31から回動体32の先端に向かうに従って下方に向く傾斜面であり、この傾斜面にそって係止爪14が折り曲がって変形する。このようであるから、潰し部35は、係止爪14の加締め時に加締め面34上を滑る方向に対する両側に設けられている。つまり、潰し部35は軸部31の軸線方向に沿って離間するようにして、回動体32の上面に設けられ、この一対の潰し部35の間に加締め面34が設けられる。同様に左側の係止爪14も左側の回動ダイによって右側に加締められる。図7は、右側の係止爪14の加締めが完了した状態を示す。

The rotating die 30 starts to rotate from the point of FIG. FIG. 5 shows a point in time when the

図6は、回動体32の加締め面34によって係止爪14を加締め中の状態を示す一部断面拡大図である。この図から分かるように、回動ダイ30は、加締め面34で係止爪14を加締めながら、図6紙面左右(図2紙面前後)二つの側壁35の上面35aにより、薄肉部24の図6紙面左右(図2紙面前後)のバリ24aを裏当て板20の隆起部22の下面に押し付けるようにして潰すことができる。これによってバリ24aが生地1との間で裏当て板20を挟む図示しない裏生地を損傷したり、あるいは裏生地から突き出て、ユーザの皮膚を傷付けるような事態を回避することができる。また、回動体32の加締め面34及び二つの側壁35は係止爪14を加締める際のガイドとしての役割を果たし、左右の係止爪14が確実に相互方向に曲げられることを助ける。なお、加締め部材30は軸部31を中心に回動する以外に、加締め部材30を裏当て板20の下方から裏当て板20に向けて垂直方向に移動することで、加締め部材30の加締め面34を係止爪14に接触させて、係止爪14を折り曲げるように変形させるようにもできる。このとき、加締め面34は係止爪14の先端14aが最初に接触する位置から、折り曲がる方向にその先端14aをガイドするように曲面形状になっていることが好ましい。

FIG. 6 is a partially enlarged cross-sectional view showing a state in which the locking

1 生地

10 フック体

14 係止爪

20 裏当て板

24 薄肉部

24a バリ

30 回動ダイ(加締め部材)

31 軸部

32 回動体

34 加締め面

35 潰し部(側壁)

35a (潰し部の)上面

DESCRIPTION OF

31

35a Upper surface (of the crushed part)

Claims (5)

前記薄肉部(24)を突き破った係止爪(14)を加締めるための加締め部材(30)を備え、

前記加締め部材(30)は、係止爪(14)を加締めるための加締め面(34)を有し、

係止爪(14)が薄肉部(24)を突き破ることによって、前記薄肉部(24)の一部が、前記フック体(10)と反対側に突出して生じ得るバリ(24a)に対し、バリ(24a)を潰すために、前記加締め面(34)に対して立ち上がる潰し部(35)を含むことを特徴とする掛止金具用取付装置。 A hook for attaching the hook body (10) having the locking claw (14) to the fabric (1) using the backing plate (20) having the thin wall portion (24) to be pierced by the locking claw (14). A fastener mounting device,

A caulking member (30) for caulking the locking claw (14) that broke through the thin wall portion (24);

The caulking member (30) has a caulking surface (34) for caulking the locking claw (14),

When the locking claw (14) breaks through the thin wall portion (24), a part of the thin wall portion (24) protrudes to the opposite side of the hook body (10), and the burr (24a) may be generated. (24a) A crushing bracket mounting device (35) including a crushing portion (35) standing up with respect to the caulking surface (34) in order to crush (24a).

Priority Applications (2)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| JP2014064270A JP6289199B2 (en) | 2014-03-26 | 2014-03-26 | Mounting device for latch |

| CN201510033018.6A CN104939385B (en) | 2014-03-26 | 2015-01-22 | Hook accessory erecting device |

Applications Claiming Priority (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| JP2014064270A JP6289199B2 (en) | 2014-03-26 | 2014-03-26 | Mounting device for latch |

Publications (3)

| Publication Number | Publication Date |

|---|---|

| JP2015187314A JP2015187314A (en) | 2015-10-29 |

| JP2015187314A5 JP2015187314A5 (en) | 2017-03-23 |

| JP6289199B2 true JP6289199B2 (en) | 2018-03-07 |

Family

ID=54154901

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| JP2014064270A Active JP6289199B2 (en) | 2014-03-26 | 2014-03-26 | Mounting device for latch |

Country Status (2)

| Country | Link |

|---|---|

| JP (1) | JP6289199B2 (en) |

| CN (1) | CN104939385B (en) |

Family Cites Families (9)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US3159843A (en) * | 1962-09-04 | 1964-12-08 | Joseph B Miceli | Hook and eye fastening device |

| JPS6118010U (en) * | 1984-07-06 | 1986-02-01 | 日本ノ−シヨン工業株式会社 | hooked male body |

| AU560548B2 (en) * | 1984-12-17 | 1987-04-09 | Yoshida Kogyo K.K. | Hook and eye assembly |

| JPH0324572Y2 (en) * | 1986-08-19 | 1991-05-29 | ||

| CN2037554U (en) * | 1988-10-22 | 1989-05-17 | 白绍华 | Quick-sewed on buttons |

| JP3109935B2 (en) * | 1993-02-08 | 2000-11-20 | ワイケイケイ株式会社 | Hook and mounting method |

| JPH0790708A (en) * | 1993-09-21 | 1995-04-04 | Oishi Kinzoku Kogyo Kk | Lower mold apparatus in hook-driving machine |

| IT1313772B1 (en) * | 1999-10-06 | 2002-09-17 | Gaetano Raccosta | IMPROVED COUNTERMASK FOR AUTOMATIC AND AUTOMATIC BUTTON EQUIPPED WITH THIS COUNTERMASK. |

| US7752718B2 (en) * | 2005-10-14 | 2010-07-13 | Orc Industries | Snap fastener |

-

2014

- 2014-03-26 JP JP2014064270A patent/JP6289199B2/en active Active

-

2015

- 2015-01-22 CN CN201510033018.6A patent/CN104939385B/en active Active

Also Published As

| Publication number | Publication date |

|---|---|

| CN104939385B (en) | 2016-12-07 |

| JP2015187314A (en) | 2015-10-29 |

| CN104939385A (en) | 2015-09-30 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| JP4726765B2 (en) | Bottom fastener for slide fastener | |

| US9060573B2 (en) | Zipper head and pull tab replacement method | |

| JP6401376B2 (en) | Slider for slide fastener | |

| JP2013100383A (en) | Hide-punching device, hide-punching method and hide sheet | |

| JPWO2009128136A1 (en) | Metal single face teeth and double swing slide fasteners | |

| JP4634976B2 (en) | Clasp | |

| JP6289199B2 (en) | Mounting device for latch | |

| JP2018120939A5 (en) | ||

| JP2013175379A (en) | Lid opening/closing mechanism for electronic apparatus | |

| CN102307491B (en) | Fastener element for concealed slide fasteners | |

| CN104329345A (en) | Riveting structure | |

| JP2009082563A (en) | Button | |

| JP2017185533A (en) | Cutting punch of device for forming slide fastener teeth | |

| WO2013099017A1 (en) | Sliding fastener slider | |

| JP6210298B2 (en) | Plating substrate holder | |

| WO2015097895A1 (en) | Button fastener | |

| CN209965327U (en) | Metal button attaching machine | |

| JP3164407U (en) | Slide fastener fastener | |

| JP5844386B2 (en) | Slider with stop mechanism | |

| JP5914074B2 (en) | Hook device | |

| KR200366791Y1 (en) | The compression tool for fixing beads | |

| JP2013241698A (en) | Compound needle of flat knitting machine | |

| JP2019088511A5 (en) | ||

| US2299380A (en) | Pig rings or the like | |

| TWI630868B (en) | Inductive mousetrap |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| A521 | Written amendment |

Free format text: JAPANESE INTERMEDIATE CODE: A523 Effective date: 20170215 |

|

| A621 | Written request for application examination |

Free format text: JAPANESE INTERMEDIATE CODE: A621 Effective date: 20170215 |

|

| A977 | Report on retrieval |

Free format text: JAPANESE INTERMEDIATE CODE: A971007 Effective date: 20171222 |

|

| TRDD | Decision of grant or rejection written | ||

| A01 | Written decision to grant a patent or to grant a registration (utility model) |

Free format text: JAPANESE INTERMEDIATE CODE: A01 Effective date: 20180109 |

|

| A61 | First payment of annual fees (during grant procedure) |

Free format text: JAPANESE INTERMEDIATE CODE: A61 Effective date: 20180206 |

|

| R150 | Certificate of patent or registration of utility model |

Ref document number: 6289199 Country of ref document: JP Free format text: JAPANESE INTERMEDIATE CODE: R150 |