JP4339759B2 - Protective film for plant cultivation and method for producing the same - Google Patents

Protective film for plant cultivation and method for producing the same Download PDFInfo

- Publication number

- JP4339759B2 JP4339759B2 JP2004207567A JP2004207567A JP4339759B2 JP 4339759 B2 JP4339759 B2 JP 4339759B2 JP 2004207567 A JP2004207567 A JP 2004207567A JP 2004207567 A JP2004207567 A JP 2004207567A JP 4339759 B2 JP4339759 B2 JP 4339759B2

- Authority

- JP

- Japan

- Prior art keywords

- film

- protective film

- adhesive layer

- adhesive

- plant cultivation

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Expired - Lifetime

Links

- 230000001681 protective effect Effects 0.000 title claims description 51

- 238000004519 manufacturing process Methods 0.000 title claims description 11

- 239000012790 adhesive layer Substances 0.000 claims description 40

- 239000010410 layer Substances 0.000 claims description 35

- 230000003014 reinforcing effect Effects 0.000 claims description 23

- 239000002985 plastic film Substances 0.000 claims description 21

- 229920006255 plastic film Polymers 0.000 claims description 21

- 239000002390 adhesive tape Substances 0.000 claims description 18

- 239000000463 material Substances 0.000 claims description 7

- 238000000034 method Methods 0.000 claims description 7

- 238000004804 winding Methods 0.000 claims description 2

- 239000010408 film Substances 0.000 description 77

- 241000196324 Embryophyta Species 0.000 description 12

- 239000013039 cover film Substances 0.000 description 12

- 239000000853 adhesive Substances 0.000 description 10

- 230000001070 adhesive effect Effects 0.000 description 10

- 239000004820 Pressure-sensitive adhesive Substances 0.000 description 9

- 229920005989 resin Polymers 0.000 description 9

- 239000011347 resin Substances 0.000 description 9

- 230000000694 effects Effects 0.000 description 3

- -1 polypropylene Polymers 0.000 description 3

- 230000002787 reinforcement Effects 0.000 description 3

- VGGSQFUCUMXWEO-UHFFFAOYSA-N Ethene Chemical compound C=C VGGSQFUCUMXWEO-UHFFFAOYSA-N 0.000 description 2

- 239000005977 Ethylene Substances 0.000 description 2

- 241000208125 Nicotiana Species 0.000 description 2

- 235000002637 Nicotiana tabacum Nutrition 0.000 description 2

- 239000004698 Polyethylene Substances 0.000 description 2

- BZHJMEDXRYGGRV-UHFFFAOYSA-N Vinyl chloride Chemical compound ClC=C BZHJMEDXRYGGRV-UHFFFAOYSA-N 0.000 description 2

- 239000003795 chemical substances by application Substances 0.000 description 2

- 230000000052 comparative effect Effects 0.000 description 2

- 229920000573 polyethylene Polymers 0.000 description 2

- 238000003825 pressing Methods 0.000 description 2

- 230000002265 prevention Effects 0.000 description 2

- QQONPFPTGQHPMA-UHFFFAOYSA-N propylene Natural products CC=C QQONPFPTGQHPMA-UHFFFAOYSA-N 0.000 description 2

- 125000004805 propylene group Chemical group [H]C([H])([H])C([H])([*:1])C([H])([H])[*:2] 0.000 description 2

- 238000005728 strengthening Methods 0.000 description 2

- JOYRKODLDBILNP-UHFFFAOYSA-N Ethyl urethane Chemical compound CCOC(N)=O JOYRKODLDBILNP-UHFFFAOYSA-N 0.000 description 1

- 239000004743 Polypropylene Substances 0.000 description 1

- NIXOWILDQLNWCW-UHFFFAOYSA-N acrylic acid group Chemical group C(C=C)(=O)O NIXOWILDQLNWCW-UHFFFAOYSA-N 0.000 description 1

- 239000002313 adhesive film Substances 0.000 description 1

- 239000003963 antioxidant agent Substances 0.000 description 1

- 230000003078 antioxidant effect Effects 0.000 description 1

- 239000013556 antirust agent Substances 0.000 description 1

- 238000005452 bending Methods 0.000 description 1

- 239000002981 blocking agent Substances 0.000 description 1

- 235000019504 cigarettes Nutrition 0.000 description 1

- 238000004581 coalescence Methods 0.000 description 1

- 238000010276 construction Methods 0.000 description 1

- 239000005038 ethylene vinyl acetate Substances 0.000 description 1

- 238000011156 evaluation Methods 0.000 description 1

- 229920001903 high density polyethylene Polymers 0.000 description 1

- 239000004700 high-density polyethylene Substances 0.000 description 1

- 239000011256 inorganic filler Substances 0.000 description 1

- 229910003475 inorganic filler Inorganic materials 0.000 description 1

- 238000011835 investigation Methods 0.000 description 1

- 238000010030 laminating Methods 0.000 description 1

- 239000004611 light stabiliser Substances 0.000 description 1

- 229920003023 plastic Polymers 0.000 description 1

- 239000004033 plastic Substances 0.000 description 1

- 239000004014 plasticizer Substances 0.000 description 1

- 229920001200 poly(ethylene-vinyl acetate) Polymers 0.000 description 1

- 229920006267 polyester film Polymers 0.000 description 1

- 229920013716 polyethylene resin Polymers 0.000 description 1

- 229920001155 polypropylene Polymers 0.000 description 1

- 229920001296 polysiloxane Polymers 0.000 description 1

- 229920000915 polyvinyl chloride Polymers 0.000 description 1

- 239000004800 polyvinyl chloride Substances 0.000 description 1

- 239000004071 soot Substances 0.000 description 1

- 239000006097 ultraviolet radiation absorber Substances 0.000 description 1

- 230000037303 wrinkles Effects 0.000 description 1

Images

Landscapes

- Protection Of Plants (AREA)

Description

本発明は、植物栽培用の保護フィルムおよびその製造方法に関するものである。 The present invention relates to a protective film for plant cultivation and a method for producing the same.

一般に、たばこ等の植物を栽培する際には保温のために、図6のように、透孔の設けられたカバーフィルムを畝に被覆し、透孔の位置に植物の種苗を植えることが行われている。しかし、この方法では種苗が風雨や霜にさらされるため育成が思うようにいかないという欠点があった。 In general, when cultivating plants such as cigarettes, for the purpose of keeping warm, as shown in FIG. 6, a cover film provided with a through hole is covered with a cocoon and plant seedlings are planted at the position of the through hole. It has been broken. However, this method has the disadvantage that the seedlings are exposed to wind and rain and frost, and the growth is not as expected.

これらの欠点を解消するために種々の提案がなされており、例えば、上記カバーフィルムの上に更に、側端部に粘着層が設けられている保護フィルムをかぶせて植物を保護することが提案されている。 Various proposals have been made in order to eliminate these drawbacks. For example, it is proposed that a protective film having an adhesive layer provided on the side edge is further covered on the cover film to protect the plant. ing.

しかし、上記保護フィルムを使用した場合は、苗がある程度生長した段階で保護フィルムを除去する必要がある。通常、保護フィルムはカバーフィルムに粘着剤で貼付されているので、保護フィルムを取り除こうとすると、粘着層から引きはがすかもしくは保護フィルムを破断して取り除く必要があった。しかしながら、上記の方法では、保護フィルムをスムーズに取り除くことができず、大きな力を要したり、破断の方向が蛇行して蛇行を修正したり、残った部分を取り除くために腰をかがめる等の無理な姿勢で作業をする必要があったりして、作業者の肉体的負担が大きいばかりでなく作業効率も非常に悪かった。 However, when the protective film is used, it is necessary to remove the protective film when the seedling has grown to some extent. Usually, since the protective film is attached to the cover film with an adhesive, it was necessary to remove the protective film by peeling it off from the adhesive layer or by removing the protective film. However, in the above method, the protective film cannot be removed smoothly, requiring a large force, the direction of the break meandering to correct the meandering, or bending down to remove the remaining part, etc. It was necessary to work in an unreasonable posture, and not only the physical burden on the worker was great, but also the work efficiency was very bad.

そこで、植物の生長を阻害しないように、保護フィルムの幅方向に折り込み部を設けると共にフィルムを容易に除去できるようにフィルムの粘着層が設けられた側端部とフィルム本体との境界部付近に沿ってミシン目やスジ状の凹部を設けることが提案されている(特許文献1)。 Therefore, in order not to inhibit the growth of the plant, a fold portion is provided in the width direction of the protective film, and the film is easily removed near the boundary between the side end portion provided with the adhesive layer of the film and the film body. It has been proposed to provide a perforation or a streak-shaped recess along the same (Patent Document 1).

しかし上記保護フィルムは、除去する際にミシン目や凹部に沿ってきれいに破断せずに、保護フィルムが柔らかいので取り除く際に、破断点への力の加わり方が一定ではないので、破断方向が蛇行し易いことがわかった。すなわち、ミシン目やスジ状の凹部が設けられたフィルムでは、ミシン目を大きくしたり、凹部でのフィルム厚さを薄くすれば上記欠点は完全に解決できるが、ミシン目や凹部のフィルムの強度が低下し、取り扱い時等に破損してしまう。取り扱い時に破損しない強度を保持するためには、ミシン目の大きさや凹部のフィルム厚さには限界があり上記欠点が十分に解決されていないことがわかった。 However, the protective film does not break cleanly along the perforations or recesses when removing, and since the protective film is soft, the way of applying force to the breaking point is not constant when removing, so the breaking direction is meandering I found it easy to do. In other words, for films with perforations and streak-like recesses, the above disadvantages can be solved completely by increasing the perforations or reducing the film thickness at the recesses. Will drop and break during handling. In order to maintain the strength that does not break during handling, it has been found that the perforation size and the film thickness of the recesses are limited and the above disadvantages are not sufficiently solved.

本発明者らは、除去の容易さを種々検討した結果、フィルム除去の際にフィルムを容易に破断するためには、必ずしもフィルムにミシン目やスジ状の凹部を設けて部分的にフィルムの強度を低下させなくても、破断時に破断部が蛇行することなく直線的に破断することができれば、上記欠点を解消でき、容易にフィルムを除去できることを見いだし本発明に至った。

すなわち本発明の目的は、フィルムの強度低下を招くことなく、不要時に容易に除去することができる植物栽培用の保護フィルム及び該保護フィルムの製造方法を提供する。

As a result of various investigations on the ease of removal, the present inventors have not always provided perforations or streak-like recesses in the film in order to break the film easily during film removal, and the strength of the film partially. The present inventors have found that the above-mentioned drawbacks can be solved and the film can be easily removed if the fracture can be linearly broken without meandering at the time of breaking without lowering the thickness.

That is, an object of the present invention is to provide a protective film for plant cultivation that can be easily removed when not needed, and a method for producing the protective film, without causing a decrease in strength of the film.

請求項1記載の発明は、長尺プラスチックフィルムの幅方向両端部付近に粘着層が設けられていると共に、粘着層の内側に強化層が設けられている植物栽培用の保護フィルムである。 The invention described in claim 1 is a protective film for plant cultivation in which an adhesive layer is provided in the vicinity of both ends in the width direction of the long plastic film and a reinforcing layer is provided inside the adhesive layer.

請求項2記載の発明は、長尺プラスチックフィルムの幅方向に折り込み部が形成されている請求項1に記載の植物栽培用の保護フィルムである。

Invention of

請求項3記載の発明は、長尺プラスチックフィルムを巻きだしながら、粘着層用材料と強化層用材料とを一つの供給装置から同時に供給しながら保護フィルムに積層させる請求項1又は2に記載の保護フィルムの製造方法である。

Invention of

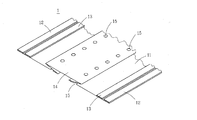

本発明の実施の形態を図面を参照しつつ説明する。図1は本発明の植物栽培用の保護フィルムの一例を示す一部切り欠き斜視図である。図中、1は植物栽培用の保護フィルムであり、長尺プラスチックフィルム11の幅方向両端部に、粘着層12が設けられ、その内側に強化層13が設けられている。

Embodiments of the present invention will be described with reference to the drawings. FIG. 1 is a partially cutaway perspective view showing an example of a protective film for plant cultivation of the present invention. In the figure, reference numeral 1 denotes a protective film for plant cultivation, in which an

長尺プラスチックフィルム11は、その幅方向に折り込み部14が形成されていると共に、複数個の小孔15、15・・が形成されている。

The long

図2は粘着層の積層状態を示す説明図であり(強化層は省略)、粘着層12は図2(a)の様に長尺プラスチックフィルム11の上面にその一部が外方に突き出し且つ粘着層が下方になるように設けられていてもよいし、図2(b)の様に長尺プラスチックフィルム11の下面に設けられていてもよい。図2(a)の場合は、粘着層の外方に突き出した部分でカバーフィルムに貼り付けられ、図2(b)の場合は粘着層全体でカバーフィルムに貼る付けられる。一般的には、粘着層には粘着層を保護したり、巻重体にした際に粘着層により巻出しが困難にならないようにセパレータフィルムが積層されるが、本発明においては、セパレーターは設けられていてもよいが、長尺プラスチックフィルムがセパレーターの役目を果たすのでセパレーターは設けられていなくてもよい。セパレーターを設けないことにより、後述の施工の際に、セパレーターを除去する必要がないので作業が容易になり、さらには、経済的にも有利になる。

FIG. 2 is an explanatory view showing the laminated state of the adhesive layer (the reinforcing layer is omitted), and the

上記粘着層としては、特に限定されず、例えば、粘着テープを用いてもよいし、プラスチックフィルム11に直接粘着剤が積層されていてもよいが、製造のし易さ等から粘着テープが好適に用いられる。

粘着テープとしては、従来公知の任意の粘着テープが使用でき、例えば、塩化ビニル樹脂フィルム、エチレン樹脂フィルム、プロピレン樹脂フィルム、ポリエステルフィルム等の基材フィルムの一面に、ゴム系粘着剤、アクリル系粘着剤、シリコーン系粘着剤、ウレタン系粘着剤等の粘着剤が積層されてなる粘着テープが挙げられる。

The pressure-sensitive adhesive layer is not particularly limited, and for example, a pressure-sensitive adhesive tape may be used, or a pressure-sensitive adhesive may be directly laminated on the

As the pressure-sensitive adhesive tape, any conventionally known pressure-sensitive adhesive tape can be used. For example, a rubber-based pressure-sensitive adhesive or an acrylic pressure-sensitive adhesive is provided on one surface of a base film such as a vinyl chloride resin film, an ethylene resin film, a propylene resin film, or a polyester film. And an adhesive tape in which an adhesive such as an adhesive, a silicone-based adhesive, and a urethane-based adhesive is laminated.

直接積層される粘着剤としては、特に限定されず、上記粘着テープに使用される粘着剤が使用され得る。 It does not specifically limit as an adhesive directly laminated | stacked, The adhesive used for the said adhesive tape may be used.

粘着層の内側に設けられる強化層としては、長尺プラスチックフィルムに他のフィルムが積層されたり、粘着テープが積層されたりしてフィルムを破断する際に破断方向が蛇行したり、長尺プラスチックフィルムの幅方向に破断するのを押さえる程度に強度が向上した層が設けられていれば良い。

上記強化層の厚さ、幅、及び強度については特に限定されず、本発明のフィルムを除去する際にフィルムが粘着層と強化層との間で破断されて蛇行を起こさないだけの補強効果があればよい。 一般的には厚さは10μ以上が好ましく、幅は3mm以上が好ましい。

また、上記粘着層と強化層との間隙は、特に限定されず、本発明のフィルムを除去する際にフィルムが粘着層と強化層との間で破断されて蛇行を防止できればよく、破断のし易さ、製造の容易さ等から0.5〜10mmが好ましい。

As the reinforcing layer provided inside the adhesive layer, other films are laminated on a long plastic film, or when the adhesive tape is laminated to break the film, the breaking direction meanders. It is only necessary to provide a layer with improved strength to the extent that it is prevented from breaking in the width direction.

The thickness, width, and strength of the reinforcing layer are not particularly limited, and when the film of the present invention is removed, the reinforcing effect is such that the film is not broken between the adhesive layer and the reinforcing layer and causes meandering. I just need it. In general, the thickness is preferably 10 μm or more, and the width is preferably 3 mm or more.

The gap between the adhesive layer and the reinforcing layer is not particularly limited as long as the film can be broken between the adhesive layer and the reinforcing layer to prevent meandering when the film of the present invention is removed. 0.5-10 mm is preferable from the easiness, the ease of manufacture, etc.

上記強化層は、長尺プラスチックフィルムの粘着層と同じ側の面に設けられてもよいし、反対側の面に設けられてもよいが、除去時の引き裂き易さ、製造の容易さ等から同じ側の面に設けられるのが好ましい。

上記強化層を設ける方法としては、特に限定されず、例えば、上記の粘着テープを積層しても良いし、粘着剤或いは接着剤を用いて他のフィルムが積層されていても良い。製造の容易さ等から上記粘着層を設ける際に同時に粘着剤を積層して強化層を設けるのが好ましい。粘着層と強化層は同じ粘着テープであってもよいし異なった粘着テープであっても良い。

The reinforcing layer may be provided on the same side as the adhesive layer of the long plastic film, or may be provided on the opposite side. From the viewpoint of ease of tearing at the time of removal, ease of manufacture, etc. It is preferable to be provided on the same side surface.

The method for providing the reinforcing layer is not particularly limited. For example, the above-mentioned adhesive tape may be laminated, or another film may be laminated using an adhesive or an adhesive. It is preferable to provide a reinforcing layer by laminating an adhesive at the same time when the adhesive layer is provided because of ease of production. The adhesive layer and the reinforcing layer may be the same adhesive tape or different adhesive tapes.

上記プラスチックフィルム11の材料は、一般に農業用フィルムとして使用されているプラスチックであればよく、例えば、ポリ塩化ビニル樹脂、ポリエチレン樹脂(特に、高密度ポリエチレン樹脂)、ポリプロピレン樹脂、エチレン−酢酸ビニル共重合体等が挙げられる。

The material of the

上記プラスチックフィルム11は、種苗の育成のため太陽光線が透過するのが好ましく、透明及び半透明が好ましい。又、その色は無色、赤色、青色、黄色等適宜決定されればよいが、青色が保温効果、防露効果、葉焼け防止効果等が優れているので好ましい。

The

又、上記プラスチックフィルム11の厚さは必要に応じ適宜決定されればよいが、一般に5〜40μmであり、好ましくは10〜15μmである。

The thickness of the

尚、上記プラスチックフィルム11には、必要に応じて、防曇剤、酸化防止剤、紫外線吸収剤、光安定剤、アンチブロッキング剤、防霧剤、防錆剤、可塑剤、無機充填剤等が添加されてもよい。

The

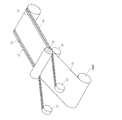

本発明の保護フィルムを製造する方法としては、特に限定されないが、粘着層及び強化層用材料として粘着テープを用いる例を、図3、図4を用いて説明する。

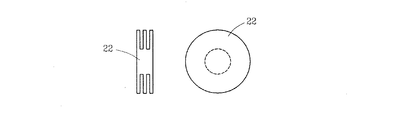

図3は全体の概略図であり、図4は粘着テープの供給装置の概略図である。

図3において長尺フィルム11は巻重体から連続的に供給され、圧着ロール21で粘着層12及び強化層13を形成する粘着テープがフィルムの両端部に積層されて、保護フィルムとして巻き取られる。この際、片方の側の粘着層12と強化層13を形成する粘着テープは1つの粘着テープ供給装置22から供給される。粘着テープ供給装置は、図4に示したように2つの溝が形成されており、各層を形成する粘着テープは粘着テープ供給装置の溝の部分にそれぞれ装填され連続的に供給される。

Although it does not specifically limit as a method to manufacture the protective film of this invention, The example which uses an adhesive tape as an adhesive layer and a material for reinforcement | strengthening layers is demonstrated using FIG. 3, FIG.

FIG. 3 is a schematic view of the whole, and FIG. 4 is a schematic view of an adhesive tape supply device.

In FIG. 3, the

図5は保護フィルムの使用状態を示す説明図である。図5(a)に示すように、畝2に苗3が植えられている。4は、塩化ビニル樹脂、エチレン樹脂、プロピレン樹脂等のプラスチックフィルムからなるカバーフィルムである。

FIG. 5 is an explanatory view showing a use state of the protective film. As shown in FIG. 5A,

1は本発明の保護フィルムであり、両端部の粘着テープ12、12をカバーフィルム4に押圧することにより、カバーフィルム4に貼付されている。保護フィルムをカバーフィルムに貼付する方法は、特に限定されず、保護フィルムの両端部に形成された粘着層をカバーフィルムに押し圧して貼付される。例えば、特開平07−111834号公報に記載されている方法等により貼付されて良い。

Reference numeral 1 denotes a protective film of the present invention, which is attached to the

このように、苗3をカバーフィルム4と保護フィルム1でカバーすることにより、保温すると同時に風雨や霜の被害からたばこの苗を保護することができる。

更に、保護フィルムには小孔が設けられており、小孔を通じて空気の出入りがあるので、保護フィルム内の空間が異常な高温になったりして苗の生育が妨げられることはない。

Thus, by covering the

Further, the protective film is provided with small holes, and air enters and exits through the small holes, so that the space in the protective film does not become an abnormally high temperature and prevents the growth of seedlings.

苗3が生長すると、図5(b)に示すように、苗3が保護フィルム1の折り込み部14を持ち上げ、保護フィルム1によりトンネル状の空間が形成される。

空間ができることにより苗3の生長は阻害されないが、更に生長すると、苗3の先端が保護フィルム1に衝突し生長が阻害されるようになるので、保護フィルム1は粘着層と強化層の間で切断されて取り除かれる。図5(c)は保護フィルムが除去された状態を示す。

When the

The growth of the

本発明の植物栽培用の保護フィルムは、上述の通りフィルムの端部付近に長さ方向に粘着層と強化層が設けられているのでフィルムの強度低下を招きことがなく、容易に施設でき、また不要になった際には容易に除去でき、多数の畝の保護フィルムを同時に除去できるので作業性も優れている。さらに、折り込み部を形成することによりある程度苗が成長するまで保護保温することができる。また、上述の製造方法により植物栽培用の保護フィルムが容易に製造できる。 The protective film for plant cultivation of the present invention is provided with an adhesive layer and a reinforcing layer in the length direction near the end of the film as described above, so that the strength of the film is not reduced and can be easily installed. Moreover, when it becomes unnecessary, it can be easily removed, and a large number of soot protective films can be removed simultaneously, so that workability is excellent. Furthermore, it is possible to protect and keep warm until a seedling grows to some extent by forming the folded portion. Moreover, the protective film for plant cultivation can be easily manufactured with the above-mentioned manufacturing method.

以下に実施例を掲げて本発明の態様を更に詳しく説明するが、本発明はこれら実施例に限定されるものではない。

(実施例1)

図1に示すごとく、ポリエチレンフィルム(幅450mm、厚さ10μm)の両端部に幅15mmの粘着テープ(粘着層厚20μm)を用いて粘着層と強化層を設けた保護フィルム(A)を作製した。粘着層は半分が外方に突き出しており、粘着層と強化層の間隙が2mmである。

(比較例1)

ポリエチレンフィルム(幅450mm、厚さ10μm)の両端部に幅15mmの粘着テープ(粘着層厚20μm)を用いて、粘着層は半分が外方に突き出している粘着層を形成し、粘着層に沿って、切り込み長さ3mm、間隔3mmのミシン目を設けて保護フィルム(B)を作成した。

(評価)

上記で得られた保護フィルム(A)、(B)を実際のタバコ栽培に用いてテストを行った。実施例1の保護フィルム(A)は、引きはがしが容易で五つの畝について同時に引きはがしても破断方向は蛇行せず容易に取り除くことができた。一方、比較例1の保護フィルム(B)は、一つの畝について引きはがした際には、破断方向が時々蛇行したけれども取り除くことができたが、二つの畝について同時に取り除こうとした際には、破断方向が畝と直角の方向に蛇行し容易に除去できなかった。

The embodiments of the present invention will be described in more detail with reference to the following examples, but the present invention is not limited to these examples.

(Example 1)

As shown in FIG. 1, a protective film (A) having an adhesive layer and a reinforcing layer provided on both ends of a polyethylene film (width 450 mm, thickness 10 μm) using an

(Comparative Example 1)

Using a 15 mm wide adhesive tape (

(Evaluation)

The protective films (A) and (B) obtained above were tested for actual tobacco cultivation. The protective film (A) of Example 1 was easily peeled off, and even when the five ridges were peeled simultaneously, the breaking direction did not meander and could be easily removed. On the other hand, when the protective film (B) of Comparative Example 1 was peeled off for one wrinkle, although the breaking direction sometimes meandered, it was able to be removed. The breaking direction meandered in a direction perpendicular to the ridges and could not be easily removed.

1 保護フィルム

11 長尺プラスチックフィルム

12 粘着層

13 強化層

14 折り込み部

15 小孔

21 圧着ロール

22 粘着テープ供給装置

DESCRIPTION OF SYMBOLS 1

Claims (4)

Priority Applications (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| JP2004207567A JP4339759B2 (en) | 2004-07-14 | 2004-07-14 | Protective film for plant cultivation and method for producing the same |

Applications Claiming Priority (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| JP2004207567A JP4339759B2 (en) | 2004-07-14 | 2004-07-14 | Protective film for plant cultivation and method for producing the same |

Publications (3)

| Publication Number | Publication Date |

|---|---|

| JP2006025667A JP2006025667A (en) | 2006-02-02 |

| JP2006025667A5 JP2006025667A5 (en) | 2007-07-19 |

| JP4339759B2 true JP4339759B2 (en) | 2009-10-07 |

Family

ID=35892714

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| JP2004207567A Expired - Lifetime JP4339759B2 (en) | 2004-07-14 | 2004-07-14 | Protective film for plant cultivation and method for producing the same |

Country Status (1)

| Country | Link |

|---|---|

| JP (1) | JP4339759B2 (en) |

Cited By (1)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| EP4241557A1 (en) * | 2022-03-09 | 2023-09-13 | Daios, Dimitrios | Cover comprising a film web intended to be placed on an asparagus bed |

Families Citing this family (2)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| JP7440846B2 (en) * | 2020-01-23 | 2024-02-29 | ユニチカ株式会社 | How to lay a weed control sheet |

| ES2812985B2 (en) * | 2020-10-06 | 2022-03-31 | Ruiz Francisco Sanchez | Extender device of a restorative sheet of soil cover for agricultural or forestry cultivation |

-

2004

- 2004-07-14 JP JP2004207567A patent/JP4339759B2/en not_active Expired - Lifetime

Cited By (1)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| EP4241557A1 (en) * | 2022-03-09 | 2023-09-13 | Daios, Dimitrios | Cover comprising a film web intended to be placed on an asparagus bed |

Also Published As

| Publication number | Publication date |

|---|---|

| JP2006025667A (en) | 2006-02-02 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| US20070245645A1 (en) | Mailbox post protector | |

| US20090127322A1 (en) | Gift Wrapping Material and Method | |

| JP2002518277A5 (en) | ||

| JP2009020513A (en) | Adhesive security tape and method for manufacturing the same | |

| JP4339759B2 (en) | Protective film for plant cultivation and method for producing the same | |

| JP2007185126A (en) | Covering structure for ridge and method for covering ridge | |

| JP4649566B2 (en) | Adhesive material | |

| JP2008094458A (en) | Wrap film roll | |

| JP2002142577A (en) | Protection film for cultivating tobacco | |

| JP2014217335A (en) | Covering material for greenhouse | |

| US5070641A (en) | Crop protection tape | |

| JP2005176789A5 (en) | ||

| JP4619236B2 (en) | Film laminate for vehicle protection | |

| JP3014589U (en) | Protective film for planting | |

| JPH11174963A (en) | Beltlike display label for gardening | |

| JP2012116497A (en) | Labeled container and winding label | |

| JP3143251U (en) | Coating sheet | |

| JP4769154B2 (en) | Garden display piece | |

| KR200409726Y1 (en) | Polyethylene tape for cleaning | |

| US12084602B1 (en) | Easy tear adhesive tape | |

| JP6165547B2 (en) | Wrap film storage box | |

| JPH11155391A (en) | Synthetic resin-made film for agriculture | |

| JP2006047390A (en) | Optical fiber cable and method for taking out coated optical fiber ribbon | |

| JPH09172881A (en) | Protection film for plant | |

| JP4008436B2 (en) | Agricultural multi-film |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| A521 | Request for written amendment filed |

Free format text: JAPANESE INTERMEDIATE CODE: A523 Effective date: 20070605 |

|

| A621 | Written request for application examination |

Free format text: JAPANESE INTERMEDIATE CODE: A621 Effective date: 20070605 |

|

| A977 | Report on retrieval |

Free format text: JAPANESE INTERMEDIATE CODE: A971007 Effective date: 20090527 |

|

| TRDD | Decision of grant or rejection written | ||

| A01 | Written decision to grant a patent or to grant a registration (utility model) |

Free format text: JAPANESE INTERMEDIATE CODE: A01 Effective date: 20090603 |

|

| A01 | Written decision to grant a patent or to grant a registration (utility model) |

Free format text: JAPANESE INTERMEDIATE CODE: A01 |

|

| A61 | First payment of annual fees (during grant procedure) |

Free format text: JAPANESE INTERMEDIATE CODE: A61 Effective date: 20090702 |

|

| R150 | Certificate of patent or registration of utility model |

Ref document number: 4339759 Country of ref document: JP Free format text: JAPANESE INTERMEDIATE CODE: R150 Free format text: JAPANESE INTERMEDIATE CODE: R150 |

|

| FPAY | Renewal fee payment (event date is renewal date of database) |

Free format text: PAYMENT UNTIL: 20120710 Year of fee payment: 3 |

|

| FPAY | Renewal fee payment (event date is renewal date of database) |

Free format text: PAYMENT UNTIL: 20120710 Year of fee payment: 3 |

|

| FPAY | Renewal fee payment (event date is renewal date of database) |

Free format text: PAYMENT UNTIL: 20130710 Year of fee payment: 4 |

|

| R250 | Receipt of annual fees |

Free format text: JAPANESE INTERMEDIATE CODE: R250 |

|

| R250 | Receipt of annual fees |

Free format text: JAPANESE INTERMEDIATE CODE: R250 |

|

| R250 | Receipt of annual fees |

Free format text: JAPANESE INTERMEDIATE CODE: R250 |

|

| R250 | Receipt of annual fees |

Free format text: JAPANESE INTERMEDIATE CODE: R250 |

|

| S111 | Request for change of ownership or part of ownership |

Free format text: JAPANESE INTERMEDIATE CODE: R313113 |

|

| R350 | Written notification of registration of transfer |

Free format text: JAPANESE INTERMEDIATE CODE: R350 |

|

| R250 | Receipt of annual fees |

Free format text: JAPANESE INTERMEDIATE CODE: R250 |

|

| R250 | Receipt of annual fees |

Free format text: JAPANESE INTERMEDIATE CODE: R250 |

|

| R250 | Receipt of annual fees |

Free format text: JAPANESE INTERMEDIATE CODE: R250 |

|

| R250 | Receipt of annual fees |

Free format text: JAPANESE INTERMEDIATE CODE: R250 |

|

| R250 | Receipt of annual fees |

Free format text: JAPANESE INTERMEDIATE CODE: R250 |

|

| R250 | Receipt of annual fees |

Free format text: JAPANESE INTERMEDIATE CODE: R250 |

|

| R250 | Receipt of annual fees |

Free format text: JAPANESE INTERMEDIATE CODE: R250 |