JP4918632B2 - Precipitation strengthened stainless steel and method for producing the same - Google Patents

Precipitation strengthened stainless steel and method for producing the same Download PDFInfo

- Publication number

- JP4918632B2 JP4918632B2 JP2011546519A JP2011546519A JP4918632B2 JP 4918632 B2 JP4918632 B2 JP 4918632B2 JP 2011546519 A JP2011546519 A JP 2011546519A JP 2011546519 A JP2011546519 A JP 2011546519A JP 4918632 B2 JP4918632 B2 JP 4918632B2

- Authority

- JP

- Japan

- Prior art keywords

- stainless steel

- precipitation

- formula

- strength

- alloy

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Expired - Fee Related

Links

Images

Classifications

-

- C—CHEMISTRY; METALLURGY

- C21—METALLURGY OF IRON

- C21D—MODIFYING THE PHYSICAL STRUCTURE OF FERROUS METALS; GENERAL DEVICES FOR HEAT TREATMENT OF FERROUS OR NON-FERROUS METALS OR ALLOYS; MAKING METAL MALLEABLE, e.g. BY DECARBURISATION OR TEMPERING

- C21D6/00—Heat treatment of ferrous alloys

- C21D6/02—Hardening by precipitation

-

- C—CHEMISTRY; METALLURGY

- C21—METALLURGY OF IRON

- C21D—MODIFYING THE PHYSICAL STRUCTURE OF FERROUS METALS; GENERAL DEVICES FOR HEAT TREATMENT OF FERROUS OR NON-FERROUS METALS OR ALLOYS; MAKING METAL MALLEABLE, e.g. BY DECARBURISATION OR TEMPERING

- C21D6/00—Heat treatment of ferrous alloys

- C21D6/004—Heat treatment of ferrous alloys containing Cr and Ni

-

- C—CHEMISTRY; METALLURGY

- C21—METALLURGY OF IRON

- C21D—MODIFYING THE PHYSICAL STRUCTURE OF FERROUS METALS; GENERAL DEVICES FOR HEAT TREATMENT OF FERROUS OR NON-FERROUS METALS OR ALLOYS; MAKING METAL MALLEABLE, e.g. BY DECARBURISATION OR TEMPERING

- C21D6/00—Heat treatment of ferrous alloys

- C21D6/04—Hardening by cooling below 0 degrees Celsius

-

- C—CHEMISTRY; METALLURGY

- C21—METALLURGY OF IRON

- C21D—MODIFYING THE PHYSICAL STRUCTURE OF FERROUS METALS; GENERAL DEVICES FOR HEAT TREATMENT OF FERROUS OR NON-FERROUS METALS OR ALLOYS; MAKING METAL MALLEABLE, e.g. BY DECARBURISATION OR TEMPERING

- C21D7/00—Modifying the physical properties of iron or steel by deformation

- C21D7/13—Modifying the physical properties of iron or steel by deformation by hot working

-

- C—CHEMISTRY; METALLURGY

- C22—METALLURGY; FERROUS OR NON-FERROUS ALLOYS; TREATMENT OF ALLOYS OR NON-FERROUS METALS

- C22C—ALLOYS

- C22C38/00—Ferrous alloys, e.g. steel alloys

- C22C38/004—Very low carbon steels, i.e. having a carbon content of less than 0,01%

-

- C—CHEMISTRY; METALLURGY

- C22—METALLURGY; FERROUS OR NON-FERROUS ALLOYS; TREATMENT OF ALLOYS OR NON-FERROUS METALS

- C22C—ALLOYS

- C22C38/00—Ferrous alloys, e.g. steel alloys

- C22C38/06—Ferrous alloys, e.g. steel alloys containing aluminium

-

- C—CHEMISTRY; METALLURGY

- C22—METALLURGY; FERROUS OR NON-FERROUS ALLOYS; TREATMENT OF ALLOYS OR NON-FERROUS METALS

- C22C—ALLOYS

- C22C38/00—Ferrous alloys, e.g. steel alloys

- C22C38/18—Ferrous alloys, e.g. steel alloys containing chromium

- C22C38/40—Ferrous alloys, e.g. steel alloys containing chromium with nickel

- C22C38/44—Ferrous alloys, e.g. steel alloys containing chromium with nickel with molybdenum or tungsten

-

- C—CHEMISTRY; METALLURGY

- C22—METALLURGY; FERROUS OR NON-FERROUS ALLOYS; TREATMENT OF ALLOYS OR NON-FERROUS METALS

- C22C—ALLOYS

- C22C38/00—Ferrous alloys, e.g. steel alloys

- C22C38/18—Ferrous alloys, e.g. steel alloys containing chromium

- C22C38/40—Ferrous alloys, e.g. steel alloys containing chromium with nickel

- C22C38/50—Ferrous alloys, e.g. steel alloys containing chromium with nickel with titanium or zirconium

-

- C—CHEMISTRY; METALLURGY

- C22—METALLURGY; FERROUS OR NON-FERROUS ALLOYS; TREATMENT OF ALLOYS OR NON-FERROUS METALS

- C22C—ALLOYS

- C22C38/00—Ferrous alloys, e.g. steel alloys

- C22C38/18—Ferrous alloys, e.g. steel alloys containing chromium

- C22C38/40—Ferrous alloys, e.g. steel alloys containing chromium with nickel

- C22C38/52—Ferrous alloys, e.g. steel alloys containing chromium with nickel with cobalt

Description

本発明は、析出強化型ステンレス鋼及びその製造方法に関するものである。 The present invention relates to precipitation strengthened stainless steel and a method for producing the same.

従来、高強度材料としては、AISI4340や300M等に代表される低合金系高抗張力鋼が知られている。これらは、熱処理条件を選べば、約1800MPaを超える引張強さと10%程度の伸びを得ることが出来る(非特許文献1参照)。しかし、これらは、低合金鋼であり、耐食性に大きく寄与するCrが1%弱と少ないため耐食性が不十分である。

また、従来から高強度のステンレス鋼としてPH13−8Mo(AISI XM−13)や17−4PH(AISI 630)等に代表されるマルテンサイト系析出強化型ステンレス鋼が知られている。これらは、耐食性の良好なステンレス鋼の中では高強度であるが、AISI4340や300M等に代表される低合金系高抗張力鋼と比較すると強度が劣っている。また、特許文献1に高強度のステンレス鋼が提案されており、優れた強度特性を持っているが、低合金系高抗張力鋼と比較すると延性が十分とは言えない。さらに、特許文献2に提案されている高張力鋼は、耐食性向上元素であるCrが無添加の場合、強度は十分高く優れているが、Cr添加をした場合、低合金系高抗張力鋼と比較すると強度がやや劣っている。

低合金鋼の耐食性と高強度ステンレス鋼の強度や延性を改善した高強度材料として本願出願人は特許文献3に示す高強度ステンレス鋼を提案した。特許文献3に示す高強度ステンレス鋼は、熱処理条件を選べば1800MPaを超える引張強さを得られ、さらに、優れた耐食性を持つ材料である。Conventionally, as a high strength material, low alloy type high strength steel represented by AISI 4340, 300M and the like is known. If these heat treatment conditions are selected, a tensile strength exceeding about 1800 MPa and an elongation of about 10% can be obtained (see Non-Patent Document 1). However, these are low-alloy steels, and their corrosion resistance is insufficient because Cr, which greatly contributes to corrosion resistance, is a little less than 1%.

Conventionally, martensitic precipitation strengthened stainless steels represented by PH13-8Mo (AISI XM-13), 17-4PH (AISI 630) and the like are known as high-strength stainless steels. These are high strength among stainless steels having good corrosion resistance, but are inferior in strength compared to low alloy high strength steels represented by AISI 4340, 300M and the like. Patent Document 1 proposes a high-strength stainless steel and has excellent strength characteristics, but it cannot be said that the ductility is sufficient as compared with a low alloy high strength steel. Furthermore, the high-strength steel proposed in Patent Document 2 has a sufficiently high strength when Cr, which is an element for improving corrosion resistance, is not added. However, when Cr is added, it is compared with a low-alloy high-strength steel. Then the strength is slightly inferior.

The present applicant has proposed a high-strength stainless steel shown in Patent Document 3 as a high-strength material in which the corrosion resistance of the low alloy steel and the strength and ductility of the high-strength stainless steel are improved. The high-strength stainless steel shown in Patent Document 3 is a material that can obtain a tensile strength exceeding 1800 MPa if heat treatment conditions are selected, and has excellent corrosion resistance.

上述した特許文献3に示す高強度ステンレス鋼は、引張強さ及び耐食性の点では優れた材料であるものの、0.2%耐力が引張強さと比較して低い。例えば、析出強化型ステンレス鋼が使用される用途の一つである航空機の構造設計には、運用荷重に安全率を乗じた破壊荷重と引張強さを用いて強度設計が行われ、加えて実用環境で航空機用脚材及び宇宙航空機一次構造部材に降伏が起きないように考慮することが求められる。そのため適用する材料の耐力比(=0.2%耐力/引張強さ)は高いことが望ましい。しかし、特許文献3に示す高強度ステンレス鋼は耐力比が低く、例えば、現在、航空機の構造部材に適用されている低合金系高抗張力鋼の替わりに使用するには、強度特性が不十分である。

そこで、本発明の目的は、低合金系高抗張力鋼レベルの引張強さ、0.2%耐力及び延性を維持しつつ、さらに優れた耐食性も有する析出強化型ステンレス鋼及びその製造方法を提供することである。The high-strength stainless steel shown in Patent Document 3 described above is an excellent material in terms of tensile strength and corrosion resistance, but 0.2% proof stress is lower than tensile strength. For example, in aircraft structural design, one of the applications where precipitation-strengthened stainless steel is used, strength design is performed using a fracture load and a tensile strength obtained by multiplying the operational load by a safety factor, and in addition to practical use. Consideration must be given to prevent yielding of aircraft legs and spacecraft primary structural members in the environment. Therefore, it is desirable that the yield strength ratio (= 0.2% yield strength / tensile strength) of the applied material is high. However, the high-strength stainless steel shown in Patent Document 3 has a low yield strength ratio. For example, the strength characteristics are insufficient for use in place of the low-alloy high-strength steel currently applied to structural members of aircraft. is there.

Accordingly, an object of the present invention is to provide a precipitation-strengthened stainless steel having excellent corrosion resistance while maintaining the tensile strength, 0.2% proof stress and ductility at the level of a low alloy high strength steel, and a method for producing the same. That is.

本発明者は、低合金系高抗張力鋼レベルの引張強さ、0.2%耐力及び延性を有し、かつ従来の高強度ステンレス鋼の耐食性を両立すべく、鋭意検討した結果、Cを低く抑えた析出強化型マルテンサイト系ステンレス鋼をベースとしてMoを添加し、Niと化合物形成するAlならびにTiの割合及び量のバランスをはかることで、耐食性を損なうことなく、引張強さと延性を維持しつつ0.2%耐力を大きく改善できることを見いだし本発明に到達した。

すなわち本発明は、質量%でC:≦0.2%、7%≦Ni≦14%、0%≦Co≦3.5%、9.5%≦Cr≦14%、0.5%≦Mo≦3%、0.25%<Al<1%、0.75%<Ti≦2.5%、残部はFe及び不純物からなり、かつ、式(1)乃至(4)を満足する析出強化型ステンレス鋼である。

式(1) 1260−65Ni−20Co−40Cr≧0

式(2) 670+75Ni+40Co−100Cr≧0

式(3) 0.125≦(Al/Ti)≦1.25

式(4) 1.45≦(Al+Ti)≦2.95

(ただし、式中のNi、Co、Cr、Al及びTiは質量%での値で計算)The present inventor has conducted a diligent study to achieve both the tensile strength, the 0.2% proof stress and the ductility of the low alloy high strength steel level, and the conventional high strength stainless steel. Mo is added based on a suppressed precipitation strengthened martensitic stainless steel, and the tensile strength and ductility are maintained without sacrificing corrosion resistance by balancing the proportion and amount of Al and Ti that form a compound with Ni. However, the present inventors have found that the 0.2% proof stress can be greatly improved and reached the present invention.

That is, in the present invention, in mass%, C: ≦ 0.2%, 7% ≦ Ni ≦ 14%, 0% ≦ Co ≦ 3.5%, 9.5% ≦ Cr ≦ 14%, 0.5% ≦ Mo. ≦ 3%, 0.25% <Al <1%, 0.75% <Ti ≦ 2.5%, the balance being Fe and impurities, and satisfying the formulas (1) to (4) Stainless steel.

Formula (1) 1260-65Ni-20Co-40Cr ≧ 0

Formula (2) 670 + 75Ni + 40Co-100Cr ≧ 0

Formula (3) 0.125 ≦ (Al / Ti) ≦ 1.25

Formula (4) 1.45 ≦ (Al + Ti) ≦ 2.95

(However, Ni, Co, Cr, Al, and Ti in the formula are calculated in terms of mass%)

また本発明は、下記の式(5)を満足することが好ましい。

式(5) 4.5≦Ni/(Al+Ti)

(ただし、式中のNi、Al及びTiは質量%での値で計算)

本発明でより好ましい式(4)の範囲は、2.1≦(Al+Ti)≦2.55である。

また、本発明でより好ましい式(3)の範囲は、0.35≦(Al/Ti)≦0.65である。

また、本発明の不純物元素であるSi、Mn、Cu、P、S、O、Nは、Si≦0.1%、Mn≦0.1%、Cu≦0.1%、P≦0.03%、S≦0.008%、O≦0.005%、N≦0.01%に制限することが好ましい。

また、本発明の析出強化型ステンレス鋼は、常温での引張試験において伸びが7.5%以上、0.2%耐力と引張強さが0.2%耐力で1600MPa以上、引張強さで1700MPa以上、破壊靭性が40MPa・m1/2以上の何れかを満たす析出強化型ステンレス鋼である。Moreover, it is preferable that this invention satisfies following formula (5).

Formula (5) 4.5 ≦ Ni / (Al + Ti)

(However, Ni, Al, and Ti in the formula are calculated in terms of mass%)

A more preferable range of the formula (4) in the present invention is 2.1 ≦ (Al + Ti) ≦ 2.55.

In the present invention, a more preferable range of the formula (3) is 0.35 ≦ (Al / Ti) ≦ 0.65.

Further, Si, Mn, Cu, P, S, O, and N, which are impurity elements of the present invention, are Si ≦ 0.1%, Mn ≦ 0.1%, Cu ≦ 0.1%, and P ≦ 0.03. %, S ≦ 0.008%, O ≦ 0.005%, and N ≦ 0.01%.

Further, the precipitation strengthened stainless steel of the present invention has an elongation of 7.5% or more, a 0.2% proof stress and a tensile strength of 1600 MPa with a 0.2% proof stress, and a tensile strength of 1700 MPa in a tensile test at room temperature. As described above, this is a precipitation strengthened stainless steel satisfying any of fracture toughness of 40 MPa · m 1/2 or more.

また、本発明の上記析出強化型ステンレス鋼の製造方法は、少なくとも溶解と熱間塑性加工を行った上記組成よりなるステンレス鋼を、940℃〜1050℃で固溶化処理した後、さらに480℃〜550℃で時効処理を行う析出強化型ステンレス鋼の製造方法である。

好ましくは、上記の固溶化処理に次いで−50℃〜−100℃でサブゼロ処理を析出強化型ステンレス鋼の製造方法である。

また、上記の熱間塑性加工の加工比が3以上である析出強化型ステンレス鋼の製造方法である。Moreover, the manufacturing method of the said precipitation strengthening type stainless steel of this invention is, after carrying out the solution treatment of the stainless steel which consists of the said composition which performed at least melt | dissolution and hot plastic working at 940 degreeC-1050 degreeC, and also 480 degreeC- It is a manufacturing method of precipitation strengthening type stainless steel which performs an aging treatment at 550 ° C.

Preferably, the sub-zero treatment is performed at −50 ° C. to −100 ° C. subsequent to the above-described solution treatment, thereby producing a precipitation strengthened stainless steel.

Moreover, it is a manufacturing method of precipitation strengthening type stainless steel whose processing ratio of said hot plastic working is 3 or more.

本発明の析出強化型ステンレス鋼は低合金系高抗張力鋼レベルの引張強さ、0.2%耐力及び延性を有し、かつ従来の高強度ステンレス鋼なみの耐食性を有しているため、例えば、耐食性が必要な航空機用部品等の設計において、耐力比が小さい材料に比べて、引張強度を有効に使用できることが効果として期待できる。 The precipitation-strengthened stainless steel of the present invention has the tensile strength, 0.2% proof stress and ductility of the low alloy high strength steel level, and has the same corrosion resistance as conventional high strength stainless steel. In designing aircraft parts and the like that require corrosion resistance, it can be expected that the tensile strength can be effectively used as compared with a material having a small yield strength ratio.

上述したように、本発明の重要な特徴は、Cを低く抑えた析出強化型マルテンサイト系ステンレス鋼の成分をベースに、引張強さと0.2%耐力を向上させるためにMoを添加し、Niと化合物形成するAlならびにTiの割合及び量のバランスをはかったことにある。

本発明にて、各化学組成や関係式を規定した理由は以下の通りである。なお、特に記載のない限り質量%として記す。As described above, an important feature of the present invention is that Mo is added to improve tensile strength and 0.2% proof stress, based on the components of precipitation strengthened martensitic stainless steel with C kept low, This is because the proportion and amount of Al and Ti forming a compound with Ni were balanced.

The reason why each chemical composition and relational expression are defined in the present invention is as follows. Unless otherwise specified, the mass% is indicated.

C:≦0.2%

Cは、本発明においては不純物として規制すべき元素である。Cは、TiやCr等の添加元素との炭化物の形成により強度と延性とのバランスを低下させ、さらには耐食性を劣化させるため、0.2%以下に制限する。好ましくは0.05%以下である。

7%≦Ni≦14%

Niは、オーステナイト形成元素であり、固溶化処理時のδフェライトの消失に有効であり、また時効処理中にAlやTiと共に微細な金属間化合物を形成して析出強化する効果があるため、必須で添加する元素である。しかし、Niが7%未満であると、固溶化処理温度においてδフェライトが安定となり、残存したδフェライトの存在形態は製造工程、特に圧延工程や鍛造工程における塑性加工方向に依存した方向性がある。そのため、最終製品の特性に方向性が現れてしまう。また、δフェライトの存在自体が強度を低下させ、その結果として強度と延性とのバランスを著しく損なう。一方、Ni添加が14%を越えるとMs点の低下が著しく、固溶化処理後の急冷処理で十分なマルテンサイト変態が行われず、大量の残留オーステナイトが残存するため、強度を著しく低下させ、強度と延性とのバランスを著しく損なう。

そのため、Niは7%〜14%の範囲とした。上述したNiの効果をより確実に得るには、Niの下限を9%とするのが好ましい。C: ≦ 0.2%

C is an element to be regulated as an impurity in the present invention. C is limited to 0.2% or less in order to lower the balance between strength and ductility by forming carbides with additive elements such as Ti and Cr, and to further deteriorate the corrosion resistance. Preferably it is 0.05% or less.

7% ≦ Ni ≦ 14%

Ni is an austenite-forming element and is effective for the disappearance of δ-ferrite during the solution treatment, and it has the effect of strengthening precipitation by forming fine intermetallic compounds with Al and Ti during the aging treatment. It is an element to be added. However, if Ni is less than 7%, δ ferrite becomes stable at the solution treatment temperature, and the remaining form of δ ferrite has directionality depending on the plastic working direction in the manufacturing process, particularly in the rolling process and the forging process. . Therefore, directionality appears in the characteristics of the final product. Further, the presence of δ ferrite itself decreases the strength, and as a result, the balance between strength and ductility is significantly impaired. On the other hand, when the Ni addition exceeds 14%, the Ms point is remarkably lowered, and sufficient martensite transformation is not performed in the rapid cooling treatment after the solution treatment, and a large amount of retained austenite remains. And the balance of ductility are significantly impaired.

Therefore, Ni is set in the range of 7% to 14%. In order to obtain the above-described effect of Ni more reliably, the lower limit of Ni is preferably 9%.

0%≦Co≦3.5%

Coは、Niと同様にオーステナイト形成元素であり、固溶化処理時のδフェライトの消失に効果があり、さらに、NiよりMs点の温度低下が大きくないため、3.5%以下の範囲で添加することは効果的である。ただし、本発明においてはNiを7〜14%の範囲で必須添加するため、Coは必ずしも添加の必要はなく、0%を含む無添加レベルであっても差し支えない任意成分である。また、Coは、Niと異なりAl、Ti等との間で金属間化合物を形成せず、間接的に金属間化合物の析出を促進することや、金属間化合物を微細化することで析出強化に寄与する。しかし、Coの添加によって析出強化へ直接の寄与は大きくなく、また、多量の添加はコストの上昇を招くことから、Coの上限を3.5%とした。

9.5%≦Cr≦14%

Crは、耐食性を付与する目的で必須添加する。しかし、Crが9.5%未満であると、ステンレス鋼として十分な耐食性が発揮されず、一方、Crはフェライト形成元素でありCr添加が14%を超えると、固溶化処理温度においてδフェライトが安定となり、強度を低下させるだけでなく、残存したδフェライトの存在形態は製造工程に依存した方向性があるため、最終製品の特性に方向性が現れてしまう。また、δフェライトの存在自体が強度と延性とのバランスを著しく損なう。そのため、Crは9.5%〜14%の範囲とした。0% ≦ Co ≦ 3.5%

Co is an austenite forming element like Ni, and is effective in disappearance of δ ferrite during solution treatment. Further, since the temperature drop at the Ms point is not larger than Ni, it is added in a range of 3.5% or less. It is effective to do. However, in the present invention, Ni is essential added in the range of 7 to 14%, so Co does not necessarily need to be added and is an optional component that may be added at an additive level including 0%. In addition, unlike Ni, Co does not form intermetallic compounds with Al, Ti, etc., but indirectly promotes precipitation of intermetallic compounds, or refines intermetallic compounds to strengthen precipitation. Contribute. However, the addition of Co does not directly contribute to precipitation strengthening, and the addition of a large amount causes an increase in cost, so the upper limit of Co was set to 3.5%.

9.5% ≦ Cr ≦ 14%

Cr is essential for the purpose of imparting corrosion resistance. However, if Cr is less than 9.5%, sufficient corrosion resistance as stainless steel is not exhibited. On the other hand, Cr is a ferrite-forming element. If Cr addition exceeds 14%, δ-ferrite is not formed at the solution treatment temperature. In addition to being stable and reducing the strength, the presence form of the remaining δ-ferrite has a direction depending on the manufacturing process, so that the directionality appears in the characteristics of the final product. In addition, the presence of δ ferrite significantly impairs the balance between strength and ductility. Therefore, Cr is set in the range of 9.5% to 14%.

0.5%≦Mo≦3%

Moは、強度と耐食性を向上させるため必須添加する。しかし、Moが0.5%未満であると、延性低下が著しく、一方、Moが3%を越えると固溶化処理温度においてδフェライトが安定となり、残存したδフェライトの存在形態は製造工程に依存した方向性があるため、最終製品の特性に方向性が現れてしまう。また、δフェライトの存在自体が強度と延性とのバランスを著しく損なう。そのため、Moを0.5%〜3%の範囲とした。

Moは、Crとの複合添加により耐食性、特に、耐孔食性の向上が期待できるため、Moの下限を0.7%とするのが好ましい。

0.25%<Al<1%

Alは、時効処理中にNiと金属間化合物を形成し析出強化する元素であるため必須で添加する。Alの添加により高強度化させるためには、0.25%以上が必要がある。一方で1%以上の添加は延性の低下が著しくなる。そのため、Alは0.25%を超えて1%未満の範囲とした。0.5% ≦ Mo ≦ 3%

Mo is essential to improve strength and corrosion resistance. However, if the Mo content is less than 0.5%, the ductility is remarkably reduced. On the other hand, if the Mo content exceeds 3%, the δ ferrite becomes stable at the solution treatment temperature, and the form of the remaining δ ferrite depends on the manufacturing process. Therefore, the directionality appears in the characteristics of the final product. In addition, the presence of δ ferrite significantly impairs the balance between strength and ductility. Therefore, Mo is set in the range of 0.5% to 3%.

Since Mo can be expected to improve corrosion resistance, particularly pitting corrosion resistance, due to combined addition with Cr, the lower limit of Mo is preferably 0.7%.

0.25% <Al <1%

Al is an essential element because it is an element that forms an intermetallic compound with Ni during aging treatment and strengthens precipitation. In order to increase the strength by adding Al, 0.25% or more is necessary. On the other hand, addition of 1% or more causes a significant decrease in ductility. Therefore, Al was made into the range exceeding 0.25% and less than 1%.

0.75%<Ti≦2.5%

Tiは、時効処理中にNiと金属間化合物を形成し析出強化する元素であるため必須で添加する。Tiの添加により高強度化させるためには、0.75%を超える添加量が必要となる。一方で2.5%を超える場合は延性の低下が著しくなる。そのため、Tiは0.75を超えて2.5%以下の範囲とした。Tiは、好ましい上限は、2.45%である。

以上、述べた元素以外はFe及び不純物とする。

代表的な不純物元素として、Si、Mn、Cu、P、S、O、N等があり、これらの元素は以下の範囲に規制することが好ましい。

Si≦0.5%、Mn≦0.5%、Cu<0.5%、P≦0.05%、S≦0.02%、O≦0.01%、N≦0.05%。

好ましくは、以下の範囲にすると良い。

Si≦0.1%、Mn≦0.1%、Cu≦0.1%、P≦0.03%、S≦0.008%、O≦0.005%、N≦0.01%。0.75% <Ti ≦ 2.5%

Since Ti is an element that forms an intermetallic compound with Ni during the aging treatment and strengthens precipitation, it is essential to add Ti. In order to increase the strength by adding Ti, an addition amount exceeding 0.75% is required. On the other hand, when it exceeds 2.5%, the ductility is remarkably reduced. Therefore, Ti is set to a range of more than 0.75 and 2.5% or less. The preferable upper limit of Ti is 2.45%.

The elements other than those described above are Fe and impurities.

Typical impurity elements include Si, Mn, Cu, P, S, O, N, and the like, and these elements are preferably regulated to the following ranges.

Si ≦ 0.5%, Mn ≦ 0.5%, Cu <0.5%, P ≦ 0.05%, S ≦ 0.02%, O ≦ 0.01%, N ≦ 0.05%.

The following range is preferable.

Si ≦ 0.1%, Mn ≦ 0.1%, Cu ≦ 0.1%, P ≦ 0.03%, S ≦ 0.008%, O ≦ 0.005%, N ≦ 0.01%.

次に関係式について説明する。

引張強さと延性を維持しつつ0.2%耐力を大きく改善するには、上述した成分の範囲を満足させるだけでなく、以下の4つの関係式の全てを満足させるように成分調整を行う必要がある。なお、式中のNi、Co、Cr、Al及びTiは質量%での値で計算する。

式(1):1260−65Ni−20Co−40Cr≧0

式(1)は固溶化処理後の冷却時におけるマルテンサイト変態のし易さの指標である。一般に、マルテンサイト変態がおこる温度は、Ms点として知られているが、本発明の析出強化型ステンレス鋼においては、この式(1)を満たさない場合、固溶化処理後の冷却処理で十分なマルテンサイト変態が行われず、残留オーステナイトが残存し、強度と延性とのバランスを著しく損なう。

式(2):670+75Ni+40Co−100Cr≧0

式(2)は固溶化処理温度においてδフェライト相が存在するか否かの指標である。このδフェライトの存在は、フェライト形成元素であるCrの添加量とオーステナイト形成元素Ni及びCoの添加量とのバランスで決定するが、本発明の析出強化型ステンレス鋼においては、この式(2)を満たさない場合、固溶化処理温度においてδフェライトが安定となり、残存したδフェライトの存在形態は製造工程に依存した方向性があるため、最終製品の特性に方向性が現れてしまう。また、δフェライトの存在自体が強度と延性とのバランスを著しく損なう。Next, the relational expression will be described.

In order to greatly improve the 0.2% proof stress while maintaining the tensile strength and ductility, it is necessary not only to satisfy the above-mentioned component ranges but also to adjust the components so as to satisfy all of the following four relational expressions. There is. In addition, Ni, Co, Cr, Al, and Ti in the formula are calculated as values in mass%.

Formula (1): 1260-65Ni-20Co-40Cr ≧ 0

Formula (1) is an index of ease of martensitic transformation during cooling after the solution treatment. In general, the temperature at which martensitic transformation occurs is known as the Ms point. However, in the precipitation-strengthened stainless steel of the present invention, if this equation (1) is not satisfied, the cooling treatment after the solution treatment is sufficient. No martensitic transformation takes place, residual austenite remains, and the balance between strength and ductility is significantly impaired.

Formula (2): 670 + 75Ni + 40Co-100Cr ≧ 0

Formula (2) is an indicator of whether or not a δ ferrite phase exists at the solution treatment temperature. The presence of this δ ferrite is determined by the balance between the addition amount of Cr, which is a ferrite forming element, and the addition amounts of austenite forming elements, Ni and Co. In the precipitation strengthened stainless steel of the present invention, this formula (2) If δ is not satisfied, the δ ferrite becomes stable at the solution treatment temperature, and the presence form of the remaining δ ferrite has a direction depending on the manufacturing process, so that the directionality appears in the characteristics of the final product. In addition, the presence of δ ferrite significantly impairs the balance between strength and ductility.

式(3):0.125≦(Al/Ti)≦1.25

式(3)は析出強化を担う析出相を最適化する指標である。この式(3)を満たす場合、L12構造であるNi3(Ti、Al)相が析出しやすく、時効処理後の強度と延性とのバランスが最も優れている。一方で、(Al/Ti)が0.125未満の場合は、六方晶系のNi3Ti相が析出しやすくなり、その結果として延性が低下する。(Al/Ti)が1.25を超える場合は、B2構造のNi(Al、Ti)相が析出しやすくなり、延性の低下が著しく、引張強さが不十分となる。そのため、式(3)で示す関係式の範囲を0.125〜1.25とした。強度と延性のバランスを考慮すると式(3)で示す関係式の範囲は0.35〜0.65であることが好ましい。

式(4):1.45≦(Al+Ti)≦2.95

式(4)は析出強化を担う析出相の析出量を最適化する指標である。この式(4)で示す(Al+Ti)が1.45未満の場合は析出量が少ないため強度が不十分となり、(Al+Ti)が2.95を超える場合は析出量が多くなり過ぎるため延性の低下が著しい。そのため、式(4)で示す関係式の範囲を1.45〜2.95とした。特に、式(4)で示す関係式が2.1〜2.55であることが好ましい。Formula (3): 0.125 ≦ (Al / Ti) ≦ 1.25

Formula (3) is an index for optimizing the precipitation phase responsible for precipitation strengthening. When satisfying this equation (3), L1 2 structure in which Ni 3 (Ti, Al) phase is liable to precipitate, the balance between strength and ductility after aging treatment is most excellent. On the other hand, when (Al / Ti) is less than 0.125, a hexagonal Ni 3 Ti phase is likely to precipitate, resulting in a decrease in ductility. When (Al / Ti) exceeds 1.25, a Ni (Al, Ti) phase having a B2 structure is likely to be precipitated, the ductility is remarkably lowered, and the tensile strength is insufficient. For this reason, the range of the relational expression represented by the expression (3) is set to 0.125 to 1.25. When the balance between strength and ductility is taken into consideration, the range of the relational expression represented by Expression (3) is preferably 0.35 to 0.65.

Formula (4): 1.45 ≦ (Al + Ti) ≦ 2.95

Equation (4) is an index for optimizing the amount of precipitation of the precipitation phase responsible for precipitation strengthening. When (Al + Ti) represented by this formula (4) is less than 1.45, the amount of precipitation is small and the strength is insufficient, and when (Al + Ti) exceeds 2.95, the amount of precipitation is excessive and the ductility decreases. Is remarkable. For this reason, the range of the relational expression represented by the formula (4) is set to 1.45 to 2.95. In particular, it is preferable that the relational expression shown by Formula (4) is 2.1 to 2.55.

さらに本発明では、以下に示す式(5)を満足させると良い。

式(5):4.5≦Ni/(Al+Ti)

式(5)は破壊靭性を最適化する指標である。この式(5)で示すNi/(Al+Ti)が4.5未満の場合は破壊靭性が低下する傾向になるため、式(5)で示す関係式が4.5以上であることが好ましい。Furthermore, in the present invention, it is preferable to satisfy the following formula (5).

Formula (5): 4.5 ≦ Ni / (Al + Ti)

Equation (5) is an index for optimizing fracture toughness. When Ni / (Al + Ti) represented by the formula (5) is less than 4.5, the fracture toughness tends to be lowered. Therefore, the relational formula represented by the formula (5) is preferably 4.5 or more.

次に本発明の析出強化型ステンレス鋼の製造方法について説明する。

先ず、本発明の析出強化型ステンレス鋼に対し、所望の機械的特性を付与する熱処理について述べておく。

一般に析出強化型ステンレス鋼は、固溶化処理においてオーステナイト相中に、析出強化元素を固溶させた後、水、油、冷却ガス等を用いた冷却により、オーステナイト相をマルテンサイトへと変態させる。その後、時効処理により金属間化合物相等を微細に析出させることにより、高強度の材料を得ることが可能になる。

本発明においても上記の組成に調整した析出強化型ステンレス鋼に固溶化処理を行う。本発明の固溶化処理温度は、940℃未満であると合金元素が十分固溶せず、一方、1050℃を超えるとオーステナイト結晶粒が粗大化しやすく、また、δフェライトが生成し、機械的性質を害しやすいことから、固溶化処理温度を940℃〜1050℃とする。なお、固溶化処理時間としては、例えば、0.5〜3時間で十分である。

本発明の析出強化型ステンレス鋼は、マルテンサイト変態開始点(Ms点)が比較的低いため固溶化処理時の冷却のみでは完全なマルテンサイト組織が得られず、オーステナイト組織が多く残留し、耐力が低下するので、固溶化処理にて、室温まで冷却したのち、さらに−50℃〜−100℃でサブゼロ処理を必要に応じて行う。サブゼロ処理の処理時間としては、例えば、0.5〜3時間とすることができる。サブゼロ処理を行うことによって残留オーステナイトを減少させ、耐力などの機械的特性を改善できる。Next, the manufacturing method of the precipitation strengthening type stainless steel of this invention is demonstrated.

First, heat treatment for imparting desired mechanical properties to the precipitation-strengthened stainless steel of the present invention will be described.

In general, precipitation strengthened stainless steel dissolves a precipitation strengthening element in an austenite phase in a solution treatment, and then transforms the austenite phase into martensite by cooling with water, oil, cooling gas, or the like. Thereafter, a high-strength material can be obtained by finely depositing an intermetallic compound phase or the like by aging treatment.

Also in the present invention, the solid solution treatment is performed on the precipitation strengthened stainless steel adjusted to the above composition. When the solution treatment temperature of the present invention is less than 940 ° C., the alloy element does not sufficiently dissolve, whereas when it exceeds 1050 ° C., austenite crystal grains are likely to be coarsened, and δ ferrite is generated, resulting in mechanical properties. Therefore, the solution treatment temperature is set to 940 ° C to 1050 ° C. As the solution treatment time, for example, 0.5 to 3 hours is sufficient.

Since the precipitation strengthened stainless steel of the present invention has a relatively low martensite transformation start point (Ms point), a complete martensite structure cannot be obtained only by cooling at the time of solution treatment, a large amount of austenite structure remains, and the proof stress Therefore, after cooling to room temperature by solution treatment, subzero treatment is further performed at −50 ° C. to −100 ° C. as necessary. The processing time of the sub-zero processing can be set to 0.5 to 3 hours, for example. By performing sub-zero treatment, retained austenite can be reduced and mechanical properties such as yield strength can be improved.

固溶化処理もしくはサブゼロ処理の後、高強度、高靭性をバランス良く得るために、480℃〜550℃で時効処理(析出強化処理)を行う。時効処理温度は、480℃未満であると強度は高いが延性が低くなる場合があり、一方550℃を超えると、強度が低下する場合がある。なお、時効処理時間は1〜24時間の保持で十分である。

本発明の析出強化型ステンレス鋼は、上述の製造方法により、常温での引張試験において伸びが7.5%以上、0.2%耐力が1600MPa以上、引張強さが1700MPa以上の機械的特性を得ることができる。また、上述の製造方法により、破壊靭性が40MPa・m1/2以上の特性を有することもできることから、航空機用部品等に安定的に用いることが可能となる。After the solution treatment or the sub-zero treatment, an aging treatment (precipitation strengthening treatment) is performed at 480 ° C. to 550 ° C. in order to obtain a high strength and high toughness with a good balance. If the aging treatment temperature is less than 480 ° C., the strength is high but the ductility may be lowered. On the other hand, if it exceeds 550 ° C., the strength may be lowered. In addition, holding | maintenance for 1 to 24 hours is enough for the aging treatment time.

The precipitation-strengthened stainless steel of the present invention has the mechanical properties of an elongation of 7.5% or more, a 0.2% proof stress of 1600 MPa or more, and a tensile strength of 1700 MPa or more according to the above-described manufacturing method in a tensile test at room temperature. Obtainable. Further, since the above-described manufacturing method can have a fracture toughness of 40 MPa · m 1/2 or more, it can be stably used for aircraft parts and the like.

なお、本発明の析出強化型ステンレス鋼において、介在物や成分偏析等が問題となる航空機用部品や発電用部品へ本発明の析出強化型ステンレス鋼を量産的に製造する場合、その溶解方法として、真空溶解を適用するのが好適である。真空溶解に続き、真空アーク再溶解やエレクトロスラグ再溶解等の再溶解法を適宜組合わせるのが良い。

また、上述の熱処理を行うには、前述の溶解の後、鍛造やプレス等の熱間塑性加工を行った素材を用いて熱処理を行う。その場合、本発明の析出強化型ステンレス鋼を実際の製品に熱処理を行うときには、時効処理前に製品形状に近い形状に機械加工を行った後に時効処理を行うのが良い。

また、熱間塑性加工を行う場合、その加工比は3以上であることが好ましい。加工比が3未満であると、0.2%耐力の低下が顕著となる場合があるためである。なお、加工比は、加工前の被加工材断面積/加工後断面積で求めるものとする。

ここで、例えば、加工前の被加工材が鋼塊とすると、鋼塊にはテーパが形成されている場合が多い。その場合、鋼塊上下の両端部で断面積が異なるため、断面積は平均断面積として計算する。In addition, in the precipitation-strengthening stainless steel of the present invention, when the precipitation-strengthening stainless steel of the present invention is mass-produced to aircraft parts and power generation parts where inclusions and component segregation are problematic, as a melting method thereof It is preferred to apply vacuum melting. Subsequent to vacuum melting, a remelting method such as vacuum arc remelting or electroslag remelting may be appropriately combined.

Moreover, in order to perform the above-mentioned heat processing, it heat-processes using the raw material which performed hot plastic working, such as a forge and a press, after the above-mentioned melt | dissolution. In this case, when the precipitation-strengthened stainless steel of the present invention is heat-treated on an actual product, it is preferable to perform the aging treatment after performing machining to a shape close to the product shape before the aging treatment.

Moreover, when performing hot plastic working, it is preferable that the working ratio is 3 or more. This is because if the processing ratio is less than 3, the 0.2% yield strength may be significantly reduced. Note that the processing ratio is obtained by the cross-sectional area of the workpiece before processing / the cross-sectional area after processing.

Here, for example, if the workpiece before processing is a steel ingot, the steel ingot is often tapered. In that case, since the cross-sectional areas differ between the upper and lower ends of the steel ingot, the cross-sectional area is calculated as an average cross-sectional area.

(実施例1)

以下の実施例で本発明をさらに詳しく説明する。

真空溶解で10kg鋼塊を作製した。鋼塊にはテーパが形成されていたため、鋼塊の上部と下部の断面積を求め、その和を2で除して求めた平均断面積は5625mm2であった。鋼塊の化学組成を表1に示す。なお、表1中に示した元素以外はFe及び不純物である。代表的な不純物元素のCu、P、S、O、Nの含有量はそれぞれ、0.1%以下、0.015%以下、0.0025%以下、0.005%以下、0.005%以下であった。

なお、以下の表1及び表2で示す従来例No.31は、特許文献3から抜粋した数値であって、特許文献3の表1に示したNo.32合金の組成と、1085℃×1時間、油冷の固溶化処理後、−75℃×2時間のサブゼロ処理、385℃×2時間の時効処理、空冷(2回)後の機械的特性値を示すものである。

また、従来例No.32は、特許文献1から抜粋した数値であって、特許文献1のTABLE1に示されている材料の一つの組成と、850℃×20分の固溶化処理後、475℃×24時間の時効処理後の機械的特性値示すものである。

さらに従来例No.33は、特許文献2から抜粋した数値であって、特許文献2の第1表に示されている鋼種Nの組成と、900℃×1時間、空冷の固溶化処理後、500℃×5時間、空冷の時効処理後の機械的特性値である。

また、従来例No.34は、低合金高抗張力鋼であるAISI4340として非特許文献1から抜粋した数値であって、非特許文献1のTableIIIに示されている1133K DOQT−steel 3Rの組成と機械的特性値である。

Example 1

The following examples further illustrate the present invention.

A 10 kg steel ingot was produced by vacuum melting. Since the steel ingot was tapered, the upper and lower cross-sectional areas of the steel ingot were obtained, and the average cross-sectional area obtained by dividing the sum by 2 was 5625 mm 2 . Table 1 shows the chemical composition of the steel ingot. In addition, elements other than those shown in Table 1 are Fe and impurities. The contents of typical impurity elements Cu, P, S, O and N are 0.1% or less, 0.015% or less, 0.0025% or less, 0.005% or less, 0.005% or less, respectively. Met.

In addition, the conventional example No. shown in the following Table 1 and Table 2. 31 is a numerical value extracted from Patent Document 3, and No. 31 shown in Table 1 of Patent Document 3. Composition of 32 alloys, mechanical properties after 1085 ° C x 1 hour, oil-cooled solid solution treatment, -75 ° C x 2 hours sub-zero treatment, 385 ° C x 2 hours aging treatment, air cooling (twice) Is shown.

Conventional example No. 32 is a numerical value extracted from Patent Document 1, which is a composition of one of the materials shown in TABLE 1 of Patent Document 1, and an aging treatment of 475 ° C. × 24 hours after a solution treatment at 850 ° C. × 20 minutes. It shows the mechanical characteristic value later.

Furthermore, the conventional example No. 33 is a numerical value extracted from Patent Document 2, and the composition of steel type N shown in Table 1 of Patent Document 2 is 900 ° C. × 1 hour, and after air-cooled solid solution treatment, 500 ° C. × 5 hours. It is a mechanical characteristic value after aging treatment of air cooling.

Conventional example No. 34 is a numerical value extracted from Non-Patent Document 1 as AISI 4340, which is a low-alloy high-strength steel, and is the composition and mechanical property value of 1133K DOQT-steel 3R shown in Table III of Non-Patent Document 1.

表1に示す本発明及び比較例の鋼塊を1050℃に加熱を行った後、鍛造を行って、No.14合金及びNo.15合金以外は45mm幅×20mm厚みの平角素材とした。また、No.14合金は38mm×38mmの角型素材とし、No.15合金は65mm幅×30mm厚の平角素材を作製した。なお、加工比(=鋼塊平均断面積/鍛造後断面積)を計算すると、No.14合金及びNo.15合金以外は6.25であった。No.14合金の加工比は3.90であり、No.15合金の加工比は2.88であった。

次に作製した各鍛造素材の熱処理を行った。熱処理は、固溶化処理、サブゼロ処理、時効処理と連続して行った。固溶化処理は、大気炉にて、950℃、1000℃及び1050℃のいずれかの温度で1時間保持した後、油中で冷却した。サブゼロ処理は、ドライアイスとエタノールを用いて、−75℃で2時間保持した。時効処理は、大気炉にて、500℃、510℃、520℃及び530℃の何れかの温度で16時間保持した後、大気中で冷却した。

固溶化処理後の断面金属組織を塩化第二鉄の水溶液にてエッチング処理して観察した。金属組織観察結果として、No.2合金及びNo.23合金の光学顕微鏡写真をそれぞれ図1及び図2に示す。

また、上述の熱処理後の素材から平行部直径6.35mm、ゲージ長さ25.4mmの丸棒引張試験片を作製し、ASTM E8に基づいて常温において引張試験を行い、0.2%耐力、引張強さ、伸び及び絞りを測定した。測定結果を表2に示す。また、表2中には固溶化処理及び時効処理の温度を示す。

なお、金属組織観察の結果、本発明No.2合金においては図1に示すようにδフェライト相は観察されなかったが、No.23合金では、図2に示すように、固溶化処理後に鍛造方向に方向性を持ったδフェライトの残存が確認されたため、引張試験は実施しなかった。The steel ingots of the present invention and comparative examples shown in Table 1 were heated to 1050 ° C., forged, and No. No. 14 alloy and no. Other than 15 alloys, 45 mm width × 20 mm thickness flat rectangular materials were used. No. No. 14 alloy is a 38 mm × 38 mm square material. 15 alloy produced 65 mm width x 30 mm thickness rectangular material. In addition, when processing ratio (= steel ingot average cross-sectional area / cross-sectional area after forging) is calculated, No. No. 14 alloy and no. Except for 15 alloy, it was 6.25. No. The processing ratio of alloy No. 14 is 3.90. The processing ratio of 15 alloy was 2.88.

Next, each forged material produced was heat-treated. The heat treatment was performed continuously with the solution treatment, sub-zero treatment, and aging treatment. The solution treatment was carried out in an atmospheric furnace at a temperature of 950 ° C., 1000 ° C. or 1050 ° C. for 1 hour, and then cooled in oil. The subzero treatment was held at -75 ° C for 2 hours using dry ice and ethanol. The aging treatment was carried out in an atmospheric furnace at 500 ° C., 510 ° C., 520 ° C., and 530 ° C. for 16 hours and then cooled in the air.

The cross-sectional metal structure after the solution treatment was observed by etching with an aqueous solution of ferric chloride. As a result of the metal structure observation, No. No. 2 alloy and No. 2 The optical micrographs of Alloy 23 are shown in FIGS. 1 and 2, respectively.

In addition, a round bar tensile test piece having a parallel part diameter of 6.35 mm and a gauge length of 25.4 mm was prepared from the above-mentioned heat-treated material, and a tensile test was performed at room temperature based on ASTM E8. Tensile strength, elongation and drawing were measured. The measurement results are shown in Table 2. Table 2 shows the temperature of the solution treatment and the aging treatment.

As a result of observation of the metal structure, the present invention No. In the alloy 2, no δ ferrite phase was observed as shown in FIG. In the case of 23 alloy, as shown in FIG. 2, δ ferrite having directionality in the forging direction was confirmed after the solution treatment, so the tensile test was not performed.

表2より、本発明の析出強化型ステンレス鋼に対して適切な熱処理を行うことにより、引張強さと延性を維持しつつ0.2%耐力が従来鋼No.31合金よりも高くなることが確認される。

一方、比較例のNo.21合金はMoが添加されていないため延性が低いことが確認され、また、No.22合金は式(1)を満たさないため、強度が非常に低い値である。No.22合金の固溶化処理後の素材より試料を採取し電解研磨で仕上げた後、X線回折法により残留オーステナイト量を測定した結果、体積率で30.1%と大量の残留オーステナイトが残存していることを確認した。また、No.22合金の金属組織を図3に示す。X線回折法と金属組織観察の結果から、固溶化処理時の急冷処理でマルテンサイト変態が十分でなく大量の残留オーステナイトが残存したため強度が非常に低い値となったと考えられる。No.23合金においては、式(2)を満たさないため、固溶化処理後にδフェライトが残存したと考えられる。No.24合金に関してはAl量が多く、また、(Al+Ti)量も多いため延性が十分ではなく引張試験中に掴み部より破断した。従来例のNo.32合金の結果は、延性に寄与する要因がMoだけでなく、NiとAlおよび/もしくはTiとの金属間化合物の析出相の構造や量にもあることを示唆すると考えられる。従来例のNo.33合金の結果は、Ti量が2.5%と比較的高くCr量が少なく、かつ式(4)の値が3.0と高いにもかかわらず著しく強度低下しており、このことは析出相の析出量に臨界的な上限があることを示唆するととらえることができる。

また、比較的合金組成が近似するNo.11合金、No.14合金及びNo.15合金を対比すると、加工比が3未満になると引張特性、特に0.2%耐力が低下することが確認された。From Table 2, by performing an appropriate heat treatment on the precipitation-strengthened stainless steel of the present invention, the 0.2% proof stress is maintained in the conventional steel No. 1 while maintaining the tensile strength and ductility. It is confirmed that it is higher than 31 alloy.

On the other hand, no. No. 21 alloy was confirmed to have low ductility because Mo was not added. Since 22 alloy does not satisfy the formula (1), the strength is very low. No. A sample was taken from the material after the solution treatment of 22 alloy and finished by electrolytic polishing, and the amount of retained austenite was measured by X-ray diffractometry. As a result, a large amount of retained austenite was 30.1% by volume. I confirmed. No. The metal structure of the 22 alloy is shown in FIG. From the results of the X-ray diffraction method and the observation of the metal structure, it is considered that the strength is very low because the martensite transformation is not sufficient and a large amount of retained austenite remains in the rapid cooling treatment during the solution treatment. No. In the alloy No. 23, since the formula (2) is not satisfied, it is considered that δ ferrite remained after the solution treatment. No. Regarding the 24 alloy, the amount of Al was large and the amount of (Al + Ti) was also large, so the ductility was not sufficient and the grip part broke during the tensile test. No. of the conventional example. The result of 32 alloy is considered to suggest that the factor contributing to ductility is not only Mo but also the structure and amount of the precipitated phase of the intermetallic compound of Ni and Al and / or Ti. No. of the conventional example. As a result of the 33 alloy, although the Ti amount is relatively high as 2.5% and the Cr amount is small and the value of the formula (4) is as high as 3.0, the strength is remarkably reduced. It can be taken to suggest that there is a critical upper limit to the amount of phase precipitation.

In addition, No. whose alloy composition is relatively similar. No. 11 alloy, no. No. 14 alloy and no. When 15 alloys were compared, it was confirmed that when the working ratio was less than 3, the tensile properties, particularly 0.2% proof stress, decreased.

(実施例2)

実施例1で用いた本発明のNo.1合金、No.2合金、No.3合金、No.4合金、No.10合金、No.11合金及びNo.13合金の熱処理後の素材から15mm×36mm×38.5mmのコンパクトテンション型試験片を作製し、ASTM E399に基づいて破壊靭性を測定した。測定結果を表3に示す。また、表3中には固溶化処理、時効処理の温度及び式(5)の値を示す。(Example 2)

No. 1 of the present invention used in Example 1. No. 1 alloy, no. No. 2 alloy, No. No. 3 alloy, No. No. 4 alloy, no. No. 10 alloy, No. No. 11 alloy and no. A compact tension type test piece of 15 mm × 36 mm × 38.5 mm was produced from the heat-treated material of 13 alloy, and fracture toughness was measured based on ASTM E399. Table 3 shows the measurement results. Table 3 shows the temperature of the solution treatment and the aging treatment and the value of the formula (5).

表3より、本発明の析出強化型ステンレス鋼において式(5)で示すNi/(Al+Ti)が4.5以上の場合は破壊靭性が40MPa・m1/2以上の優れた特性が得られることがわかる。From Table 3, when Ni / (Al + Ti) represented by the formula (5) is 4.5 or more in the precipitation strengthened stainless steel of the present invention, excellent characteristics with fracture toughness of 40 MPa · m 1/2 or more can be obtained. I understand.

(実施例3)

実施例1で用いたNo.11合金及びNo.13合金の熱処理後の素材及び低合金系高抗張力鋼のAISI4340相当材を35℃、5%塩化ナトリウム溶液での塩水噴霧試験で72時間後の発錆状況観察を行った。観察結果を表4に示す。No.11合金及びNo.13合金においては、試験を2000時間まで延長し、発錆状況観察を行ったが、発錆は確認されなかった。(Example 3)

No. 1 used in Example 1. No. 11 alloy and no. The raw material after heat treatment of 13 alloy and AISI4340 equivalent material of low alloy type high strength steel were observed for rusting after 72 hours in a salt spray test at 35 ° C. and 5% sodium chloride solution. The observation results are shown in Table 4. No. No. 11 alloy and no. In 13 alloys, the test was extended to 2000 hours and the rusting state was observed, but no rusting was confirmed.

表4より、本発明の析出強化型ステンレス鋼は、従来の低合金高抗張力鋼と比較し耐食性が優れていることがわかる。 From Table 4, it can be seen that the precipitation-strengthened stainless steel of the present invention is superior in corrosion resistance as compared with the conventional low alloy high strength steel.

(実施例4)

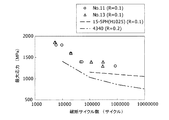

実施例1で用いたNo.11合金及びNo.13合金の熱処理後の素材から全長110mm、評価部の直径5.00mm、切欠き係数Kt=1.0の丸棒疲労試験片を作製し、ASTM E466にしたがって常温環境、応力比0.1で応力制御軸力疲労試験を行った。

試験片が破断したときのサイクル数を測定し、試験で得られた破断したサイクル数と試験片にかけた最大応力をまとめたものを表5に示す。加えて、非特許文献2に記載されているAISI4340材の疲労曲線、15−5PHステンレス鋼の疲労曲線とNo.11、No.13の疲労試験結果をまとめたものを図4に示す。Example 4

No. 1 used in Example 1. No. 11 alloy and no. A round bar fatigue test piece having a total length of 110 mm, a diameter of the evaluation part of 5.00 mm, and a notch coefficient Kt = 1.0 is prepared from the heat-treated material of 13 alloy, and is subjected to a normal temperature environment and a stress ratio of 0.1 according to ASTM E466. A stress controlled axial force fatigue test was conducted.

Table 5 shows the number of cycles when the test piece was broken and the maximum number of cycles obtained in the test and the maximum stress applied to the test piece were summarized. In addition, the fatigue curve of AISI 4340 described in Non-Patent Document 2, the fatigue curve of 15-5PH stainless steel, and 11, no. FIG. 4 shows a summary of the 13 fatigue test results.

図4より、本発明の析出強化型ステンレス鋼は、従来の低合金高抗張力鋼やステンレス鋼と比較し疲労特性が優れていることがわかる。 FIG. 4 shows that the precipitation-strengthened stainless steel of the present invention is excellent in fatigue characteristics as compared with conventional low alloy high strength steel and stainless steel.

本発明は0.2%耐力、引張強さに優れ、更に優れた耐食性も兼備する高強度ステンレス鋼であるため、高い強度が必要な航空機用脚材及び宇宙航空機一次構造部材、例えばフラップトラックレール、スラットトラックレール、ファスナーなどの締結部材、種々のアクチュエータ、ドアヒンジ、エンジン部品等に好適である。その他の用途としては、発電プラント用タービンブレード材、エンジン用シャフト材、ゴルフクラブのヘッドなどのスポーツ用品、または自転車部品、自動車部品、船舶部品などへの適用も期待できる。

Since the present invention is a high-strength stainless steel having excellent 0.2% proof stress, tensile strength, and excellent corrosion resistance, aircraft legs and spacecraft primary structural members that require high strength, such as flap track rails. It is suitable for fastening members such as slat track rails and fasteners, various actuators, door hinges, engine parts and the like. As other applications, application to sports equipment such as turbine blade materials for power plants, shaft materials for engines, and heads of golf clubs, bicycle parts, automobile parts, ship parts, and the like can also be expected.

Claims (11)

式(1) 1260−65Ni−20Co−40Cr≧0

式(2) 670+75Ni+40Co−100Cr≧0

式(3) 0.125≦(Al/Ti)≦1.25

式(4) 1.45≦(Al+Ti)≦2.95

(ただし、式中のNi、Co、Cr、Al及びTiは質量%での値で計算)の全てを満足することを特徴とする析出強化型ステンレス鋼。In mass%, C: ≦ 0.2%, 7% ≦ Ni ≦ 14%, 0% ≦ Co ≦ 3.5%, 9.5% ≦ Cr ≦ 14%, 0.5% ≦ Mo ≦ 3%, 0.25% <Al <1%, 0.75% <Ti ≦ 2.5%, the balance is made of Fe and impurities, and the following formulas (1) to (4):

Formula (1) 1260-65Ni-20Co-40Cr ≧ 0

Formula (2) 670 + 75Ni + 40Co-100Cr ≧ 0

Formula (3) 0.125 ≦ (Al / Ti) ≦ 1.25

Formula (4) 1.45 ≦ (Al + Ti) ≦ 2.95

(Note that Ni, Co, Cr, Al, and Ti in the formula are calculated by mass%) and satisfy all of the above.

(ただし、式中のNi、Al及びTiは質量%での値で計算)を満足することを特徴とする請求項1に記載の析出強化型ステンレス鋼。Formula (5) 4.5 ≦ Ni / (Al + Ti)

The precipitation-strengthened stainless steel according to claim 1, wherein Ni, Al, and Ti in the formula are calculated in terms of mass%.

Priority Applications (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| JP2011546519A JP4918632B2 (en) | 2010-06-28 | 2011-06-22 | Precipitation strengthened stainless steel and method for producing the same |

Applications Claiming Priority (6)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| JP2010146100 | 2010-06-28 | ||

| JP2010146100 | 2010-06-28 | ||

| JP2011055430 | 2011-03-14 | ||

| JP2011055430 | 2011-03-14 | ||

| JP2011546519A JP4918632B2 (en) | 2010-06-28 | 2011-06-22 | Precipitation strengthened stainless steel and method for producing the same |

| PCT/JP2011/064229 WO2012002208A1 (en) | 2010-06-28 | 2011-06-22 | Precipitation-hardened stainless steel and process for production thereof |

Publications (2)

| Publication Number | Publication Date |

|---|---|

| JP4918632B2 true JP4918632B2 (en) | 2012-04-18 |

| JPWO2012002208A1 JPWO2012002208A1 (en) | 2013-08-22 |

Family

ID=45401928

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| JP2011546519A Expired - Fee Related JP4918632B2 (en) | 2010-06-28 | 2011-06-22 | Precipitation strengthened stainless steel and method for producing the same |

Country Status (3)

| Country | Link |

|---|---|

| JP (1) | JP4918632B2 (en) |

| TW (1) | TW201207127A (en) |

| WO (1) | WO2012002208A1 (en) |

Cited By (1)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| JP2013001949A (en) * | 2011-06-16 | 2013-01-07 | Hitachi Ltd | Precipitate hardening martensitic stainless steel and long blade using the same for steam turbine |

Families Citing this family (11)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| JP5528986B2 (en) * | 2010-11-09 | 2014-06-25 | 株式会社日立製作所 | Precipitation hardening type martensitic stainless steel and steam turbine member using the same |

| JP5764503B2 (en) * | 2012-01-19 | 2015-08-19 | 三菱日立パワーシステムズ株式会社 | Precipitation hardening type martensitic stainless steel, steam turbine long blade, turbine rotor and steam turbine using the same |

| JP6317542B2 (en) * | 2012-02-27 | 2018-04-25 | 三菱日立パワーシステムズ株式会社 | Steam turbine rotor |

| JP6312367B2 (en) * | 2013-04-05 | 2018-04-18 | 三菱日立パワーシステムズ株式会社 | Precipitation hardening martensitic stainless steel, steam turbine blades and steam turbines |

| FR3013738B1 (en) * | 2013-11-25 | 2016-10-14 | Aubert & Duval Sa | MARTENSITIC STAINLESS STEEL, PIECE PRODUCED IN THIS STEEL AND METHOD OF MANUFACTURING THE SAME |

| JP6575756B2 (en) * | 2015-10-01 | 2019-09-18 | 日立金属株式会社 | Method for producing precipitation strengthened stainless steel |

| JP7298382B2 (en) | 2018-09-13 | 2023-06-27 | 大同特殊鋼株式会社 | Precipitation Hardening Martensitic Stainless Steel and Drill Parts for Underground Drilling |

| WO2020054540A1 (en) * | 2018-09-13 | 2020-03-19 | 大同特殊鋼株式会社 | Precipitation hardening-type martensite-based stainless steel and underground excavation drill component |

| CN115667570A (en) * | 2020-02-26 | 2023-01-31 | Crs控股有限责任公司 | High fracture toughness, high strength, precipitation hardening stainless steel |

| CN113981200A (en) * | 2021-10-20 | 2022-01-28 | 陕钢集团产业创新研究院有限公司 | 40Cr round steel heat treatment method taking water as medium |

| CN114645117A (en) * | 2022-03-21 | 2022-06-21 | 河南中原特钢装备制造有限公司 | Heat treatment process for 17-4PH material after forging through nitrogen-controlling alloying |

Citations (4)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| JPH05125490A (en) * | 1991-10-31 | 1993-05-21 | Japan Steel Works Ltd:The | Deposition hardening type stainless steel |

| JPH0610042A (en) * | 1992-06-24 | 1994-01-18 | Daido Steel Co Ltd | Method for forging precipitation hardening stainless steel |

| JPH0892699A (en) * | 1994-09-21 | 1996-04-09 | Daido Steel Co Ltd | Precipitation hardening type stainless steel |

| JP2008528797A (en) * | 2005-01-25 | 2008-07-31 | ケステック イノベーションズ エルエルシー | Martensitic stainless steel strengthened by Ni3Tiη phase precipitation |

-

2011

- 2011-06-22 JP JP2011546519A patent/JP4918632B2/en not_active Expired - Fee Related

- 2011-06-22 WO PCT/JP2011/064229 patent/WO2012002208A1/en active Application Filing

- 2011-06-27 TW TW100122416A patent/TW201207127A/en unknown

Patent Citations (4)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| JPH05125490A (en) * | 1991-10-31 | 1993-05-21 | Japan Steel Works Ltd:The | Deposition hardening type stainless steel |

| JPH0610042A (en) * | 1992-06-24 | 1994-01-18 | Daido Steel Co Ltd | Method for forging precipitation hardening stainless steel |

| JPH0892699A (en) * | 1994-09-21 | 1996-04-09 | Daido Steel Co Ltd | Precipitation hardening type stainless steel |

| JP2008528797A (en) * | 2005-01-25 | 2008-07-31 | ケステック イノベーションズ エルエルシー | Martensitic stainless steel strengthened by Ni3Tiη phase precipitation |

Cited By (1)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| JP2013001949A (en) * | 2011-06-16 | 2013-01-07 | Hitachi Ltd | Precipitate hardening martensitic stainless steel and long blade using the same for steam turbine |

Also Published As

| Publication number | Publication date |

|---|---|

| TW201207127A (en) | 2012-02-16 |

| JPWO2012002208A1 (en) | 2013-08-22 |

| WO2012002208A1 (en) | 2012-01-05 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| JP4918632B2 (en) | Precipitation strengthened stainless steel and method for producing the same | |

| JP6111763B2 (en) | Steam turbine blade steel with excellent strength and toughness | |

| KR102037086B1 (en) | Low alloy steel for geothermal power generation turbine rotor, and low alloy material for geothermal power generation turbine rotor and method for manufacturing the same | |

| JP5574283B1 (en) | Precipitation strengthened martensitic steel and method for producing the same | |

| WO2017058456A1 (en) | Corrosion and cracking resistant high manganese austenitic steels containing passivating elements | |

| US10000830B2 (en) | Method for manufacturing martensite-based precipitation strengthening stainless steel | |

| DE102010026808A1 (en) | Austenite-containing cast steel, useful e.g. as component of composites, comprises carbon, nitrogen, manganese, nickel, chromium, molybdenum, aluminum, silicon, niobium, tantalum, titanium, tungsten, copper, phosphorus and vanadium | |

| JP6166953B2 (en) | Maraging steel | |

| JP5088455B2 (en) | Duplex stainless steel | |

| CN106460100A (en) | Titanium alloys exhibiting resistance to impact or shock loading and method of making a part therefrom | |

| WO2007123164A1 (en) | Piston ring material for internal combustion engine | |

| JP2006526711A (en) | Nanoprecipitation strengthened ultra high strength corrosion resistant structural steel | |

| JP6582960B2 (en) | Maraging steel | |

| JP2014208869A (en) | Precipitation-strengthened martensitic steel | |

| JP5512494B2 (en) | High-strength, high-toughness non-tempered hot forged parts and manufacturing method thereof | |

| KR101301617B1 (en) | Material having high strength and toughness and method for forming tower flange using the same | |

| JP7131225B2 (en) | Precipitation Hardening Martensitic Stainless Steel | |

| JP6501652B2 (en) | Martensitic stainless steel with excellent precipitation hardenability | |

| WO2021173976A1 (en) | High fracture toughness, high strength, precipitation hardenable stainless steel | |

| CA2930153A1 (en) | Maraging steel | |

| RU76647U1 (en) | SHAFT (OPTIONS) | |

| JP3384515B2 (en) | High thermal expansion steel and high strength high thermal expansion bolt | |

| JP4332446B2 (en) | High strength steel with excellent cold workability and delayed fracture resistance, and high strength steel parts with excellent delayed fracture resistance | |

| JP2020045560A (en) | Precipitation curing martensitic stainless steel and drill component for underground excavation |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| TRDD | Decision of grant or rejection written | ||

| A01 | Written decision to grant a patent or to grant a registration (utility model) |

Free format text: JAPANESE INTERMEDIATE CODE: A01 Effective date: 20120106 |

|

| A01 | Written decision to grant a patent or to grant a registration (utility model) |

Free format text: JAPANESE INTERMEDIATE CODE: A01 |

|

| A61 | First payment of annual fees (during grant procedure) |

Free format text: JAPANESE INTERMEDIATE CODE: A61 Effective date: 20120130 |

|

| FPAY | Renewal fee payment (event date is renewal date of database) |

Free format text: PAYMENT UNTIL: 20150203 Year of fee payment: 3 |

|

| R150 | Certificate of patent or registration of utility model |

Ref document number: 4918632 Country of ref document: JP Free format text: JAPANESE INTERMEDIATE CODE: R150 Free format text: JAPANESE INTERMEDIATE CODE: R150 |

|

| R250 | Receipt of annual fees |

Free format text: JAPANESE INTERMEDIATE CODE: R250 |

|

| R250 | Receipt of annual fees |

Free format text: JAPANESE INTERMEDIATE CODE: R250 |

|

| R250 | Receipt of annual fees |

Free format text: JAPANESE INTERMEDIATE CODE: R250 |

|

| R250 | Receipt of annual fees |

Free format text: JAPANESE INTERMEDIATE CODE: R250 |

|

| S111 | Request for change of ownership or part of ownership |

Free format text: JAPANESE INTERMEDIATE CODE: R313117 |

|

| S531 | Written request for registration of change of domicile |

Free format text: JAPANESE INTERMEDIATE CODE: R313531 |

|

| S533 | Written request for registration of change of name |

Free format text: JAPANESE INTERMEDIATE CODE: R313533 |

|

| R350 | Written notification of registration of transfer |

Free format text: JAPANESE INTERMEDIATE CODE: R350 |

|

| R250 | Receipt of annual fees |

Free format text: JAPANESE INTERMEDIATE CODE: R250 |

|

| LAPS | Cancellation because of no payment of annual fees |