JP4885705B2 - Harness connector - Google Patents

Harness connector Download PDFInfo

- Publication number

- JP4885705B2 JP4885705B2 JP2006354756A JP2006354756A JP4885705B2 JP 4885705 B2 JP4885705 B2 JP 4885705B2 JP 2006354756 A JP2006354756 A JP 2006354756A JP 2006354756 A JP2006354756 A JP 2006354756A JP 4885705 B2 JP4885705 B2 JP 4885705B2

- Authority

- JP

- Japan

- Prior art keywords

- wire terminal

- holder

- electric wire

- harness

- terminal

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Active

Links

Images

Description

本発明は、例えば自動車のハーネス回路に使用するハーネス接続体に関するものである。 The present invention relates to a harness connector used for a harness circuit of an automobile, for example.

自動車のハーネス回路においては、幹線から複数の枝線を分岐する必要が屡々ある。そのために従来では、幹線の一部の被覆を剥ぎ取り、露出した導体に枝線を圧着加工し分岐するスプライスジョイント方式と、幹線の端末部に回路分岐用コネクタを配し、幹線、枝線共に汎用コネクタ及び圧着端子を使用して分岐加工する例えば特許文献1に記載のジョイントコネクタ方式との2通りの方式が多く用いられている。

In an automobile harness circuit, it is often necessary to branch a plurality of branch lines from a trunk line. Therefore, conventionally, a part of the trunk line is stripped, a splice joint method that branches by crimping the branch line to the exposed conductor, and a circuit branch connector is arranged at the terminal part of the trunk line. For example, two types of methods such as a joint connector method described in

前者のスプライスジョイント方式では、電線を1〜3本毎に圧着加工しなければならず、それらの加工後の状態では作業性が非常に悪いという問題があり、また製造ライン上で圧着加工することが困難なので、ライン生産には不向きである。 In the former splice joint method, one to three electric wires must be crimped, and there is a problem that workability is very poor in the state after the machining, and crimping is performed on the production line. Is difficult for line production.

そこで、このスプライスジョイント方式の問題点を解決するものとして、後者のジョイントコネクタ方式が開発されている。このジョイントコネクタ方式では、ハーネス製造ライン上でのジョイント加工が可能となるため、スプライスジョイント方式と比較して生産効率が向上し、ハーネス回路の修正にも対応可能である。しかし、コネクタ及び嵌合する相手側汎用コネクタ、バスバー、電線端子などの部品点数が多くなることから、ハーネス回路の組立には時間がかかるのが実状である。 Therefore, the latter joint connector system has been developed as a solution to the problems of the splice joint system. This joint connector method enables joint processing on the harness production line, so that the production efficiency is improved as compared with the splice joint method, and it is possible to cope with the modification of the harness circuit. However, since the number of components such as the connector and the mating general-purpose connector, bus bar, and electric wire terminal to be increased increases, it takes a long time to assemble the harness circuit.

特に、特許文献1に開示されているジョイントコネクタを使用したワイヤハーネスでは、ジョイントコネクタが大きいために、分岐すべき個所で分岐することができない。従って、ジョイントコネクタを収容できるスペースがある個所まで電線を延長しなければならず、ワイヤハーネスの小型化に反している。

In particular, in the wire harness using the joint connector disclosed in

つまり、ジョイントコネクタ方式においても、省スペース化、更なる作業性の向上、構造の簡素化、円部の防水化など、解決しなければならない課題が多々ある。 In other words, the joint connector system also has many problems that need to be solved, such as space saving, further improvement of workability, simplification of the structure, and waterproofing of the circular portion.

本発明の目的は、上述の課題を解決し、製造し易くワイヤハーネスの組立性に優れたハーネス接続体を提供することにある。 The objective of this invention is providing the harness connection body which was easy to manufacture and was excellent in the assembly property of a wire harness which solves the above-mentioned subject.

上述の目的を達成するための本発明に係るハーネス接続体の技術的特徴は、複数の電線端子挿入口を有する外部ホルダと、該外部ホルダに設けた入口部から挿入して前記外部ホルダ内で使用し、前記電線端子挿入口と連通する電線端子保持孔を有すると共に、これらの電線端子保持孔と内部で交叉するピン端子挿入孔を有する内部ホルダと、一端に接続部を有すると共に中間部に位置決めのための係止部を有し更に他端に電線を接続し前記接続部を前記電線端子挿入口を経て前記内部ホルダの電線端子保持孔内に挿入する電線端子と、前記外部ホルダの入口部から前記内部ホルダのピン端子挿入孔に挿入することにより前記内部ホルダ内の前記電線端子の接続部の接点に接触し前記電線端子同士を電気接続するピン端子とから成り、前記内部ホルダの電線端子保持孔には前記電線端子を保持する可動の保持板を設け、該保持板に前記電線端子の係止部と係合する係止部を設けたことにある。 Technical characteristics of the harness connector according to the present invention for achieving the above object includes an external holder having a plurality of wire terminal insertion openings, in the insertion to the outer holder from the inlet portion provided in the outer holder And having an electric wire terminal holding hole communicating with the electric wire terminal insertion port, an internal holder having a pin terminal insertion hole intersecting with the electric wire terminal holding hole, and having a connecting portion at one end and an intermediate portion A wire terminal having a locking portion for positioning, further connecting an electric wire to the other end, and inserting the connection portion into the wire terminal holding hole of the internal holder through the wire terminal insertion port, and an inlet of the external holder It becomes a by inserting the pin terminal insertion hole of the inner holder from parts in contact with the contacts of the connecting portion of the wire terminal in the inner holder the wire terminals to each other and a pin terminal electrically connected to the internal The wire terminal holding holes of the holder is provided a holding plate of the movable holding the wire terminal, in providing the locking portion engages the engaging portion of the wire terminal in the holding plate.

本発明に係るハーネス接続体によれば、内部ホルダを外部ホルダ内に入れ、電線端子を外部ホルダの電線端子挿入口を介して内部ホルダに挿入して位置決めし、内部ホルダ内でピン端子により電線端子同士を導通し、電気的接続を行う。また、電線端子の取り外しが可能で、電線端子の再組換えが可能となる。 According to the harness connector according to the present invention, the inner holder is placed in the outer holder, the electric wire terminal is inserted into the inner holder through the electric wire terminal insertion port of the outer holder and positioned, and the electric wire is connected by the pin terminal in the inner holder. Conducts electrical connection between terminals. Moreover, the electric wire terminal can be removed, and the electric wire terminal can be recombined.

更に、小型化によりワイヤハーネス中での設置個所が限定されず、任意の個所に配置することができ、電線を延長しなくとも回路配線を行うことができる。 Furthermore, the installation location in the wire harness is not limited due to the miniaturization, and the wiring harness can be arranged at an arbitrary location, and circuit wiring can be performed without extending the electric wire.

特に、自動車のハーネス回路に使用すれば、従来のジョイント構造よりも格段に接続構造がコンパクトになり、ワイヤハーネス作業時間が短縮化される。 In particular, when used in a harness circuit of an automobile, the connection structure becomes much more compact than the conventional joint structure, and the wire harness working time is shortened.

本発明を図示の実施例に基づいて詳細に説明する。

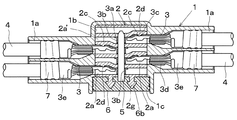

図1の分解斜視図に示すように、ハーネス接続体は複数の電線端子挿入口1aを有する直方体状の外部ホルダ1と、電線端子保持孔2a、ピン端子挿入孔2bを有する内部ホルダ2と、前端の接続部3aに筒状接点3bを設け、後端に電線4を接続した複数の電線端子3と、棒状のスルーピンタイプのピン端子5と、合成ゴムから成る防水部材6とにより構成されている。

The present invention will be described in detail based on the embodiments shown in the drawings.

As shown in the exploded perspective view of FIG. 1, the harness connection body includes a rectangular parallelepiped

外部ホルダ1には、左右両側から中央方向に向けて、例えば2個ずつの円形断面を有する電線端子挿入口1aが形成され、その内部に内部ホルダ2を内挿する空間部1bが設けられ、更に例えば下面に内部ホルダ2を挿入するための開口部1cが設けられている。

The

外部ホルダ1として使用する材料としては、例えば熱可塑性合成樹脂が適用され、中でも熱変形温度が高く、高剛性、電気絶縁特性、機械的特性の点で、ポリブチレンテレフタレート(PBT)やポリプロピレン(PP)などが好適である。また、縦横の大きさは使用する電線4の本数や径などにより適宜決定すればよいが、長さは通常では20mm〜150mm程度である。この外部ホルダ1の製造は、所定の金型を用いて熱可塑性樹脂を射出成形させて製作する方法を採用することが一般的である。

As a material used as the

内部ホルダ2は略直方体の形状とされ、図2の断面図にも示すように、外部ホルダ1の空間部1b内に収納した場合に、電線端子挿入口1aと連通し、電線端子3の接続部3aを挿入する電線端子保持孔2aが水平方向に設けられている。また、この電線端子保持孔2aと内部において交叉するピン端子挿入孔2bは、上下方向に向けて形成されている。なお、2a’は電線端子保持孔2aの挿入側と反対側の開口を示している。各電線端子保持孔2a内の上側には先端部が可動とされる可動保持板2cが形成され、可動保持板2cの下面には電線端子3を位置決めするための係止爪2dが設けられている。

The

また内部ホルダ2には、可動保持板2cを押し上げるために、後述する治具を挿入する溝部2eが、内部ホルダ2の電線端子保持孔2aの両入口側の入口部近傍の両側にそれぞれ設けられている。そして、各可動保持板2cの両側部には操作片2fが側方に突出され、これらの操作片2fは上下の可動保持板2c同士で前後にずれて形成されている。

In addition, the

更に、内部ホルダ2の下部には防水部材6を係止するための例えば2個の鉤状の係止突起2gが下方に向けて突出されている。内部ホルダ2の外面の片側にリブ2hが形成され、他側にはリブが設けられておらず、外部ホルダ1の内部ホルダ2を挿入する空間部1bには、リブ2hを受け入れる溝部が形成されている。

Further, for example, two hook-

この内部ホルダ2の材料は外部ホルダ1と同等でよく、射出成形により製作することが好ましい。また、内部形状が複雑な場合には、複数個に分割して製作し、使用時に接着したり嵌め合わせて形成することができる。

The material of the

電線端子3は1枚の導電金属板を打抜いて形成されており、前端の舌片状の接続部3aには短円筒状に絞り加工された筒状接点3bが下方に向けて設けられている。更に中間部には、内部ホルダ2の係止爪2dに嵌合するための係止孔3cが設けられ、後端に導体圧着部3d、被覆圧着部3eが設けられている。導体圧着部3dにより電線4の導体が圧着して接続され、電線4には防水のために合成ゴムから成る筒状のシール部材7が挿着され、その一部は固定のために電線被覆と共に被覆圧着部3eにより圧着固定されている。

The

この電線端子3は銅板又は銅合金板から所定の形状に打抜き成形したものに、Sn鍍金をしたもの、又はSn鍍金した銅板又は銅合金板を所定の形状に打抜き成形したものを使用すればよい。材質は強度と導電性の点で黄銅が好ましく、更にはSn鍍金することで耐食性が向上し、かつピン端子5との接点との導電性が得易くなる点で好適である。

The

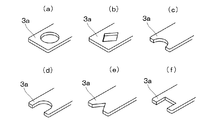

筒状接点3bはピン端子5と接触することで導通する形状であればよく、何れの側からもピン端子5を挿入できるように、筒状接点3bの基部及び先端にテーパ状のガイドを設けることが望ましい。また、接続部3aに設ける接点3bは、実施例のような円筒状でなくとも、図3に示すような(a)円孔状、(b)多角形孔の孔部(c)半円状、(d)U字状、(e)V字状、(f)四角状の切抜きであってもよい。しかし、導電性、接続の持続性等を考慮すると、円筒状、孔状が好ましい。

The

電線4は導体の外周に絶縁層を被覆した絶縁電線が適用され、公知の電線径のものが適用できる。導体は従来から自動車ハーネス回路に使用される軟銅線や硬銅線の撚線、又は引張強度を維持し、線径を小さくした例えばCu−Sn合金線などの銅合金線の撚線や単線が適用される。また、絶縁層には従来から公知の絶縁材料が適用され、中でも環境対策としてノンハロゲンの絶縁材料を絶縁層に適用することが環境対策の面で好適である。

As the

また、電線4の導体と電線端子3との導体接続は、公知のかしめ、溶接、ハンダ付け、圧着などが適用されるが、導電性、接続性、得られる接続強度の点で、実施例のような導体圧着部3dによる圧着接続が好適である。

The conductor connection between the conductor of the

ピン端子5は内部ホルダ2のピン端子挿入孔2bに挿入し、複数の電線端子3の接続部3a同士を導通させるための導電金属製の棒状部材であり、断面形状としては円形、三角形、四角形、多角形などが挙げられる。しかし、製造が容易で、挿入する際に大きな力が必要としない点、かつ安定して確実な導通が得易いということで、断面四角形が好適であり、この場合の電線端子3の接点形状は円筒状又は円孔状が好適である。

The

ピン端子5は例えば1枚の導電金属板を折曲して折り畳むことにより、図4に示すような断面略四角形が得られるので、その後に先端部をプレス又は切削などにより錐状とすることができる。このような方法で作製することで、断面積の小さなピン端子5でも、湾曲したり折損することが少なくなる。

For example, the

また、ピン端子5の硬さを接続部3aよりも硬くすることで、電線端子3の接続部3aの側を変形させながら挿入することが好ましい。このピン端子5の硬さ及び接続部3aの硬さは、加工、熱処理や材料の選択で適宜に調整することもできる。更に、筒状接点3bに確実に挿入させる点で、先端部を円錐形、角錐形又は円錐台形、角錐台形などの錐状台形とすることが好適である。

Moreover, it is preferable to insert the

接続部3aの接点が筒形状又は円形状であって、その内径がd1で、ピン端子5の横断面形状を略四角形とし、その対角線の長さをxとすると、d1<xであることが好ましい。また、ピン端子5の横断面を円形状とし、接続部3aの接点を四角形の一辺の長さをd1とした孔部とすることもできる。この場合のピン端子5の円形外径をd2とした場合には、d1<d2であることが好ましい。

When the contact of the connecting

防水部材6は外部ホルダ1の開口部1cに嵌まり込む直方体とされ、周囲に波形部6aが形成されている。また、防水部材6の上面には内部ホルダ2の係止突起2gが挿入される係止孔6bが設けられている。

The

図5は組立状態の断面図を示し、先ず外部ホルダ1の空間部1bに内部ホルダ2を挿入すると、内部ホルダ2は図示しない係合機構により空間部1b内に固定される。この挿入に際しては、前後面で非対称に配置されたリブ2hが空間部1bの溝部に嵌合することにより、挿入方向を誤ることはない。

FIG. 5 shows a sectional view of the assembled state. First, when the

続いて、外部ホルダ1に設けた計4個の電線端子挿入口1aから電線端子3を挿入すると、例えば右上の電線端子3の接続部3aは、内部ホルダ2内にそれぞれ可動保持板2cを押し上げながら挿入される。更に押し込み、係止孔3cに内部ホルダ2の係止爪2dが嵌合すると、右下の電線端子3のように可動保持板2cが元の位置に復元する。これにより、電線端子3は所定位置に位置決めされ、接続部3aの筒状接点3bの中心がピン端子挿入孔2bの中心軸に合致することになる。

Subsequently, when the

なお実施例では、筒状接点3bが内部ホルダ2の中心で積み重なるために、電線端子挿入口1aは左右で段違いに形成されている。電線端子3が内部ホルダ2内に挿入されると、電線端子3に設けたシール部材7が外部ホルダ1の電線端子挿入口1aの内壁に密着し、外部からの浸水が防止される。

In the embodiment, since the

接続部3aを電線端子挿入口1a内に挿入するに際して、筒状接点3bが上下何れの側を向いているかは重要である。つまり、各接続部3aを任意の向きで挿入すると、内部において整然と所定位置に位置付けすることができなくなるので、電線端子挿入口1aの入口部に筒状接点3bの向きを表示することなどを必要とする場合がある。

When the connecting

このようにして電線端子3を挿着した後に、図6に示すように、内部ホルダ2のピン端子挿入孔2bに、例えば挿入治具を用いてピン端子5を挿入すると、ピン端子5はそれぞれの電線端子3の筒状接点3bを挿通することにより接触し、各電線端子3同士が導通される。

After inserting the

更に、防水のために防水部材6を開口部1cに挿入すると、防水部材6の係止孔6bに内部ホルダ2の係止突起2gが嵌入し、防水部材6の脱落が防止され、波形部6aにより外部ホルダ1内に水が浸入することはない。防水部材6による閉止を更に確実にするために、開口部1cの防水部材6の上から合成樹脂製の板体を嵌合することもできる。なお、図7は図6と同じ状態の外部ホルダ1のみを断面とした側面図である。

Further, when the

このような構成の実施例においては、外部ホルダ1の内部には、電線4に装着したシール部材7及び防水部材6により水の浸入が阻止され、このハーネス接続体内を防水構造とすることができる。電線端子3を挿入しない電線端子挿入口1aについては、合成ゴムなどから成る盲栓により封止すれば、内部に水が浸入することはない。なお、防水構造としない場合もあり得るので、この場合にはシール部材7を使用せず、防水部材6の代りに合成樹脂による板体を開口部1cに嵌合すればよい。

In the embodiment having such a configuration, the entry of water is prevented inside the

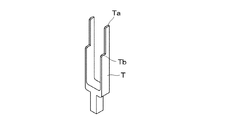

図8は内部ホルダ2の操作片2fを押し上げる治具Tの斜視図を示し、治具Tは2つの端部Ta、Tbを有し、また操作片2fは上下の可動保持板2cで前後にずれているために、これらの操作片2fを治具Tにより同時に操作して、2つの可動保持板2cを同時に押し上げ可能とされている。

FIG. 8 shows a perspective view of a jig T that pushes up the

図9は内部ホルダ2に対する治具Tの操作説明図であり、外部ホルダ1、電線端子3の図示は省略している。電線端子3を取り外すために可動保持板2cの操作片2fを治具Tを内部ホルダ2の溝部2eから挿入して押し上げる。即ち、回路の組換え等のために、電線端子3を組立体から取り外すには、防水部材6を外してからピン端子5を抜き取り、電線端子3を内部ホルダ2から取り外す必要がある。

FIG. 9 is an explanatory diagram of the operation of the jig T with respect to the

開口部1cを介して治具Tの端部Ta、Tbを溝部2eに下方から挿し込み、図9の左側に示すように、上下の可動保持板2cを操作片2fを介して同時に押し上げる。この押し上げにより、電線端子3の係止孔3cから係止爪2dが外れ、電線4を引いて2個の電線端子3を同時に外部に引き出すことができる。残りの2個の電線端子3については、他側の溝部2eに治具Tを挿し込んで同様に引き出せばよい。

The ends Ta and Tb of the jig T are inserted into the

実施例では、可動保持板2cに係止爪2dを設け、電線端子3に係止孔3cを設けたが、これらを逆にして、可動保持板2cに凹部を設け、電線端子3に凸部を設けるようにしてもよい。また、外部ホルダ1に電線端子挿入口1aを計4個設けて、4個の電線端子3を挿入したが、更に多数或いは少数の電線端子挿入口1aを設けて回路を設計することができる。

In the embodiment, the latching

1 外部ホルダ

1a 電線端子挿入口

1b 空間部

1c 開口部

2 内部ホルダ

2a 電線端子保持孔

2b ピン端子挿入孔

2c 可動保持板

2d 係止爪

2e 溝部

2f 操作片

2h リブ

3 電線端子

3a 接続部

3b 筒状接点

3c 係止孔

3d 導体圧着部

3e 被覆圧着部

4 電線

5 ピン端子

6 防水部材

7 シール部材

DESCRIPTION OF

Claims (5)

Priority Applications (6)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| JP2006354756A JP4885705B2 (en) | 2006-12-28 | 2006-12-28 | Harness connector |

| CN200780048301XA CN101569065B (en) | 2006-12-28 | 2007-09-12 | Connection member and harness connector |

| US12/520,980 US7867001B2 (en) | 2006-12-28 | 2007-09-12 | Connection member and harness connector |

| PCT/JP2007/067717 WO2008081620A1 (en) | 2006-12-28 | 2007-09-12 | Connection member and harness connector |

| EP07807124.8A EP2101376B1 (en) | 2006-12-28 | 2007-09-12 | Connection member and harness connector |

| KR1020097012789A KR101352706B1 (en) | 2006-12-28 | 2007-09-12 | Connection member and harness connector |

Applications Claiming Priority (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| JP2006354756A JP4885705B2 (en) | 2006-12-28 | 2006-12-28 | Harness connector |

Publications (3)

| Publication Number | Publication Date |

|---|---|

| JP2008166136A JP2008166136A (en) | 2008-07-17 |

| JP2008166136A5 JP2008166136A5 (en) | 2010-12-16 |

| JP4885705B2 true JP4885705B2 (en) | 2012-02-29 |

Family

ID=39695322

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| JP2006354756A Active JP4885705B2 (en) | 2006-12-28 | 2006-12-28 | Harness connector |

Country Status (1)

| Country | Link |

|---|---|

| JP (1) | JP4885705B2 (en) |

Families Citing this family (2)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| JP5520565B2 (en) * | 2009-10-15 | 2014-06-11 | 矢崎総業株式会社 | Power interrupting structure and power distributor |

| JP7473439B2 (en) | 2020-09-30 | 2024-04-23 | 矢崎総業株式会社 | connector |

Family Cites Families (5)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| JPH0427587A (en) * | 1990-05-24 | 1992-01-30 | Dainippon Printing Co Ltd | Manufacture of thermal transfer sheet |

| JP2813716B2 (en) * | 1993-02-24 | 1998-10-22 | 矢崎総業株式会社 | Connector terminal release structure |

| JP3266064B2 (en) * | 1997-09-02 | 2002-03-18 | 住友電装株式会社 | Continuity connector |

| JP2005071614A (en) * | 2003-08-21 | 2005-03-17 | Ryosei Electro-Circuit Systems Ltd | Joint connector |

| JP2005141954A (en) * | 2003-11-04 | 2005-06-02 | Sumitomo Wiring Syst Ltd | Waterproof case of joint connector |

-

2006

- 2006-12-28 JP JP2006354756A patent/JP4885705B2/en active Active

Also Published As

| Publication number | Publication date |

|---|---|

| JP2008166136A (en) | 2008-07-17 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| KR101352706B1 (en) | Connection member and harness connector | |

| JP4898296B2 (en) | Connecting member | |

| JP4833826B2 (en) | Connection member and harness connection body using the member | |

| JP5140407B2 (en) | Joint connector | |

| US7883361B2 (en) | Connection member and harness connection body using the connection member | |

| JP2013004347A (en) | Shield connector | |

| JP5390792B2 (en) | Connecting member | |

| JP4885704B2 (en) | Harness connector | |

| JP4885705B2 (en) | Harness connector | |

| JP2014075245A (en) | Electric wire, and connection structure of the same | |

| JP4800066B2 (en) | Connecting member | |

| JP2011060426A (en) | Connector | |

| JP7144290B2 (en) | Terminal connection structure | |

| JP2018181555A (en) | Connector | |

| JP4813973B2 (en) | Connecting member | |

| JP4695013B2 (en) | Waterproof joint connector | |

| JP4933246B2 (en) | Connection member and harness connection body using the connection member | |

| JP4898295B2 (en) | Connecting member | |

| KR100922154B1 (en) | Connector | |

| JP2011060427A (en) | Connector | |

| JP2020064751A (en) | Terminal structure | |

| JP2000091004A (en) | Connector | |

| KR20090105164A (en) | Connector |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| A621 | Written request for application examination |

Free format text: JAPANESE INTERMEDIATE CODE: A621 Effective date: 20091029 |

|

| A521 | Written amendment |

Free format text: JAPANESE INTERMEDIATE CODE: A523 Effective date: 20100225 |

|

| A521 | Written amendment |

Free format text: JAPANESE INTERMEDIATE CODE: A523 Effective date: 20101026 |

|

| A131 | Notification of reasons for refusal |

Free format text: JAPANESE INTERMEDIATE CODE: A131 Effective date: 20110830 |

|

| A521 | Written amendment |

Free format text: JAPANESE INTERMEDIATE CODE: A523 Effective date: 20111007 |

|

| TRDD | Decision of grant or rejection written | ||

| A01 | Written decision to grant a patent or to grant a registration (utility model) |

Free format text: JAPANESE INTERMEDIATE CODE: A01 Effective date: 20111122 |

|

| A01 | Written decision to grant a patent or to grant a registration (utility model) |

Free format text: JAPANESE INTERMEDIATE CODE: A01 |

|

| A61 | First payment of annual fees (during grant procedure) |

Free format text: JAPANESE INTERMEDIATE CODE: A61 Effective date: 20111208 |

|

| FPAY | Renewal fee payment (event date is renewal date of database) |

Free format text: PAYMENT UNTIL: 20141216 Year of fee payment: 3 |

|

| R150 | Certificate of patent or registration of utility model |

Ref document number: 4885705 Country of ref document: JP Free format text: JAPANESE INTERMEDIATE CODE: R150 Free format text: JAPANESE INTERMEDIATE CODE: R150 |

|

| FPAY | Renewal fee payment (event date is renewal date of database) |

Free format text: PAYMENT UNTIL: 20141216 Year of fee payment: 3 |

|

| S111 | Request for change of ownership or part of ownership |

Free format text: JAPANESE INTERMEDIATE CODE: R313113 |

|

| FPAY | Renewal fee payment (event date is renewal date of database) |

Free format text: PAYMENT UNTIL: 20141216 Year of fee payment: 3 |

|

| R350 | Written notification of registration of transfer |

Free format text: JAPANESE INTERMEDIATE CODE: R350 |

|

| S531 | Written request for registration of change of domicile |

Free format text: JAPANESE INTERMEDIATE CODE: R313531 |

|

| R350 | Written notification of registration of transfer |

Free format text: JAPANESE INTERMEDIATE CODE: R350 |