JP4682795B2 - Expander-integrated compressor and refrigeration cycle apparatus - Google Patents

Expander-integrated compressor and refrigeration cycle apparatus Download PDFInfo

- Publication number

- JP4682795B2 JP4682795B2 JP2005304167A JP2005304167A JP4682795B2 JP 4682795 B2 JP4682795 B2 JP 4682795B2 JP 2005304167 A JP2005304167 A JP 2005304167A JP 2005304167 A JP2005304167 A JP 2005304167A JP 4682795 B2 JP4682795 B2 JP 4682795B2

- Authority

- JP

- Japan

- Prior art keywords

- expander

- compressor

- refrigeration cycle

- suction

- communication path

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Expired - Fee Related

Links

Images

Landscapes

- Compressors, Vaccum Pumps And Other Relevant Systems (AREA)

Description

本発明は、流体を膨張させる膨張機と流体を圧縮する圧縮機を備えた膨張機一体型圧縮機及び冷凍サイクル装置に関するものである。 The present invention relates to an expander-integrated compressor and an refrigeration cycle apparatus including an expander that expands fluid and a compressor that compresses fluid.

冷媒の膨張エネルギーを膨張機で回収し、圧縮機で冷媒を圧縮する仕事の一部として利用する動力回収式の冷凍サイクルとして、膨張機一体型圧縮機を用いたものが知られている。(例えば、特許文献1、2を参照)。

2. Description of the Related Art As a power recovery type refrigeration cycle that recovers expansion energy of a refrigerant with an expander and uses it as part of work for compressing the refrigerant with a compressor, one using an expander-integrated compressor is known. (For example, see

従来の膨張機一体型圧縮機を用いた冷凍サイクルについて説明する。図10に従来特許文献1と同じ構成の膨張機一体型圧縮機を用いた冷凍サイクルを示す。この冷凍サイクルは圧縮機1、ガスクーラ2、膨張機3、蒸発器4、電動モータ5、および、圧縮機1と膨張機3と電動モータ5を直結するシャフト6と、膨張機吸入菅11と膨張機吐出管12との間をバイパスするバイパス回路31とその流量を調節する膨張弁30から構成されている。冷媒は、圧縮機1において常温低圧から高温高圧へと圧縮された後、ガスクーラ2において常温高圧へと冷却される。そして、膨張機3および膨張弁30において低温低圧へと膨張した後、蒸発器4で常温まで加熱される。図11に特許文献2と同じ構成の膨張機一体型圧縮機を用いた冷凍サイクルを示す。特許文献2は特許文献1のバイパス回路31と膨張弁30がない構成となっている。

A refrigeration cycle using a conventional expander-integrated compressor will be described. FIG. 10 shows a refrigeration cycle using an expander-integrated compressor having the same configuration as that of

このような冷凍サイクルシステムにおいて、膨張機3では、冷媒の膨張エネルギーを回収してシャフト6の回転エネルギーに変換し、圧縮機1を駆動する仕事の一部をとして利用することで、電動モータ5の動力を低減し、サイクルの高効率運転を実現していた。

In such a refrigeration cycle system, the

図12には、このような冷凍サイクル装置の作動の一例として、高圧冷媒である二酸化炭素を冷媒として用いたモリエル線図を示しているが、このサイクルでは、圧縮機出口(点D)からガスクーラ2によって冷却された冷媒(点A)が膨張機3に流入し、これを前記膨張機3において等エントロピー膨張によって膨張させる。この場合、蒸発器入口「点B」と、従来のように膨張弁によって「点A」から等エンタルピー膨張させた場合における蒸発器入口「点E」との間のエンタルピー量「ha」だけ、冷凍システム側に回収される。その結果、圧縮機には、その必要入力「hb」から前記回収動力「ha」を差し引いた値「hb-ha」だけを実際に入力すればよく、圧縮機入力の低減分だけ冷凍サイクルの高効率運転が実現されるものである。

FIG. 12 shows a Mollier diagram using carbon dioxide, which is a high-pressure refrigerant, as an example of the operation of such a refrigeration cycle apparatus. In this cycle, a gas cooler is connected from the compressor outlet (point D). The refrigerant (point A) cooled by 2 flows into the

しかし、特許文献1によれば、図10に示すように、膨張機の吸入管11と吐出管12との間にバイパス回路31を設置した冷凍サイクルにおいて、起動時では、膨張機3における動力回収効果よりも、機械的損失のほうが大きくなるため、膨張弁30を全開にして差圧を解消していた。

しかしながら、図11に示すようなバイパス回路のない動力回収式の冷凍サイクル装置では、膨張エネルギーの一部を膨張機で回収できるため高効率であり、バイパス回路と膨張弁がないため、省スペースで構成できるという長所があったが、膨張弁がないため、起動時では、膨張機における動力回収効果よりも、機械的損失のほうが大きくなり、効率の高い運転ができなかった。また、冷凍サイクル装置を運転後に停止すると、圧縮機吐出部から膨張機吸入部までを構成する高圧部と、膨張機吐出部から圧縮機吸入部までを構成する低圧部では差圧が残る。差圧が存在すると、電動モータにかかる負荷トルクが大きくなり圧縮機を起動することができない、低圧側に存在する液冷媒が外気温度の上昇などにより膨張し、蒸発器に非常に高い圧力がかかり熱交換器を破壊するという恐れがあった。つまり、差圧が存在すると、起動時では、機械的損失により運転効率が低下する、圧縮機が起動できないという効率と制御性の課題と、停止時では、熱交換器を破壊するという安全性の課題を有していた。 However, the power recovery type refrigeration cycle apparatus without a bypass circuit as shown in FIG. 11 is highly efficient because a part of the expansion energy can be recovered by the expander, and since there is no bypass circuit and an expansion valve, space is saved. Although there was an advantage that it could be configured, since there was no expansion valve, at the time of startup, the mechanical loss was larger than the power recovery effect in the expander, and high-efficiency operation was not possible. Further, when the refrigeration cycle apparatus is stopped after operation, a differential pressure remains in the high-pressure part that constitutes the compressor discharge part to the expander suction part and the low-pressure part that constitutes the expander discharge part to the compressor suction part. If there is a differential pressure, the load torque applied to the electric motor increases and the compressor cannot be started. The liquid refrigerant present on the low-pressure side expands due to an increase in the outside air temperature, and a very high pressure is applied to the evaporator. There was a risk of destroying the heat exchanger. In other words, if there is a differential pressure, the operating efficiency is reduced due to mechanical loss at startup, the problem of efficiency and controllability that the compressor cannot be started, and the safety of destroying the heat exchanger when stopped Had problems.

この差圧の問題を解決するには、図10に示すバイパス回路とバイパス回路上に膨張弁を設けた構成とすれば、膨張弁を開にすることで差圧を解消することが可能である。しかし、図10の構成では、システムの構成が大きくなるという課題を有していた。 In order to solve the problem of the differential pressure, if the expansion valve is provided on the bypass circuit and the bypass circuit shown in FIG. 10, it is possible to eliminate the differential pressure by opening the expansion valve. . However, the configuration of FIG. 10 has a problem that the configuration of the system becomes large.

本発明は、前記従来の課題を解決するもので、膨張機一体型圧縮機を用いた動力回収式の冷凍サイクルにおいて、高圧部と低圧部を膨張機一体型圧縮機の密閉容器内部で均圧することにより、起動時では、機械的損失の低減による効率の向上と電動モータの起動トルク低減による起動特性を向上し、停止時では、低圧冷媒の膨張によって、高圧力が熱交換器にかかるために発生する熱交換器の破壊から守り、また、膨張機一体型圧縮機内部に連通路と開閉手段を設けることによってバイパス回路や弁などをとり回す必要がなくなるため、効率と制御性の向上、安全性の向上、省スペース性を実現した膨張機一体型圧縮機とそれを用いた冷凍サイクル装置を提供することを目的とする。 The present invention solves the above-mentioned conventional problems, and in a power recovery type refrigeration cycle using an expander-integrated compressor, the high-pressure part and the low-pressure part are pressure-equalized inside the sealed container of the expander-integrated compressor. As a result, at startup, the efficiency is improved by reducing mechanical loss and the startup characteristics are reduced by reducing the startup torque of the electric motor.At the time of shutdown, high pressure is applied to the heat exchanger due to expansion of the low-pressure refrigerant. Protects against heat exchanger breakage, and eliminates the need for bypass circuits and valves by providing a communication path and opening / closing means inside the expander-integrated compressor, improving efficiency and controllability and safety It is an object of the present invention to provide an expander-integrated compressor that realizes improved performance and space saving, and a refrigeration cycle apparatus using the same.

本発明に係る膨張機一体型圧縮機は、容積式の膨張機と、容積式の圧縮機と、前記膨張機と前記圧縮機とを一軸で連結した電動モータを密閉容器内に収納し、

前記密閉容器において、前記圧縮機吐出部である高圧部と、前記膨張機吐出部または前記圧縮機吸入部である低圧部とを連通するための、前記膨張機内に設けられた連通路を有し、

前記連通路には開閉可能な手段を設けたものである。

The expander-integrated compressor according to the present invention stores a positive displacement expander, a positive displacement compressor, and an electric motor in which the expander and the compressor are connected in a single shaft in a sealed container,

The closed container has a communication path provided in the expander for communicating the high pressure portion that is the compressor discharge portion and the low pressure portion that is the expander discharge portion or the compressor suction portion. ,

The communication path is provided with means that can be opened and closed.

上記膨張機一体型圧縮機では、前記高圧部と前記低圧部を連通させないときには、高圧部と低圧部の圧力差は維持するが、連通させることにより、高圧部から低圧部へと冷媒が流入し、前記膨張機内において前記高圧部と前記低圧部を均圧することが可能となる。 In the expander-integrated compressor, when the high pressure portion and the low pressure portion are not communicated with each other, the pressure difference between the high pressure portion and the low pressure portion is maintained, but by allowing the communication, the refrigerant flows from the high pressure portion to the low pressure portion. In the expander, the high pressure part and the low pressure part can be equalized.

前記膨張機は、膨張室へ流入する流体の容積を変更可能な手段を設ける。 The expander is provided with means capable of changing the volume of fluid flowing into the expansion chamber.

このことにより、冷媒の体積流量を可変にできるバイパス回路を用いずに冷凍サイクルを循環する体積流量を変化させることができ、高効率で、省スペースな膨張機一体型圧縮機を実現できる。 As a result, the volume flow rate circulating in the refrigeration cycle can be changed without using a bypass circuit that can change the volume flow rate of the refrigerant, and a highly efficient and space-saving expander-integrated compressor can be realized.

前記膨張機は、円筒形のシリンダと、偏心軸を有するシャフトと、前記偏心軸に嵌合し、前記シリンダの内側で偏心回転するピストンと、前記シリンダと前記ピストンの間の空間を、吸入側空間と吐出側空間に仕切る仕切り部材で構成されたロータリ式の流体機構をn個(nは2以上の整数)備えたロータリ式膨張機で、前記ロータリ式膨張機のシリンダの端面を閉塞する端板の少なくとも一部が回転可能な可動部とし、前記可動部には前記シリンダへの吸入口と前記連通路を設けてもよい。 The expander includes a cylindrical cylinder, a shaft having an eccentric shaft, a piston that is fitted to the eccentric shaft and rotates eccentrically inside the cylinder, and a space between the cylinder and the piston is provided on the suction side. A rotary expander provided with n rotary type fluid mechanisms (n is an integer of 2 or more) composed of partition members for partitioning a space and a discharge side space, and closing an end face of a cylinder of the rotary type expander At least a part of the plate may be a rotatable movable part, and the movable part may be provided with a suction port to the cylinder and the communication path.

このことにより、前記第2の吸入孔により前記膨張機の吸入容積を可変にし、バイパス回路を用いずに冷凍サイクルを循環する冷媒の質量流量を変化させることができ、高効率化を実現できる。また、前記可動部と、固定部で前記開閉手段を構成し、前記可動部に設けた連通路を連通することができ、装置の簡略化を実現できる。 As a result, the suction volume of the expander can be made variable by the second suction hole, and the mass flow rate of the refrigerant circulating in the refrigeration cycle can be changed without using a bypass circuit, thereby realizing high efficiency. In addition, the opening and closing means can be configured by the movable part and the fixed part, and the communication path provided in the movable part can be communicated, thereby simplifying the apparatus.

前記圧縮機は、圧縮室へ流入する流体の吸入容積を変更可能な手段を設けていてもよい。 The compressor may be provided with means capable of changing the suction volume of the fluid flowing into the compression chamber.

このことにより、バイパス回路を用いずに冷凍サイクルを循環する冷媒の体積流量を変化させることができ、バイパス用の配管が不要となり、省スペースな膨張機一体型圧縮機を実現できる。 This makes it possible to change the volume flow rate of the refrigerant circulating in the refrigeration cycle without using a bypass circuit, eliminating the need for bypass piping, and realizing a space-saving expander-integrated compressor.

前記冷凍サイクル装置は、前記膨張機一体型圧縮機と、ガスクーラと、蒸発器と、

を有し、前記圧縮機からの吐出冷媒が、前記ガスクーラ、前記膨張機、前記蒸発器の順に循環する。

The refrigeration cycle apparatus includes the expander-integrated compressor, a gas cooler, an evaporator,

The refrigerant discharged from the compressor circulates in the order of the gas cooler, the expander, and the evaporator.

このことにより、省スペースで高効率な冷凍サイクル装置が実現できる。 As a result, a space-saving and highly efficient refrigeration cycle apparatus can be realized.

前記電動モータの停止時には、前記開閉手段により前記連通路を連通するように設定する。 When the electric motor is stopped, the opening / closing means is set to communicate with the communication path.

このことにより、停止時において高圧部と低圧部を均圧し、熱交換器の保護と、起動特性の向上を実現できる。 As a result, it is possible to equalize the high-pressure part and the low-pressure part at the time of stoppage, and to protect the heat exchanger and improve the start-up characteristics.

本発明の膨張機一体型圧縮機によれば、膨張機を用いた動力回収式の冷凍サイクルにおいて、膨張機一体型圧縮機の密閉容器の内部に設けられた連通路を連通することによって高圧部と低圧部を均圧することができ、停止時には、低圧冷媒の膨張によって、高圧力が熱交換器にかかるために発生する熱交換器の破壊から守り、また、起動時には、電動モータの起動トルクを小さくすることで、起動特性を向上することができる。さらに、連通路と開閉手段を膨張機一体型圧縮機の密閉容器の内部に設けることにより、省スペース性を実現できる。 According to the expander-integrated compressor of the present invention, in the power recovery type refrigeration cycle using the expander, the high-pressure unit is formed by communicating the communication path provided in the sealed container of the expander-integrated compressor. When stopping, the low-pressure refrigerant expands to protect against damage to the heat exchanger caused by high pressure on the heat exchanger. By making it smaller, the starting characteristics can be improved. Further, space saving can be realized by providing the communication path and the opening / closing means inside the hermetic container of the expander-integrated compressor.

以下、本発明の実施の形態を図面に基づいて詳細に説明する。 Hereinafter, embodiments of the present invention will be described in detail with reference to the drawings.

(第1の実施形態)

図1に、本実施形態における冷凍サイクル装置の冷媒回路図を示す。冷凍サイクル装置は、圧縮機1とガスクーラ2と膨張機3と蒸発器4とが順に接続されてなる冷媒回路10を備え、圧縮機1と膨張機3とを電動モータ5に対して一軸に連結し、矢印は冷媒の流れる方向を表している。また、圧縮機1の吐出部と膨張機3の吐出部を連通する連通路8と、その連通路8を開閉する開閉手段9を備えている。本実施形態では、このような開閉手段に、ボールバルブを使用している。ただし、開閉手段9は特に限定されるものではなく、差圧の調節できる膨張弁であっても、開閉のみの電磁弁でもよい。この冷媒回路10には、高圧部分(圧縮機1からガスクーラ2を経て膨張機3に至る部分)において超臨界状態となる冷媒が充填されている。本実施形態では、そのような冷媒として二酸化炭素(CO2)が充填されている。ただし、冷媒の種類は特に限定されるものではない。前記冷媒回路10の冷媒は、運転時に超臨界状態とならない冷媒であってもよい。

(First embodiment)

In FIG. 1, the refrigerant circuit figure of the refrigerating-cycle apparatus in this embodiment is shown. The refrigeration cycle apparatus includes a

次に、本実施形態における冷凍サイクルに用いる膨張機一体型圧縮機について説明する。図2に膨張機一体型圧縮機の縦断面図を示す。密閉容器41の内部の上側にはスクロール式の圧縮機1、下側には2段ロータリ式の膨張機3、その間には、回転子21と固定子22から成る電動モータ5が配置されており、これらはシャフト結合部32により連結されている。

Next, the expander-integrated compressor used in the refrigeration cycle in the present embodiment will be described. FIG. 2 shows a longitudinal sectional view of the expander-integrated compressor. A

ただし、圧縮機1及び膨張機3の形式は他の回転式圧縮機であってもよい。例えば、ロータリ式、スクロール式、マルチベーン式を好適に用いることができる。さらに、圧縮機1、膨張機3、電動モータ5の配置関係は何ら限定されない。

However, the types of the

図2に示すように、スクロール式の圧縮機1は、固定スクロール74と、旋回スクロール73と、オルダムリング75と、軸受部材77と、マフラー79と、吸入管71と、吐出管72とから構成されている。旋回スクロール73は、圧縮機シャフト76の偏心軸に嵌合され、かつ、オルダムリング75により自転運動を拘束されている。また、旋回スクロール73は、渦巻き形状のラップ73aを有し、固定スクロール74はラップ74aを有しており、ラップ73aとラップ74aは互いに噛み合っている。旋回スクロール73は、シャフト76の回転に伴い旋回運動を行い、ラップ73a、74aの間に形成される三日月形状の作動室80が外側から内側に移動しながら容積を縮小することで、吸入管71から吸入された作動流体を圧縮し、固定スクロール74の中央部に設けた吐出孔72aと固定スクロール74および軸受部材77に設けた流路72bから、マフラー79の内側空間79aを経由して密閉容器41の内部空間41aへと吐出する。作動流体は、内部空間41aに滞留する間に、混入した潤滑用のオイルを重力や遠心力などにより分離された後、吐出管72から冷凍サイクルへと吐出される。

As shown in FIG. 2, the

図2において、2段ロータリ式の膨張機3は、第1のシリンダ42、第1のシリンダ42よりも厚みのある第2のシリンダ43、および、これらを仕切る中板57を有し、膨張機シャフト44の偏心部44aと嵌合している第1のピストン45は、第1のシリンダ42の中で偏心回転運動し、シャフト44の偏心部44aと嵌合している第2のピストン46は、第2のシリンダ43の中で偏心回転運動する。第1のベーン47(図9に記載)は、第1のシリンダ42のベーン溝42a(図9に記載)に往復動自在に保持され、先端が第1のピストン45に接し、第2のベーン(図示せず)は第2のシリンダ43のベーン溝43a(図示せず)に往復動自在に保持され、先端が第2のピストン46に接する。第1のベーン47を押す第1のばね49(図9にまた記載)はベーン溝42aに、第2のベーン48を押す第2のばね(図示せず)はベーン溝43aに格納され、吸入管53と、吐出管54とから構成された上側端板51とマフラー58と接する下側端板52は、シャフト44を支える軸受を備えている。第1のシリンダ42の吐出側と、第2のシリンダ43の吸入側は、中板57に設けた連通孔57aにより連通しており、一つの作動室として機能する。高圧の作動流体は吸入管53から上側端板51に設けた吸入孔51aから第1のシリンダ42の作動室に流入した後、第2のシリンダ43の作動室とから形成される作動室にて膨張してシャフト44を回転させて低圧になった後、下側端板52を経てマフラー58の内部空間52cに一旦吐出され、吐出流路52bを経て吐出管54から冷凍サイクルへと吐出される。ここで、下側端板52の吐出孔52aには、吐出弁59を設けている。吐出弁59は金属の薄板であり、吐出孔52aをマフラー58の内部空間52c側から塞ぐように設置されており、吐出弁59の上流側の圧力が下流側の圧力より高くなると開く差圧弁となっている。

In FIG. 2, the two-

図2において、2段ロータリ膨張機3の上側端板51の内部に、膨張後の低圧冷媒が吐出管54へと導かれる吐出流路51bと、前記吐出流路51bと分岐して膨張部外部の圧縮後の高圧冷媒が存在する密閉容器41の内部空間41aへと導かれる連通路8を備えている。また、連通路8の出口である上側端板51の内部空間41a側には、連通路8を開閉するような開閉手段9を備えている。この開閉手段9を閉じたときは、冷媒は吐出流路51bを経て吐出管54から冷凍サイクルへと吐出され、連通路8には流れないが、開閉手段9が開いているときは、吐出流路51bと密閉容器の内部空間41aが連通する。このような構成により、膨張後の低圧部と圧縮直後の高圧部が連通することができる。

In FIG. 2, inside the

以上のように、本実施形態によれば、膨張機3の上側端板51に設けた連通路8と、開閉手段9により、高低圧を均圧することが可能となる。

As described above, according to the present embodiment, it is possible to equalize high and low pressures by the

なお、本実施の形態において、連通路8と開閉手段9を膨張機3の上側端板51に設けた。しかし、膨張機3は圧縮機吐出後の高圧冷媒が存在する密閉容器41の内部空間41aに存在するため、連通路8は、膨張後の低圧冷媒と密閉容器内部空間41aに存在する高圧冷媒とを連通するように形成できれば、連通路8と開閉手段9は密閉容器41の内部のどこに設置してもよい。つまり、連通路8は上側端板51の吐出流路51bから分岐するのではなく、第1のシリンダ42の吐出流露42b、中板57の吐出流路57b、第2のシリンダ43の吐出流路43bのいずれから分岐してもよく、また、下側端板52、マフラー58についてはどこに設けてもよい。また、開閉手段9は上側端板の内部空間41a側に設けるのではなく、第1のシリンダ42、中板57、第2のシリンダ43、下側端板52、マフラー58のどこに設けてもよい。

In the present embodiment, the

また、本実施の形態において、前記連通路8によって膨張機吐出部の低圧部と、圧縮機吐出後の高圧部とを連通させるのは、電動モータ5の停止時である。図3に電動モータ5の速度と開閉手段9の開閉タイミングを示す。電動モータ5が定速状態から減速し、停止した状態になると開閉手段9を‘開’とし、連通路8を連通させる。また、加速時には連通路8を‘閉’とし、連通させない。しかし、定速状態から停止状態への遷移時(減速時)、停止状態から定速状態への遷移時(加速時)において連通路8を連通させてもよいし、停止時に連通路8を常時連通させなくてもよい。

In the present embodiment, the low-pressure part of the expander discharge part and the high-pressure part after discharge of the compressor are communicated by the

また、図1に示した冷媒回路10は、冷媒を一方向のみに流通させる冷媒回路10に限られない。膨張機一体型圧縮機は、冷媒の流通方向の変更が可能な冷媒回路に設けられていてもよい。例えば、図4に示すように、四方弁等を有することによって暖房運転及び冷房運転の可能な冷媒回路に膨張機一体型圧縮機を設けることも可能である。

(第2の実施形態)

第1の実施形態にかかる連通路8と開閉手段9は、膨張機3に設置するものであった。しかし、本発明にかかる連通路8と開閉手段9は、圧縮機1に設置してもよい。以下図面に基づいて詳細に説明する。

Moreover, the

(Second Embodiment)

The

図5に本実施形態における冷凍サイクル装置の冷媒回路図を示す。冷凍サイクル装置は、圧縮機1とガスクーラ2と膨張機3と蒸発器4とが順に接続されてなる冷媒回路10を備え、圧縮機1と膨張機3とを電動モータ5に対して一軸に連結している。また、圧縮機1の吸入部と圧縮機1の吐出部を連通する連通路8と、その連通路8を開閉する開閉手段9を備えている。図2において図1と同じ構成要素については同じ符号を用い、説明を省略する。

FIG. 5 shows a refrigerant circuit diagram of the refrigeration cycle apparatus in the present embodiment. The refrigeration cycle apparatus includes a

図6に本実施の形態の膨張機一体型圧縮機断面を示す。図6に示すように、電動モータ5、スクロール式の圧縮機1、および、2段ロータリ式の膨張機3は、図2を用いて説明した第一の実施の形態とほぼ同様の構成である。同一部品については同一番号を使用し、第1の実施の形態と同一の構成及び作用の説明を省略する。

FIG. 6 shows a cross section of the expander-integrated compressor according to the present embodiment. As shown in FIG. 6, the

図6において、スクロール式の圧縮機1の固定スクロール74に、圧縮前の低圧流体が作動室へと導かれる吸入流路71bと、前記吸入流路71bと分岐して圧縮部外部の高圧流体が存在する密閉容器41の内部空間41aへと導かれる連通路8を備えている。また、連通路8の出口である固定スクロール74には、連通路8を開閉するような開閉手段9を備えている。この開閉手段9が閉じているときは、吸入流路71bを経て吸入孔71aから作動室80へ流入し、開いているときは、吸入流路71bと密閉容器の内部空間41aが連通する。このような構成により、圧縮前の低圧部と圧縮直後の高圧部が連通することになる。

In FIG. 6, the

以上のように、本実施形態によれば、圧縮機の固定スクロール74に設けた連通路8と、開閉手段9により、高低圧を均圧することができる。

As described above, according to the present embodiment, the high and low pressures can be equalized by the

なお、本実施の形態において、連通路8と開閉手段9として圧縮機の固定スクロール74に設けたが、圧縮機1において圧縮前の低圧流体が作動室80へと導かれる流路と、分岐して圧縮部外部の圧縮直後の高圧流体が存在する膨張機一体型圧縮機の密閉容器41の内部空間41aとの間に連通路8と開閉手段9が形成されれば、密閉容器41の内部のどこに設置してもよい。つまり、連通路8は固定スクロール74から分岐するのではなく、軸受部材77から分岐してもよい。また、開閉手段9も同様に軸受部材77に設けてもよい。

(第3の実施形態)

第1の実施形態にかかる連通路8と開閉手段9は、膨張機3に設置するものであった。しかし、本発明にかかる連通路8と開閉手段9は、容積可変機構を持つ膨張機3に設けてもよい。

In this embodiment, the

(Third embodiment)

The

冷凍サイクル装置については、図1と同様の構成となるため説明は省略する。 The refrigeration cycle apparatus has the same configuration as that shown in FIG.

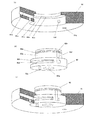

次に、冷凍サイクルに用いる膨張機一体型圧縮機について説明する。図7に、本実施形態における膨張機一体型圧縮機の縦断面図を示す。本実施の形態では、2段ロータリ式の膨張機3には上側端板固定部61と上側端板可動部62を備えている。また、電動モータ5、スクロール式の圧縮機1、および、2段ロータリ式の膨張機3は、図2を用いて説明した第一の実施の形態と同様の構成である。同一部品については同一番号を使用し、第1の実施の形態と同一の構成及び作用の説明を省略する。

Next, the expander-integrated compressor used in the refrigeration cycle will be described. In FIG. 7, the longitudinal cross-sectional view of the expander integrated compressor in this embodiment is shown. In the present embodiment, the two-

図8(a)は、図7の膨張機一体型圧縮機における膨張機3の上側端板固定部61の斜視図、図8(b)は、図7の膨張機一体型圧縮機における膨張機3の上側端板可動部62の斜視図、図8(c)は図7の膨張機一体型圧縮機における膨張機3の上側端板固定部61と可動部62を組んだ状態の斜視図である。

8A is a perspective view of the upper end

図8(a)に示すように、固定部61は、内側にシャフト44と同じ中心軸の円筒面61a、および、円筒面61aよりも小さな内径の円筒面61bと、その間の段差部61cを有する。また、吸入管53からの作動流体が導かれる流入路61dと、そこから縦方向に分岐した流入路61eと、円筒面61aと吐出流路61gを固定部61の内部で連通する連通路61fを備える。また、流入経路61eと連通する流路として、図9に示すように、第1のシリンダ42には、流入経路42c、および、流入経路42cと連通した第1吸入孔42dを設けている。また、円筒面には膨張機の吐出流体が流れる吐出流路42bを有する。

As shown in FIG. 8A, the fixed

図8(b)に示すように、可動部62は、内側にシャフト44が嵌合するシャフト孔62aを有し、外側には、固定部61の円筒面61aに嵌合する円柱面62b、および、固定部61の円筒面61bに嵌合する円柱面62cを有し、円柱面62bには円周方向の流路溝62dをシャフト44の回転方向に180度備えている。また、可動部62の上面には上面流入孔62eを設け、連通路62fと連通し、円柱面62cには円周方向に歯車62aを備え、流路溝62dから下側方向へ向けて第2吸入孔62gを有する。

As shown in FIG. 8 (b), the

図8(c)に示すように、固定部61と可動部62は嵌合し、固定部61の内側で可動部62は回転可能に支持されている。そして、可動部62を回転させることにより、シャフト44を中心に第2吸入孔62gと連通路62fを回転させることができる。このとき、固定部61の段差61cと可動部62の円筒部62b、62cの間の段差(図示せず)が接触することにより、可動部62が固定部61から上側に抜け出るのを防止している。また、固定部61の下端面と可動部62の下端面は、同一平面を構成している。また、上側端板固定部61には、可動部62に設けられた歯車62aと噛み合う歯車65(図7に示す)と、それを駆動する回転電動機63(図7に示す)を備えており、回転電動機63により上側端板可動部62をシャフト44の軸まわりに回転させることができる。

As shown in FIG. 8C, the fixed

本実施形態における上側端板可動部61と固定部62は以下に示すように2つの機能を備える。1つ目の機能は、吸入管53から2段ロータリ膨張機3に流入した作動流体を、上側端板固定部61の流入経路61dから2つの経路に分けて上作動室55に流入させる吸入容積可変機構である。第1の経路は、流入経路61dから流入経路61e、第1のシリンダ42の流入経路42c、第1吸入孔42dを経る経路であり、第2の経路は、流入経路61dから可動部62の流路溝62d、第2吸入孔62gを経る経路である。つまり、この第2吸入孔の位置を制御し変化させることで、上作動室55へ流入する作動流体の吸入容積を変化させることができる。2つ目の機能は、連通路62fの位置を上側端板固定部61の吐出流路61gの位置と一致させると、連通路62fと吐出流路61gが連通し、一致させないと連通しないという開閉手段である。これらの2つの機能は、可動部62の回転位置によって使い分けることができる。本実施形態においては、前記2つの機能は同時に利用することができないが、同時に利用できるような構成でもよい。例えば、第2吸入孔62gと連通路62fの配置を変えることにより対応することができる。以下に可動部62の位置とその機能ついて説明する。

The upper end plate

図9(a1)、(b1)、(c1)は図7の膨張機一体型圧縮機の膨張機のD1−D1における断面図、図9(a2)、(b2)、(c2)は図7の膨張機一体型圧縮機の膨張機のD2−D2における断面図を示す。ここでは、第1吸入孔42dと第2吸入孔62g、また、上端板上面吸入孔62eと連通路62fの位置と機能の関係を示す。

9 (a1), (b1), and (c1) are cross-sectional views of the expander D1-D1 of the expander-integrated compressor of FIG. 7, and FIGS. 9 (a2), (b2), and (c2) are FIG. Sectional drawing in D2-D2 of the expander of the expander integrated compressor of this is shown. Here, the relationship between the positions and functions of the

本実施形態において、図9(a2)、(b2)、(c2)に示すように、第2吸入孔62gと連通路62fはシャフトを中心として180°の位置に配置する。第1吸入孔42dの位置は、シャフト44を中心にベーン47の位置を基準として20degに固定されているのに対し、第2吸入孔62gの位置は外部から変化させることが可能である。図9(a1)、(a2)は、シャフト44を中心にベーン47の位置を基準とした第2吸入孔62gの回転角φが20degの場合、(b1)、(b2)は90degの場合、(c1)、(c2)は180degの場合を示している。なお、第2吸入孔62gの回転角φは0degから360degまで自在に変えることができることは言うまでも無い。

In the present embodiment, as shown in FIGS. 9 (a2), (b2), and (c2), the

次に、上側端板可動部62の位置を制御することによって、容積可変機構とする場合と、差圧を解消するための均圧装置とする場合について、第2吸入孔62gと連通路62fの位置の関係を詳細に説明する。

Next, by controlling the position of the upper end plate

まず、1つめの機能である容積可変機構について説明する。上側端板可動部62の位置を制御して、第2吸入孔62gの位置φを20degにすると図9(a1)、(a2)となる。第2吸入孔62gは第1吸入孔42dと同じ位置にあるため、吸入容積は第1吸入孔42dのみの時と同じになる。このとき、上端板上面吸入孔62eと連通路62fは連通していない。また、第2吸入孔62gの位置φを90degとすると図9(b1)、(b2)となる。第2吸入孔62gの位置φは第1吸入孔42dよりも角度が大きいため、吸入時間が長くなり、吸入容積は図9(a1)、(a2)のときよりも大きくなる。このとき、上端板上面吸入孔62eと連通路62fは先ほどと同様に連通していない。

First, the volume variable mechanism that is the first function will be described. When the position of the upper end plate

次に、2つめの機能である容積可変機構について説明する。第2吸入孔62gの位置φを180degとすると図9(c1)、(c2)となる。このとき連通路62fと固定部61の吐出流路61gは連通し、高低圧の差圧を解消することができる。つまり、可動部62と固定部61の位置を制御することにより開閉手段9を実現することができる。

Next, the volume variable mechanism which is the second function will be described. When the position φ of the

以上のように、本実施形態によれば、膨張機の上側端板可動部62に連通路8と開閉手段9を備え、前記可動部62の位置を制御することにより、吸入容積を可変にすることができる容積可変機構と、高圧部と低圧部の差圧を解消する均圧機能を一つの機構で実現することができる。これにより、新たな装置を必要とせず、従来の膨張機一体型圧縮機を用いた冷凍サイクルでは不可能であった均圧が可能となる。

As described above, according to the present embodiment, the upper end plate

なお、本実施の形態において、連通路8と開閉手段9として膨張機の上側端板固定部61と可動部62を利用したが、容積可変を実現するための可動部と固定部で開閉手段9を構成すれば、上側端板に限定せずに膨張機のどこに連通路8と開閉手段9を設置してもよい。さらに、容積可変機構を有する圧縮機の可動部と固定部で開閉手段9と連通路8を構成すれば、膨張機に限定せずに圧縮機に設置してもよい。

In the present embodiment, the upper end

以上で説明したように、本発明は、膨張機一体型圧縮機を有する動力回収型冷凍サイクル装置として、例えば、エアコン、給湯器において有用である。 As described above, the present invention is useful as, for example, an air conditioner and a water heater as a power recovery refrigeration cycle apparatus having an expander-integrated compressor.

1 圧縮機

2 ガスクーラ

3 膨張機

4 蒸発器

5 電動モータ

6 シャフト

7 膨張機一体型圧縮機

8 連通路

9 開閉手段

10 冷媒回路

11 吸入菅

12 吐出管

30 膨張弁

31 バイパス回路

32 シャフト結合部

34 オイル溜り

63 回転電動機

64 第1吸入孔

65 歯車

DESCRIPTION OF

Claims (6)

前記密閉容器において、前記圧縮機吐出部である高圧部と、前記膨張機吐出部または前記圧縮機吸入部である低圧部とを連通するための、前記膨張機内に設けられた連通路を有し、

前記連通路には開閉可能な開閉手段を設けた膨張機一体型圧縮機。 A positive displacement expander, a positive displacement compressor, and an electric motor in which the expander and the compressor are connected in one shaft are housed in a sealed container,

The closed container has a communication path provided in the expander for communicating the high pressure portion that is the compressor discharge portion and the low pressure portion that is the expander discharge portion or the compressor suction portion. ,

An expander-integrated compressor provided with an openable / closable means in the communication path.

前記圧縮機からの吐出冷媒が、前記ガスクーラ、前記膨張機、前記蒸発器の順に循環する冷凍サイクル装置。 The expander-integrated compressor according to any one of claims 1 to 4 , a gas cooler, and an evaporator,

A refrigeration cycle apparatus in which refrigerant discharged from the compressor circulates in the order of the gas cooler, the expander, and the evaporator.

Priority Applications (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| JP2005304167A JP4682795B2 (en) | 2005-10-19 | 2005-10-19 | Expander-integrated compressor and refrigeration cycle apparatus |

Applications Claiming Priority (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| JP2005304167A JP4682795B2 (en) | 2005-10-19 | 2005-10-19 | Expander-integrated compressor and refrigeration cycle apparatus |

Publications (3)

| Publication Number | Publication Date |

|---|---|

| JP2007113447A JP2007113447A (en) | 2007-05-10 |

| JP2007113447A5 JP2007113447A5 (en) | 2008-11-20 |

| JP4682795B2 true JP4682795B2 (en) | 2011-05-11 |

Family

ID=38095877

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| JP2005304167A Expired - Fee Related JP4682795B2 (en) | 2005-10-19 | 2005-10-19 | Expander-integrated compressor and refrigeration cycle apparatus |

Country Status (1)

| Country | Link |

|---|---|

| JP (1) | JP4682795B2 (en) |

Cited By (1)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| KR101515537B1 (en) | 2013-09-03 | 2015-05-04 | 인천대학교 산학협력단 | Integral compressor-expander |

Families Citing this family (3)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| JP5296065B2 (en) * | 2008-05-22 | 2013-09-25 | パナソニック株式会社 | Refrigeration cycle equipment |

| JP2010043556A (en) * | 2008-08-08 | 2010-02-25 | Mitsubishi Electric Corp | Expander unit and refrigeration cycle device including the same |

| ES2732350T3 (en) * | 2010-01-19 | 2019-11-22 | Mitsubishi Electric Corp | Positive displacement expander and refrigeration cycle device using the positive displacement expander |

Citations (6)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| JP2000297770A (en) * | 1999-04-15 | 2000-10-24 | Mitsubishi Heavy Ind Ltd | Clutchless scroll type fluid machine |

| JP2001116371A (en) * | 1999-10-20 | 2001-04-27 | Daikin Ind Ltd | Air conditioner |

| JP2004190559A (en) * | 2002-12-11 | 2004-07-08 | Daikin Ind Ltd | Displacement expander and fluid machine |

| JP2004197640A (en) * | 2002-12-18 | 2004-07-15 | Daikin Ind Ltd | Positive displacement expander and fluid machinery |

| JP2004251528A (en) * | 2003-02-20 | 2004-09-09 | Mitsubishi Electric Corp | Refrigerating air-conditioning device |

| JP2005240561A (en) * | 2004-02-24 | 2005-09-08 | Matsushita Electric Ind Co Ltd | Expander |

-

2005

- 2005-10-19 JP JP2005304167A patent/JP4682795B2/en not_active Expired - Fee Related

Patent Citations (6)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| JP2000297770A (en) * | 1999-04-15 | 2000-10-24 | Mitsubishi Heavy Ind Ltd | Clutchless scroll type fluid machine |

| JP2001116371A (en) * | 1999-10-20 | 2001-04-27 | Daikin Ind Ltd | Air conditioner |

| JP2004190559A (en) * | 2002-12-11 | 2004-07-08 | Daikin Ind Ltd | Displacement expander and fluid machine |

| JP2004197640A (en) * | 2002-12-18 | 2004-07-15 | Daikin Ind Ltd | Positive displacement expander and fluid machinery |

| JP2004251528A (en) * | 2003-02-20 | 2004-09-09 | Mitsubishi Electric Corp | Refrigerating air-conditioning device |

| JP2005240561A (en) * | 2004-02-24 | 2005-09-08 | Matsushita Electric Ind Co Ltd | Expander |

Cited By (1)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| KR101515537B1 (en) | 2013-09-03 | 2015-05-04 | 인천대학교 산학협력단 | Integral compressor-expander |

Also Published As

| Publication number | Publication date |

|---|---|

| JP2007113447A (en) | 2007-05-10 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| US10378539B2 (en) | System including high-side and low-side compressors | |

| AU2005240929B2 (en) | Rotary compressor | |

| JP5306478B2 (en) | Heat pump device, two-stage compressor, and operation method of heat pump device | |

| JP4396773B2 (en) | Fluid machinery | |

| JP4367567B2 (en) | Compressor and refrigeration equipment | |

| JP4806027B2 (en) | Rotary expander | |

| WO2006013959A1 (en) | Displacement type expansion machine and fluid machine | |

| EP3382205B1 (en) | Compressor | |

| JPWO2007052569A1 (en) | Expander and heat pump using the same | |

| JP5228905B2 (en) | Refrigeration equipment | |

| KR100725893B1 (en) | Scroll-type fluid machine | |

| JP4682795B2 (en) | Expander-integrated compressor and refrigeration cycle apparatus | |

| JP6568841B2 (en) | Hermetic rotary compressor and refrigeration air conditioner | |

| JP5338314B2 (en) | Compressor and refrigeration equipment | |

| JP5515289B2 (en) | Refrigeration equipment | |

| JP4924092B2 (en) | Refrigeration cycle equipment | |

| JP2012127565A (en) | Refrigeration cycle device | |

| JP5401899B2 (en) | Refrigeration equipment | |

| JP4784385B2 (en) | Refrigeration cycle equipment | |

| JP2010156246A (en) | Compressor | |

| JPH03260391A (en) | Closed type rotary compressor | |

| WO2012104934A1 (en) | Scroll expander, and refrigeration cycle with the scroll expander | |

| JP5321055B2 (en) | Refrigeration equipment | |

| JP6915398B2 (en) | Compressor | |

| JP2013224595A (en) | Two-cylinder rotary compressor |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| A521 | Written amendment |

Free format text: JAPANESE INTERMEDIATE CODE: A523 Effective date: 20081007 |

|

| A621 | Written request for application examination |

Free format text: JAPANESE INTERMEDIATE CODE: A621 Effective date: 20081007 |

|

| RD01 | Notification of change of attorney |

Free format text: JAPANESE INTERMEDIATE CODE: A7421 Effective date: 20091126 |

|

| TRDD | Decision of grant or rejection written | ||

| A01 | Written decision to grant a patent or to grant a registration (utility model) |

Free format text: JAPANESE INTERMEDIATE CODE: A01 Effective date: 20110111 |

|

| A01 | Written decision to grant a patent or to grant a registration (utility model) |

Free format text: JAPANESE INTERMEDIATE CODE: A01 |

|

| A61 | First payment of annual fees (during grant procedure) |

Free format text: JAPANESE INTERMEDIATE CODE: A61 Effective date: 20110124 |

|

| FPAY | Renewal fee payment (event date is renewal date of database) |

Free format text: PAYMENT UNTIL: 20140218 Year of fee payment: 3 |

|

| FPAY | Renewal fee payment (event date is renewal date of database) |

Free format text: PAYMENT UNTIL: 20140218 Year of fee payment: 3 |

|

| LAPS | Cancellation because of no payment of annual fees |