JP3844704B2 - Write-once type optical recording medium capable of multi-value recording and multi-value recording method - Google Patents

Write-once type optical recording medium capable of multi-value recording and multi-value recording method Download PDFInfo

- Publication number

- JP3844704B2 JP3844704B2 JP2002066570A JP2002066570A JP3844704B2 JP 3844704 B2 JP3844704 B2 JP 3844704B2 JP 2002066570 A JP2002066570 A JP 2002066570A JP 2002066570 A JP2002066570 A JP 2002066570A JP 3844704 B2 JP3844704 B2 JP 3844704B2

- Authority

- JP

- Japan

- Prior art keywords

- recording

- layer

- organic material

- material layer

- undercoat layer

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Expired - Fee Related

Links

Images

Landscapes

- Optical Record Carriers And Manufacture Thereof (AREA)

- Optical Recording Or Reproduction (AREA)

Description

【0001】

【発明の属する技術分野】

本発明は、記録データに応じ記録マーク長や振幅に加えて記録極性も変化させることにより多値記録を行うことができる追記型光記録媒体、その記録原理、及び多値記録方法に関する。

【0002】

【従来の技術】

近年、光記録媒体は更なる大容量化、高密度化が要求されている。光記録媒体の大容量化、高密度化を実現するための一方法として、多値記録がある。

多値記録は、情報を3通り以上の値に対応付けて記録再生を行うことを意味し、「0」又は「1」の2値に対応させて記録再生を行う2値記録と区別するための概念である。多値記録の詳細については、例えば特開平6−76399号公報に記載されている。

この従来例は、マークエッジ方式の記録再生方法において、記録マークのエッジの位置を記録データに対応させて基準位置から段階的にシフトさせることより、多値情報を記録する。このマークエッジ方式の多値記録では、エッジ位置のシフト数(段数)が多いほど多値化即ち高密度化に有利である。

しかしながら、限られた基準クロックの周期に対してエッジ位置のシフト数を増やそうとすれば、エッジの形成を精密に制御する必要がある。

一方、レーザ光の照射によって形成される記録マークのエッジ位置を制御することは容易ではない。

【0003】

別の従来例として、特開平8−287468号公報に記載されている光記録再生方法は、上記の従来例のようなマークエッジ方式ではなく、ピットポジション方式での多値記録を実現している。

この場合、記録マークの中心位置を基準クロックのエッジに対して段階的にシフトさせて多値記録を行う。

更に他の多値記録技術としては、以下のようなものが挙げられる。

即ち、CDと同じ再生専用型の光ディスクにおいて、記録データに対応したピットのエッジを8段階にシフトするというSCIPERという多値記録技術が、例えば「S. Kobayashi,J.P.de Kock,T.Horigome,H.Yamatsu and H.Ooki,Tech.Dig.ofOptical Data Storage Conference,p.130(1994)」に記載されている。

この技術では、従来のディスク構造がそのまま使えるというメリットはあるが、信号処理回路が非常に複雑化するという問題がある。

【0004】

また、ピットの深さを段階的に変化させた8レベルの多値記録技術が、例えば「S.Spielman,B.V.Johnson,G.A.McDermott,M.P.O’Neil,C.Pietrzyk,T.Shafaat,D.K.Warland and T.L.Wong,Proc.SPIE,3109,p.98(1997)」に記載されている。

この技術では、信号処理回路の複雑化はある程度抑えることができるが、ディスクの製造が困難となる。

また、光磁気ディスクにおいて、複数の磁性体記録膜を導入し、記録用磁界の強度を切替えることによって各層の磁化反転を選択的に起させる4値記録技術が、例えば「N.Saito,R.Sato,N.Kawamura and M.Kajiura,Jpn.J.Appl.Phys.,28,p.343(1989)」に記載されている。

【0005】

また、光磁気ディスクにおいて、記録用の高周波磁界の周期を変えることによって、磁化反転間隔を段階的に変化させた4値記録技術が、例えば「M.Arai and S.Kobayashi,Tech.Dig.of Joint MORIS/ISOM,p.32(1997)」に記載されている。

また、相変化型の光ディスクにおいて、記録レーザ光の強度変調によって記録マークの大きさを制御した多値記録技術が、例えば「T.Ohta,K.Nishiuchi,K.Narumi,Y.Kitaoka,H.Ishibashi,N.Yamada and T.Kozaki,Jpn.J.Appl.Phys.,39,p.770(2000)」に記載されている。

また、相変化型の光ディスクにおいて、専用の相変化記録材料を用い記録パルス波形を工夫して記録マーク長の制御を行うことにより、8値記録を行う多値記録技術が、例えば「M.P.O’Neil and T.L.Wong,Tech.Dig.of Optical Data Storage Conference,p.170(2000)」に記載されている。

【0006】

【発明が解決しようとする課題】

高密度化を図るためには多値レベルの数を増やす必要があるが、多値レベルの数を増やすと多値レベルの判定がより困難になるので、再生信頼性が大幅に低下するという問題がある。

また、従来、再生専用型光記録媒体、光磁気記録媒体、又は相変化型光記録媒体に適用できる多値記録技術は提案されているものの、有機材料を用いた追記型光記録媒体に有効な多値記録技術は殆んど提案されていない。

そこで、本発明は、上記のような従来の問題を解決し、有機材料を用いた追記型光記録媒体に有効な多値記録技術、多値レベルの数を増やしながらも精度の高い多値記録が可能で、350〜500nm程度の青色レーザ領域にも適用可能な追記型光記録媒体、その記録原理、及び多値記録方法の提供を目的とする。

【0007】

【課題を解決するための手段】

上記課題は、次の1)〜11)の発明によって解決される。

1) 基板上に、下引層を介して、未記録時に記録再生波長の光に対して吸収機能を有しない有機材料層を、該有機材料層との屈折率差が大きい下引層と上引層とで挟み込む層構造を有し、下引層又は上引層が光吸収機能を有する光記録媒体であって、記録の際に変形方向と変形界面の位置(種類)を変えることができ、これにより記録マーク長や振幅の違いに加えて記録極性も異なる再生信号が得られることを特徴とする多値記録可能な追記型光記録媒体。

2) 基板上に、下引層を介して、未記録時に記録再生波長の光に対して吸収機能を有しない有機材料層を、該有機材料層との屈折率差が大きい下引層と上引層とで挟み込む層構造を有し、下引層又は上引層が光吸収機能を有する光記録媒体であって、有機材料層中の有機材料の状態変化に伴う有機材料層から下引層への圧力、又は有機材料層から上引層への圧力による記録マーク形成の記録原理と、下引層や上引層の応力緩和、又は基板の熱膨張による記録マーク形成の記録原理によって、記録の際に記録マーク部の変形方向と変形界面の位置(種類)を変えることができ、これにより記録マーク長や振幅の違いに加えて記録極性も異なる再生信号が得られることを特徴とする多値記録可能な追記型光記録媒体。

3) 基板上に、下引層を介して、未記録時の主吸収帯が記録再生波長に対して長波長側に存在し、かつ未記録時に記録再生波長の光に対して吸収機能を有しない有機材料層を、該有機材料層との屈折率差が大きい下引層と上引層とで挟み込む層構造を有し、下引層又は上引層が光吸収機能を有する光記録媒体であって、記録の際に変形方向と変形界面の位置(種類)を変えることができ、これにより記録マーク長や振幅の違いに加えて記録極性も異なる再生信号が得られることを特徴とする多値記録可能な追記型光記録媒体。

4) 基板上に、下引層を介して、未記録時の主吸収帯が記録再生波長に対して長波長側に存在し、かつ未記録時に記録再生波長の光に対して吸収機能を有しない有機材料層を、該有機材料層との屈折率差が大きい下引層と上引層とで挟み込む層構造を有し、下引層又は上引層が光吸収機能を有する光記録媒体であって、有機材料層中の有機材料の状態変化に伴う有機材料層から下引層への圧力、又は有機材料層から上引層への圧力による記録マーク形成の記録原理と、下引層や上引層の応力緩和、又は基板の熱膨張による記録マーク形成の記録原理によって、記録の際に記録マーク部の変形方向と変形界面の位置(種類)を変えることができ、これにより記録マーク長や振幅の違いに加えて記録極性も異なる再生信号が得られることを特徴とする多値記録可能な追記型光記録媒体。

5) 記録再生波長が350nm以上500nm以下であることを特徴とする1)乃至4)の何れか1項に記載の多値記録可能な追記型光記録媒体。

6) 有機材料層と上引層の界面形状が、基板の溝形状と同一となるように形成されていることを特徴とする1)乃至5)の何れか1項に記載の多値記録可能な追記型光記録媒体。

7) 基板上に、下引層を介して、未記録時に記録再生波長の光に対して吸収機能を有しない有機材料層を、該有機材料層との屈折率差が大きい下引層と上引層とで挟み込む層構造を有し、下引層又は上引層が光吸収機能を有する多値記録可能な追記型光記録媒体に対し、記録の際に変形方向と変形界面の位置(種類)を変えることにより、記録マーク長や振幅の違いに加えて記録極性も異なる再生信号が得られるようにすることを特徴とする多値記録方法。

8) 基板上に、下引層を介して、未記録時に記録再生波長の光に対して吸収機能を有しない有機材料層を、該有機材料層との屈折率差が大きい下引層と上引層とで挟み込む層構造を有し、下引層又は上引層が光吸収機能を有する多値記録可能な追記型光記録媒体に対し、有機材料層中の有機材料の状態変化に伴う有機材料層から下引層への圧力、又は有機材料層から上引層への圧力による記録マーク形成の記録原理と、下引層や上引層の応力緩和、又は基板の熱膨張による記録マーク形成の記録原理によって、記録の際に記録マーク部の変形方向と変形界面の位置(種類)を変え、これにより記録マーク長や振幅の違いに加えて記録極性も異なる再生信号が得られるようにすることを特徴とする多値記録方法。

9) 基板上に、下引層を介して、未記録時の主吸収帯が記録再生波長に対して長波長側に存在し、かつ未記録時に記録再生波長の光に対して吸収機能を有しない有機材料層を、該有機材料層との屈折率差が大きい下引層と上引層とで挟み込む層構造を有し、下引層又は上引層が光吸収機能を有する多値記録可能な追記型光記録媒体に対し、記録の際に変形方向と変形界面の位置(種類)を変えることにより、記録マーク長や振幅の違いに加えて記録極性も異なる再生信号が得られるようにすることを特徴とする多値記録方法。

10) 基板上に、下引層を介して、未記録時の主吸収帯が記録再生波長に対して長波長側に存在し、かつ未記録時に記録再生波長の光に対して吸収機能を有しない有機材料層を、該有機材料層との屈折率差が大きい下引層と上引層とで挟み込む層構造を有し、下引層又は上引層が光吸収機能を有する多値記録可能な追記型光記録媒体に対し、有機材料層中の有機材料の状態変化に伴う有機材料層から下引層への圧力、又は有機材料層から上引層への圧力による記録マーク形成の記録原理と、下引層や上引層の応力緩和、又は基板の熱膨張による記録マーク形成の記録原理によって、記録の際に記録マーク部の変形方向と変形界面の位置(種類)を変え、これにより記録マーク長や振幅の違いに加えて記録極性の異なる再生信号が得られるようにすることを特徴とする多値記録方法。

11) 記録再生波長が350nm以上500nm以下であることを特徴とする7)乃至10)の何れか1項に記載の多値記録方法。

【0008】

以下、上記本発明について詳しく説明する。

(1)本発明の概要(特徴)

本発明では、記録の際に変形方向と変形界面の位置(種類)を変えて多値記録を行うことにより、記録マーク長や振幅の違いに加えて記録極性も異なる再生信号を得ることができる。また、本発明では、有機材料層中の有機材料の状態変化に伴う有機材料層から下引層への圧力、又は有機材料層から上引層への圧力による記録マーク形成の記録原理と、下引層や上引層の応力緩和、又は基板の熱膨張による記録マーク形成の記録原理を用い、これを制御することにより多値記録を行うことができる。

即ち、従来は記録極性が同一であったため〔いわゆるHigh to Low(ハイ・トゥー・ロー)記録か、Low to High(ロー・トゥー・ハイ)記録のどちらか一方〕、多値レベルの数を増やすと多値レベルの判定がより困難になり、再生信頼性が大幅に低下するという問題があったが、本発明では、記録マーク長や振幅の違いだけでなく、記録極性も異なる再生信号が得られるので、より信頼性の高い追記型光記録媒体を提供することができる。

なお、本発明で言う「有機材料の状態変化」とは、溶融、昇華、分解、爆発、構造変化等を指すが、通常は分解、爆発が主であり、この場合、有機材料に唯一要求されるのは、熱による分解特性(分解温度、爆発性、明確な分解閾値の存在、分解スピード、分解量等)が優れていることである。

【0009】

(2)「変形方向と変形界面の位置(種類)を変える」という表現の説明

本発明で言う「変形方向と変形界面の位置(種類)を変える」という表現について説明する。

変形方向とは、ある基準となる側から見た場合に、変形が凸状に生じているか、或いは凹状に生じているかを意味する。

また、変形界面の位置(種類)とは、どの層の界面に凹凸状の変形が生じているかを指す。変形界面としては、基板と下引層の界面、下引層と有機材料層の界面、有機材料層と上引層の界面、上引層とその上層(保護層、カバー層、空気層等)との界面が存在する。

本発明では、変形界面が単一であっても良いし、上記の変形界面が複数組み合わさっていてもよい。要は、変形界面の組み合わせと、各界面の変形方向、変形量によって記録極性と記録マークのコントラストを変えるのである。

本発明では、変形界面の組み合わせ及び各界面の変形量を制御するが、これらは各層の膜厚、記録波長に対する吸収係数の大小、熱伝導率、硬度によって変化させることができる。最も簡単なのは、記録パワーを制御することで、変形界面の組み合わせ及び各界面の変形量を制御する方法である。

【0010】

また、本発明では、各界面の変形方向を制御するが、これは異なる記録原理を光記録媒体に持たせることで実現する。

即ち、有機材料層中の有機材料の状態変化に伴う有機材料層から下引層への圧力、又は有機材料層から上引層への圧力による記録マーク形成の記録原理と、下引層や上引層の応力緩和、又は基板の熱膨張による記録マーク形成の記録原理を併せ持たせることによって、各界面の変形方向を制御する。

例えば、有機材料層中の有機材料の状態変化に伴う有機材料層から下引層への圧力による記録マーク形成の記録原理を用いることによって、基板や下引層を、基板側から見て手前側に変形させることができる(ここでは凹状と表現する)。また、下引層の応力緩和、又は基板の熱膨張による記録マーク形成の記録原理を用いることによって、逆に、基板や下引層を、基板側から見て奥側に変形させることができる(ここでは凸状と表現する)。

本発明の重要な特徴は、従来の変形を利用した記録原理では変形の方向が一方に決まっていたが、本発明では、変形の方向を可変にできる記録原理を用いた点である。

【0011】

(3)「有機材料層を、有機材料層との屈折率差が大きい下引層と上引層とで挟み込む構造」とする理由

本発明では、「有機材料層を、有機材料層との屈折率差が大きい下引層と上引層とで挟み込む構造」を有することを特徴とする。

この構造によって、反射率の向上、信号品質の向上を図ることができ、或いは記録によって生じた変形方向や変形界面の位置(種類)の違いによって、記録マーク長や振幅の違いに加えて記録極性も異なる再生信号を効率よく発生させることができる。

なお、有機材料層と下引層及び上引層との屈折率差は、通常0.5以上とする。

【0012】

(4)有機材料層に用いられる有機材料の要件

本発明では、記録極性を可変とするために、記録マークの変形方向(凸変形か、或いは凹変形か)を制御する。

従来の光記録媒体(図1参照)の基本変形原理であった、基板の熱膨張による記録マーク形成では、基板は必ず有機材料層の方向へ変形し、逆の方向へは変形しない。これは、基板の熱膨張による力が十分大きく、これを阻害する力、或いはこれに逆らう大きな力が存在しないためである。

そこで本発明者は、基板の熱膨張に対し、この熱膨張による変形方向と逆方向の力を生じさせる手段について検討し、その結果、有機材料の状態変化に伴う力(特に分解・爆発力)が利用できることを見出したものである。

しかし、この状態変化に伴う力を有効に利用するためには、有機材料層と隣接する層との界面近傍の有機材料が最も状態変化を起し易いようにする必要があるが、従来の層構成では、有機材料層の中央部が最も高温になるため、有機材料層と隣接する層との界面近傍の有機材料は十分な状態変化を起さない。

そこで、本発明では、有機材料層と隣接する層との界面近傍の有機材料が最も状態変化を起し易いようにするため、有機材料層に隣接して光吸収層(光吸収機能を有する下引層又は上引層)を設ける構造とした。

【0013】

この光吸収層の吸収係数は、有機材料層の吸収係数よりも十分大きく設定されるため(光吸収層は光吸収機能を有するのに対し、有機材料層は記録再生波長の光に対して光吸収機能を有しないから当然そのようになる)、光吸収層近傍の有機材料が最も高温になり、有機材料の状態変化に伴う力により、従来とは変形方向が逆の記録を行うことが可能となる。

そして、この光吸収層を設けたことで、従来の、記録層と光吸収層の機能を兼ね備えていた有機材料層から光吸収機能を分離することができる。

これによって、有機材料層に課せられる厳しい光学定数条件が緩和されるため、本発明の追記型光記録媒体は、350〜500nm程度の青色レーザ波長領域でも容易に記録することが可能となる(従来の層構成では、有機材料層に厳しい光学定数条件が存在したため、青色レーザ波長領域に対応できる有機材料が殆んど存在せず、有機材料を用いた追記型光記録媒体の実現は困難であった)。

更に、従来の有機材料を用いた追記型光記録媒体では、有機材料層で熱を発生させる必要があったため、有機材料層を薄膜化できず、深い溝(例えば150〜180nm)を必要としていたが、本発明の記録原理によって有機材料の薄膜化が可能となり、成形性に優れた浅い溝を有する基板を用いることが出来るので、信頼性の高い追記型光記録媒体を提供することが可能となる。

【0014】

本発明で用いた「未記録時の主吸収帯が記録再生波長に対して長波長側に存在し、かつ記録再生波長の光に対して吸収機能を有しない有機材料層」、或いは「未記録時に記録再生波長の光に対して吸収機能を有しない有機材料層」という表現における、「記録再生波長の光に対して吸収機能を有しない」とは、有機材料層単独の吸収機能では、有機材料層の隣接層を変形させたり、有機材料自身を状態変化させるような温度に至らないことを意味する(即ち、実質上、光吸収層として必要な吸収機能を果さないことを意味する)。従って、具体的には、有機材料の吸収係数が小さい場合や、膜厚が薄い場合を指すことになる。

また、「未記録時の主吸収帯が記録再生波長に対して長波長側に存在し、かつ記録再生波長の光に対して吸収機能を有しない有機材料層」、或いは「未記録時に記録再生波長の光に対して吸収機能を有しない有機材料層」が、本発明の光記録媒体の構成要件として重要な理由は、本発明では従来の追記型光記録媒体に用いられる光吸収機能を有する有機材料に代えて、比較的大きな吸収係数を有する下引層や上引層を用いることにより、有機材料層での吸収機能を低下させて反射率の向上を図ることが出来るためである。

【0015】

また、前述したように、反射率の向上、信号品質の向上、或いは記録によって生じた変形方向や変形界面の位置(種類)の違いによって、記録マーク長や振幅の違いに加えて記録極性の異なる信号を効率よく発生させるためには、有機材料層を、有機材料層との屈折率差が大きい下引層と上引層とで挟み込む構造が適しており、そのためには有機材料層の屈折率を低く設定した方が、下引層と上引層の材料選択の上で有利である。

何故ならば、本発明の好ましい層構成として、例えば、基板/下引層(光吸収層)/有機材料層/上引層(反射層)が挙げられるが、この層構成を考えた場合、反射層の屈折率は通常0.1程度で非常に小さく、光吸収層の屈折率は例えば2.0〜4.0程度であって、有機材料層と光吸収層の屈折率差が小さくなり易い。そこで、この屈折率差を大きくすることが重要となるが、それには、有機材料層の屈折率を低く設定すれば、有機材料層と光吸収層の屈折率差を大きくし、かつ光吸収層の選択の幅を広げることが出来るからである。

【0016】

従って、「未記録時の主吸収帯が記録再生波長に対して長波長側に存在し、かつ記録再生波長の光に対して吸収機能を有しない有機材料層」、或いは「未記録時に記録再生波長の光に対して吸収機能を有しない有機材料層」とすることにより、即ち、有機材料の最大吸収帯と記録再生波長を大きくずらすことにより有機材料層の屈折率を低くすることが可能となる。

また、記録再生波長が500nm以上、例えばDVD系光記録媒体の記録再生波長である650nm近傍、或いはCD系光記録媒体の記録再生波長である780nm近傍では、有機材料層の要件として「未記録時に記録再生波長の光に対して吸収機能を有しない有機材料層」を満足すれば十分であり、有機材料の主吸収帯の波長と記録再生波長の大小関係は殆んど問題にならない。

【0017】

しかし、記録再生波長が350〜500nm程度の青色レーザ゛領域、例えば400nm近傍に設定される場合、未記録時の主吸収帯が記録再生波長に対して短波長側に存在し、かつ記録再生波長の光に対して吸収機能を有しないような状態にすることは、有機材料の分子の大きさを非常に小さくすることを意味し、これは有機材料の状態変化に伴う有機材料層から下引層への圧力、又は有機材料層から上引層への圧力が大幅に低下することを意味するため、本発明の記録原理を用いる追記型光記録媒体には好ましくない。

そこで、記録再生波長が350〜500nm、例えば400nm近傍に設定される場合は、有機材料の状態変化に伴う有機材料層から下引層への圧力、又は有機材料層から上引層への圧力を十分に発生させるために、分子骨格の大きい有機材料を選択し、未記録時の主吸収帯が記録再生波長に対して長波長側に存在し、かつ記録再生波長の光に対して光吸収機能を有しない有機材料層とすることが好ましい。

【0018】

(5)有機材料層と上引層の界面形状が、基板の溝形状と同一となるように形成する理由

有機材料層の膜厚は任意であり、その形成形態も任意である。

この形成形態とは、有機材料層の表面形状(有機材料層と上引層の界面形状)がどのような形状であるかを指し、例えば、有機材料層の表面形状が基板形状と同一(図8参照)となる場合や、有機材料層の表面形状がフラット(図9参照)となる場合がある。

本発明では、比較的記録極性の変化が生じ易くなる条件の一つとして、有機材料層の表面形状が重要であることを見出したものであり、有機材料層の表面形状が基板形状と同一(図8参照)となる場合は、記録極性の変化が生じ易くなる(記録極性が変化する条件が緩和される)ことを見出したものである。

しかし、ここで「同一となるように形成する」という記載の意味するところは、

文字通り同一である場合だけでなく、有機材料層と上引層の界面形状が、ほぼ基板の溝形状に倣って形成されている場合、即ち、基板上にスパッタリング等の通常の膜形成方法で各層を形成したときに、多少の膜厚のばらつきはあるものの、ほぼ基板の溝形状に倣って各層が形成されているような場合を含むものとする。

なお、本発明の追記型光記録媒体は、上記各層以外に、従来より公知の中間層、バックコート層等の種々の層を設けてもよい。

【0019】

(6)他の記録原理の併用について

本発明では、上記記録原理に加えて、レーザ光の照射による下引層又は上引層の発熱によって有機材料層に状態変化を生じ、該状態変化による記録再生波長での吸収係数の増加による記録原理を併用してもよい。

但し、この記録原理では、有機材料層の屈折率や膜厚が大きく変化しない限り、記録極性がHigh to Lowとなるので、この記録原理を併用するのは、前記変形による記録原理において記録極性がHigh to Lowとなる場合に限られる。

この有機材料層の吸収係数の増加による記録原理を、図18〜図20を参照しつつ説明する。

図18に示すような未記録状態の吸収スペクトルを有する有機材料を選択し、この有機材料を状態変化(特に分解、爆発)させると、分解により有機材料を構成していた分子や分子団の吸収が発生する。この吸収は、通常、分解、爆発前の有機材料の吸収よりも短波長であるため、元の有機材料の大きな吸収帯よりも短波長側での吸収係数が増加する(記録状態の吸収スペクトル参照)。この短波長側の吸収波長の変化の大きい範囲と記録再生波長(例えば図の矢印の位置)とを合わせれば、記録後の記録再生波長における吸収係数を増加させることができるので、これによって変調度を発生させることが可能となる。

【0020】

この記録原理についてもう少し詳しく説明すると、本発明で用いる有機材料は、小さな分子や分子団が結合して、或いは、錯体や会合体等を形成して大きな共役系を形成した有機材料であって、分子や分子団が持っていた固有の吸収波長(図19の吸収スペクトルA、Bに相当)よりも長波長側に大きな吸収帯を持ち、個々の分子や分子団が持っていた固有の吸収帯が消滅、又は減衰した吸収スペクトルを持つ(図20の吸収スペクトルCに相当)。

このような有機材料に対し、図20で示すようなλ1を記録再生波長として選択すると、未記録時はλ1での吸収が少なかった状態から、分解、爆発などによって、大きな分子を形成していた分子や分子団が持つ固有の吸収が増加し(図19参照)、λ1での吸収も増加し、吸収係数の変化による記録部が形成できる。

従って、ただ小さな分子や分子団が結合しているだけであって、共役系の広がりが形成されないような分子は、図20のような状態、即ち、分子や分子団が持っていた固有の吸収帯が消滅又は減衰し、新たに大きな鋭い吸収帯が形成されるような状態が実現されないため、記録前後での吸収係数の変化が大きくならず、記録ピットを形成することができない。

【0021】

(7)各層の材料について

基板の素材としては、熱的、機械的に優れた特性を有し、基板側から(基板を通して)記録再生が行われる場合には光透過特性にも優れたものであれば、特別な制限はない。

具体例としては、ポリカーボネート、ポリメタクリル酸メチル、非晶質ポリオレフィン、セルロースアセテート、ポリエチレンテレフタレートなどが挙げられるが、ポリカーボネートや非晶質ポリオレフィンが好ましい。

基板の厚さは用途により異なり、特に制限はない。

【0022】

光を吸収し熱を発生させる光吸収層として機能する下引層又は上引層には、比較的熱伝導率の低い材料が適している。比較的低い熱伝導率の材料を選択する理由は、効率よく(低記録パワーで)各層の界面を変形させるためであり、更には、効率よく(低記録パワーで)有機材料を状態変化させるためである。

なお、ここで言う比較的熱伝導率が低いとは、記録によって局所的に有機材料を状態変化させるだけの温度に達するような熱伝導率であることを意味する。

以上の点から、光吸収層として機能する下引層や上引層には、SiC等のセラミックス、Si等の半金属、Ge等の金属、又はそれらの混合物を用いることが好ましい。また、下引層や上引層の厚さは、通常20〜500Åとする。

【0023】

上記下引層や上引層の材料となるセラミックスとしては、Al2O3、MgO、BeO、ZrO2、UO2、ThO2などの単純酸化物系の酸化物;SiO2、2MgO・SiO2、MgO・SiO2、CaO・SiO3、ZrO2・SiO2、3Al2O3・2SiO2、2MgO・2Al2O3・5SiO2、Li2O・Al2O3・4SiO2などのケイ酸塩系の酸化物;Al2TiO5、MgAl2O4、Ca10(PO4)6(OH)2、BaTiO3、LiNbO3、PZT〔Pb(Zr,Ti)O3〕、PLZT〔(Pb,La)(Zr,Ti)O3〕、フェライトなどの複酸化物系の酸化物;Si3N4、Si6−ZAlZOZN8−Z、AlN、BN、TiNなどの窒化物系の非酸化物;SiC、B4C、TiC、WCなどの炭化物系の非酸化物;LaB6、TiB2、ZrB2などのホウ化物系の非酸化物;CdS、MoS2などの硫化物系の非酸化物;MoSi2などのケイ化物系の非酸化物;アモルファス炭素、黒鉛、ダイヤモンド等の炭素系の非酸化物などを用いることができる。

また、金属としては、Au、Al、Ag、Cu、Pd、Pt、Ti、Ta、Cr、Ni、Fe、及びこれらの合金を用いることができる。

【0024】

有機材料層に用いられる有機材料としては、いわゆる色素が好ましい。また、下引層や上引層を十分変形させるためには、昇華性又は分解・爆発性が高い色素、或いは昇華性又は分解・爆発性の高い置換基が導入された色素が好ましい。

また、高い分解・爆発性を確保するには、分子骨格が大きい有機材料が好ましい。更に、構造変化によって体積変化を起こす色素も用いることができる。

上記の要件を満足する色素としては、ポリメチン色素、ナフタロシアニン系、フタロシアニン系、スクアリリウム系、クロコニウム系、ピリリウム系、ナフトキノン系、アントラキノン(インダンスレン)系、キサンテン系、トリフェニルメタン系、アズレン系、テトラヒドロコリン系、フェナンスレン系、トリフェノチアジン系染料、及び金属錯体化合物などが挙げられる。

色素層の膜厚は、100Å〜10μm、好ましくは100〜2000Åが適当である。

【0025】

色素層の形成は、蒸着、スパッタリング、CVD、溶剤塗布などの通常の手段によって行なうことができる。塗布法を用いる場合には、上記染料などを有機溶剤に溶解して、スプレー、ローラーコーティング、ディッピング、スピンコーティングなどの慣用のコーティング法で行なうことができる。

用いられる有機溶剤としては、一般にメタノール、エタノール、イソプロパノールなどアルコール類;アセトン、メチルエチルケトン、シクロヘキサノンなどのケトン類;N,N−ジメチルアセトアミド、N,N−ジメチルホルムアミドなどのアミド類;ジメチルスルホキシドなどのスルホキシド類;テトラヒドロフラン、ジオキサン、ジエチルエーテル、エチレングリコールモノメチルエーテルなどのエーテル類;酢酸メチル、酢酸エチルなどのエステル類;クロロホルム、塩化メチレン、ジクロルエタン、四塩化炭素、トリクロルエタンなどの脂肪族ハロゲン化炭素類;ベンゼン、キシレン、モノクロルベンゼン、ジクロルベンゼンなどの芳香族類;メトキシエタノール、エトキシエタノールなどのセロソルブ類;ヘキサン、ペンタン、シクロヘキサン、メチルシクロヘキサンなどの炭化水素類などが挙げられる。

【0026】

光吸収層として機能しない下引層又は上引層としては、金属又はセラミックスが好ましい。

この金属又はセラミックスは、反射率の向上又は記録再生特性の向上を図るために、有機材料層との屈折率差のある材料を用いることが好ましい。

下引層と上引層のうち、入射レーザ光に対し手前側の層に光吸収能がある場合には、反射率の向上又は記録再生特性の向上を図るために、入射レーザ光に対し奥側の層は金属であることが好ましい。

逆に、下引層と上引層のうち、入射レーザ光に対し奥側の層に光吸収能がある場合には、反射率の向上又は記録再生特性の向上を図るために、入射レーザ光に対し手前側の層は、記録再生波長に対し吸収係数が小さな(0.02以下程度)セラミックスであることが好ましい。

上記金属としては、Au、Al、Cu、Cr、Ag、Ti及びこれらの合金からなる群より選択される金属が好ましく、上記記録再生波長(ここでは青色領域近傍)に対し吸収係数が小さなセラミックスとしては、前述したセラミックスやZnS・SiO2等が好ましい。

これらの材料は、一般に真空蒸着又はスパッタリング法により50〜5000Å、好ましくは50〜3000Åの厚さで形成される。

【0027】

【実施例】

以下、実施例及び比較例により本発明を具体的に説明するが、本発明はこれらの実施例により何ら限定されるものではない。

【0028】

実施例1

(本発明の追記型光記録媒体によって、記録マーク長や振幅の違いに加えて記録極性も異なる再生信号が得られることを明らかにし、また、その記録原理を確認するための実施例)

溝深さ50nmの案内溝を有するポリカーボネート基板上に、スパッタ法により光吸収層として機能する膜厚10nmの下引層(SiC)を設け、その上に、下記〔化1〕で示される有機材料をスピンコート法で成膜し(膜厚約60nm)、更にその上に、膜厚100nmの上引層(Ag)を設けて光記録媒体を作製した。

【化1】

【0029】

上記光記録媒体に対し、パルステック工業(株)製の光ディスク評価装置DDU−1000(波長:405nm、NA:0.65)を用いて、下記の記録条件で、記録時の記録パワーをある時間間隔で6.0(mW)と10.0(mW)に切替えて記録を行った。

<記録条件>

記録線密度:1T=0.0917(μm)

記録線速度:6.0(m/s)

記録ストラテジ:Basic strategy(基本ストラテジー)

Ttop−Tmp=1.40−0.75(T)

記録パワー:6.0(mW)、10.0(mW)

記録パターン:8−16変調信号

その結果、図2に示すように、記録パワーが6.0(mW)の時はLow to High記録が行え、記録パワーが10.0(mW)の時はHigh toLow記録が行えることが確認できた。

【0030】

次いで、この記録が前述したような記録原理に基づいて行われているかどうかを確認するため、SiCと有機材料層界面の変形状態をAFM(アトミックフォースマイクロスコープ、Atomic force microscope)により測定した。

図3は、記録パワーが6.0(mW)の時に発生したLow to High記録部分の、SiCと有機材料層界面の変形状態を三次元で表した結果である(下側が基板である)。なお、図3では、濃淡によって高さを表し、色が薄い部分が高く、色が濃い部分が低い。

図4は、図3を二次元的に表した図(a)と、記録トラックの断面図(凹凸形状)を表した図(b)である。

これらの図に示された結果から、記録パワーが6.0(mW)の時に発生したLow to High記録部分は、SiCと有機材料層界面が基板側へ変形(凹変形)していることが確認できた。

【0031】

一方、図5は、記録パワーが10.0(mW)の時に発生したHigh toLow記録部分の、SiCと有機材料層界面の変形状態を三次元で表した結果である(下側が基板である)。なお、図5では、濃淡によって高さを表し、色が薄い部分が高く、色が濃い部分が低い。

図6は、図5を二次元的に表した図(a)と、記録トラックの断面図(凹凸形状)を表した図(b)である。

これらの図に示された結果から、記録パワーが10.0(mW)の時に発生したHigh to Low記録部分は、SiCと有機材料層界面が基板側とは反対方向へ変形(凸変形)していることが確認できた。

【0032】

以上の結果から、本発明の追記型光記録媒体は、記録マーク長や振幅に加えて記録極性も変えて記録できることが明らかになり、この記録極性は、少なくともSiCと有機材料層の界面形状の変形方向の差異によって生じていることが確認できた。

なお、この実施例ではAFM像を見易くするためランド部に記録を行ったが、本発明はランド記録に限定されるものではない。

また、変形形状の測定のし易さからSiCと有機材料層の界面形状を測定したが、他の界面が同時に変形していても構わない。

更に、従来の有機材料を用いた光記録媒体では、有機材料層で熱を発生させる必要があったため、有機材料層を薄膜化できず、深い溝(例えば150〜180nm)を必要としていたが、本発明の記録原理によって、有機材料の薄膜化が可能となり、50nmという非常に浅い溝を有する基板を適用できることが確かめられた。このことは信頼性の高い光記録媒体を作製する上で、非常に大きなメリットとなる。

【0033】

比較例1

実施例1における有機材料に代えてポリメチルメタクリレートを用いた点以外は、実施例1と同様の実験を行った。

その結果、6.0(mW)で記録した部分も、10.0(mW)で記録した部分も記録極性が同一であり、また、SiCとポリマー層の界面は、図5〜図6と同様に基板と反対方向(凸変形)に変形していた。

これによって、実施例1においてSiCと有機材料層の界面が基板側へ変形(凹変形)した現象は、有機材料の働きによるものであり、有機材料の状態変化(分解・爆発)がこの凹変形に寄与していることが裏付けられた。

【0034】

実施例2

実際に記録部の変形方向や変形界面の位置(種類)を正確に測定することは非常に困難であるから(実施例1では、下引層と有機材料層の界面の状態のみを評価した)、ここでは光学シュミレーションによって、変形方向と変形界面の位置(種類)を変えることで、記録マーク長や振幅の違いに加えて記録極性も異なる再生信号が得られることを証明する。

下記の計算条件下で、次の(i)〜(iv)のように記録条件を変えて、再生信号がどのように変化するかを計算した。

(i)記録部分(ランド部又はグルーブ部)

(ii)有機材料層の形成状態〔有機材料層の表面形状が基板形状と同一(図8参照)、又は、有機材料層の表面形状はフラット(図9参照)〕

(iii)記録マーク形成界面〔下引層と有機材料層の界面のみが変形(図10、11、14、15参照)、又は、下引層/有機材料層の界面と有機材料層/上引層の界面が変形(図12、13、16、17参照)〕

(iv)記録マーク変形方向〔基板側へ凹変形(図14〜17参照)、又は、上引層側へ凸変形(図10〜13参照)〕

【0035】

<計算条件詳細>

以下、長さ、大きさは記録再生波長λを単位として表した。

・ビーム形状:ガウス分布

・振幅が1/eとなる半径(x方向、y方向):6000λ、6000λ

・対物レンズ開口半径:3000λ

・対物レンズNA(開口数):0.60

・対物レンズ焦点距離:5000λ

・溝形状〔A、B、C、D、ζ(図7参照)〕:(0.2λ、0.8λ、1.0λ、1.8525λ、0.1375λ)

・基板屈折率:1.60(基板側入射)

・下引層複素屈折率:2.810−i0.561、膜厚=0.025λ

・有機材料層複素屈折率:1.500−i0.050、膜厚=0.150λ

・上引層複素屈折率:0.1078−i2.0495、膜厚=0.250λ

・検出器:4分割PD

・検出器の半径(x方向、y方向):3000λ、3000λ

・記録マーク長さ、幅、高さ:1.0λ、0.60λ、±0.10λ

【0036】

計算の結果は、図21〜図24に示す通りである。

図21は、グルーブに記録した場合で、有機材料層の形成状態は、図8に示すように、有機材料層の表面形状が基板形状と同一となるように形成されている場合の結果である。

なお、記録部の高さは±0.10λとした(記録再生波長を400nmとした場合は±40nmとなる)。

凡例「+40nm−0,4」は、記録部が図16であることを、凡例「−40nm−0,4」は、記録部が図12であることを、凡例「+40nm−0,2」は、記録部が図14であることを、凡例「−40nm−0,2」は、記録部が図10であることを示す。

なお、以上の図ではグルーブ部に記録された状態が示されているが、ランド部の場合も、記録部の変形方向と変形界面の位置(種類)は同一である。

【0037】

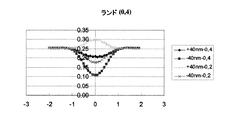

図22は、ランドに記録した場合で、有機材料層の形成状態は、図8に示すように、有機材料層の表面形状が基板形状と同一となるように形成されている場合の結果である。

なお、記録部の高さは±0.10λとした(記録再生波長を400nmとした場合は±40nmとなる)。

凡例「+40nm−0,4」は、記録部が図16であることを、凡例「−40nm−0,4」は、記録部が図12であることを、凡例「+40nm−0,2」は、記録部が図14であることを、凡例「−40nm−0,2」は、記録部が図10であることを示す。

【0038】

図23は、グルーブに記録した場合で、有機材料層の形成状態は、図9に示すように、有機材料層の表面形状がフラットとなるように形成されている場合の結果である。

なお、記録部の高さは±0.10λとした(記録再生波長を400nmとした場合は±40nmとなる)。

凡例「+40nm−0,4」は、記録部が図17であることを、凡例「−40nm−0,4」は、記録部が図13であることを、凡例「+40nm−0,2」は、記録部が図15であることを、凡例「−40nm−0,2」は、記録部が図11であることを示す。

なお、以上の図ではグルーブ部に記録された状態が示されているが、ランド部の場合も、記録部の変形方向と変形界面の位置(種類)は同一である。

【0039】

図24は、ランドに記録した場合で、有機材料層の形成状態は、図9に示すように、有機材料層の表面形状がフラットとなるように形成されている場合の結果である。

なお、記録部の高さは±0.10λとした(記録再生波長を400nmとした場合は±40nmとなる)。

凡例「+40nm−0,4」は、記録部が図17であることを、凡例「−40nm−0,4」は、記録部が図13であることを、凡例「+40nm−0,2」は、記録部が図15であることを、凡例「−40nm−0,2」は、記録部が図11であることを示す。

【0040】

この図21〜図24の結果より、記録マークの変形方向と変形界面の位置(種類)を変えることで、記録極性を制御できるという考え方が、原理的に正しいことが証明された。

なお、図24に示す結果から、有機材料層の形成状態が、図9に示すように、有機材料層の表面形状がフラットとなるように形成されている場合には、ランド記録では記録極性の変化が現われ難いことが分る。

つまり、請求項6の「有機材料層と上引層の界面形状が、基板の溝形状と同一となるように形成されていることを特徴とする多値記録可能な光記録媒体」が、多値記録を可能にする有機材料を用いた光記録媒体として好ましいことが確認された。

但し、各層の複素屈折率や、記録による各層の複素屈折率の変化、或いは記録マークの高さ、形状によって記録極性が変化する条件が変るため、有機材料層の表面形状がフラットとなるように形成されている場合を否定するものではない。

【0041】

【発明の効果】

本発明によれば、多値レベルの数を増やしながらも精度の高い多値記録が可能で、350〜500nm程度の青色レーザ領域にも適用可能な追記型光記録媒体、及び多値記録方法を提供できる。

【図面の簡単な説明】

【図1】従来の光記録媒体の層構成を示す図。

【図2】本発明の記録媒体で記録極性の異なる記録マークが形成されたことを示す図。

【図3】本発明の記録媒体でLow to High記録が行われた部分をAFMで観察した結果を示す図。

【図4】本発明の記録媒体でLow to High記録が行われた部分をAFMで観察した結果を示す別の図。

(a) 図3を二次元的に表した図

(b) 記録トラックの断面図(凹凸形状)

【図5】本発明の記録媒体でHigh to Low記録が行われた部分をAFMで観察した結果を示す図。

【図6】本発明の記録媒体でHigh to Low記録が行われた部分をAFMで観察した結果を示す別の図。

(a) 図5を二次元的に表した図

(b) 記録トラックの断面図(凹凸形状)

【図7】実施例2で用いた溝形状のパラメータを説明するための図。

【図8】本発明の層構成を示す図であり、有機材料層の1形成形態を説明するための図。

【図9】本発明の層構成を示す図であり、有機材料層の他の1形成形態を説明するための図。

【図10】有機材料層の形成形態と、記録マークの形成形態の一例を示す図。

【図11】有機材料層の形成形態と、記録マークの形成形態の他の一例を示す図。

【図12】有機材料層の形成形態と、記録マークの形成形態の他の一例を示す図。

【図13】有機材料層の形成形態と、記録マークの形成形態の他の一例を示す図。

【図14】有機材料層の形成形態と、記録マークの形成形態の他の一例を示す図。

【図15】有機材料層の形成形態と、記録マークの形成形態の他の一例を示す図。

【図16】有機材料層の形成形態と、記録マークの形成形態の他の一例を示す図。

【図17】有機材料層の形成形態と、記録マークの形成形態の他の一例を示す図。

【図18】有機材料の吸収係数の増加による記録原理を説明するための図。

【図19】有機材料の吸収係数の増加による記録原理を実現し得る有機材料層の特性を説明するための図。

【図20】有機材料の吸収係数の増加による記録原理を実現し得る有機材料層の特性を説明するための図。

【図21】有機材料層が図8のように形成され、グルーブ部に記録が行われた場合の再生信号を計算した結果を示す図。

【図22】有機材料層が図8のように形成され、ランド部に記録が行われた場合の再生信号を計算した結果を示す図。

【図23】有機材料層が図9のように形成され、グルーブ部に記録が行われた場合の再生信号を計算した結果を示す図。

【図24】有機材料層が図9のように形成され、ランド部に記録が行われた場合の再生信号を計算した結果を示す図。

【符号の説明】

A ランドの上面端部と、隣接するグルーブの該ランドに近い方の底面端部との幅

B ランドの上面端部と、隣接するグルーブの該ランドから遠い方の底面端部との幅

C ランドの上面端部と、隣接するランドの、前記ランドに近い方の上面端部との幅

D ランドの上面端部と、隣接するランドの、前記ランドから遠い方の上面端部との幅

ζ ランドの高さ(溝の深さ)[0001]

BACKGROUND OF THE INVENTION

The present invention relates to a write-once type optical recording medium capable of performing multilevel recording by changing recording polarity in addition to recording mark length and amplitude according to recording data, a recording principle thereof, and a multilevel recording method.

[0002]

[Prior art]

In recent years, optical recording media have been required to have larger capacity and higher density. As one method for realizing an increase in capacity and density of an optical recording medium, there is multi-value recording.

Multi-level recording means that information is recorded / reproduced in association with three or more values, and is distinguished from binary recording in which recording / reproduction is performed in association with binary values “0” or “1”. Concept. Details of multilevel recording are described in, for example, Japanese Patent Laid-Open No. 6-76399.

In this conventional example, in the mark edge type recording / reproducing method, multi-value information is recorded by shifting the position of the edge of the recording mark stepwise from the reference position corresponding to the recording data. In this mark edge type multi-value recording, the greater the number of edge position shifts (the number of stages), the more advantageous for multi-value recording, that is, higher density.

However, if an attempt is made to increase the number of shifts of the edge position with respect to a limited reference clock cycle, it is necessary to precisely control the edge formation.

On the other hand, it is not easy to control the edge position of the recording mark formed by laser light irradiation.

[0003]

As another conventional example, the optical recording / reproducing method described in Japanese Patent Application Laid-Open No. 8-287468 realizes multi-value recording by the pit position method instead of the mark edge method as in the conventional example. .

In this case, multi-level recording is performed by shifting the center position of the recording mark stepwise with respect to the edge of the reference clock.

Still other multi-value recording techniques include the following.

That is, a multi-value recording technique called SCIPER that shifts the edge of a pit corresponding to recording data in eight stages on the same read-only optical disk as a CD is, for example, “S. Kobayashi, JP De Kock, T. Horigome, H. Yamatsu and H. Oki, Tech. Dig. Of Optical Data Storage Conference, p. 130 (1994) ".

Although this technique has an advantage that the conventional disk structure can be used as it is, there is a problem that the signal processing circuit becomes very complicated.

[0004]

Further, an eight-level multilevel recording technique in which the pit depth is changed stepwise is disclosed in, for example, “S. Spielman, BV Johnson, GA McDermott, MP O'Neil, C.I. Pietrzyk, T. Shafaat, DK Warland and TL Wong, Proc. SPIE, 3109, p. 98 (1997).

This technique can suppress the complication of the signal processing circuit to some extent, but makes it difficult to manufacture a disk.

In addition, a quaternary recording technique for selectively causing magnetization reversal of each layer by introducing a plurality of magnetic recording films and switching the intensity of a recording magnetic field in a magneto-optical disk is, for example, “N. Saito, R. Sato, N. Kawamura and M. Kajiura, Jpn. J. Appl. Phys., 28, p. 343 (1989).

[0005]

In the magneto-optical disk, a four-value recording technique in which the magnetization reversal interval is changed stepwise by changing the period of the recording high-frequency magnetic field is, for example, “M. Arai and S. Kobayashi, Tech. Dig. Of”. Joint MORIS / ISOM, p. 32 (1997) ”.

In addition, in a phase change type optical disk, a multi-value recording technique in which the size of a recording mark is controlled by intensity modulation of a recording laser beam is described in, for example, “T. Ohta, K. Nishiuchi, K. Narumi, Y. Kitaoka, H. Ishibashi, N. Yamada and T. Kozaki, Jpn. J. Appl. Phys., 39, p. 770 (2000).

In a phase change type optical disc, a multi-value recording technique for performing 8-level recording by controlling a recording mark length by devising a recording pulse waveform using a dedicated phase change recording material is, for example, “MP. O'Neil and TL Wong, Tech.Dig.of Optical Data Storage Conference, p.170 (2000) ".

[0006]

[Problems to be solved by the invention]

To increase the density, it is necessary to increase the number of multi-levels. However, increasing the number of multi-levels makes it more difficult to judge multi-levels, so the playback reliability is greatly reduced. There is.

Conventionally, although a multi-value recording technique that can be applied to a read-only optical recording medium, a magneto-optical recording medium, or a phase change optical recording medium has been proposed, it is effective for a write-once optical recording medium using an organic material. Most multi-value recording techniques have not been proposed.

Therefore, the present invention solves the conventional problems as described above, is a multi-value recording technique effective for a write-once optical recording medium using an organic material, and highly accurate multi-value recording while increasing the number of multi-value levels. An object of the present invention is to provide a write-once optical recording medium that can be applied to a blue laser region of about 350 to 500 nm, a recording principle thereof, and a multi-value recording method.

[0007]

[Means for Solving the Problems]

The above problems are solved by the following inventions 1) to 11).

1) An organic material layer that does not have an absorption function with respect to light of a recording / reproducing wavelength when unrecorded is placed on the substrate with an undercoat layer having a large refractive index difference from the organic material layer. An optical recording medium having a layer structure sandwiched between the undercoat layer and the undercoat layer or the overcoat layer having a light absorption function, and can change the deformation direction and the position (type) of the deformation interface during recording. Thus, a multi-level recordable write-once optical recording medium, wherein a reproduction signal having a different recording polarity in addition to a difference in recording mark length and amplitude is obtained.

2) An organic material layer that does not have an absorption function with respect to light having a recording / reproducing wavelength when unrecorded is placed on the substrate with an undercoat layer having a large refractive index difference from the organic material layer. An optical recording medium having a layer structure sandwiched between an undercoat layer and an undercoat layer or an overcoat layer having a light absorption function, wherein the undercoat layer is changed from an organic material layer to a change in state of the organic material in the organic material layer. The recording principle of recording mark formation by the pressure on the substrate or the pressure from the organic material layer to the overcoating layer and the recording principle of recording mark formation by the stress relaxation of the undercoating layer or the overcoating layer or the thermal expansion of the substrate In this case, the deformation direction of the recording mark portion and the position (type) of the deformation interface can be changed, whereby a reproduction signal having a different recording polarity in addition to a difference in recording mark length and amplitude can be obtained. A write-once optical recording medium capable of recording values.

3) An unrecorded main absorption band exists on the substrate on the long wavelength side with respect to the recording / reproducing wavelength via an undercoat layer, and has an absorption function for light of the recording / reproducing wavelength when not recorded. An optical recording medium having a layer structure in which an organic material layer is sandwiched between an undercoat layer and an overcoat layer having a large refractive index difference from the organic material layer, and the undercoat layer or the overcoat layer has a light absorption function Thus, it is possible to change the deformation direction and the position (type) of the deformation interface during recording, and in this way, reproduction signals having different recording polarities in addition to differences in recording mark length and amplitude can be obtained. A write-once optical recording medium capable of recording values.

4) An unrecorded main absorption band exists on the substrate on the longer wavelength side with respect to the recording / reproducing wavelength via an undercoat layer, and has an absorption function for light of the recording / reproducing wavelength when not recorded. An optical recording medium having a layer structure in which an organic material layer is sandwiched between an undercoat layer and an overcoat layer having a large refractive index difference from the organic material layer, and the undercoat layer or the overcoat layer has a light absorption function The recording principle of recording mark formation by the pressure from the organic material layer to the undercoat layer or the pressure from the organic material layer to the undercoat layer accompanying the change in the state of the organic material in the organic material layer, Depending on the recording principle of recording mark formation by stress relaxation of the overcoat layer or thermal expansion of the substrate, the deformation direction of the recording mark portion and the position (type) of the deformation interface can be changed during recording, thereby the recording mark length And playback signals with different recording polarities in addition to amplitude differences A write-once optical recording medium capable of multi-value recording.

5) Recording / reproducing wavelength is 350nm more than 500nm Less than It is characterized by In any one of 1) to 4) Write-once type optical recording medium capable of multi-value recording as described.

6) The interface shape of the organic material layer and the overcoat layer is formed to be the same as the groove shape of the substrate. In any one of 1) to 5) Write-once type optical recording medium capable of multi-value recording as described.

7) An organic material layer that does not have an absorption function with respect to light of the recording / reproducing wavelength when unrecorded is placed on the substrate with an undercoat layer having a large refractive index difference from the organic material layer. For a write-once type optical recording medium that has a layer structure sandwiched between the underlayer and the undercoat layer or the overcoat layer has a light absorption function and is capable of multi-value recording, the direction of deformation and the position of the deformation interface (type) ) To obtain a reproduction signal having a different recording polarity in addition to a difference in recording mark length and amplitude.

8) An organic material layer that does not have an absorption function with respect to light of the recording / reproducing wavelength when not recorded is placed on the substrate with an undercoat layer having a large refractive index difference from the organic material layer. An organic layer with a change in the state of the organic material in the organic material layer with respect to the write-once type optical recording medium having a layer structure sandwiched between the underlayer and the undercoat layer or the overcoat layer having a light absorption function. Recording principle of recording mark formation by pressure from material layer to undercoat layer or pressure from organic material layer to overcoat layer, and recording mark formation by stress relaxation of undercoat layer or overcoat layer, or thermal expansion of substrate According to the recording principle, during recording, the deformation direction of the recording mark portion and the position (type) of the deformation interface are changed so that a reproduction signal having a different recording polarity in addition to the difference in recording mark length and amplitude can be obtained. A multi-value recording method characterized by that.

9) An unrecorded main absorption band exists on the substrate on the long wavelength side with respect to the recording / reproducing wavelength via an undercoat layer, and has an absorption function for light of the recording / reproducing wavelength when not recorded. Has a layer structure in which an organic material layer is sandwiched between an undercoat layer and an overcoat layer having a large refractive index difference from the organic material layer, and the undercoat layer or the overcoat layer has a light absorption function and can perform multi-value recording By changing the deformation direction and the position (type) of the deformation interface for a recordable optical recording medium, it is possible to obtain a reproduction signal having a different recording polarity in addition to a difference in recording mark length and amplitude. A multi-value recording method characterized by that.

10) The main absorption band at the time of unrecording exists on the substrate on the long wavelength side with respect to the recording / reproducing wavelength via the undercoat layer, and has an absorption function for the light at the recording / reproducing wavelength when not recorded. Has a layer structure in which an organic material layer is sandwiched between an undercoat layer and an overcoat layer having a large refractive index difference from the organic material layer, and the undercoat layer or the overcoat layer has a light absorption function and can perform multi-value recording Recording principle of recording mark formation on a write-once optical recording medium by pressure from the organic material layer to the undercoat layer or pressure from the organic material layer to the overcoat layer as the state of the organic material in the organic material layer changes And the recording principle of recording mark formation by the stress relaxation of the undercoat layer and the overcoat layer or the thermal expansion of the substrate, the deformation direction of the recording mark portion and the position (type) of the deformation interface are changed during recording, thereby Reproduced signals with different recording polarities in addition to recording mark length and amplitude A multi-value recording method characterized by comprising:

11) Recording / reproducing wavelength is 350 nm more than 500nm Less than It is characterized by 7) to any one of 10) The multi-value recording method described.

[0008]

Hereinafter, the present invention will be described in detail.

(1) Summary (features) of the present invention

In the present invention, by performing multi-value recording by changing the deformation direction and the position (type) of the deformation interface during recording, it is possible to obtain a reproduction signal having a different recording polarity in addition to a difference in recording mark length and amplitude. . In the present invention, the recording principle of recording mark formation by the pressure from the organic material layer to the undercoat layer or the pressure from the organic material layer to the overcoat layer accompanying the change in the state of the organic material in the organic material layer, Multi-level recording can be performed by using the recording principle of recording mark formation by stress relaxation of the drawing layer and the overcoat layer or thermal expansion of the substrate, and controlling this.

In other words, since the recording polarity is the same in the past (either so-called High to Low recording or Low to High recording), the number of multi-levels is increased. However, in the present invention, not only the recording mark length and the amplitude but also the reproduction signal having a different recording polarity is obtained. Therefore, a more reliable write once optical recording medium can be provided.

In the present invention, the “change in the state of the organic material” refers to melting, sublimation, decomposition, explosion, structural change, etc., but usually decomposition and explosion are the main, and in this case, it is the only requirement for the organic material. This is because the thermal decomposition characteristics (decomposition temperature, explosiveness, existence of a clear decomposition threshold, decomposition speed, decomposition amount, etc.) are excellent.

[0009]

(2) Explanation of the expression “change the deformation direction and the position (type) of the deformation interface”

The expression “changing the deformation direction and the position (type) of the deformation interface” in the present invention will be described.

The deformation direction means whether the deformation occurs in a convex shape or a concave shape when viewed from a certain reference side.

Also, the position (type) of the deformation interface refers to which layer interface has uneven deformation. The deformation interface includes the interface between the substrate and the undercoat layer, the interface between the undercoat layer and the organic material layer, the interface between the organic material layer and the overcoat layer, the overcoat layer and its upper layer (protective layer, cover layer, air layer, etc.) There is an interface with.

In the present invention, the deformation interface may be single or a plurality of the deformation interfaces may be combined. In short, the recording polarity and the contrast of the recording mark are changed according to the combination of the deformation interfaces, the deformation direction and the deformation amount of each interface.

In the present invention, the combination of the deformation interfaces and the deformation amount of each interface are controlled, and these can be changed depending on the film thickness of each layer, the magnitude of the absorption coefficient with respect to the recording wavelength, the thermal conductivity, and the hardness. The simplest is a method of controlling the combination of deformation interfaces and the deformation amount of each interface by controlling the recording power.

[0010]

In the present invention, the deformation direction of each interface is controlled, which is realized by giving the optical recording medium a different recording principle.

That is, the recording principle of recording mark formation by the pressure from the organic material layer to the undercoat layer or the pressure from the organic material layer to the overcoat layer accompanying the change in the state of the organic material in the organic material layer, The deformation direction of each interface is controlled by combining the recording principle of recording mark formation by stress relaxation of the drawing layer or thermal expansion of the substrate.

For example, by using the recording principle of recording mark formation by pressure from the organic material layer to the undercoat layer accompanying the state change of the organic material in the organic material layer, the substrate or the undercoat layer can be seen from the front side when viewed from the substrate side. (It is expressed as a concave shape here). Further, by using the recording principle of recording mark formation by stress relaxation of the undercoat layer or thermal expansion of the substrate, the substrate and the undercoat layer can be deformed to the back side when viewed from the substrate side ( This is expressed as a convex shape).

An important feature of the present invention is that the direction of deformation is determined in one direction in the conventional recording principle using deformation, but in the present invention, the recording principle capable of making the direction of deformation variable is used.

[0011]

(3) Reason why “the organic material layer is sandwiched between the undercoat layer and the overcoat layer having a large refractive index difference from the organic material layer”

The present invention is characterized by having a “structure in which an organic material layer is sandwiched between an undercoat layer and an overcoat layer having a large refractive index difference from the organic material layer”.

With this structure, it is possible to improve the reflectance and signal quality, or the recording polarity in addition to the recording mark length and amplitude depending on the deformation direction and the position (type) of the deformation interface caused by recording. However, different reproduction signals can be generated efficiently.

The refractive index difference between the organic material layer, the undercoat layer, and the overcoat layer is usually 0.5 or more.

[0012]

(4) Requirements for organic materials used in organic material layers

In the present invention, in order to make the recording polarity variable, the deformation direction (convex deformation or concave deformation) of the recording mark is controlled.

In forming a recording mark by thermal expansion of a substrate, which is the basic deformation principle of a conventional optical recording medium (see FIG. 1), the substrate is always deformed in the direction of the organic material layer and not in the opposite direction. This is because the force due to the thermal expansion of the substrate is sufficiently large, and there is no force that obstructs this or a large force against it.

Therefore, the present inventor examined a means for generating a force in the direction opposite to the deformation direction due to the thermal expansion of the substrate, and as a result, the force accompanying the state change of the organic material (particularly decomposition / explosion force). Was found to be available.

However, in order to effectively use the force accompanying this state change, it is necessary to make the organic material in the vicinity of the interface between the organic material layer and the adjacent layer most likely to undergo the state change. In the configuration, since the central portion of the organic material layer has the highest temperature, the organic material in the vicinity of the interface between the organic material layer and the adjacent layer does not change sufficiently.

Therefore, in the present invention, in order to make the organic material in the vicinity of the interface between the organic material layer and the adjacent layer most likely to undergo a state change, a light absorption layer (a layer having a light absorption function) is adjacent to the organic material layer. (Slipping layer or overcoating layer).

[0013]

Since the absorption coefficient of the light absorption layer is set sufficiently larger than the absorption coefficient of the organic material layer (the light absorption layer has a light absorption function, the organic material layer has a light Naturally, it does not have an absorption function, so the organic material near the light-absorbing layer is at the highest temperature, and recording with the direction of deformation reversed can be performed by the force accompanying the state change of the organic material. It becomes.

By providing this light absorption layer, it is possible to separate the light absorption function from the conventional organic material layer having the functions of the recording layer and the light absorption layer.

As a result, severe optical constant conditions imposed on the organic material layer are relaxed, and the write-once type optical recording medium of the present invention can easily record even in the blue laser wavelength region of about 350 to 500 nm (conventional). In this layer configuration, since there are strict optical constant conditions in the organic material layer, there is almost no organic material that can cope with the blue laser wavelength region, and it is difficult to realize a write-once optical recording medium using the organic material. )

Further, in a write-once optical recording medium using a conventional organic material, it is necessary to generate heat in the organic material layer, so that the organic material layer cannot be thinned and a deep groove (for example, 150 to 180 nm) is required. However, the recording principle of the present invention makes it possible to reduce the thickness of the organic material, and it is possible to use a substrate having a shallow groove with excellent moldability. Therefore, it is possible to provide a highly reliable write once optical recording medium. Become.

[0014]

“Organic material layer in which the main absorption band at the time of unrecording exists on the longer wavelength side with respect to the recording / reproducing wavelength and does not have an absorption function for light of the recording / reproducing wavelength” used in the present invention, or “unrecorded In the expression “sometimes an organic material layer that does not have an absorption function for light at the recording / reproducing wavelength”, “it does not have an absorption function for light at the recording / reproducing wavelength” This means that the temperature does not reach the temperature at which the adjacent layer of the material layer is deformed or the state of the organic material itself changes (that is, it does not substantially perform the absorption function required as the light absorption layer). . Therefore, specifically, the case where the absorption coefficient of the organic material is small or the case where the film thickness is thin is pointed out.

In addition, “an organic material layer in which the main absorption band at the time of unrecording exists on the long wavelength side with respect to the recording / reproducing wavelength and does not have an absorption function for light at the recording / reproducing wavelength” or “recording / reproducing at the time of unrecorded” The reason why the “organic material layer that does not have an absorption function with respect to light of a wavelength” is an important component of the optical recording medium of the present invention is that the present invention has a light absorption function that is used in a conventional write-once optical recording medium. This is because, by using an undercoat layer or an overcoat layer having a relatively large absorption coefficient instead of the organic material, the absorption function in the organic material layer can be reduced to improve the reflectance.

[0015]

Further, as described above, in addition to the difference in recording mark length and amplitude, the recording polarity differs depending on the improvement in reflectivity, the improvement in signal quality, or the difference in deformation direction and deformation interface position (type) caused by recording. In order to generate a signal efficiently, a structure in which the organic material layer is sandwiched between an undercoat layer and an overcoat layer having a large refractive index difference from the organic material layer is suitable. For this purpose, the refractive index of the organic material layer is suitable. It is more advantageous to select a material for the undercoat layer and the overcoat layer if the value is set low.

This is because, for example, a substrate / undercoat layer (light absorption layer) / organic material layer / overcoat layer (reflective layer) can be cited as a preferred layer structure of the present invention. The refractive index of the layer is usually very small at about 0.1, and the refractive index of the light absorption layer is, for example, about 2.0 to 4.0, and the difference in refractive index between the organic material layer and the light absorption layer tends to be small. . Therefore, it is important to increase this difference in refractive index. For that purpose, if the refractive index of the organic material layer is set low, the refractive index difference between the organic material layer and the light absorption layer is increased, and the light absorption layer This is because the range of choices can be expanded.

[0016]

Therefore, “an organic material layer in which the main absorption band at the time of unrecording exists on the longer wavelength side with respect to the recording / reproducing wavelength and does not have an absorption function for light at the recording / reproducing wavelength” or “recording / reproducing at the time of unrecording” It is possible to lower the refractive index of the organic material layer by making the organic material layer having no absorption function for light of a wavelength, that is, by greatly shifting the maximum absorption band of the organic material and the recording / reproducing wavelength. Become.

In addition, when the recording / reproducing wavelength is 500 nm or more, for example, in the vicinity of 650 nm which is the recording / reproducing wavelength of the DVD-based optical recording medium or near 780 nm which is the recording / reproducing wavelength of the CD-based optical recording medium, It is sufficient to satisfy the “organic material layer that does not have an absorption function with respect to light of the recording / reproducing wavelength”, and the magnitude relationship between the wavelength of the main absorption band of the organic material and the recording / reproducing wavelength hardly poses a problem.

[0017]

However, when the recording / reproducing wavelength is set to a blue laser region of about 350 to 500 nm, for example, near 400 nm, the main absorption band when not recorded exists on the short wavelength side with respect to the recording / reproducing wavelength, and the recording / reproducing wavelength In a state that does not have an absorption function for light, it means that the molecular size of the organic material is very small, and this is subtracted from the organic material layer as the state of the organic material changes. This means that the pressure on the layer or the pressure from the organic material layer to the overcoat layer is significantly reduced, which is not preferable for the write-once type optical recording medium using the recording principle of the present invention.

Therefore, when the recording / reproducing wavelength is set to 350 to 500 nm, for example, in the vicinity of 400 nm, the pressure from the organic material layer to the undercoat layer or the pressure from the organic material layer to the overcoat layer accompanying the state change of the organic material is set. In order to generate sufficiently, an organic material with a large molecular skeleton is selected, the main absorption band when not recorded exists on the long wavelength side with respect to the recording / reproducing wavelength, and the light absorption function with respect to the light of the recording / reproducing wavelength It is preferable to use an organic material layer that does not include

[0018]

(5) Reason for forming the interface shape of the organic material layer and the overcoat layer to be the same as the groove shape of the substrate

The thickness of the organic material layer is arbitrary, and the formation form is also arbitrary.

The formation form refers to the shape of the surface shape of the organic material layer (interface shape between the organic material layer and the overcoat layer). For example, the surface shape of the organic material layer is the same as the substrate shape (see FIG. 8) or the surface shape of the organic material layer may be flat (see FIG. 9).

In the present invention, the surface shape of the organic material layer has been found to be important as one of the conditions where the change in recording polarity is relatively likely to occur. The surface shape of the organic material layer is the same as the substrate shape ( In the case of (see FIG. 8), it has been found that the change in recording polarity is likely to occur (the condition for changing the recording polarity is relaxed).

However, here, the meaning of the phrase “form to be the same” means

Not only the case where they are literally the same, but also when the interface shape of the organic material layer and the overcoat layer is formed substantially following the groove shape of the substrate, that is, each layer is formed on the substrate by a normal film forming method such as sputtering. In this case, it is assumed that each layer is formed substantially following the groove shape of the substrate, although there is some variation in film thickness.

The write-once type optical recording medium of the present invention may be provided with various layers such as a conventionally known intermediate layer and back coat layer in addition to the above layers.

[0019]

(6) Combination of other recording principles

In the present invention, in addition to the recording principle described above, a state change occurs in the organic material layer due to heat generation of the undercoat layer or the overcoat layer due to laser light irradiation, and recording is performed by increasing the absorption coefficient at the recording / reproducing wavelength due to the state change. The principle may be used in combination.

However, in this recording principle, unless the refractive index or film thickness of the organic material layer changes significantly, the recording polarity becomes High to Low. Therefore, this recording principle is used in combination with the recording principle by the deformation described above. Only when High to Low.

The recording principle by increasing the absorption coefficient of the organic material layer will be described with reference to FIGS.

When an organic material having an unrecorded absorption spectrum as shown in FIG. 18 is selected and this organic material changes its state (especially decomposition or explosion), the absorption of the molecules or molecular groups constituting the organic material by decomposition is performed. Occurs. Since this absorption is usually shorter than the absorption of the organic material before decomposition or explosion, the absorption coefficient on the shorter wavelength side of the large absorption band of the original organic material increases (see the absorption spectrum in the recorded state). ). If the range in which the change in the absorption wavelength on the short wavelength side is large and the recording / reproducing wavelength (for example, the position of the arrow in the figure) are combined, the absorption coefficient at the recording / reproducing wavelength after recording can be increased. Can be generated.

[0020]

To explain this recording principle in more detail, the organic material used in the present invention is an organic material in which a small molecule or molecular group is bonded, or a complex or aggregate is formed to form a large conjugated system, It has a large absorption band on the longer wavelength side than the intrinsic absorption wavelength (corresponding to absorption spectra A and B in FIG. 19) possessed by the molecule or molecular group, and the intrinsic absorption band possessed by each molecule or molecular group Has an absorption spectrum that disappears or is attenuated (corresponding to the absorption spectrum C in FIG. 20).

For such an organic material, when λ1 as shown in FIG. 20 is selected as the recording / reproducing wavelength, a large molecule was formed by decomposition, explosion, etc. from a state where absorption at λ1 was small when unrecorded. Intrinsic absorption of molecules and molecular groups increases (see FIG. 19), absorption at λ1 also increases, and a recording portion can be formed by a change in absorption coefficient.

Accordingly, a molecule in which only a small molecule or molecular group is bonded and a conjugated system does not form a spread is in a state as shown in FIG. 20, that is, the intrinsic absorption that the molecule or molecular group has. Since a state in which the band disappears or attenuates and a new large sharp absorption band is formed is not realized, the change in the absorption coefficient before and after recording does not increase, and a recording pit cannot be formed.

[0021]

(7) Material of each layer

As a material of the substrate, there are special restrictions as long as it has excellent thermal and mechanical properties, and has excellent light transmission characteristics when recording / reproducing is performed from the substrate side (through the substrate). Absent.

Specific examples include polycarbonate, polymethyl methacrylate, amorphous polyolefin, cellulose acetate, polyethylene terephthalate and the like, and polycarbonate and amorphous polyolefin are preferred.

The thickness of the substrate varies depending on the application and is not particularly limited.

[0022]

A material having a relatively low thermal conductivity is suitable for the undercoat layer or the overcoat layer that functions as a light absorption layer that absorbs light and generates heat. The reason for selecting a material having a relatively low thermal conductivity is to efficiently deform the interface of each layer (with low recording power), and to change the state of the organic material efficiently (with low recording power). It is.

Here, the relatively low thermal conductivity means that the thermal conductivity reaches such a temperature that the state of the organic material is locally changed by recording.

From the above points, it is preferable to use ceramics such as SiC, semimetals such as Si, metals such as Ge, or a mixture thereof for the undercoat layer and the overcoat layer that function as the light absorption layer. Further, the thickness of the undercoat layer and the overcoat layer is usually 20 to 500 mm.

[0023]

As ceramics used as the material for the undercoat layer and the overcoat layer, Al 2 O 3 , MgO, BeO, ZrO 2 , UO 2 , ThO 2 Simple oxide based oxides such as SiO 2 2MgO · SiO 2 , MgO / SiO 2 , CaO / SiO 3 , ZrO 2 ・ SiO 2 3Al 2 O 3 ・ 2SiO 2 2MgO · 2Al 2 O 3 ・ 5SiO 2 , Li 2 O ・ Al 2 O 3 ・ 4SiO 2 Silicate oxides such as Al 2 TiO 5 , MgAl 2 O 4 , Ca 10 (PO 4 ) 6 (OH) 2 , BaTiO 3 LiNbO 3 , PZT [Pb (Zr, Ti) O 3 ], PLZT [(Pb, La) (Zr, Ti) O 3 ], Double oxide oxides such as ferrite; Si 3 N 4 , Si 6-Z Al Z O Z N 8-Z Non-oxides of nitrides such as AlN, BN, TiN; SiC, B 4 Non-oxides of carbides such as C, TiC and WC; LaB 6 TiB 2 , ZrB 2 Non-oxides of borides such as CdS, MoS 2 Sulfide non-oxide such as MoSi 2 Silicide-based non-oxides such as amorphous carbon, graphite, diamond and other carbon-based non-oxides can be used.

As the metal, Au, Al, Ag, Cu, Pd, Pt, Ti, Ta, Cr, Ni, Fe, and alloys thereof can be used.

[0024]

As the organic material used for the organic material layer, a so-called dye is preferable. In order to sufficiently deform the undercoat layer and the overcoat layer, a dye having a high sublimation property or decomposition / explosive property, or a dye into which a substituent having a high sublimation property or decomposition / explosive property is introduced is preferable.

In order to ensure high decomposition and explosive properties, an organic material having a large molecular skeleton is preferable. Further, a dye that causes a volume change due to a structural change can also be used.

The dyes that satisfy the above requirements include polymethine dyes, naphthalocyanine series, phthalocyanine series, squarylium series, croconium series, pyrylium series, naphthoquinone series, anthraquinone (indanthrene) series, xanthene series, triphenylmethane series, and azulene series. , Tetrahydrocholine-based, phenanthrene-based, triphenothiazine-based dyes, metal complex compounds, and the like.

The film thickness of the dye layer is 100 to 10 μm, preferably 100 to 2000 mm.

[0025]

The dye layer can be formed by ordinary means such as vapor deposition, sputtering, CVD, and solvent coating. In the case of using the coating method, the above-described dye or the like can be dissolved in an organic solvent, and the coating can be performed by a conventional coating method such as spraying, roller coating, dipping, or spin coating.

As the organic solvent to be used, alcohols such as methanol, ethanol and isopropanol; ketones such as acetone, methyl ethyl ketone and cyclohexanone; amides such as N, N-dimethylacetamide and N, N-dimethylformamide; sulfoxide such as dimethyl sulfoxide Ethers such as tetrahydrofuran, dioxane, diethyl ether and ethylene glycol monomethyl ether; esters such as methyl acetate and ethyl acetate; aliphatic halogenated carbons such as chloroform, methylene chloride, dichloroethane, carbon tetrachloride and trichloroethane; Aromatics such as benzene, xylene, monochlorobenzene and dichlorobenzene; cellosolves such as methoxyethanol and ethoxyethanol; hexane, pentane, Cyclohexane, and hydrocarbons such as methylcyclohexane.

[0026]

As the undercoating layer or the overcoating layer that does not function as a light absorbing layer, a metal or a ceramic is preferable.

For the metal or ceramic, it is preferable to use a material having a refractive index difference from the organic material layer in order to improve the reflectance or the recording / reproducing characteristics.

Of the undercoat layer and the overcoat layer, when the layer on the near side with respect to the incident laser beam has a light absorption capability, in order to improve the reflectance or the recording / reproduction characteristics, The side layer is preferably a metal.

On the other hand, if the back layer of the undercoat layer and the overcoat layer has a light absorption capability with respect to the incident laser beam, the incident laser beam is used to improve the reflectance or the recording / reproduction characteristics. On the other hand, the near layer is preferably a ceramic having a small absorption coefficient (about 0.02 or less) with respect to the recording / reproducing wavelength.

As the metal, a metal selected from the group consisting of Au, Al, Cu, Cr, Ag, Ti and alloys thereof is preferable, and ceramics having a small absorption coefficient with respect to the recording / reproducing wavelength (here, near the blue region). Is the above-mentioned ceramics or ZnS · SiO 2 Etc. are preferred.

These materials are generally formed to a thickness of 50 to 5000 mm, preferably 50 to 3000 mm, by vacuum deposition or sputtering.

[0027]

【Example】

EXAMPLES Hereinafter, although an Example and a comparative example demonstrate this invention concretely, this invention is not limited at all by these Examples.

[0028]

Example 1

(Embodiment for clarifying that the write-once type optical recording medium of the present invention can provide a reproduction signal having a different recording polarity in addition to a difference in recording mark length and amplitude, and confirming the recording principle)

An undercoating layer (SiC) having a thickness of 10 nm functioning as a light absorption layer is provided by sputtering on a polycarbonate substrate having a guide groove with a groove depth of 50 nm, and an organic material represented by the following [Chemical Formula 1] is provided thereon. Was formed by spin coating (film thickness of about 60 nm), and an overcoat layer (Ag) with a film thickness of 100 nm was further provided thereon to produce an optical recording medium.

[Chemical 1]

[0029]

Using the optical disk evaluation apparatus DDU-1000 (wavelength: 405 nm, NA: 0.65) manufactured by Pulstec Industrial Co., Ltd. for the above optical recording medium, the recording power during recording for a certain time under the following recording conditions Recording was performed by switching between 6.0 (mW) and 10.0 (mW) at intervals.

<Recording conditions>

Recording linear density: 1T = 0.0917 (μm)

Recording linear velocity: 6.0 (m / s)

Recording strategy: Basic strategy

T top -T mp = 1.40-0.75 (T)

Recording power: 6.0 (mW), 10.0 (mW)

Recording pattern: 8-16 modulation signal

As a result, as shown in FIG. 2, it can be confirmed that when the recording power is 6.0 (mW), Low to High recording can be performed and when the recording power is 10.0 (mW), High to Low recording can be performed. It was.

[0030]

Next, in order to confirm whether or not this recording was performed based on the recording principle as described above, the deformation state of the interface between the SiC and the organic material layer was measured by an AFM (Atomic Force Microscope).

FIG. 3 shows a three-dimensional representation of the deformation state of the interface between SiC and the organic material layer in the Low to High recording portion generated when the recording power is 6.0 (mW) (the lower side is the substrate). In FIG. 3, the height is represented by shading, where the light color portion is high and the dark color portion is low.

FIG. 4 is a diagram (a) representing the two-dimensional representation of FIG. 3 and a diagram (b) representing a cross-sectional view (uneven shape) of the recording track.

From the results shown in these figures, it is found that the interface between SiC and the organic material layer is deformed (concavely deformed) toward the substrate side in the Low to High recording portion generated when the recording power is 6.0 (mW). It could be confirmed.

[0031]

On the other hand, FIG. 5 shows a three-dimensional representation of the deformation state of the interface between SiC and the organic material layer in the High to Low recording portion generated when the recording power is 10.0 (mW) (the lower side is the substrate). . In FIG. 5, the height is represented by shading, where the light color portion is high and the dark color portion is low.

6A and 6B are a two-dimensional view of FIG. 5A and a cross-sectional view (uneven shape) of the recording track.

From the results shown in these figures, in the High to Low recording portion generated when the recording power is 10.0 (mW), the interface between the SiC and the organic material layer is deformed in the direction opposite to the substrate side (convex deformation). It was confirmed that

[0032]

From the above results, it becomes clear that the recordable optical recording medium of the present invention can be recorded by changing the recording polarity in addition to the recording mark length and amplitude, and this recording polarity is at least of the interface shape between SiC and the organic material layer. It was confirmed that it was caused by the difference in deformation direction.

In this embodiment, recording is performed on the land portion in order to make the AFM image easy to see. However, the present invention is not limited to land recording.

Moreover, although the interface shape of SiC and an organic material layer was measured from the ease of measurement of a deformation | transformation shape, the other interface may be deform | transforming simultaneously.

Furthermore, in the conventional optical recording medium using an organic material, since it was necessary to generate heat in the organic material layer, the organic material layer could not be thinned, and a deep groove (for example, 150 to 180 nm) was required. The recording principle of the present invention makes it possible to reduce the thickness of the organic material, and it has been confirmed that a substrate having a very shallow groove of 50 nm can be applied. This is a great advantage in producing a highly reliable optical recording medium.

[0033]

Comparative Example 1

The same experiment as in Example 1 was performed except that polymethyl methacrylate was used instead of the organic material in Example 1.

As a result, the portion recorded at 6.0 (mW) and the portion recorded at 10.0 (mW) have the same recording polarity, and the interface between the SiC and the polymer layer is the same as in FIGS. It was deformed in the opposite direction (convex deformation) to the substrate.

As a result, the phenomenon in which the interface between the SiC and the organic material layer is deformed (concave deformation) toward the substrate side in Example 1 is due to the action of the organic material, and the state change (decomposition / explosion) of the organic material is caused by the concave deformation. It was proved that it contributed to.

[0034]

Example 2

Actually, it is very difficult to accurately measure the deformation direction of the recording portion and the position (type) of the deformation interface (in Example 1, only the interface state between the undercoat layer and the organic material layer was evaluated). In this example, it is proved that a reproduction signal having a different recording polarity in addition to a difference in recording mark length and amplitude can be obtained by changing the deformation direction and the position (type) of the deformation interface by optical simulation.

Under the following calculation conditions, the recording conditions were changed as in the following (i) to (iv) to calculate how the reproduction signal changes.

(I) Recording part (land part or groove part)

(Ii) Formation state of the organic material layer [the surface shape of the organic material layer is the same as the substrate shape (see FIG. 8), or the surface shape of the organic material layer is flat (see FIG. 9))

(Iii) Recording mark forming interface (only the interface between the undercoat layer and the organic material layer is deformed (see FIGS. 10, 11, 14, and 15), or the interface between the undercoat layer / organic material layer and the organic material layer / overcoating) Layer interface is deformed (see FIGS. 12, 13, 16, and 17)

(Iv) Deformation direction of recording mark [concave deformation toward the substrate (see FIGS. 14 to 17) or convex deformation toward the overcoat layer (see FIGS. 10 to 13)]

[0035]

<Details of calculation conditions>

Hereinafter, the length and size are expressed in units of the recording / reproducing wavelength λ.

-Beam shape: Gaussian distribution

Radius with

Objective lens aperture radius: 3000λ

Objective lens NA (numerical aperture): 0.60

Objective lens focal length: 5000λ

Groove shape [A, B, C, D, ζ (see FIG. 7)]: (0.2λ, 0.8λ, 1.0λ, 1.8525λ, 0.1375λ)

・ Substrate refractive index: 1.60 (substrate side incidence)

Undercoat layer complex refractive index: 2.810-i0.561, film thickness = 0.025λ

Organic material layer complex refractive index: 1.500-i0.050, film thickness = 0.150λ

・ Upper layer complex refractive index: 0.1078-i2.0495, film thickness = 0.250λ

・ Detector: 4-section PD

Detector radius (x direction, y direction): 3000λ, 3000λ

Recording mark length, width, height: 1.0λ, 0.60λ, ± 0.10λ

[0036]

The calculation results are as shown in FIGS.

FIG. 21 shows a case where recording is performed on a groove, and the formation state of the organic material layer is a result when the surface shape of the organic material layer is formed to be the same as the substrate shape as shown in FIG. .

The height of the recording portion was ± 0.10λ (when the recording / reproducing wavelength is 400 nm, the height is ± 40 nm).

The legend “+40 nm-0, 4” indicates that the recording part is FIG. 16, the legend “−40 nm-0, 4” indicates that the recording part is FIG. 12, and the legend “+40 nm-0, 2” The legend “−40 nm−0, 2” indicates that the recording unit is shown in FIG. 10.

In the above drawings, the state recorded in the groove portion is shown, but also in the land portion, the deformation direction of the recording portion and the position (type) of the deformation interface are the same.

[0037]

FIG. 22 shows the result when recording is performed on a land, and the organic material layer is formed so that the surface shape of the organic material layer is the same as the substrate shape as shown in FIG. .

The height of the recording portion was ± 0.10λ (when the recording / reproducing wavelength is 400 nm, the height is ± 40 nm).

The legend “+40 nm-0, 4” indicates that the recording part is FIG. 16, the legend “−40 nm-0, 4” indicates that the recording part is FIG. 12, and the legend “+40 nm-0, 2” The legend “−40 nm−0, 2” indicates that the recording unit is shown in FIG. 10.

[0038]

FIG. 23 shows a result of recording in the groove, and the organic material layer is formed in a state where the surface shape of the organic material layer is flat as shown in FIG.

The height of the recording portion was ± 0.10λ (when the recording / reproducing wavelength is 400 nm, the height is ± 40 nm).

The legend “+40 nm-0, 4” indicates that the recording portion is FIG. 17, the legend “−40 nm-0, 4” indicates that the recording portion is FIG. 13, and the legend “+40 nm-0, 2” indicates The legend “−40 nm−0, 2” indicates that the recording unit is FIG. 11.

In the above drawings, the state recorded in the groove portion is shown, but also in the land portion, the deformation direction of the recording portion and the position (type) of the deformation interface are the same.

[0039]

FIG. 24 shows the result when recording is performed on a land, and the organic material layer is formed so that the surface shape of the organic material layer is flat as shown in FIG.

The height of the recording portion was ± 0.10λ (when the recording / reproducing wavelength is 400 nm, the height is ± 40 nm).

The legend “+40 nm-0, 4” indicates that the recording portion is FIG. 17, the legend “−40 nm-0, 4” indicates that the recording portion is FIG. 13, and the legend “+40 nm-0, 2” indicates The legend “−40 nm−0, 2” indicates that the recording unit is FIG. 11.

[0040]

The results shown in FIGS. 21 to 24 prove that the idea that the recording polarity can be controlled by changing the deformation direction of the recording mark and the position (type) of the deformation interface is theoretically correct.

From the results shown in FIG. 24, when the organic material layer is formed so that the surface shape of the organic material layer is flat as shown in FIG. It turns out that change is difficult to appear.

In other words, the “multi-level recordable optical recording medium characterized in that the interface shape between the organic material layer and the overcoat layer is the same as the groove shape of the substrate” in

However, since the condition for changing the recording polarity depends on the complex refractive index of each layer, the change of the complex refractive index of each layer due to recording, or the height and shape of the recording mark, the surface shape of the organic material layer should be flat. It does not deny the case where it is formed.

[0041]

【The invention's effect】

According to the present invention, there is provided a write-once type optical recording medium and a multi-value recording method capable of high-precision multi-value recording while increasing the number of multi-value levels and applicable to a blue laser region of about 350 to 500 nm. Can be provided.

[Brief description of the drawings]

FIG. 1 is a diagram showing a layer structure of a conventional optical recording medium.

FIG. 2 is a diagram showing that recording marks having different recording polarities are formed on the recording medium of the present invention.

FIG. 3 is a view showing a result of observing a portion where Low to High recording is performed on the recording medium of the present invention by AFM.

FIG. 4 is another diagram showing a result of observing a portion where Low to High recording is performed on the recording medium of the present invention by AFM.

(A) A two-dimensional representation of FIG.

(B) Cross section of recording track (uneven shape)

FIG. 5 is a view showing a result of observing a portion where High to Low recording is performed on the recording medium of the present invention by AFM.

FIG. 6 is another diagram showing a result of observing a portion where High to Low recording is performed on the recording medium of the present invention by AFM.

(A) A two-dimensional representation of FIG.

(B) Cross section of recording track (uneven shape)

7 is a diagram for explaining parameters of a groove shape used in Example 2. FIG.