JP4307332B2 - Electromagnetic cooker - Google Patents

Electromagnetic cooker Download PDFInfo

- Publication number

- JP4307332B2 JP4307332B2 JP2004168907A JP2004168907A JP4307332B2 JP 4307332 B2 JP4307332 B2 JP 4307332B2 JP 2004168907 A JP2004168907 A JP 2004168907A JP 2004168907 A JP2004168907 A JP 2004168907A JP 4307332 B2 JP4307332 B2 JP 4307332B2

- Authority

- JP

- Japan

- Prior art keywords

- input

- heating

- amount

- temperature

- water

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Expired - Fee Related

Links

Images

Landscapes

- Induction Heating Cooking Devices (AREA)

Description

本発明は、加熱コイルの上に被調理物を配置し、誘導加熱によって被調理物を加熱する電磁調理器に関する。 The present invention relates to an electromagnetic cooker that arranges a food item on a heating coil and heats the food item by induction heating.

一般の電磁調理器では、器具本体の天面に装着した耐熱ガラス製の天板の下に誘導加熱コイルを配置設すると共に、この誘導加熱コイルの略中心位置に温度センサを配置し、この温度センサにより被調理物の温度を検出して誘導加熱コイルに供給する電力を制御することで、被調理物を設定温度に加熱して調理を行っている。 In a general electromagnetic cooker, an induction heating coil is disposed under the heat-resistant glass top plate mounted on the top surface of the appliance body, and a temperature sensor is disposed at a substantially central position of the induction heating coil. Cooking is performed by heating the cooking object to the set temperature by detecting the temperature of the cooking object by the sensor and controlling the power supplied to the induction heating coil.

又、上記電磁調理器では、例えば特許文献1に示される様に、揚げ物機能や湯沸し機能を備え、湯沸し機能においては、温度センサである鍋底サーミスタ73の検出温度に基づいて沸騰検知等の湯沸し制御を行っている。

一方、上記特許文献1に示される様に、温度センサの検出温度に基づいて湯沸し制御を行った場合には、鍋の材質や天板の初期温度等によって温度センサの温度変化精度が悪くなり、沸騰時間が長くなる等の問題がある。

On the other hand, as shown in the above-mentioned

又、被調理物の温度を赤外線センサにより検出するものもあるが、この場合には製造コストが高価になるという問題がある。 Moreover, although there exist some which detect the temperature of a to-be-cooked object with an infrared sensor, there exists a problem that manufacturing cost becomes expensive in this case.

そこで本発明は、比較的安価な構成にて、より短時間に湯沸し制御を行う事を目的とするものである。 SUMMARY OF THE INVENTION Accordingly, an object of the present invention is to perform boiling water control in a shorter time with a relatively inexpensive configuration.

本発明の請求項1の構成は、被調理物を加熱する熱源と、被調理物の温度を検出する温度センサと、熱源による加熱条件等を手動により入力する入力手段と、この入力手段による入力内容等を表示する表示手段と、温度センサからの温度データや入力手段からの入力データに基づいて熱源や表示手段を制御する制御手段とを備えたものにおいて、この制御手段を、被調理物の水量を入力手段にて入力し、入力された水量に応じて予め設定した所定時間熱源を作動することで湯沸し調理を行う様に構成したものである。 According to a first aspect of the present invention, there is provided a heat source for heating the object to be cooked, a temperature sensor for detecting the temperature of the object to be cooked, an input means for manually inputting heating conditions by the heat source, and an input by the input means. A display means for displaying contents and the like, and a control means for controlling the heat source and the display means based on temperature data from the temperature sensor and input data from the input means. The water amount is input by the input means, and the water source is cooked by operating the heat source for a predetermined time set in accordance with the input water amount.

本発明の請求項2の構成は、請求項1の構成において、制御手段を、被調理物の温度が加熱開始から予め設定した所定温度に上昇するまでの積算入力電力量を計測し、この積算入力電力量が予め設定した設定電力量より不足している場合には、追加加熱を行う様に構成したものである。 According to a second aspect of the present invention, in the configuration of the first aspect, the control means measures the integrated input electric energy until the temperature of the object to be cooked rises to a predetermined temperature set in advance from the start of heating. In the case where the input power amount is less than the preset set power amount, additional heating is performed .

本発明の請求項3の構成は、請求項1または2の構成において、制御手段を、入力手段より入力された水量を表示手段にて表示する様に構成したものである。 According to a third aspect of the present invention, in the configuration of the first or second aspect, the control means is configured to display the amount of water input from the input means on the display means.

本発明の請求項4の構成は、請求項1〜3の何れかに記載の構成において、制御手段を、入力手段より入力された水量に応じた残り時間を表示手段により表示する様に構成したものである。 According to a fourth aspect of the present invention, in the configuration according to any one of the first to third aspects, the control means is configured to display the remaining time corresponding to the amount of water input from the input means by the display means. Is.

本発明の請求項5の構成は、請求項1〜4の何れかに記載の構成において、制御手段を、所定時間又は所定時間より設定時間前迄は、入力手段により設定可能な最大火力にて被調理物を加熱した後、熱源の火力を下げて更に加熱する様に構成したものである。 According to a fifth aspect of the present invention, in the configuration according to any one of the first to fourth aspects, the control means is operated at a maximum heating power that can be set by the input means until a predetermined time or a set time before the predetermined time . After the cooking object is heated, the heating power of the heat source is lowered and further heated.

本発明の請求項6の構成は、請求項1〜5の何れかに記載の構成において、制御手段を、被調理物の水量を設定して加熱する手動加熱と、温度センサの検出温度に応じて調理時間を設定する自動加熱とを切換え可能に構成したものである。 According to a sixth aspect of the present invention, in the configuration according to any one of the first to fifth aspects, the control means is configured to respond to manual heating for setting and heating the amount of water to be cooked, and a temperature detected by the temperature sensor. it is obtained by enabling constructed switching between automatic heating to set the cooking time Te.

本発明の請求項1に記載の構成により、被調理物の水量を設定して湯沸し調理を行う様に構成したことで、被調理物を収納する鍋の材質による温度センサの特性変化に影響されることなく、比較的短時間でより精度の高い湯沸し制御を行う事が出来るものである。 According to the configuration of the first aspect of the present invention, it is configured such that the amount of water to be cooked is set and boiling water cooking is performed, so that it is influenced by the characteristic change of the temperature sensor depending on the material of the pan for storing the food to be cooked. Therefore, it is possible to perform the water heater control with higher accuracy in a relatively short time.

本発明の請求項2に記載の構成により、被調理物の温度が加熱開始から予め設定した所定温度に上昇するまでの積算入力電力量を計測し、この積算入力電力量が予め設定した設定電力量より不足している場合には追加加熱を行う様に構成したことで、調理容器を置く位置がずれていたり、調理容器の材質が誘導加熱に適さない場合でも、手動加熱による湯沸し制御を、失敗することなくより的確に行う事が出来るものである。 According to the configuration of the second aspect of the present invention, the integrated input electric energy is measured until the temperature of the object to be cooked rises to a predetermined temperature set in advance from the start of heating, and the integrated input electric energy is set in advance. When it is less than the amount, it is configured to perform additional heating, so even if the position where the cooking container is placed is misaligned or the material of the cooking container is not suitable for induction heating, boiling water control by manual heating is performed. failure in which it can be done more accurately without.

本発明の請求項3に記載の構成により、入力手段より入力した水量を表示手段により表示する様に構成したことで、設定した水量を容易に確認でき、設定ミスによる吹き零れ等を防止する事が出来るものである。 With the configuration according to the third aspect of the present invention, the display unit displays the amount of water input from the input unit, so that the set amount of water can be easily confirmed, and it is possible to prevent spilling due to a setting error. Is something you can do.

本発明の請求項4に記載の構成により、湯沸し調理を開始すると表示手段により残り時間を表示する様に構成したことで、加熱時間を目視により容易に確認でき、他の作業等の作業性を向上する事が出来るものである。

With the configuration according to

本発明の請求項5に記載の構成により、所定時間又は所定時間より設定時間前迄は、入力手段により設定可能な最大火力にて加熱した後、火力を下げて更に加熱する様に構成したことで、所定時間の間は例えば3kW等の強い火力で加熱し、沸騰の前後に火力を下げることで、加熱時間の短縮を図りながら、突沸による吹き零れ等を防止する事が出来るものである。

According to the configuration described in

本発明の請求項6に記載の構成により、入力手段により水量を設定して加熱する手動加熱と、温度センサの検出温度に応じて制御する自動加熱を切り換えて使用する様に構成したことで、使用する容器の種類や使用者の使用頻度等に応じて好みのモードを選択する事が出来、これにより使い勝手を向上出来るものである。

By the configuration according to

本発明による実施例を先ず図1に基づき説明すると、1は例えばシステムキッチン等にドロップイン方式にて組み込まれて使用される電磁調理器の調理器本体で、上面に耐熱ガラス製の天板2を装着していると共に、この天板の下方内部に熱源となる左右一対の誘導加熱コイル3,4とラジエントヒータ5を内蔵している。

First, an embodiment according to the present invention will be described with reference to FIG. 1.

一方、上記電磁調理器本体1内の前面右側には操作パネル6を配設していると共に、この操作パネルの左側にはグリル7用のグリル扉8を引き出し自在に配設し、かつ、上記操作パネル6には、シーソー式の電源スイッチ9、複数の操作キー10・・やプッシュプッシュ式の操作摘み11・・等を配設している。尚、上記操作摘み11・・は、プッシュ操作により引き出すと誘導加熱コイル3,4やラジエントヒータ5への通電を開始し、押し込むと運転を停止し、引き出し位置で回転操作すると火力や調理時間、調理温度等を設定する様に構成している。

On the other hand, an

又、上記天板2の外周縁を天板枠12により押圧固定していると共に、この天板枠の前端部には操作窓13を穿孔し、この操作窓内に非接触式のタッチキーにて構成した操作部14を配置し、かつ天板枠12の後端部には左右一対の吸排気カバー15,15を着脱自在に装着している。一方、上記操作窓13の下方には図2にても示す様に入力時の操作面となるガラス板15を配置していると共に、このガラス板の表面又は裏面には、火力キー16・・、湯沸しキー17、揚げ物キー18等のタッチ領域を印刷により配置している。尚、これら各キーへの入力操作は、ガラス板15の裏面に配置した後述の操作用回路基板により行い、この操作用回路基板にて、上記タッチ領域への指等の接触による静電容量の変化により入力操作を検出する様に構成している。

Further, the outer peripheral edge of the

更に、上記天板2の上記誘導加熱コイル3,4間の手前部分の下方には、バックライト付きの液晶表示器等で構成した表示器19を配設し、この表示器にて設定火力や調理時間、調理温度等を表示する様に構成している。

Further, a

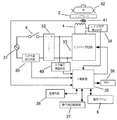

図3は上記誘導加熱コイル3,4等への通電を制御する回路ブロック図の一部を示すもので、商用の200V電源31に上記電源スイッチ9を介して直流変換回路32を接続すると共に、この直流変換回路の出力にインバータ回路33を接続し、かつこのインバータ回路の出力に上記誘導加熱コイル4と、このコイルへ供給される電流値を検出するコイル電流検出手段34との直列回路を接続している。

FIG. 3 shows a part of a circuit block diagram for controlling energization to the

35は主にマイクロコンピュータにて構成した制御回路で、出力ポートに上記インバータ回路33や報知用のブザー36を接続していると共に、入出力ポートに上記操作パネル6や操作用回路基板37、不揮発性メモリ等の記憶手段38を接続し、かつ入力ポートに、上記電源31と直流変換回路32との間に接続した入力電流検出手段39の出力と、上記直流変換回路32の出力に接続した入力電圧検出手段40の出力、上記誘導加熱コイル4の略中央部に配設したサーミスタ等の温度センサ41の出力を接続している。

尚、上記温度センサ41は、上記天板2の上に載置される被調理物を収容する調理容器42の温度を、天板2を介して検出する様に構成している。

The

又、上記入力電流検出手段39と入力電圧検出手段40の出力から入力電力を算出するもので、これらにて入力電力モニター回路を構成している。 Also, the input power is calculated from the outputs of the input current detection means 39 and the input voltage detection means 40, and these constitute an input power monitor circuit.

而して、本発明の構成により湯沸し加熱を行う場合の動作を説明すると、天板2の例えば誘導加熱コイル4の上方に調理容器42を載せた後電源スイッチ9をオン操作し、次いで操作パネル6の摘み11aをプッシュ操作して引き出し、湯沸しキー17をオン操作することで、例えば自動による湯沸し調理を開始する。

Thus, the operation when boiling and heating is performed according to the configuration of the present invention will be described. After the

一方、上記湯沸しキー17を更にオン操作すると手動による湯沸し調理のモードに設定され、ここで摘み11aを回転操作して調理容器42内に入れた水量を設定入力した後、再度湯沸しキー17をオン操作すれば、設定可能な最大火力である例えば3kWの出力にて誘導加熱コイル4に通電されて加熱を開始する。

On the other hand, when the

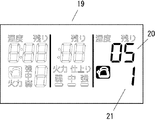

又、上記水量の入力時には、例えば図4にて示す様に、例えば設定水量が0.5リットルであれば「0.5」と表示20すると同時に、実施例の場合、設定水量を例えば0.5、1、1.5、2、2.5、3、3.5、4の8段階に設定し、便宜上、0.5リットルを「1」、1リットルを「2」と順次設定して表示21する様に制御回路35を構成している。

When the water amount is input, for example, as shown in FIG. 4, if the set water amount is 0.5 liter, for example, “0.5” is displayed 20. Set to 8 steps of 5, 1, 1.5, 2, 2.5, 3, 3.5, 4 and for convenience, 0.5 liter is set to “1” and 1 liter is set to “2” sequentially. The

尚、上記湯沸しキー17を2度押しして手動加熱設定時には、例えば上記の表示を「00」で点滅表示することで、次の入力操作が判り易く、操作性を向上出来る。

When manual heating is set by pressing the

更に、上記実施例では湯沸しキー17を一度オン操作すると自動加熱に設定される様に構成しているが、一度オン操作すると手動加熱に設定され、2度押しすると自動加熱に設定する様に構成しても良く、かつ、水量を入力した後湯沸しキー17をオンすることで誘導加熱コイルに通電する様に構成し、誤操作や操作時間の相違による湯沸し性能の低下を防止する様に構成しているが、例えば水量を入力した後所定時間入力操作が無ければ通電を開始する様に構成しても良い。

Further, in the above embodiment, it is configured to set automatic heating when the

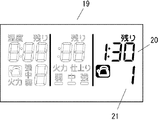

一方、上記手動による湯沸し調理モードにて誘導加熱コイル4に通電して加熱を開始すると、例えば図5にて示す様に上記表示20に残り時間を表示すると共に、表示21はそのまま残し、設定された水量を常時確認出来る様に制御回路35を構成している。これにより、表示20にて残り時間を常に確認でき、他の作業を効率的に行う事が出来るものである。

On the other hand, when the

又、上記手動加熱による湯沸し調理時には、例えば0.5リットルの場合は60秒、1リットルの場合には2分等の所定時間を予め設定して加熱を行うと共に、加熱開始から温度センサ41が例えば98℃への温度上昇を検出する迄の積算入力電力量を計測し、この入力電力量が、調理容器42の材質の影響等、何らかの原因により予め設定した設定電力量より不足している場合には、不足電力量分追加加熱を行う様に制御回路35を構成している。

In addition, during boiling water cooking by the above-mentioned manual heating, for example, 60 seconds in the case of 0.5 liters and heating for a predetermined time such as 2 minutes in the case of 1 liter, the

これらの構成により、調理容器42を置く位置が中心よりずれている場合や、調理用容器42の材質が誘導加熱に適さない場合でも、手動加熱にも係わらず、失敗の少ない湯沸し調理を行う事が出来、湯沸し性能を向上出来るものである。

With these configurations, even when the position where the

上記実施例では、水量設定による調理時間設定と温度センサ41による加熱補正を組み合わせているが、これに限定されることなく、設定時間のみ加熱する様に構成しても良い。

In the above embodiment, the cooking time setting by the water amount setting and the heating correction by the

尚、上記誘導加熱コイル4の不足電力量は、入力電力モニター回路により検出する入力電力量と、コイル電流検出手段34にて検出するコイル電流の差により計測出来る。

The insufficient power amount of the

更に上記実施例では、例えば図6にて示す様に、上記所定時間Tに達する設定時間前Taに誘導加熱コイル4の火力を例えば2kWに下げる様に制御回路35を構成しており、これにより、水量が少ない場合の突沸現象を防止すると共に、調理容器42と天板2の温度差を少なくして、温度センサ41による検出精度を向上させる事が出来るものである。

Further in the above embodiment, for example, as shown in FIG. 6, constitutes the

又、上記実施例では、所定時間が経過、或いは所定時間経過後の追加加熱経過後には、ブザー36を作動して湯沸し調理の終了を報知すると同時に、誘導加熱コイル4への供給電力を例えば0.5kWに設定し、調理容器42を保温する様に構成している。

In the above embodiment, after the predetermined time has elapsed or after the additional heating has elapsed, the

尚、上記実施例では、所定時間に到達する設定時間前に誘導加熱コイルの火力を下げる様に構成しているが、これに限定されることなく、所定時間最大火力で加熱しても良く、例えば設定水量が少ない場合のみ火力を下げる様に構成しても良い。 In addition, in the said Example, although comprised so that the thermal power of an induction heating coil may be reduced before the set time which reaches | attains predetermined time, you may heat with the maximum thermal power for predetermined time, without being limited to this, For example, the thermal power may be reduced only when the set water amount is small.

更に、上記実施例では手動加熱時には設定水量に基づき加熱時間を設定しているが、自動加熱時の理想的な温度特性データを記憶し、温度センサ41で検出する温度上昇特性が記憶データに近い場合には、この温度センサの出力を優先させ、温度センサ41の検出温度に基づいて調理時間を設定する様に制御回路35を構成しても良い。

Further, in the above embodiment, the heating time is set based on the set water amount at the time of manual heating, but ideal temperature characteristic data at the time of automatic heating is stored, and the temperature rise characteristic detected by the

この構成により、調理容器42の材質等、調理条件の良い場合には自動的に自動加熱に切り替る様に構成することで、調理時の条件に応じて最も適切な加熱モードを選択することができ、調理性能の向上や調理時間の短縮を図る事が出来るものである。

With this configuration, it is possible to select the most appropriate heating mode according to the cooking conditions by automatically switching to automatic heating when the cooking conditions such as the material of the

3 誘導加熱コイル(熱源)

4 誘導加熱コイル(熱源)

6 操作パネル(入力手段)

14 操作部(入力手段)

19 表示器(表示手段)

35 制御回路(制御手段)

41 温度センサ

42 調理容器(被調理物)

3 Induction heating coil (heat source)

4 Induction heating coil (heat source)

6 Operation panel (input means)

14 Operation part (input means)

19 Display (display means)

35 Control circuit (control means)

41

Claims (6)

Priority Applications (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| JP2004168907A JP4307332B2 (en) | 2004-06-07 | 2004-06-07 | Electromagnetic cooker |

Applications Claiming Priority (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| JP2004168907A JP4307332B2 (en) | 2004-06-07 | 2004-06-07 | Electromagnetic cooker |

Publications (3)

| Publication Number | Publication Date |

|---|---|

| JP2005347217A JP2005347217A (en) | 2005-12-15 |

| JP2005347217A5 JP2005347217A5 (en) | 2007-06-28 |

| JP4307332B2 true JP4307332B2 (en) | 2009-08-05 |

Family

ID=35499387

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| JP2004168907A Expired - Fee Related JP4307332B2 (en) | 2004-06-07 | 2004-06-07 | Electromagnetic cooker |

Country Status (1)

| Country | Link |

|---|---|

| JP (1) | JP4307332B2 (en) |

Cited By (1)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| KR20170075913A (en) * | 2015-12-23 | 2017-07-04 | 쿠쿠전자주식회사 | Induction heating cooker |

Families Citing this family (12)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| JP2008218322A (en) * | 2007-03-07 | 2008-09-18 | Sanyo Electric Co Ltd | Electromagnetic cooker |

| JP5076655B2 (en) * | 2007-06-08 | 2012-11-21 | 三菱電機株式会社 | Cooking equipment |

| JP2011014363A (en) * | 2009-07-01 | 2011-01-20 | Sanyo Electric Co Ltd | Electromagnetic cooker |

| JP2012102996A (en) * | 2011-12-12 | 2012-05-31 | Mitsubishi Electric Corp | Heating cooking unit |

| JP5454562B2 (en) * | 2011-12-12 | 2014-03-26 | 三菱電機株式会社 | Cooking equipment |

| JP5429270B2 (en) * | 2011-12-12 | 2014-02-26 | 三菱電機株式会社 | Cooking equipment |

| JP5454563B2 (en) * | 2011-12-12 | 2014-03-26 | 三菱電機株式会社 | Cooking equipment |

| JP5429271B2 (en) * | 2011-12-12 | 2014-02-26 | 三菱電機株式会社 | Cooking equipment |

| JP6161315B2 (en) * | 2013-02-18 | 2017-07-12 | 三菱電機株式会社 | Heating cooker and heating cooker control method |

| JP6101930B2 (en) * | 2013-03-19 | 2017-03-29 | パナソニックIpマネジメント株式会社 | Induction heating cooker |

| JP6983058B2 (en) * | 2017-12-25 | 2021-12-17 | リンナイ株式会社 | Induction heating cooker |

| JP7008250B2 (en) * | 2018-09-10 | 2022-01-25 | パナソニックIpマネジメント株式会社 | Induction heating cooker |

Family Cites Families (2)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| JPH01260787A (en) * | 1988-04-08 | 1989-10-18 | Matsushita Electric Ind Co Ltd | Induction heating cooker |

| JP3924720B2 (en) * | 2001-07-13 | 2007-06-06 | 三菱電機株式会社 | Induction heating cooker |

-

2004

- 2004-06-07 JP JP2004168907A patent/JP4307332B2/en not_active Expired - Fee Related

Cited By (2)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| KR20170075913A (en) * | 2015-12-23 | 2017-07-04 | 쿠쿠전자주식회사 | Induction heating cooker |

| KR102382949B1 (en) * | 2015-12-23 | 2022-04-06 | 쿠쿠전자 주식회사 | Induction heating cooker |

Also Published As

| Publication number | Publication date |

|---|---|

| JP2005347217A (en) | 2005-12-15 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| JP4307332B2 (en) | Electromagnetic cooker | |

| US9777927B2 (en) | Double oven preheat boost using cooking chamber lockout | |

| JP5116292B2 (en) | Cooker | |

| KR20170003027A (en) | Cooking apparatus having automatic keep wark function and method for controlling the same | |

| JP2023010934A (en) | heating cooker | |

| JP2008071550A (en) | Heating cooker | |

| JPH10205771A (en) | Safety device of microwave oven having heater | |

| JP6050063B2 (en) | Cooker | |

| JP4879564B2 (en) | Cooker | |

| JP4198074B2 (en) | Cooker | |

| JP2009008294A (en) | Heating cooker | |

| JP6091356B2 (en) | rice cooker | |

| JP5100135B2 (en) | Cooker | |

| JP2017107766A (en) | Induction heating cooker | |

| JP3800191B2 (en) | Electric rice cooker with bread fermentation mode | |

| JP2011014363A (en) | Electromagnetic cooker | |

| JP4115372B2 (en) | Induction heating cooker | |

| KR101130389B1 (en) | Method for controlling the heater for a warming drawer | |

| JP2007280941A (en) | Heating cooker | |

| JP4315864B2 (en) | Cooker | |

| JP4443366B2 (en) | Cooker | |

| JP4942522B2 (en) | Induction heating cooker | |

| JP4989165B2 (en) | Cooker | |

| JP4925529B2 (en) | Electromagnetic cooker | |

| JP2013238358A (en) | Heating cooker |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| RD01 | Notification of change of attorney |

Free format text: JAPANESE INTERMEDIATE CODE: A7421 Effective date: 20051227 |

|

| A521 | Written amendment |

Free format text: JAPANESE INTERMEDIATE CODE: A523 Effective date: 20070510 |

|

| A621 | Written request for application examination |

Free format text: JAPANESE INTERMEDIATE CODE: A621 Effective date: 20070510 |

|

| A977 | Report on retrieval |

Free format text: JAPANESE INTERMEDIATE CODE: A971007 Effective date: 20080818 |

|

| A131 | Notification of reasons for refusal |

Free format text: JAPANESE INTERMEDIATE CODE: A131 Effective date: 20080826 |

|

| A521 | Written amendment |

Free format text: JAPANESE INTERMEDIATE CODE: A523 Effective date: 20080925 |

|

| TRDD | Decision of grant or rejection written | ||

| A01 | Written decision to grant a patent or to grant a registration (utility model) |

Free format text: JAPANESE INTERMEDIATE CODE: A01 Effective date: 20090331 |

|

| A01 | Written decision to grant a patent or to grant a registration (utility model) |

Free format text: JAPANESE INTERMEDIATE CODE: A01 |

|

| A61 | First payment of annual fees (during grant procedure) |

Free format text: JAPANESE INTERMEDIATE CODE: A61 Effective date: 20090428 |

|

| FPAY | Renewal fee payment (event date is renewal date of database) |

Free format text: PAYMENT UNTIL: 20120515 Year of fee payment: 3 |

|

| FPAY | Renewal fee payment (event date is renewal date of database) |

Free format text: PAYMENT UNTIL: 20130515 Year of fee payment: 4 |

|

| FPAY | Renewal fee payment (event date is renewal date of database) |

Free format text: PAYMENT UNTIL: 20130515 Year of fee payment: 4 |

|

| S531 | Written request for registration of change of domicile |

Free format text: JAPANESE INTERMEDIATE CODE: R313531 |

|

| S533 | Written request for registration of change of name |

Free format text: JAPANESE INTERMEDIATE CODE: R313533 |

|

| FPAY | Renewal fee payment (event date is renewal date of database) |

Free format text: PAYMENT UNTIL: 20130515 Year of fee payment: 4 |

|

| R350 | Written notification of registration of transfer |

Free format text: JAPANESE INTERMEDIATE CODE: R350 |

|

| FPAY | Renewal fee payment (event date is renewal date of database) |

Free format text: PAYMENT UNTIL: 20130515 Year of fee payment: 4 |

|

| S531 | Written request for registration of change of domicile |

Free format text: JAPANESE INTERMEDIATE CODE: R313531 |

|

| R250 | Receipt of annual fees |

Free format text: JAPANESE INTERMEDIATE CODE: R250 |

|

| R350 | Written notification of registration of transfer |

Free format text: JAPANESE INTERMEDIATE CODE: R350 |

|

| S111 | Request for change of ownership or part of ownership |

Free format text: JAPANESE INTERMEDIATE CODE: R313117 |

|

| R360 | Written notification for declining of transfer of rights |

Free format text: JAPANESE INTERMEDIATE CODE: R360 |

|

| R360 | Written notification for declining of transfer of rights |

Free format text: JAPANESE INTERMEDIATE CODE: R360 |

|

| R371 | Transfer withdrawn |

Free format text: JAPANESE INTERMEDIATE CODE: R371 |

|

| S111 | Request for change of ownership or part of ownership |

Free format text: JAPANESE INTERMEDIATE CODE: R313117 |

|

| R350 | Written notification of registration of transfer |

Free format text: JAPANESE INTERMEDIATE CODE: R350 |

|

| R250 | Receipt of annual fees |

Free format text: JAPANESE INTERMEDIATE CODE: R250 |

|

| LAPS | Cancellation because of no payment of annual fees |