JP4471966B2 - Mask cushion and mask - Google Patents

Mask cushion and mask Download PDFInfo

- Publication number

- JP4471966B2 JP4471966B2 JP2006340971A JP2006340971A JP4471966B2 JP 4471966 B2 JP4471966 B2 JP 4471966B2 JP 2006340971 A JP2006340971 A JP 2006340971A JP 2006340971 A JP2006340971 A JP 2006340971A JP 4471966 B2 JP4471966 B2 JP 4471966B2

- Authority

- JP

- Japan

- Prior art keywords

- mask

- cushioning material

- cell foam

- nose

- sides

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Active

Links

- 239000006260 foam Substances 0.000 claims description 59

- 239000000463 material Substances 0.000 claims description 53

- 229920000098 polyolefin Polymers 0.000 claims description 48

- 229920005989 resin Polymers 0.000 claims description 20

- 239000011347 resin Substances 0.000 claims description 20

- 239000005038 ethylene vinyl acetate Substances 0.000 claims description 17

- 229920001200 poly(ethylene-vinyl acetate) Polymers 0.000 claims description 17

- 238000000034 method Methods 0.000 claims description 13

- 229920005672 polyolefin resin Polymers 0.000 claims description 13

- 230000006835 compression Effects 0.000 claims description 11

- 238000007906 compression Methods 0.000 claims description 11

- 230000035699 permeability Effects 0.000 claims description 9

- QTBSBXVTEAMEQO-UHFFFAOYSA-M Acetate Chemical compound CC([O-])=O QTBSBXVTEAMEQO-UHFFFAOYSA-M 0.000 claims description 2

- 125000000391 vinyl group Chemical group [H]C([*])=C([H])[H] 0.000 claims description 2

- 229920002554 vinyl polymer Polymers 0.000 claims description 2

- 238000005187 foaming Methods 0.000 description 23

- 210000004027 cell Anatomy 0.000 description 18

- -1 polyethylene Polymers 0.000 description 10

- XTXRWKRVRITETP-UHFFFAOYSA-N Vinyl acetate Chemical compound CC(=O)OC=C XTXRWKRVRITETP-UHFFFAOYSA-N 0.000 description 8

- 230000000052 comparative effect Effects 0.000 description 7

- 239000003431 cross linking reagent Substances 0.000 description 6

- 239000004088 foaming agent Substances 0.000 description 5

- 239000011521 glass Substances 0.000 description 5

- 239000004745 nonwoven fabric Substances 0.000 description 5

- 239000004698 Polyethylene Substances 0.000 description 4

- XLOMVQKBTHCTTD-UHFFFAOYSA-N Zinc monoxide Chemical compound [Zn]=O XLOMVQKBTHCTTD-UHFFFAOYSA-N 0.000 description 4

- 229920001684 low density polyethylene Polymers 0.000 description 4

- 239000004702 low-density polyethylene Substances 0.000 description 4

- 229920000573 polyethylene Polymers 0.000 description 4

- 239000004814 polyurethane Substances 0.000 description 4

- 229920002635 polyurethane Polymers 0.000 description 4

- 239000004156 Azodicarbonamide Substances 0.000 description 3

- 239000004743 Polypropylene Substances 0.000 description 3

- XOZUGNYVDXMRKW-AATRIKPKSA-N azodicarbonamide Chemical compound NC(=O)\N=N\C(N)=O XOZUGNYVDXMRKW-AATRIKPKSA-N 0.000 description 3

- 235000019399 azodicarbonamide Nutrition 0.000 description 3

- 229920001577 copolymer Polymers 0.000 description 3

- 238000010586 diagram Methods 0.000 description 3

- 239000000835 fiber Substances 0.000 description 3

- 239000000945 filler Substances 0.000 description 3

- 239000000203 mixture Substances 0.000 description 3

- 229920001155 polypropylene Polymers 0.000 description 3

- 229920002994 synthetic fiber Polymers 0.000 description 3

- 239000012209 synthetic fiber Substances 0.000 description 3

- OZAIFHULBGXAKX-UHFFFAOYSA-N 2-(2-cyanopropan-2-yldiazenyl)-2-methylpropanenitrile Chemical compound N#CC(C)(C)N=NC(C)(C)C#N OZAIFHULBGXAKX-UHFFFAOYSA-N 0.000 description 2

- XMNIXWIUMCBBBL-UHFFFAOYSA-N 2-(2-phenylpropan-2-ylperoxy)propan-2-ylbenzene Chemical compound C=1C=CC=CC=1C(C)(C)OOC(C)(C)C1=CC=CC=C1 XMNIXWIUMCBBBL-UHFFFAOYSA-N 0.000 description 2

- 208000035285 Allergic Seasonal Rhinitis Diseases 0.000 description 2

- XSQUKJJJFZCRTK-UHFFFAOYSA-N Urea Chemical compound NC(N)=O XSQUKJJJFZCRTK-UHFFFAOYSA-N 0.000 description 2

- 239000000853 adhesive Substances 0.000 description 2

- 230000001070 adhesive effect Effects 0.000 description 2

- 150000001336 alkenes Chemical class 0.000 description 2

- 239000004202 carbamide Substances 0.000 description 2

- 239000003795 chemical substances by application Substances 0.000 description 2

- 238000013329 compounding Methods 0.000 description 2

- 235000014113 dietary fatty acids Nutrition 0.000 description 2

- 230000000694 effects Effects 0.000 description 2

- 229940022424 everflex Drugs 0.000 description 2

- 239000000194 fatty acid Substances 0.000 description 2

- 229930195729 fatty acid Natural products 0.000 description 2

- 150000004665 fatty acids Chemical class 0.000 description 2

- 238000010438 heat treatment Methods 0.000 description 2

- 229920001903 high density polyethylene Polymers 0.000 description 2

- 239000004700 high-density polyethylene Substances 0.000 description 2

- 238000004898 kneading Methods 0.000 description 2

- 238000004519 manufacturing process Methods 0.000 description 2

- JRZJOMJEPLMPRA-UHFFFAOYSA-N olefin Natural products CCCCCCCC=C JRZJOMJEPLMPRA-UHFFFAOYSA-N 0.000 description 2

- 239000002984 plastic foam Substances 0.000 description 2

- 239000002994 raw material Substances 0.000 description 2

- 238000009423 ventilation Methods 0.000 description 2

- 239000011787 zinc oxide Substances 0.000 description 2

- UJXFNIQSAHCTTA-UHFFFAOYSA-N 1-butylperoxyhexane Chemical group CCCCCCOOCCCC UJXFNIQSAHCTTA-UHFFFAOYSA-N 0.000 description 1

- GOOMUPCAOADBSA-UHFFFAOYSA-N 1-n,2-n-dimethyl-1-n,2-n-dinitrosobenzene-1,2-dicarboxamide Chemical compound O=NN(C)C(=O)C1=CC=CC=C1C(=O)N(C)N=O GOOMUPCAOADBSA-UHFFFAOYSA-N 0.000 description 1

- ATRRKUHOCOJYRX-UHFFFAOYSA-N Ammonium bicarbonate Chemical compound [NH4+].OC([O-])=O ATRRKUHOCOJYRX-UHFFFAOYSA-N 0.000 description 1

- 229910000013 Ammonium bicarbonate Inorganic materials 0.000 description 1

- 229920000742 Cotton Polymers 0.000 description 1

- MWRWFPQBGSZWNV-UHFFFAOYSA-N Dinitrosopentamethylenetetramine Chemical compound C1N2CN(N=O)CN1CN(N=O)C2 MWRWFPQBGSZWNV-UHFFFAOYSA-N 0.000 description 1

- VGGSQFUCUMXWEO-UHFFFAOYSA-N Ethene Chemical compound C=C VGGSQFUCUMXWEO-UHFFFAOYSA-N 0.000 description 1

- 239000005977 Ethylene Substances 0.000 description 1

- 239000004677 Nylon Substances 0.000 description 1

- UIIMBOGNXHQVGW-DEQYMQKBSA-M Sodium bicarbonate-14C Chemical compound [Na+].O[14C]([O-])=O UIIMBOGNXHQVGW-DEQYMQKBSA-M 0.000 description 1

- MOVRNJGDXREIBM-UHFFFAOYSA-N aid-1 Chemical compound O=C1NC(=O)C(C)=CN1C1OC(COP(O)(=O)OC2C(OC(C2)N2C3=C(C(NC(N)=N3)=O)N=C2)COP(O)(=O)OC2C(OC(C2)N2C3=C(C(NC(N)=N3)=O)N=C2)COP(O)(=O)OC2C(OC(C2)N2C3=C(C(NC(N)=N3)=O)N=C2)COP(O)(=O)OC2C(OC(C2)N2C(NC(=O)C(C)=C2)=O)COP(O)(=O)OC2C(OC(C2)N2C3=C(C(NC(N)=N3)=O)N=C2)COP(O)(=O)OC2C(OC(C2)N2C3=C(C(NC(N)=N3)=O)N=C2)COP(O)(=O)OC2C(OC(C2)N2C3=C(C(NC(N)=N3)=O)N=C2)COP(O)(=O)OC2C(OC(C2)N2C(NC(=O)C(C)=C2)=O)COP(O)(=O)OC2C(OC(C2)N2C3=C(C(NC(N)=N3)=O)N=C2)COP(O)(=O)OC2C(OC(C2)N2C3=C(C(NC(N)=N3)=O)N=C2)COP(O)(=O)OC2C(OC(C2)N2C3=C(C(NC(N)=N3)=O)N=C2)COP(O)(=O)OC2C(OC(C2)N2C(NC(=O)C(C)=C2)=O)COP(O)(=O)OC2C(OC(C2)N2C3=C(C(NC(N)=N3)=O)N=C2)COP(O)(=O)OC2C(OC(C2)N2C3=C(C(NC(N)=N3)=O)N=C2)COP(O)(=O)OC2C(OC(C2)N2C3=C(C(NC(N)=N3)=O)N=C2)CO)C(O)C1 MOVRNJGDXREIBM-UHFFFAOYSA-N 0.000 description 1

- 235000012538 ammonium bicarbonate Nutrition 0.000 description 1

- 239000001099 ammonium carbonate Substances 0.000 description 1

- VJRITMATACIYAF-UHFFFAOYSA-N benzenesulfonohydrazide Chemical compound NNS(=O)(=O)C1=CC=CC=C1 VJRITMATACIYAF-UHFFFAOYSA-N 0.000 description 1

- 235000010290 biphenyl Nutrition 0.000 description 1

- 239000004305 biphenyl Substances 0.000 description 1

- 125000006267 biphenyl group Chemical group 0.000 description 1

- 239000000872 buffer Substances 0.000 description 1

- CQEYYJKEWSMYFG-UHFFFAOYSA-N butyl acrylate Chemical class CCCCOC(=O)C=C CQEYYJKEWSMYFG-UHFFFAOYSA-N 0.000 description 1

- 229910052791 calcium Inorganic materials 0.000 description 1

- NKWPZUCBCARRDP-UHFFFAOYSA-L calcium bicarbonate Chemical group [Ca+2].OC([O-])=O.OC([O-])=O NKWPZUCBCARRDP-UHFFFAOYSA-L 0.000 description 1

- 229910000020 calcium bicarbonate Inorganic materials 0.000 description 1

- 210000002421 cell wall Anatomy 0.000 description 1

- 230000006854 communication Effects 0.000 description 1

- 239000002131 composite material Substances 0.000 description 1

- 150000001875 compounds Chemical class 0.000 description 1

- 238000004132 cross linking Methods 0.000 description 1

- 238000005520 cutting process Methods 0.000 description 1

- 238000001514 detection method Methods 0.000 description 1

- 229920001971 elastomer Polymers 0.000 description 1

- 238000010894 electron beam technology Methods 0.000 description 1

- 125000001495 ethyl group Chemical group [H]C([H])([H])C([H])([H])* 0.000 description 1

- 230000004927 fusion Effects 0.000 description 1

- 229910000464 lead oxide Inorganic materials 0.000 description 1

- 239000000314 lubricant Substances 0.000 description 1

- 238000005259 measurement Methods 0.000 description 1

- 229910052751 metal Chemical class 0.000 description 1

- 239000002184 metal Chemical class 0.000 description 1

- 229910044991 metal oxide Inorganic materials 0.000 description 1

- 150000004706 metal oxides Chemical class 0.000 description 1

- 125000002496 methyl group Chemical group [H]C([H])([H])* 0.000 description 1

- ALIFPGGMJDWMJH-UHFFFAOYSA-N n-phenyldiazenylaniline Chemical compound C=1C=CC=CC=1NN=NC1=CC=CC=C1 ALIFPGGMJDWMJH-UHFFFAOYSA-N 0.000 description 1

- 229920001778 nylon Polymers 0.000 description 1

- 150000001451 organic peroxides Chemical class 0.000 description 1

- YEXPOXQUZXUXJW-UHFFFAOYSA-N oxolead Chemical compound [Pb]=O YEXPOXQUZXUXJW-UHFFFAOYSA-N 0.000 description 1

- ZUOUZKKEUPVFJK-UHFFFAOYSA-N phenylbenzene Natural products C1=CC=CC=C1C1=CC=CC=C1 ZUOUZKKEUPVFJK-UHFFFAOYSA-N 0.000 description 1

- 239000000049 pigment Substances 0.000 description 1

- 229920003023 plastic Polymers 0.000 description 1

- 239000004033 plastic Substances 0.000 description 1

- 238000005498 polishing Methods 0.000 description 1

- 229920000642 polymer Polymers 0.000 description 1

- 125000001436 propyl group Chemical group [H]C([*])([H])C([H])([H])C([H])([H])[H] 0.000 description 1

- 238000004080 punching Methods 0.000 description 1

- 150000003839 salts Chemical class 0.000 description 1

- 238000003860 storage Methods 0.000 description 1

- 208000024891 symptom Diseases 0.000 description 1

Images

Description

本発明は、マスク本体の内面上部に取り付けられるマスク用緩衝材とそのマスク用緩衝材を取り付けたマスクに関する。 The present invention relates to a mask cushioning material that is attached to the upper part of the inner surface of a mask body and a mask having the mask cushioning material attached thereto.

従来、風邪や花粉症の症状、あるいは埃の多い場所での作業等の際に使用されるマスクは、メガネと共に使用すると、鼻の両側とマスクの間から漏れる呼気がメガネのレンズに当たって、レンズの曇りを生じる問題がある。 Conventional masks used for cold and hay fever symptoms, dusty work, etc., when used with glasses, exhales from both sides of the nose and between the masks and hits the lenses of the glasses. There is a problem of cloudiness.

前記メガネレンズの曇りを抑えるため、マスク本体の内面上部に横長形状のマスク用緩衝材を取り付けて鼻の両側とマスクの間の隙間を塞ぐことが提案されている。 In order to suppress the fogging of the spectacle lens, it has been proposed to attach a horizontally long mask cushioning material to the upper part of the inner surface of the mask body to close the gap between both sides of the nose and the mask.

しかし、従来のマスク用緩衝材は、特許文献1に記載されているように再生繊維や合成繊維の不織布で構成され、通気性が良すぎて呼気が通過しやすく、メガネレンズの曇り防止効果が完全とは言い難かった。また、特許文献2に記載されているマスク用緩衝材は、その材質が実質的に特定されておらず、ポリエチレンやポリウレタン等のプラスチックの連通気泡発泡体のスポンジ状の部材や、綿状もしくはガーゼ状の材質のものを加工したものが列記されており、緩衝材そのものの通気性については検討されていない。

However, conventional cushioning materials for masks are made of non-woven fabrics of regenerated fibers and synthetic fibers as described in

また、特許文献1には、マスク用緩衝材を、オレフィン系のプラスチックフォーム、商品名:ペフ(登録商標、東レ製)で構成した比較例も示されている。しかし、ペフ(登録商標)は、電子線架橋によって形成されたオレフィン系のプラスチックフォームであるため、表面にスキン層を有し、折れ皺を生じやすい。そのため、ペフ(登録商標)で構成されたマスク用緩衝材は、鼻の形状に沿って変形し難く、鼻の両側で顔面との間に隙間を生じてメガネレンズの曇りを充分に防ぐことができない問題がある。

本発明は前記の点に鑑みなされたものであって、メガネと共に使用した場合に、メガネレンズの曇り防止効果が高いマスク用緩衝材およびそのマスク用緩衝材を取り付けたマスクの提供を目的とする。 The present invention has been made in view of the above points, and an object of the present invention is to provide a mask cushioning material having a high anti-fogging effect of a spectacle lens when used with glasses, and a mask provided with the mask cushioning material. .

請求項1の発明は、鼻と口を覆う大きさからなるマスク本体の内面上部に取り付けられる横長形状のマスク用緩衝材において、ポリオレフィン樹脂100重量部中にエチレン−酢酸ビニル共重合体樹脂を70重量部以上含む発泡倍率20〜40倍の架橋ポリオレフィン連続気泡発泡体からなり、前記エチレン−酢酸ビニル共重合体樹脂が酢酸ビニル含有率5〜25%からなり、前記架橋ポリオレフィン連続気泡発泡体が、架橋ポリオレフィン独立気泡発泡体を連続気泡化し、表面にはスキン層が無いものであることを特徴とする。 According to the first aspect of the present invention, there is provided a horizontally long mask cushioning material attached to an upper part of an inner surface of a mask main body having a size covering a nose and a mouth. In 100 parts by weight of polyolefin resin, 70 wt. comprising consist expansion ratio 20 to 40 times the cross-linked polyolefin open cell foam or parts, wherein the ethylene - vinyl acetate copolymer resins is Ri vinyl content of 5-25% Tona acetate, the crosslinked polyolefin open cell foam The cross-linked polyolefin closed-cell foam is formed into an open cell and has no skin layer on the surface .

請求項2の発明は、請求項1において、前記架橋ポリオレフィン連続気泡発泡体の圧縮応力−ひずみ(50%時、JIS K 6767準拠)が3〜10kPaであることを特徴とする。 According to a second aspect of the present invention, in the first aspect, the crosslinked polyolefin open-cell foam has a compressive stress-strain (at 50%, conforming to JIS K 6767) of 3 to 10 kPa.

請求項3の発明は、請求項1または2において、前記架橋ポリオレフィン連続気泡発泡体の通気性(JIS K 6400−7 B法 サンプル厚み10mm)が0〜6cc/cm 2 ・secであることを特徴とする。

The invention of

請求項4の発明は、請求項1から3の何れか一項において、前記架橋ポリオレフィン連続気泡発泡体は、ASTM D 2856に準拠した方法により測定した独立気泡率が20%以下であることを特徴とする。

The invention of claim 4 is characterized in that, in any one of

請求項5の発明は、請求項1から4の何れか一項において、前記架橋ポリオレフィン連続気泡発泡体が、架橋ポリオレフィン独立気泡発泡体を圧縮により連続気泡化したものからなることを特徴とする。A fifth aspect of the present invention is characterized in that, in any one of the first to fourth aspects, the crosslinked polyolefin open-cell foam is formed by compressing a cross-linked polyolefin closed-cell foam by compression.

請求項6の発明は、請求項1から5の何れか一項において、前記横長形状は、両端間の中央部が括れてその両側に膨らみ部を有する形状からなり、前記中央部の括れには鼻柱が位置し、前記両側の膨らみ部には顔面における鼻の両側が位置し、前記膨らみ部は顔面側に膨らんだ形状とされ、前記マスク本体にマスク用緩衝材が取り付けられたマスクが顔面に装着された際に、鼻の両側で生じるマスク本体と顔面間の隙間を塞ぐことのできる厚みからなることを特徴とする。The invention of claim 6 is the invention according to any one of

請求項7の発明は、鼻と口を覆う大きさからなるマスク本体と、前記マスク本体の両側に取り付けられた耳掛け用紐と、前記マスク本体の内面上部に取り付けられた横長なマスク用緩衝材とからなるマスクにおいて、前記マスク用緩衝材が請求項1から6の何れか一項に記載のマスク用緩衝材からなり、メガネ装着時には、メガネレンズの曇りを防ぐことができることを特徴とする。The invention according to claim 7 is a mask main body having a size covering a nose and a mouth, ear straps attached to both sides of the mask main body, and a horizontally long mask buffer attached to the upper part of the inner surface of the mask main body. The mask cushioning material is made of the mask cushioning material according to any one of

本発明のマスク用緩衝材は、ポリオレフィン樹脂100重量部中にエチレン−酢酸ビニル共重合体樹脂を70重量部以上含む架橋ポリオレフィン連続気泡発泡体からなるため、表面にはスキン層が無く、柔軟性が良好で鼻の形状に沿って変形しやすく、鼻の両側で顔面との間に隙間を生じ難くなることから、マスク用緩衝材と顔面との隙間から漏れる呼気によってメガネレンズが曇るのを防ぐことができる。しかもポリオレフィン樹脂100重量部中にエチレン−酢酸ビニル共重合体樹脂を70重量部以上含む架橋ポリオレフィン連続気泡発泡体は、再生繊維や合成繊維の不織布、あるいはポリエチレンやポリウレタン等の連通気泡発泡体に比べ、適度な通気性を有することから、本発明のマスク用緩衝材は、効果的にメガネレンズの曇りを防ぐことができる。 The mask cushioning material of the present invention is composed of a crosslinked polyolefin open-cell foam containing 70 parts by weight or more of ethylene-vinyl acetate copolymer resin in 100 parts by weight of polyolefin resin. It is good and easily deforms along the shape of the nose, making it difficult to create a gap between the face and the face on both sides of the nose, thus preventing the spectacle lens from being clouded by the exhalation that leaks through the gap between the cushioning material for the mask and the face be able to. Moreover, the crosslinked polyolefin open-cell foam containing 70 parts by weight or more of ethylene-vinyl acetate copolymer resin in 100 parts by weight of the polyolefin resin is compared with open-cell foams such as recycled fibers and synthetic fiber nonwoven fabrics, or polyethylene and polyurethane. Since it has moderate air permeability, the cushioning material for a mask of the present invention can effectively prevent fogging of the spectacle lens.

本発明のマスクは、マスク本体の内面上部に取り付けられる横長なマスク用緩衝材が、樹脂成分100重量部中にエチレン−酢酸ビニル共重合体樹脂を70重量部以上含む連続気泡架橋ポリオレフィン発泡体からなるため、マスクを顔面に装着した際にマスク用緩衝材が鼻の形状に沿って変形しやすく、鼻の両側で隙間を生じ難いのでマスク用緩衝材と鼻の両側の顔面から漏れる呼気によってメガネが曇るのを防ぐ効果が高い。しかも、ポリオレフィン樹脂100重量部中にエチレン−酢酸ビニル共重合体樹脂を70重量部以上含む架橋ポリオレフィン連続気泡発泡体は、再生繊維や合成繊維の不織布、あるいはポリエチレンやポリウレタン等の連通気泡発泡体に比べ、適度な通気性を有することから、マスク用緩衝材によって効果的にメガネレンズの曇りを防ぐことができる。 The mask of the present invention is an open-cell crosslinked polyolefin foam in which the cushioning material for a horizontally long mask attached to the upper inner surface of the mask body contains 70 parts by weight or more of ethylene-vinyl acetate copolymer resin in 100 parts by weight of the resin component. Therefore, when the mask is attached to the face, the cushioning material for the mask is easily deformed along the shape of the nose, and it is difficult to form a gap on both sides of the nose. Highly effective in preventing fogging. Moreover, the crosslinked polyolefin open-cell foam containing 70 parts by weight or more of ethylene-vinyl acetate copolymer resin in 100 parts by weight of the polyolefin resin is a recycled fiber or a synthetic fiber nonwoven fabric, or an open-cell foam such as polyethylene or polyurethane. Compared with the moderate air permeability, the spectacle lens can be effectively prevented from being fogged by the mask cushioning material.

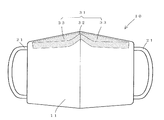

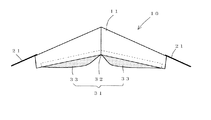

以下、本発明の実施形態について説明する。図1は本発明の一実施例に係るマスクの外面側を示す図、図2は同実施例に係るマスクの内面側を示す図、図3は同実施例に係るマスクを上から見た図である。 Hereinafter, embodiments of the present invention will be described. 1 is a diagram showing an outer surface side of a mask according to an embodiment of the present invention, FIG. 2 is a diagram showing an inner surface side of the mask according to the embodiment, and FIG. 3 is a diagram of the mask according to the embodiment as viewed from above. It is.

図1〜図3に示すマスク10は、マスク本体11と、耳掛け用紐21と、マスク用緩衝材31とよりなり、風邪や花粉症、あるいは埃の多い場所での作業等の際に使用されるものである。

The

マスク本体11は、通気性材質からなって鼻と口を覆う大きさからなる。通気性材質としては、不織布やガーゼ等、適宜のものが用いられる。前記マスク本体11は、略長方形からなり、図示のように鼻の位置となる中央部が盛り上がった形状や、盛り上がりの無い平面形状等、適宜の形状とされる。 The mask body 11 is made of a breathable material and has a size covering the nose and mouth. As the breathable material, an appropriate material such as a nonwoven fabric or gauze is used. The mask body 11 has a substantially rectangular shape, and has an appropriate shape such as a shape in which the central portion that is the position of the nose is raised as shown in the drawing, or a planar shape that is not raised.

耳掛け用紐21は、前記マスク本体11の左右両側にそれぞれ設けられ、耳に掛けることによりマスク10を顔面に装着できるようになっている。前記耳掛け用紐21は、ゴム等のように伸縮性を有するものが好ましい。

The

マスク用緩衝材31は、横長形状からなり、前記マスク本体11の内面上部(すなわち顔面側上部)に接着剤や熱融着等で取り付けられる。前記横長形状は、両端間の中央部32が括れてその両側に膨らみ部33を有する形状が好ましい。前記中央部32の括れは鼻柱が位置する部分に相当し、一方、両側の膨らみ部33は顔面における鼻の両側が位置する部分に相当する。なお、前記膨らみ部33は顔面側に膨らんだ形状とされ、前記マスク10を顔面に装着した際に、鼻の両側で生じるマスク本体11と顔面間の隙間を塞ぐことのできる厚みとされている。前記マスク用緩衝材31を中央部32の捻れと、その両側の膨らみ部33を有する横長形状としたことにより、前記マスク10を顔面に装着した際に、前記マスク用緩衝材31が鼻柱およびその両側で顔面と良好に密着し、顔面とマスク用緩衝材31との間に隙間を一層生じ難くできる。

The cushioning material 31 for the mask has a horizontally long shape, and is attached to the upper part of the inner surface of the mask main body 11 (that is, the upper part on the face side) by an adhesive or heat fusion. The horizontally long shape is preferably a shape in which the

前記マスク用緩衝材31は、ポリオレフィン樹脂100重量部中にエチレン−酢酸ビニル共重合体樹脂を70重量部以上含む架橋ポリオレフィン連続気泡発泡体からなる。前記エチレン−酢酸ビニル共重合体樹脂を70重量部以上とすることにより、前記マスク用緩衝材31が柔軟性および弾性に富んだものとなり、マスク用緩衝材31が鼻に沿って変形し易くなる。前記エチレン−酢酸ビニル共重合体樹脂は、酢酸ビニル含有率が5〜25%(m/m)のものが好ましい。酢酸ビニル含有率が5%(m/m)未満の場合には発泡体が硬くなり、肌触りが悪くなる。一方25%(m/m)を超える場合には耐熱性が悪くなり、使用環境等によっては変形をおこしやすくなる。前記酢酸ビニルのより好ましい含有率は10〜20%(m/m)である。 The cushioning material 31 for mask is made of a crosslinked polyolefin open cell foam containing 70 parts by weight or more of ethylene-vinyl acetate copolymer resin in 100 parts by weight of polyolefin resin. By setting the ethylene-vinyl acetate copolymer resin to 70 parts by weight or more, the mask cushioning material 31 is rich in flexibility and elasticity, and the mask cushioning material 31 is easily deformed along the nose. . The ethylene-vinyl acetate copolymer resin preferably has a vinyl acetate content of 5 to 25% (m / m). When the vinyl acetate content is less than 5% (m / m), the foam becomes hard and the touch becomes poor. On the other hand, if it exceeds 25% (m / m), the heat resistance is deteriorated, and deformation is likely to occur depending on the use environment. A more preferable content of the vinyl acetate is 10 to 20% (m / m).

前記エチレン−酢酸ビニル共重合体樹脂を70〜100重量部未満とした場合にポリオレフィン樹脂に含まれる他のポリオレフィン樹脂としては、低密度ポリエチレン(LDPE)、高密度ポリエチレン(HDPE)、エチレン−プロピレン共重合体、エチレン−ブテン共重合体、エチレンとメチル、エチル、プロピル若しくはブチルの各アクリル酸エステルとの共重合体、又はこれらの塩素化物、あるいはそれらの混合物、さらにはそれらとアイソタクチックポリプロピレン若しくはアタクチックポリプロピレンの混合物等を挙げることができる。それらの中でも、柔軟性などの点から低密度ポリエチレンが好ましい。なお、本発明における架橋ポリオレフィン連続気泡発泡体は、ASTM D 2856に準拠した方法により測定した独立気泡率が20%以下、すなわち連続気泡率が80%以上のものをいう。 Other polyolefin resins included in the polyolefin resin when the ethylene-vinyl acetate copolymer resin is less than 70 to 100 parts by weight include low density polyethylene (LDPE), high density polyethylene (HDPE), and ethylene-propylene copolymer. Polymers, ethylene-butene copolymers, copolymers of ethylene and methyl, ethyl, propyl or butyl acrylates, or chlorinated products thereof, or mixtures thereof, and also isotactic polypropylene or And a mixture of atactic polypropylene. Among them, low density polyethylene is preferable from the viewpoint of flexibility. In addition, the crosslinked polyolefin open-cell foam in this invention says the closed cell rate measured by the method based on ASTM D2856 20% or less, ie, the open cell rate is 80% or more.

前記マスク用緩衝材31を構成する架橋ポリオレフィン連続気泡発泡体の通気性(JIS K 6400−7 B法 サンプル厚み10mm)は0〜6cc/cm2・sec、圧縮応力−ひずみ(50%時、JIS K 6767準拠)は3〜10kPaが好ましい。通気性が6cc/cm2・secより高い場合、呼気が通過し易くなってメガネレンズの曇り防止効果が得がたくなる。一方、通気がない場合は、上記規格による通気度測定の検出限界を下回っている程度の通気性を示しており、この発明に示す架橋ポリオレフィン発泡体を連続気泡とする加工を施したものであれば制限なく使用できる。また、圧縮応力−ひずみ(50%時)が3kPa未満の場合、人肌に密着する力が弱く、隙間から呼気が漏れるようになる。一方、10kPaを超える場合、硬くて追従性に劣り、人肌との間に隙間を生じるようになる。

The air permeability (JIS K 6400-7 B

前記架橋ポリオレフィン連続気泡発泡体は、発泡倍率20〜40倍の架橋ポリオレフィン独立気泡発泡体を物理的な圧縮で破泡(気泡を破壊)させて連続気泡化したものが好ましい。発泡倍率が20倍未満の場合、前記マスク用緩衝材31が柔軟性および弾性に劣るものとなり、一方、発泡倍率が40倍を超える場合、製造が難しくなる。 The cross-linked polyolefin open-celled foam is preferably one in which a cross-linked polyolefin closed-cell foam having an expansion ratio of 20 to 40 times is broken into bubbles (disrupted) by physical compression to form open cells. If the expansion ratio is less than 20 times, the cushioning material 31 for the mask is inferior in flexibility and elasticity. On the other hand, if the expansion ratio exceeds 40 times, the manufacturing becomes difficult.

前記発泡倍率20〜40倍の架橋ポリオレフィン独立気泡発泡体は、公知の二段発泡により製造される。二段発泡による架橋ポリオレフィン独立気泡発泡体の製造は、前記ポリオレフィン樹脂の他に架橋剤、発泡剤、および適宜添加される配合剤を含む樹脂原料を用い、混練工程、二段発泡工程によって行われる。なお、発泡倍率は、JIS K 6767−1999 付属書1に記載された方法で測定した見掛け密度の逆数からなる。

The crosslinked polyolefin closed-cell foam having an expansion ratio of 20 to 40 is produced by a known two-stage foaming. The production of a crosslinked polyolefin closed-cell foam by two-stage foaming is performed by a kneading process and a two-stage foaming process using a resin raw material containing a crosslinking agent, a foaming agent, and a compounding agent added as appropriate in addition to the polyolefin resin. . The expansion ratio is composed of the reciprocal of the apparent density measured by the method described in JIS K 6767-1999

架橋剤としては、従来、架橋ポリオレフィン独立気泡発泡体の発泡に使用されている公知のものが用いられる。例えば、ジクミルパーオキサイド、2,5−ジメチル−2,5−ビス−ターシャリーブチルパーオキシヘキサン、1,3−ビス−ターシャリーパーオキシ−イソプロピルベンゼンなどの有機過酸化物等を挙げることができる。前記架橋剤の配合量は、通常、ポリオレフィン樹脂100重量部に対し0.5〜1.3重量部である。 As the crosslinking agent, known ones conventionally used for foaming crosslinked polyolefin closed-cell foams are used. Examples thereof include organic peroxides such as dicumyl peroxide, 2,5-dimethyl-2,5-bis-tertiary butyl peroxyhexane, 1,3-bis-tertiary peroxy-isopropylbenzene, and the like. . The amount of the crosslinking agent is usually 0.5 to 1.3 parts by weight with respect to 100 parts by weight of the polyolefin resin.

発泡剤としては、加熱により分解してガスを発生するものが用いられ、特に制限されるものではない。例えばアゾジカルボンアミド、2,2’−アゾビスイソブチロニトリル、ジアゾアミノベンゼン、ベンゼンスルホニルヒドラジド、ベンゼン−1,3−スルホニルヒドラジド、ジフェニルオキシド−4,4’−ジスルフォニルヒドラジド、4,4’−オキシビスベンゼンスルフォニルヒドラジド、パラトルエンスルフォニルヒドラジド、N,N’−ジニトロソペンタメチレンテトラミン、N,N’−ジニトロソ−N,N’−ジメチルフタルアミド、テレフタルアジド、p−t−ブチルベンズアジド、重炭酸ナトリウム、重炭酸アンモニウム等の一種又は二種以上が用いられる。特にアゾジカルボンアミド、4,4’−オキシビスベンゼンスルホニルヒドラジドが好適である。添加量としては、通常、ポリオレフィン樹脂100重量部に対して2〜30重量部とされる。 As a foaming agent, what decomposes | disassembles by heating and generate | occur | produces gas is used, and it does not restrict | limit in particular. For example, azodicarbonamide, 2,2'-azobisisobutyronitrile, diazoaminobenzene, benzenesulfonyl hydrazide, benzene-1,3-sulfonyl hydrazide, diphenyl oxide-4,4'-disulfonyl hydrazide, 4,4 ' -Oxybisbenzenesulfonyl hydrazide, paratoluenesulfonyl hydrazide, N, N'-dinitrosopentamethylenetetramine, N, N'-dinitroso-N, N'-dimethylphthalamide, terephthalazide, pt-butylbenzazide, One or more of sodium bicarbonate, ammonium bicarbonate and the like are used. In particular, azodicarbonamide and 4,4′-oxybisbenzenesulfonyl hydrazide are preferable. The addition amount is usually 2 to 30 parts by weight with respect to 100 parts by weight of the polyolefin resin.

、

適宜添加される配合剤としては、発泡助剤、充填剤等がある。発泡助剤としては、尿素を主成分とする化合物、酸化亜鉛、酸化鉛等の金属酸化物、低級若しくは高級脂肪酸、低級若しくは高級脂肪酸の金属塩等を挙げることができる。また充填剤としては、滑剤や顔料等が挙げられる。

,

Examples of compounding agents that are added as appropriate include foaming aids and fillers. Examples of the foaming aid include compounds containing urea as a main component, metal oxides such as zinc oxide and lead oxide, lower or higher fatty acids, and metal salts of lower or higher fatty acids. Examples of the filler include a lubricant and a pigment.

混練工程では、前記ポリオレフィン樹脂、架橋剤、発泡剤等の配合物をニーダーやロールで混練して混練物とする。 In the kneading step, the polyolefin resin, the crosslinking agent, the foaming agent and the like are kneaded with a kneader or a roll to obtain a kneaded product.

二段発泡工程では、前記混練物を、公知の架橋ポリオレフィン独立気泡発泡体の製造に用いられる二段発泡方法にしたがい、密閉式の一次発泡金型に充填し、加圧下加熱して架橋剤および発泡剤の一部を分解し、その後除圧することにより一次発泡(一次膨張)させて一次発泡体(中間発泡体)を形成する。次に前記一次発泡体(中間発泡体)を常圧で加熱して二次発泡(二次膨張)させ、所望の発泡倍率からなる架橋ポリオレフィン独立気泡発泡体を得る。二段発泡では発泡倍率の高い架橋ポリオレフィン独立気泡発泡体を一度に発泡させず、二段階に分けて順次発泡させるため、得られる発泡体に急激な発泡による割れ等を生じることがなく、品質のよい架橋ポリオレフィン独立気泡発泡体を得ることができる。本発明では、架橋ポリオレフィン独立気泡発泡体の発泡倍率が20〜40倍と高いため、二段発泡により発泡させるのが好ましい。 In the two-stage foaming step, the kneaded product is filled in a hermetic primary foaming mold according to a two-stage foaming method used for producing a known crosslinked polyolefin closed-cell foam, and heated under pressure to form a crosslinking agent and A part of the foaming agent is decomposed and then subjected to primary foaming (primary expansion) by releasing the pressure to form a primary foam (intermediate foam). Next, the primary foam (intermediate foam) is heated at normal pressure to undergo secondary foaming (secondary expansion) to obtain a crosslinked polyolefin closed-cell foam having a desired foaming ratio. In two-stage foaming, the cross-linked polyolefin closed-cell foam with a high foaming ratio is not foamed at once, but is foamed in two stages in order, so that the resulting foam does not cause cracks due to sudden foaming, and the quality A good cross-linked polyolefin closed cell foam can be obtained. In the present invention, since the expansion ratio of the crosslinked polyolefin closed-cell foam is as high as 20 to 40 times, it is preferable to perform foaming by two-stage foaming.

前記二段発泡後の架橋ポリオレフィン独立気泡発泡体に対して連通化工程を行い、物理的な圧縮により破泡(気泡を破壊)させ、連続気泡化した架橋ポリオレフィン連続気泡発泡体とする。前記架橋ポリオレフィン独立気泡発泡体に対する物理的な圧縮は、気泡を物理的に破壊できる方法であればよく、冷間プレス、熱間プレス、あるいは等速2軸ロールに通して圧縮する等の方法によって行われる。その際における架橋ポリオレフィン独立気泡発泡体の圧縮程度は、架橋ポリオレフィン独立気泡発泡体の気泡を破壊できる圧縮程度であればよく、特に限定されない。一般的には、圧縮前の元厚に対して1/2〜1/5程度となるように圧縮される。 The cross-linked polyolefin closed-cell foam after the two-stage foaming is subjected to a communication process, and bubbles are broken by physical compression (bubbles are destroyed), thereby obtaining a cross-linked polyolefin open-cell foam having open cells. The cross-linked polyolefin closed-cell foam may be physically compressed as long as it is a method capable of physically destroying the bubbles, and may be a cold press, a hot press, or a method of compressing through a constant speed biaxial roll. Done. In this case, the degree of compression of the crosslinked polyolefin closed cell foam is not particularly limited as long as it is a degree of compression that can break the bubbles of the crosslinked polyolefin closed cell foam. Generally, compression is performed so that the original thickness before compression is about 1/2 to 1/5.

前記物理的な圧縮により連通化した架橋ポリオレフィン連続気泡発泡体は、打ち抜きや切り出しおよび研磨等により、所望の横長形状のマスク用緩衝材、例えば前記中央部32が括れて両側に膨らみ部33を有する横長形状のマスク用緩衝材31とされる。

The cross-linked polyolefin open-cell foam communicated by the physical compression has a desired horizontally long mask cushioning material, for example, the

以下、本発明の実施例について、比較例とともに具体的に説明する。表1の配合からなる樹脂原料900gを1Lニーダー・8inchロールの順で混練りして混練物とし、この混練物を、深さ30mm、幅170mm、長さ170mmの収容空間を有する一次発泡金型に密閉し、加圧下40分加熱し、その後除圧することにより一次発泡させて一次発泡体を得た。次に、前記一次発泡体を、常圧下160℃で100分加熱することにより二次発泡させ、その後冷却して架橋ポリオレフィン独立気泡発泡体を得た。 Examples of the present invention will be specifically described below together with comparative examples. 900 g of a resin raw material having the composition shown in Table 1 is kneaded in the order of 1 L kneader and 8 inch roll to obtain a kneaded product. This kneaded product is a primary foaming mold having a storage space of 30 mm in depth, 170 mm in width, and 170 mm in length. And heated for 40 minutes under pressure, and then depressurized for primary foaming to obtain a primary foam. Next, the primary foam was subjected to secondary foaming by heating at 160 ° C. under normal pressure for 100 minutes, and then cooled to obtain a crosslinked polyolefin closed cell foam.

表1のエチレン−酢酸ビニル共重合体樹脂1は、酢酸ビニル含有率14%(m/m)、品番:エバフレックス P−1403、三井・デュポンポリケミカル株式会社製、エチレン−酢酸ビニル共重合体樹脂2は、酢酸ビニル含有率25%(m/m)、品番:エバフレックス P−2505、三井・デュポンポリケミカル株式会社製、エチレン−酢酸ビニル共重合体樹脂3は、酢酸ビニル含有率6%(m/m)、品番:ウルトラセン511F、東ソー株式会社製、エチレン−酢酸ビニル共重合体樹脂4は、酢酸ビニル含有率28%(m/m)、品番:エバフレックス P−2805、三井・デュポンポリケミカル株式会社製、低密度ポリエチレンは品番:ペトロセン170、東ソー株式会社製、発泡剤はアゾジカルボンアミド、品番:ビニホールAC#3、永和化成工業株式会社製、発泡助剤1は酸化亜鉛二種、堺化学株式会社製、発泡助剤2は尿素、品番:セルペースト10、永和化成工業株式会社製、架橋剤はジクミルパーオキサイド、化薬アクゾ株式会社製、充填剤は重炭酸カルシウム、品番:スーパー3S、丸尾カルシウム株式会社製である。

The ethylene-vinyl

このようにして得られた架橋ポリオレフィン独立気泡発泡体を、100×450×450mmに裁断した後、ロール間隔が20mmに調整された等速2軸ロールに通して1/5の厚みに圧縮し、この圧縮を2回行うことによって架橋ポリオレフィン独立気泡発泡体の気泡壁を破壊して連通化させ、架橋ポリオレフィン連続気泡発泡体を得た。このようにして得られた架橋ポリオレフィン連続気泡発泡体に対して見掛け密度(JIS K 6767準拠)、発泡倍率(見掛け密度の逆数)、圧縮応力−ひずみ(50%時、JIS K 6767準拠)、通気性(JIS K 6400−7 B法 サンプル厚み10mm)を測定した。結果は表1の下部に示すとおりである。

The crosslinked polyolefin closed cell foam thus obtained was cut to 100 × 450 × 450 mm, and then compressed to a thickness of 1/5 through a constant-speed biaxial roll whose roll interval was adjusted to 20 mm. By performing this compression twice, the cell walls of the cross-linked polyolefin closed cell foam were broken and communicated to obtain a cross-linked polyolefin open-cell foam. The cross-linked polyolefin open-cell foam thus obtained has an apparent density (according to JIS K 6767), expansion ratio (inverse of apparent density), compressive stress-strain (at 50%, according to JIS K 6767), ventilation (JIS K 6400-7 B

各実施例および各比較例の架橋ポリオレフィン連続気泡発泡体から打ち抜き加工により、図1〜図3に示すマスク用緩衝材31を、長さ120mm、高さ10mm、中央部32の括れ部分の厚み2mm、両側の膨らみ部33の厚み15mmとして形成した。これにより得られたマスク用緩衝材31を、図1〜図3に示したマスク本体11(両側端部の高さ95mm、中央部の高さ115mm、横方向の長さ155mm、材質:ポリエチレン、ポリプロピレン不織布)の内面(顔面側)上端に接着剤で取り付けて、実施例1〜6および比較例1〜3のマスクを形成した。なお、マスク本体11の両側には、それぞれ長さ150mm、幅6mmのナイロン、ポリウレタン複合材からなる耳掛け用紐21を、略コの字状にして接着することにより取り付けた。

The mask cushioning material 31 shown in FIGS. 1 to 3 is punched from the crosslinked polyolefin open-cell foams of each Example and each Comparative Example, and the length of the constricted portion of the

各実施例および各比較例のマスクを、メガネと共にモニターが一日、普段通りに使用し、メガネレンズに曇りが発生するか否か調べた。その結果、実施例1〜6のマスクについては、マスク用緩衝材が鼻柱およびその両側で顔面に密着し、メガネレンズの曇りを防ぐことができた。それに対し、比較例1のマスクでは、メガネレンズに曇りが僅か発生し、また比較例2および3のマスクはメガネレンズの曇りがはっきり発生した。このことから、マスク用緩衝材を構成する架橋ポリオレフィン連続気泡発泡体は、ポリオレフィン樹脂100重量部中にエチレン−酢酸ビニル共重合体樹脂を70重量部以上含むもの、特には発泡倍率20〜40倍の架橋ポリオレフィン独立気泡発泡体を圧縮により連続気泡化したもの、およびエチレン−酢酸ビニル共重合体樹脂に酢酸ビニルを5〜25%含有するものが、メガネレンズの曇り防止に最も効果のあることがわかる。 The masks of each Example and each Comparative Example were used as usual with glasses for one day, and it was examined whether or not the spectacle lens was fogged. As a result, for the masks of Examples 1 to 6, the cushioning material for the mask adhered to the face on the nasal column and both sides thereof, and fogging of the spectacle lens could be prevented. On the other hand, in the mask of Comparative Example 1, the fogging of the spectacle lens slightly occurred, and in the masks of Comparative Examples 2 and 3, the fogging of the spectacle lens was clearly generated. From this fact, the crosslinked polyolefin open-cell foam constituting the mask cushioning material contains 70 parts by weight or more of ethylene-vinyl acetate copolymer resin in 100 parts by weight of polyolefin resin, in particular, the expansion ratio is 20 to 40 times. The crosslinked polyolefin closed-cell foams obtained by compression, and those containing 5 to 25% vinyl acetate in the ethylene-vinyl acetate copolymer resin, are most effective in preventing fogging of spectacle lenses. Recognize.

10 マスク

11 マスク本体

21 耳掛け用紐

31 マスク用緩衝材

DESCRIPTION OF

Claims (7)

ポリオレフィン樹脂100重量部中にエチレン−酢酸ビニル共重合体樹脂を70重量部以上含む発泡倍率20〜40倍の架橋ポリオレフィン連続気泡発泡体からなり、

前記エチレン−酢酸ビニル共重合体樹脂が酢酸ビニル含有率5〜25%からなり、

前記架橋ポリオレフィン連続気泡発泡体が、架橋ポリオレフィン独立気泡発泡体を連続気泡化し、表面にはスキン層が無いものであることを特徴とするマスク用緩衝材。 In the mask material for the horizontally long mask that is attached to the upper part of the inner surface of the mask body that covers the nose and mouth,

It consists of a crosslinked polyolefin open-cell foam having an expansion ratio of 20 to 40 times and containing 70 parts by weight or more of ethylene-vinyl acetate copolymer resin in 100 parts by weight of polyolefin resin,

The ethylene - vinyl acetate copolymer resins is Ri vinyl content of 5-25% Tona acetate,

A cushioning material for a mask, wherein the cross-linked polyolefin open-cell foam is made of a cross-linked polyolefin closed-cell foam and has no skin layer on the surface .

前記中央部の括れには鼻柱が位置し、 A nose column is located in the constriction of the central part,

前記両側の膨らみ部には顔面における鼻の両側が位置し、 The bulges on both sides are located on both sides of the nose in the face,

前記膨らみ部は顔面側に膨らんだ形状とされ、前記マスク本体にマスク用緩衝材が取り付けられたマスクが顔面に装着された際に、鼻の両側で生じるマスク本体と顔面間の隙間を塞ぐことのできる厚みからなることを特徴とする請求項1から5の何れか一項に記載のマスク用緩衝材。 The bulge portion is shaped to bulge to the face side, and when a mask having a mask cushion attached to the mask body is attached to the face, the gap between the mask body and the face generated on both sides of the nose is blocked. The cushioning material for a mask according to any one of claims 1 to 5, wherein the cushioning material has a thickness that can be formed.

前記マスク用緩衝材が請求項1から6の何れか一項に記載のマスク用緩衝材からなり、メガネ装着時には、メガネレンズの曇りを防ぐことができることを特徴とするマスク。 The mask cushioning material is made of the mask cushioning material according to any one of claims 1 to 6, and can prevent fogging of a spectacle lens when wearing spectacles.

Priority Applications (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| JP2006340971A JP4471966B2 (en) | 2006-12-19 | 2006-12-19 | Mask cushion and mask |

Applications Claiming Priority (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| JP2006340971A JP4471966B2 (en) | 2006-12-19 | 2006-12-19 | Mask cushion and mask |

Publications (3)

| Publication Number | Publication Date |

|---|---|

| JP2008148984A JP2008148984A (en) | 2008-07-03 |

| JP2008148984A5 JP2008148984A5 (en) | 2010-01-07 |

| JP4471966B2 true JP4471966B2 (en) | 2010-06-02 |

Family

ID=39651835

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| JP2006340971A Active JP4471966B2 (en) | 2006-12-19 | 2006-12-19 | Mask cushion and mask |

Country Status (1)

| Country | Link |

|---|---|

| JP (1) | JP4471966B2 (en) |

Families Citing this family (8)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| JP2012031219A (en) * | 2010-07-27 | 2012-02-16 | Sanwa Kako Co Ltd | Crosslinked polyolefin open-cellular body with excellent recyclability, method of manufacturing the same, and shock-absorbing material for mask |

| JP2012115647A (en) * | 2010-11-09 | 2012-06-21 | Tomoko Takase | Health mask |

| JP6062679B2 (en) * | 2011-07-31 | 2017-01-18 | 一子 小林 | Cushion pad for mask |

| JP2015063596A (en) * | 2013-09-25 | 2015-04-09 | 三和化工株式会社 | Polyethylene-based open-celled foam and production method thereof |

| JP6524390B2 (en) * | 2015-01-28 | 2019-06-05 | 京都ケミカル株式会社 | mask |

| JPWO2018235698A1 (en) * | 2017-06-20 | 2020-04-16 | 横井定株式会社 | mask |

| KR102585442B1 (en) | 2017-11-13 | 2023-10-06 | 쓰리엠 이노베이티브 프로퍼티즈 캄파니 | Inner shell and mask including same |

| JP2020136666A (en) * | 2019-02-20 | 2020-08-31 | 東レ株式会社 | Method for manufacturing photovoltaic device |

-

2006

- 2006-12-19 JP JP2006340971A patent/JP4471966B2/en active Active

Also Published As

| Publication number | Publication date |

|---|---|

| JP2008148984A (en) | 2008-07-03 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| JP4471966B2 (en) | Mask cushion and mask | |

| JP2008148984A5 (en) | ||

| AU2013290178B2 (en) | Push-in earplug | |

| US8679607B2 (en) | Foamable article | |

| WO2019073607A1 (en) | Member for shoe soles and shoe | |

| AU2013289055B2 (en) | Method of making an earplug | |

| AU2021202336B2 (en) | Thermoplastic cast | |

| US20140033390A1 (en) | Polychloroprene-free wetsuit and material | |

| US20160000159A1 (en) | Hypoallergenic exercise garment and material | |

| KR101909214B1 (en) | Thermoplastic Orthopedic Cast | |

| JP2015012990A (en) | Face guard cushion member for three-dimensional mask, and three-dimensional mask fitted with the cushion member | |

| US20140033389A1 (en) | Polychloroprene-free wetsuit and material | |

| KR101622883B1 (en) | Thermoplastic Orthopedic Cast Having Buffer Pad | |

| JP3072164U (en) | Press fixing protector | |

| JP2005068233A (en) | Hygroscopic sheet | |

| JP3091964U (en) | Dry wood | |

| CN220872782U (en) | Mask and head-mounted display device | |

| JP2014204905A (en) | Head support tool | |

| CN211211617U (en) | High-comfort impact-resistant helmet lining and helmet | |

| TWI471367B (en) | Multiple shapes fixable foam and application thereof | |

| KR20220042327A (en) | Thermoplastic Orthopedic Cast | |

| JP2001232709A (en) | Composite material for manufacturing foam, method for manufacturing foam using the same, coated foam and foam sheet | |

| KR20210148986A (en) | Thermoplastic Orthopedic Cast | |

| KR20210098889A (en) | Thermoplastic Orthopedic Cast | |

| KR20210133189A (en) | Thermoplastic Orthopedic Cast |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| A521 | Request for written amendment filed |

Free format text: JAPANESE INTERMEDIATE CODE: A523 Effective date: 20091113 |

|

| A621 | Written request for application examination |

Free format text: JAPANESE INTERMEDIATE CODE: A621 Effective date: 20091116 |

|

| A871 | Explanation of circumstances concerning accelerated examination |

Free format text: JAPANESE INTERMEDIATE CODE: A871 Effective date: 20091117 |

|

| A975 | Report on accelerated examination |

Free format text: JAPANESE INTERMEDIATE CODE: A971005 Effective date: 20091203 |

|

| A131 | Notification of reasons for refusal |

Free format text: JAPANESE INTERMEDIATE CODE: A131 Effective date: 20091208 |

|

| A521 | Request for written amendment filed |

Free format text: JAPANESE INTERMEDIATE CODE: A523 Effective date: 20100129 |

|

| TRDD | Decision of grant or rejection written | ||

| A01 | Written decision to grant a patent or to grant a registration (utility model) |

Free format text: JAPANESE INTERMEDIATE CODE: A01 Effective date: 20100302 |

|

| A01 | Written decision to grant a patent or to grant a registration (utility model) |

Free format text: JAPANESE INTERMEDIATE CODE: A01 |

|

| A61 | First payment of annual fees (during grant procedure) |

Free format text: JAPANESE INTERMEDIATE CODE: A61 Effective date: 20100302 |

|

| FPAY | Renewal fee payment (event date is renewal date of database) |

Free format text: PAYMENT UNTIL: 20130312 Year of fee payment: 3 |

|

| R150 | Certificate of patent or registration of utility model |

Ref document number: 4471966 Country of ref document: JP Free format text: JAPANESE INTERMEDIATE CODE: R150 Free format text: JAPANESE INTERMEDIATE CODE: R150 |

|

| FPAY | Renewal fee payment (event date is renewal date of database) |

Free format text: PAYMENT UNTIL: 20140312 Year of fee payment: 4 |

|

| R250 | Receipt of annual fees |

Free format text: JAPANESE INTERMEDIATE CODE: R250 |

|

| R250 | Receipt of annual fees |

Free format text: JAPANESE INTERMEDIATE CODE: R250 |

|

| R250 | Receipt of annual fees |

Free format text: JAPANESE INTERMEDIATE CODE: R250 |

|

| R250 | Receipt of annual fees |

Free format text: JAPANESE INTERMEDIATE CODE: R250 |

|

| R250 | Receipt of annual fees |

Free format text: JAPANESE INTERMEDIATE CODE: R250 |

|

| R250 | Receipt of annual fees |

Free format text: JAPANESE INTERMEDIATE CODE: R250 |

|

| R250 | Receipt of annual fees |

Free format text: JAPANESE INTERMEDIATE CODE: R250 |

|

| R250 | Receipt of annual fees |

Free format text: JAPANESE INTERMEDIATE CODE: R250 |

|

| R250 | Receipt of annual fees |

Free format text: JAPANESE INTERMEDIATE CODE: R250 |

|

| R250 | Receipt of annual fees |

Free format text: JAPANESE INTERMEDIATE CODE: R250 |

|

| R250 | Receipt of annual fees |

Free format text: JAPANESE INTERMEDIATE CODE: R250 |

|

| R250 | Receipt of annual fees |

Free format text: JAPANESE INTERMEDIATE CODE: R250 |