JP4460309B2 - ドラグラインスイングシャフト用密閉球状ローラベアリング - Google Patents

ドラグラインスイングシャフト用密閉球状ローラベアリング Download PDFInfo

- Publication number

- JP4460309B2 JP4460309B2 JP2003588095A JP2003588095A JP4460309B2 JP 4460309 B2 JP4460309 B2 JP 4460309B2 JP 2003588095 A JP2003588095 A JP 2003588095A JP 2003588095 A JP2003588095 A JP 2003588095A JP 4460309 B2 JP4460309 B2 JP 4460309B2

- Authority

- JP

- Japan

- Prior art keywords

- ring

- resistant seal

- wear

- inner ring

- seal ring

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Expired - Fee Related

Links

- 238000007789 sealing Methods 0.000 claims description 22

- 239000000356 contaminant Substances 0.000 description 15

- 239000000314 lubricant Substances 0.000 description 11

- 238000000034 method Methods 0.000 description 5

- 238000012423 maintenance Methods 0.000 description 3

- 239000000463 material Substances 0.000 description 3

- 238000005065 mining Methods 0.000 description 3

- 238000011109 contamination Methods 0.000 description 2

- 238000006073 displacement reaction Methods 0.000 description 2

- 238000007689 inspection Methods 0.000 description 2

- 238000009434 installation Methods 0.000 description 2

- 238000003466 welding Methods 0.000 description 2

- 239000003795 chemical substances by application Substances 0.000 description 1

- 230000001143 conditioned effect Effects 0.000 description 1

- 238000010276 construction Methods 0.000 description 1

- 230000008878 coupling Effects 0.000 description 1

- 238000010168 coupling process Methods 0.000 description 1

- 238000005859 coupling reaction Methods 0.000 description 1

- 230000006866 deterioration Effects 0.000 description 1

- 238000005553 drilling Methods 0.000 description 1

- 230000002708 enhancing effect Effects 0.000 description 1

- 238000003754 machining Methods 0.000 description 1

- 238000012986 modification Methods 0.000 description 1

- 230000004048 modification Effects 0.000 description 1

- 230000002265 prevention Effects 0.000 description 1

- 230000000717 retained effect Effects 0.000 description 1

Images

Classifications

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F16—ENGINEERING ELEMENTS AND UNITS; GENERAL MEASURES FOR PRODUCING AND MAINTAINING EFFECTIVE FUNCTIONING OF MACHINES OR INSTALLATIONS; THERMAL INSULATION IN GENERAL

- F16C—SHAFTS; FLEXIBLE SHAFTS; ELEMENTS OR CRANKSHAFT MECHANISMS; ROTARY BODIES OTHER THAN GEARING ELEMENTS; BEARINGS

- F16C33/00—Parts of bearings; Special methods for making bearings or parts thereof

- F16C33/72—Sealings

- F16C33/76—Sealings of ball or roller bearings

- F16C33/78—Sealings of ball or roller bearings with a diaphragm, disc, or ring, with or without resilient members

- F16C33/7803—Sealings of ball or roller bearings with a diaphragm, disc, or ring, with or without resilient members suited for particular types of rolling bearings

- F16C33/7806—Sealings of ball or roller bearings with a diaphragm, disc, or ring, with or without resilient members suited for particular types of rolling bearings for spherical roller bearings

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F16—ENGINEERING ELEMENTS AND UNITS; GENERAL MEASURES FOR PRODUCING AND MAINTAINING EFFECTIVE FUNCTIONING OF MACHINES OR INSTALLATIONS; THERMAL INSULATION IN GENERAL

- F16C—SHAFTS; FLEXIBLE SHAFTS; ELEMENTS OR CRANKSHAFT MECHANISMS; ROTARY BODIES OTHER THAN GEARING ELEMENTS; BEARINGS

- F16C23/00—Bearings for exclusively rotary movement adjustable for aligning or positioning

- F16C23/06—Ball or roller bearings

- F16C23/08—Ball or roller bearings self-adjusting

- F16C23/082—Ball or roller bearings self-adjusting by means of at least one substantially spherical surface

- F16C23/086—Ball or roller bearings self-adjusting by means of at least one substantially spherical surface forming a track for rolling elements

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F16—ENGINEERING ELEMENTS AND UNITS; GENERAL MEASURES FOR PRODUCING AND MAINTAINING EFFECTIVE FUNCTIONING OF MACHINES OR INSTALLATIONS; THERMAL INSULATION IN GENERAL

- F16C—SHAFTS; FLEXIBLE SHAFTS; ELEMENTS OR CRANKSHAFT MECHANISMS; ROTARY BODIES OTHER THAN GEARING ELEMENTS; BEARINGS

- F16C33/00—Parts of bearings; Special methods for making bearings or parts thereof

- F16C33/30—Parts of ball or roller bearings

- F16C33/46—Cages for rollers or needles

- F16C33/48—Cages for rollers or needles for multiple rows of rollers or needles

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F16—ENGINEERING ELEMENTS AND UNITS; GENERAL MEASURES FOR PRODUCING AND MAINTAINING EFFECTIVE FUNCTIONING OF MACHINES OR INSTALLATIONS; THERMAL INSULATION IN GENERAL

- F16C—SHAFTS; FLEXIBLE SHAFTS; ELEMENTS OR CRANKSHAFT MECHANISMS; ROTARY BODIES OTHER THAN GEARING ELEMENTS; BEARINGS

- F16C33/00—Parts of bearings; Special methods for making bearings or parts thereof

- F16C33/72—Sealings

- F16C33/76—Sealings of ball or roller bearings

- F16C33/78—Sealings of ball or roller bearings with a diaphragm, disc, or ring, with or without resilient members

- F16C33/7886—Sealings of ball or roller bearings with a diaphragm, disc, or ring, with or without resilient members mounted outside the gap between the inner and outer races, e.g. sealing rings mounted to an end face or outer surface of a race

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F16—ENGINEERING ELEMENTS AND UNITS; GENERAL MEASURES FOR PRODUCING AND MAINTAINING EFFECTIVE FUNCTIONING OF MACHINES OR INSTALLATIONS; THERMAL INSULATION IN GENERAL

- F16C—SHAFTS; FLEXIBLE SHAFTS; ELEMENTS OR CRANKSHAFT MECHANISMS; ROTARY BODIES OTHER THAN GEARING ELEMENTS; BEARINGS

- F16C19/00—Bearings with rolling contact, for exclusively rotary movement

- F16C19/22—Bearings with rolling contact, for exclusively rotary movement with bearing rollers essentially of the same size in one or more circular rows, e.g. needle bearings

- F16C19/34—Bearings with rolling contact, for exclusively rotary movement with bearing rollers essentially of the same size in one or more circular rows, e.g. needle bearings for both radial and axial load

- F16C19/38—Bearings with rolling contact, for exclusively rotary movement with bearing rollers essentially of the same size in one or more circular rows, e.g. needle bearings for both radial and axial load with two or more rows of rollers

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F16—ENGINEERING ELEMENTS AND UNITS; GENERAL MEASURES FOR PRODUCING AND MAINTAINING EFFECTIVE FUNCTIONING OF MACHINES OR INSTALLATIONS; THERMAL INSULATION IN GENERAL

- F16C—SHAFTS; FLEXIBLE SHAFTS; ELEMENTS OR CRANKSHAFT MECHANISMS; ROTARY BODIES OTHER THAN GEARING ELEMENTS; BEARINGS

- F16C2350/00—Machines or articles related to building

- F16C2350/26—Excavators

Landscapes

- Engineering & Computer Science (AREA)

- General Engineering & Computer Science (AREA)

- Mechanical Engineering (AREA)

- Rolling Contact Bearings (AREA)

- Component Parts Of Construction Machinery (AREA)

Description

Claims (6)

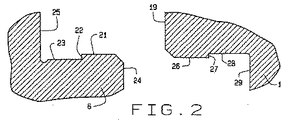

- 外輪と、

内輪であって、前記外輪と前記内輪との間に環状の空間が存在するように、前記外輪内に設けられ、ドラグラインスイングシャフトと整合する大きさの中央ボアを有するところの内輪と、

前記内輪と前記外輪との間の前記環状の空間に設けられた第1の複数の球状回転要素及び第2の複数の球状回転要素と、

前記内輪の上端に設けられた上側耐磨耗シールリングと、

前記内輪の下端に設けられた下側耐磨耗シールリングと、

前記上側耐磨耗シールリングに取り付けられ、前記環状の空間の上端を覆う上側密閉リングと、

前記下側耐磨耗シールリングに取り付けられ、前記環状の空間の下端を覆う下側密閉リングと、

前記外輪から伸びる少なくとも1つの接触リップシール保持器と、

前記接触リップシール保持器によって保持され、前記上側耐磨耗シールリング及び前記下側耐磨耗シールリングのうちの1つと接触する少なくとも1つの接触リップシールと、

を備える、ドラグライン掘削機のドラグラインスイングシャフト用密閉球状ローラベアリング。 - 前記内輪及び前記外輪の各々が、第1の傾斜した軌道面及び第2の傾斜した軌道面を有し、前記第1の傾斜した軌道面は、前記第2の傾斜した軌道面から間隔をあけて配置され、そして、前記軌道面に対して反対向きに傾斜しており、前記第1及び第2の軌道面の各々は、前記第1及び第2の複数の球状回転要素の曲率と同一の曲率を有する、請求項1に記載の密閉球状ローラベアリング。

- 前記下側耐磨耗シールリングと前記内輪との間、及び、前記上側耐磨耗シールリングと前記内輪との間がロック係合されている、請求項2に記載の密閉球状ローラベアリング。

- 前記上側耐磨耗シールリング上に配置され、前記上側耐磨耗シールリングの前記第1のロックショルダに動作的に係合しこれに固定されるように構成された第1のロックオフセットをさらに前記内輪の前面に備え、そして、前記下側耐磨耗シールリング上に配置され、前記下側耐磨耗シールリングの前記第2のロックショルダに動作的に係合しこれに固定されるように構成された第2のロックオフセットをさらに前記内輪の後面に備える、請求項3に記載の密閉球状ローラベアリング。

- 前記第1及び第2のロックショルダの各々が、環状リップ、第1のオフセット、第1の環状溝、第1の環状面、及び第1のオフセット面を備え、そして、前記第1及び第2のロックオフセット各々が、第2の環状リップ、第2のオフセット、第2の環状溝、第2のオフセット面及び前面を備える、請求項4に記載の密閉球状ローラベアリング。

- 前記下側密閉リングの端部と前記少なくとも1つの接触リップシール保持器との間に、前記フランジ先端部と前記少なくとも1つの接触リップシール保持器との間に接触を起こすことなく、前記内輪と前記外輪との間の軸方向位置ずれを許容するための隙間がある、請求項1に記載の密閉球状ローラベアリング。

Applications Claiming Priority (2)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| US37486602P | 2002-04-23 | 2002-04-23 | |

| PCT/US2003/012574 WO2003091587A1 (en) | 2002-04-23 | 2003-04-22 | Sealed spherical roller bearing for dragline swing shaft |

Publications (3)

| Publication Number | Publication Date |

|---|---|

| JP2005524030A JP2005524030A (ja) | 2005-08-11 |

| JP2005524030A5 JP2005524030A5 (ja) | 2006-06-08 |

| JP4460309B2 true JP4460309B2 (ja) | 2010-05-12 |

Family

ID=29270557

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| JP2003588095A Expired - Fee Related JP4460309B2 (ja) | 2002-04-23 | 2003-04-22 | ドラグラインスイングシャフト用密閉球状ローラベアリング |

Country Status (6)

| Country | Link |

|---|---|

| US (1) | US6814494B2 (ja) |

| EP (1) | EP1497569B1 (ja) |

| JP (1) | JP4460309B2 (ja) |

| AU (1) | AU2003239161A1 (ja) |

| DE (1) | DE60306638T2 (ja) |

| WO (1) | WO2003091587A1 (ja) |

Families Citing this family (20)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| EP1705392B2 (en) * | 2003-11-18 | 2016-08-31 | NTN Corporation | Double-row self-aligning roller bearing and device for supporting wind turbine generator main shaft |

| WO2006033320A1 (ja) * | 2004-09-21 | 2006-03-30 | Ntn Corporation | 複列自動調心ころ軸受および風力発電機の主軸支持構造 |

| US7523912B1 (en) * | 2004-12-17 | 2009-04-28 | Pelco Products, Inc. | Pivot base assembly for traffic pole |

| WO2006080127A1 (ja) * | 2005-01-25 | 2006-08-03 | Ntn Corporation | はすば歯車支持構造、風力発電機用増速機および垂直軸支持構造 |

| DE102007047527A1 (de) * | 2007-10-04 | 2009-04-09 | Schaeffler Kg | Radialwälzlager, insbesondere zweireihiges Schrägwälzlager |

| CN102138015A (zh) * | 2008-08-27 | 2011-07-27 | Skf公司 | 用于船舱推进系统的轴承 |

| DE102009014922A1 (de) * | 2009-03-25 | 2010-09-30 | Ab Skf | Fettgeschmiertes zweireihiges Wälzlager und Lagersystem mit einem derartigen Wälzlager und einer Schmiervorrichtung |

| DE102010051230A1 (de) * | 2010-11-12 | 2012-05-16 | Schaeffler Technologies Gmbh & Co. Kg | Abgedichtetes Wälzlager |

| DE102011003513A1 (de) * | 2011-02-02 | 2012-08-02 | Aktiebolaget Skf | Wälzlager |

| DE102011075548B4 (de) * | 2011-05-10 | 2015-12-17 | Schaeffler Technologies AG & Co. KG | Lager mit einer Energieerfassungseinheit, insbesondere Pendelrollen-Lager zur Lagerung einer Walze |

| DE102011078840A1 (de) | 2011-07-08 | 2013-01-10 | Schaeffler Technologies AG & Co. KG | Pendelrollenlager mit Dichtungsanordnung sowie Flossenstabilisator mit dem Pendelrollenlager |

| DE102012202592A1 (de) | 2012-02-21 | 2013-08-22 | Schaeffler Technologies AG & Co. KG | Wälzlager |

| EP2871377B1 (en) * | 2013-11-07 | 2017-01-25 | Aktiebolaget SKF | Bearing unit for fluid machinery application |

| DE102014219700A1 (de) * | 2014-09-29 | 2016-03-31 | Aktiebolaget Skf | Dichtung bei einem Lager und Verfahren für einen verschleißmindernden Betrieb einer Dichtung bei einem Lager |

| US9732793B2 (en) * | 2015-04-09 | 2017-08-15 | Aktiebolaget Skf | Bearing and bearing arrangement |

| US9797440B2 (en) * | 2015-04-09 | 2017-10-24 | Aktiebolaget Skf | Bearing |

| US9850942B2 (en) * | 2015-04-09 | 2017-12-26 | Aktiebolaget Skf | Bearing and bearing arrangement |

| JP2018179078A (ja) * | 2017-04-07 | 2018-11-15 | 株式会社ジェイテクト | 自動調心ころ軸受 |

| DE102019201353A1 (de) * | 2019-02-01 | 2020-08-06 | Horsch Maschinen Gmbh | Lagereinheit und landwirtschaftliche Maschine mit einer solchen Lagereinheit |

| DE102020118645B4 (de) | 2020-07-15 | 2022-02-17 | Schaeffler Technologies AG & Co. KG | Lagerring mit Dichtscheibe |

Family Cites Families (5)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US3957319A (en) * | 1975-01-29 | 1976-05-18 | Reliance Electric Company | Pillow block and bearing assembly |

| SE450851B (sv) * | 1986-01-24 | 1987-08-03 | Skf Mekanprodukter Ab | Anordning for montering av ett lager innefattande tetningar |

| US5017025A (en) * | 1990-04-05 | 1991-05-21 | The Timken Company | Bearing assembly for a shaft journal |

| US5104239A (en) * | 1991-03-06 | 1992-04-14 | Sague John E | In situ replaceable bearing |

| US5462367A (en) * | 1994-08-18 | 1995-10-31 | The Timken Company | Compact bearing and stiffened journal |

-

2003

- 2003-04-22 DE DE60306638T patent/DE60306638T2/de not_active Expired - Lifetime

- 2003-04-22 US US10/420,382 patent/US6814494B2/en not_active Expired - Lifetime

- 2003-04-22 JP JP2003588095A patent/JP4460309B2/ja not_active Expired - Fee Related

- 2003-04-22 WO PCT/US2003/012574 patent/WO2003091587A1/en active IP Right Grant

- 2003-04-22 EP EP03733877A patent/EP1497569B1/en not_active Expired - Lifetime

- 2003-04-22 AU AU2003239161A patent/AU2003239161A1/en not_active Abandoned

Also Published As

| Publication number | Publication date |

|---|---|

| DE60306638T2 (de) | 2007-06-21 |

| US20030198416A1 (en) | 2003-10-23 |

| EP1497569B1 (en) | 2006-07-05 |

| US6814494B2 (en) | 2004-11-09 |

| JP2005524030A (ja) | 2005-08-11 |

| AU2003239161A1 (en) | 2003-11-10 |

| DE60306638D1 (de) | 2006-08-17 |

| EP1497569A1 (en) | 2005-01-19 |

| WO2003091587A1 (en) | 2003-11-06 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| JP4460309B2 (ja) | ドラグラインスイングシャフト用密閉球状ローラベアリング | |

| US11022176B2 (en) | Slewing bearing with sealing arrangement | |

| EP2452090B1 (en) | Self-aligning maintenance free bearing unit for agricultural applications | |

| US7832815B2 (en) | Track roller assembly and machine using same | |

| US6234293B1 (en) | Conveyor-belt roller assembly | |

| US5904356A (en) | Labyrinth seal with contaminant purging passageway for bearing housings | |

| WO2015041337A1 (ja) | 転がり軸受の密封装置 | |

| US7946661B1 (en) | Sprocket hub mounted guard | |

| EP0156552B1 (en) | Interlocking universal joint seal assembly | |

| EP0243406B1 (en) | Sealing method for bearing assemblies | |

| CA2888307C (en) | Redundant seal apparatus and method | |

| US8075068B2 (en) | Track roller assembly and machine using same | |

| BRPI1001021A2 (pt) | conjunto de mancal afixado a um eixo e método para vedar um conjunto de mancal afixado a um eixo | |

| KR20160045035A (ko) | 드릴 워시 장치의 미리 장착된 교환 인서트 | |

| US4339161A (en) | Bearing seal for a drill head assembly | |

| US12024951B2 (en) | Roller cutting tool with improved sealing | |

| US8388230B2 (en) | Seal guard | |

| US12049923B2 (en) | Cutting-ring assembly | |

| GB2573194A (en) | Slewing bearing with sealing arrangement | |

| US11585379B2 (en) | Bearing with removable sealing module | |

| US20240200523A1 (en) | Sealing system for underwater turbine | |

| US20220196072A1 (en) | Rolling bearing with removable sealing module | |

| GB2573196A (en) | Slewing bearing with sealing arrangement |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| A521 | Request for written amendment filed |

Free format text: JAPANESE INTERMEDIATE CODE: A523 Effective date: 20060413 |

|

| A621 | Written request for application examination |

Free format text: JAPANESE INTERMEDIATE CODE: A621 Effective date: 20060413 |

|

| A131 | Notification of reasons for refusal |

Free format text: JAPANESE INTERMEDIATE CODE: A131 Effective date: 20081104 |

|

| A601 | Written request for extension of time |

Free format text: JAPANESE INTERMEDIATE CODE: A601 Effective date: 20090129 |

|

| A602 | Written permission of extension of time |

Free format text: JAPANESE INTERMEDIATE CODE: A602 Effective date: 20090205 |

|

| A521 | Request for written amendment filed |

Free format text: JAPANESE INTERMEDIATE CODE: A523 Effective date: 20090227 |

|

| A521 | Request for written amendment filed |

Free format text: JAPANESE INTERMEDIATE CODE: A523 Effective date: 20090302 |

|

| A131 | Notification of reasons for refusal |

Free format text: JAPANESE INTERMEDIATE CODE: A131 Effective date: 20090811 |

|

| A521 | Request for written amendment filed |

Free format text: JAPANESE INTERMEDIATE CODE: A523 Effective date: 20091105 |

|

| TRDD | Decision of grant or rejection written | ||

| A01 | Written decision to grant a patent or to grant a registration (utility model) |

Free format text: JAPANESE INTERMEDIATE CODE: A01 Effective date: 20100119 |

|

| A01 | Written decision to grant a patent or to grant a registration (utility model) |

Free format text: JAPANESE INTERMEDIATE CODE: A01 |

|

| A61 | First payment of annual fees (during grant procedure) |

Free format text: JAPANESE INTERMEDIATE CODE: A61 Effective date: 20100212 |

|

| R150 | Certificate of patent or registration of utility model |

Free format text: JAPANESE INTERMEDIATE CODE: R150 |

|

| FPAY | Renewal fee payment (event date is renewal date of database) |

Free format text: PAYMENT UNTIL: 20130219 Year of fee payment: 3 |

|

| FPAY | Renewal fee payment (event date is renewal date of database) |

Free format text: PAYMENT UNTIL: 20130219 Year of fee payment: 3 |

|

| R250 | Receipt of annual fees |

Free format text: JAPANESE INTERMEDIATE CODE: R250 |

|

| FPAY | Renewal fee payment (event date is renewal date of database) |

Free format text: PAYMENT UNTIL: 20140219 Year of fee payment: 4 |

|

| FPAY | Renewal fee payment (event date is renewal date of database) |

Free format text: PAYMENT UNTIL: 20140219 Year of fee payment: 4 |

|

| R250 | Receipt of annual fees |

Free format text: JAPANESE INTERMEDIATE CODE: R250 |

|

| R250 | Receipt of annual fees |

Free format text: JAPANESE INTERMEDIATE CODE: R250 |

|

| R250 | Receipt of annual fees |

Free format text: JAPANESE INTERMEDIATE CODE: R250 |

|

| LAPS | Cancellation because of no payment of annual fees |