JP4359385B2 - Pressure reducing valve for aerosol - Google Patents

Pressure reducing valve for aerosol Download PDFInfo

- Publication number

- JP4359385B2 JP4359385B2 JP2000308201A JP2000308201A JP4359385B2 JP 4359385 B2 JP4359385 B2 JP 4359385B2 JP 2000308201 A JP2000308201 A JP 2000308201A JP 2000308201 A JP2000308201 A JP 2000308201A JP 4359385 B2 JP4359385 B2 JP 4359385B2

- Authority

- JP

- Japan

- Prior art keywords

- pressure

- piston

- aerosol

- stem

- aerosol container

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Expired - Fee Related

Links

Images

Landscapes

- Nozzles (AREA)

- Containers And Packaging Bodies Having A Special Means To Remove Contents (AREA)

Description

【0001】

【産業上の利用分野】

本発明はエアゾール容器内に充填した加圧ガス、噴射剤に加圧された内容物等のエアゾール内容物を、エアゾール容器内の充填圧力よりも低く減圧すると共に定圧で噴射する事を可能にするものである。例えば生ビールのサーバーと接続するビール収納タンク内に、エアゾール容器内の高圧炭酸ガスを減圧すると共に、一定圧で供給する場合等に於いて用いるものである。

【0002】

【従来の技術】

従来、高圧の炭酸ガス等を減圧して、ビールサーバーのビール収納タンク等に供給する減圧弁は存在した。しかしながら、これらの従来公知の減圧弁は、高圧ガスを収納したガスボンベとは全く別個に形成し、減圧弁も高圧ガスを収納したガスボンベも各々別個にバルブ機構を備えたものであった。

【0003】

【発明が解決しようとする課題】

そのため、機構を複雑とし装置を高価なものにすると共に、高圧ガスを充填したガスボンベと減圧弁とを連結用の管等で連結する必要があり、操作性も悪いものであった。

【0004】

本発明は上述の如き課題を解決しようとするものであって、エアゾール容器が本来備えるバルブ機構を減圧弁のバルブとしても併用し、機構を簡略化して廉価な減圧装置を提供する。また、エアゾール容器に一体に組み込む事によって操作性を良好とする事ができるようにしようとするものである。

【0005】

【課題を解決するための手段】

本発明は、上述の如き課題を解決するため、エアゾール容器に連結固定したコネクターに、断面コ字型のケーシングを接続し、このケーシング内に、エアゾール容器内のガス圧よりも弱い復元力とした調圧発条の押圧力によってエアゾール容器のステムを押圧するピストンを配置し、このピストンとエアゾール容器側のコネクターとの間に、ステムと連通する圧力調整室を形成すると共にこの圧力調整室に、エアゾール内容物の噴出口を連通して形成し、また、前記ピストンに、ケーシング外まで突出すると共に圧力調整室と連通する連通管を突出し、この連通管の先端にエアゾール内容物の噴出口を設けて圧力調整室と噴出口との連通を行うとともに、上記連通管の先端突出部に固定ナットを装着することにより、ピストンをステムの非押圧状態に固定可能として成るものである。

【0006】

【作用】

本発明は、上述の如く構成したものであるから、調圧発条の押圧力によってピストンがステムを押圧すると、ステムはエアゾール容器のバルブ機構を開放しエアゾール内容物を連通管内に導入し、噴出口から噴出させるか若しくは誘導管等で適宜の位置まで誘導する。エアゾール内容物は同時に、ピストンの押圧方向とコネクターとの間に設け、ステムと連通形成した圧力調整室にも流入する。そして、この流入したエアゾール内容物は、調圧発条の復元力よりもガス圧が高いから、調圧発条の復元力に抗してピストンを押圧し、ピストンのステムへの押圧を解除する。

【0007】

このピストンのステムへの押圧解除により、ステムはエアゾール容器のバルブ機構を閉止しエアゾール内容物の噴出を停止する。この噴出停止後も圧力調整室内のエアゾール内容物は噴出口を介して外部に放出されるから、ピストンへのエアゾール内容物による押圧力は、調圧発条のピストンへの押圧力よりも小さなものとなる。

【0008】

ピストンへのエアゾール内容物による押圧力が、調圧発条のピストンへの押圧力よりも小さくなると、調圧発条の押圧力によりピストンがステムを押し下げ、エアゾール容器のバルブ機構を開放しエアゾール内容物を噴出口から噴出させるか若しくは適宜の位置まで誘導する。

【0009】

エアゾール内容物は噴出口から噴出すると共に圧力調整室にも流入する。そして、この流入したエアゾール内容物は、調圧発条の復元力よりもガス圧が高いものであるから、調圧発条の復元力に抗してピストンを押圧し、ピストンのステムへの押圧を解除する。

【0010】

このピストンによるステムへの押圧解除により、ステムはエアゾール容器のバルブ機構を閉止し、エアゾール内容物の噴出を停止する。この噴出停止後も圧力調整室のエアゾール内容物は、噴出口を介して外部に放出されるから、ピストンへのエアゾール内容物による押圧力は、調圧発条のピストンへの押圧力よりも小さなものとなる。

【0011】

以上の操作を短時間の間に繰り返すことにより、エアゾール容器から噴出するエアゾール内容物は、エアゾール容器内のガス圧よりも減圧され、一定圧の範囲に保たれ、減圧定圧噴射を可能とするものである。

【0012】

【実施例】

以下、本発明の第1実施例を図面に於て説明すれば、(1)はエアゾール容器で、高圧炭酸ガス、噴射剤に加圧された内容物等のエアゾール内容物を充填している。このエアゾール容器(1)は、上端に固定したマウテンカップ(2)の立上部(3)内にバルブ機構(図示せず)を備えると共に、このバルブ機構の一部を構成するステム(8)を立上部(3)から上面に突出している。また、この立上部(3)の外周には、螺着部(4)を介してコネクター(5)を螺着固定している。また、このコネクター(5)には、断面コ字型のケーシング(6)を螺着により接続固定し、このケーシング(6)とコネクター(5)間にパッキン(7)を介装している。

【0013】

このケーシング(6)内に、エアゾール容器(1)内のガス圧よりも弱い復元力とした調圧発条(10)の押圧力によって、エアゾール容器(1)のステム(8)を押圧するピストン(11)を摺動可能に配置している。このピストン(11)とケーシング(6)間にはオーリング(12)を介装し気密性を保持している。

【0014】

また、このピストン(11)には、調圧発条(10)側に、ケーシング(6)外まで突出する連通管(13)を突出している。この連通管(13)の上端には、エアゾール内容物の噴出口(14)を設け、この噴出口(14)とステム(8)とを、連通路(15)を介して連通している。

【0015】

また、ピストン(11)の押圧方向とコネクター(5)との間に圧力調整室(16)を形成し、この圧力調整室(16)とステム(8)とを、連通溝(17)を介して連通形成している。また、この連通溝(17)は圧力調整室(16)とステム(8)とを連通するばかりでなく、連通管(13)の連通路(15)とも連通している。

【0016】

また、図面中(20)はケーシング(6)の調圧発条(10)側の側面に開口した外気導入口、(21)は噴出口(14)から減圧噴射されたエアゾール内容物を、適宜の位置まで誘導する誘導管、(22)は、本発明装置の展示、配送、保存等を行う場合に、ピストン(11)をステムの非押圧状態に固定するための固定ナットである。

【0017】

上述の如く構成したものに於て、エアゾール内容物の減圧噴射を行うには、まず固定ナット(22)を連通管(13)の先端から取り外して、ピストン(11)によるステム(8)の押圧を可能とする。そして、調圧発条(10)の押圧力によってピストン(11)がステム(8)を押圧すると、ステム(8)はエアゾール容器(1)のバルブ機構(図示せず)を開放し、高圧炭酸ガス等のエアゾール内容物を連通管(13)内に導入し、噴出口(14)から噴出させるか若しくはビールサーバー等の適宜の位置まで誘導管(21)によって誘導する。

【0018】

エアゾール内容物は同時に、連通溝(17)を介してステム(8)と連通形成したた圧力調整室(16)にも流入する。そして、この流入したエアゾール内容物は、調圧発条(10)の復元力よりもガス圧が高いものであるから、調圧発条(10)の復元力に抗してピストン(11)を押圧し、ピストン(11)のステム(8)への押圧を解除する。

【0019】

このピストン(11)のステム(8)への押圧解除により、ステム(8)はエアゾール容器(1)のバルブ機構を閉止し、エアゾール内容物の噴出を停止する。この噴出停止と同時に、圧力調整室(16)のエアゾール内容物は連通溝(17)、連通管(13)を介して外部に放出されるから、ピストン(11)へのエアゾール内容物による押圧力は、調圧発条(10)のピストン(11)への押圧力よりも小さなものとなる。

【0020】

ピストン(11)へのエアゾール内容物による押圧力が、調圧発条(10)のピストン(11)への押圧力よりも小さくなると、調圧発条(10)の押圧力によりピストン(11)がステム(8)を押し下げ、エアゾール容器(1)のバルブ機構を開放し、エアゾール内容物を連通管(13)内に導入し、噴出口(14)から噴出させるか若しくは適宜の位置まで誘導する。

【0021】

エアゾール内容物は同時に、連通溝(17)を介して圧力調整室(16)にも流入する。そして、この流入したエアゾール内容物は、調圧発条(10)の復元力よりもガス圧が高いものであるから、調圧発条(10)の復元力に抗してピストン(11)を押圧し、ピストン(11)のステム(8)への押圧を解除する。このピストン(11)のステム(8)への押圧解除により、ステム(8)はエアゾール容器(1)のバルブ機構を閉止し、エアゾール内容物の噴出を停止する。この噴出停止と同時に、圧力調整室(16)のエアゾール内容物は、連通溝(17)、連通管(13)を介して外部に放出されるから、ピストン(11)へのエアゾール内容物による押圧力は、調圧発条(10)のピストン(11)への押圧力よりも小さなものとなる。

【0022】

以上の操作を短時間の間に繰り返すことにより、噴出口(14)から噴出するエアゾール内容物は、エアゾール容器(1)内のガス圧を減圧した、一定圧の範囲に保たれ減圧定量噴射を可能とするものである。

【0023】

【発明の効果】

本発明は上述の如く構成したものであるから、エアゾール容器が本来備えるバルブ機構を減圧弁のバルブとしても併用し、機構を簡略化して廉価な減圧装置を提供する。また、エアゾール容器に一体に組み込む事によって操作性を良好とする事ができるものである。

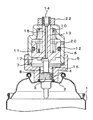

【図面の簡単な説明】

【図1】 本発明の第1実施例を示す断面図。

【図2】 ピストンをステムの押圧不能に固定した状態の断面図。

【符号の説明】

1 エアゾール容器

5 コネクター

6 ケーシング

8 ステム

10 調圧発条

11 ピストン

13 連通管

14 噴出口

16 圧力調整室[0001]

[Industrial application fields]

The present invention makes it possible to depressurize aerosol contents such as pressurized gas filled in an aerosol container, contents pressurized in a propellant to a pressure lower than the filling pressure in the aerosol container, and at a constant pressure. Is. For example, it is used when a high pressure carbon dioxide gas in an aerosol container is decompressed and supplied at a constant pressure in a beer storage tank connected to a draft beer server.

[0002]

[Prior art]

Conventionally, there has been a pressure reducing valve that decompresses high-pressure carbon dioxide gas and supplies it to a beer storage tank or the like of a beer server. However, these conventionally known pressure reducing valves are formed completely separately from the gas cylinder containing the high-pressure gas, and the pressure reducing valve and the gas cylinder containing the high-pressure gas are each provided with a valve mechanism.

[0003]

[Problems to be solved by the invention]

Therefore, the mechanism is complicated and the apparatus is expensive, and it is necessary to connect the gas cylinder filled with the high pressure gas and the pressure reducing valve with a connecting pipe or the like, and the operability is also poor.

[0004]

The present invention is intended to solve the above-described problems, and provides a low-pressure decompression device that simplifies the mechanism by using the valve mechanism originally provided in the aerosol container as a valve of the decompression valve. In addition, it is intended to improve the operability by integrating it into an aerosol container.

[0005]

[Means for Solving the Problems]

In order to solve the above-described problems, the present invention connects a casing having a U-shaped cross section to a connector connected and fixed to an aerosol container, and has a restoring force weaker than the gas pressure in the aerosol container in the casing. A piston that presses the stem of the aerosol container by the pressing force of the pressure regulation ridge is disposed, and a pressure adjustment chamber that communicates with the stem is formed between the piston and the connector on the aerosol container side, and the aerosol is placed in the pressure adjustment chamber. The content injection port is formed in communication, and the piston protrudes out of the casing and communicates with the pressure adjusting chamber, and the aerosol content injection port is provided at the tip of the communication tube. The pressure adjustment chamber communicates with the jet port, and a fixing nut is attached to the projecting end of the communication pipe, so that the piston is not pushed by the stem. Those formed by the state fixable.

[0006]

[Action]

Since the present invention is configured as described above, when the piston presses the stem by the pressing force of the pressure regulating ridge, the stem opens the valve mechanism of the aerosol container and introduces the aerosol contents into the communication pipe, and the jet outlet Or is guided to an appropriate position by a guide tube or the like. At the same time, the aerosol content flows between the pressure direction of the piston and the connector, and flows into the pressure regulation chamber formed in communication with the stem. And since the inflowing aerosol content has a gas pressure higher than the restoring force of the pressure regulation ridge, the piston is pressed against the restoring force of the pressure regulation ridge, and the pressure on the stem of the piston is released.

[0007]

By releasing the pressure of the piston on the stem, the stem closes the valve mechanism of the aerosol container and stops the ejection of the aerosol contents. Even after the ejection stops, the aerosol content in the pressure adjustment chamber is released to the outside through the ejection port, so that the pressing force by the aerosol content on the piston is smaller than the pressing force on the piston of the pressure regulation ridge. Become.

[0008]

When the pressing force by the aerosol content on the piston becomes smaller than the pressing force on the piston of the pressure-regulating ridge, the piston pushes down the stem by the pressing force of the pressure-regulating ridge, opens the valve mechanism of the aerosol container, and removes the aerosol contents. It ejects from a spout or guides to an appropriate position.

[0009]

The aerosol contents are ejected from the ejection port and flow into the pressure regulation chamber. And, since the inflowing aerosol content has a higher gas pressure than the restoring force of the pressure regulating ridge, the piston is pressed against the restoring force of the pressure regulating ridge, and the pressure on the piston stem is released. To do.

[0010]

By releasing the pressure applied to the stem by the piston, the stem closes the valve mechanism of the aerosol container and stops the ejection of the aerosol contents. Even after the ejection stops, the aerosol content in the pressure adjustment chamber is released to the outside through the ejection port, so that the pressing force by the aerosol content to the piston is smaller than the pressing force to the piston of the pressure regulation ridge It becomes.

[0011]

By repeating the above operation in a short time, the aerosol content ejected from the aerosol container is depressurized from the gas pressure in the aerosol container and kept within a constant pressure range, enabling decompression and constant pressure injection. It is.

[0012]

【Example】

Hereinafter, a first embodiment of the present invention will be described with reference to the drawings. (1) is an aerosol container filled with an aerosol content such as a high-pressure carbon dioxide gas or a content pressurized by a propellant. This aerosol container (1) is provided with a valve mechanism (not shown) in an upright portion (3) of a mauten cup (2) fixed to the upper end, and a stem (8) constituting a part of this valve mechanism. It protrudes from the upper part (3) to the upper surface. A connector (5) is screwed and fixed to the outer periphery of the upright portion (3) via a screwing portion (4). In addition, a U-shaped casing (6) is connected and fixed to the connector (5) by screwing, and a packing (7) is interposed between the casing (6) and the connector (5).

[0013]

In this casing (6), a piston (pushing the stem (8) of the aerosol container (1) by the pressing force of the pressure regulating ridge (10) having a restoring force weaker than the gas pressure in the aerosol container (1) ( 11) is slidably arranged. An O-ring (12) is interposed between the piston (11) and the casing (6) to maintain airtightness.

[0014]

The piston (11) has a communication pipe (13) protruding outside the casing (6) on the pressure regulation line (10) side. This upper end of the communicating pipe (13), spout of aerosol content (14) is provided, the spout (14) and the stem (8), communicates via a communication passage (15).

[0015]

A pressure adjusting chamber (16) is formed between the pressing direction of the piston (11) and the connector (5), and the pressure adjusting chamber (16) and the stem (8) are connected via the communication groove (17). The communication is formed. The communication groove (17) not only communicates the pressure adjusting chamber (16) and the stem (8) but also communicates with the communication path (15) of the communication pipe (13).

[0016]

In the drawing, (20) is an outside air inlet opening on the side of the casing (6) on the side of the pressure regulation ridge (10), and (21) is the aerosol content injected under reduced pressure from the outlet (14). A guide tube (22) for guiding to a position is a fixing nut for fixing the piston (11) to the non-pressed state of the stem when the apparatus of the present invention is displayed, delivered, stored or the like.

[0017]

In order to perform aerosol injection of the aerosol contents under the above-described configuration, the fixing nut (22) is first removed from the tip of the communication pipe (13), and the stem (8) is pressed by the piston (11). Is possible. Then, when the piston (11) presses the stem (8) by the pressing force of the pressure regulation ridge (10), the stem (8) opens the valve mechanism (not shown) of the aerosol container (1), and the high-pressure carbon dioxide gas Is introduced into the communication pipe (13) and ejected from the spout (14) or guided to an appropriate position such as a beer server by the guide pipe (21).

[0018]

At the same time, the aerosol content flows into the pressure regulation chamber (16) formed in communication with the stem (8) through the communication groove (17). And since the inflowing aerosol content has a gas pressure higher than the restoring force of the pressure regulation ridge (10), the piston (11) is pressed against the restoration force of the pressure regulation ridge (10). Then, the pressure of the piston (11) on the stem (8) is released.

[0019]

By releasing the pressing of the piston (11) to the stem (8), the stem (8) closes the valve mechanism of the aerosol container (1) and stops the ejection of the aerosol contents. Simultaneously with the stop of the ejection, the aerosol content in the pressure adjusting chamber (16) is discharged to the outside through the communication groove (17) and the communication pipe (13). Is smaller than the pressing force to the piston (11) of the pressure regulation ridge (10).

[0020]

When the pressing force of the aerosol content on the piston (11) is smaller than the pressing force of the pressure adjusting ridge (10) to the piston (11), the piston (11) is caused to stem by the pressing force of the pressure adjusting ridge (10). (8) is pushed down, the valve mechanism of the aerosol container (1) is opened, and the aerosol contents are introduced into the communication pipe (13) and ejected from the ejection port (14) or guided to an appropriate position.

[0021]

At the same time, the aerosol content flows into the pressure regulation chamber (16) through the communication groove (17). And since the inflowing aerosol content has a gas pressure higher than the restoring force of the pressure regulation ridge (10), the piston (11) is pressed against the restoration force of the pressure regulation ridge (10). Then, the pressure of the piston (11) on the stem (8) is released. By releasing the pressing of the piston (11) to the stem (8), the stem (8) closes the valve mechanism of the aerosol container (1) and stops the ejection of the aerosol contents. Simultaneously with the stop of the ejection, the aerosol content in the pressure adjusting chamber (16) is discharged to the outside through the communication groove (17) and the communication pipe (13), so that the piston (11) is pushed by the aerosol content. The pressure is smaller than the pressing force of the pressure regulation ridge (10) on the piston (11).

[0022]

By repeating the above operation in a short time, the aerosol content ejected from the ejection port (14) is maintained in a constant pressure range in which the gas pressure in the aerosol container (1) is reduced, and the reduced pressure quantitative injection is performed. It is possible.

[0023]

【The invention's effect】

Since the present invention is configured as described above, the valve mechanism originally provided in the aerosol container is also used as the valve of the pressure reducing valve, and the mechanism is simplified to provide an inexpensive pressure reducing device. In addition, the operability can be improved by being integrated into the aerosol container.

[Brief description of the drawings]

FIG. 1 is a cross-sectional view showing a first embodiment of the present invention.

FIG. 2 is a cross-sectional view of a state where a piston is fixed so that a stem cannot be pressed.

[Explanation of symbols]

DESCRIPTION OF

Claims (1)

Priority Applications (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| JP2000308201A JP4359385B2 (en) | 2000-10-06 | 2000-10-06 | Pressure reducing valve for aerosol |

Applications Claiming Priority (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| JP2000308201A JP4359385B2 (en) | 2000-10-06 | 2000-10-06 | Pressure reducing valve for aerosol |

Publications (3)

| Publication Number | Publication Date |

|---|---|

| JP2002114281A JP2002114281A (en) | 2002-04-16 |

| JP2002114281A5 JP2002114281A5 (en) | 2007-03-29 |

| JP4359385B2 true JP4359385B2 (en) | 2009-11-04 |

Family

ID=18788555

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| JP2000308201A Expired - Fee Related JP4359385B2 (en) | 2000-10-06 | 2000-10-06 | Pressure reducing valve for aerosol |

Country Status (1)

| Country | Link |

|---|---|

| JP (1) | JP4359385B2 (en) |

Families Citing this family (1)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| CN109731707B (en) * | 2019-03-11 | 2020-11-27 | 安徽以诺木塑板材科技有限公司 | Paint spraying head for processing ecological waterproof floor |

-

2000

- 2000-10-06 JP JP2000308201A patent/JP4359385B2/en not_active Expired - Fee Related

Also Published As

| Publication number | Publication date |

|---|---|

| JP2002114281A (en) | 2002-04-16 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| US4934543A (en) | Bottle cap and dispenser | |

| US4674662A (en) | Dispenser for bottled liquid | |

| EP2596277B1 (en) | Closure device | |

| US6851575B2 (en) | Pressurized package comprising a pressure control device | |

| US8455032B2 (en) | Carbonating device, method of use, and related discharge and cap assemblies | |

| JPH07508954A (en) | Pressure generator and distribution device using the pressure generator | |

| KR900012833A (en) | Home Soda Dispensing System | |

| HU222971B1 (en) | Safety device for liquid aerating apparatus | |

| US20160251211A1 (en) | Pressure regulation in beverage containers | |

| US8079500B2 (en) | Liquid dispenser | |

| US8556133B2 (en) | Valve and dispenser | |

| USH2205H1 (en) | Method and apparatus for purging a propellant from a filling head during the filling of an aerosol container | |

| JP4359385B2 (en) | Pressure reducing valve for aerosol | |

| WO2008078174A3 (en) | Valve for filling a bottle with a liquid, and apparatus and method for filling bottles by means of the filling valve itself | |

| US7178551B2 (en) | Valve | |

| US5224525A (en) | Hose nozzle | |

| US3970221A (en) | Applicator system for fluids | |

| JPH07251884A (en) | Large quantity flow regulating valve chargeable with pressure | |

| JP2009193312A (en) | Valve device with pressure reducing valve | |

| CN221208512U (en) | Extraction and dosing valve, device for discharging an injection medium and head | |

| TWI667187B (en) | Pressurized liquid storage device and its distribution method | |

| MX2011013332A (en) | Fluid pressure regulator. | |

| JPH0536444Y2 (en) | ||

| US3880333A (en) | Applicator system for fluids | |

| JP2008027206A (en) | Valve device |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| RD02 | Notification of acceptance of power of attorney |

Free format text: JAPANESE INTERMEDIATE CODE: A7422 Effective date: 20061107 |

|

| A521 | Written amendment |

Free format text: JAPANESE INTERMEDIATE CODE: A523 Effective date: 20070213 |

|

| A621 | Written request for application examination |

Free format text: JAPANESE INTERMEDIATE CODE: A621 Effective date: 20070213 |

|

| A977 | Report on retrieval |

Free format text: JAPANESE INTERMEDIATE CODE: A971007 Effective date: 20090514 |

|

| A131 | Notification of reasons for refusal |

Free format text: JAPANESE INTERMEDIATE CODE: A131 Effective date: 20090522 |

|

| A521 | Written amendment |

Free format text: JAPANESE INTERMEDIATE CODE: A523 Effective date: 20090630 |

|

| TRDD | Decision of grant or rejection written | ||

| A01 | Written decision to grant a patent or to grant a registration (utility model) |

Free format text: JAPANESE INTERMEDIATE CODE: A01 Effective date: 20090803 |

|

| A01 | Written decision to grant a patent or to grant a registration (utility model) |

Free format text: JAPANESE INTERMEDIATE CODE: A01 |

|

| A61 | First payment of annual fees (during grant procedure) |

Free format text: JAPANESE INTERMEDIATE CODE: A61 Effective date: 20090810 |

|

| FPAY | Renewal fee payment (event date is renewal date of database) |

Free format text: PAYMENT UNTIL: 20120814 Year of fee payment: 3 |

|

| R150 | Certificate of patent or registration of utility model |

Free format text: JAPANESE INTERMEDIATE CODE: R150 |

|

| FPAY | Renewal fee payment (event date is renewal date of database) |

Free format text: PAYMENT UNTIL: 20120814 Year of fee payment: 3 |

|

| FPAY | Renewal fee payment (event date is renewal date of database) |

Free format text: PAYMENT UNTIL: 20130814 Year of fee payment: 4 |

|

| S531 | Written request for registration of change of domicile |

Free format text: JAPANESE INTERMEDIATE CODE: R313531 |

|

| R350 | Written notification of registration of transfer |

Free format text: JAPANESE INTERMEDIATE CODE: R350 |

|

| R250 | Receipt of annual fees |

Free format text: JAPANESE INTERMEDIATE CODE: R250 |

|

| R250 | Receipt of annual fees |

Free format text: JAPANESE INTERMEDIATE CODE: R250 |

|

| R250 | Receipt of annual fees |

Free format text: JAPANESE INTERMEDIATE CODE: R250 |

|

| R250 | Receipt of annual fees |

Free format text: JAPANESE INTERMEDIATE CODE: R250 |

|

| LAPS | Cancellation because of no payment of annual fees |