JP4604388B2 - Rolling bearing unit with combination seal ring with encoder - Google Patents

Rolling bearing unit with combination seal ring with encoder Download PDFInfo

- Publication number

- JP4604388B2 JP4604388B2 JP2001138350A JP2001138350A JP4604388B2 JP 4604388 B2 JP4604388 B2 JP 4604388B2 JP 2001138350 A JP2001138350 A JP 2001138350A JP 2001138350 A JP2001138350 A JP 2001138350A JP 4604388 B2 JP4604388 B2 JP 4604388B2

- Authority

- JP

- Japan

- Prior art keywords

- ring

- encoder

- inner ring

- peripheral surface

- fixed

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Expired - Fee Related

Links

Images

Classifications

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F16—ENGINEERING ELEMENTS AND UNITS; GENERAL MEASURES FOR PRODUCING AND MAINTAINING EFFECTIVE FUNCTIONING OF MACHINES OR INSTALLATIONS; THERMAL INSULATION IN GENERAL

- F16C—SHAFTS; FLEXIBLE SHAFTS; ELEMENTS OR CRANKSHAFT MECHANISMS; ROTARY BODIES OTHER THAN GEARING ELEMENTS; BEARINGS

- F16C41/00—Other accessories, e.g. devices integrated in the bearing not relating to the bearing function as such

- F16C41/007—Encoders, e.g. parts with a plurality of alternating magnetic poles

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F16—ENGINEERING ELEMENTS AND UNITS; GENERAL MEASURES FOR PRODUCING AND MAINTAINING EFFECTIVE FUNCTIONING OF MACHINES OR INSTALLATIONS; THERMAL INSULATION IN GENERAL

- F16C—SHAFTS; FLEXIBLE SHAFTS; ELEMENTS OR CRANKSHAFT MECHANISMS; ROTARY BODIES OTHER THAN GEARING ELEMENTS; BEARINGS

- F16C33/00—Parts of bearings; Special methods for making bearings or parts thereof

- F16C33/72—Sealings

- F16C33/76—Sealings of ball or roller bearings

- F16C33/78—Sealings of ball or roller bearings with a diaphragm, disc, or ring, with or without resilient members

- F16C33/7816—Details of the sealing or parts thereof, e.g. geometry, material

- F16C33/783—Details of the sealing or parts thereof, e.g. geometry, material of the mounting region

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F16—ENGINEERING ELEMENTS AND UNITS; GENERAL MEASURES FOR PRODUCING AND MAINTAINING EFFECTIVE FUNCTIONING OF MACHINES OR INSTALLATIONS; THERMAL INSULATION IN GENERAL

- F16C—SHAFTS; FLEXIBLE SHAFTS; ELEMENTS OR CRANKSHAFT MECHANISMS; ROTARY BODIES OTHER THAN GEARING ELEMENTS; BEARINGS

- F16C33/00—Parts of bearings; Special methods for making bearings or parts thereof

- F16C33/72—Sealings

- F16C33/76—Sealings of ball or roller bearings

- F16C33/78—Sealings of ball or roller bearings with a diaphragm, disc, or ring, with or without resilient members

- F16C33/7869—Sealings of ball or roller bearings with a diaphragm, disc, or ring, with or without resilient members mounted with a cylindrical portion to the inner surface of the outer race and having a radial portion extending inward

- F16C33/7879—Sealings of ball or roller bearings with a diaphragm, disc, or ring, with or without resilient members mounted with a cylindrical portion to the inner surface of the outer race and having a radial portion extending inward with a further sealing ring

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F16—ENGINEERING ELEMENTS AND UNITS; GENERAL MEASURES FOR PRODUCING AND MAINTAINING EFFECTIVE FUNCTIONING OF MACHINES OR INSTALLATIONS; THERMAL INSULATION IN GENERAL

- F16C—SHAFTS; FLEXIBLE SHAFTS; ELEMENTS OR CRANKSHAFT MECHANISMS; ROTARY BODIES OTHER THAN GEARING ELEMENTS; BEARINGS

- F16C19/00—Bearings with rolling contact, for exclusively rotary movement

- F16C19/02—Bearings with rolling contact, for exclusively rotary movement with bearing balls essentially of the same size in one or more circular rows

- F16C19/14—Bearings with rolling contact, for exclusively rotary movement with bearing balls essentially of the same size in one or more circular rows for both radial and axial load

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F16—ENGINEERING ELEMENTS AND UNITS; GENERAL MEASURES FOR PRODUCING AND MAINTAINING EFFECTIVE FUNCTIONING OF MACHINES OR INSTALLATIONS; THERMAL INSULATION IN GENERAL

- F16C—SHAFTS; FLEXIBLE SHAFTS; ELEMENTS OR CRANKSHAFT MECHANISMS; ROTARY BODIES OTHER THAN GEARING ELEMENTS; BEARINGS

- F16C2326/00—Articles relating to transporting

- F16C2326/01—Parts of vehicles in general

- F16C2326/02—Wheel hubs or castors

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F16—ENGINEERING ELEMENTS AND UNITS; GENERAL MEASURES FOR PRODUCING AND MAINTAINING EFFECTIVE FUNCTIONING OF MACHINES OR INSTALLATIONS; THERMAL INSULATION IN GENERAL

- F16C—SHAFTS; FLEXIBLE SHAFTS; ELEMENTS OR CRANKSHAFT MECHANISMS; ROTARY BODIES OTHER THAN GEARING ELEMENTS; BEARINGS

- F16C33/00—Parts of bearings; Special methods for making bearings or parts thereof

- F16C33/72—Sealings

- F16C33/76—Sealings of ball or roller bearings

- F16C33/768—Sealings of ball or roller bearings between relatively stationary parts, i.e. static seals

Landscapes

- Engineering & Computer Science (AREA)

- General Engineering & Computer Science (AREA)

- Mechanical Engineering (AREA)

- Sealing Of Bearings (AREA)

- Rolling Contact Bearings (AREA)

Description

【0001】

【発明の属する技術分野】

この発明に係るエンコーダ付組み合わせシールリングを備えた転がり軸受ユニットは、自動車の車輪を懸架装置に対し回転自在に支持する。又、エンコーダ付組み合わせシールリングにより、転がり軸受ユニットを密封すると共に、この転がり軸受ユニットにより支持された車輪の回転速度を検出する。

【0002】

【従来の技術】

自動車の車輪を懸架装置に対して回転自在に支持すると共に、アンチロックブレーキシステム(ABS)やトラクションコントロールシステム(TCS)を制御すべく、この車輪の回転速度を検出する為に従来から、例えば特開昭64−21219号公報に記載されている様なエンコーダ付転がり軸受ユニットが知られている。又、転がり軸受ユニットの端部開口を塞ぐシールリングの一部にエンコーダを組み付ける構造も、例えば特開平5−26233号公報、同5−238369号公報、同6−281018号公報、同9−274051号公報、同11−44702号公報、欧州特許公報EP 0 495 323 A1 等に記載されている様に、従来から知られている。

【0003】

車輪の回転速度検出を磁気的に行なう場合、上記エンコーダとして、円周方向に関して磁気特性が交互に(一般的には等間隔に)変化するものを使用する。この様に円周方向に関して磁気特性が交互に変化するエンコーダとしては、磁性材に円周方向に亙り多数の除肉部と充実部とを交互に形成したもの、或はS極とN極とを交互に配置した永久磁石が使用される。このうち、永久磁石製のエンコーダは、センサ側の構造を簡単に構成し、しかも低速時の検出精度を確保する面から、近年使用される場合が増大している。

【0004】

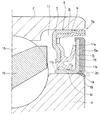

図2は、この様な永久磁石製のエンコーダを使用したエンコーダ付組み合わせシールリングを備えた転がり軸受ユニットの従来構造の1例を示している。このエンコーダ付組み合わせシールリング1は、固定輪である外輪2の端部に内嵌固定するシールリング3と、鋼板或はステンレス鋼板等の磁性金属板製で、回転輪である内輪4の端部に外嵌固定するスリンガ5と、このスリンガ5に支持固定されるエンコーダ6とを備える。

【0005】

このうちのシールリング3は、断面L字形で全体が円環状の芯金7と、弾性材8とから成る。このうちの芯金7は、軟鋼板等の金属板により、断面L字形で全体を円環状に形成して成り、上記外輪2の端部内周面に締り嵌めにより内嵌固定される固定円筒部9と、この固定円筒部9の軸方向(図2の左右方向)端縁から、上記内輪4の外周面に向け、直径方向内方に折れ曲がった固定円輪部10とを有する。又、上記弾性材8は、上記芯金7の全周に亙って添着されたもので、1乃至複数本(図示の例では3本)のシールリップ11a〜11cを有する。一般的には、上記弾性材8は、ゴム製とし、上記芯金7に対し焼き付けにより結合している。

【0006】

一方、上記スリンガ5は、上記内輪4の端部外周面に締り嵌めにより外嵌固定される回転円筒部12と、この回転円筒部12の軸方向端縁から、上記外輪2の内周面に向け、直径方向に折れ曲がった回転円輪部13とを備える。又、上記スリンガ5は、弾性材を備えず、上記回転円筒部12の外周面及び上記回転円輪部13の片側面で上記シールリップ11a〜11cの先端縁を摺接させる部分を、それぞれ平滑面としている。

【0007】

上記エンコーダ6は、円周方向に亙って、S極とN極とを交互に配置したゴム磁石製である。即ち、このエンコーダ6は、ゴム中にフェライト粉末を混入したゴム磁石を円輪状に形成したもので、軸方向に亙って着磁している。着磁方向は、円周方向に亙って交互に且つ等間隔で変化させている。従って、上記エンコーダ6の側面にはS極とN極とが、円周方向に亙って交互に且つ等間隔で配置されている。この様なエンコーダ6は、上記回転円輪部13の側面で上記各シールリップ11a〜11cとは反対側に位置する面に添着支持されている。又、上記エンコーダ6は、内周縁部を上記スリンガ5の上記回転円筒部12と上記回転円輪部13とを連続させる曲面部14にまで延長している。これにより上記エンコーダ6と上記スリンガ5との接合強度の向上を図っている。

【0008】

上述の様に構成するエンコーダ付組み合わせシールリング1を組み込む転がり軸受ユニットは、固定輪である上記外輪2を自動車の懸架装置に対して支持固定し、上記内輪4と共に回転輪を構成するハブに車輪を固定している。そして、この内輪4及びハブの外周面と上記外輪2の内周面との間に複数個の玉15を、保持器16により保持した状態で転動自在に設け、上記内輪4及びハブの上記外輪2に対する回転を自在としている。

【0009】

又、上記外輪2の内周面と上記内輪4及びハブの外周面との間に存在する空間17の開口端部を、上記エンコーダ付組み合わせシールリング1で塞ぐ事により、この空間17に塵芥及び雨水等の異物が進入する事を防止すると共に、この空間17部分に存在するグリースが外部に漏洩するのを防止する。即ち、上記外輪2の端部に前記固定円筒部8を内嵌固定すると共に、上記内輪4の端部に前記回転円筒部12を締り嵌めで外嵌固定し、この状態で、上記シールリング3を構成するシールリップ11a〜11cの先端縁を上記回転円筒部12の外周面及び前記回転円輪部13の側面に摺接させる事により、上記空間17の開口端部を塞いでいる。尚、上記空間17の(図示しない)他方の開口端部は、エンコーダを備えない組み合わせシールリングにより塞ぐ。又、上記エンコーダ6の前記回転円輪部13と反対側の面を図示しない回転速度検出器に対向させ、上記内輪4と共に回転輪を構成するハブに固定された車輪の回転速度を検出自在とする。尚、上記エンコーダ6の側面と上記内輪4の端面とは、一般的には同一平面上に位置させる。この理由は、上記エンコーダ6が内輪4の端面から突出する事によりこのエンコーダ6が損傷し易くなるのを防止すると共に、このエンコーダ6の側面が内輪4の端面より引っ込む事で、このエンコーダ6の側面とセンサの検出部とを近接対向させにくくなるのを防止する為である。

【0010】

上述した従来構造の第1例のエンコーダ付組み合わせシールリングを備えた転がり軸受ユニットの場合、塵芥等の比較的大きい異物の進入は防止できるが、雨水や泥水等の進入を防ぐには不十分である。これは、図2に示す様に、上記エンコーダ6の内周縁部と上記内輪4の外周面との間に隙間18が存在する為である。雨水等がこの隙間18から進入した場合、上記エンコーダ5を構成する回転円筒部12と内輪4との嵌合部の僅かな隙間から、上記雨水等が上記空間17に進入する可能性がある。即ち、上記回転円筒部12は内輪4の外周面に締り嵌めで外嵌するが、嵌合面が金属同士の接触であり、回転円筒部12の内周面と内輪4の外周面の真円度や表面粗さ等の精度によっては、上記嵌合面同士の間に僅かな隙間が生じる。そして、上記空間17内の圧力が外部の圧力より(例えば温度変化により)低下した時、上記隙間18から進入した雨水等を空間17内に吸い込む可能性がある。そして、この空間17内に水分が入り込んだ場合には、上記内輪4及び外輪2の各軌道面及び玉15の転動面が錆びて、転がり軸受ユニットの性能及び寿命の低下を招く。

【0011】

上述の様な雨水等の空間17内への進入を防ぐ為、図3に示す様なエンコーダ付組み合わせシールリング1aを使用する事が考えられる。この改良された構造では、エンコーダ6aの内周縁に舌状部19を、全周に亙って形成している。スリンガ5に設けた回転円筒部12を内輪4の端部に外嵌した状態でこの舌状部19は、弾性的に圧縮された状態で内輪4の外周面に当接する。即ち、上記舌状部19の自由状態での内径は上記内輪4の外径よりも小さく、上記エンコーダ6aを回転円輪部13に添着したスリンガ5の回転円筒部12を内輪4に外嵌すると、上記舌状部19は弾性変形した状態で内輪4の外周面に当接する。この改良された構造では、この舌状部19がこの内輪4の外周面に、全周に亙り弾性的に当接する事で、上記回転円筒部12と内輪4との嵌合部をシールする。この結果、雨水等が上記回転円筒部12と内輪4との嵌合部を通って上記空間17内に進入する事を十分に防止できる。

【0012】

【発明が解決しようとする課題】

しかし、上述した様な改良された構造では、舌状部19により空間17内への雨水等の進入を防ぐ事はできるが、この舌状部19が上記内輪4の外周面に当接して弾性変形する事に伴い、図3に鎖線で示す様に、舌状部19の一部が、エンコーダ5aの本体部分の側面及び上記内輪4の端面から軸方向に突出する。この様にして内輪4の端面から突出した突出部20は、回転速度検出等の機能上の問題とはならないが、搬送時等に、他の部材と干渉し、エンコーダ6aの破損に結び付く可能性があり、好ましくない。

本発明のエンコーダ付組み合わせシールリングを備えた転がり軸受ユニットは、上述の様な事情に鑑みて発明したものである。

【0013】

【課題を解決する為の手段】

本発明のエンコーダ付組み合わせシールリングを備えた転がり軸受ユニットは、固定輪である外輪と、回転輪である内輪と、この外輪の内周面とこの内輪の外周面との間に転動自在に設けた複数の転動体と、この外輪の内周面とこの内輪の外周面との間に存在する空間の開口端部を塞ぐと共に、上記内輪の回転速度を検出する為に使用するエンコーダ付組み合わせシールリングとを備える。

又、上記内輪の外周面のうちの上記空間の開口端部側の端縁部に、面取りを形成している。

又、上記エンコーダ付組み合わせシールリングは、上記外輪の内周面に固定されるシールリングと、上記内輪の外周面に固定される金属製のスリンガと、このスリンガに支持固定されるエンコーダとを備える。

又、上記シールリングは、上記外輪の内周面に嵌合固定される固定円筒部及びこの固定円筒部の端縁から径方向内方に折れ曲がった固定円輪部から成る芯金と、この芯金の全周に亙って添着された、シールリップを有する弾性材とを備える。

又、上記スリンガは、上記内輪の外周面に嵌合固定される回転円筒部と、この回転円筒部の端縁から径方向外方に折れ曲がった回転円輪部とを備えて、弾性材を備えず、上記回転円筒部の外周面及び上記回転円輪部の片側面で上記シールリップの先端縁を摺接させる部分を平滑面とすると共に、この回転円輪部のうちで上記回転円筒部との連続部を除く部分を平板状としている。

更に、上記エンコーダは、円周方向に亙ってS極とN極とを交互に配置したゴム磁石製で、上記回転円輪部の側面で上記シールリップとは反対側に位置する面に添着支持されていて、軸方向に関する厚さが、外周縁の係止部を形成した部分及び内周縁寄りの凹入部を形成した部分を除き、一定である。

特に、本発明のエンコーダ付組み合わせシールリングを備えた転がり軸受ユニットの場合、上記エンコーダの内周縁に、弾性変形した状態で上記内輪の外周面のうち上記面取りを形成した部分から外れた部分に当接する舌状部を全周に亙って形成すると共に、上記エンコーダの軸方向両側面のうちの上記回転円輪部と反対側面の内周縁寄り部分に、他の部分よりも上記回転円輪部側に凹入した凹入部を、全周に亙って設けている。

又、上記舌状部の先端縁を、上記内輪の外周面端縁部に形成した上記面取りの外径側に存在させ、この内輪の上記空間の開口端部側の端面から突出しない様にしている。

【0014】

【作用】

上述の様に構成される本発明のエンコーダ付組み合わせシールリングを備えた転がり軸受ユニットで、外輪の内周面と内輪の外周面との間の空間内に異物が進入する事を防止すると共に、この空間内に充填されたグリースが外部に漏洩する事を防止する作用、及び、内輪の回転速度を検出自在とする作用は、前述の従来構造或は改良した構造のエンコーダ付組み合わせシールリングを備えた転がり軸受ユニットの場合と同様である。

特に、本発明のエンコーダ付組み合わせシールリングを備えた転がり軸受ユニットの場合、十分なシール性能を確保しつつ、エンコーダの一部が上記内輪の端面から突出しない様にできる。即ち、エンコーダの内周縁に形成した舌状部が、弾性的に圧縮された状態で、上記内輪の外周面のうち面取りを形成した部分から外れた部分に、全周に亙って当接する事により、上記エンコーダの内周縁と上記内輪との間を、全周に亙ってシールする。そして、この内輪と回転円筒部との嵌合面から上記空間内に雨水等が進入するのを防止する。又、上記エンコーダの軸方向両側面のうち、回転円輪部と反対側面で上記舌状部を形成した周縁寄り部分に、他の部分よりも上記回転円輪部側に凹入した凹入部を、上記内輪の外周面端縁部に上記面取りを、それぞれ設けている為、上記舌状部が上記内輪の外周面に当接して弾性変形しても、上記凹入部の存在により上記舌状部の弾性変形部分がこの凹入部内に留まり、上記舌状部が内輪の端面から突出しない。

【0015】

【発明の実施の形態】

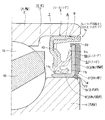

図1は、本発明の実施の形態の1例を示している。尚、本発明の特徴は、エンコーダ6bの内周縁に舌状部19を形成すると共に、片側面(図1の右面)の内周縁寄り部分に凹入部21を形成し、この舌状部19の先端縁を、内輪4の外周面端縁部に形成した面取り23の外径側に存在させ、この内輪4の端面から突出しない様にした点にある。その他の部分の構成及び作用は、前述の図2に示した従来構造、或は前述の図3に示した改良した構造と同様であるから、同等部分には同一符号を付して、重複する説明を省略若しくは簡略にし、以下、本発明の特徴部分、並びに上記先に述べた各構造と異なる部分を中心に説明する。

【0016】

図1に示すエンコーダ付組み合わせシールリング1bは、従来構造と同様に、外輪2の内周面に内嵌固定されたシールリング3と、内輪4に外嵌固定されたスリンガ5と、このスリンガ5の回転円輪部13の片側面に添着したエンコーダ6bとから成る。本発明の場合、前述の図3に示した改良した構造の様に、このエンコーダ6bの内周縁に、弾性変形した状態で上記内輪4の外周面のうち上記面取り23を形成した部分から外れた部分に当接する舌状部19を、全周に亙って形成している。即ち、この舌状部19は、上記エンコーダ6aと一体に形成されたゴム磁石製で、自由状態での内径は上記内輪4の外径よりも小さい。この為、このエンコーダ6bを添着した上記スリンガ5を内輪4に外嵌した場合に、上記舌状部19は、弾性的に圧縮された状態で、この内輪4の外周面のうち上記面取り23を形成した部分から外れた部分に、全周に亙って弾性的に当接する。

【0017】

又、上記エンコーダ6bの軸方向(図1の左右方向)両側面のうちの上記回転円輪部13と反対側面(図1の右側面)で、上記舌状部19を形成した内周縁寄り部分に、他の部分よりも上記回転円輪部13側に凹入した凹入部21を、全周に亙って設けている。この凹入部21の大きさは、上記舌状部19が上記内輪の外周面との当接に基づいて弾性的に圧縮された状態での弾性変形量を考慮して決める。即ち、この舌状部19が弾性変形した状態でも、この舌状部19の先端部が上記内輪4の端面から軸方向(図1の右方)に突出しない様に、上記凹入部21の大きさを定める。又、上記舌状部19の先端縁を、上記内輪4の外周面端縁部に形成した面取り23の外径側に存在させ、この内輪4の端面から突出しない様にしている。

【0018】

尚、上記エンコーダ6bの外周縁部には、上記回転円輪部13の外周縁を越えて回転円輪部13のシールリップ11aが摺接する面にまで延長した係止部22を形成している。これにより上記エンコーダ6bと上記スリンガ5との接合強度の向上を図っている。

【0019】

上述の様に構成される本発明のエンコーダ付組み合わせシールリングを備えた転がり軸受ユニットは、前述した従来構造及び改良した構造の場合と同様に、自動車の車輪を支持する。又、エンコーダ付組み合わせシールリング1bにより、内輪4と外輪2との間で玉15が存在する空間17に異物が侵入する事を防止すると共に、上記車輪の回転速度を検出自在とする。

特に、本発明の場合、十分なシール性能を確保しつつ、上記エンコーダ6bの一部が上記内輪4の端面から軸方向に突出しない様にできる。即ち、上記エンコーダ6bの内周縁に形成した舌状部19が上記内輪4の端部外周面との当接に基づいて弾性変形した状態で、この舌状部19が上記内輪4の外周面のうち上記面取り23を形成した部分から外れた部分に、全周に亙って弾性的に当接する事により、上記エンコーダ6bの内周縁と前記内輪4との間を全周に亙ってシールする。そして、この内輪4の外周面と上記スリンガ5の回転円筒部12の内周面との当接部である嵌合面から、上記空間17内に雨水等が進入するのを防止する。又、上記エンコーダ6bの上記回転円輪部13と反対側面で上記舌状部19を形成した内周縁寄り部分に、他の部分よりも上記回転円輪部13側に凹入した凹入部21を設けている為、上記舌状部19が上記内輪4の外周面に当接して弾性変形しても、上記凹入部21の存在により上記舌状部19の弾性変形部分が、図1に鎖線で示す様にこの凹入部21内に留まり、上記舌状部19が、上記エンコーダ6bの本体部分の側面及び内輪4の端面から軸方向に突出しない。従って、搬送時等にも、このエンコーダ6bが他の部材と干渉しにくい。

【0020】

尚、本例の場合、転動体として玉15を使用しているが、重量の嵩む自動車用の転がり軸受ユニットの場合には、この玉15に代えてテーパころを使用する場合もある。

【0021】

【発明の効果】

本発明のエンコーダ付組み合わせシールリングを備えた転がり軸受ユニットは、以上に述べた通り構成され作用する為、優れたシール性を有し、しかも、搬送時等にエンコーダが他の部材と干渉して、破損する事がない。

【図面の簡単な説明】

【図1】 本発明の実施の形態の1例を示す部分拡大断面図。

【図2】 従来構造の1例を示す部分拡大断面図。

【図3】 この従来構造を改良した構造を示す部分拡大断面図。

【符号の説明】

1、1a、1b エンコーダ付組み合わせシールリング

2 外輪

3 シールリング

4 内輪

5 スリンガ

6、6a、6b エンコーダ

7 芯金

8 弾性変形

9 固定円筒部

10 固定円輪部

11a、11b、11c シールリップ

12 回転円筒部

13 回転円輪部

14 曲面部

15 玉

16 保持器

17 空間

18 隙間

19 舌状部

20 突出部

21 凹入部

22 係止部

23 面取り [0001]

BACKGROUND OF THE INVENTION

A rolling bearing unit including a combined seal ring with an encoder according to the present invention supports a wheel of an automobile so as to be rotatable with respect to a suspension device . The rolling bearing unit is hermetically sealed by a combined seal ring with an encoder, and the rotational speed of the wheel supported by the rolling bearing unit is detected.

[0002]

[Prior art]

Conventionally, in order to detect the rotational speed of an automobile wheel to detect the rotational speed of the wheel in order to support the wheel of the automobile rotatably with respect to the suspension system and to control the anti-lock brake system (ABS) and the traction control system (TCS), for example, A rolling bearing unit with an encoder as described in Japanese Utility Model Laid-Open No. 64-21219 is known. In addition, a structure in which an encoder is assembled to a part of a seal ring that closes an end opening of a rolling bearing unit is disclosed in, for example, Japanese Patent Laid-Open Nos. 5-26233, 5-238369, 6-281018, and 9-274051. No. 11-44702, European Patent Publication EP 0 495 323 A1, and the like are conventionally known.

[0003]

When the rotational speed of a wheel is detected magnetically, an encoder whose magnetic characteristics change alternately (generally at regular intervals) in the circumferential direction is used as the encoder. In this way, as an encoder whose magnetic characteristics alternately change in the circumferential direction, a magnetic material is formed by alternately forming a number of thinned portions and solid portions in the circumferential direction, or S pole and N pole. Permanent magnets arranged alternately are used. Of these, encoders made of permanent magnets are increasingly used in recent years from the viewpoint of simply configuring the sensor-side structure and ensuring detection accuracy at low speeds.

[0004]

FIG. 2 shows an example of a conventional structure of a rolling bearing unit provided with a combined seal ring with an encoder using such a permanent magnet encoder. This combination seal ring 1 with an encoder is made of a

[0005]

Among these, the

[0006]

On the other hand, the

[0007]

The

[0008]

The rolling bearing unit incorporating the combined seal ring 1 with an encoder configured as described above supports and fixes the

[0009]

Further, the open end of the

[0010]

In the case of the rolling bearing unit provided with the combination seal ring with the encoder of the first example of the conventional structure described above, the entry of relatively large foreign matters such as dust can be prevented, but it is not sufficient to prevent the entry of rainwater, muddy water, etc. is there. This is because a

[0011]

In order to prevent the rain water or the like from entering the

[0012]

[Problems to be solved by the invention]

However, with the improved structure as described above, it is possible to prevent rainwater or the like from entering the

The rolling bearing unit provided with the combined seal ring with an encoder of the present invention has been invented in view of the above-described circumstances.

[0013]

[Means for solving the problems]

The rolling bearing unit provided with the combined seal ring with an encoder according to the present invention is capable of rolling between an outer ring that is a fixed ring, an inner ring that is a rotating ring, and an inner peripheral surface of the outer ring and an outer peripheral surface of the inner ring. A plurality of rolling elements provided, and a combination with an encoder used for closing the opening end of the space existing between the inner peripheral surface of the outer ring and the outer peripheral surface of the inner ring and detecting the rotational speed of the inner ring A seal ring.

Further, a chamfer is formed on the edge of the inner ring on the opening end side of the space.

The combined seal ring with an encoder includes a seal ring fixed to the inner peripheral surface of the outer ring, a metal slinger fixed to the outer peripheral surface of the inner ring, and an encoder supported and fixed to the slinger. .

The seal ring includes a cored bar including a fixed cylindrical part fitted and fixed to the inner peripheral surface of the outer ring, a fixed ring part bent radially inward from an edge of the fixed cylindrical part, and the core And an elastic material having a seal lip attached over the entire circumference of the gold.

The slinger includes a rotating cylindrical portion that is fitted and fixed to the outer peripheral surface of the inner ring, and a rotating annular portion that is bent radially outward from an edge of the rotating cylindrical portion, and includes an elastic material. First, a portion of the outer peripheral surface of the rotating cylindrical portion and the one side surface of the rotating annular portion that is in sliding contact with the tip edge of the seal lip is a smooth surface, and of the rotating annular portion, The part excluding the continuous part is flat .

Further, the encoder is made of a rubber magnet in which S poles and N poles are alternately arranged in the circumferential direction, and is attached to a surface located on the side opposite to the seal lip on the side surface of the rotating annular portion. It is supported, and the thickness in the axial direction is constant except for the portion where the outer peripheral edge locking portion is formed and the portion where the inner peripheral edge-side recessed portion is formed .

In particular, in the case of the rolling bearing unit with an encoder with combination seal ring of the present invention, the inner peripheral edge of the encoder, the portion deviated from the portion formed with the chamfer of the outer circumferential surface of the inner ring in an elastically deformed state those A tongue-like portion that is in contact with each other is formed over the entire circumference, and the rotating annular portion is located closer to the inner peripheral edge of the side surface opposite to the rotating annular portion of both sides in the axial direction of the encoder than the other portions. The recessed part recessed in the side is provided over the perimeter.

Further, the tip edge of the tongue-like portion is present on the outer diameter side of the chamfer formed on the outer peripheral surface edge of the inner ring so as not to protrude from the end surface of the inner ring on the opening end side. Yes.

[0014]

[Action]

In the rolling bearing unit provided with the combined seal ring with an encoder of the present invention configured as described above, while preventing foreign matter from entering the space between the inner peripheral surface of the outer ring and the outer peripheral surface of the inner ring, The function of preventing the grease filled in the space from leaking to the outside and the function of allowing the rotational speed of the inner ring to be detected include the above-described conventional structure or a combined seal ring with an encoder having an improved structure. This is the same as the case of the rolling bearing unit.

In particular, in the case of a rolling bearing unit provided with the combined seal ring with an encoder of the present invention, it is possible to prevent a part of the encoder from protruding from the end face of the inner ring while ensuring sufficient sealing performance. That is, the tongue portion formed on the inner peripheral edge of the encoder is in a state of being elastically compressed in a portion deviated from the portion forming a chamfer of the outer circumferential surface of the inner ring, it abuts over the entire circumference Accordingly, between the inner peripheral edge and the inner ring of the encoder and the seal over the entire periphery. Then, rainwater and the like are prevented from entering the space from the fitting surface between the inner ring and the rotating cylindrical portion. Further, of the both sides in the axial direction of the encoder, a recessed portion that is recessed closer to the rotating ring part than the other part is formed on the side near the periphery where the tongue-shaped part is formed on the side opposite to the rotating ring part. , the chamfered outer circumference edge portion of the inner ring, because they respectively, be elastically deformed the tongues in contact with the outer peripheral surface of the inner ring, the tongue by the presence of the recessed portion The elastically deformed portion remains in the recessed portion, and the tongue portion does not protrude from the end face of the inner ring.

[0015]

DETAILED DESCRIPTION OF THE INVENTION

FIG. 1 shows an example of an embodiment of the present invention. The feature of the present invention is that a tongue-shaped

[0016]

A combined

[0017]

Further, the inner peripheral edge portion where the tongue-shaped

[0018]

The outer peripheral edge of the encoder 6b is formed with a locking

[0019]

The rolling bearing unit including the combined seal ring with an encoder of the present invention configured as described above supports the wheel of an automobile as in the case of the conventional structure and the improved structure described above. Further, the combined

In particular, in the case of the present invention, it is possible to prevent a part of the encoder 6b from protruding in the axial direction from the end face of the

[0020]

In this example, the

[0021]

【The invention's effect】

The rolling bearing unit provided with the combined seal ring with an encoder according to the present invention is configured and operates as described above, and thus has an excellent sealing property, and the encoder interferes with other members during transportation. No damage.

[Brief description of the drawings]

FIG. 1 is a partially enlarged sectional view showing an example of an embodiment of the present invention.

FIG. 2 is a partially enlarged sectional view showing an example of a conventional structure.

FIG. 3 is a partially enlarged sectional view showing a structure obtained by improving the conventional structure.

[Explanation of symbols]

DESCRIPTION OF

23 Chamfering

Claims (1)

上記内輪の外周面のうちの上記空間の開口端部側の端縁部に、面取りを形成しており、

上記エンコーダ付組み合わせシールリングは、上記外輪の内周面に固定されるシールリングと、上記内輪の外周面に固定される金属製のスリンガと、このスリンガに支持固定されるエンコーダとを備え、

上記シールリングは、上記外輪の内周面に嵌合固定される固定円筒部及びこの固定円筒部の端縁から径方向内方に折れ曲がった固定円輪部から成る芯金と、この芯金の全周に亙って添着された、シールリップを有する弾性材とを備え、

上記スリンガは、上記内輪の外周面に嵌合固定される回転円筒部と、この回転円筒部の端縁から径方向外方に折れ曲がった回転円輪部とを備えて、弾性材を備えず、上記回転円筒部の外周面及び上記回転円輪部の片側面で上記シールリップの先端縁を摺接させる部分を平滑面とすると共に、この回転円輪部のうちで上記回転円筒部との連続部を除く部分を平板状としており、

上記エンコーダは、円周方向に亙ってS極とN極とを交互に配置したゴム磁石製で、上記回転円輪部の側面で上記シールリップとは反対側に位置する面に添着支持されていて、軸方向に関する厚さが、外周縁の係止部を形成した部分及び内周縁寄りの凹入部を形成した部分を除き一定であり、

上記エンコーダの内周縁に、弾性変形した状態で上記内輪の外周面のうち上記面取りを形成した部分から外れた部分に当接する舌状部を全周に亙って形成すると共に、上記エンコーダの軸方向両側面のうちの上記回転円輪部と反対側面の内周縁寄り部分に、他の部分よりも上記回転円輪部側に凹入した上記凹入部を全周に亙って設けており、

上記舌状部の先端縁は、上記内輪の外周面端縁部に形成した上記面取りの外径側に存在し、この内輪の上記空間の開口端部側の端面から突出しない事を特徴とするエンコーダ付組み合わせシールリングを備えた転がり軸受ユニット。An outer ring that is a fixed ring, an inner ring that is a rotating ring, a plurality of rolling elements provided between the inner peripheral surface of the outer ring and the outer peripheral surface of the inner ring, the inner peripheral surface of the outer ring and the inner ring Rolling with a combined seal ring with an encoder that closes the open end of the space that exists between the outer ring and the inner ring and that has a combined seal ring with an encoder that is used to detect the rotational speed of the inner ring A bearing unit,

A chamfer is formed at the edge of the outer ring of the inner ring on the opening end side of the space,

The combined seal ring with an encoder includes a seal ring fixed to the inner peripheral surface of the outer ring, a metal slinger fixed to the outer peripheral surface of the inner ring, and an encoder supported and fixed to the slinger.

The seal ring includes a fixed cylindrical portion that is fitted and fixed to the inner peripheral surface of the outer ring, a fixed metal portion that is bent radially inward from an edge of the fixed cylindrical portion, An elastic material having a seal lip attached to the entire circumference,

The slinger includes a rotating cylindrical portion that is fitted and fixed to the outer peripheral surface of the inner ring, and a rotating annular portion that is bent radially outward from an edge of the rotating cylindrical portion, and does not include an elastic material. A portion where the tip edge of the seal lip is slidably contacted on the outer peripheral surface of the rotating cylindrical portion and one side surface of the rotating annular portion is a smooth surface, and the rotation annular portion is continuous with the rotating cylindrical portion. The part excluding the part is flat ,

The encoder is made of a rubber magnet in which S poles and N poles are alternately arranged in the circumferential direction, and is attached to and supported by a surface located on the side opposite to the seal lip on the side surface of the rotating ring portion. And the thickness in the axial direction is constant except for the portion where the outer peripheral engaging portion is formed and the portion where the inner peripheral peripheral recess is formed,

The inner peripheral edge of the encoder, so as to form across the tongues abutting the entire circumference at a portion deviated from the portion formed with the chamfer of the outer circumferential surface of the inner ring in an elastically deformed state, of the encoder shaft the inner peripheral edge portion close to the opposite side the rotating annular portion of the opposite sides surfaces, which are provided over the concave portion was also recessed in the rotating annular portion side than the other portion in the entire circumference,

A tip edge of the tongue-like portion is present on the outer diameter side of the chamfer formed on the outer peripheral surface edge of the inner ring, and does not protrude from the end surface on the opening end side of the space of the inner ring. Rolling bearing unit with combined seal ring with encoder.

Priority Applications (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| JP2001138350A JP4604388B2 (en) | 2001-05-09 | 2001-05-09 | Rolling bearing unit with combination seal ring with encoder |

Applications Claiming Priority (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| JP2001138350A JP4604388B2 (en) | 2001-05-09 | 2001-05-09 | Rolling bearing unit with combination seal ring with encoder |

Publications (3)

| Publication Number | Publication Date |

|---|---|

| JP2002333035A JP2002333035A (en) | 2002-11-22 |

| JP2002333035A5 JP2002333035A5 (en) | 2008-06-19 |

| JP4604388B2 true JP4604388B2 (en) | 2011-01-05 |

Family

ID=18985300

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| JP2001138350A Expired - Fee Related JP4604388B2 (en) | 2001-05-09 | 2001-05-09 | Rolling bearing unit with combination seal ring with encoder |

Country Status (1)

| Country | Link |

|---|---|

| JP (1) | JP4604388B2 (en) |

Families Citing this family (10)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| JP4582775B2 (en) * | 2004-10-28 | 2010-11-17 | Ntn株式会社 | Wheel bearing device |

| JP2009127668A (en) * | 2007-11-20 | 2009-06-11 | Koyo Sealing Techno Co Ltd | Hermetically sealing device |

| JP2010261598A (en) * | 2010-08-24 | 2010-11-18 | Nsk Ltd | Sealing device and rolling bearing unit with sealing device |

| JP5853563B2 (en) * | 2011-10-05 | 2016-02-09 | 日本精工株式会社 | Manufacturing method of hub unit with encoder and combination seal ring |

| JP6036215B2 (en) * | 2011-11-29 | 2016-11-30 | 日本精工株式会社 | Rolling bearing unit with combination seal ring |

| ITTO20130802A1 (en) * | 2013-10-03 | 2015-04-04 | Skf Ab | DRIP HOLDING DEVICE, IN PARTICULAR FOR ROLLING BEARINGS |

| ITTO20130799A1 (en) * | 2013-10-03 | 2015-04-04 | Skf Ab | LOW FRICTION SEALING COMPLEX, IN PARTICULAR FOR ROLLING BEARINGS |

| ITTO20130800A1 (en) * | 2013-10-03 | 2015-04-04 | Skf Ab | SEALING UNIT, IN PARTICULAR FOR ROLLING BEARINGS |

| JP7308963B2 (en) | 2019-09-24 | 2023-07-14 | Nok株式会社 | sealing device |

| US12013038B2 (en) | 2020-06-12 | 2024-06-18 | Nok Corporation | Sealing device |

Citations (2)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| JPH06281018A (en) * | 1993-01-19 | 1994-10-07 | Snr Roulements | Coder built-in sealing structure |

| JPH11304827A (en) * | 1998-04-22 | 1999-11-05 | Nippon Seiko Kk | Rolling bearing unit with encoder |

-

2001

- 2001-05-09 JP JP2001138350A patent/JP4604388B2/en not_active Expired - Fee Related

Patent Citations (2)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| JPH06281018A (en) * | 1993-01-19 | 1994-10-07 | Snr Roulements | Coder built-in sealing structure |

| JPH11304827A (en) * | 1998-04-22 | 1999-11-05 | Nippon Seiko Kk | Rolling bearing unit with encoder |

Also Published As

| Publication number | Publication date |

|---|---|

| JP2002333035A (en) | 2002-11-22 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| JP3968857B2 (en) | Seal structure of rotation speed detector | |

| JP4925397B2 (en) | Sealing device | |

| JP4925398B2 (en) | Sealing device | |

| JP2000289405A (en) | Combined seal ring with encoder | |

| US20110089642A1 (en) | Bearing Seal | |

| JPH08278319A (en) | Packing device | |

| JP4206550B2 (en) | Rolling bearing unit with rotational speed detector | |

| JP4604388B2 (en) | Rolling bearing unit with combination seal ring with encoder | |

| JP3656530B2 (en) | Combination seal ring with encoder and rolling bearing unit for wheel support incorporating this | |

| JP4278324B2 (en) | Wheel bearing | |

| JP2001241435A (en) | Rolling bearing unit with encoder for automobile | |

| JP5145958B2 (en) | Combination seal ring with encoder | |

| JP4720400B2 (en) | Rolling bearing unit for wheel support with combined seal ring and manufacturing method thereof | |

| JP2002333035A5 (en) | ||

| JP4867454B2 (en) | SEALING DEVICE WITH MULTI-POLE MAGNET ENCODER Rolling bearing and wheel support bearing unit provided with the sealing device | |

| JP2007333188A (en) | Rotating speed detecting mechanism, rolling bearing equipped with rotating speed detecting mechanism, and wheel support bearing unit | |

| JP4239669B2 (en) | Rolling bearing unit for wheel support | |

| JP5061652B2 (en) | Magnetized pulsar ring and sensor-equipped rolling bearing device using the same | |

| JP4798763B2 (en) | Tone wheel with protective cover | |

| JP4105379B2 (en) | Wheel bearing | |

| JP2002328133A (en) | Bearing for wheel with revolution speed detector | |

| JP2006064180A5 (en) | ||

| JP2005140334A (en) | Bearing with magnetic encoder | |

| JP5598150B2 (en) | Rolling bearing unit with encoder | |

| JP2006153110A (en) | Bearing seal |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| A521 | Written amendment |

Free format text: JAPANESE INTERMEDIATE CODE: A523 Effective date: 20080507 |

|

| A621 | Written request for application examination |

Free format text: JAPANESE INTERMEDIATE CODE: A621 Effective date: 20080507 |

|

| A977 | Report on retrieval |

Free format text: JAPANESE INTERMEDIATE CODE: A971007 Effective date: 20100115 |

|

| A131 | Notification of reasons for refusal |

Free format text: JAPANESE INTERMEDIATE CODE: A131 Effective date: 20100202 |

|

| A521 | Written amendment |

Free format text: JAPANESE INTERMEDIATE CODE: A523 Effective date: 20100329 |

|

| TRDD | Decision of grant or rejection written | ||

| A01 | Written decision to grant a patent or to grant a registration (utility model) |

Free format text: JAPANESE INTERMEDIATE CODE: A01 Effective date: 20100907 |

|

| A01 | Written decision to grant a patent or to grant a registration (utility model) |

Free format text: JAPANESE INTERMEDIATE CODE: A01 |

|

| A61 | First payment of annual fees (during grant procedure) |

Free format text: JAPANESE INTERMEDIATE CODE: A61 Effective date: 20100920 |

|

| R150 | Certificate of patent or registration of utility model |

Ref document number: 4604388 Country of ref document: JP Free format text: JAPANESE INTERMEDIATE CODE: R150 Free format text: JAPANESE INTERMEDIATE CODE: R150 |

|

| FPAY | Renewal fee payment (event date is renewal date of database) |

Free format text: PAYMENT UNTIL: 20131015 Year of fee payment: 3 |

|

| LAPS | Cancellation because of no payment of annual fees |