JP4798570B2 - Joint structure - Google Patents

Joint structure Download PDFInfo

- Publication number

- JP4798570B2 JP4798570B2 JP2001079964A JP2001079964A JP4798570B2 JP 4798570 B2 JP4798570 B2 JP 4798570B2 JP 2001079964 A JP2001079964 A JP 2001079964A JP 2001079964 A JP2001079964 A JP 2001079964A JP 4798570 B2 JP4798570 B2 JP 4798570B2

- Authority

- JP

- Japan

- Prior art keywords

- joint structure

- water stop

- opening

- joint

- stop plate

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Expired - Fee Related

Links

Images

Landscapes

- Building Environments (AREA)

Description

【0001】

【発明の属する技術分野】

本発明は、止水板同士を連結するために用いる継手構造体および該継手構造体を用いる止水板の連結方法に関する。

【0002】

【従来の技術】

コンクリート構造物を施工する場合、構造物を構成するコンクリートを一度に打設することは困難であり、すでに固まったコンクリートに新しいコンクリートを打ち込んで一体化する打継ぎが行われている。この打継ぎによって生じる打継部は、曲げ、剪断、引張りなどの強度上、防水機能上、耐久性上に問題があるために、コンクリートの乾燥収縮や温度変化による体積変化に対して変形が行えるように伸縮目地が設けられている。特に止水を要するコンクリート構造物の伸縮目地や打継部には、漏水を防止するために止水板が設けられている。止水板は、両端がコンクリート構造物に埋め込まれ、中央部が伸縮目地や打設部となるように設けられる。従来、止水板は、銅製またはステンレス製などの金属板が用いられていたが、近年においては、十分な変形能力や完全な復元力を有し、水圧に耐え、コンクリートに密着して水みちのつかない、耐久性の良い、施工が容易といった点からゴム製のものや塩化ビニル樹脂製のものが用いられている。また、上述した曲げなどの伸縮目地の変形に応じて止水板も変形できるように複雑な形状とされている。

【0003】

伸縮目地や打継部に設けられる止水板同士の連結においては、単なる重ね合わせでは漏水の原因となりやすいために、止水板に銅板やステンレス板などの金属板を用いる場合においては突き合わせ溶接が行われている。また、上述したゴム製または塩化ビニル樹脂製の止水板を使用する場合においては、互いの止水板の先端部を溶着させることにより行われている。

【0004】

しかしながら、上述した複雑な形状においては、止水板同士の面合わせが難しく、さらに溶接や溶着を行うことは困難であった。こうして溶接または溶着された止水板においては、溶接不良または溶着不良を招いている場合が多いといった問題があった。

【0005】

【発明が解決しようとする課題】

本発明は、上述した止水板の施工に関し、溶着や溶接を行うことなく、適切に止水板同士を連結することができ、高い止水性を付与することができる継手構造体および該継手構造体を用いる連結方法を提供することを目的とする。

【0006】

【課題を解決するための手段】

本発明の上記目的は、本発明の継手構造体および該継手構造体を用いる連結方法を提供することにより達成される。

【0007】

本発明によれば、構造物の目地や打継部に設けられる、V字形を連ねた断面形状を有する止水板を互いに連結するために用いられる継手構造体であって、平坦な外面を有する直方体状のものとされ、両端に前記V字形を連ねた断面形状と同じ形状で、かつ前記止水板を嵌合可能な大きさとされた開口と、前記開口と同じ形状かつ同じ大きさとされたまま挿嵌方向に形設された前記止水板を挿嵌させるための該開口に連続する嵌合部とを備える継手構造体が提供される。

【0008】

本発明によれば、構造物の目地や打継部に設けられる、断面が矩形とされた平板の両端部に半円筒および該半円筒の内側に角柱が設けられ、中央部に中空とされた半円筒が設けられた形状とされた止水板を互いに連結するために用いられる継手構造体であって、平坦な外面を有する直方体状のものとされ、両端に前記止水板の断面形状と同じ形状で、かつ前記止水板を嵌合可能な大きさとされた開口と、前記開口と同じ形状かつ同じ大きさとされたまま挿嵌方向に形設された前記止水板を挿嵌させるための該開口に連続する嵌合部とを備える継手構造体が提供される。

【0009】

本発明によれば、前記継手構造体は、ゴムまたは塩化ビニル樹脂により製造される継手構造体が提供される。

【0011】

本発明によれば、前記止水板を挿嵌した前記開口が、コーキング材または接着剤を用いて封止される継手構造体が提供される。

【0012】

本発明によれば、前記コーキング材または接着剤は、エポキシ樹脂、樹脂モルタル、レジンコンクリート、セメントモルタル、コンクリートから選択される継手構造体が提供される。

【0013】

【発明の実施の形態】

以下、本発明を図面を参照して詳細に説明する。図1は、本発明の継手構造体を用いて止水板を連結し、連結した止水板を伸縮目地に配設したところを示した図である。図1に示す伸縮目地1は、構造物2のコンクリート施工する際、所定位置に設けられ、コンクリートの乾燥収縮や温度による体積変化による変形を可能にしている。また、伸縮目地1には、目地材が詰め込まれ隙間が埋められている。図1に示す止水板3は、構造物2の伸縮目地1に跨るように両端がコンクリート内部に埋め込まれるように配設され、伸縮目地1に詰め込まれた目地材の隙間を通して流れる水を止水するために用いられている。また、図1に示す止水板3は、鉄筋4の間に配設され、コンクリートとの密着を良好にするために断面に凹凸が設けられて付着面積が大きくされている。また、止水板3同士は、本発明の継手構造体5により連結され、止水板3と同様に伸縮目地1を跨ぐように設けられている。

【0014】

図1に示す実施の形態では、伸縮目地1が水平方向に設けられていて、伸縮目地1に跨るように垂直方向に止水板3が設置されている。また、止水板3は、鉄筋4の間に配置されるとともに別の止水板3と継手構造体5を用いて連結され、まわりをコンクリートで固定されている。また、伸縮目地1には、セメントペースト、モルタル、アスファルト、樹脂モルタルなどの充填材が目地材として詰め込まれている。図1に示す本発明の継手構造体5は、両端に開口および嵌合部が設けられていて止水板3を挿嵌することにより互いに隣接する止水板3を連結することができるようになっている。以下、本発明の継手構造体5を、図2および図3に示す実施例を用いて詳細に説明する。

【0015】

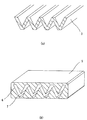

図2は、本発明の継手構造体の第1の実施例を示した図である。図2に示す継手構造体5は、止水板3同士を連結して隙間から漏水しないようにするために用いられる。図2(a)には、止水板3の一部を示し、図2(b)には、本発明の継手構造体5の第1の実施例を示す。図2(a)に示す止水板3は、V字形を連ねた断面形状をしていて、同じ断面形状でかつ同じ大きさとされたまま一方向に延ばされている。また、図2(b)に示す継手構造体5は、略矩形とされた断面の中央に図2(a)と同じ断面形状の開口6と、開口6に連続する開口6と同じ形状かつ同じ大きさのまま挿嵌方向に形設された嵌合部7が設けられている。

【0016】

図2(b)に示す嵌合部7は、所定の挿入長とされていて、止水板3が容易に抜けない長さとなっている。また、図2(b)に示す継手構造体5は、継手構造体5の裏側にも同様の開口6および嵌合部7が設けられていて、図2(a)に示す止水板3を挿嵌できるようになっている。したがって、止水板3と隣接する止水板3とを継手構造体5に挿嵌させることにより、止水板3と隣接する止水板3とを互いに連結させることができる。

【0017】

本発明の継手構造体5は、使用する止水板の材質によって金属製、塩化ビニル樹脂製、ゴム製といったものを用いることができる。近年においては、塩化ビニル樹脂製やゴム製の止水板が用いられており、本発明の継手構造体5においても適切に止水することができ、耐久性が良いものとして塩化ビニル樹脂製とすることができる。さらに、変形能力や水圧、水みちのつかないといった点においてゴム製とすることもできる。

【0018】

また、本発明の継手構造体5は、略矩形に限らず、いかなる形状のものでも用いることができる。本発明の継手構造体5の開口6は、上述した止水板3を挿入することができるのであればいかなる形状または大きさであっても良い。本発明の継手構造体5の嵌合部7は、止水板3を適切に挿嵌させることができ、止水板3が容易に抜けない挿入長とすることができる。また、挿入長は、止水板3と嵌合部7との隙間を通して漏水する水を止水するためには長いほど効果的であるが、施工性を考慮して適切な長さとすることができる。さらに、本発明の継手構造体5の嵌合部7は、異なる形状の止水板3を連結することができるように互いに異なる形状または大きさとされていても良い。

【0019】

図3は、本発明の継手構造体の第2の実施例を示した図である。図3に示す継手構造体5は、止水板3同士を連結して隙間から漏水しないようにするために用いられる。図3(a)には、止水板3の一部を示し、図3(b)には、本発明の継手構造体5の第2の実施例を示す。図3(a)に示す止水板3は、断面が矩形とされた平板に、両端部に半円筒が上下に設けられ、また角柱が上下に、さらに中央部が中空とされた半円筒が設けられた形状とされている。図3(b)に示す継手構造体5は、略矩形とされた断面の中央に図3(a)と同じ断面形状の開口6と、開口6に連続する開口6と同じ形状かつ同じ大きさのまま挿嵌方向に形設された嵌合部7が設けられている。

【0020】

図3(b)に示す嵌合部7は、所定の挿入長とされていて、止水板3が容易に抜けない長さとなっている。図3(b)に示す継手構造体5は、継手構造体5の裏側にも同様の開口6および嵌合部7が設けられていて、図3(a)に示す止水板3を挿嵌できるようになっている。これにより、裏側に設けられた同様の嵌合部7にも、隣接する止水板3を挿嵌させて止水板3と隣接する止水板3とを互いに連結させることができるようになっている。

【0021】

図4は、本発明の継手構造体により止水板を連結しているところを示した図である。図4に示す継手構造体5は、止水板3を挿入するための開口6と、止水板3を適切に挿嵌できる嵌合部7とが設けられている。また、継手構造体5には、裏側の面にも同様の嵌合部6が設けられ、隣接する止水板3が挿嵌できるようになっている。図4に示す実施の形態では、継手構造体5の一端の開口6に向けて止水板3を挿入し、止水板3を押し込むことによって、止水板3が嵌合部7に挿嵌されるようになっている。

【0022】

また、図4に示す継手構造物5の他端の開口6に向けて隣接する止水板3を挿入し、隣接する止水板3を押し込むこんで嵌合部7に挿嵌する。こうすることにより、止水板3と隣接する止水板3とは、継手構造体5により連結される。連結された止水板3を図1に示す伸縮目地1などに設置することにより、止水板3同士の隙間からの漏水も防止することができる。また、従来においては、止水板3同士を溶接や溶着などして隙間を無くしていたが、継手構造体5を用いる連結方法により容易に連結して漏水も防止することができる。

【0023】

また、止水板3を挿嵌した後に継手構造体5の開口6にコーキング材や接着剤を用いて封止することができる。本発明に用いることができるコーキング材としては、エポキシ樹脂、樹脂モルタル、レジンコンクリート、セメントモルタル、コンクリートなどを用いて止水板3と開口6との隙間を埋めることができる。また、エポキシ樹脂を原料とした接着材を用いて互いを接合させることで開口6または嵌合部7と止水板3との隙間を埋めることができる。本発明においては、上述したコーキング材や接着剤のほか隙間を埋めることができるのであればこれまで知られたいかなるものでも用いることができる。

【0024】

また、本発明においては、打継部に止水板3を配置する場合には、すでに打設されたコンクリートに止水板3を挿入できる溝を設けておき、止水板3を挿入して継手構造体5を用いて連結し、隙間を充填材などを用いてシールした後に打継することで止水板3を設置することができる。

【0025】

上述したように本発明の継手構造体および該継手構造体を用いる連結方法について説明してきたが、本発明においては、上述した実施の形態に限定されるわけではなく、使用する止水板に応じていかなる断面形状、大きさ、挿入長とされていても良い。また、使用する止水板の数に応じて必要な数の継手構造体を用いることができる。さらに、異なる止水板を用いて止水する場合には、異なる止水板を嵌合することのできる嵌合部を設けることができる。

【0026】

【発明の効果】

上述したように、本発明の継手構造体および該継手構造体を用いる連結方法を提供することにより、止水板の施工に関し、溶着や溶接を行うことなく、適切に止水板同士を連結することができ、高い止水性を確保することができる。また、本発明の継手構造体および該継手構造体を用いる連結方法を用いることにより、構造物に止水板を設置する作業が容易となり、作業の効率化を図ることができる。

【図面の簡単な説明】

【図1】 本発明の継手構造体を用いて止水板を連結し、連結した止水板を伸縮目地に配設したところを示した図。

【図2】 本発明の継手構造体の第1の実施例を示した図。

【図3】 本発明の継手構造体の第2の実施例を示した図。

【図4】 本発明の継手構造体により止水板を連結しているところを示した図。

【符号の説明】

1…伸縮目地

2…構造物

3…止水板

4…鉄筋

5…継手構造体

6…開口

7…嵌合部[0001]

BACKGROUND OF THE INVENTION

The present invention relates to a joint structure used for connecting water stop plates to each other and a method for connecting water stop plates using the joint structure.

[0002]

[Prior art]

When constructing a concrete structure, it is difficult to place concrete constituting the structure at a time, and jointing is performed in which new concrete is poured into solid concrete and integrated. The joint part produced by this joint has problems in terms of strength such as bending, shearing, and tensile, waterproof function, and durability, so it can be deformed against volumetric changes due to drying shrinkage of concrete and temperature changes. An expansion joint is provided. In particular, a water stop plate is provided at an expansion joint or joint of a concrete structure that requires water stop to prevent water leakage. The water stop plate is provided so that both ends are embedded in the concrete structure and the center portion becomes an expansion joint or a placement portion. Conventionally, a metal plate such as copper or stainless steel has been used as the water stop plate, but in recent years, it has sufficient deformability and complete restoring force, withstands water pressure, adheres to concrete, and has a water channel. Rubber and vinyl chloride resins are used because they are non-sticky, durable and easy to install. Moreover, it is set as the complicated shape so that a water stop board can also deform | transform according to deformation | transformation of expansion-contraction joints, such as the bending mentioned above.

[0003]

In the connection of water stop plates provided on expansion joints and joints, mere welding is likely to cause water leakage, so butt welding is required when using a metal plate such as a copper plate or stainless steel plate for the water stop plate. Has been done. Moreover, when using the water-stopping board made from the rubber or the vinyl chloride resin mentioned above, it is carried out by welding the front-end | tip part of each water-stopping board.

[0004]

However, in the complicated shape described above, it is difficult to match the surfaces of the water stop plates, and further, it is difficult to perform welding or welding. In the water stop plate welded or welded in this way, there is a problem that in many cases, poor welding or poor welding is caused.

[0005]

[Problems to be solved by the invention]

The present invention relates to the construction of the water stop plate described above, and can appropriately connect the water stop plates without performing welding or welding, and a joint structure capable of providing high water stop and the joint structure It aims at providing the connection method using a body.

[0006]

[Means for Solving the Problems]

The above object of the present invention is achieved by providing a joint structure of the present invention and a connecting method using the joint structure.

[0007]

According to the present invention , there is provided a joint structure used for connecting waterstop plates having cross-sectional shapes connected to each other, which are provided at joints and joint portions of a structure, and have a flat outer surface. It is a rectangular parallelepiped shape, has the same shape as the cross-sectional shape in which the V-shape is connected to both ends , and the size that can fit the water stop plate, and the same shape and the same size as the opening Mom joint structure and a fitting portion that is continuous with inserting direction Katachi設been the waterstop in the opening for which inserted is provided.

[0008]

According to the present invention , a semi-cylinder is provided at both ends of a flat plate having a rectangular cross section provided at a joint or a joint portion of a structure, and a prism is provided inside the semi-cylinder, and is hollow at the center. A joint structure used for connecting waterstop plates having a shape provided with a semi-cylinder to each other, and having a rectangular parallelepiped shape having a flat outer surface, and a cross-sectional shape of the waterstop plate at both ends the same shape, and an opening of the waterstop is a fittable size, in order to inserting the same shape and the waterstop that is Katachi設in inserting direction while being the same size as the opening There is provided a joint structure including a fitting portion continuous with the opening .

[0009]

According to the present invention , the joint structure is provided with a joint structure made of rubber or vinyl chloride resin.

[0011]

According to the present invention, the opening is inserted the waterstop is joint structure is provided that will be sealed with caulk or adhesive.

[0012]

According to the present invention , there is provided a joint structure in which the caulking material or adhesive is selected from epoxy resin, resin mortar, resin concrete, cement mortar, and concrete.

[0013]

DETAILED DESCRIPTION OF THE INVENTION

Hereinafter, the present invention will be described in detail with reference to the drawings. FIG. 1 is a view showing a state where a water stop plate is connected using the joint structure of the present invention, and the connected water stop plate is disposed on an expansion joint. The

[0014]

In the embodiment shown in FIG. 1, the

[0015]

FIG. 2 is a view showing a first embodiment of the joint structure of the present invention. The

[0016]

The

[0017]

The

[0018]

Further, the

[0019]

FIG. 3 is a view showing a second embodiment of the joint structure of the present invention. The

[0020]

The

[0021]

FIG. 4 is a view showing a state where the water stop plates are connected by the joint structure of the present invention. The

[0022]

Further, the adjacent

[0023]

Moreover, after inserting the

[0024]

Moreover, in this invention, when arrange | positioning the

[0025]

As described above, the joint structure of the present invention and the connecting method using the joint structure have been described. However, the present invention is not limited to the above-described embodiment, and depends on the water stop plate to be used. Any cross-sectional shape, size, and insertion length may be used. Moreover, a required number of joint structures can be used according to the number of the water stop plates to be used. Furthermore, when stopping water using a different water stop plate, a fitting portion capable of fitting different water stop plates can be provided.

[0026]

【The invention's effect】

As described above, by providing the joint structure of the present invention and a connection method using the joint structure, the water stop plates are appropriately connected to each other without performing welding or welding with respect to the construction of the water stop plates. And high water-stopping properties can be ensured. Further, by using the joint structure of the present invention and the connecting method using the joint structure, the work of installing the water stop plate on the structure becomes easy, and the work efficiency can be improved.

[Brief description of the drawings]

FIG. 1 is a view showing a state where a water stop plate is connected using the joint structure of the present invention, and the connected water stop plate is disposed on an expansion joint.

FIG. 2 is a view showing a first embodiment of the joint structure of the present invention.

FIG. 3 is a view showing a second embodiment of the joint structure of the present invention.

FIG. 4 is a view showing a state where a water stop plate is connected by the joint structure of the present invention.

[Explanation of symbols]

DESCRIPTION OF

Claims (5)

Priority Applications (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| JP2001079964A JP4798570B2 (en) | 2001-03-21 | 2001-03-21 | Joint structure |

Applications Claiming Priority (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| JP2001079964A JP4798570B2 (en) | 2001-03-21 | 2001-03-21 | Joint structure |

Publications (2)

| Publication Number | Publication Date |

|---|---|

| JP2002276045A JP2002276045A (en) | 2002-09-25 |

| JP4798570B2 true JP4798570B2 (en) | 2011-10-19 |

Family

ID=18936328

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| JP2001079964A Expired - Fee Related JP4798570B2 (en) | 2001-03-21 | 2001-03-21 | Joint structure |

Country Status (1)

| Country | Link |

|---|---|

| JP (1) | JP4798570B2 (en) |

Families Citing this family (2)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| KR200449777Y1 (en) | 2008-02-22 | 2010-08-09 | 이용빈 | Civil engineering index plate connection cap |

| JP6394287B2 (en) * | 2014-10-31 | 2018-09-26 | 住友金属鉱山株式会社 | Water stop plate, its connection, and concrete construction method using the water stop plate |

Family Cites Families (11)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| JPS5332173B2 (en) * | 1972-08-11 | 1978-09-07 | ||

| JPS6048504U (en) * | 1983-09-12 | 1985-04-05 | 旭電化工業株式会社 | Connection parts for water stop plate |

| JPS60102448A (en) * | 1983-11-07 | 1985-06-06 | 東海コンクリート工業株式会社 | Pole connecting method |

| JPH0213612U (en) * | 1988-07-11 | 1990-01-29 | ||

| JPH0418126U (en) * | 1990-06-05 | 1992-02-14 | ||

| JPH0726443B2 (en) * | 1990-07-26 | 1995-03-22 | 西武ポリマ化成株式会社 | Method and device for joining water stop plates |

| JPH0468102U (en) * | 1990-10-24 | 1992-06-17 | ||

| JP3133356B2 (en) * | 1991-02-07 | 2001-02-05 | 不二サッシ株式会社 | Handrail mounting method |

| JPH06305030A (en) * | 1993-04-22 | 1994-11-01 | Shinei Rubber Kogyo Kk | Connecting method for rubber materials |

| JP3359145B2 (en) * | 1994-02-25 | 2002-12-24 | 前田建設工業株式会社 | How to install the water stop plate |

| JPH0924549A (en) * | 1995-07-11 | 1997-01-28 | Seibu Polymer Corp | Connecting method for water cut-off plate and apparatus used therefor |

-

2001

- 2001-03-21 JP JP2001079964A patent/JP4798570B2/en not_active Expired - Fee Related

Also Published As

| Publication number | Publication date |

|---|---|

| JP2002276045A (en) | 2002-09-25 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| CN109356201B (en) | Interface waterproof structure of new and old concrete and interface waterproof treatment method | |

| US9879804B2 (en) | Duct coupler devices, systems, and related methods | |

| JP3793852B2 (en) | Method of joining concrete structures between blocks using precast concrete blocks | |

| JP4798570B2 (en) | Joint structure | |

| KR100805842B1 (en) | Concrete Structure Fittings and Installation Method | |

| JP3946477B2 (en) | Precast concrete board joining method | |

| KR102767391B1 (en) | Waterproof construction method and structure of PC wall joint using folded impermeabl plate | |

| KR100617507B1 (en) | Watertight Manhole | |

| JP4510999B2 (en) | Anticorrosion plate joint member and construction method using the same | |

| CN215802344U (en) | Novel concatenation formula stagnant water steel sheet | |

| CN107190869B (en) | Plugging piece for plugging during prefabricated double-T plate assembly and construction method thereof | |

| JP4656966B2 (en) | Joint structure of underground concrete structure and its construction method | |

| JP4537225B2 (en) | Flexible waterproof joint and its construction method | |

| CN211973946U (en) | Prefabricated waterproof coincide component and have its coincide wall | |

| US5737889A (en) | Device for sealing of concrete joints | |

| CN113981904A (en) | A water-stop installation structure and installation method between new and old concrete | |

| JP2868994B2 (en) | Concrete joint structure | |

| KR19990036482A (en) | Mesh structure of anticorrosive concrete structural member | |

| KR200330651Y1 (en) | Expantion joint filler device | |

| JPH0949204A (en) | Seal construction of overpass expansion device | |

| CN215166670U (en) | Composite water-stopping steel belt with water-swelling water-stopping strip | |

| JP7428618B2 (en) | Relay member for buried pipe in precast concrete wall and installation method for precast concrete wall | |

| JPH0710149U (en) | Joint joint sheath | |

| KR20050082101A (en) | A concrete manhole, connecting structure and method between manhole and pipe | |

| CN118639696A (en) | A kind of straight buried water stop belt after folding corner and its construction method |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| A621 | Written request for application examination |

Free format text: JAPANESE INTERMEDIATE CODE: A621 Effective date: 20080205 |

|

| A977 | Report on retrieval |

Free format text: JAPANESE INTERMEDIATE CODE: A971007 Effective date: 20101028 |

|

| A131 | Notification of reasons for refusal |

Free format text: JAPANESE INTERMEDIATE CODE: A131 Effective date: 20101207 |

|

| A521 | Written amendment |

Free format text: JAPANESE INTERMEDIATE CODE: A523 Effective date: 20110207 |

|

| TRDD | Decision of grant or rejection written | ||

| A01 | Written decision to grant a patent or to grant a registration (utility model) |

Free format text: JAPANESE INTERMEDIATE CODE: A01 Effective date: 20110726 |

|

| A01 | Written decision to grant a patent or to grant a registration (utility model) |

Free format text: JAPANESE INTERMEDIATE CODE: A01 |

|

| A61 | First payment of annual fees (during grant procedure) |

Free format text: JAPANESE INTERMEDIATE CODE: A61 Effective date: 20110726 |

|

| FPAY | Renewal fee payment (event date is renewal date of database) |

Free format text: PAYMENT UNTIL: 20140812 Year of fee payment: 3 |

|

| R150 | Certificate of patent or registration of utility model |

Ref document number: 4798570 Country of ref document: JP Free format text: JAPANESE INTERMEDIATE CODE: R150 Free format text: JAPANESE INTERMEDIATE CODE: R150 |

|

| R250 | Receipt of annual fees |

Free format text: JAPANESE INTERMEDIATE CODE: R250 |

|

| R250 | Receipt of annual fees |

Free format text: JAPANESE INTERMEDIATE CODE: R250 |

|

| R250 | Receipt of annual fees |

Free format text: JAPANESE INTERMEDIATE CODE: R250 |

|

| R250 | Receipt of annual fees |

Free format text: JAPANESE INTERMEDIATE CODE: R250 |

|

| R250 | Receipt of annual fees |

Free format text: JAPANESE INTERMEDIATE CODE: R250 |

|

| R250 | Receipt of annual fees |

Free format text: JAPANESE INTERMEDIATE CODE: R250 |

|

| LAPS | Cancellation because of no payment of annual fees |