JP5846229B2 - Shaft coupling mechanism for electric power steering device - Google Patents

Shaft coupling mechanism for electric power steering device Download PDFInfo

- Publication number

- JP5846229B2 JP5846229B2 JP2014023876A JP2014023876A JP5846229B2 JP 5846229 B2 JP5846229 B2 JP 5846229B2 JP 2014023876 A JP2014023876 A JP 2014023876A JP 2014023876 A JP2014023876 A JP 2014023876A JP 5846229 B2 JP5846229 B2 JP 5846229B2

- Authority

- JP

- Japan

- Prior art keywords

- pair

- protrusions

- rotation

- base portion

- peripheral surface

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Active

Links

- 230000008878 coupling Effects 0.000 title claims description 59

- 238000010168 coupling process Methods 0.000 title claims description 59

- 238000005859 coupling reaction Methods 0.000 title claims description 59

- 230000007246 mechanism Effects 0.000 title claims description 39

- 230000002093 peripheral effect Effects 0.000 claims description 55

- 230000005540 biological transmission Effects 0.000 claims description 53

- 230000002265 prevention Effects 0.000 claims description 27

- 230000000903 blocking effect Effects 0.000 claims description 16

- 230000008961 swelling Effects 0.000 claims description 3

- 229920005989 resin Polymers 0.000 description 8

- 239000011347 resin Substances 0.000 description 8

- 230000005489 elastic deformation Effects 0.000 description 7

- 125000006850 spacer group Chemical group 0.000 description 7

- 229920001971 elastomer Polymers 0.000 description 5

- 238000010586 diagram Methods 0.000 description 4

- 229930182556 Polyacetal Natural products 0.000 description 3

- 210000000078 claw Anatomy 0.000 description 3

- 230000007774 longterm Effects 0.000 description 3

- 229920006122 polyamide resin Polymers 0.000 description 3

- 229920006324 polyoxymethylene Polymers 0.000 description 3

- 229920006311 Urethane elastomer Polymers 0.000 description 2

- 230000006835 compression Effects 0.000 description 2

- 238000007906 compression Methods 0.000 description 2

- 239000000806 elastomer Substances 0.000 description 2

- 239000000463 material Substances 0.000 description 2

- 229920000728 polyester Polymers 0.000 description 2

- 229920002379 silicone rubber Polymers 0.000 description 2

- 239000004945 silicone rubber Substances 0.000 description 2

- 239000000758 substrate Substances 0.000 description 2

- 238000001514 detection method Methods 0.000 description 1

- 230000001747 exhibiting effect Effects 0.000 description 1

- 238000000926 separation method Methods 0.000 description 1

Images

Landscapes

- Power Steering Mechanism (AREA)

Description

本発明は、電動式パワーステアリング装置における電動モータ等の回転源側の回転軸と自動車のステアリング軸等の作動側の回転軸とを連結するに適した軸連結機構に関する。 The present invention relates to a shaft coupling mechanism suitable for coupling a rotation shaft on a rotation source side such as an electric motor in an electric power steering device and a rotation shaft on an operation side such as a steering shaft of an automobile.

電動式パワーステアリング装置は、手動操作されるステアリングホイール(ハンドル)の回転に基づく回転力に電動モータの出力回転軸の回転に基づく回転力を付加してステアリングホイールの手動による操舵を容易に行い得るようにするものであって、斯かる電動式パワーステアリング装置においては、ステアリングホイール側のステアリング軸と電動モータの出力回転軸側の回転軸とを軸連結機構(カップリング)を介して連結している。 The electric power steering apparatus can easily perform manual steering of the steering wheel by adding the rotational force based on the rotation of the output rotation shaft of the electric motor to the rotational force based on the rotation of the manually operated steering wheel (handle). In such an electric power steering device, the steering shaft on the steering wheel side and the rotating shaft on the output rotating shaft side of the electric motor are coupled via a shaft coupling mechanism (coupling). Yes.

軸連結機構を介してステアリング軸と回転軸とを連結する場合、電動モータの出力回転軸の反転時の衝撃、電動モータのブラシ振動が軸連結機構及びステアリング軸を介してステアリングホイールに伝達されて運転者に不快な操舵感を生じさせる虞があり、これを回避するために軸連結機構にゴム又は軟質樹脂等のスペーサを設けることが提案されている。 When the steering shaft and the rotating shaft are connected via the shaft connecting mechanism, the impact when the output rotating shaft of the electric motor is reversed and the brush vibration of the electric motor are transmitted to the steering wheel via the shaft connecting mechanism and the steering shaft. There is a possibility of causing an unpleasant steering feeling to the driver, and in order to avoid this, it has been proposed to provide a spacer such as rubber or soft resin in the shaft coupling mechanism.

ところで、衝撃、振動の低減を重視してスペーサをより柔軟なものにすると、柔軟なスペーサはクリープ変形が生じ易いために、スペーサへの繰り返し荷重によるスペーサの永久的な変形で軸連結機構にガタが生じてこれによってもまた運転者の操舵感覚が不快なものとなる虞がある。 By the way, if the spacer is made more flexible by placing importance on the reduction of impact and vibration, the flexible spacer is likely to undergo creep deformation. Therefore, the shaft coupling mechanism is not rattled by permanent deformation of the spacer due to repeated load on the spacer. This may also cause the driver's steering feeling to be uncomfortable.

一方、耐久性を重視してスペーサを硬質なものにすると、前記と逆にガタのない点で操舵感覚は良くなるが、上述の通りステアリングホイールに伝達された衝撃、振動で操舵感覚が不快なものとなる。 On the other hand, if the spacers are made harder with emphasis on durability, the steering feeling will be better in the absence of backlash, but the steering feeling is uncomfortable due to the impact and vibration transmitted to the steering wheel as described above. It will be a thing.

本発明は、前記諸点に鑑みてなされたものであって、その目的とするところは、長期の使用によっても一方の回転軸である例えば電動モータの出力回転軸に連結された回転軸と他方の回転軸である例えばステアリングホイールに連結されたステアリング軸との間に軸心周りの方向についてのガタが生じ難く、しかも、電動モータの反転時の衝撃、ブラシ振動のステアリングホイールへの伝達を低減でき、而して、耐久性に優れ操舵感覚を不快にさせない電動式パワーステアリング装置用の軸連結機構を提供することにある。 The present invention has been made in view of the above-mentioned points. The object of the present invention is to provide a rotary shaft connected to an output rotary shaft of an electric motor, for example, the rotary shaft and the other rotary shaft, even after long-term use. For example, there is little backlash in the direction around the axis between the rotating shaft, for example, the steering shaft connected to the steering wheel, and it is possible to reduce the impact when the electric motor is reversed and the transmission of brush vibration to the steering wheel. Accordingly, it is an object of the present invention to provide a shaft coupling mechanism for an electric power steering apparatus that has excellent durability and does not make the steering feeling uncomfortable.

一方の回転軸の回転を他方の回転軸に伝達するように二つの回転軸の間に配されて二つの回転軸を連結する本発明による軸連結機構は、軸方向において重ね合わされた一対の回転伝達部材と、この一対の回転伝達部材間に介在されている中間介在部材とを具備しており、ここで、一対の回転伝達部材の夫々が、軸心周りの方向において互いに離間していると共に径方向に伸びた少なくとも一対の突部を有しており、中間介在部材が、軸方向において一対の回転伝達部材の一対の突部間に配されていると共に各対の突部における軸心周りの方向の幅よりも大きな幅をもった一対の突部を有しており、中間介在部材の一対の突部の夫々が、各対の回転伝達部材の一対の突部の剛性よりも小さな剛性を有すると共に弾性変形可能であり、一対の回転伝達部材のうちの少なくとも一方が、中間介在部材の一対の突部の径方向の自由端面の径方向の一定以上の膨出を阻止する膨出阻止手段を有している。 The shaft coupling mechanism according to the present invention, which is arranged between two rotation shafts so as to transmit the rotation of one rotation shaft to the other rotation shaft and connects the two rotation shafts, is a pair of rotations that are overlapped in the axial direction. A transmission member and an intermediate interposed member interposed between the pair of rotation transmission members, wherein the pair of rotation transmission members are spaced apart from each other in the direction around the axis. It has at least a pair of protrusions extending in the radial direction, and the intermediate interposed member is disposed between the pair of protrusions of the pair of rotation transmitting members in the axial direction and around the axis of each pair of protrusions Each of the pair of protrusions of the intermediate interposed member has a rigidity smaller than the rigidity of the pair of protrusions of each pair of rotation transmitting members. A pair of rotations that are elastically deformable At least one of the reaches member has a bulging preventing means for preventing certain level of swelling in the radial direction of the free end face of the radial direction of the pair of projections of the intermediate interposed member.

本発明の軸連結機構によれば、中間介在部材が、軸方向において一対の回転伝達部材の一対の突部間に配されていると共に各対の突部における軸心周りの方向の幅よりも大きな幅をもった一対の突部を有している結果、一方の回転軸の回転の他方の回転軸への伝達が中間介在部材の一対の突部の弾性変形を介して行われるために、一方の回転軸の微小な回転の他方の回転軸への伝達を中間介在部材の一対の突部の弾性変形で低減又は阻止できると共に一方の回転軸の他方の回転軸に対する大きな相対回転の他方の回転軸への伝達を中間介在部材の一対の突部よりも大きな剛性を有している一対の回転伝達部材を介してそのまま行い得、しかも、中間介在部材の一対の突部における軸心周りの方向の一定以上の弾性変形では大きい剛性をもった一対の回転伝達部材で中間介在部材の一対の突部の大きな変形を阻止できるために、中間介在部材に対して柔軟性のある剛性の小さい樹脂材料を用いてもクリープによる中間介在部材の永久的な変形を低減でき、その上、一対の回転伝達部材のうちの少なくとも一方が、中間介在部材の一対の突部の径方向の自由端面の径方向の膨出を阻止する膨出阻止手段を有しているために、これによっても、クリープによる中間介在部材の永久的な変形を低減できて、而して、長期の使用によっても一方の回転軸である例えば電動モータの出力回転軸に連結された回転軸と他方の回転軸である例えばステアリングホイールに連結されたステアリング軸との間に軸心周りの方向についてのガタが生じ難く、しかも、電動モータの反転時の衝撃、ブラシ振動のステアリングホイールへの伝達を低減できて、耐久性に優れ操舵感覚を不快にさせない電動式パワーステアリング装置用の軸連結機構を提供することができる。 According to the shaft coupling mechanism of the present invention, the intermediate interposed member is disposed between the pair of protrusions of the pair of rotation transmitting members in the axial direction and is wider than the width in the direction around the axis of each pair of protrusions. As a result of having a pair of protrusions having a large width, transmission of rotation of one rotation shaft to the other rotation shaft is performed via elastic deformation of the pair of protrusions of the intermediate interposed member. Transmission of minute rotation of one rotating shaft to the other rotating shaft can be reduced or prevented by elastic deformation of the pair of protrusions of the intermediate interposed member, and the other of the large relative rotation of the one rotating shaft with respect to the other rotating shaft can be reduced. Transmission to the rotation shaft can be performed as it is through the pair of rotation transmission members having rigidity greater than that of the pair of protrusions of the intermediate interposed member, and the shaft center around the pair of protrusions of the intermediate intermediate member High rigidity in elastic deformation beyond a certain direction Since the pair of rotation transmission members can prevent a large deformation of the pair of protrusions of the intermediate interposed member, the intermediate intermediate member is made permanent by creep even when a resin material having flexibility and low rigidity is used for the intermediate intermediate member. In addition, at least one of the pair of rotation transmission members has a bulging prevention means for preventing the radial free end surfaces of the pair of protrusions of the intermediate interposed member from bulging in the radial direction. Therefore, the permanent deformation of the intermediate interposition member due to creep can also be reduced by this, and therefore, it can be coupled to the output rotation shaft of one of the rotation shafts, for example, the electric rotation shaft even after long-term use. Between the rotating shaft and the other rotating shaft, for example, the steering shaft connected to the steering wheel, is less likely to cause backlash in the direction around the shaft center. And reduces the transmission to the steering wheel, it is possible to provide a shaft coupling mechanism for an electric power steering apparatus that does not uncomfortable excellent steering feeling durability.

一対の回転伝達部材の夫々は、円環状の外周面を有した中央基部と、この中央基部に対して同心であって径方向外側に配された円環状の外側基部とを具備していてもよく、この場合、一対の回転伝達部材の夫々の一対の突部は、対応の回転伝達部材の中央基部の外周面から円環状の外側基部の内周面まで径方向に伸びて当該中央基部及び外側基部に一体的に設けられているとよい。斯かる軸連結機構では、中間介在部材は、円環状の外周面を有した中央基部を具備しており、中間介在部材の一対の突部は、中間介在部材の中央基部の外周面に一体的に設けられていると共に当該中間介在部材の中央基部の外周面から径方向外側に伸びており、膨出阻止手段は、一対の回転伝達部材のうちの少なくとも一方の外側基部の軸方向の端面に一体的に設けられていると共に中間介在部材の一対の突部の径方向外側の先端における自由端面の径方向外側への膨出を阻止する外側阻止突部を有していても、これに代えて又はこれと共に、中間介在部材は、円環状の内周面を有した外側基部を具備しており、中間介在部材の一対の突部は、中間介在部材の外側基部の内周面に一体的に設けられていると共に当該中間介在部材の外側基部の内周面から径方向内側に伸びており、膨出阻止手段は、一対の回転伝達部材のうちの少なくとも一方の内側基部の軸方向の端面に一体的に設けられていると共に中間介在部材の一対の突部の径方向内側の先端における自由端面の径方向内側への膨出を阻止する内側阻止突部を有していてもよい。 Each of the pair of rotation transmitting members may include a central base portion having an annular outer peripheral surface, and an annular outer base portion that is concentric with the central base portion and is disposed radially outward. Well, in this case, each of the pair of protrusions of the pair of rotation transmitting members extends in a radial direction from the outer peripheral surface of the central base portion of the corresponding rotation transmitting member to the inner peripheral surface of the annular outer base portion, and the central base portion and It is good to be provided integrally with the outer base. In such a shaft coupling mechanism, the intermediate interposed member has a central base portion having an annular outer peripheral surface, and the pair of protrusions of the intermediate intermediate member are integrated with the outer peripheral surface of the central base portion of the intermediate intermediate member. And is extended radially outward from the outer peripheral surface of the central base portion of the intermediate interposed member, and the bulging prevention means is provided on the axial end surface of at least one outer base portion of the pair of rotation transmitting members. Even if it has an outer blocking protrusion that is provided integrally and blocks the bulging of the free end surface radially outward at the radially outer tip of the pair of protrusions of the intermediate interposed member, it replaces this. The intermediate interposed member includes an outer base portion having an annular inner peripheral surface, and the pair of protrusions of the intermediate intermediate member are integrated with the inner peripheral surface of the outer base portion of the intermediate intermediate member. And the outer base of the intermediate interposed member The bulge prevention means is integrally provided on the axial end face of at least one inner base portion of the pair of rotation transmitting members and is also provided in a pair of intermediate interposed members. You may have the inner side prevention protrusion which prevents the bulge to the radial direction inner side of the free end surface in the front-end | tip of the radial direction inner side of a protrusion.

軸連結機構は、軸心周りの方向のスペーサとして二つの回転軸の間に配した回転伝達部材と中間介在部材とを具備していればよいのであるが、一方の回転軸に連結される一方の連結基体と、他方の回転軸に連結される他方の連結基体とを更に具備していてもよく、この場合、一方の連結基体は、基部と、この基部から軸方向に一体的に突出した突部とを具備しており、他方の連結基体は、基部と、この基部から軸方向に一体的に突出した突部とを具備しており、一方の連結基体の突部は、軸心周りの方向における一対の回転伝達部材の各対の突部間のうちの一方の突部間及び軸心周りの方向における中間介在部材の一対の突部間のうちの一方の突部間に配されており、他方の連結基体の突部は、軸心周りの方向における一対の回転伝達部材の各対の突部間のうちの他方の突部間及び軸心周りの方向における中間介在部材の一対の突部間のうちの他方の突部間に配されているとよい。斯かる軸連結機構では、一方及び他方の連結基体の突部は、軸心周りの方向のその各側面で、両回転軸の一定以下の相対回転では軸心周りの方向において対面する中間介在部材の突部の軸心周りの方向の側面に接触している一方、軸心周りの方向において対面する一対の回転伝達部材の突部の軸心周りの方向の側面に、両回転軸の一定以下の相対回転では非接触となり、両回転軸の一定以上の相対回転では接触するようになっているとよい。 The shaft coupling mechanism only needs to include a rotation transmission member and an intermediate interposition member disposed between two rotation shafts as a spacer in the direction around the shaft center. And the other connecting base connected to the other rotating shaft. In this case, one connecting base protrudes integrally from the base and the base in the axial direction. And the other connecting base includes a base and a protrusion integrally protruding in the axial direction from the base, and the protrusion of the one connecting base is around the axis. Between one pair of protrusions of each pair of rotation transmitting members in the direction of the center and between one protrusion of the pair of protrusions of the intermediate interposed member in the direction around the axis. The projection of the other connecting base is formed by the pair of rotation transmitting members in the direction around the axis. It may have been disposed between the other projecting portion of the pair of protrusions of the intermediate interposed member in the other projection and between the direction around the axis of between pairs of projections. In such a shaft coupling mechanism, the protrusions of the one and the other coupling bases are on the respective side surfaces in the direction around the axis, and the intermediate interposed members that face in the direction around the axis when the rotation of the two rotation shafts is less than a certain amount. While contacting the side surface in the direction around the axial center of the protrusion, the side surfaces in the direction around the axial center of the pair of rotation transmitting members facing in the direction around the axial center are below a certain value of both rotation shafts. It is desirable that the relative rotation is non-contact and the two rotation shafts are in contact with each other at a certain relative rotation.

本発明の軸連結機構では、一対の回転伝達部材を相互に結合する結合手段を更に具備していてもよい。 The shaft coupling mechanism of the present invention may further include coupling means for coupling the pair of rotation transmission members to each other.

本発明のいずれの軸連結機構においても、回転伝達部材は、好ましくは、ポリアセタール樹脂、ポリアミド樹脂等の硬質の樹脂から形成されるが、その他の剛性を呈する硬質の樹脂から形成されていてもよく、中間介在部材は、ウレタンゴム、シリコーンゴム、ポリエステルエラストマー等のゴム弾性体から形成されているとよい。 In any of the shaft coupling mechanisms of the present invention, the rotation transmission member is preferably formed from a hard resin such as polyacetal resin or polyamide resin, but may be formed from a hard resin exhibiting other rigidity. The intermediate interposed member may be formed of a rubber elastic body such as urethane rubber, silicone rubber, or polyester elastomer.

本発明の軸連結機構は、電動式パワーステアリング装置用のものであってもよく、この場合、一方の回転軸は、電動モータの出力回転軸に連結されるようになっており、他方の回転軸は、自動車のステアリング軸に連結されるようになっていてもよい。 The shaft coupling mechanism of the present invention may be for an electric power steering apparatus. In this case, one rotating shaft is coupled to the output rotating shaft of the electric motor, and the other rotating shaft. The shaft may be connected to the steering shaft of the automobile.

本発明によれば、長期の使用によっても一方の回転軸である例えば電動モータの出力回転軸に連結された回転軸と他方の回転軸である例えばステアリングホイールに連結されたステアリング軸との間に軸心周りの方向についてのガタが生じ難く、しかも、電動モータの反転時の衝撃、ブラシ振動のステアリングホイールへの伝達を低減でき、而して、耐久性に優れ操舵感覚を不快にさせない電動式パワーステアリング装置用の軸連結機構を提供することができる。 According to the present invention, even when used for a long time, between one rotating shaft, for example, the rotating shaft connected to the output rotating shaft of the electric motor, and the other rotating shaft, for example, the steering shaft connected to the steering wheel. Electric type that does not cause looseness in the direction around the shaft center, and that can reduce the impact of the electric motor when it is reversed and the transmission of brush vibration to the steering wheel. A shaft coupling mechanism for a power steering apparatus can be provided.

次に本発明の実施の形態を、図に示す好ましい例に基づいて更に詳細に説明する。なお、本発明はこれら例に何等限定されないのである。 Next, embodiments of the present invention will be described in more detail based on preferred examples shown in the drawings. The present invention is not limited to these examples.

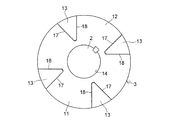

図1から図17において、本例の電動式パワーステアリング装置用の軸連結機構1は、回転軸2に連結される連結基体3と、回転軸4に連結される連結基体5と、軸方向Aにおいて重ね合わされた一対の回転伝達部材6及び7と、一対の回転伝達部材6及び7間に介在されている中間介在部材8と、一対の回転伝達部材6及び7を相互に結合する結合手段9とを具備しており、回転軸2の軸心O周りの方向、即ち、R方向の回転を回転軸4に伝達するように二つの回転軸2及び4の間に配されて二つの回転軸2及び4を連結するようになっている。

1 to 17, the

回転軸2は、電動式パワーステアリング装置の電動モータ側の回転軸であり、電動モータの出力回転軸に連結されるようになっている。

The

剛性の連結基体3は、円環状の基部11と、基部11の一方の環状面12から軸方向Aに一体的に突出していると共にR方向において90°の等角度間隔をもって互いに離間されて配された三角柱形状の四個の突部13と、回転軸2が嵌着された貫通孔14とを具備している。突部13の夫々は、R方向において一対の剛性回転伝達面としての側面17及び18を有している。

The rigid connecting

回転軸4は、ステアリングホイールの操作(操舵)により回転されるようにステアリングホイールに連結された回転軸である。

The

剛性の連結基体5は、円環状の基部21と、基部21の一方の環状面22から軸方向Aに一体的に突出していると共にR方向において90°の等角度間隔をもって互いに離間されて配された三角柱形状の四個の突部23と、回転軸4が嵌着された貫通孔24とを具備している。突部23の夫々は、R方向において一対の剛性回転伝達面としての側面27及び28を有している。

The rigid connecting

ポリアセタール樹脂、ポリアミド樹脂等から一体に形成されている剛性の回転伝達部材6は、円環状の外周面31を有した円環状の中央基部32と、R方向において互いに等角度間隔をもって離間していると共に径方向に伸びた八個の突部33と、中央基部32に対して同心であって径方向外側に配されていると共に円環状の内周面34及び円環状の外周面35を有した円環状の外側基部36とを具備している。

The rigid

R方向において互いに45°の等角度間隔をもって配された突部33の夫々は、中央基部32の外周面31から外側基部36の内周面34まで径方向に伸びて当該中央基部32の外周面31及び外側基部36の内周面34に一体的に設けられており、R方向において一対の剛性回転伝達面としての側面38及び39を有しており、突部33により中央基部32及び外側基部36は互いに連結されている。

Each of the

中央基部32、各突部33及び外側基部36の軸方向Aの一方の端面である外側端面41、42及び43は面一となっており、中央基部32、各突部33及び外側基部36のA方向の他方の端面である内側端面44、45及び46もまた面一となっており、中央基部32の外周面31、外側基部36の内周面34及び突部33の側面38及び39は、突部13及び突部23が挿入される八個の三角柱形状の貫通孔47を規定している。

Outer end surfaces 41, 42, and 43, which are one end surfaces in the axial direction A of the

ポリアセタール樹脂、ポリアミド樹脂等から一体に形成されている剛性の回転伝達部材7は、回転伝達部材6と同様に形成されており、円環状の外周面51を有した円環状の中央基部52と、R方向において互いに等角度間隔をもって離間していると共に径方向に伸びた八個の突部53と、中央基部52に対して同心であって径方向外側に配されていると共に円環状の内周面54及び円環状の外周面55を有した円環状の外側基部56とを具備している。

A rigid

R方向において互いに45°の等角度間隔をもって配された突部53の夫々は、中央基部52の外周面51から外側基部56の内周面54まで径方向に伸びて当該中央基部52の外周面51及び外側基部56の内周面54に一体的に設けられており、R方向において一対の剛性回転伝達面としての側面58及び59を有しており、突部53により中央基部52及び外側基部56は互いに連結されている。

Each of the

中央基部52、各突部53及び外側基部56のA方向の一方の端面である外側端面61、62及び63は面一となっており、中央基部52、各突部53及び外側基部56のA方向の他方の端面である内側端面64、65及び66もまた面一となっており、中央基部52の外周面51、外側基部56の内周面54及び突部53の側面58及び59は、突部13及び突部23が挿入される八個の三角柱形状の貫通孔67を規定している。

Outer end surfaces 61, 62, and 63, which are one end surfaces in the A direction of the

回転伝達部材6及び7の間に配されている中間介在部材8は、回転伝達部材6及び7よりも小さな剛性を有すると共に弾性変形可能であってウレタンゴム、シリコーンゴム、ポリエステルエラストマー等のゴム弾性体から一体形成されており、斯かる中間介在部材8は、互いに同心の円環状の内周面71及び外周面72を有した円環状の中央基部73と、中央基部73の外周面72に一体的に設けられていると共に当該中央基部73の外周面72から径方向外側に伸びた八個の突部74とを有している。

The intermediate interposed

回転伝達部材6及び7の夫々の突部33及び53の合計個数の夫々と同数であってR方向において45°の等角度間隔で互いに離間して配された突部74の夫々は、軸方向Aにおいて一対の回転伝達部材6及び7の対応の一対の突部33及び53間に配されていると共に突部33及び53におけるR方向の幅dよりも大きな幅Dをもっている。回転伝達部材6及び7の夫々の突部33及び53の剛性よりも小さな剛性を有すると共に弾性変形可能である突部74の夫々は、R方向において側面75及び76を有しており、各突部74の側面75は、各突部13の側面17及び各突部23の側面27にR方向において交互に接触しており、各突部74の側面76は、各突部23の側面28及び各突部13の側面18にR方向において交互に接触している。

The

中間介在部材8は、回転伝達部材6及び7の夫々のA方向の平坦な内側端面44、45及び46並びに内側端面64、65及び66に対面する面77及び78で平坦になっており、面77は、内側端面44、45及び46に摺動自在に接触しており、面78は、内側端面64、65及び66に摺動自在に接触している。

The intermediate interposed

結合手段9は、外側基部36の内側端面46から回転伝達部材7側に向かって軸方向Aに伸びて外側基部36の内側端面46に一体的に設けられていると共にR方向において互いに90°の等角度間隔をもって配された回転伝達部材6側の四個の結合本体部81と、各結合本体部81の先端に一体的に形成されたつめ部82と、外側基部56の内側端面66から回転伝達部材6側に向かって軸方向Aに伸びて外側基部56の内側端面66に一体的に設けられていると共にR方向において互いに90°の等角度間隔をもって配された回転伝達部材7側の四個の結合本体部83と、各結合本体部83の先端に一体的に形成されたつめ部84と、外側基部36の外周面35にR方向において互いに90°の等角度間隔をもってかつR方向において結合本体部81間の中間に形成されていると共に対応の結合本体部83が嵌められて配された複数の浅溝85と、各浅溝85に連通していると共に外側端面43で開口して外側基部36の外周面35に形成されている深溝86と、外側基部56の外周面55にR方向において互いに90°の等角度間隔をもってかつR方向において結合本体部83間の中間に形成されていると共に対応の結合本体部81が嵌められて配された複数の浅溝87と、各浅溝87に連通すると共に外側端面63で開口して外側基部56の外周面55に形成された深溝88とを具備している。

The coupling means 9 extends in the axial direction A from the

つめ部82は、深溝88において外側基部56にスナップフィット式に係合しており、つめ部84は、深溝86において外側基部36にスナップフィット式係合しており、これにより、回転伝達部材6及び7は、軸方向Aにおいて中間介在部材8を挟んで互いに分離しないように、結合されている。

The

以上のように、中間介在部材8と、中間介在部材8を間にしてしかも結合手段9により相互に結合された回転伝達部材6及び7とに対して、連結基体3の突部13の夫々は、R方向において、回転伝達部材6及び7の各対の突部33及び53間のうちの一方の突部33及び53間、すなわち一つおきの突部33及び53間及び中間介在部材8の各対の突部74間のうちの一方の突部74間、すなわち一つおきの突部74間に配されており、連結基体5の突部23は、R方向において、回転伝達部材6及び7の各対の突部33及び53間のうちの他方の突部33及び53間、すなわち残る一つおきの突部33及び53間及び中間介在部材8の各対の突部74間のうちの他方の突部74間、すなわち残る一つおきの突部74間に配されており、回転軸2及び回転軸4の一定以下のR方向の相対回転では、連結基体3の各突部13は、R方向のその各側面17及び18で、R方向において対面する中間介在部材8の各突部74のR方向の側面75及び76に夫々接触している一方、R方向において対面する回転伝達部材6及び7の突部33及び53の側面38及び39並びに58及び59に夫々非接触となっており、連結基体5の突部23は、R方向のその各側面27及び28で、R方向において対面する中間介在部材8の各突部74のR方向の側面75及び76に夫々接触している一方、R方向において対面する回転伝達部材6及び7の突部33及び53の側面38及び39並びに58及び59に夫々非接触となっている。

As described above, with respect to the intermediate interposed

一対の回転伝達部材6及び7のうちの少なくとも一方、本例では、一対の回転伝達部材6及び7は、中間介在部材8の各突部74の径方向の自由端面91の径方向の一定以上の膨出を阻止する膨出阻止手段92を有しており、膨出阻止手段92は、一対の回転伝達部材6及び7の外側基部36及び56のA方向の内側端面46及び66の夫々に一体的に設けられていると共に中間介在部材8の各突部74の径方向外側の先端における自由端面91の径方向外側への膨出を阻止する外側阻止突部93及び94と、一対の回転伝達部材6及び7の中央基部32及び52のA方向の内側端面44及び64の夫々に一体的に設けられていると共に外側阻止突部93及び94による自由端面91の径方向外側への膨出阻止において中間介在部材8の中央基部73の径方向内側への膨出を阻止して外側阻止突部93及び94による自由端面91の径方向外側への膨出阻止を補助する円環状の膨出阻止補助突部95及び96とを有している。

At least one of the pair of

A方向において内側端面46から外側阻止突部94に向かって伸びてA方向の頂面97において外側阻止突部94のA方向の頂面98に接触している外側阻止突部93は、対応の突部74の自由端面91に対して所定の幅の隙間99をもって自由端面91に対面する径方向の内面100を有しており、A方向において内側端面66から外側阻止突部93に向かって伸びている外側阻止突部94は、対応の突部74の自由端面91に対して所定の幅の隙間99をもって自由端面91に対面する径方向の内面101を有している。

The

A方向において内側端面44から膨出阻止補助突部96に向かって伸びていると共にA方向の頂面105において膨出阻止補助突部96のA方向の頂面106に接触している円環状の膨出阻止補助突部95は、中間介在部材8の中央基部73の内周面71に接触している円環状の径方向の外周面107を有しており、A方向において内側端面64から膨出阻止補助突部95に向かって伸びている円環状の膨出阻止補助突部96は、中間介在部材8の中央基部73の内周面71に接触している円環状の径方向の外周面108を有している。

An annular shape extending from the

膨出阻止手段92は、突部74のR方向の圧縮変形による突部74の径方向の伸張における突部74の自由端面91の径方向外側への膨出で当該突部74の自由端面91の外側阻止突部93及び94の内面100及び101への接触により、それ以上の突部74の自由端面91の径方向外側への膨出を阻止するようになっている。

The bulging prevention means 92 bulges outward of the

内周面71で規定される中央円孔111を有しない中間介在部材8を用いる場合には、膨出阻止補助突部95及び96を省くことができる。

When the intermediate interposed

中間介在部材8の中央円孔111並びに回転伝達部材6及び7の中央円孔112及び113に回転軸2又は回転軸4から一体的に延伸された支持軸を挿通して斯かる支持軸でもって中間介在部材8並びに回転伝達部材6及び7のより確実な中心位置決めを必要により行ってもよいが、この中心位置決めを行わない場合には、中央円孔111、112及び113を有しない中間介在部材8並びに回転伝達部材6及び7を用いてもよい。

A support shaft integrally extended from the

回転軸2のR方向の回転を回転軸4に伝達するように回転軸2及び回転軸4の間に配されて二つの回転軸である回転軸2及び回転軸4を相互に連結する軸連結機構1を具備した以上の電動式パワーステアリング装置では、ステアリングホイールが運転者により手動操作されると、回転軸4がR方向に回転されて、回転軸4のR方向の回転は、図示しない歯車等の伝達機構を介してドラッグ・リンク等に往復動として伝達されて操向輪(車輪)に対する操舵力を与える。運転者によるステアリングホイールの手動操作において、ステアリングホイールに加えられるトルクを検出するトルク検出器からの検出信号により制御される電動モータが作動されると、回転軸2がR方向に回転されて、突部13による突部74のR方向の変形後における側面75への側面17の接触又は側面76への側面18の接触に基づく突部13による突部74のR方向への押圧を介して連結基体3のR方向の回転が連結基体5の突部23に伝達されて、これにより回転軸4のR方向の回転力に対して回転軸2のR方向の回転力を付加して運転者によるステアリングホイールの手動操作を補助するようになっている。

A shaft connection that is arranged between the

軸連結機構1では、ステアリングホイールが運転者により手動操作されないで回転軸4がR方向に回転されない状態又はステアリングホイールが運転者により手動操作されて回転軸4がR方向に回転される状態のいずれの状態においても、回転軸4に対する回転軸2のR方向の相対回転が幅Dと幅dとの差の半分程度以内の微小なものである場合には、突部74が容易に圧縮変形する結果、斯かる回転軸2の微小なR方向の相対回転は回転軸4には殆ど伝達されず、而して、軸連結機構1及び回転軸4を介する電動モータの反転時の衝撃、ブラシ振動のステアリングホイールへの伝達を低減でき操舵感覚を不快にさせないようにできる上に、突部74の一定以上の圧縮変形後、側面38及び59への側面17の接触又は側面39及び58への側面18の接触及び側面38及び59への側面27の接触又は側面39及び58への側面28の接触が生じて突部74のそれ以上の圧縮変形を抑止できる結果、突部74の夫々のクリープによるへたりを防止でき、突部13及び23と突部74とのR方向における側面17及び18並びに27及び28と側面75及び76との互いの接触を長期に亘って維持でき、回転軸4と回転軸2との間にR方向についてのガタが生じ難いことになる。そして、回転伝達部材6は、ステアリングホイールの運転者による手動操作で回転軸4がR方向に回転されると共に電動モータの作動で回転軸2がR方向に回転されて回転軸4に対して回転軸2が一定以上、すなわち幅Dと幅dとの差の半分程度以上にR方向に相対回転されようとする場合には、側面38及び側面59への側面17の接触又は側面39及び側面58への側面18の接触に基づく突部13による突部23のR方向への押圧でもって斯かる一定以上のR方向の相対回転に応答して回転軸2のR方向の回転を回転軸4に伝達して回転軸4の回転を補助するようになる。

In the

以上のように軸連結機構1によれば、回転伝達部材6及び7間に配されている中間介在部材8がA方向において回転伝達部材6及び7の突部33及び53間の夫々に配されていると共に突部33及び53の夫々のR方向の幅dよりも大きな幅Dをもった突部74を有しており、中間介在部材8の各突部74が回転伝達部材6及び7の突部33及び53の夫々の剛性よりも小さな剛性を有している結果、回転軸2のR方向の回転の回転軸4への伝達が中間介在部材8の突部74の弾性変形を介して行われるために、回転軸2のR方向の微小な回転の回転軸4への伝達を中間介在部材8の突部74の弾性変形で低減又は阻止できると共に回転軸2の回転軸4に対する大きなR方向の相対回転の回転軸4への伝達を中間介在部材8の突部74よりも大きな剛性を有している回転伝達部材6及び7の突部33及び53を介してそのまま行い得、しかも、回転軸4に対する回転軸2のR方向の一定以上の相対回転では大きい剛性をもった回転伝達部材6及び7の突部33及び53で中間介在部材8の突部74の大きな弾性変形を阻止できるために、中間介在部材8に対して柔軟性のある剛性の小さい樹脂材料を用いてもクリープによる中間介在部材8の永久的な変形を低減でき、その上、一対の回転伝達部材6及び7が結合手段9を介して相互に連結されているために、組み付け性を向上できると共に中間介在部材8の弾性変形による一対の回転伝達部材6及び7のA方向の相互の離反をなくし得て一対の回転伝達部材6及び7のA方向の広がりを一定に抑えることができ、而して、電動モータの反転時の衝撃、ブラシ振動のステアリングホイールへの伝達を低減できる上に回転軸2及び回転軸4間のR方向についてのガタをなくし得て、操舵感覚を不快にさせないと共に耐久性に優れ特性の安定したものとし得る。

As described above, according to the

加えて、軸連結機構1によれば、回転伝達部材6及び7が、中間介在部材8の突部74の径方向の自由端面91の径方向の膨出を阻止する膨出阻止手段92を有しているために、これによっても、クリープによる中間介在部材8の永久的な変形を低減できて、而して、長期の使用によっても回転軸2と回転軸4との間にR方向についてのガタが生じ難く、しかも、電動モータの反転時の衝撃、ブラシ振動のステアリングホイールへの伝達を低減できて、耐久性に優れ操舵感覚を不快にさせない電動式パワーステアリング装置用の軸連結機構を提供することができる。

In addition, according to the

上記の例の軸連結機構1では、外側阻止突部93及び94と膨出阻止補助突部95及び96とをもって膨出阻止手段92を構成したが、外側阻止突部93及び94を省略して、膨出阻止補助突部95及び96を内側阻止突部として膨出阻止手段92を構成してもよく、この場合には、中間介在部材8を、図18に示すように、円環状の内周面121及び外周面122を有した外側基部123と、外側基部122の内周面121にR方向において45°の等角度間隔で互いに離間して配されて一体的に設けられていると共に外側基部123の内周面121から径方向内側に伸びた八個の突部74と、結合手段9の結合本体部81及び83が嵌められると共に外周面122に形成された溝124とを具備して構成してもよく、内側基部32及び52の内側端面44及び64に一体的に設けられていると共に円環状外面を有した内側阻止突部としての膨出阻止補助突部95及び96は、中間介在部材8の突部74の径方向内側の先端における円弧状凹面からなる自由端面125の径方向内側の膨出を阻止するようになっている。

In the

図18に示す中間介在部材8を用いる場合には、外側基部36の内側端面46及び外側基部56の内側端面66でもって外側基部123を挟んで中間介在部材8をA方向において回転伝達部材6及び7間に配して軸連結機構1を構成するとよい。

When the intermediate interposed

また、上記の例の軸連結機構1は、一個の中間介在部材8からなっているが、これに代えて、二個以上の中間介在部材8からなっていてもよく、回転伝達部材6及び7の夫々もまた二個以上からなっていてもよい。また、連結基体3及び5の突部13及び23、回転伝達部材6及び7の突部33及び53、中間介在部材8の突部74、結合手段9の結合本体部81等は、上記の個数に限らないのである。

Further, the

1 軸連結機構

2 回転軸

3 連結基体

4 回転軸

5 連結基体

6、7 回転伝達部材

8 中間介在部材

9 結合手段

92 膨出阻止手段

93、94 外側阻止突部

DESCRIPTION OF

Claims (5)

Priority Applications (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| JP2014023876A JP5846229B2 (en) | 2014-02-10 | 2014-02-10 | Shaft coupling mechanism for electric power steering device |

Applications Claiming Priority (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| JP2014023876A JP5846229B2 (en) | 2014-02-10 | 2014-02-10 | Shaft coupling mechanism for electric power steering device |

Related Parent Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| JP2012142538A Division JP5549708B2 (en) | 2012-06-25 | 2012-06-25 | Shaft coupling mechanism for electric power steering device |

Publications (3)

| Publication Number | Publication Date |

|---|---|

| JP2014095478A JP2014095478A (en) | 2014-05-22 |

| JP2014095478A5 JP2014095478A5 (en) | 2014-07-03 |

| JP5846229B2 true JP5846229B2 (en) | 2016-01-20 |

Family

ID=50938692

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| JP2014023876A Active JP5846229B2 (en) | 2014-02-10 | 2014-02-10 | Shaft coupling mechanism for electric power steering device |

Country Status (1)

| Country | Link |

|---|---|

| JP (1) | JP5846229B2 (en) |

Families Citing this family (2)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| JP7140189B2 (en) * | 2018-07-12 | 2022-09-21 | 日本精工株式会社 | Couplings, torque transmission devices, and electric power steering devices |

| JP6753624B1 (en) * | 2020-01-22 | 2020-09-09 | 株式会社Freepower Innovations | Rotation transmission mechanism, rotation transmission joint, motor and generator |

Family Cites Families (5)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| FR1080977A (en) * | 1953-07-07 | 1954-12-15 | Ass Francaise Des Ind Plastiqu | Coupling enhancements |

| US6342011B1 (en) * | 1999-04-01 | 2002-01-29 | The Falk Corporation | Flexible shaft coupling with improved elastomeric element |

| JP2004068943A (en) * | 2002-08-07 | 2004-03-04 | Nok Corp | Shaft coupling |

| BRPI0512140A (en) * | 2004-05-28 | 2008-02-12 | Oiles Industry Co Ltd | shaft coupling mechanism |

| JP2006290181A (en) * | 2005-04-12 | 2006-10-26 | Yokohama Rubber Co Ltd:The | Shaft coupling for steering shaft |

-

2014

- 2014-02-10 JP JP2014023876A patent/JP5846229B2/en active Active

Also Published As

| Publication number | Publication date |

|---|---|

| JP2014095478A (en) | 2014-05-22 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| JP5168972B2 (en) | Shaft coupling mechanism for electric power steering device | |

| JP4779358B2 (en) | Shaft coupling mechanism for electric power steering device | |

| JP5169042B2 (en) | Shaft coupling mechanism for electric power steering device | |

| JP5428852B2 (en) | Shaft coupling mechanism | |

| JP6384134B2 (en) | Shaft coupling mechanism for electric power steering device | |

| JP4779356B2 (en) | Shaft coupling mechanism for electric power steering device | |

| KR20070024537A (en) | Shaft coupling mechanism for electric power steering | |

| JP2017032105A (en) | Shaft coupling mechanism for electric power steering device | |

| JP5846229B2 (en) | Shaft coupling mechanism for electric power steering device | |

| WO2007063780A1 (en) | Shaft coupling mechanism for electric power steering device | |

| JP6057611B2 (en) | Shaft coupling mechanism | |

| JP5549708B2 (en) | Shaft coupling mechanism for electric power steering device | |

| JP5003637B2 (en) | Shaft coupling mechanism for electric power steering device | |

| JP5733372B2 (en) | Shaft coupling mechanism | |

| JP5929108B2 (en) | Shaft coupling mechanism for electric power steering device | |

| JP2017067134A (en) | Shaft connecting mechanism for electric power steering device | |

| JP5407741B2 (en) | Shaft coupling mechanism | |

| JP6019724B2 (en) | Shaft coupling mechanism |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| A521 | Request for written amendment filed |

Free format text: JAPANESE INTERMEDIATE CODE: A523 Effective date: 20140311 |

|

| A621 | Written request for application examination |

Free format text: JAPANESE INTERMEDIATE CODE: A621 Effective date: 20140311 |

|

| A521 | Request for written amendment filed |

Free format text: JAPANESE INTERMEDIATE CODE: A523 Effective date: 20140509 |

|

| A977 | Report on retrieval |

Free format text: JAPANESE INTERMEDIATE CODE: A971007 Effective date: 20141017 |

|

| A131 | Notification of reasons for refusal |

Free format text: JAPANESE INTERMEDIATE CODE: A131 Effective date: 20141202 |

|

| A521 | Request for written amendment filed |

Free format text: JAPANESE INTERMEDIATE CODE: A523 Effective date: 20150202 |

|

| A131 | Notification of reasons for refusal |

Free format text: JAPANESE INTERMEDIATE CODE: A131 Effective date: 20150616 |

|

| A521 | Request for written amendment filed |

Free format text: JAPANESE INTERMEDIATE CODE: A523 Effective date: 20150817 |

|

| TRDD | Decision of grant or rejection written | ||

| A01 | Written decision to grant a patent or to grant a registration (utility model) |

Free format text: JAPANESE INTERMEDIATE CODE: A01 Effective date: 20151027 |

|

| A61 | First payment of annual fees (during grant procedure) |

Free format text: JAPANESE INTERMEDIATE CODE: A61 Effective date: 20151109 |

|

| R150 | Certificate of patent or registration of utility model |

Ref document number: 5846229 Country of ref document: JP Free format text: JAPANESE INTERMEDIATE CODE: R150 |

|

| R250 | Receipt of annual fees |

Free format text: JAPANESE INTERMEDIATE CODE: R250 |

|

| R250 | Receipt of annual fees |

Free format text: JAPANESE INTERMEDIATE CODE: R250 |

|

| R250 | Receipt of annual fees |

Free format text: JAPANESE INTERMEDIATE CODE: R250 |

|

| R250 | Receipt of annual fees |

Free format text: JAPANESE INTERMEDIATE CODE: R250 |

|

| R250 | Receipt of annual fees |

Free format text: JAPANESE INTERMEDIATE CODE: R250 |

|

| R250 | Receipt of annual fees |

Free format text: JAPANESE INTERMEDIATE CODE: R250 |

|

| R250 | Receipt of annual fees |

Free format text: JAPANESE INTERMEDIATE CODE: R250 |