JP5668469B2 - Method for thermal decomposition of plant biomass - Google Patents

Method for thermal decomposition of plant biomass Download PDFInfo

- Publication number

- JP5668469B2 JP5668469B2 JP2010292630A JP2010292630A JP5668469B2 JP 5668469 B2 JP5668469 B2 JP 5668469B2 JP 2010292630 A JP2010292630 A JP 2010292630A JP 2010292630 A JP2010292630 A JP 2010292630A JP 5668469 B2 JP5668469 B2 JP 5668469B2

- Authority

- JP

- Japan

- Prior art keywords

- heating

- biomass

- heating step

- product

- derived

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Expired - Fee Related

Links

- 239000002028 Biomass Substances 0.000 title claims description 81

- 238000000034 method Methods 0.000 title claims description 51

- 238000005979 thermal decomposition reaction Methods 0.000 title description 17

- 238000010438 heat treatment Methods 0.000 claims description 147

- 239000000047 product Substances 0.000 claims description 56

- YLQBMQCUIZJEEH-UHFFFAOYSA-N Furan Chemical compound C=1C=COC=1 YLQBMQCUIZJEEH-UHFFFAOYSA-N 0.000 claims description 34

- 229920002488 Hemicellulose Polymers 0.000 claims description 29

- 229920005610 lignin Polymers 0.000 claims description 26

- 238000000354 decomposition reaction Methods 0.000 claims description 24

- 239000007857 degradation product Substances 0.000 claims description 24

- ISWSIDIOOBJBQZ-UHFFFAOYSA-N Phenol Chemical compound OC1=CC=CC=C1 ISWSIDIOOBJBQZ-UHFFFAOYSA-N 0.000 claims description 21

- QTWJRLJHJPIABL-UHFFFAOYSA-N 2-methylphenol;3-methylphenol;4-methylphenol Chemical compound CC1=CC=C(O)C=C1.CC1=CC=CC(O)=C1.CC1=CC=CC=C1O QTWJRLJHJPIABL-UHFFFAOYSA-N 0.000 claims description 18

- 229930003836 cresol Natural products 0.000 claims description 18

- 238000002309 gasification Methods 0.000 claims description 4

- 241000196324 Embryophyta Species 0.000 description 35

- 238000005259 measurement Methods 0.000 description 21

- 241000218645 Cedrus Species 0.000 description 19

- 238000000197 pyrolysis Methods 0.000 description 16

- 229920002678 cellulose Polymers 0.000 description 15

- 239000001913 cellulose Substances 0.000 description 15

- 241000218691 Cupressaceae Species 0.000 description 14

- 150000001875 compounds Chemical class 0.000 description 13

- 150000002894 organic compounds Chemical class 0.000 description 12

- 238000004458 analytical method Methods 0.000 description 9

- 150000002989 phenols Chemical class 0.000 description 8

- 244000004281 Eucalyptus maculata Species 0.000 description 6

- 239000002994 raw material Substances 0.000 description 6

- 239000001307 helium Substances 0.000 description 4

- 229910052734 helium Inorganic materials 0.000 description 4

- SWQJXJOGLNCZEY-UHFFFAOYSA-N helium atom Chemical compound [He] SWQJXJOGLNCZEY-UHFFFAOYSA-N 0.000 description 4

- 239000000463 material Substances 0.000 description 4

- 239000000446 fuel Substances 0.000 description 3

- 238000011084 recovery Methods 0.000 description 3

- XLYOFNOQVPJJNP-UHFFFAOYSA-N water Substances O XLYOFNOQVPJJNP-UHFFFAOYSA-N 0.000 description 3

- QSZCGGBDNYTQHH-UHFFFAOYSA-N 2,3-dimethoxyphenol Chemical compound COC1=CC=CC(O)=C1OC QSZCGGBDNYTQHH-UHFFFAOYSA-N 0.000 description 2

- NOEGNKMFWQHSLB-UHFFFAOYSA-N 5-hydroxymethylfurfural Chemical compound OCC1=CC=C(C=O)O1 NOEGNKMFWQHSLB-UHFFFAOYSA-N 0.000 description 2

- GUBGYTABKSRVRQ-CUHNMECISA-N D-Cellobiose Chemical compound O[C@@H]1[C@@H](O)[C@H](O)[C@@H](CO)O[C@H]1O[C@@H]1[C@@H](CO)OC(O)[C@H](O)[C@H]1O GUBGYTABKSRVRQ-CUHNMECISA-N 0.000 description 2

- 240000000731 Fagus sylvatica Species 0.000 description 2

- 235000010099 Fagus sylvatica Nutrition 0.000 description 2

- 244000068988 Glycine max Species 0.000 description 2

- 235000010469 Glycine max Nutrition 0.000 description 2

- 241000219492 Quercus Species 0.000 description 2

- 240000000111 Saccharum officinarum Species 0.000 description 2

- 235000007201 Saccharum officinarum Nutrition 0.000 description 2

- YCIMNLLNPGFGHC-UHFFFAOYSA-N catechol Chemical compound OC1=CC=CC=C1O YCIMNLLNPGFGHC-UHFFFAOYSA-N 0.000 description 2

- 230000003247 decreasing effect Effects 0.000 description 2

- TXCDCPKCNAJMEE-UHFFFAOYSA-N dibenzofuran Chemical compound C1=CC=C2C3=CC=CC=C3OC2=C1 TXCDCPKCNAJMEE-UHFFFAOYSA-N 0.000 description 2

- 150000002240 furans Chemical class 0.000 description 2

- HYBBIBNJHNGZAN-UHFFFAOYSA-N furfural Chemical compound O=CC1=CC=CO1 HYBBIBNJHNGZAN-UHFFFAOYSA-N 0.000 description 2

- LHGVFZTZFXWLCP-UHFFFAOYSA-N guaiacol Chemical compound COC1=CC=CC=C1O LHGVFZTZFXWLCP-UHFFFAOYSA-N 0.000 description 2

- RJGBSYZFOCAGQY-UHFFFAOYSA-N hydroxymethylfurfural Natural products COC1=CC=C(C=O)O1 RJGBSYZFOCAGQY-UHFFFAOYSA-N 0.000 description 2

- TWNIBLMWSKIRAT-VFUOTHLCSA-N levoglucosan Chemical compound O[C@@H]1[C@@H](O)[C@H](O)[C@H]2CO[C@@H]1O2 TWNIBLMWSKIRAT-VFUOTHLCSA-N 0.000 description 2

- 230000014759 maintenance of location Effects 0.000 description 2

- 239000000203 mixture Substances 0.000 description 2

- 239000003921 oil Substances 0.000 description 2

- 238000000746 purification Methods 0.000 description 2

- 238000003303 reheating Methods 0.000 description 2

- 238000000926 separation method Methods 0.000 description 2

- 239000000126 substance Substances 0.000 description 2

- 238000002411 thermogravimetry Methods 0.000 description 2

- 230000007704 transition Effects 0.000 description 2

- VRVIADYRIJKCRW-UHFFFAOYSA-N 2-phenylethoxymethanol Chemical compound OCOCCC1=CC=CC=C1 VRVIADYRIJKCRW-UHFFFAOYSA-N 0.000 description 1

- YLZOPXRUQYQQID-UHFFFAOYSA-N 3-(2,4,6,7-tetrahydrotriazolo[4,5-c]pyridin-5-yl)-1-[4-[2-[[3-(trifluoromethoxy)phenyl]methylamino]pyrimidin-5-yl]piperazin-1-yl]propan-1-one Chemical compound N1N=NC=2CN(CCC=21)CCC(=O)N1CCN(CC1)C=1C=NC(=NC=1)NCC1=CC(=CC=C1)OC(F)(F)F YLZOPXRUQYQQID-UHFFFAOYSA-N 0.000 description 1

- WKLYPBXWXAIONF-UHFFFAOYSA-N 3-phenylpropoxymethanol Chemical compound OCOCCCC1=CC=CC=C1 WKLYPBXWXAIONF-UHFFFAOYSA-N 0.000 description 1

- 241000208140 Acer Species 0.000 description 1

- 241001133760 Acoelorraphe Species 0.000 description 1

- 241000609240 Ambelania acida Species 0.000 description 1

- 235000017166 Bambusa arundinacea Nutrition 0.000 description 1

- 235000017491 Bambusa tulda Nutrition 0.000 description 1

- 241000219310 Beta vulgaris subsp. vulgaris Species 0.000 description 1

- 241000167854 Bourreria succulenta Species 0.000 description 1

- 240000002791 Brassica napus Species 0.000 description 1

- 235000006008 Brassica napus var napus Nutrition 0.000 description 1

- ZINFAXMZLBBDRN-UHFFFAOYSA-N COC(CC1=C(C=CC=C1)O)OC Chemical compound COC(CC1=C(C=CC=C1)O)OC ZINFAXMZLBBDRN-UHFFFAOYSA-N 0.000 description 1

- SWYKDDOKZVEAIV-UHFFFAOYSA-N COC(CCC1=C(C=CC=C1)O)OC Chemical compound COC(CCC1=C(C=CC=C1)O)OC SWYKDDOKZVEAIV-UHFFFAOYSA-N 0.000 description 1

- 241001070941 Castanea Species 0.000 description 1

- 235000014036 Castanea Nutrition 0.000 description 1

- 241000422842 Chamaecyparis pisifera Species 0.000 description 1

- 241000195493 Cryptophyta Species 0.000 description 1

- 240000008067 Cucumis sativus Species 0.000 description 1

- 235000010799 Cucumis sativus var sativus Nutrition 0.000 description 1

- 244000166124 Eucalyptus globulus Species 0.000 description 1

- 208000033962 Fontaine progeroid syndrome Diseases 0.000 description 1

- 235000011201 Ginkgo Nutrition 0.000 description 1

- 244000194101 Ginkgo biloba Species 0.000 description 1

- 235000008100 Ginkgo biloba Nutrition 0.000 description 1

- 241000282816 Giraffa camelopardalis Species 0.000 description 1

- 241000282821 Hippopotamus Species 0.000 description 1

- 241000221089 Jatropha Species 0.000 description 1

- 240000007049 Juglans regia Species 0.000 description 1

- 235000009496 Juglans regia Nutrition 0.000 description 1

- 240000007472 Leucaena leucocephala Species 0.000 description 1

- 235000010643 Leucaena leucocephala Nutrition 0.000 description 1

- CZCPHPIOAZZAJO-UHFFFAOYSA-N OCOC=CC1=CC=CC=C1 Chemical compound OCOC=CC1=CC=CC=C1 CZCPHPIOAZZAJO-UHFFFAOYSA-N 0.000 description 1

- 240000007594 Oryza sativa Species 0.000 description 1

- 235000007164 Oryza sativa Nutrition 0.000 description 1

- 235000014676 Phragmites communis Nutrition 0.000 description 1

- 244000082204 Phyllostachys viridis Species 0.000 description 1

- 235000015334 Phyllostachys viridis Nutrition 0.000 description 1

- 235000008331 Pinus X rigitaeda Nutrition 0.000 description 1

- 241000018646 Pinus brutia Species 0.000 description 1

- 235000011613 Pinus brutia Nutrition 0.000 description 1

- 241000219000 Populus Species 0.000 description 1

- 240000005499 Sasa Species 0.000 description 1

- 244000061456 Solanum tuberosum Species 0.000 description 1

- 235000002595 Solanum tuberosum Nutrition 0.000 description 1

- 235000021536 Sugar beet Nutrition 0.000 description 1

- 244000186561 Swietenia macrophylla Species 0.000 description 1

- 240000002871 Tectona grandis Species 0.000 description 1

- 241000736892 Thujopsis dolabrata Species 0.000 description 1

- 235000021307 Triticum Nutrition 0.000 description 1

- 244000098338 Triticum aestivum Species 0.000 description 1

- 240000008042 Zea mays Species 0.000 description 1

- 235000005824 Zea mays ssp. parviglumis Nutrition 0.000 description 1

- 235000002017 Zea mays subsp mays Nutrition 0.000 description 1

- 241000190021 Zelkova Species 0.000 description 1

- 230000004931 aggregating effect Effects 0.000 description 1

- 239000010905 bagasse Substances 0.000 description 1

- 239000011425 bamboo Substances 0.000 description 1

- RFRXIWQYSOIBDI-UHFFFAOYSA-N benzarone Chemical compound CCC=1OC2=CC=CC=C2C=1C(=O)C1=CC=C(O)C=C1 RFRXIWQYSOIBDI-UHFFFAOYSA-N 0.000 description 1

- 235000019693 cherries Nutrition 0.000 description 1

- 239000011258 core-shell material Substances 0.000 description 1

- 235000005822 corn Nutrition 0.000 description 1

- MIHINWMALJZIBX-UHFFFAOYSA-N cyclohexa-2,4-dien-1-ol Chemical class OC1CC=CC=C1 MIHINWMALJZIBX-UHFFFAOYSA-N 0.000 description 1

- RBWKALYSJJBYDR-UHFFFAOYSA-N dimethoxy(phenyl)methanol Chemical compound COC(O)(OC)C1=CC=CC=C1 RBWKALYSJJBYDR-UHFFFAOYSA-N 0.000 description 1

- 238000004821 distillation Methods 0.000 description 1

- 238000005516 engineering process Methods 0.000 description 1

- 239000003925 fat Substances 0.000 description 1

- 229960001867 guaiacol Drugs 0.000 description 1

- 238000005984 hydrogenation reaction Methods 0.000 description 1

- 238000006460 hydrolysis reaction Methods 0.000 description 1

- 239000012535 impurity Substances 0.000 description 1

- 239000011261 inert gas Substances 0.000 description 1

- 235000021374 legumes Nutrition 0.000 description 1

- 238000004519 manufacturing process Methods 0.000 description 1

- 239000003208 petroleum Substances 0.000 description 1

- -1 phenol Chemical class 0.000 description 1

- PETXWIMJICIQTQ-UHFFFAOYSA-N phenylmethoxymethanol Chemical compound OCOCC1=CC=CC=C1 PETXWIMJICIQTQ-UHFFFAOYSA-N 0.000 description 1

- 235000009566 rice Nutrition 0.000 description 1

- 239000013076 target substance Substances 0.000 description 1

- MWOOGOJBHIARFG-UHFFFAOYSA-N vanillin Chemical compound COC1=CC(C=O)=CC=C1O MWOOGOJBHIARFG-UHFFFAOYSA-N 0.000 description 1

- FGQOOHJZONJGDT-UHFFFAOYSA-N vanillin Natural products COC1=CC(O)=CC(C=O)=C1 FGQOOHJZONJGDT-UHFFFAOYSA-N 0.000 description 1

- 235000012141 vanillin Nutrition 0.000 description 1

- 235000020234 walnut Nutrition 0.000 description 1

- PJVWKTKQMONHTI-UHFFFAOYSA-N warfarin Chemical compound OC=1C2=CC=CC=C2OC(=O)C=1C(CC(=O)C)C1=CC=CC=C1 PJVWKTKQMONHTI-UHFFFAOYSA-N 0.000 description 1

- 239000002699 waste material Substances 0.000 description 1

- 239000013585 weight reducing agent Substances 0.000 description 1

- 239000002023 wood Substances 0.000 description 1

Images

Classifications

-

- C—CHEMISTRY; METALLURGY

- C10—PETROLEUM, GAS OR COKE INDUSTRIES; TECHNICAL GASES CONTAINING CARBON MONOXIDE; FUELS; LUBRICANTS; PEAT

- C10B—DESTRUCTIVE DISTILLATION OF CARBONACEOUS MATERIALS FOR PRODUCTION OF GAS, COKE, TAR, OR SIMILAR MATERIALS

- C10B53/00—Destructive distillation, specially adapted for particular solid raw materials or solid raw materials in special form

- C10B53/02—Destructive distillation, specially adapted for particular solid raw materials or solid raw materials in special form of cellulose-containing material

-

- C—CHEMISTRY; METALLURGY

- C10—PETROLEUM, GAS OR COKE INDUSTRIES; TECHNICAL GASES CONTAINING CARBON MONOXIDE; FUELS; LUBRICANTS; PEAT

- C10B—DESTRUCTIVE DISTILLATION OF CARBONACEOUS MATERIALS FOR PRODUCTION OF GAS, COKE, TAR, OR SIMILAR MATERIALS

- C10B57/00—Other carbonising or coking processes; Features of destructive distillation processes in general

- C10B57/02—Multi-step carbonising or coking processes

-

- Y—GENERAL TAGGING OF NEW TECHNOLOGICAL DEVELOPMENTS; GENERAL TAGGING OF CROSS-SECTIONAL TECHNOLOGIES SPANNING OVER SEVERAL SECTIONS OF THE IPC; TECHNICAL SUBJECTS COVERED BY FORMER USPC CROSS-REFERENCE ART COLLECTIONS [XRACs] AND DIGESTS

- Y02—TECHNOLOGIES OR APPLICATIONS FOR MITIGATION OR ADAPTATION AGAINST CLIMATE CHANGE

- Y02E—REDUCTION OF GREENHOUSE GAS [GHG] EMISSIONS, RELATED TO ENERGY GENERATION, TRANSMISSION OR DISTRIBUTION

- Y02E50/00—Technologies for the production of fuel of non-fossil origin

- Y02E50/10—Biofuels, e.g. bio-diesel

-

- Y—GENERAL TAGGING OF NEW TECHNOLOGICAL DEVELOPMENTS; GENERAL TAGGING OF CROSS-SECTIONAL TECHNOLOGIES SPANNING OVER SEVERAL SECTIONS OF THE IPC; TECHNICAL SUBJECTS COVERED BY FORMER USPC CROSS-REFERENCE ART COLLECTIONS [XRACs] AND DIGESTS

- Y02—TECHNOLOGIES OR APPLICATIONS FOR MITIGATION OR ADAPTATION AGAINST CLIMATE CHANGE

- Y02E—REDUCTION OF GREENHOUSE GAS [GHG] EMISSIONS, RELATED TO ENERGY GENERATION, TRANSMISSION OR DISTRIBUTION

- Y02E50/00—Technologies for the production of fuel of non-fossil origin

- Y02E50/30—Fuel from waste, e.g. synthetic alcohol or diesel

Landscapes

- Chemical & Material Sciences (AREA)

- Engineering & Computer Science (AREA)

- Oil, Petroleum & Natural Gas (AREA)

- Materials Engineering (AREA)

- Organic Chemistry (AREA)

- Organic Low-Molecular-Weight Compounds And Preparation Thereof (AREA)

- Processing Of Solid Wastes (AREA)

- Furan Compounds (AREA)

Description

本発明は植物系バイオマスを熱分解することにより有用な有機化合物を得るための方法に関する。 The present invention relates to a method for obtaining useful organic compounds by pyrolyzing plant biomass.

植物系バイオマスを熱分解すると、植物系バイオマスに含まれるセルロース、ヘミセルロース、リグニンおよび油脂などに由来する分解物が多く生成する。この熱分解物の中にはフェノールなどの有用な有機化合物が含まれる一方、それ以外の有用性に乏しい物質も多く含まれる。そのような雑多な混合物から特定の化合物のみを抽出するにはかなりの労力が必要となり工業的応用には適していない。このような問題を解決するために、例えば植物系バイオマス原料を前処理することによりセルロースのみを取り出して熱分解することも考えられるが、その前処理自体にも労力がかかり、やはり工業的応用には適していない。 When plant biomass is pyrolyzed, many decomposition products derived from cellulose, hemicellulose, lignin, fats and oils, etc. contained in plant biomass are generated. While this pyrolyzate contains useful organic compounds such as phenol, it contains many other poorly useful substances. Extracting only certain compounds from such miscellaneous mixtures requires considerable effort and is not suitable for industrial applications. In order to solve such problems, for example, it may be possible to extract only cellulose by pretreatment of plant-based biomass raw material and pyrolyze, but the pretreatment itself is labor intensive and is also useful for industrial application. Is not suitable.

非特許文献1には、ブナ木材を600〜900Kで熱分解した際に生じる化合物について記載されており、熱分解温度の違いによって得られる化合物が異なることなどが開示されている。特許文献1には、植物系バイオマスから得られる熱分解油から分離、濃縮、水素化などの工程を経て有用な化合物を取り出す工程が開示されている。 Non-Patent Document 1 describes a compound generated when beech wood is pyrolyzed at 600 to 900 K, and discloses that compounds obtained by differences in pyrolysis temperature are different. Patent Document 1 discloses a process of taking out a useful compound through processes such as separation, concentration and hydrogenation from pyrolysis oil obtained from plant biomass.

植物系バイオマスの熱分解物には有用な有機化合物が多く含まれているにもかかわらず、そこから所望の化合物を取り出すのに簡便かつ有効な方法は知られていない。植物系バイオマスの有効利用を図るため、植物系バイオマスから所望の有機化合物を取り出すことを可能する、工業的応用に適した簡便な方法が求められている。 Although the pyrolyzate of plant biomass contains a lot of useful organic compounds, a simple and effective method for extracting a desired compound therefrom is not known. In order to make effective use of plant-based biomass, a simple method suitable for industrial application that can extract a desired organic compound from plant-based biomass is required.

本発明者は、検討の結果、少なくとも2段階の加熱工程により植物系バイオマスを熱分解することにより、加熱処理のみで植物系バイオマスに含まれるリグニンやヘミセルロースなどの各成分のそれぞれに由来する一群の化合物あるいは特定の化合物を分けて取り出すことが可能であることを見出した。本発明の要旨は以下のとおりである。 As a result of the study, the inventor thermally decomposes the plant biomass by at least two stages of heating processes, and thereby a group of components derived from each component such as lignin and hemicellulose contained in the plant biomass only by heat treatment. It has been found that a compound or a specific compound can be separated and taken out. The gist of the present invention is as follows.

(1)植物系バイオマスを熱分解することにより有用な有機化合物を得る方法であって、

バイオマスを第1の加熱温度で加熱する第1加熱工程と、

第1加熱工程で得られたガス化物またはバイオマス残渣のいずれかを、第1の加熱温度よりも高い第2の加熱温度で加熱する第2加熱工程

を含む、前記方法。

(1) A method for obtaining a useful organic compound by pyrolyzing plant biomass,

A first heating step of heating the biomass at a first heating temperature;

The said method including the 2nd heating process which heats either the gasification thing or biomass residue obtained at the 1st heating process at 2nd heating temperature higher than 1st heating temperature.

(2)第1加熱工程で植物系バイオマスを400℃以下の第1の加熱温度で加熱し、第2加熱工程でバイオマス残渣を500℃以上の第2の加熱温度で加熱してリグニン由来分解物を得る、(1)に記載の方法。 (2) The plant biomass is heated at a first heating temperature of 400 ° C. or lower in the first heating step, and the biomass residue is heated at a second heating temperature of 500 ° C. or higher in the second heating step to decompose lignin-derived degradation products. The method according to (1), wherein:

(3)第2加熱工程で、第1加熱工程で得られたバイオマス残渣を加熱し、さらに生じたバイオマス残渣を第2の加熱温度よりも高い第3の加熱温度で加熱する第3加熱工程をさらに含む、(1)または(2)に記載の方法。 (3) In the second heating step, the third heating step of heating the biomass residue obtained in the first heating step, and further heating the generated biomass residue at a third heating temperature higher than the second heating temperature. The method according to (1) or (2), further comprising:

(4)第1の加熱温度が400℃以下、第2の加熱温度が500〜600℃の範囲であり、第3加熱工程でバイオマス残渣を600℃以上の第3の加熱温度で加熱してリグニン由来分解物を得る、(3)に記載の方法。 (4) The first heating temperature is 400 ° C. or less, the second heating temperature is in the range of 500 to 600 ° C., and the biomass residue is heated at the third heating temperature of 600 ° C. or more in the third heating step to form lignin. The method according to (3), wherein a degradation product is obtained.

(5)リグニン由来分解物が少なくともフェノールまたはクレゾールを含む、(1)〜(4)のいずれかに記載の方法。

(6)第1加熱工程でバイオマスを280〜320℃の範囲の第1の加熱温度で加熱し、第1加熱工程で得られたガス化物を600〜800℃の範囲の第2の加熱温度で加熱してヘミセルロース由来の分解物を得る、(1)〜(5)のいずれかに記載の方法。

(7)ヘミセルロース由来の分解物が少なくともフランを含む、(6)に記載の方法。

(5) The method according to any one of (1) to (4), wherein the lignin-derived degradation product contains at least phenol or cresol.

(6) The biomass is heated at the first heating temperature in the range of 280 to 320 ° C in the first heating step, and the gasified product obtained in the first heating step is at the second heating temperature in the range of 600 to 800 ° C. The method according to any one of (1) to (5), wherein a decomposition product derived from hemicellulose is obtained by heating.

(7) The method according to (6), wherein the degradation product derived from hemicellulose contains at least furan.

本発明の方法によれば、加熱処理のみにより植物系バイオマスに含まれるリグニンやヘミセルロースなどの各成分のそれぞれに由来する一群または特定の化合物を分けて取り出すことが可能となる。従って、本発明によれば、植物系バイオマスから有用な化合物をある程度の純度で取り出すことができ、石油などを利用せずにフェノール類などの有機化合物を調製することが可能となる。 According to the method of the present invention, a group or a specific compound derived from each component such as lignin and hemicellulose contained in plant biomass can be separated and extracted only by heat treatment. Therefore, according to the present invention, useful compounds can be extracted from plant biomass with a certain degree of purity, and organic compounds such as phenols can be prepared without using petroleum or the like.

図1は本発明の概略を示したフローチャートである。本発明の方法をこのフローチャートに沿って説明する。 FIG. 1 is a flowchart showing an outline of the present invention. The method of this invention is demonstrated along this flowchart.

本発明の方法は、植物系バイオマスを第1の加熱温度で加熱する第1加熱工程(A)と、第1加熱工程で得られたガス化物(a1)またはバイオマス残渣(a2)のいずれかを第1の加熱温度よりも高い第2の加熱温度で加熱する第2加熱工程(BまたはC)を含む。また、本発明の方法は、第1加熱工程で得られたバイオマス残渣(a2)を加熱する第2加熱工程(C)において生じたバイオマス残渣(c2)を、第2の加熱温度よりも高い第3の加熱温度で加熱する第3加熱工程(D)を含んでいてもよい。 The method of the present invention comprises a first heating step (A) for heating plant biomass at a first heating temperature, and a gasified product (a1) or biomass residue (a2) obtained in the first heating step. A second heating step (B or C) for heating at a second heating temperature higher than the first heating temperature is included. Further, the method of the present invention is configured so that the biomass residue (c2) generated in the second heating step (C) for heating the biomass residue (a2) obtained in the first heating step is higher than the second heating temperature. 3rd heating process (D) heated at the heating temperature of 3 may be included.

本明細書において「植物系バイオマス」とは、セルロース、ヘミセルロース、リグニンなどを含む植物由来原料を意味し、木質系バイオマスおよび草本系バイオマスの双方がこれに含まれる。木質系バイオマスには、スギ、ヒノキ、マツ、クヌギ、サクラ、タモ、ケヤキ、ブナ、ナラ、カエデ、イチョウ、キリ、カシ、クリ、ユーカリ、チーク、マホガニー、ヒバ、ポプラ、アカシア、モミ、カバ、ワラン、ウォールナット、サワラ、カヤ、イチイ、オーク、カツラ、モミ、ヤトロファなどの日本国産材、北米材、ロシア材(北洋材)、南洋材、アフリカ材、南米材、オセアニア材、中国材、欧州材を例とする木質化した幹組織を有する植物に由来する材料が含まれる。草本系バイオマスには、イネ、ムギ、サトウキビ、トウモロコシ、アブラナ、ダイズ、ヤシ、ヨシ、ササ、タケ、テンサイ、イモ類、マメ科植物、藻類などの木質化した幹組織を有しない植物に由来する材料が含まれる。当然ながら、上記の木質系バイオマスおよび草本系バイオマスの残渣、例えばバガス(サトウキビの搾りかす)やダイズ、アブラナ、パームヤシなどの搾油後の残渣なども植物系バイオマスに含まれる。本発明の方法で用いる植物系バイオマスとしては、リグニンを多く含む木質系バイオマスが、後述するフェノール類を多く製造するためにはより好ましい。 In the present specification, “plant biomass” means a plant-derived raw material containing cellulose, hemicellulose, lignin and the like, and includes both woody biomass and herbaceous biomass. Woody biomass includes cedar, cypress, pine, cucumber, cherry, tamamo, zelkova, beech, oak, maple, ginkgo, giraffe, oak, chestnut, eucalyptus, teak, mahogany, hiba, poplar, acacia, fir, hippopotamus, Japanese timber such as waran, walnut, sawara, kayak, yew, oak, wig, fir, jatropha, etc. The material derived from the plant which has the wooded stem tissue which is made into an example is included. Herbaceous biomass is derived from plants that do not have woody stem tissue such as rice, wheat, sugarcane, corn, rape, soybean, palm, reed, sasa, bamboo, sugar beet, potato, legumes, algae Material is included. Naturally, residues of the above woody biomass and herbaceous biomass such as bagasse (sugarcane squeezed), soybeans, oilseed rape, palm palm, and the like are also included in plant biomass. As the plant biomass used in the method of the present invention, a woody biomass containing a large amount of lignin is more preferable for producing a large amount of phenols described later.

本発明の方法において「有用な有機化合物」とは、化学工業における原料として、あるいはエンジンや燃料電池用の燃料などとして有用な有機化合物を意味する。有用な有機化合物の具体例としては、1価フェノール類、2価フェノール類、3価フェノール類、フラン類、レボグルコサン、セロビオースなどが挙げられる。植物系バイオマスの熱分解により得られる有用な有機化合物としては、特にフェノール、クレゾールおよびフランを挙げることができる。 The “useful organic compound” in the method of the present invention means an organic compound useful as a raw material in the chemical industry or as a fuel for an engine or a fuel cell. Specific examples of useful organic compounds include monohydric phenols, dihydric phenols, trihydric phenols, furans, levoglucosan, cellobiose and the like. Examples of useful organic compounds obtained by pyrolysis of plant biomass include phenol, cresol and furan.

本発明の方法における各加熱工程(A〜D)では、加熱に供される原料(バイオマス、ガス化物またはバイオマス残渣)を熱分解する。従って、加水分解反応を極力少なくし、熱分解反応を進行させるために、加熱を行う際には系中に過剰な水が存在しない方がよい。各加熱工程は、例えば不活性ガスの存在下、原料に元来含まれている以外の水分が存在しない状態で行うのが好ましい。必要に応じて、原料を加熱工程に供する前に乾燥させ、予め水分を除去してもよい。 In each heating step (A to D) in the method of the present invention, a raw material (biomass, gasified product or biomass residue) to be heated is pyrolyzed. Therefore, in order to minimize the hydrolysis reaction and advance the thermal decomposition reaction, it is preferable that no excess water exists in the system when heating is performed. Each heating step is preferably performed, for example, in the presence of an inert gas and in the absence of moisture other than that originally contained in the raw material. If necessary, the raw material may be dried before being subjected to the heating step to remove moisture in advance.

本発明の方法は、各加熱工程(A〜D)の後に、熱分解により生じたガス化物と、ガス化せずに残った残渣とを分離することを含む。分離は当業者に知られた通常の方法、例えば加熱を行う炉の排気系に凝縮器を設けて排気に含まれるガス化物を液化させて回収し、加熱後に炉に残った残渣を別途回収することにより行われる。 The method of the present invention includes, after each heating step (A to D), separating a gasified product generated by thermal decomposition from a residue remaining without being gasified. Separation is performed by a normal method known to those skilled in the art, for example, a condenser is provided in the exhaust system of the furnace to be heated to collect and collect the gasified product contained in the exhaust, and separately collect the residue remaining in the furnace after the heating. Is done.

第1加熱工程(A)では、植物系バイオマスを400℃以下、特に380℃以下の温度で加熱することが好ましい。これは、植物系バイオマスに含まれる成分のうちセルロースおよびヘミセルロースは比較的低い温度でも熱分解を起こすという知見に基づく。そのような温度であれば、植物系バイオマスを構成する成分のうち、リグニンは殆ど分解せず、セルロースおよびヘミセルロースのみが熱分解してガス化物(a1)へと変化する。ただし、温度が低すぎると熱分解が進行しないため、植物系バイオマスの加熱は275℃以上、特に280℃以上の温度で行うことが好ましい。 In the first heating step (A), it is preferable to heat the plant biomass at a temperature of 400 ° C. or lower, particularly 380 ° C. or lower. This is based on the knowledge that cellulose and hemicellulose among components contained in plant-based biomass cause thermal decomposition even at a relatively low temperature. At such a temperature, lignin is hardly decomposed among the components constituting the plant biomass, and only cellulose and hemicellulose are thermally decomposed and changed into a gasified product (a1). However, since the thermal decomposition does not proceed when the temperature is too low, it is preferable to heat the plant biomass at a temperature of 275 ° C. or higher, particularly 280 ° C. or higher.

第1加熱工程(A)における最適な加熱温度(第1の加熱温度)は、植物系バイオマスの種類によって異なるが、通常400℃以下の範囲である。例えば植物系バイオマスがスギまたはヒノキなどの木質系バイオマスに由来するものである場合、第1の加熱温度は380℃以下、特に375℃以下、とりわけ370℃以下の温度が好ましい。また、ヘミセルロース由来のガス化物を主として得ることを目的とするのであれば、セルロースと比べてヘミセルロースはより低い温度で熱分解し始めるため、第1の加熱温度は例えば275〜325℃、特に280〜320℃の範囲とするのが好ましい。 Although the optimal heating temperature (1st heating temperature) in a 1st heating process (A) changes with kinds of plant biomass, it is the range of 400 degrees C or less normally. For example, when the plant-based biomass is derived from woody biomass such as cedar or cypress, the first heating temperature is preferably 380 ° C. or lower, particularly 375 ° C. or lower, particularly 370 ° C. or lower. If the purpose is mainly to obtain a gasification product derived from hemicellulose, hemicellulose begins to thermally decompose at a lower temperature compared to cellulose, so the first heating temperature is, for example, 275 to 325 ° C., particularly 280 to 280 ° C. A range of 320 ° C. is preferable.

第2加熱工程(BまたはC)では、第1加熱工程で生じたガス化物(a1)またはバイオマス残渣(a2)のいずれかを、第1の加熱温度よりも高い第2の加熱温度で加熱する。ここで、バイオマス残渣とは、加熱に供した材料から熱分解により生じたガス化物が離脱した後の残渣物を意味する。第2の加熱温度は、例えば450℃以上、特に500℃以上の温度に設定することが好ましい。 In the second heating step (B or C), either the gasified product (a1) or the biomass residue (a2) generated in the first heating step is heated at a second heating temperature higher than the first heating temperature. . Here, the biomass residue means a residue after the gasified product generated by thermal decomposition is separated from the material subjected to heating. The second heating temperature is preferably set to a temperature of, for example, 450 ° C. or higher, particularly 500 ° C. or higher.

第1加熱工程(A)で植物系バイオマスを400℃以下の第1の加熱温度で加熱し、第2加熱工程(C)でバイオマス残渣(a2)を500℃以上の第2の加熱温度で加熱すると、ガス化物(c1)としてリグニン由来分解物が得られる。リグニン由来分解物には、フェノール、クレゾール、グアヤコール、ヒドロキシメトキシトルエン、ヒドロキシメトキシエチルベンゼン、ヒドロキシメトキシビニルベンゼン、ヒドロキシメトキシプロピルベンゼン、ジメトキシフェノール、ヒドロキシジメトキシトルエン、ヒドロキシジメトキシエチルベンゼン、ヒドロキシジメトキシプロピルベンゼン、ピロカテコール、ベンゾフラン、ジベンゾフラン、バニリンなどのフェノール類が含まれる。これらのフェノール類のうち、フェノールおよびクレゾールは工業上特に重要な化合物である。ここで得られるリグニン由来分解物には、少なくともフェノールまたはクレゾールが含まれる。ここで得られるリグニン由来分解物におけるフェノールおよび/またはクレゾールの含有量は、得られたガス化物(c1)を凝集させた後の全体の重量に対して20重量%以上であることが好ましい。より好ましくは、ここで得られるリグニン由来分解物は実質的にフェノールおよび/またはクレゾールからなる。ここで「実質的に−からなる」とは、対象に含まれる目的物以外の不純物が5重量%未満、特に3重量%未満、とりわけ1重量%未満であることを意味する。 The plant biomass is heated at a first heating temperature of 400 ° C. or lower in the first heating step (A), and the biomass residue (a2) is heated at a second heating temperature of 500 ° C. or higher in the second heating step (C). Then, a lignin-derived decomposition product is obtained as the gasified product (c1). Lignin-derived degradation products include phenol, cresol, guaiacol, hydroxymethoxytoluene, hydroxymethoxyethylbenzene, hydroxymethoxyvinylbenzene, hydroxymethoxypropylbenzene, dimethoxyphenol, hydroxydimethoxytoluene, hydroxydimethoxyethylbenzene, hydroxydimethoxypropylbenzene, pyrocatechol, Phenols such as benzofuran, dibenzofuran and vanillin are included. Of these phenols, phenol and cresol are particularly important compounds in the industry. The lignin-derived degradation product obtained here contains at least phenol or cresol. The content of phenol and / or cresol in the lignin-derived degradation product obtained here is preferably 20% by weight or more based on the total weight after the obtained gasified product (c1) is aggregated. More preferably, the lignin-derived degradation product obtained here consists essentially of phenol and / or cresol. Here, “consisting essentially of” means that impurities other than the target substance contained in the object are less than 5% by weight, particularly less than 3% by weight, especially less than 1% by weight.

第2加熱工程(C)でバイオマス残渣(a2)を加熱し、ガス化物(c1)が離脱した後にさらに生じたバイオマス残渣(c2)は、第3加熱工程(D)に供してもよい。第3加熱工程(D)では、第2加熱工程(C)における第2の加熱温度よりも高い第3の加熱温度で加熱する。第3の加熱温度は、例えば550℃以上、特に600℃以上の温度に設定することが好ましい。ただし、あまりに温度を高くするとバイオマス残渣(a2)が炭化してしまうため、第3の加熱温度は650℃以下にすることが好ましい。 The biomass residue (c2) further generated after the biomass residue (a2) is heated in the second heating step (C) and the gasified product (c1) is released may be subjected to the third heating step (D). In the third heating step (D), heating is performed at a third heating temperature that is higher than the second heating temperature in the second heating step (C). The third heating temperature is preferably set to a temperature of, for example, 550 ° C. or higher, particularly 600 ° C. or higher. However, since the biomass residue (a2) is carbonized if the temperature is too high, the third heating temperature is preferably 650 ° C. or lower.

第1加熱工程(A)で植物系バイオマスを400℃以下(より好ましくは380℃以下、特に370℃以下)の第1の加熱温度で加熱し、第2加熱工程(C)でバイオマス残渣(a2)を500〜600℃の範囲(より好ましくは500〜550℃の範囲)の第2の加熱温度で加熱し、さらに第3加熱工程(D)で600℃以上(より好ましくは620℃以上)の第3の加熱温度でバイオマス残渣(c2)を加熱することにより、分解されず残っていたリグニンが熱分解され、ガス化物(d1)としてリグニン由来分解物が得られる。ここで得られるリグニン由来分解物は上記と同様であり、少なくともフェノールまたはクレゾールが含まれる。ここで得られるリグニン由来分解物におけるフェノールおよび/またはクレゾールの含有量は、得られたガス化物(d1)を凝集させた後の全体の重量に対して50重量%以上であることが好ましい。より好ましくは、ここで得られるリグニン由来分解物は実質的にフェノールおよび/またはクレゾールからなる。第3加熱工程(D)で生じるバイオマス残渣(d2)は、もはや有用な化合物は含んでいないため、通常は熱源原料として利用される。 The plant biomass is heated at a first heating temperature of 400 ° C. or less (more preferably 380 ° C. or less, particularly preferably 370 ° C. or less) in the first heating step (A), and the biomass residue (a2) in the second heating step (C) ) At a second heating temperature in the range of 500 to 600 ° C. (more preferably in the range of 500 to 550 ° C.), and further in the third heating step (D) at 600 ° C. or higher (more preferably 620 ° C. or higher). By heating the biomass residue (c2) at the third heating temperature, the lignin remaining without being decomposed is thermally decomposed to obtain a lignin-derived decomposed product as a gasified product (d1). The lignin-derived degradation product obtained here is the same as described above, and contains at least phenol or cresol. The content of phenol and / or cresol in the lignin-derived decomposition product obtained here is preferably 50% by weight or more based on the total weight after the obtained gasified product (d1) is aggregated. More preferably, the lignin-derived degradation product obtained here consists essentially of phenol and / or cresol. Since the biomass residue (d2) generated in the third heating step (D) no longer contains a useful compound, it is usually used as a heat source material.

第1加熱工程(A)で植物系バイオマスを280〜320℃の範囲(より好ましくは300〜320℃の範囲)の第1の加熱温度で加熱し、第2加熱工程(B)でガス化物(a1)を600〜800℃の範囲(より好ましくは630〜660℃の範囲)の第2の加熱温度で加熱することにより、生成物(b1)としてヘミセルロース由来分解物が得られる。ヘミセルロース由来分解物には、フラン、フルフラールなどのフラン類が含まれる。ここで得られるヘミセルロース由来分解物には、少なくともフランが含まれる。ここで得られるヘミセルロース由来分解物におけるフランの含有量は、得られた生成物(b1)を凝集させた後の全体の重量に対して30重量%以上であることが好ましい。より好ましくは、ここで得られるヘミセルロース由来分解物は実質的にフランのみからなる。 In the first heating step (A), the plant biomass is heated at a first heating temperature in the range of 280 to 320 ° C. (more preferably in the range of 300 to 320 ° C.), and in the second heating step (B), the gasified product ( By heating a1) at a second heating temperature in the range of 600 to 800 ° C (more preferably in the range of 630 to 660 ° C), a hemicellulose-derived decomposition product is obtained as the product (b1). The hemicellulose-derived decomposition products include furans such as furan and furfural. The hemicellulose-derived decomposition product obtained here contains at least furan. The furan content in the hemicellulose-derived decomposition product obtained here is preferably 30% by weight or more based on the total weight after the obtained product (b1) is aggregated. More preferably, the hemicellulose-derived degradation product obtained here consists essentially of furan.

なお、フランをより高純度で得ることを目的とするならば、第2の加熱温度は700℃以上、特に750℃以上の温度とすることが好ましい。この場合、得られるヘミセルロース由来分解物におけるフランの含有量は、得られた生成物(b1)を凝集させた後の全体の重量に対して50重量%以上であることが好ましい。また、純度の面ではやや劣っても、フランを高収率で得ることを目的とするならば、第2の加熱温度は630〜660℃の範囲、特に640〜660℃の範囲の温度とすることが好ましい。 If the purpose is to obtain furan with higher purity, the second heating temperature is preferably 700 ° C. or higher, particularly 750 ° C. or higher. In this case, the content of furan in the obtained hemicellulose-derived decomposition product is preferably 50% by weight or more based on the total weight after the obtained product (b1) is aggregated. Moreover, even if it is a little inferior in terms of purity, if the purpose is to obtain furan in a high yield, the second heating temperature is in the range of 630 to 660 ° C., particularly in the range of 640 to 660 ° C. It is preferable.

ヘミセルロース由来分解物に加えてセルロース由来分解物も得るのであれば、第1加熱工程(A)における第1の加熱温度を320℃以上、例えば320〜400℃の範囲(より好ましくは350〜380℃の範囲)の温度としてもよい。セルロース由来分解物には、ヒドロキシメチルフルフラール、レボグルコサン、セロビオースなどが含まれる。 If a cellulose-derived degradation product is obtained in addition to the hemicellulose-derived degradation product, the first heating temperature in the first heating step (A) is 320 ° C. or higher, for example, a range of 320 to 400 ° C. (more preferably 350 to 380 ° C. Temperature). Cellulose-derived degradation products include hydroxymethylfurfural, levoglucosan, cellobiose and the like.

上述した各手順、すなわち

(i)植物系バイオマスから第1加熱工程(A)を経てバイオマス残渣(a2)を得て、それを第2加熱工程(C)に付してガス化物(c1)を得る手順、

(ii)植物系バイオマスから第1加熱工程(A)を経てバイオマス残渣(a2)を得て、それを第2加熱工程(C)に付してさらに生じたバイオマス残渣(c2)を第3加熱工程(D)に付してガス化物(d1)を得る手順、および

(iii)植物系バイオマスから第1加熱工程(A)を経てガス化物(a1)を得て、それを第2加熱工程(B)に付して生成物(b1)を得る手順

は、全てを並行して行ってもよく、あるいは1つまたは2つの特定の手順のみを行ってもよい。

Each procedure mentioned above, ie, (i) A biomass residue (a2) is obtained from a plant biomass through the first heating step (A), and it is subjected to a second heating step (C) to give a gasified product (c1). Procedure to get,

(Ii) A biomass residue (a2) is obtained from the plant-based biomass through the first heating step (A), and the biomass residue (c2) generated by applying it to the second heating step (C) is subjected to the third heating. A procedure for obtaining a gasified product (d1) by subjecting it to the step (D), and (iii) obtaining a gasified product (a1) from the plant biomass through the first heating step (A), which is obtained in the second heating step ( The procedure for obtaining the product (b1) by attaching to B) may be performed all in parallel, or only one or two specific procedures may be performed.

各手順の全てを並行して行うとは、第1加熱工程(A)で生じたガス化物(a1)を上記(iii)の手順に利用する一方、バイオマス残渣(a2)を上記(i)の手順に利用し、さらに生じたバイオマス残渣(c2)も上記(ii)の手順に利用することを意味する。各手順の全てを並行して行うことにより、バイオマスに含まれる有用な有機化合物を無駄なく取り出すことができる。 Performing each procedure in parallel means that the gasified product (a1) generated in the first heating step (A) is used for the procedure (iii) above, while the biomass residue (a2) is used in the procedure (i) above. This means that the biomass residue (c2) generated in the procedure and also in the procedure (ii) is used. By performing all the steps in parallel, useful organic compounds contained in the biomass can be taken out without waste.

一方、各手順のうち1つの手順のみを行うとは、例えば上記(i)の手順のみ行い、第1加熱工程(A)で生じたガス化物(a1)および第2加熱工程(C)で生じたバイオマス残渣(c2)にはそれ以上の処理を行わず、雑多な混合物のまま燃料などとして利用するか廃棄処分することを意味する。同様に、2つの手順のみを行うとは、例えば上記(i)と(iii)の手順のみを行い、第2加熱工程(C)で生じたバイオマス残渣(c2)にはそれ以上の処理を行わないことを意味する。特定の手順のみを行うことにより、所望の有機化合物(例えばフェノールやクレゾール)が優れた純度で、および/または最大の収率で得られる条件(加熱温度など)を選択することが可能となる。 On the other hand, performing only one of the procedures means that, for example, only the procedure (i) is performed, and the gasified product (a1) generated in the first heating step (A) and the second heating step (C) are generated. This means that the biomass residue (c2) is not subjected to any further treatment and is used as a fuel or the like as a miscellaneous mixture or disposed of. Similarly, performing only two procedures means, for example, that only the procedures (i) and (iii) above are performed, and the biomass residue (c2) generated in the second heating step (C) is further processed. Means no. By performing only a specific procedure, it is possible to select conditions (such as heating temperature) at which a desired organic compound (for example, phenol or cresol) is obtained with excellent purity and / or maximum yield.

各手順で得られる生成物(b1、c1、d1)は、必要に応じてさらに精製してもよい。本発明の方法によれば、これらの生成物に含まれる化合物は、単に植物系バイオマスを1段階で熱分解した際に得られる熱分解物と比較して種類がかなり少ないため、精製には特に困難を伴わない。精製は従来知られた方法、例えば蒸留などにより行うことができる。 The product (b1, c1, d1) obtained in each procedure may be further purified as necessary. According to the method of the present invention, since the compounds contained in these products are considerably less in kind compared to the pyrolyzate obtained by simply pyrolyzing plant biomass in one stage, it is particularly useful for purification. There is no difficulty. Purification can be performed by a conventionally known method such as distillation.

以下、実施例を用いて本発明をより詳細に説明するが、本発明はこれら実施例に限定されるものではない。 EXAMPLES Hereinafter, although this invention is demonstrated in detail using an Example, this invention is not limited to these Examples.

1−1.スギの熱分解揮発成分の分析(500℃)

スギを500℃で熱分解し、生じた揮発成分のGC/MS測定を行った。使用した測定装置は以下のとおりである。

パイロライザー:PY−2020iD(フロンティアラボ製)

GC/MS :GCMS−QP2010(島津製作所製)

カラム :DB−17(アジレント・テクノロジー製)

1-1. Analysis of pyrolysis volatile components of cedar (500 ℃)

The cedar was pyrolyzed at 500 ° C., and GC / MS measurement of the generated volatile components was performed. The measuring devices used are as follows.

Pyrolyzer: PY-2020iD (manufactured by Frontier Lab)

GC / MS: GCMS-QP2010 (manufactured by Shimadzu Corporation)

Column: DB-17 (manufactured by Agilent Technologies)

500℃に設定したパイロライザーの加熱炉(ヘリウム雰囲気)にスギ試料を5分間入れ、生成した揮発成分をGC/MSにて測定した(熱分解開始後1.5分〜30分)。測定により得られたチャートを図2に示す。図中に示したように、500℃での熱分解により得られた揮発成分には、セルロース、ヘミセルロースおよびリグニンのそれぞれに由来する分解物が多数含まれていた。 A cedar sample was placed in a pyrolyzer heating furnace (helium atmosphere) set at 500 ° C. for 5 minutes, and the generated volatile components were measured by GC / MS (1.5 to 30 minutes after the start of thermal decomposition). A chart obtained by the measurement is shown in FIG. As shown in the figure, the volatile components obtained by thermal decomposition at 500 ° C. contained many decomposition products derived from cellulose, hemicellulose, and lignin.

なお、今回使用した装置および測定条件を用いたGC/MS測定における主な化合物の保持時間(Retention Time)は下記の表1のとおりである(以降のGC/MS測定において同様)。 In addition, the retention time (Retention Time) of main compounds in GC / MS measurement using the apparatus and measurement conditions used this time is as shown in Table 1 below (the same applies to the subsequent GC / MS measurements).

1−2.スギの熱分解挙動の分析(370℃)

スギの熱分解挙動を分析するために熱重量測定(TG測定)を行った。50℃/分で昇温し、370℃でホールドした際のスギ試料の重量減少率の推移を図3に示す。スギ試料の重量は約280℃付近から減少を開始し、370℃に到達したのち約2分程度で減少速度が低下し、この時点で残渣重量は当初重量の3割程度であった。このことから、スギ試料の熱分解では約5分間で揮発成分が殆ど抜けることがわかった。

1-2. Analysis of thermal decomposition behavior of cedar (370 ℃)

Thermogravimetry (TG measurement) was performed to analyze the thermal decomposition behavior of cedar. FIG. 3 shows the transition of the weight reduction rate of the cedar sample when the temperature is raised at 50 ° C./min and held at 370 ° C. The weight of the cedar sample started to decrease from about 280 ° C., and after reaching 370 ° C., the decrease rate decreased in about 2 minutes. At this point, the residual weight was about 30% of the initial weight. From this, it was found that in the thermal decomposition of the cedar sample, almost all volatile components were removed in about 5 minutes.

1−3.スギの熱分解揮発成分の分析(370℃→500℃)

スギの熱分解を2段階の温度で行い、生じた揮発成分のGC/MS測定を行った。使用した測定装置は上記1−1と同じである。370℃に設定したパイロライザーの加熱炉(ヘリウム雰囲気)にスギ試料を5分間入れた。その後、スギ試料を一旦加熱炉より引き上げて室温に戻した。加熱炉を500℃にセットし、試料を再び加熱炉に入れ、5分間保持した。それぞれの温度で生じた揮発成分をGC/MSで測定した。得られたチャートを図4に示す。370℃で揮発した成分にはヘミセルロース由来およびセルロース由来の分解物が多く含まれていた。一方、500℃で揮発した成分にはリグニン由来の分解物(フェノール類)が多く含まれていた。図4のチャートを図2のチャートと比較すると、直接500℃に加熱した場合と比較して、370℃で保持した後500℃で加熱した場合では、ヘミセルロース由来およびセルロース由来の分解物が減少しているのがわかる(図4中、破線で囲んだ領域AおよびBを参照)。

1-3. Analysis of pyrolysis volatile components of cedar (370 ℃ → 500 ℃)

The cedar was thermally decomposed at two stages of temperature, and GC / MS measurement of the generated volatile components was performed. The measuring apparatus used is the same as 1-1. A cedar sample was placed in a pyrolyzer heating furnace (helium atmosphere) set at 370 ° C. for 5 minutes. Then, the cedar sample was once pulled up from the heating furnace and returned to room temperature. The heating furnace was set to 500 ° C., and the sample was put into the heating furnace again and held for 5 minutes. Volatile components generated at each temperature were measured by GC / MS. The obtained chart is shown in FIG. The components volatilized at 370 ° C. contained many hemicellulose-derived and cellulose-derived degradation products. On the other hand, the components volatilized at 500 ° C. contained a large amount of degradation products (phenols) derived from lignin. When the chart of FIG. 4 is compared with the chart of FIG. 2, when it is heated at 500 ° C. after being held at 370 ° C., the degradation products derived from hemicellulose and cellulose are reduced as compared with the case where it is directly heated to 500 ° C. (See regions A and B surrounded by broken lines in FIG. 4).

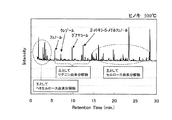

1−4.ヒノキの熱分解揮発成分の分析(500℃)

試料をヒノキに変えた以外は上記1−1と同様にして、生成した揮発成分をGC/MSにて測定した。測定により得られたチャートを図5に示す。スギ試料と同様に、セルロース、ヘミセルロースおよびリグニンのそれぞれに由来する分解物が多数含まれていた。

1-4. Analysis of pyrolysis volatile components of Japanese cypress (500 ° C)

The generated volatile components were measured by GC / MS in the same manner as in 1-1 above except that the sample was changed to cypress. A chart obtained by the measurement is shown in FIG. Similar to the cedar sample, many degradation products derived from cellulose, hemicellulose, and lignin were contained.

1−5.ヒノキの熱分解挙動の分析(370℃→500℃)

試料をヒノキに変えた以外は上記1−3と同様にしてGC/MS測定を行った。370℃と500℃のそれぞれの温度で生じた揮発成分をGC/MSで測定し得られたチャートを図6に示す。スギ試料と同様に、370℃で揮発した成分にはヘミセルロース由来およびセルロース由来の分解物が多く含まれていた。一方、500℃で揮発した成分にはリグニン由来の分解物(フェノール類)が多く含まれていた。図6のチャートを図5のチャートと比較すると、直接500℃に加熱した場合と比較して、370℃で保持した後500℃で加熱した場合では、ヘミセルロース由来およびセルロース由来の分解物が減少しているのがわかる(図6中、破線で囲んだ領域AおよびBを参照)。

1-5. Analysis of thermal decomposition behavior of cypress (370 ℃ → 500 ℃)

GC / MS measurement was performed in the same manner as in 1-3 above except that the sample was changed to cypress. FIG. 6 shows a chart obtained by measuring volatile components generated at temperatures of 370 ° C. and 500 ° C. by GC / MS. Similar to the cedar sample, the components volatilized at 370 ° C. contained many hemicellulose-derived and cellulose-derived degradation products. On the other hand, the components volatilized at 500 ° C. contained a large amount of degradation products (phenols) derived from lignin. When the chart of FIG. 6 is compared with the chart of FIG. 5, the hemicellulose-derived and cellulose-derived degradation products are reduced when heated at 500 ° C. after being held at 370 ° C., as compared with the case of being directly heated to 500 ° C. (See regions A and B surrounded by a broken line in FIG. 6).

2−1.ヒノキの熱分解試験(270℃、330℃)

ヒノキを270℃または330℃で熱分解し、生じた揮発成分のGC/MS測定を行った。測定条件等は上記1−1と同様とした。測定により得られたチャートを図7に示す。270℃では温度が低すぎるため熱分解物のピークは観測されなかった。一方、330℃ではヘミセルロース由来の熱分解物のみならず、セルロース由来のヒドロキシメチルフルフラールまで生成していることがわかった。ヘミセルロース由来の熱分解物を得る温度域としては280〜320℃が好適であることがわかった。

2-1. Cypress thermal decomposition test (270 ° C, 330 ° C)

Cypress was pyrolyzed at 270 ° C. or 330 ° C., and GC / MS measurement of the volatile components produced was performed. The measurement conditions and the like were the same as those in 1-1. A chart obtained by the measurement is shown in FIG. At 270 ° C., the temperature was too low, and no pyrolyzate peak was observed. On the other hand, at 330 ° C., it was found that not only the pyrolysis product derived from hemicellulose but also hydroxymethylfurfural derived from cellulose was produced. It was found that 280 to 320 ° C. is suitable as a temperature range for obtaining a thermal decomposition product derived from hemicellulose.

2−2.ヒノキの熱分解によるガス化物の再加熱(300℃→600〜800℃)

2つの加熱ゾーンを有する管状炉(図8参照)の前段部にヒノキ試料(約0.1g)をセットし、300℃、ヘリウム雰囲気下で加熱した際に生成したガス化物を、後段部の加熱部(二次分解反応炉)で更に加熱(600℃、650℃、670℃または800℃)して熱分解させ、得られた分解物をGPCにより分析した。GPC分析により得られたチャートを図9に示す。チャート中の「300−600」の表示は、前段部の加熱を300℃で行い、後段部の加熱を600℃で行った場合のチャートであることを意味する(他についても同様)。チャート中、フランおよび水に対応するピークは、それぞれ、「300−800」のチャートにおいて矢印で示した位置に出現している。フラン量論生成量に対する回収率は下記表2のとおりであった。

2-2. Reheating gasified product by thermal decomposition of cypress (300 ° C → 600-800 ° C)

A cypress sample (about 0.1 g) is set in the front stage of a tubular furnace having two heating zones (see FIG. 8), and the gasified product generated when heated in a helium atmosphere at 300 ° C. is heated in the rear stage. In a part (secondary decomposition reactor) was further heated (600 ° C., 650 ° C., 670 ° C. or 800 ° C.) for thermal decomposition, and the resulting decomposition product was analyzed by GPC. A chart obtained by GPC analysis is shown in FIG. The display of “300-600” in the chart means that the chart is obtained when the front stage is heated at 300 ° C. and the rear stage is heated at 600 ° C. (the same applies to others). In the chart, peaks corresponding to furan and water appear at the positions indicated by arrows in the chart “300-800”, respectively. The recovery rate with respect to the furan stoichiometric amount was as shown in Table 2 below.

フランは二次分解温度が600℃の場合でも生成しており、二次分解温度を650℃とした時に生成量がピークとなっていた。また、二次分解温度を800℃とした時、分解物を凝集させることにより得られた生成物にはフランと水のみが含まれていた。このことから、フラン回収率に最も優れた二次分解温度は650℃であり、フランの選択的回収に最も優れた二次分解温度は800℃であることがわかった。 Furan was produced even when the secondary decomposition temperature was 600 ° C., and the production amount peaked when the secondary decomposition temperature was 650 ° C. Further, when the secondary decomposition temperature was 800 ° C., the product obtained by aggregating the decomposed product contained only furan and water. From this, it was found that the secondary decomposition temperature with the highest furan recovery rate was 650 ° C., and the secondary decomposition temperature with the highest furan selective recovery was 800 ° C.

3−1.ユーカリの熱分解揮発成分の分析(370℃→500℃→600℃)

ユーカリの熱分解を3段階の温度で行い、生じた揮発成分のGC/MS測定を行った。使用した測定装置は上記1−1と同じである。370℃に設定したパイロライザーの加熱炉(ヘリウム雰囲気)にユーカリ試料を5分間入れた。その後、ユーカリ試料を一旦加熱炉より引き上げて室温に戻した。加熱炉を500℃にセットし、試料を再び加熱炉に入れて5分間保持した。同様に、ユーカリ試料を一旦引き上げた後、加熱炉を600℃にセットし、試料を再び加熱炉に入れて5分間保持した。それぞれの温度で生じた揮発成分をGC/MSで測定した。得られたチャートを図10に示す。370℃→500℃→600℃と3段階の温度で熱分解した場合、600℃ではフェノールおよびクレゾールを主成分とする熱分解物が生成することがわかった。

3-1. Analysis of pyrolysis volatile components of eucalyptus (370 ℃ → 500 ℃ → 600 ℃)

Eucalyptus was thermally decomposed at three stages of temperature, and GC / MS measurement of the generated volatile components was performed. The measuring apparatus used is the same as 1-1. The eucalyptus sample was placed in a pyrolyzer heating furnace (helium atmosphere) set at 370 ° C. for 5 minutes. Then, the eucalyptus sample was once pulled up from the heating furnace and returned to room temperature. The heating furnace was set to 500 ° C., and the sample was put back into the heating furnace and held for 5 minutes. Similarly, after pulling up the eucalyptus sample once, the heating furnace was set to 600 ° C., and the sample was put in the heating furnace again and held for 5 minutes. Volatile components generated at each temperature were measured by GC / MS. The obtained chart is shown in FIG. It was found that when pyrolysis was performed at three stages of 370 ° C. → 500 ° C. → 600 ° C., a pyrolyzate mainly composed of phenol and cresol was generated at 600 ° C.

3−2.パーム核殻の熱分解揮発成分の分析(500℃→600℃/350℃→500℃→600℃)

パーム核殻の熱分解を2段階の温度(500℃→600℃)または3段階の温度(350℃→500℃→600℃)で行い、生じた揮発成分のGC/MS測定を行った。使用した測定装置は上記1−1と同じである。2段階または3段階の温度による熱分解の手順は上記1−3および3−1と同様である。得られたチャートを図11および図12にそれぞれ示す。500℃→600℃の2段階で熱分解を行い、低温での熱分解工程を経なかった場合、600℃での熱分解でフェノールおよびクレゾールのピークが殆ど観測されなかった。一方、比較的低温である350℃での熱分解を含む350℃→500℃→600℃の3段階で熱分解を行った場合では、600℃での熱分解でフェノールおよびクレゾールのピークが観測された。

3-2. Analysis of pyrolysis volatile components of palm kernel shell (500 ℃ → 600 ℃ / 350 ℃ → 500 ℃ → 600 ℃)

The palm core shell was pyrolyzed at two stages (500 ° C. → 600 ° C.) or three stages (350 ° C. → 500 ° C. → 600 ° C.), and GC / MS measurement of the generated volatile components was performed. The measuring apparatus used is the same as 1-1. The procedure for thermal decomposition at two or three stages of temperature is the same as in 1-3 and 3-1. The obtained charts are shown in FIGS. 11 and 12, respectively. When pyrolysis was performed in two stages from 500 ° C. to 600 ° C. and the pyrolysis process was not performed at a low temperature, peaks of phenol and cresol were hardly observed in the pyrolysis at 600 ° C. On the other hand, when pyrolysis is performed in three stages of 350 ° C. → 500 ° C. → 600 ° C. including pyrolysis at 350 ° C., which is a relatively low temperature, phenol and cresol peaks are observed in the pyrolysis at 600 ° C. It was.

Claims (5)

バイオマスを400℃以下の第1の加熱温度で加熱してガス化物を取り出す第1加熱工程と、

第1加熱工程で得られたバイオマス残渣を、500〜600℃の範囲の第2の加熱温度で加熱してガス化物を取り出す第2加熱工程と、

第2加熱工程でさらに生じたバイオマス残渣を600℃以上の第3の加熱温度で加熱してフェノールとクレゾールを主とする分解物を得る第3加熱工程

を含む、前記方法。 A method for obtaining a decomposed product mainly composed of phenol and cresol by thermally decomposing plant biomass,

A first heating step of extracting biomass by heating biomass at a first heating temperature of 400 ° C. or lower;

A second heating step in which the biomass residue obtained in the first heating step is heated at a second heating temperature in the range of 500 to 600 ° C. to take out the gasified product ;

A third heating step, wherein the biomass residue further generated in the second heating step is heated at a third heating temperature of 600C or higher to obtain a decomposition product mainly comprising phenol and cresol .

バイオマスを280〜320℃の範囲の第1の加熱温度で加熱する第1加熱工程と、

第1加熱工程で得られたガス化物を、600〜800℃の範囲の第2の加熱温度で加熱してヘミセルロース由来の分解物を得る第2加熱工程

を含む、前記方法。 A method for obtaining a degradation product derived from hemicellulose containing at least furan by thermally decomposing plant biomass,

A first heating step of heating the biomass at a first heating temperature in the range of 280 to 320 ° C;

The said method including the 2nd heating process which heats the gasification product obtained at the 1st heating process at the 2nd heating temperature of the range of 600-800 degreeC, and obtains the decomposition product derived from hemicellulose.

バイオマスを280〜320℃の範囲の加熱温度で加熱する加熱工程Aと、

加熱工程Aで得られたガス化物を、600〜800℃の範囲の加熱温度で加熱してヘミセルロース由来の分解物を得る加熱工程Bと、

加熱工程Aで得られたバイオマス残渣を、500℃以上の加熱温度で加熱してリグニン由来分解物を得る加熱工程Cと

を含む、前記方法。 A method for obtaining a lignin-derived degradation product containing at least phenol or cresol and a hemicellulose-derived degradation product containing at least furan by thermally decomposing plant biomass,

Heating step A for heating the biomass at a heating temperature in the range of 280 to 320 ° C;

A heating step B in which the gasified product obtained in the heating step A is heated at a heating temperature in the range of 600 to 800 ° C. to obtain a decomposition product derived from hemicellulose;

The said process including the heating process C which heats the biomass residue obtained by the heating process A at the heating temperature of 500 degreeC or more, and obtains a lignin origin decomposition product.

Priority Applications (3)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| JP2010292630A JP5668469B2 (en) | 2010-12-28 | 2010-12-28 | Method for thermal decomposition of plant biomass |

| MYPI2013700862A MY162947A (en) | 2010-12-28 | 2011-10-28 | Pyrolysis method for plant biomass |

| PCT/JP2011/006030 WO2012090369A1 (en) | 2010-12-28 | 2011-10-28 | Pyrolysis method for plant biomass |

Applications Claiming Priority (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| JP2010292630A JP5668469B2 (en) | 2010-12-28 | 2010-12-28 | Method for thermal decomposition of plant biomass |

Publications (3)

| Publication Number | Publication Date |

|---|---|

| JP2012140346A JP2012140346A (en) | 2012-07-26 |

| JP2012140346A5 JP2012140346A5 (en) | 2013-06-20 |

| JP5668469B2 true JP5668469B2 (en) | 2015-02-12 |

Family

ID=45440610

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| JP2010292630A Expired - Fee Related JP5668469B2 (en) | 2010-12-28 | 2010-12-28 | Method for thermal decomposition of plant biomass |

Country Status (3)

| Country | Link |

|---|---|

| JP (1) | JP5668469B2 (en) |

| MY (1) | MY162947A (en) |

| WO (1) | WO2012090369A1 (en) |

Cited By (1)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| WO2020036248A1 (en) * | 2018-08-17 | 2020-02-20 | 서울시립대학교 산학협력단 | Apparatus for recycling wood or lignin and method for producing phenol from wood or lignin using same |

Families Citing this family (5)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| JP5967707B2 (en) * | 2012-07-10 | 2016-08-10 | トヨタ自動車株式会社 | Method for producing phenol from biomass feedstock |

| US9505668B2 (en) | 2014-05-01 | 2016-11-29 | Iogen Corporation | Process for producing a fuel and byproduct from biomass or biomass derived material |

| CN104355968B (en) * | 2014-10-20 | 2015-12-30 | 北京林业大学 | A kind of cellulose catalytic thermo-cracking transforms the method preparing aldehydes matter |

| CN106946658B (en) * | 2017-03-06 | 2021-02-12 | 华北电力大学 | Method for preparing 4-ethylphenol by catalytically pyrolyzing bagasse with activated carbon |

| CN111849526B (en) * | 2020-07-22 | 2021-03-23 | 中国电力工程顾问集团西北电力设计院有限公司 | Method for co-producing coke and phenol by pyrolyzing biomass |

Family Cites Families (8)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| AUPP729098A0 (en) * | 1998-11-24 | 1998-12-17 | University Of Melbourne, The | Process for the recovery of low molecular weight phenols and/or cellulose or cellulose-rich residue |

| FR2827609B1 (en) * | 2001-07-18 | 2004-05-21 | Inst Francais Du Petrole | PROCESS AND PLANT FOR PRODUCING FUEL GASES FROM GASES FROM THE THERMAL CONVERSION OF A SOLID LOAD |

| JP2003212797A (en) * | 2002-01-15 | 2003-07-30 | National Institute Of Advanced Industrial & Technology | Method for recovering oxygen-containing compound from biomass-cracked tar |

| JP2004300419A (en) * | 2003-03-19 | 2004-10-28 | Jgc Corp | Method for manufacturing modified filtrate and modified filtrate obtained by this manufacturing method |

| JP4394989B2 (en) * | 2004-03-24 | 2010-01-06 | 新日本製鐵株式会社 | Method for producing coke for blast furnace using woody biomass |

| EP1852493A1 (en) | 2006-05-05 | 2007-11-07 | BIOeCON International Holding N.V. | Hydrothermal treatment of carbon-based energy carrier material |

| US20100223839A1 (en) * | 2009-03-04 | 2010-09-09 | Washington State University | Systems and processes for producing bio-fuels from lignocellulosic materials |

| GB0908082D0 (en) * | 2009-05-11 | 2009-06-24 | Univ Aston | Biomass pyrolysis |

-

2010

- 2010-12-28 JP JP2010292630A patent/JP5668469B2/en not_active Expired - Fee Related

-

2011

- 2011-10-28 WO PCT/JP2011/006030 patent/WO2012090369A1/en active Application Filing

- 2011-10-28 MY MYPI2013700862A patent/MY162947A/en unknown

Cited By (1)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| WO2020036248A1 (en) * | 2018-08-17 | 2020-02-20 | 서울시립대학교 산학협력단 | Apparatus for recycling wood or lignin and method for producing phenol from wood or lignin using same |

Also Published As

| Publication number | Publication date |

|---|---|

| JP2012140346A (en) | 2012-07-26 |

| MY162947A (en) | 2017-07-31 |

| WO2012090369A1 (en) | 2012-07-05 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| JP5668469B2 (en) | Method for thermal decomposition of plant biomass | |

| Moraes et al. | Analysis of products from pyrolysis of Brazilian sugar cane straw | |

| Tahir et al. | Demonstrating the suitability of canola residue biomass to biofuel conversion via pyrolysis through reaction kinetics, thermodynamics and evolved gas analyses | |

| Biswas et al. | Pyrolysis of azolla, sargassum tenerrimum and water hyacinth for production of bio-oil | |

| Shuping et al. | Production and characterization of bio-oil from hydrothermal liquefaction of microalgae Dunaliella tertiolecta cake | |

| Alhumade et al. | Investigation of pyrolysis kinetics and thermal behavior of Invasive Reed Canary (Phalaris arundinacea) for bioenergy potential | |

| Jamari et al. | The effect of the hydrothermal carbonization process on palm oil empty fruit bunch | |

| Zhang et al. | Study on two-step pyrolysis of soybean stalk by TG-FTIR and Py-GC/MS | |

| da Silva et al. | Bioenergetic potential of Ponkan peel waste (Citrus reticulata) pyrolysis by kinetic modelling and product characterization | |

| Kim et al. | Non-isothermal pyrolysis of citrus unshiu peel | |

| Cunha et al. | Waste biomass to liquids: Low temperature conversion of sugarcane bagasse to bio-oil. The effect of combined hydrolysis treatments | |

| Muñoz et al. | Preliminary biorefinery process proposal for protein and biofuels recovery from microalgae | |

| WO2010033512A1 (en) | Improved process for preparing bio-oils from biomass | |

| Chen et al. | Pyrolysis characteristics of tobacco stem after different solvent leaching treatments | |

| EP2017325A3 (en) | Apparatus for decomposition of vegetable organic substances and thermochemical fuel gas production, and related method | |

| Charusiri et al. | Biofuel production via the pyrolysis of sugarcane (Saccharum officinarum L.) leaves: Characterization of the optimal conditions | |

| Mohammed et al. | Bio-oil from pyrolysis of castor shell | |

| Liu et al. | Thermogravimetry‐infrared spectroscopy analysis of the pyrolysis of willow leaves, stems, and branches | |

| Silveira Junior et al. | Fast pyrolysis of peanut husk agroindustrial waste: intensification of anhydro sugar (levoglucosan) production | |

| Özbay | Pyrolysis of firwood (Abies bornmülleriana Mattf.) sawdust: Characterization of bio-oil and bio-char | |

| KR101205780B1 (en) | Method of extracting lipids from microalgae by two step pyrolysis | |

| Demirbaş | Relationships between carbonization temperature and pyrolysis products from biomass | |

| Sulaiman et al. | Valorization of banana bunch waste as a feedstock via hydrothermal carbonization for energy purposes | |

| Tekin et al. | Experimental design for extraction of bio-oils from flax seeds under supercritical ethanol conditions | |

| Butnaru et al. | Valorization of forestry residues by thermal methods. The effect of temperature on gradual degradation of structural components in bark from silver fir (Abies alba Mill.) |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| A521 | Request for written amendment filed |

Free format text: JAPANESE INTERMEDIATE CODE: A523 Effective date: 20130502 |

|

| A621 | Written request for application examination |

Free format text: JAPANESE INTERMEDIATE CODE: A621 Effective date: 20130502 |

|

| A131 | Notification of reasons for refusal |

Free format text: JAPANESE INTERMEDIATE CODE: A131 Effective date: 20140715 |

|

| A521 | Request for written amendment filed |

Free format text: JAPANESE INTERMEDIATE CODE: A523 Effective date: 20140916 |

|

| TRDD | Decision of grant or rejection written | ||

| A01 | Written decision to grant a patent or to grant a registration (utility model) |

Free format text: JAPANESE INTERMEDIATE CODE: A01 Effective date: 20141118 |

|

| A61 | First payment of annual fees (during grant procedure) |

Free format text: JAPANESE INTERMEDIATE CODE: A61 Effective date: 20141201 |

|

| R151 | Written notification of patent or utility model registration |

Ref document number: 5668469 Country of ref document: JP Free format text: JAPANESE INTERMEDIATE CODE: R151 |

|

| LAPS | Cancellation because of no payment of annual fees |