JP4890103B2 - Hot water storage water heater - Google Patents

Hot water storage water heater Download PDFInfo

- Publication number

- JP4890103B2 JP4890103B2 JP2006149878A JP2006149878A JP4890103B2 JP 4890103 B2 JP4890103 B2 JP 4890103B2 JP 2006149878 A JP2006149878 A JP 2006149878A JP 2006149878 A JP2006149878 A JP 2006149878A JP 4890103 B2 JP4890103 B2 JP 4890103B2

- Authority

- JP

- Japan

- Prior art keywords

- hot water

- water storage

- storage tank

- heat insulating

- insulating material

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Active

Links

- XLYOFNOQVPJJNP-UHFFFAOYSA-N water Substances O XLYOFNOQVPJJNP-UHFFFAOYSA-N 0.000 title claims description 185

- 238000003860 storage Methods 0.000 title claims description 112

- 239000011810 insulating material Substances 0.000 claims description 74

- 238000003825 pressing Methods 0.000 claims description 2

- 239000012774 insulation material Substances 0.000 claims 1

- 239000000463 material Substances 0.000 description 40

- 230000002093 peripheral effect Effects 0.000 description 20

- 239000002184 metal Substances 0.000 description 5

- 238000000034 method Methods 0.000 description 4

- 238000004519 manufacturing process Methods 0.000 description 3

- CURLTUGMZLYLDI-UHFFFAOYSA-N Carbon dioxide Chemical compound O=C=O CURLTUGMZLYLDI-UHFFFAOYSA-N 0.000 description 2

- 230000002542 deteriorative effect Effects 0.000 description 2

- 230000001771 impaired effect Effects 0.000 description 2

- 238000009413 insulation Methods 0.000 description 2

- 239000000853 adhesive Substances 0.000 description 1

- 230000001070 adhesive effect Effects 0.000 description 1

- 239000002390 adhesive tape Substances 0.000 description 1

- 229910002092 carbon dioxide Inorganic materials 0.000 description 1

- 239000001569 carbon dioxide Substances 0.000 description 1

- 238000009826 distribution Methods 0.000 description 1

- 229920006248 expandable polystyrene Polymers 0.000 description 1

- 230000017525 heat dissipation Effects 0.000 description 1

- 239000008236 heating water Substances 0.000 description 1

- 230000005855 radiation Effects 0.000 description 1

- 239000003507 refrigerant Substances 0.000 description 1

- 239000011347 resin Substances 0.000 description 1

- 229920005989 resin Polymers 0.000 description 1

Images

Landscapes

- Details Of Fluid Heaters (AREA)

Description

本発明は、温水を貯留する貯湯タンクを備えた貯湯式給湯機に関するものである。 The present invention relates to a hot water storage type hot water supply apparatus having a hot water storage tank for storing hot water.

ヒートポンプ給湯機や電気温水器等の貯湯式給湯機は、ヒートポンプやヒータ等の熱源器により水を加熱して得た温水を貯湯タンクに一旦貯留し、貯湯タンクに接続された給湯管の端部に配置した給水栓をユーザが開けたときに貯湯タンク内の温水が出湯するように構成されている。熱源器による温水の生成から出湯までの時間が不定であることから、貯湯式給湯機では貯湯タンクの周囲を断熱材で囲繞して、当該貯湯タンク内の温水の降温を抑えている。断熱材による貯湯タンクの保温性を高めるうえからは、断熱材同士を互いに密着させること、および断熱材と貯湯タンクとを互いに密着させることが重要となる。このため、貯湯式給湯機の断熱構造については、種々の工夫が凝らされている。 Hot water storage hot water heaters such as heat pump water heaters and electric water heaters are used to store hot water obtained by heating water with a heat source such as a heat pump or heater in a hot water storage tank, and the end of a hot water pipe connected to the hot water storage tank. The hot water in the hot water storage tank is discharged when the user opens the water faucet arranged in the hot water tank. Since the time from the generation of hot water by the heat source to the hot water is indefinite, the hot water storage type water heater surrounds the hot water storage tank with a heat insulating material to suppress the temperature drop of the hot water in the hot water storage tank. In order to improve the heat retaining property of the hot water storage tank by the heat insulating material, it is important to make the heat insulating materials in close contact with each other and to make the heat insulating material and the hot water storage tank in close contact with each other. For this reason, various ideas have been elaborated about the heat insulation structure of the hot water storage type water heater.

例えば、断熱材と貯湯タンクとの密着を図るために貯湯タンクに断熱材を巻き付けたり、複数の断熱材で貯湯タンクを囲繞するにあたって粘着テープ等で断熱材同士を固定したりし、これにより断熱材同士の密着および断熱材と貯湯タンクとの密着を図るという手法もあるが、より作業性の高いものとして、特許文献1および特許文献2に記載された貯湯タンクが知られている。

For example, in order to achieve close contact between the heat insulating material and the hot water storage tank, the heat insulating material is wrapped around the hot water storage tank, or when the hot water storage tank is surrounded by a plurality of heat insulating materials, the heat insulating material is fixed to each other with an adhesive tape, etc. Although there is a method of achieving close contact between the materials and close contact between the heat insulating material and the hot water storage tank, the hot water storage tanks described in

特許文献1,2に記載されている貯湯タンクは、該貯湯タンクを囲繞する複数の断熱材それぞれに所定の嵌合部、すなわち互いに隣接配置されるもの同士が嵌り合う凹凸部を設けたものであり、各断熱材に上記の凹凸部を設けることにより、これらの断熱材を互いに密着させて貯湯タンクの周囲に配置する際の作業性を向上させている。また、特許文献1,2に記載された断熱材の外周は部分的に肉抜きされており、これらの特許文献1,2に記載された貯湯タンクでは、断熱材において肉抜きされていない部分が外装ケース(貯湯タンク用の外装体)の内面に接することになるように当該断熱材および外装ケースを配置することで断熱材を貯湯タンクに押し付け、断熱材と貯湯タンクとを互いに密着させている。

The hot water storage tanks described in

しかしながら、貯湯タンクの外装ケースは、多くの場合、低コスト化を図るために比較的薄肉の板金により作製される。このため、外装ケースをその内面が断熱材と部分的に接触するように、かつ断熱材が貯湯タンクに押し付けられることになるように配置すると、外装ケースのうちで断熱材と接する領域およびその周辺が外側に歪んで外観が損なわれ易い。一方、断熱材と外装ケースとの接触圧を外装ケースの外観が損なわれない程度の大きさにすると、断熱材と貯湯タンクとの密着性を十分に高めることが困難になり、保温性を高め難くなり易い。 However, in many cases, the outer case of the hot water storage tank is made of a relatively thin sheet metal in order to reduce the cost. Therefore, when the outer case is arranged so that the inner surface thereof is partially in contact with the heat insulating material and the heat insulating material is pressed against the hot water storage tank, the region of the outer case that contacts the heat insulating material and its periphery Is distorted outward and the appearance is likely to be impaired. On the other hand, if the contact pressure between the heat insulating material and the outer case is set to such a level that the appearance of the outer case is not impaired, it becomes difficult to sufficiently improve the adhesion between the heat insulating material and the hot water storage tank, and the heat retention is improved. It tends to be difficult.

勿論、断熱材を肉抜きすることなく、断熱材の外周面全体が外装ケースの内面に接するようにすれば、外装ケースの外観を損なうことなく断熱材を貯湯タンクに押し付けて両者の密着性を高め易くなるが、外装ケースと断熱材との接触面積が大きくなると、両者の接触部からの放熱量が増大して断熱材による保温性能が悪化する。 Of course, if the entire outer peripheral surface of the heat insulating material is in contact with the inner surface of the outer case without removing the heat insulating material, the heat insulating material is pressed against the hot water storage tank without impairing the outer appearance of the outer case, thereby improving the adhesion between the two. Although it becomes easy to raise, when the contact area of an exterior case and a heat insulating material becomes large, the heat dissipation from both contact parts will increase and the heat retention performance by a heat insulating material will deteriorate.

本発明は上記に鑑みてなされたものであり、外装ケースの外観を損なうことなく保温性を高めることが容易な貯湯式給湯機を得ることを目的とする。 The present invention has been made in view of the above, and an object of the present invention is to obtain a hot water storage type hot water heater that can easily improve heat retention without impairing the appearance of the exterior case.

上記の目的を達成する本発明の貯湯式給湯機は、温水が貯留される貯湯タンクと、貯湯タンクを囲繞する複数の断熱材と、貯湯タンクおよび断熱材を収納する外装ケースとを有する貯湯式給湯機であって、外装ケースは、断熱材を貯湯タンクに押し付ける複数の凸部をその内側面に有することを特徴とするものである。 A hot water storage type water heater of the present invention that achieves the above object is a hot water storage type having a hot water storage tank for storing hot water, a plurality of heat insulating materials surrounding the hot water storage tank, and an exterior case for storing the hot water storage tank and the heat insulating material. In the water heater, the outer case has a plurality of convex portions on its inner surface for pressing the heat insulating material against the hot water storage tank.

本発明の貯湯式給湯機では、外装ケースに上述の凸部が設けられているので、当該外装ケースを比較的薄肉にした場合でも比較的高い剛性を得ることができる。このため、上記の凸部により断熱材が貯湯タンクに押し付けられることになるように、また隣り合う断熱材同士が互いに密着することになるように外装ケースを断熱材に押し当てて配置しても、外装ケースの外観が損なわれ難い。さらに、外装ケースと断熱材とは上記の凸部で接触するので、外装ケースと断熱材との接触面積を小さくし易い。 In the hot water storage type water heater of the present invention, since the above-mentioned convex part is provided in the exterior case, relatively high rigidity can be obtained even when the exterior case is made relatively thin. For this reason, even if the outer case is pressed against the heat insulating material and arranged so that the heat insulating material is pressed against the hot water storage tank by the convex portion and the adjacent heat insulating materials are in close contact with each other. The appearance of the outer case is hardly damaged. Furthermore, since the outer case and the heat insulating material are in contact with each other at the above-described convex portion, it is easy to reduce the contact area between the outer case and the heat insulating material.

これらの結果として、外装ケースを比較的薄肉にした場合でも、当該外装ケースの外観を損なうことなく断熱材同士を密着させると共に断熱材と貯湯タンクとを密着させ、かつ外装ケースと断熱材との接触部からの放熱量を抑えることが容易になる。したがって、本発明によれば、貯湯式給湯機の外装ケースの外観を損なうことなく保温性を高めることが容易になり、結果として、保温性および外観がそれぞれ良好な貯湯式給湯機を低コストの下に得易くなる。 As a result of these, even when the outer case is made relatively thin, the heat insulating materials are brought into close contact with each other without impairing the appearance of the outer case, and the heat insulating material and the hot water storage tank are brought into close contact with each other. It becomes easy to suppress the heat radiation from the contact portion. Therefore, according to the present invention, it becomes easy to improve the heat retaining property without deteriorating the appearance of the outer case of the hot water storage type hot water heater, and as a result, the hot water type hot water heater having good heat retaining property and good appearance can be obtained at low cost. It becomes easier to obtain below.

以下、本発明の貯湯式給湯機の実施の形態について、図面を参照して詳細に説明する。なお、本発明は以下に説明する実施の形態に限定されるものではない。 DESCRIPTION OF EMBODIMENTS Hereinafter, embodiments of a hot water storage type water heater of the present invention will be described in detail with reference to the drawings. The present invention is not limited to the embodiments described below.

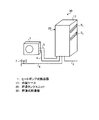

図1は、本発明の貯湯式給湯機の一例を概略的に示す斜視図である。同図に示す貯湯式給湯機30は、二酸化炭素等を冷媒として用いたヒートポンプ式熱源器1と、貯湯タンクユニット20とを備えている。貯湯タンクユニット20は、貯湯タンク(図1には現れていない。)と、該貯湯タンクを囲繞する複数の断熱材(図1には現れていない。)と、図示を省略した各種の制御部品および配管部品と、これらを収納した外装ケース17とを有しており、外装ケース17の内側面には計4つの凸部S1〜S4が設けられている。ただし、図1においては4つの凸部S1〜S4のうちの2つの凸部S1〜S2それぞれの背面が現れている。

FIG. 1 is a perspective view schematically showing an example of a hot water storage type water heater of the present invention. A hot water storage

上記の貯湯タンクユニット20には、第1給水管3と、第2給水管4と、第1給湯管5と、第2給湯管6とが接続されており、第2給湯管6の一端部には給湯栓7が設けられている。第1給水管3は、貯湯タンクの下部に接続されて非加熱の水を当該貯湯タンクに供給するものであり、貯湯タンクに供給された非加熱の水は第2給水管4によりヒートポンプ式熱源器1に供給され、ここで加熱されて温水となる。この温水は第1給湯管5を介して貯湯タンクに送られ、当該貯湯タンクの上部からその中に供給される。第2給湯管6は貯湯タンクの上部に接続されており、貯湯タンクに貯留された温水は、ユーザが給湯栓7を開けたときに第2給湯管6から出湯する。

The hot water

図2は、図1に示した貯湯タンクユニット20を概略的に示す分解斜視図である。同図に示すように、上述の貯湯タンク11は貯湯タンクユニット20のほぼ中央部に収納されており、貯湯タンク11の下部には図示を省略した第1給水管3および第2給水管4(図1参照)それぞれの一端が、また上部には図示を省略した第1給湯管5および第2給湯管6(図1参照)それぞれの一端が接続されている。この貯湯タンク11の下部には複数のタンク支持脚13が取り付けられている。

FIG. 2 is an exploded perspective view schematically showing the hot water

また、貯湯タンク11の周囲には4つの断熱材15a〜15d、すなわち、貯湯タンク11の右外周面(貯湯タンクユニット20を正面視したときの貯湯タンク11の右半分の外周面を意味する。)に接する右外周部断熱材15aと、貯湯タンク11の左外周面(貯湯タンクユニット20を正面視したときの貯湯タンク11の左半分の外周面を意味する。)に接する左外周部断熱材15bと、貯湯タンク11の上面に接する上部断熱材15cと、貯湯タンク11の下面に接する下部断熱材15dとが配置されている。

Further, around the hot

これらの断熱材15a〜15dのうち、右外周部断熱材15aおよび左外周部断熱材15bの各々は、これらの断熱材15a,15bが配置される箇所での貯湯タンク11の表面形状に応じた内周面形状を有しており、上部断熱材15cは、該上部断熱材15cが配置される箇所での貯湯タンク11、第1給湯管5および第2給湯管6(図1参照)それぞれの表面形状に対応した内周面形状を有している。そして、下部断熱材15dは、該下部断熱材15dが配置される箇所での貯湯タンク11、第1給水管3および第2給水管4(図1参照)それぞれの表面形状に対応した内周面形状を有している。

Among these

各断熱材15a〜15bは、外装ケース17に収容された状態下では当該外装ケース17により貯湯タンク11に押し当てられて、隣り合うもの同士が互いに密着して貯湯タンク11を囲繞する。個々の断熱材15a〜15dの材料としては種々のものを用いることができるが、貯湯式給湯機30の製造コストを抑えるうえからは、例えば耐熱性発泡スチロールによりこれらの断熱材15a〜15dを作製することが好ましい。

The

上述した貯湯タンク11と各断熱材15a〜15dとを収容する外装ケース17は6つのケーシング材、すなわち外装ケース17での右側面を形成する右側部ケーシング材17a、左側面を形成する左側部ケーシング材17b、前面を形成する前部ケーシング材17c、背面を形成する後部ケーシング材17d、上面を形成する上部ケーシング材17eおよび下面を形成する下部ケーシング材17fにより構成されている。これらのケーシング材17a〜17fは、隣り合うもの同士が互いにネジ等の固定具により固定されて、外装ケース17を形成する。下部ケーシング材17fの下面には、貯湯タンクユニット20全体を支える複数の支持脚19が取り付けられている。

The

上記6つのケーシング材17a〜17fのうち、右側部ケーシング材17aは2つの凸部S1,S2(図2においてはこれらの凸部S1,S2の背面が現れている。)を内側面に有しており、左側部ケーシング材17bは2つの凸部S3,S4を内側面に有している。これらの凸部S1〜S4は、いずれも、比較的薄肉の板金から右側部ケーシング材17aまたは左側部ケーシング材17bを作製する際に一体成形されたものであり、水平方向に延びた長尺状の凸部(直線状あるいは真直ぐな帯状に形成された凸部)である。凸部S1,S2は互いに並設されており、凸部S3,S4もまた互いに並設されている。

Of the six

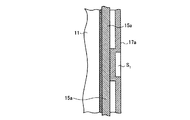

図3は、図2に示した貯湯タンクユニット20を部分的に示す垂直断面図であり、図4は図3の一部を拡大して示す概略図である。図3に示すように、右側部ケーシング材17aは、該右側部ケーシング材17aに設けられている凸部S1が右外周部断熱材15aに押し当てられた状態で他の所定のケーシング材に固定されて、外装ケース17(図1および図2参照)を形成している。また、左側部ケーシング材17bは、該左側部ケーシング材17bに設けられている凸部S3が左外周部断熱材15bに押し当てられた状態で他の所定のケーシング材に固定されて、外装ケース17を形成している。図3には現れていないが、右側部ケーシング材17aに設けられている凸部S2(図2参照)は右外周部断熱材15aに押し当てられており、左側部ケーシング材17bに設けられている凸部S4(図1参照)は左外周部断熱材15bに押し当てられている。

3 is a vertical sectional view partially showing the hot water

図3および図4に示すように、凸部S1は右側部ケーシング材17aの元となる板金を絞り加工することで形成されている。同様に、凸部S2,S3,S4(図2参照)の各々も絞り加工により形成されている。

As shown in FIG. 3 and FIG. 4, the convex portion S 1 is formed by drawing a sheet metal that is the base of the

このように構成された貯湯タンクユニット20を有する貯湯式給湯機30(図1参照)では、右外周部断熱材15aおよび左外周部断熱材15bがそれぞれ右側部ケーシング材17aまたは左側部ケーシング材17bにより貯湯タンク11に押し付けられて貯湯タンク11に密着するので、これら2つの断熱材15a,15bと前述した上部断熱材15cおよび下部断熱材15dとによって高い保温性能を容易に得ることができる。また、比較的薄肉の板金により右側部ケーシング材17aおよび左側部ケーシング材17bを作製した場合でも、その剛性を比較的高くすることができるので、右外周部断熱材15aまたは左外周部断熱材15bに凸部S1〜S4を押し当てたときにこれら凸部S1〜S4の周辺に歪みが生じ難く、結果として、外装ケース17の外観も損なわれ難い。

In the hot water storage water heater 30 (see FIG. 1) having the hot water

したがって、貯湯式給湯機30では、外装ケース17の外観を損なうことなく保温性を高めることが容易である。また、凸部S1〜S4の各々が水平方向に延びる長尺な凸部であるので、貯湯タンク11内の温度分布に起因して当該貯湯タンク11の周囲の空気に生じる鉛直方向の対流を凸部S1〜S4の各々により遮断することができ、この点からも保温性能が向上する。そして、外装ケース17を作製するにあたって比較的薄肉の板金を用いることができるので、その製造コストを抑え易い。さらに、右側部ケーシング材17aおよび左側部ケーシング材17bそれぞれの剛性が比較的高いことに伴って、当該ケーシング材17a,17bの製造現場での搬送性や、外装ケース17を組み立てる際の作業性等も良好なものとなる。

Therefore, in the hot water storage type

以上、本発明の貯湯式給湯機の実施の形態について詳述したが、本発明は上述した実施の形態に限定されるものではない。例えば、貯湯タンクを幾つの断熱材で囲繞するかは適宜選定可能である。また、貯湯タンクの前後(貯湯タンクユニットを正面視したときの貯湯タンクの前後)および上下にそれぞれ断熱部材を配置し、これらの断熱部材によって貯湯タンクを囲繞すると共に、図2に示した6つのケーシング材で外装ケースを構成することもでき、この場合には、例えば前部ケーシング材と後部ケーシング材の各々に上述した凸部S1〜S4と同様の凸部が設けられる。 As mentioned above, although embodiment of the hot water storage type water heater of this invention was explained in full detail, this invention is not limited to embodiment mentioned above. For example, it is possible to appropriately select how many insulating materials the hot water storage tank is surrounded by. In addition, heat insulating members are arranged before and after the hot water tank (front and rear of the hot water tank when the hot water tank unit is viewed from the front) and above and below, respectively, and the hot water tank is surrounded by these heat insulating members. can also configure the exterior case in the casing material, in this case, for example, similar to the convex portion and the convex portion S 1 to S 4 described above on each of the front casing member and the rear casing member is provided.

勿論、上部ケーシング材および下部ケーシング材の各々に上述した凸部S1〜S4と同様の凸部を設けることもでき、この場合には、上部断熱材および下部断熱部材の各々と貯湯タンクとの密着性や、上部ケーシング材および下部ケーシングそれぞれの剛性が向上する。外装ケースを構成するケーシング材の各々に上述した凸部S1〜S4と同様の凸部を設けると、断熱部材の各々と貯湯タンクとの密着性や断熱部材同士の密着性が更に向上した貯湯式給湯機を容易に得ることができる。 Of course, each of the upper casing material and the lower casing material can be provided with convex portions similar to the convex portions S 1 to S 4 described above. In this case, each of the upper heat insulating material and the lower heat insulating member, the hot water storage tank, And the rigidity of the upper casing material and the lower casing are improved. Providing the same convex portions as the convex portions S 1 to S 4 described above in each casing material constituting the outer case further improves the adhesion between each of the heat insulating members and the hot water storage tank and the heat insulating members. A hot water storage type water heater can be obtained easily.

個々のケーシング材に設ける凸部の形状や個数は、断熱材との接触面積が貯湯式給湯機の保温性能に与える影響や、外装ケースに要求される剛性等を考慮して適宜選定可能である。貯湯タンクユニットにおける貯湯タンクの数は1以上の所望数とすることができ、貯湯タンクの数が多いほど外装ケースが大型化して個々のケーシング材の面積が広くなるので、各ケーシング材にも高い剛性が要求されるようになる。 The shape and number of protrusions provided on each casing material can be selected as appropriate in consideration of the influence of the contact area with the heat insulating material on the heat insulation performance of the hot water storage type water heater, the rigidity required for the exterior case, etc. . The number of hot water storage tanks in the hot water storage tank unit can be set to a desired number of 1 or more. The larger the number of hot water storage tanks, the larger the outer case and the larger the area of each casing material. Rigidity is required.

個々の凸部の全体形状は、鉛直方向に延びた長尺状(直線状または真直ぐな帯状)、環形、矩形等であってもよい。また、凸部の形成方法は絞り加工に限定されるものではなく、例えばケーシング材とは別部品として作製したものを接着剤や工程具等によりケーシング材の所定箇所に取り付けることで凸部を有するケーシング材を得ることもできる。さらに、ケーシング材を樹脂成形品とすることもでき、この場合には当該ケーシング材の成形時に凸部を一体成形してもよい。 The overall shape of each convex portion may be a long shape (straight or straight strip) extending in the vertical direction, a ring shape, a rectangle, or the like. Further, the method for forming the convex portion is not limited to the drawing process. For example, the convex portion is formed by attaching a part prepared as a separate part from the casing material to a predetermined portion of the casing material with an adhesive or a process tool. Casing material can also be obtained. Furthermore, the casing material can be a resin molded product, and in this case, the convex portion may be integrally formed when the casing material is molded.

本発明の貯湯式給湯機を構成する熱源器はヒートポンプ式以外のもの、例えば貯湯タンク内に配置されたヒータ等であってもよい。貯湯式給湯機であれば、熱源の種類は問わない。また、貯湯タンクの数も、1以上の所望数とすることができる。本発明の貯湯式給湯機については、上述した以外にも種々の変形、修飾、組合せ等が可能である。 The heat source device constituting the hot water storage type water heater of the present invention may be other than a heat pump type, for example, a heater or the like disposed in a hot water storage tank. If it is a hot water storage type water heater, the kind of heat source is not ask | required. Moreover, the number of hot water storage tanks can also be made into the desired number of 1 or more. The hot water storage type water heater of the present invention can be variously modified, modified, combined, etc. in addition to those described above.

1 ヒートポンプ式熱源器

11 貯湯タンク

15a 右外周部断熱材

15b 左外周部断熱材

15c 上部断熱材

15d 下部断熱材

17 外装ケース

17a 右側部ケーシング材

17b 左側部ケーシング材

17c 前部ケーシング材

17d 後部ケーシング材

17e 上部ケーシング材

17f 下部ケーシング材

20 貯湯タンクユニット

30 貯湯式給湯機

S1〜S4 凸部

DESCRIPTION OF

Claims (5)

前記外装ケースは、前記断熱材を前記貯湯タンクに押し付ける複数の凸部をその内側面に有し、

複数の凸部のそれぞれは、水平方向に延びている

ことを特徴とする貯湯式給湯機。 A hot water storage water heater having a hot water storage tank for storing hot water, a plurality of heat insulating materials surrounding the hot water storage tank, and an exterior case for storing the hot water storage tank and the heat insulating material,

The outer case may have a plurality of protrusions for pressing the insulation material to the hot water storage tank on its inner surface,

Each of the plurality of convex portions extends in the horizontal direction .

Priority Applications (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| JP2006149878A JP4890103B2 (en) | 2006-05-30 | 2006-05-30 | Hot water storage water heater |

Applications Claiming Priority (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| JP2006149878A JP4890103B2 (en) | 2006-05-30 | 2006-05-30 | Hot water storage water heater |

Publications (3)

| Publication Number | Publication Date |

|---|---|

| JP2007322015A JP2007322015A (en) | 2007-12-13 |

| JP2007322015A5 JP2007322015A5 (en) | 2008-12-18 |

| JP4890103B2 true JP4890103B2 (en) | 2012-03-07 |

Family

ID=38854997

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| JP2006149878A Active JP4890103B2 (en) | 2006-05-30 | 2006-05-30 | Hot water storage water heater |

Country Status (1)

| Country | Link |

|---|---|

| JP (1) | JP4890103B2 (en) |

Families Citing this family (6)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| JP2009180488A (en) * | 2008-02-01 | 2009-08-13 | Daikin Ind Ltd | Heat pump type water heater |

| JP2012052674A (en) * | 2010-08-31 | 2012-03-15 | Hitachi Appliances Inc | Water heater |

| JP5465161B2 (en) * | 2010-11-26 | 2014-04-09 | リンナイ株式会社 | Insulated hot water storage system |

| JP5555611B2 (en) * | 2010-11-26 | 2014-07-23 | リンナイ株式会社 | Insulated hot water storage system |

| JP5327213B2 (en) * | 2010-12-28 | 2013-10-30 | ダイキン工業株式会社 | Hot water storage tank unit |

| JP5924151B2 (en) * | 2012-06-20 | 2016-05-25 | 三菱電機株式会社 | Hot water storage water heater |

Family Cites Families (3)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| GB2113550B (en) * | 1982-01-21 | 1985-06-05 | Microsurgical Administrative S | Surgical knife |

| JP2001336827A (en) * | 2000-05-29 | 2001-12-07 | Corona Corp | Hot water storing type hot water feeder |

| JP3561260B2 (en) * | 2002-05-28 | 2004-09-02 | 株式会社コロナ | Hot water storage tank |

-

2006

- 2006-05-30 JP JP2006149878A patent/JP4890103B2/en active Active

Also Published As

| Publication number | Publication date |

|---|---|

| JP2007322015A (en) | 2007-12-13 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| JP4890103B2 (en) | Hot water storage water heater | |

| JP3561239B2 (en) | Hot water storage tank | |

| JP2009047375A (en) | Hot water storage tank | |

| JP2007131329A (en) | Thermal insulation material for storage tank | |

| JP5195773B2 (en) | Hot water storage tank | |

| JP5958040B2 (en) | Hot water storage water heater | |

| JP5465161B2 (en) | Insulated hot water storage system | |

| JP5280153B2 (en) | Hot water storage tank apparatus and assembly method thereof | |

| JP4864118B2 (en) | Induction heating cooker | |

| JP5555611B2 (en) | Insulated hot water storage system | |

| JP5835042B2 (en) | Hot water storage water heater | |

| JP4262223B2 (en) | Hot water storage tank | |

| JP2006204447A (en) | Heated toilet seat | |

| JP6334425B2 (en) | Hot water storage water heater and method of assembling hot water storage water heater | |

| JP6447191B2 (en) | Hot water storage water heater | |

| JP4894364B2 (en) | Water heater | |

| JP7485198B2 (en) | Storage water heater and its manufacturing method | |

| JP2006064339A (en) | Hot-water storage type water heater | |

| JP7009970B2 (en) | Water heater | |

| JP5327213B2 (en) | Hot water storage tank unit | |

| JP2007333257A (en) | Hot water supply apparatus | |

| JP7206943B2 (en) | Storage hot water heater | |

| JP6252368B2 (en) | Hot water storage water heater | |

| JP2019013440A (en) | Toilet seat device | |

| JP2007278652A (en) | Hot water supplier |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| A521 | Request for written amendment filed |

Free format text: JAPANESE INTERMEDIATE CODE: A523 Effective date: 20081104 |

|

| A621 | Written request for application examination |

Free format text: JAPANESE INTERMEDIATE CODE: A621 Effective date: 20081104 |

|

| A977 | Report on retrieval |

Free format text: JAPANESE INTERMEDIATE CODE: A971007 Effective date: 20110422 |

|

| A131 | Notification of reasons for refusal |

Free format text: JAPANESE INTERMEDIATE CODE: A131 Effective date: 20110510 |

|

| A521 | Request for written amendment filed |

Free format text: JAPANESE INTERMEDIATE CODE: A523 Effective date: 20110621 |

|

| TRDD | Decision of grant or rejection written | ||

| A01 | Written decision to grant a patent or to grant a registration (utility model) |

Free format text: JAPANESE INTERMEDIATE CODE: A01 Effective date: 20111213 |

|

| A01 | Written decision to grant a patent or to grant a registration (utility model) |

Free format text: JAPANESE INTERMEDIATE CODE: A01 |

|

| A61 | First payment of annual fees (during grant procedure) |

Free format text: JAPANESE INTERMEDIATE CODE: A61 Effective date: 20111214 |

|

| R150 | Certificate of patent or registration of utility model |

Free format text: JAPANESE INTERMEDIATE CODE: R150 Ref document number: 4890103 Country of ref document: JP Free format text: JAPANESE INTERMEDIATE CODE: R150 |

|

| FPAY | Renewal fee payment (event date is renewal date of database) |

Free format text: PAYMENT UNTIL: 20141222 Year of fee payment: 3 |

|

| R250 | Receipt of annual fees |

Free format text: JAPANESE INTERMEDIATE CODE: R250 |

|

| R250 | Receipt of annual fees |

Free format text: JAPANESE INTERMEDIATE CODE: R250 |

|

| R250 | Receipt of annual fees |

Free format text: JAPANESE INTERMEDIATE CODE: R250 |

|

| R250 | Receipt of annual fees |

Free format text: JAPANESE INTERMEDIATE CODE: R250 |

|

| R250 | Receipt of annual fees |

Free format text: JAPANESE INTERMEDIATE CODE: R250 |

|

| R250 | Receipt of annual fees |

Free format text: JAPANESE INTERMEDIATE CODE: R250 |

|

| R250 | Receipt of annual fees |

Free format text: JAPANESE INTERMEDIATE CODE: R250 |

|

| R250 | Receipt of annual fees |

Free format text: JAPANESE INTERMEDIATE CODE: R250 |

|

| R250 | Receipt of annual fees |

Free format text: JAPANESE INTERMEDIATE CODE: R250 |