JP2018159508A - Scrap preheating device of melting furnace - Google Patents

Scrap preheating device of melting furnace Download PDFInfo

- Publication number

- JP2018159508A JP2018159508A JP2017056740A JP2017056740A JP2018159508A JP 2018159508 A JP2018159508 A JP 2018159508A JP 2017056740 A JP2017056740 A JP 2017056740A JP 2017056740 A JP2017056740 A JP 2017056740A JP 2018159508 A JP2018159508 A JP 2018159508A

- Authority

- JP

- Japan

- Prior art keywords

- exhaust gas

- scrap

- preheating

- preheating chamber

- melting furnace

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Pending

Links

Images

Classifications

-

- Y—GENERAL TAGGING OF NEW TECHNOLOGICAL DEVELOPMENTS; GENERAL TAGGING OF CROSS-SECTIONAL TECHNOLOGIES SPANNING OVER SEVERAL SECTIONS OF THE IPC; TECHNICAL SUBJECTS COVERED BY FORMER USPC CROSS-REFERENCE ART COLLECTIONS [XRACs] AND DIGESTS

- Y02—TECHNOLOGIES OR APPLICATIONS FOR MITIGATION OR ADAPTATION AGAINST CLIMATE CHANGE

- Y02P—CLIMATE CHANGE MITIGATION TECHNOLOGIES IN THE PRODUCTION OR PROCESSING OF GOODS

- Y02P10/00—Technologies related to metal processing

- Y02P10/20—Recycling

Landscapes

- Vertical, Hearth, Or Arc Furnaces (AREA)

- Waste-Gas Treatment And Other Accessory Devices For Furnaces (AREA)

- Furnace Details (AREA)

- Refinement Of Pig-Iron, Manufacture Of Cast Iron, And Steel Manufacture Other Than In Revolving Furnaces (AREA)

Abstract

Description

本発明は溶解炉のスクラップ予熱装置に関し、特に、予熱室を流通する排ガス量を適正に管理できるスクラップ予熱装置に関するものである。 The present invention relates to a scrap preheating device for a melting furnace, and more particularly to a scrap preheating device capable of appropriately managing the amount of exhaust gas flowing through a preheating chamber.

炉体の上方に設けたシャフト内にスクラップを予熱する単一の予熱室を設けた構造の溶解炉は例えば特許文献1に示されており、ここでは予熱室の下方を炉体側方から溶解室へ向けて開放して、予熱室内へ供給されたスクラップを溶解炉からの排ガスで予熱しつつ溶湯中へ供給している。

A melting furnace having a structure in which a single preheating chamber for preheating scrap is provided in a shaft provided above the furnace body is shown, for example, in

しかし上記従来のスクラップ予熱装置では、溶解炉から予熱室へ流入する排ガスは全く管理されていない。このため、排ガス温度が1600℃前後に上昇する操業終盤の特に昇温還元期には、スクラップが排ガスで過度に加熱されて酸化し、歩留まりの低減や還元時間の長期化による生産性の低下を招くという問題がある。 However, in the conventional scrap preheating apparatus, exhaust gas flowing from the melting furnace into the preheating chamber is not managed at all. For this reason, especially at the end of the temperature increase and reduction period when the exhaust gas temperature rises to around 1600 ° C, the scrap is excessively heated and oxidized by the exhaust gas, reducing the yield and reducing the productivity due to the longer reduction time. There is a problem of inviting.

そこで、本発明はこのような問題を解決するもので、単一の予熱室を設けた溶解炉において、スクラップの過度な酸化を効果的に防止できる溶解炉のスクラップ予熱装置を提供することを目的とする。 Accordingly, the present invention solves such problems, and an object of the present invention is to provide a scrap preheating apparatus for a melting furnace that can effectively prevent excessive oxidation of scrap in a melting furnace provided with a single preheating chamber. And

上記目的を達成するために、本第1発明では、炉体(11)の上方に設けたシャフト(13)内にスクラップ(Sc)を予熱する単一の予熱室(14)を設けて、溶解炉(1)の排ガスをシャフト(13)内の予熱室(14)に流通させてスクラップ(Sc)を予熱し、かつ、予熱室(14)の排ガス流入側と排ガス流出側を結ぶバイパス路(2)を設けて、当該バイパス路(2)に流量調節手段(21,4)を設ける。 In order to achieve the above object, according to the first aspect of the present invention, a single preheating chamber (14) for preheating scrap (Sc) is provided in a shaft (13) provided above the furnace body (11) for melting. Bypassing the exhaust gas from the furnace (1) to the preheating chamber (14) in the shaft (13) to preheat the scrap (Sc) and connecting the exhaust gas inflow side to the exhaust gas outflow side of the preheating chamber (14) ( 2), and the flow rate adjusting means (21, 4) is provided in the bypass passage (2).

本第1発明において、溶解炉の排ガス温度が上昇し、あるいは排ガス量が増大すると、予熱室内のスクラップへの入熱量が過度に大きくなってその酸化が進行してしまう。そこで本発明ではバイパス路の流量調節手段によって排ガスの一部を、スクラップに供給することなくバイパス路に分流させる。これによって、スクラップの過度な予熱が防止されその酸化の進行が回避される。 In the first invention, when the temperature of the exhaust gas in the melting furnace rises or the amount of exhaust gas increases, the amount of heat input to the scrap in the preheating chamber becomes excessively large and the oxidation proceeds. Therefore, in the present invention, a part of the exhaust gas is diverted to the bypass passage without being supplied to the scrap by the flow rate adjusting means of the bypass passage. This prevents excessive preheating of the scrap and avoids its oxidation progress.

本第2発明では、前記流量調節手段として弁体(21)ないしファン(4)の少なくとも一方を設ける。 In the second invention, at least one of the valve body (21) and the fan (4) is provided as the flow rate adjusting means.

本第3発明では、前記バイパス路(2)を流れる排ガス量の上限が溶解炉(1)から排出される排ガス量の25〜35%になるように前記バイパス路(2)の圧損が設定されている。 In the third invention, the pressure loss of the bypass passage (2) is set so that the upper limit of the amount of exhaust gas flowing through the bypass passage (2) is 25 to 35% of the amount of exhaust gas discharged from the melting furnace (1). ing.

なお、本発明は以下の操業方法であっても良い。すなわち、炉体(11)の上方に設けたシャフト(13)内にスクラップ(Sc)を予熱する単一の予熱室(14)を設けて、溶解炉(1)の排ガスをシャフト(13)内の予熱室(14)に流通させてスクラップ(Sc)を予熱し、かつ、予熱室(14)の排ガス流入側と排ガス流出側を結ぶバイパス路(2)を設けた溶解炉のスクラップ予熱装置において、前記バイパス路(2)を流れる排ガス量の上限を溶解炉(1)から排出される排ガス量の25〜35%に設定することを特徴とする溶解炉のスクラップ予熱装置の操業方法。 In addition, the following operation methods may be sufficient as this invention. That is, a single preheating chamber (14) for preheating the scrap (Sc) is provided in the shaft (13) provided above the furnace body (11), and the exhaust gas from the melting furnace (1) is discharged into the shaft (13). In the preheating chamber (14) of the melting furnace, the scrap (Sc) is preheated, and a bypass passage (2) connecting the exhaust gas inflow side and the exhaust gas outflow side of the preheating chamber (14) is provided. The upper limit of the amount of exhaust gas flowing through the bypass passage (2) is set to 25 to 35% of the amount of exhaust gas discharged from the melting furnace (1).

上記カッコ内の符号は、後述する実施形態に記載の具体的手段との対応関係を参考的に示すものである。 The reference numerals in the parentheses refer to the correspondence with specific means described in the embodiments described later.

以上のように、本発明の溶解炉のスクラップ予熱装置によれば、単一の予熱室を設けた溶解炉において、スクラップの過度な酸化を効果的に防止することができる。 As described above, according to the scrap preheating apparatus for a melting furnace of the present invention, excessive oxidation of scrap can be effectively prevented in a melting furnace provided with a single preheating chamber.

なお、以下に説明する実施形態はあくまで一例であり、本発明の要旨を逸脱しない範囲で当業者が行う種々の設計的改良も本発明の範囲に含まれる。 The embodiment described below is merely an example, and various design improvements made by those skilled in the art without departing from the gist of the present invention are also included in the scope of the present invention.

(第1実施形態)

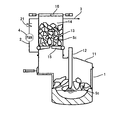

図1には溶解炉の一例としてシャフト式アーク炉を示す。図1において、アーク炉1の炉体11内にその中心上方から電極12が挿入されてアーク放電によって炉内のスクラップScが溶融されている。炉体11上方の偏心位置に筒状のシャフト13が立設されて内部に単一の予熱室14が形成されている。予熱室14の下端開口には、下方へ開放可能なフォーク型ゲート15が設けられている。フォーク型ゲート15は複数の平行棒体をフォーク状に並べた構造のゲートで、平行棒体間の間隙を排ガスが流通できるようになっている。

(First embodiment)

FIG. 1 shows a shaft type arc furnace as an example of a melting furnace. In FIG. 1, an

予熱室14の上端開口にはスライド開閉可能な扉体16が設けられている。予熱室14内にスクラップScを装入する場合には、扉体16を開いてバケット(図示略)で搬送されてきたスクラップScを予熱室14内へ落下供給する。操業中にアーク炉1の炉内で発生する高温の排ガスはゲート15を通過して予熱室14内を上昇しこの間にスクラップScを予熱する。予熱されたスクラップScは操業中の適当タイミングでゲート15が開放されて下方の炉体11内へ落下供給される。

A

ここで、本実施形態ではバイパス路2が設けられており、当該バイパス路2は、排ガス流入側である、シャフト13の下端開口に近い下方の側壁に下端が開口している。バイパス路には途中に流量調節手段を構成する弁体としてのダンパ21が設けられており、当該ダンパ21は手動で開閉されても良いし、後述する計算式に基づいて自動で開閉されるようにしても良い。

Here, in this embodiment, the

ただし、発明者等の経験によると、ダンパ21を全開にした場合にも、アーク炉1から排出される排ガス量の30%程度のみがバイパス路2へ流れる上限排ガス量となるように当該バイパス路2の圧損を設定しておくのが良い。上記バイパス路2の上端は排ガス流出側である、予熱室14の上端部側壁に開口している。なお、この開口位置は予熱室14内にスクラップSrを充填した際のスクラップSrの高さよりも高い位置とする。予熱室14の上端部側壁には煙道3が連結されており、煙道3は図略の冷却塔からブロアを経て集塵機に至っている。

However, according to the experience of the inventors, even when the

ここで、アーク炉1から排出される排ガス量のどの程度をバイパス路2へ流すのが最適であるかをさらに詳細に実験した結果を表1に示す。表1によれば、予熱されたスクラップScの表面酸化を抑制する(スクラップの酸化抑制度)ためには、アーク炉1から排出される排ガス量の25%以上をバイパス路2へ流すのが良い。一方、スクラップScを十分予熱できる予熱時間を比較すると、アーク炉1から排出される排ガス量の5〜35%をバイパス路2へ流した場合の予熱時間がT(min)である場合に、35〜40%とした場合には予熱時間はT〜1.5T(min)と長くなり、43%以上にすると1.5T(min)以上の予熱時間を必要とする。したがって、スクラップSrの表面酸化を抑制しつつ予熱時間を可及的に短くするためには、アーク炉1から排出される排ガス量の25〜35%をバイパス路2へ流すのが最適である。

Here, Table 1 shows the results of experiments in more detail on how much of the amount of exhaust gas discharged from the

このような構造において、アーク炉1からの高温の排ガスが既述のようにゲート15を通過して予熱室14内を上昇してこの間にスクラップScを予熱し、その後、予熱室14の上端部から煙道3を経て排気される。排ガス温度が上昇し、あるいは排ガス量が増大すると、スクラップScへの入熱量が過度に大きくなってその酸化が進行してしまう。

In such a structure, the high-temperature exhaust gas from the

そこでこの場合、本実施例では、ダンパ21を適当量開放して、排ガスの一部を、スクラップScに供給することなくバイパス路2を介して直接予熱室14上端部に流入させ、ここから煙道3に排出させる。これによって、スクラップScの過度な予熱が防止されその酸化の進行が回避される。

In this case, in this embodiment, an appropriate amount of the

ここで、アーク炉1から排出される熱量速度Qvaは、アーク炉1の排ガス量をQ(m3/min)、排ガス温度をt(℃)とすると、下式(1)で示される。

Qva=(Q・t・ガス比熱)・K1(Kwh/min)…(1)

ここで、K1は適当な係数である(以下、同様)。

Here, the heat rate Qva discharged from the

Qva = (Q · t · gas specific heat) · K1 (Kwh / min) (1)

Here, K1 is an appropriate coefficient (the same applies hereinafter).

また、煙道3の持ち去り熱量速度Qveは、煙道3の排ガス温度をt1(℃)とすると、煙道3に設置された図略のブロアの回転数で決定される排気量(煙道3の気流量)をQ1として、下式(2)で示すようなものになる。

Qve=(Q1・t1・ガス比熱)・K1(Kwh/min)…(2)

The amount of heat Q Qve taken away from the flue 3 is the exhaust amount (flue) determined by the rotational speed of a blower (not shown) installed in the flue 3 when the exhaust gas temperature in the flue 3 is t1 (3 air flow rate) is Q1, and the following equation (2) is obtained.

Qve = (Q1, t1, gas specific heat), K1 (Kwh / min) (2)

さらに、バイパス路2の持ち去り熱量速度Qvbは、当該バイパス路2の排ガス温度はt(℃)であるから、ダンパ21の開度で決定されるバイパス路2の気流量をQ2として、下式(3)で示すようなものになる。

Qvb=(Q2・t・ガス比熱)・K1(Kwh/min)…(3)

Furthermore, since the exhaust gas temperature of the

Qvb = (Q2 · t · gas specific heat) · K1 (Kwh / min) (3)

したがって、他の熱損失を考慮しなければ、予熱室14への入熱速度Qvpは下式(4)で得られる。

Qvp=Qva−(Qve+Qvb)…(4)

Therefore, if other heat loss is not taken into consideration, the heat input speed Qvp to the preheating

Qvp = Qva- (Qve + Qvb) (4)

これにより、予熱室14内のスクラップScの熱容量を予め算出しておけば、式(4)で算出される入熱速度QvpよりスクラップScの予熱温度変化を推定することができる。そこで、推定される予熱温度が適正範囲内に維持されるように、ダンパ21の開度を制御して式(3)における排気量Q2を調整する。この調整は例えば、排ガス量Qが増加した場合には排気量Q2をこれに応じて増加させ、温度tが高くなった場合にも排気量Q2をこれに応じて増加させるように行う。なお、式(1)〜(3)中の温度t,t1および排ガス量Qは適当な測定手段によって測定される。

Thereby, if the heat capacity of the scrap Sc in the preheating

排ガス量Qの直接的な測定が困難な場合には、アーク炉への投入電力、[C]吹込み速度、[O2]吹込み速度、助燃エネルギー吹精速度、先入れ[C]量、金属酸化量、想定スラグ生成熱、廃タイヤ量、廃プラスチック量、想定付着油分量から熱量速度Qvaを直接演算するようにしても良い。 When direct measurement of the exhaust gas quantity Q is difficult, the electric power input to the arc furnace, [C] blowing speed, [O2] blowing speed, auxiliary combustion energy blowing speed, first-in [C] quantity, metal The calorific value Qva may be directly calculated from the oxidation amount, assumed slag generation heat, waste tire amount, waste plastic amount, and assumed attached oil amount.

式(4)で他の熱損失を考慮する場合、当該熱損失としては、フォーク型ゲートの冷却水抜熱速度Q21、予熱室水冷パネル冷却水抜熱速度Q22(Kwh/min)、予熱室鉄皮表面からの放熱速度Q23(Kwh/min)、漏煙排ガスによる放熱速度Q24(Kwh/min)等があり、この場合には式(4)のQvaから、Qve,Qvbに加えてQ21〜Q24も減じてQvpを算出する。 When other heat losses are considered in equation (4), the heat losses include fork gate cooling water removal heat rate Q21, preheating chamber water cooling panel cooling water removal heat rate Q22 (Kwh / min), preheating chamber iron surface Heat dissipation rate Q23 (Kwh / min) from the air, and heat dissipation rate Q24 (Kwh / min) due to the flue gas, etc. In this case, in addition to Qve and Qvb, Q21 to Q24 are subtracted from Qva in equation (4) Qvp is calculated.

(第2実施形態)

図2に示すようにバイパス路2にダンパ21に直列に、自動で回転制御されるブースタファン4を設ける。このようにすると、予熱室内のスクラップの形状が変動してその圧損が大きく変化しても、ブースタファン4によってバイパス路2の気流量Q2を正確に制御することができるから、スクラップScの酸化の進行を効果的に防止することができる。

(Second Embodiment)

As shown in FIG. 2, a booster fan 4 that is automatically controlled in rotation is provided in the

1…アーク炉(溶解炉)、11…炉体、13…シャフト、14…予熱室、2…バイパス路、21…ダンパ(流量調節手段)、4…ブースターファン、Sc…スクラップ。

DESCRIPTION OF

Claims (3)

Priority Applications (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| JP2017056740A JP2018159508A (en) | 2017-03-23 | 2017-03-23 | Scrap preheating device of melting furnace |

Applications Claiming Priority (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| JP2017056740A JP2018159508A (en) | 2017-03-23 | 2017-03-23 | Scrap preheating device of melting furnace |

Publications (2)

| Publication Number | Publication Date |

|---|---|

| JP2018159508A true JP2018159508A (en) | 2018-10-11 |

| JP2018159508A5 JP2018159508A5 (en) | 2019-10-03 |

Family

ID=63796549

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| JP2017056740A Pending JP2018159508A (en) | 2017-03-23 | 2017-03-23 | Scrap preheating device of melting furnace |

Country Status (1)

| Country | Link |

|---|---|

| JP (1) | JP2018159508A (en) |

Cited By (1)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| JPWO2022172771A1 (en) * | 2021-02-10 | 2022-08-18 |

-

2017

- 2017-03-23 JP JP2017056740A patent/JP2018159508A/en active Pending

Cited By (1)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| JPWO2022172771A1 (en) * | 2021-02-10 | 2022-08-18 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| JP3796617B2 (en) | Melting and holding furnace such as aluminum ingot | |

| CN206469667U (en) | A kind of energy-conserving and environment-protective mineral hot furnace for being easy to feed | |

| CN104344710A (en) | Metal melting furnace | |

| TW201114917A (en) | Arc melting equipment and molten metal manufacturing method using arc melting equipment | |

| JP2018159508A (en) | Scrap preheating device of melting furnace | |

| CN105452420A (en) | Coke dry-quenching device and coke dry-quenching method | |

| US10767929B2 (en) | Furnace | |

| CN209113961U (en) | A kind of two-phase steel casting solution device | |

| CN105861846A (en) | Energy-saving smelting device for aluminum processing | |

| CN108754176B (en) | Continuous refining furnace and process method for refining secondary copper by using same | |

| JP2018017474A (en) | Scrap preheating device of melting furnace | |

| CN104344726B (en) | Vanadium goods raw material preheating system | |

| CN107421329A (en) | A kind of casting furnace heating plant | |

| CN207779149U (en) | A kind of heating recovery of liquid slag utilizes device | |

| CN206875967U (en) | A kind of hardware smelts melting furnace | |

| CN103162539B (en) | Method of transferring and pouring aluminum liquid in process of preparation of electrician round aluminum rod | |

| JP2017075069A (en) | Glass melting furnace, glass melting method and method for manufacturing glass | |

| CN209726790U (en) | Smelting apparatus | |

| JP2020139180A (en) | Slag discharging method and molten metal producing method in an arc-type electric furnace | |

| KR102012099B1 (en) | Hot air suppling device for furnace | |

| JP4362712B2 (en) | Crucible melting and holding furnace | |

| CN216482225U (en) | Novel crucible type smelting heat preservation furnace hearth structure | |

| JP2012193922A (en) | Metal melting furnace and metal melting method | |

| CN211527059U (en) | Cupola furnace for casting speed reducer box | |

| KR100598920B1 (en) | nonferrous metals rapidity smelting furnace |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| A521 | Written amendment |

Free format text: JAPANESE INTERMEDIATE CODE: A523 Effective date: 20190814 |

|

| A621 | Written request for application examination |

Free format text: JAPANESE INTERMEDIATE CODE: A621 Effective date: 20200127 |

|

| A977 | Report on retrieval |

Free format text: JAPANESE INTERMEDIATE CODE: A971007 Effective date: 20201224 |

|

| A131 | Notification of reasons for refusal |

Free format text: JAPANESE INTERMEDIATE CODE: A131 Effective date: 20210112 |

|

| A02 | Decision of refusal |

Free format text: JAPANESE INTERMEDIATE CODE: A02 Effective date: 20210706 |