JP3880924B2 - Power supply control device and control method thereof - Google Patents

Power supply control device and control method thereof Download PDFInfo

- Publication number

- JP3880924B2 JP3880924B2 JP2002367054A JP2002367054A JP3880924B2 JP 3880924 B2 JP3880924 B2 JP 3880924B2 JP 2002367054 A JP2002367054 A JP 2002367054A JP 2002367054 A JP2002367054 A JP 2002367054A JP 3880924 B2 JP3880924 B2 JP 3880924B2

- Authority

- JP

- Japan

- Prior art keywords

- storage battery

- engine

- generator

- frequency

- value

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Expired - Fee Related

Links

Images

Classifications

-

- Y—GENERAL TAGGING OF NEW TECHNOLOGICAL DEVELOPMENTS; GENERAL TAGGING OF CROSS-SECTIONAL TECHNOLOGIES SPANNING OVER SEVERAL SECTIONS OF THE IPC; TECHNICAL SUBJECTS COVERED BY FORMER USPC CROSS-REFERENCE ART COLLECTIONS [XRACs] AND DIGESTS

- Y02—TECHNOLOGIES OR APPLICATIONS FOR MITIGATION OR ADAPTATION AGAINST CLIMATE CHANGE

- Y02E—REDUCTION OF GREENHOUSE GAS [GHG] EMISSIONS, RELATED TO ENERGY GENERATION, TRANSMISSION OR DISTRIBUTION

- Y02E60/00—Enabling technologies; Technologies with a potential or indirect contribution to GHG emissions mitigation

- Y02E60/10—Energy storage using batteries

-

- Y—GENERAL TAGGING OF NEW TECHNOLOGICAL DEVELOPMENTS; GENERAL TAGGING OF CROSS-SECTIONAL TECHNOLOGIES SPANNING OVER SEVERAL SECTIONS OF THE IPC; TECHNICAL SUBJECTS COVERED BY FORMER USPC CROSS-REFERENCE ART COLLECTIONS [XRACs] AND DIGESTS

- Y02—TECHNOLOGIES OR APPLICATIONS FOR MITIGATION OR ADAPTATION AGAINST CLIMATE CHANGE

- Y02T—CLIMATE CHANGE MITIGATION TECHNOLOGIES RELATED TO TRANSPORTATION

- Y02T10/00—Road transport of goods or passengers

- Y02T10/60—Other road transportation technologies with climate change mitigation effect

- Y02T10/62—Hybrid vehicles

Landscapes

- Control Of Vehicle Engines Or Engines For Specific Uses (AREA)

- Control Of Charge By Means Of Generators (AREA)

- Secondary Cells (AREA)

- Hybrid Electric Vehicles (AREA)

- Output Control And Ontrol Of Special Type Engine (AREA)

Abstract

Description

【0001】

【発明の属する技術分野】

本発明は、電源制御装置及びその制御方法に関する。

【0002】

【従来の技術】

近年、大気汚染への関心の高まりから、不要な排気ガスの排出を抑えるために、車が駐停車した時、短時間で又は直ちに自動的にエンジンを停止し(アイドリング状態を停止し)、燃費を改善するアイドルストップ機能を有する車(以下、「アイドルストップ車」と言う。)が開発されている。アイドルストップ車は、アイドルストップ機能を有さない車と比較して、エンジンを停止状態から再起動する頻度(蓄電池からエンジン始動用のセルモータへ電力供給する頻度)がはるかに高い。また、アイドルストップ中には蓄電池から、車両の制御系統や、ライト、オーディオ等に電力を供給する。このようなアイドルストップ車の蓄電池には、従来より使用されている安価な液式鉛蓄電池が検討されている。

【0003】

液式鉛蓄電池は、アイドルストップによる放電でSOC(充電状態。State of Charge。放電容量を意味する。)が大きく低下し、充電不足の状態が続くと、電解液の成層化が生じ、サルフェーションが発生するので寿命が急激に短くなる。このため従来の、安価な液式鉛蓄電池を使用する車にアイドルストップ機能を搭載する場合、電池の劣化を防止する電源制御が重要である。アイドルストップを行わない従来の車では、常時SOCを100%近くに保つように充電電圧を高く設定し、充電不足にならないよう制御されている。

【0004】

特許第3211699号公報に、従来例1の動力出力装置が開示されている。従来例1の動力出力装置は、車両の走行条件及び予測される走行条件に応じてバッテリのSOCの目標値を設定し、エンジンと発電機とを制御する。走行条件は、車両の速度、加速度、高度、ナビゲーションシステムに記憶されている地図情報のうち少なくともひとつの情報を使用して定量化する。

【0005】

特開平11−008909号公報に従来例2のハイブリッド電気自動車の発電制御装置が開示されている。従来例2のハイブリッド電気自動車の発電制御装置は、車両が登坂する時に、降坂完了までに得られる積算回生エネルギーを予測する。そして、その回生エネルギーで電池を充電した場合に予測される充電量の分だけ、電池のSOCの目標値を引き下げる。従って、降坂時の回生エネルギーを、無駄なく電池の充電という形で受け入れることができる。

【0006】

特開2001−268708号公報に、従来例3のハイブリッド車両の制御装置が開示されている。従来例3のハイブリッド車両の制御装置は、バッテリの劣化度に応じて充電レベルの目標値を変更する。更に、定常運転時には減速運転時よりも充電レベルの目標値を低く設定する。

【0007】

【特許文献1】

特許第3211699号公報

【特許文献2】

特開平11−008909号公報

【特許文献3】

特開2001−268708号公報

【0008】

【発明が解決しようとする課題】

アイドルストップ車は、停止中及び停止後のエンジン始動やスタート時に蓄電池を放電する故に、蓄電池のSOCを減少させる。蓄電池のSOCが低下した場合、アイドルストップ車が暫くの間走り続ければ蓄電池は充電され、そのSOCは再び高くなる。しかし、渋滞する市街地等を走行するアイドルストップ車は、僅かの距離を走行しては停止することを繰り返す場合がある。この場合、蓄電池はほとんど充電されないまま放電を繰り返すことになる。このような場合、蓄電池のSOCがアイドルストップ車のスタートに必要な最低限度未満になって、アイドルストップ車が動けなくなる恐れがあった。このため、SOCの下限値を設定し、この下限値になるとアイドルストップをキャンセルするような制御も提案されているが、アイドルストップの回数が減少するので燃費改善の効果が少なくなる。また、SOCが低い状態のまま使用されるので、液式鉛蓄電池では特に、成層化によるサルフェーションが生じ、短寿命になる恐れがあった。一方、高速道路や信号機の少ない走行では、アイドルストップの頻度が少ないので蓄電池の放電が少なく充電時間が長くなる。従って、従来の充電制御のように一定の充電電圧で充電し、SOCを100%近くに制御する方法では過充電となり、燃費改善の効果は期待できない。また、SOCが100%近くに制御されるので回生の充電も受け入れることができない。

【0009】

従来例1〜3の動力出力装置等は、自動車の走行条件、バッテリの状態に応じて蓄電池の充放電を制御している。しかし、従来例1〜3の電源装置等は、渋滞した市街地での走行等において蓄電池が短寿命になる恐れがあるという上記の問題を解決するものではなかった。

【0010】

本発明は上記従来の問題点を解決するもので、アイドルストップの頻度が少ない、高速道路や信号機の少ない走行でも回生エネルギーを蓄電池に回収して車の燃費を向上し排気ガスを減少させ、且つ渋滞した市街地での走行等において蓄電池が短寿命になることを防止する電源制御装置及びその制御方法を提供する。

【0011】

【課題を解決するための手段】

上記課題を解決するため、本発明は以下の構成を有する。請求項1に記載の発明は、エンジンと、前記エンジンによって駆動される発電機と、前記発電機によって充電される蓄電池と、前記蓄電池の充電状態が所定の範囲内になるように前記蓄電池の充放電を制御する蓄電池充放電制御部と、を有し、車に搭載されており、前記蓄電池充放電制御部は、前記エンジン又は前記車が停止した状態が発生する頻度を検出し、前記頻度が所定の閾値以上である場合における前記所定の範囲の上限値を、前記頻度が前記所定の閾値未満である場合における前記上限値より高く設定することを特徴とする電源制御装置である。

【0012】

請求項2に記載の発明は、前記発電機は、前記エンジンを補助する電動機として動作することができ、前記蓄電池充放電制御部は、少なくとも前記エンジンが停止状態から動作状態に変化した時に前記蓄電池が放電して前記発電機を電動機として駆動し、前記エンジンが動作状態を継続した後は前記蓄電池が前記発電機によって充電されるように前記蓄電池の充放電を制御することを特徴とする請求項1に記載の電源制御装置である。

【0013】

請求項3に記載の発明は、前記蓄電池充放電制御部は、前記頻度が前記所定の閾値以上である場合における前記上限値を前記蓄電池の最大定格に設定し、前記頻度が前記所定の閾値未満である場合又は前記所定の閾値より低い値である他の閾値未満である場合における前記上限値を前記蓄電池が前記発電機からの回生エネルギーを充電可能な値に設定することを特徴とする請求項1又は請求項2に記載の電源制御装置である。

【0014】

請求項4に記載の発明は、前記蓄電池が鉛蓄電池であることを特徴とする請求項1又は請求項2に記載の電源制御装置である。

【0015】

請求項5に記載の発明は、エンジンと、前記エンジンによって駆動される発電機と、前記発電機によって充電される蓄電池とを有し、車に搭載された電源制御装置の制御方法であって、前記蓄電池の充電状態が所定の範囲内になるように前記蓄電池の充放電を制御する制御ステップと、前記エンジン又は前記車が停止した状態が発生する頻度を検出する検出ステップと、を有し、前記頻度が所定の閾値以上である場合における前記制御ステップの前記所定の範囲の上限値を、前記頻度が前記所定の閾値未満である場合における前記上限値より高く設定することを特徴とする電源制御装置の制御方法である。

【0016】

請求項6に記載の発明は、前記発電機は、前記エンジンを補助する電動機として動作することができ、少なくとも前記エンジンが停止状態から動作状態に変化した時に前記蓄電池が放電して前記発電機を電動機として駆動し、前記エンジンが動作状態を継続した後は前記蓄電池が前記発電機によって充電されるように前記蓄電池の充放電を制御することを特徴とする請求項5に記載の電源制御装置の制御方法である。

【0017】

請求項7に記載の発明は、前記頻度が前記所定の閾値以上である場合における前記上限値を前記蓄電池の最大定格に設定し、前記頻度が前記所定の閾値未満である場合又は前記所定の閾値より低い値である他の閾値未満である場合における前記上限値を前記蓄電池が前記発電機からの回生エネルギーを充電可能な値に設定することを特徴とする請求項5又は請求項6に記載の電源制御装置の制御方法である。

【0018】

本発明の発明者は、アイドルストップ車に搭載された蓄電池は、エンジン始動やスタート時に放電する故に、特に渋滞する市街地等で僅かの距離を走行しては停止することを繰り返す場合、蓄電池の放電量が、エンジン又は車の停止回数に比例することを発見した。エンジン又は車が停止した状態が発生する頻度が高ければ、蓄電池の充電量が放電量に追いつかない恐れがある。このような場合、蓄電池のSOCを高くするように制御することにより、蓄電池の寿命が短くなることを防止できる。一方、車が高速道路を走行する場合、エンジン又は車が停止した状態の発生頻度は低い。このような場合、蓄電池のSOCを低くするように制御することにより、回生エネルギーを確実に蓄電池に回収することができる。

鉛蓄電池を使用するアイドルストップ車においては、蓄電池をほとんど充電しないまま放電を繰り返すと、鉛蓄電池の寿命が縮む。

「エンジン又は車が停止した状態が発生する頻度」は、動作状態から停止状態に変化する頻度をカウントしても良く、停止状態から動作状態に変化する頻度をカウントしても良い。

【0019】

本発明は、回生エネルギーを蓄電池に回収して車の燃費を向上し排気ガスを減少させ、且つ渋滞した市街地での走行等において、蓄電池の過放電を防ぎ、鉛蓄電池等の蓄電池の寿命が短くなることを防止する電源制御装置及びその制御方法を実現できるという作用を有する。

【0020】

【発明の実施の形態】

以下本発明の実施をするための最良の形態を具体的に示した実施例について、図面とともに記載する。

【0021】

《実施例》

図1〜図3を用いて、本発明の実施例の電源制御装置及びその制御方法を説明する。実施例の電源制御装置は、アイドルストップ車に搭載されている。

図2は、実施例の電源制御装置の構成を示すブロック図である。図2において、200はアイドルストップ車、201は発電機、202は負荷、203は12V、50Ahの液式鉛蓄電池、204は電流センサ、205は電流計測部、206は電圧計測部、210はエンジン、211は蓄電池充放電制御部である。蓄電池充放電制御部211は、SOC算出部207、アイドルストップ頻度算出部208、発電機制御部209を有する。

【0022】

アイドルストップ車200は、駐停車にアイドリング状態にすることなく自動的にエンジンを停止する又は短時間のアイドリングの後自動的にエンジンを停止する、アイドルストップ機能を有する。発電機201はアイドルストップ車200のエンジン210によって駆動されて発電を行う。発電された電力は負荷202及び液式鉛蓄電池203に供給される。負荷202は、具体的にはオーディオ装置、エアコン、ランプ等の電装品、エンジン始動用のセルモータである。液式鉛蓄電池203は走行中はほとんど常に、発電機201からの電力によって定電圧充電されている。アイドルストップ等によりエンジン210が停止している間は、液式鉛蓄電池203は負荷202(オーディオ装置、エアコン、ランプ等)に電力を供給するために放電する。エンジン210が始動する時、液式鉛蓄電池203が放電して発電機201を電動機として駆動し且つ負荷202(エンジン始動用のセルモータ)に電力を供給する。アイドルストップ車200の減速及びブレーキ時に、発電機201に回生電流(回生エネルギー)が発生する。液式鉛蓄電池203は、この回生電流によって充電される。

【0023】

電流センサ204は液式鉛蓄電池203に流れる電流を検出する。電流センサ204の出力は電流計測部205に入力され、更にSOC算出部207に電流値として入力される。電圧計測部206は液式鉛蓄電池203の電圧を測定し、測定した電圧値を発電機制御部209に出力する。

蓄電池充放電制御部211は、液式鉛蓄電池203のSOCが所定の範囲内になるように、液式鉛蓄電池203の充放電を制御する。SOC算出部207は、液式鉛蓄電池203の満充電時の電池容量に充放電電気量の積算値を加算することによりSOCを算出し、発電機制御部209に出力する。

【0024】

発電機制御部209は、発電機201の励磁電流を制御することにより、発電機201の出力電圧を制御する。

アイドルストップ頻度算出部208は、10分当たりのアイドルストップの発生回数(発生頻度)を算出し、発電機制御部209に出力する。

【0025】

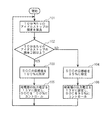

図1は、実施例の電源制御装置の制御方法を示すフローチャートである。ステップ101でアイドルストップ頻度算出部208は、10分当たりのアイドルストップの頻度を算出する。発電機制御部209は、10分当たりのアイドルストップの頻度が2回以上か否か判断する(ステップ102)。2回以上の場合はステップ103に進み、SOCの目標値(蓄電池の放電容量の制御範囲の上限値)を100%(満充電)に設定する。発電機制御部209は発電機201の出力電圧を15Vに設定し、SOCを100%に近づける充電を行う(ステップ105)。ステップ101に戻る。

【0026】

ステップ102で、10分当たりのアイドルストップの頻度が2回未満の場合はステップ104に進み、SOCの目標値を95%に設定する。発電機制御部209は発電機201の出力電圧を13Vに設定し、SOCを95%に近づける制御を行う(ステップ105)。ステップ101に戻る。

【0027】

図3は、従来例と本発明の電源制御装置をそれぞれ有するアイドルストップ車において、10分当たりのアイドルストップの頻度と走行1時間当たりの過充電量との関係を示す図である。電圧が12V、電池容量が50Ahの液式鉛蓄電池をアイドルストップ車200及び従来の電源制御装置を有するアイドルストップ車にそれぞれ搭載し、10分当たりのアイドルストップの頻度を様々に変え、走行1時間当たりの過充電量を調べる実験を行った。アイドルストップ1回当たりの平均放電量は、電池容量の0.5%とした。実線301は、図1のフローチャートに示した方法で蓄電池の充放電制御を行う本発明の電源制御装置を有するアイドルストップ車の実験結果である。破線302は、常にSOCを100%に近づける定電圧充電(充電電圧は14V)を行う従来例の電源制御装置を有するアイドルストップ車の実験結果である。

【0028】

液式鉛蓄電池203は、完全充電せずに使用され続けると、サルフェーションが発生する。つまり、放電生成物である硫酸鉛が蓄積して充電できなくなり、性能低下を引き起こす。サルフェーションが発生すると、液式鉛蓄電池203の寿命は急速に短くなる。市街地での走行のようにアイドルストップの頻度が高い場合は、アイドルストップ中の液式鉛蓄電池203の放電量が多くなるとともに、充電時間が短くなるのでSOCが低下しやすい。本実施例によれば、このような場合には発電機201を制御し、充電電圧を高く設定するので、液式鉛蓄電池203を短時間で充電するとともにSOCを高く保てる。これにより、液式鉛蓄電池203の電解液の成層化を抑え、長寿命化を図ることができる。

【0029】

高速走行時のようにアイドルストップの頻度が低い場合には、液式鉛蓄電池203が充電不足になる恐れが少ないため、SOCの設定値を下げる(実施例においては95%)。鉛蓄電池203は常に満充電されていない状態である故に、ブレーキや減速による回生エネルギーを効率的に液式鉛蓄電池203に蓄積できる。実施例において、回生エネルギーが無駄なく液式鉛蓄電池203の充電に使用されていることが図3(発生した過充電量の大きさが無駄に消費された回生エネルギーの大きさを示す。)より分かる。図3の破線302に示すように、常にSOCを100%に近づける充電を行った場合は、回生エネルギーのロスが発生する。本発明により、過充電による電池の劣化や電解液の減少を防止でき、且つ燃費が向上する。

【0030】

ステップ102で用いる、10分当たりのアイドルストップ頻度の閾値は走行条件及び使用する蓄電池の種類によって変更して良い。実施例では、アイドルストップの頻度に応じてSOCの目標値を2段階に設定したが、3段階以上設定しても良く、連続的に変化する値(例えばアイドルストップの発生頻度をパラメータとし、SOCの目標値を導出する関数を使用する。)にしても良い。

実施例においては、エンジンが停止する頻度が高い場合にSOCの目標値を高くし、頻度が低い場合にSOCの目標値を低くした。これに代えて、車が停止した状態が発生する頻度が高い場合にSOCの目標値を高くし、頻度が低い場合にSOCの目標値を低くしても良い。

【0031】

【発明の効果】

本発明によれば、回生エネルギーを蓄電池に回収して車の燃費を向上し排気ガスを減少させ、且つ渋滞した市街地での走行等において、蓄電池の過放電を防ぎ、鉛蓄電池等の蓄電池の寿命が短くなることを防止する電源制御装置及びその制御方法を実現できるという有利な効果が得られる。

【図面の簡単な説明】

【図1】本発明の実施例の電源制御装置の制御方法を示すフローチャート

【図2】本発明の実施例の電源制御装置の構成を示すブロック図

【図3】従来例と本発明の電源制御装置をそれぞれ有するアイドルストップ車において、10分当たりのアイドルストップの頻度と走行1時間当たりの過充電量との関係を示す図

【符号の説明】

200 アイドルストップ車

201 発電機

202 負荷

203 液式鉛蓄電池

204 電流センサ

205 電流計測部

206 電圧計測部

207 SOC算出部

208 アイドルストップ頻度算出部

209 発電機制御部

210 エンジン

211 蓄電池充放電制御部[0001]

BACKGROUND OF THE INVENTION

The present invention relates to a power supply control device and a control method therefor.

[0002]

[Prior art]

In recent years, due to the increasing interest in air pollution, the engine is automatically stopped (stops idling) in a short time or immediately when the vehicle is parked to stop unnecessary exhaust emissions. A vehicle having an idle stop function (hereinafter referred to as an “idle stop vehicle”) has been developed. The idle stop vehicle has a much higher frequency of restarting the engine from the stopped state (frequency of supplying power from the storage battery to the cell motor for starting the engine) than a vehicle having no idle stop function. Also, during idle stop, power is supplied from the storage battery to the vehicle control system, lights, audio, and the like. As such a storage battery for an idle stop vehicle, an inexpensive liquid lead storage battery that has been conventionally used has been studied.

[0003]

In a liquid lead-acid battery, SOC (state of charge; meaning discharge capacity) is greatly reduced due to discharge due to idle stop, and if the state of insufficient charge continues, stratification of the electrolyte occurs and sulfation occurs. Because it occurs, the life is shortened rapidly. For this reason, when an idle stop function is mounted on a conventional vehicle using an inexpensive liquid lead-acid battery, power supply control for preventing battery deterioration is important. In a conventional vehicle that does not perform idle stop, the charging voltage is set high so as to keep the SOC close to 100% at all times, and control is performed so as not to cause insufficient charging.

[0004]

Japanese Patent No. 3211699 discloses a power output apparatus of Conventional Example 1. The power output apparatus of Conventional Example 1 sets the target value of the SOC of the battery in accordance with the traveling condition of the vehicle and the predicted traveling condition, and controls the engine and the generator. The driving condition is quantified using at least one of the vehicle speed, acceleration, altitude, and map information stored in the navigation system.

[0005]

Japanese Patent Laid-Open No. 11-008909 discloses a power generation control device for a hybrid electric vehicle according to Conventional Example 2. The power generation control device for the hybrid electric vehicle of Conventional Example 2 predicts the integrated regenerative energy obtained until the completion of the downhill when the vehicle climbs the hill. Then, the target SOC value of the battery is lowered by the amount of charge predicted when the battery is charged with the regenerative energy. Therefore, the regenerative energy at the time of downhill can be accepted in the form of battery charging without waste.

[0006]

Japanese Patent Laid-Open No. 2001-268708 discloses a control device for a hybrid vehicle of Conventional Example 3. The control device for the hybrid vehicle of Conventional Example 3 changes the target value of the charge level according to the degree of deterioration of the battery. Furthermore, the target value of the charge level is set lower during steady operation than during deceleration operation.

[0007]

[Patent Document 1]

Japanese Patent No. 3211699 [Patent Document 2]

JP-A-11-008909 [Patent Document 3]

Japanese Patent Laid-Open No. 2001-268708

[Problems to be solved by the invention]

The idle stop vehicle discharges the storage battery at the time of engine start and start after the stop and after the stop, so the SOC of the storage battery is reduced. When the SOC of the storage battery decreases, the storage battery is charged if the idle stop vehicle continues to run for a while, and the SOC increases again. However, an idle stop vehicle that travels in a congested urban area may repeatedly stop after traveling a short distance. In this case, the storage battery is repeatedly discharged while being hardly charged. In such a case, the SOC of the storage battery may be less than the minimum necessary for starting the idle stop vehicle, and the idle stop vehicle may not move. For this reason, a control has been proposed in which a lower limit value of the SOC is set and the idling stop is canceled when the lower limit value is reached. However, since the number of idling stops is reduced, the effect of improving the fuel consumption is reduced. Further, since the SOC is used in a low state, sulfation due to stratification occurs particularly in a liquid lead-acid battery, and there is a possibility that the life may be shortened. On the other hand, when traveling on a highway or with a small number of traffic lights, the frequency of idling stops is low, so the storage battery is less discharged and the charging time is longer. Therefore, when charging is performed at a constant charging voltage as in conventional charging control and the SOC is controlled to be close to 100%, overcharging occurs, and an effect of improving fuel efficiency cannot be expected. In addition, since the SOC is controlled to be close to 100%, regenerative charging cannot be accepted.

[0009]

The power output devices and the like of Conventional Examples 1 to 3 control charging / discharging of the storage battery according to the driving condition of the automobile and the state of the battery. However, the power supply devices of Conventional Examples 1 to 3 do not solve the above problem that the storage battery may have a short life in traveling in a congested urban area.

[0010]

The present invention solves the above-mentioned conventional problems, recovers regenerative energy in a storage battery even when traveling on a highway or with a small number of traffic lights, reducing idling stop frequency, improving vehicle fuel efficiency, reducing exhaust gas, and Provided are a power supply control device and a control method thereof for preventing a storage battery from having a short life during traveling in a congested urban area.

[0011]

[Means for Solving the Problems]

In order to solve the above problems, the present invention has the following configuration. The invention according to

[0012]

According to a second aspect of the present invention, the generator can operate as an electric motor that assists the engine, and the storage battery charge / discharge control unit is configured to operate the storage battery at least when the engine changes from a stopped state to an operating state. And discharging and driving the generator as an electric motor, and controlling the charge and discharge of the storage battery so that the storage battery is charged by the generator after the engine continues operating. 1. The power supply control device according to 1.

[0013]

According to a third aspect of the present invention, the storage battery charge / discharge control unit sets the upper limit value when the frequency is equal to or higher than the predetermined threshold value to a maximum rating of the storage battery, and the frequency is less than the predetermined threshold value. The storage battery sets the upper limit value to a value at which the storage battery can charge regenerative energy from the generator when the value is less than another threshold value that is lower than the predetermined threshold value. A power supply control device according to

[0014]

The invention according to claim 4 is the power supply control device according to

[0015]

The invention according to claim 5 is a control method for a power supply control device mounted on a vehicle, comprising an engine, a generator driven by the engine, and a storage battery charged by the generator, A control step for controlling charging / discharging of the storage battery so that a charging state of the storage battery is within a predetermined range; and a detection step for detecting a frequency at which the engine or the vehicle is stopped. The upper limit value of the predetermined range of the control step when the frequency is equal to or higher than a predetermined threshold is set higher than the upper limit value when the frequency is less than the predetermined threshold. This is a method for controlling the apparatus.

[0016]

According to a sixth aspect of the present invention, the generator can operate as an electric motor that assists the engine, and at least when the engine changes from a stopped state to an operating state, the storage battery is discharged to cause the generator to operate. 6. The power supply control device according to claim 5, wherein the storage battery is charged and discharged so that the storage battery is charged by the generator after being driven as an electric motor and the engine continues operating. It is a control method.

[0017]

The invention according to claim 7 sets the upper limit value when the frequency is equal to or higher than the predetermined threshold value to a maximum rating of the storage battery, and the frequency is lower than the predetermined threshold value or the predetermined threshold value. The said upper limit in case it is less than the other threshold value which is a lower value sets the said storage battery to the value which can charge the regenerative energy from the said generator, The Claim 5 or Claim 6 characterized by the above-mentioned. It is a control method of a power supply control device.

[0018]

The inventor of the present invention discharges the battery when the battery mounted on the idle stop vehicle is discharged at the time of engine start or start, and thus repeatedly stops running after a short distance especially in a congested urban area. It has been found that the quantity is proportional to the number of engine or car stops. If the frequency at which the engine or the vehicle is stopped is high, the charge amount of the storage battery may not catch up with the discharge amount. In such a case, it can prevent that the lifetime of a storage battery becomes short by controlling so that SOC of a storage battery is made high. On the other hand, when a vehicle travels on a highway, the frequency of occurrence of a state where the engine or the vehicle is stopped is low. In such a case, the regenerative energy can be reliably recovered in the storage battery by controlling the storage battery to have a low SOC.

In an idle stop vehicle using a lead storage battery, the life of the lead storage battery is shortened if the discharge is repeated while the storage battery is hardly charged.

“Frequency of occurrence of a state where the engine or the vehicle is stopped” may be counted as a frequency of changing from the operating state to the stopped state, or may be counted as a frequency of changing from the stopped state to the operating state.

[0019]

The present invention recovers regenerative energy in a storage battery to improve vehicle fuel efficiency, reduce exhaust gas, and prevent overdischarge of the storage battery during traveling in a congested urban area, and shorten the life of the storage battery such as a lead storage battery. It has the effect | action that the power supply control apparatus which prevents becoming, and its control method are realizable.

[0020]

DETAILED DESCRIPTION OF THE INVENTION

Hereinafter, examples specifically showing the best mode for carrying out the present invention will be described with reference to the drawings.

[0021]

"Example"

A power supply control device and a control method thereof according to an embodiment of the present invention will be described with reference to FIGS. The power supply control device of the embodiment is mounted on an idle stop vehicle.

FIG. 2 is a block diagram illustrating a configuration of the power supply control device according to the embodiment. In FIG. 2, 200 is an idle stop car, 201 is a generator, 202 is a load, 203 is a 12V, 50Ah liquid lead acid battery, 204 is a current sensor, 205 is a current measuring unit, 206 is a voltage measuring unit, and 210 is an engine. , 211 is a storage battery charge / discharge control unit. The storage battery charge / discharge control unit 211 includes an

[0022]

The idling stop vehicle 200 has an idling stop function that automatically stops the engine without idling to park or stop, or automatically stops the engine after idling for a short time. The

[0023]

The current sensor 204 detects the current flowing through the liquid

The storage battery charge / discharge control unit 211 controls the charge / discharge of the liquid

[0024]

The

The idle stop

[0025]

FIG. 1 is a flowchart illustrating a control method of the power supply control device according to the embodiment. In

[0026]

In

[0027]

FIG. 3 is a diagram showing the relationship between the frequency of idle stop per 10 minutes and the amount of overcharge per hour of travel in an idle stop vehicle having the conventional example and the power supply control device of the present invention. A liquid lead-acid battery with a voltage of 12V and a battery capacity of 50Ah is mounted on an idle stop vehicle 200 and an idle stop vehicle having a conventional power supply control device, respectively, and the frequency of idle stop per 10 minutes is variously changed to run for 1 hour An experiment was conducted to check the amount of overcharge per unit. The average discharge amount per idle stop was 0.5% of the battery capacity. A

[0028]

If the liquid lead-

[0029]

When the frequency of idle stops is low, such as during high-speed driving, the liquid lead-

[0030]

The threshold for the idle stop frequency per 10 minutes used in

In the embodiment, the SOC target value is increased when the frequency at which the engine stops is high, and the SOC target value is decreased when the frequency is low. Alternatively, the SOC target value may be increased when the frequency at which the vehicle is stopped is high, and the SOC target value may be decreased when the frequency is low.

[0031]

【The invention's effect】

According to the present invention, regenerative energy is recovered in a storage battery to improve vehicle fuel efficiency, reduce exhaust gas, and prevent overdischarge of the storage battery in traveling in congested urban areas, etc., and the life of the storage battery such as a lead storage battery The advantageous effect that the power supply control apparatus and its control method which prevent that becomes short can be implement | achieved is acquired.

[Brief description of the drawings]

FIG. 1 is a flowchart showing a control method of a power supply control apparatus according to an embodiment of the present invention. FIG. 2 is a block diagram showing a configuration of a power supply control apparatus according to an embodiment of the present invention. Figure showing the relationship between the frequency of idle stops per 10 minutes and the amount of overcharge per hour of travel in an idle stop vehicle with each device

200

Claims (7)

前記蓄電池充放電制御部は、前記エンジン又は前記車が停止した状態が発生する頻度を検出し、前記頻度が所定の閾値以上である場合における前記所定の範囲の上限値を、前記頻度が前記所定の閾値未満である場合における前記上限値より高く設定することを特徴とする電源制御装置。An engine, a generator driven by the engine, a storage battery charged by the generator, and a storage battery charge / discharge control unit that controls charging / discharging of the storage battery so that a charging state of the storage battery is within a predetermined range And mounted on the car,

The storage battery charge / discharge control unit detects the frequency of occurrence of a state in which the engine or the vehicle is stopped, and sets the upper limit value of the predetermined range when the frequency is equal to or higher than a predetermined threshold value. The power supply control device is set to be higher than the upper limit value when the value is less than the threshold value.

前記蓄電池充放電制御部は、少なくとも前記エンジンが停止状態から動作状態に変化した時に前記蓄電池が放電して前記発電機を電動機として駆動し、前記エンジンが動作状態を継続した後は前記蓄電池が前記発電機によって充電されるように前記蓄電池の充放電を制御することを特徴とする請求項1に記載の電源制御装置。The generator can operate as an electric motor to assist the engine,

The storage battery charge / discharge control unit discharges the storage battery at least when the engine changes from a stopped state to an operating state, drives the generator as an electric motor, and after the engine continues to operate, the storage battery The power supply control device according to claim 1, wherein charge / discharge of the storage battery is controlled so as to be charged by a generator.

前記蓄電池の充電状態が所定の範囲内になるように前記蓄電池の充放電を制御する制御ステップと、

前記エンジン又は前記車が停止した状態が発生する頻度を検出する検出ステップと、

を有し、

前記頻度が所定の閾値以上である場合における前記制御ステップの前記所定の範囲の上限値を、前記頻度が前記所定の閾値未満である場合における前記上限値より高く設定することを特徴とする電源制御装置の制御方法。A control method for a power supply control device mounted on a car, comprising an engine, a generator driven by the engine, and a storage battery charged by the generator,

A control step of controlling charging / discharging of the storage battery so that the state of charge of the storage battery is within a predetermined range;

A detection step of detecting a frequency of occurrence of a state in which the engine or the vehicle is stopped;

Have

The upper limit value of the predetermined range of the control step when the frequency is equal to or higher than a predetermined threshold is set higher than the upper limit value when the frequency is less than the predetermined threshold. Control method of the device.

少なくとも前記エンジンが停止状態から動作状態に変化した時に前記蓄電池が放電して前記発電機を電動機として駆動し、前記エンジンが動作状態を継続した後は前記蓄電池が前記発電機によって充電されるように前記蓄電池の充放電を制御することを特徴とする請求項5に記載の電源制御装置の制御方法。The generator can operate as an electric motor to assist the engine,

At least when the engine changes from a stopped state to an operating state, the storage battery is discharged to drive the generator as an electric motor so that the storage battery is charged by the generator after the engine continues to operate. The control method of the power supply control device according to claim 5, wherein charging / discharging of the storage battery is controlled.

Priority Applications (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| JP2002367054A JP3880924B2 (en) | 2002-12-18 | 2002-12-18 | Power supply control device and control method thereof |

Applications Claiming Priority (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| JP2002367054A JP3880924B2 (en) | 2002-12-18 | 2002-12-18 | Power supply control device and control method thereof |

Publications (3)

| Publication Number | Publication Date |

|---|---|

| JP2004201411A JP2004201411A (en) | 2004-07-15 |

| JP2004201411A5 JP2004201411A5 (en) | 2005-11-04 |

| JP3880924B2 true JP3880924B2 (en) | 2007-02-14 |

Family

ID=32764073

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| JP2002367054A Expired - Fee Related JP3880924B2 (en) | 2002-12-18 | 2002-12-18 | Power supply control device and control method thereof |

Country Status (1)

| Country | Link |

|---|---|

| JP (1) | JP3880924B2 (en) |

Cited By (1)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US10677176B2 (en) | 2016-06-10 | 2020-06-09 | Denso Corporation | Vehicle power system |

Families Citing this family (11)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| JP5198660B2 (en) * | 2009-06-09 | 2013-05-15 | 住友重機械工業株式会社 | Hybrid excavator and control method thereof |

| JP5407945B2 (en) | 2010-03-05 | 2014-02-05 | 株式会社デンソー | Charge control system |

| JP5359937B2 (en) * | 2010-03-08 | 2013-12-04 | トヨタ自動車株式会社 | Hybrid vehicle |

| KR101198801B1 (en) * | 2010-09-30 | 2012-11-12 | 기아자동차주식회사 | System and method for idle charge of hybrid vehicle |

| US9008883B2 (en) | 2011-07-27 | 2015-04-14 | Toyota Jidosha Kabushiki Kaisha | Control device and control method for hybrid vehicle |

| RU2573687C2 (en) * | 2011-11-18 | 2016-01-27 | Тойота Дзидося Кабусики Кайся | Device for control over vehicle, vehicle and method for its control |

| JP5915443B2 (en) * | 2012-01-17 | 2016-05-11 | トヨタ自動車株式会社 | Running environment estimation device, vehicle control device, vehicle, running environment estimation method, and vehicle control method |

| JP5965775B2 (en) * | 2012-08-07 | 2016-08-10 | 株式会社デンソー | Vehicle power system |

| JP5831400B2 (en) * | 2012-08-23 | 2015-12-09 | トヨタ自動車株式会社 | Vehicle control apparatus, vehicle, and vehicle control method |

| CN114123444B (en) * | 2021-11-26 | 2024-08-06 | 隆鑫通用动力股份有限公司 | Charging and discharging control method and device for storage battery and related equipment |

| CN115871579B (en) * | 2023-01-03 | 2024-05-24 | 重庆长安汽车股份有限公司 | Vehicle electricity consumption monitoring method, system, electronic equipment and storage medium |

-

2002

- 2002-12-18 JP JP2002367054A patent/JP3880924B2/en not_active Expired - Fee Related

Cited By (1)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US10677176B2 (en) | 2016-06-10 | 2020-06-09 | Denso Corporation | Vehicle power system |

Also Published As

| Publication number | Publication date |

|---|---|

| JP2004201411A (en) | 2004-07-15 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| JP3772765B2 (en) | Refresh charge control device | |

| JP3736268B2 (en) | Control device for hybrid vehicle | |

| JP5029331B2 (en) | Vehicle power supply | |

| CN103660961B (en) | The control setup of vehicle power and control method | |

| KR101251502B1 (en) | System for learning driver's propensity to drive of hybrid vehicle and method thereof | |

| US20020196027A1 (en) | State-of-charge detection device for a battery | |

| JP3465293B2 (en) | Vehicle power control device | |

| KR100867795B1 (en) | Mehtod for controlling dc/dc converter of hev | |

| CN103326648B (en) | Power generation control | |

| JP3880924B2 (en) | Power supply control device and control method thereof | |

| CN109314399B (en) | Vehicle-mounted power supply system | |

| KR101836586B1 (en) | Method and system for controlling charging of low-voltage battery | |

| US9889764B2 (en) | Apparatus and method for controlling battery of green car | |

| CN112238830A (en) | DC/AC inverter system powered by integrated grid | |

| KR101926896B1 (en) | Controlling method and apparatus for charging low-voltage battery | |

| JP2004328906A (en) | Charging controller of hybrid vehicle | |

| JP2004060526A (en) | Controlling method and device for vehicle, program for embodying the method, and recording medium to record the program | |

| CN112290622A (en) | Energy distribution method, equipment and medium for automobile hybrid energy storage system | |

| JP2004166350A (en) | Battery controller | |

| JP2001292506A (en) | Control apparatus for hybrid vehicle | |

| JP3624334B2 (en) | Deceleration energy regeneration device for vehicles | |

| JP2004190604A (en) | Device and method for judging life of battery | |

| JP4192658B2 (en) | Vehicle control apparatus and control method | |

| JP3975937B2 (en) | Battery charge control device and charge control method | |

| JP2010288357A (en) | Power supply unit |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| RD02 | Notification of acceptance of power of attorney |

Free format text: JAPANESE INTERMEDIATE CODE: A7422 Effective date: 20050525 |

|

| A521 | Written amendment |

Free format text: JAPANESE INTERMEDIATE CODE: A523 Effective date: 20050816 |

|

| A621 | Written request for application examination |

Free format text: JAPANESE INTERMEDIATE CODE: A621 Effective date: 20050816 |

|

| A977 | Report on retrieval |

Free format text: JAPANESE INTERMEDIATE CODE: A971007 Effective date: 20061025 |

|

| TRDD | Decision of grant or rejection written | ||

| A01 | Written decision to grant a patent or to grant a registration (utility model) |

Free format text: JAPANESE INTERMEDIATE CODE: A01 Effective date: 20061031 |

|

| A61 | First payment of annual fees (during grant procedure) |

Free format text: JAPANESE INTERMEDIATE CODE: A61 Effective date: 20061108 |

|

| R150 | Certificate of patent or registration of utility model |

Free format text: JAPANESE INTERMEDIATE CODE: R150 |

|

| FPAY | Renewal fee payment (event date is renewal date of database) |

Free format text: PAYMENT UNTIL: 20091117 Year of fee payment: 3 |

|

| FPAY | Renewal fee payment (event date is renewal date of database) |

Free format text: PAYMENT UNTIL: 20101117 Year of fee payment: 4 |

|

| LAPS | Cancellation because of no payment of annual fees |