JP2020040407A5 - - Google Patents

Download PDFInfo

- Publication number

- JP2020040407A5 JP2020040407A5 JP2019201637A JP2019201637A JP2020040407A5 JP 2020040407 A5 JP2020040407 A5 JP 2020040407A5 JP 2019201637 A JP2019201637 A JP 2019201637A JP 2019201637 A JP2019201637 A JP 2019201637A JP 2020040407 A5 JP2020040407 A5 JP 2020040407A5

- Authority

- JP

- Japan

- Prior art keywords

- composition

- model

- group

- materials according

- ethylenically unsaturated

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Granted

Links

Description

本発明のモデル材用組成物におけるオリゴマー(C)の含有量は、モデル材用組成物に含まれる重合性化合物の総質量に対して、好ましくは1〜30質量%であり、より好ましくは5質量%以上であり、さらに好ましくは10質量%以上であり、より好ましくは25質量%以下であり、さらに好ましくは23質量%以下である。オリゴマー(C)の含有量が上記上限下限の範囲内にあると、モデル材用組成物の粘度を適度な範囲に維持したまま、得られるモデル材の破断強度を高め、適度な靱性を有し、曲げても割れにくい光造形品を得ることができる。 The content of the oligomer (C) in the composition for model material of the present invention is preferably 1 to 30% by mass, more preferably 5% by mass based on the total mass of the polymerizable compounds contained in the composition for model material. It is at least mass%, more preferably at least 10 mass%, more preferably at most 25 mass % , further preferably at most 23 mass % . When the content of the oligomer (C) is within the range of the above upper and lower limits, the breaking strength of the obtained model material is increased while maintaining the viscosity of the model material composition within an appropriate range, and the model material has appropriate toughness. Therefore, it is possible to obtain a stereolithography product that is hard to break even when bent.

本発明のモデル材用組成物の表面張力は、好ましくは24〜30mN/mであり、より好ましくは24.5mN/m以上であり、さらに好ましくは25mN/m以上であり、より好ましくは29.5mN/m以下であり、さらに好ましくは29mN/m以下である。表面張力が上記範囲内であると、マテリアルジェットの高速吐出時においてもノズルからの吐出液滴を正常に形成することができ、適切な液滴量や着弾精度を確保することやサテライトの発生を抑制することが可能であり、造形精度を向上させやすくなる。

The surface tension of the composition for model materials of the present invention is preferably 24 to 30 mN / m, more preferably 24.5 mN / m or more, further preferably 25 mN / m or more, and more preferably 29. 5 mN / m or less, still more preferably below 29 mN / m. When the surface tension is within the above range, the droplets ejected from the nozzle can be formed normally even during high-speed ejection of the material jet, and it is possible to ensure an appropriate droplet amount and landing accuracy and to prevent satellite generation. It is possible to suppress, and it becomes easy to improve modeling accuracy.

Claims (17)

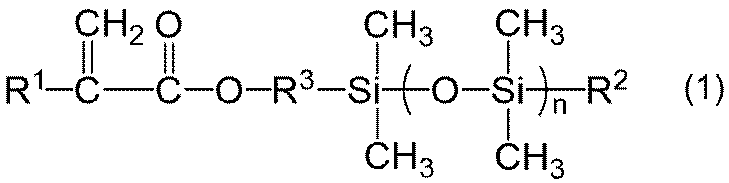

R1は水素原子またはメチル基を表し、

R2は水素原子または炭素数1〜4のアルキル基を表し、

R3は、(CH2)m、(EO)x、(PO)yおよびこれらの組み合わせからなる群から選択され、mは1〜10であり、(EO)は(C2H4O)を示し、(PO)は(C3H6O)を示し、xおよびyは、それぞれ0〜50であり、

nは3〜220である〕

で示される構造を有する、請求項1〜6のいずれかに記載のモデル材用組成物。 The siloxane compound has the following formula (1):

R 1 represents a hydrogen atom or a methyl group,

R 2 represents a hydrogen atom or an alkyl group having 1 to 4 carbon atoms,

R 3 is selected from the group consisting of (CH 2 ) m , (EO) x , (PO) y and combinations thereof, m is 1 to 10 and (EO) is (C 2 H 4 O) , (PO) represents (C 3 H 6 O), x and y are each 0 to 50,

n is 3 to 220]

The composition for model materials according to any one of claims 1 to 6, which has a structure shown by.

Priority Applications (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| JP2019201637A JP6941654B2 (en) | 2017-11-22 | 2019-11-06 | Composition for model material |

Applications Claiming Priority (2)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| JP2017225156A JP6615849B2 (en) | 2017-11-22 | 2017-11-22 | Composition for model materials |

| JP2019201637A JP6941654B2 (en) | 2017-11-22 | 2019-11-06 | Composition for model material |

Related Parent Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| JP2017225156A Division JP6615849B2 (en) | 2017-11-22 | 2017-11-22 | Composition for model materials |

Publications (3)

| Publication Number | Publication Date |

|---|---|

| JP2020040407A JP2020040407A (en) | 2020-03-19 |

| JP2020040407A5 true JP2020040407A5 (en) | 2020-04-30 |

| JP6941654B2 JP6941654B2 (en) | 2021-09-29 |

Family

ID=69797310

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| JP2019201637A Active JP6941654B2 (en) | 2017-11-22 | 2019-11-06 | Composition for model material |

Country Status (1)

| Country | Link |

|---|---|

| JP (1) | JP6941654B2 (en) |

Families Citing this family (1)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| CN114957563A (en) * | 2022-04-29 | 2022-08-30 | 广州大学 | Photocuring 3D printing hydrophobic resin and preparation method thereof |

Family Cites Families (5)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| JP2010006870A (en) * | 2008-06-24 | 2010-01-14 | Fujifilm Corp | Curable composition for nanoimprinting, cured product and method for producing the same |

| JP2013138179A (en) * | 2011-11-30 | 2013-07-11 | Central Glass Co Ltd | Photopolymerizable composition and pattern formation method using the same |

| KR102639863B1 (en) * | 2015-07-02 | 2024-02-22 | 도아고세이가부시키가이샤 | Curable composition |

| JP6679234B2 (en) * | 2015-07-29 | 2020-04-15 | マクセルホールディングス株式会社 | Model material resin composition, support material resin composition, stereolithography product, and method for producing stereolithography product |

| US20180258297A1 (en) * | 2015-09-15 | 2018-09-13 | Maxell Holdings, Ltd. | Resin composition for modeling material, light curing molding ink set, and method for manufacturing optically shaped article |

-

2019

- 2019-11-06 JP JP2019201637A patent/JP6941654B2/en active Active

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| EP3753957B1 (en) | Photolithographic curable composition, evaporative pattern, and method for producing three dimensional shaped article | |

| JP2012015324A5 (en) | ||

| EP3418037A1 (en) | Rubber composition for three-dimensional additive manufacturing | |

| EP3265877B1 (en) | Method for producing a tridimensional structure by 3d printing | |

| US11370928B2 (en) | Inks for 3D printing having low polymerization shrinkage | |

| CN111349201A (en) | Resin composition for support material and method for producing stereolithography product | |

| JP2000186071A5 (en) | ||

| US20190381784A1 (en) | Hydrogel object and method of manufacturing hydrogel object | |

| JP6381614B2 (en) | Support material composition | |

| WO2015100243A1 (en) | Three dimensional printing materials, systems, and methods | |

| JP2016117273A (en) | Three-dimensional molding and method for producing the same | |

| JP2020040407A5 (en) | ||

| JP2020040408A5 (en) | ||

| CN107199695A (en) | Three-dimensional modeling machine and three-dimensionally shaped method | |

| JP2015080921A5 (en) | ||

| JP2018122499A5 (en) | ||

| JP2009262370A5 (en) | ||

| JP2023051761A5 (en) | ||

| JP7062778B2 (en) | Cyclic polymerizable compounds for 3D printing | |

| US11919074B2 (en) | Additive manufacturing using thermal inkjet printheads | |

| JP7133619B2 (en) | Support material composition | |

| JP2016023274A (en) | Cellulosic material and cellulosic member | |

| JP2020055140A (en) | Inkjet optically shaping photocurable resin composition set, and optically shaping article using the same and manufacturing method thereof | |

| JP7052397B2 (en) | Composition for three-dimensional model, manufacturing device for three-dimensional model, and method for manufacturing three-dimensional model | |

| JP6390236B2 (en) | Manufacturing method of three-dimensional structure and three-dimensional structure |