JP2016208018A - 清浄な/汚れた基板のハンドリングのためのエンドエフェクタアセンブリ - Google Patents

清浄な/汚れた基板のハンドリングのためのエンドエフェクタアセンブリ Download PDFInfo

- Publication number

- JP2016208018A JP2016208018A JP2016077712A JP2016077712A JP2016208018A JP 2016208018 A JP2016208018 A JP 2016208018A JP 2016077712 A JP2016077712 A JP 2016077712A JP 2016077712 A JP2016077712 A JP 2016077712A JP 2016208018 A JP2016208018 A JP 2016208018A

- Authority

- JP

- Japan

- Prior art keywords

- substrate

- substrate support

- height

- end effector

- support pads

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Pending

Links

- 239000000758 substrate Substances 0.000 title claims abstract description 329

- 239000012636 effector Substances 0.000 title claims abstract description 91

- 238000012545 processing Methods 0.000 claims abstract description 93

- 238000000034 method Methods 0.000 claims abstract description 57

- 230000002093 peripheral effect Effects 0.000 claims abstract description 26

- 230000008569 process Effects 0.000 description 18

- 238000012546 transfer Methods 0.000 description 18

- NJPPVKZQTLUDBO-UHFFFAOYSA-N novaluron Chemical compound C1=C(Cl)C(OC(F)(F)C(OC(F)(F)F)F)=CC=C1NC(=O)NC(=O)C1=C(F)C=CC=C1F NJPPVKZQTLUDBO-UHFFFAOYSA-N 0.000 description 15

- 239000004065 semiconductor Substances 0.000 description 10

- 238000005530 etching Methods 0.000 description 9

- 230000014509 gene expression Effects 0.000 description 8

- 238000000151 deposition Methods 0.000 description 6

- 230000008021 deposition Effects 0.000 description 6

- 238000004519 manufacturing process Methods 0.000 description 6

- 230000008878 coupling Effects 0.000 description 4

- 238000010168 coupling process Methods 0.000 description 4

- 238000005859 coupling reaction Methods 0.000 description 4

- 239000002245 particle Substances 0.000 description 4

- 238000000231 atomic layer deposition Methods 0.000 description 3

- 238000005229 chemical vapour deposition Methods 0.000 description 3

- 238000004140 cleaning Methods 0.000 description 3

- 238000011109 contamination Methods 0.000 description 3

- 239000000463 material Substances 0.000 description 3

- 230000007246 mechanism Effects 0.000 description 3

- 239000002184 metal Substances 0.000 description 3

- 229910052751 metal Inorganic materials 0.000 description 3

- 238000005240 physical vapour deposition Methods 0.000 description 3

- 239000002243 precursor Substances 0.000 description 3

- VYPSYNLAJGMNEJ-UHFFFAOYSA-N Silicium dioxide Chemical compound O=[Si]=O VYPSYNLAJGMNEJ-UHFFFAOYSA-N 0.000 description 2

- 230000009471 action Effects 0.000 description 2

- 230000002411 adverse Effects 0.000 description 2

- 238000010586 diagram Methods 0.000 description 2

- 230000006870 function Effects 0.000 description 2

- 238000005259 measurement Methods 0.000 description 2

- 239000000203 mixture Substances 0.000 description 2

- 238000001020 plasma etching Methods 0.000 description 2

- 238000000623 plasma-assisted chemical vapour deposition Methods 0.000 description 2

- 238000007747 plating Methods 0.000 description 2

- 238000010926 purge Methods 0.000 description 2

- 239000004020 conductor Substances 0.000 description 1

- 239000000356 contaminant Substances 0.000 description 1

- 238000001816 cooling Methods 0.000 description 1

- 230000007547 defect Effects 0.000 description 1

- 238000009826 distribution Methods 0.000 description 1

- 239000012530 fluid Substances 0.000 description 1

- 238000010438 heat treatment Methods 0.000 description 1

- 238000005468 ion implantation Methods 0.000 description 1

- 239000010410 layer Substances 0.000 description 1

- 150000002739 metals Chemical class 0.000 description 1

- 238000012986 modification Methods 0.000 description 1

- 230000004048 modification Effects 0.000 description 1

- -1 oxides Substances 0.000 description 1

- 239000000376 reactant Substances 0.000 description 1

- 238000012552 review Methods 0.000 description 1

- 238000004904 shortening Methods 0.000 description 1

- 229910052710 silicon Inorganic materials 0.000 description 1

- 239000010703 silicon Substances 0.000 description 1

- 235000012239 silicon dioxide Nutrition 0.000 description 1

- 239000000377 silicon dioxide Substances 0.000 description 1

Images

Classifications

-

- H—ELECTRICITY

- H01—ELECTRIC ELEMENTS

- H01L—SEMICONDUCTOR DEVICES NOT COVERED BY CLASS H10

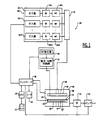

- H01L21/00—Processes or apparatus adapted for the manufacture or treatment of semiconductor or solid state devices or of parts thereof

- H01L21/67—Apparatus specially adapted for handling semiconductor or electric solid state devices during manufacture or treatment thereof; Apparatus specially adapted for handling wafers during manufacture or treatment of semiconductor or electric solid state devices or components ; Apparatus not specifically provided for elsewhere

- H01L21/677—Apparatus specially adapted for handling semiconductor or electric solid state devices during manufacture or treatment thereof; Apparatus specially adapted for handling wafers during manufacture or treatment of semiconductor or electric solid state devices or components ; Apparatus not specifically provided for elsewhere for conveying, e.g. between different workstations

- H01L21/67739—Apparatus specially adapted for handling semiconductor or electric solid state devices during manufacture or treatment thereof; Apparatus specially adapted for handling wafers during manufacture or treatment of semiconductor or electric solid state devices or components ; Apparatus not specifically provided for elsewhere for conveying, e.g. between different workstations into and out of processing chamber

- H01L21/67742—Mechanical parts of transfer devices

-

- H—ELECTRICITY

- H01—ELECTRIC ELEMENTS

- H01L—SEMICONDUCTOR DEVICES NOT COVERED BY CLASS H10

- H01L21/00—Processes or apparatus adapted for the manufacture or treatment of semiconductor or solid state devices or of parts thereof

- H01L21/67—Apparatus specially adapted for handling semiconductor or electric solid state devices during manufacture or treatment thereof; Apparatus specially adapted for handling wafers during manufacture or treatment of semiconductor or electric solid state devices or components ; Apparatus not specifically provided for elsewhere

- H01L21/677—Apparatus specially adapted for handling semiconductor or electric solid state devices during manufacture or treatment thereof; Apparatus specially adapted for handling wafers during manufacture or treatment of semiconductor or electric solid state devices or components ; Apparatus not specifically provided for elsewhere for conveying, e.g. between different workstations

- H01L21/67703—Apparatus specially adapted for handling semiconductor or electric solid state devices during manufacture or treatment thereof; Apparatus specially adapted for handling wafers during manufacture or treatment of semiconductor or electric solid state devices or components ; Apparatus not specifically provided for elsewhere for conveying, e.g. between different workstations between different workstations

- H01L21/67715—Changing the direction of the conveying path

-

- H—ELECTRICITY

- H01—ELECTRIC ELEMENTS

- H01L—SEMICONDUCTOR DEVICES NOT COVERED BY CLASS H10

- H01L21/00—Processes or apparatus adapted for the manufacture or treatment of semiconductor or solid state devices or of parts thereof

- H01L21/67—Apparatus specially adapted for handling semiconductor or electric solid state devices during manufacture or treatment thereof; Apparatus specially adapted for handling wafers during manufacture or treatment of semiconductor or electric solid state devices or components ; Apparatus not specifically provided for elsewhere

- H01L21/677—Apparatus specially adapted for handling semiconductor or electric solid state devices during manufacture or treatment thereof; Apparatus specially adapted for handling wafers during manufacture or treatment of semiconductor or electric solid state devices or components ; Apparatus not specifically provided for elsewhere for conveying, e.g. between different workstations

- H01L21/67763—Apparatus specially adapted for handling semiconductor or electric solid state devices during manufacture or treatment thereof; Apparatus specially adapted for handling wafers during manufacture or treatment of semiconductor or electric solid state devices or components ; Apparatus not specifically provided for elsewhere for conveying, e.g. between different workstations the wafers being stored in a carrier, involving loading and unloading

- H01L21/67766—Mechanical parts of transfer devices

-

- H—ELECTRICITY

- H01—ELECTRIC ELEMENTS

- H01L—SEMICONDUCTOR DEVICES NOT COVERED BY CLASS H10

- H01L21/00—Processes or apparatus adapted for the manufacture or treatment of semiconductor or solid state devices or of parts thereof

- H01L21/67—Apparatus specially adapted for handling semiconductor or electric solid state devices during manufacture or treatment thereof; Apparatus specially adapted for handling wafers during manufacture or treatment of semiconductor or electric solid state devices or components ; Apparatus not specifically provided for elsewhere

- H01L21/683—Apparatus specially adapted for handling semiconductor or electric solid state devices during manufacture or treatment thereof; Apparatus specially adapted for handling wafers during manufacture or treatment of semiconductor or electric solid state devices or components ; Apparatus not specifically provided for elsewhere for supporting or gripping

- H01L21/687—Apparatus specially adapted for handling semiconductor or electric solid state devices during manufacture or treatment thereof; Apparatus specially adapted for handling wafers during manufacture or treatment of semiconductor or electric solid state devices or components ; Apparatus not specifically provided for elsewhere for supporting or gripping using mechanical means, e.g. chucks, clamps or pinches

- H01L21/68707—Apparatus specially adapted for handling semiconductor or electric solid state devices during manufacture or treatment thereof; Apparatus specially adapted for handling wafers during manufacture or treatment of semiconductor or electric solid state devices or components ; Apparatus not specifically provided for elsewhere for supporting or gripping using mechanical means, e.g. chucks, clamps or pinches the wafers being placed on a robot blade, or gripped by a gripper for conveyance

-

- H—ELECTRICITY

- H01—ELECTRIC ELEMENTS

- H01L—SEMICONDUCTOR DEVICES NOT COVERED BY CLASS H10

- H01L21/00—Processes or apparatus adapted for the manufacture or treatment of semiconductor or solid state devices or of parts thereof

- H01L21/67—Apparatus specially adapted for handling semiconductor or electric solid state devices during manufacture or treatment thereof; Apparatus specially adapted for handling wafers during manufacture or treatment of semiconductor or electric solid state devices or components ; Apparatus not specifically provided for elsewhere

- H01L21/683—Apparatus specially adapted for handling semiconductor or electric solid state devices during manufacture or treatment thereof; Apparatus specially adapted for handling wafers during manufacture or treatment of semiconductor or electric solid state devices or components ; Apparatus not specifically provided for elsewhere for supporting or gripping

- H01L21/687—Apparatus specially adapted for handling semiconductor or electric solid state devices during manufacture or treatment thereof; Apparatus specially adapted for handling wafers during manufacture or treatment of semiconductor or electric solid state devices or components ; Apparatus not specifically provided for elsewhere for supporting or gripping using mechanical means, e.g. chucks, clamps or pinches

- H01L21/68714—Apparatus specially adapted for handling semiconductor or electric solid state devices during manufacture or treatment thereof; Apparatus specially adapted for handling wafers during manufacture or treatment of semiconductor or electric solid state devices or components ; Apparatus not specifically provided for elsewhere for supporting or gripping using mechanical means, e.g. chucks, clamps or pinches the wafers being placed on a susceptor, stage or support

-

- H—ELECTRICITY

- H01—ELECTRIC ELEMENTS

- H01L—SEMICONDUCTOR DEVICES NOT COVERED BY CLASS H10

- H01L21/00—Processes or apparatus adapted for the manufacture or treatment of semiconductor or solid state devices or of parts thereof

- H01L21/67—Apparatus specially adapted for handling semiconductor or electric solid state devices during manufacture or treatment thereof; Apparatus specially adapted for handling wafers during manufacture or treatment of semiconductor or electric solid state devices or components ; Apparatus not specifically provided for elsewhere

- H01L21/683—Apparatus specially adapted for handling semiconductor or electric solid state devices during manufacture or treatment thereof; Apparatus specially adapted for handling wafers during manufacture or treatment of semiconductor or electric solid state devices or components ; Apparatus not specifically provided for elsewhere for supporting or gripping

- H01L21/687—Apparatus specially adapted for handling semiconductor or electric solid state devices during manufacture or treatment thereof; Apparatus specially adapted for handling wafers during manufacture or treatment of semiconductor or electric solid state devices or components ; Apparatus not specifically provided for elsewhere for supporting or gripping using mechanical means, e.g. chucks, clamps or pinches

- H01L21/68714—Apparatus specially adapted for handling semiconductor or electric solid state devices during manufacture or treatment thereof; Apparatus specially adapted for handling wafers during manufacture or treatment of semiconductor or electric solid state devices or components ; Apparatus not specifically provided for elsewhere for supporting or gripping using mechanical means, e.g. chucks, clamps or pinches the wafers being placed on a susceptor, stage or support

- H01L21/68785—Apparatus specially adapted for handling semiconductor or electric solid state devices during manufacture or treatment thereof; Apparatus specially adapted for handling wafers during manufacture or treatment of semiconductor or electric solid state devices or components ; Apparatus not specifically provided for elsewhere for supporting or gripping using mechanical means, e.g. chucks, clamps or pinches the wafers being placed on a susceptor, stage or support characterised by the mechanical construction of the susceptor, stage or support

Landscapes

- Engineering & Computer Science (AREA)

- Physics & Mathematics (AREA)

- Condensed Matter Physics & Semiconductors (AREA)

- General Physics & Mathematics (AREA)

- Manufacturing & Machinery (AREA)

- Computer Hardware Design (AREA)

- Microelectronics & Electronic Packaging (AREA)

- Power Engineering (AREA)

- Robotics (AREA)

- Container, Conveyance, Adherence, Positioning, Of Wafer (AREA)

- Mechanical Engineering (AREA)

- Manipulator (AREA)

Abstract

Description

Claims (20)

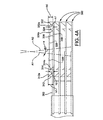

- 基板処理システムにおいてエンドエフェクタによって基板をハンドリングする方法であって、前記エンドエフェクタは、第1の、第2の、第3の、第4の、第5の、第6の、及び第7の基板支持パッドを有し、前記方法は、

前記基板の周縁部に前記第2の、第5の、及び第6の基板支持パッドを係合させることと、

前記エンドエフェクタを前記基板処理システムの処理チャンバ内へ第1の距離だけ移動させることと、

前記基板の前記周縁部を前記第2の、第5の、及び第6の基板支持パッドから切り離すことと、

前記エンドエフェクタを前記基板処理システムの前記処理チャンバ内へ第2の距離だけ移動させることと、

前記基板の前記周縁部に前記第1の、第3の、第4の、及び第7の基板支持パッドを係合させることと、

を備える方法。 - 請求項1に記載の方法であって、

前記第1の及び第3の基板支持パッドは、第1の高さを形成し、前記第4の及び第6の基板支持パッドは、前記第1の高さよりも小さい第2の高さを形成する、方法。 - 請求項1に記載の方法であって、

前記第2の基板支持パッドは、第1の高さを形成し、前記第5の及び第6の基板支持パッドは、前記第1の高さよりも大きい第2の高さを形成する、方法。 - 請求項3に記載の方法であって、

前記第1の及び第3の基板支持パッドは、前記第2の高さに等しい第3の高さを形成し、前記第4の及び第6の基板支持パッドは、前記第1の高さに等しい第4の高さを形成する、方法。 - 請求項1に記載の方法であって、

前記基板の周縁部に前記第2の、第5の、及び第6の基板支持パッドを係合させることは、前記第4の及び第7の基板支持パッドを前記基板の前記周縁部の半径方向内側に位置決めすることを含む。方法。 - 請求項1に記載の方法であって、

前記基板の周縁部に前記第1の、第3の、第4の、及び第7の基板支持パッドを係合させることは、更に、前記第2の基板支持パッドを前記基板の前記周縁部の半径方向内側に位置決めすることを含む、方法。 - 請求項1に記載の方法であって、

前記第2の、第5の、及び第6の基板支持パッドは、第1の直径と第1の中心軸とを有する第1の円を形成し、前記第1の、第3の、第4の、及び第7の基板支持パッドは、第2の直径と第2の中心軸とを有する第2の円を形成し、前記基板は、第3の中心軸を有する第3の円を形成し、

前記基板の前記周縁部に前記第2の、第5の、及び第6の基板支持パッドを係合させることは、前記第2の中心軸を第3の中心軸に対して第1の角度に配置することを含み、

前記基板の前記周縁部に第1の、第3の、第4の、及び第7の基板支持パッドを係合させることは、前記第1の中心軸を前記第3の中心軸に対して第2の角度に配置することを含む、方法。 - 請求項7に記載の方法であって、

前記第1の角度は、前記第2の角度に等しい、方法。 - 請求項1に記載の方法であって、

前記第1の直径は、前記第2の直径に等しい、方法。 - 請求項1に記載の方法であって、

前記第1の、第2の、第3の、第4の、第5の、第6の、及び第7の基板支持パッドは、それぞれ、第1の、第2の、第3の、第4の、第5の、第6の、及び第7の傾斜した基板支持表面を含む、方法。 - エンドエフェクタであって、

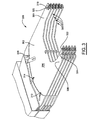

第1の、第2の、及び第3の基板支持パッドを有する本体であって、前記第1の基板支持パッドは、第1の高さを形成し、前記第2の基板支持パッドは、前記第1の高さよりも小さい第2の高さを形成し、前記第3の基板支持パッドは、前記第1の高さに等しい第3の高さを形成する、本体と、

前記本体から伸び、第4の及び第5の基板支持パッドを有する第1の枝であって、前記第4の基板支持パッドは、前記第2の高さに等しい第4の高さを形成し、前記第5の基板支持パッドは、前記第1の及び第3の高さに等しい第5の高さを形成する、第1の枝と、

前記本体から伸び、第6の及び第7の基板支持パッドを有する第2の枝であって、前記第6の基板支持パッドは、前記第1の、第3の、及び第5の高さに等しい第6の高さを形成し、前記第7の基板支持パッドは、前記第2の及び第4の高さに等しい第7の高さを形成する、第2の枝と、

を備えるエンドエフェクタ。 - 請求項11に記載のエンドエフェクタであって、

前記第1の、第3の、第4の、及び第7の基板支持パッドは、第1の直径と第1の中心軸とを有する第1の円を形成し、前記第2の、第5の、及び第6の基板支持パッドは、第2の直径と第2の中心軸とを有する第2の円を形成する、エンドエフェクタ。 - 請求項12に記載のエンドエフェクタであって、

前記第1の直径は、前記第2の直径に等しい、エンドエフェクタ。 - 請求項12に記載のエンドエフェクタであって、

前記第1の中心軸は、前記第2の中心軸から直線的にずれている、エンドエフェクタ。 - 請求項12に記載のエンドエフェクタであって、

前記第1の中心軸と前記第2の中心軸とは、一定の角度を形成する、エンドエフェクタ。 - 請求項11に記載のエンドエフェクタであって、

前記本体の部分は、前記第1の及び第2の枝の部分と一体成形される、エンドエフェクタ。 - エンドエフェクタであって、

第1の、第2の、第3の、第4の、第5の、第6の、及び第7の基板支持パッドを備え、前記第1の、第3の、第4の、及び第7の基板支持パッドは、第1の円を形成し、前記第2の、第5の、及び第6の基板支持パッドは、第2の円を形成し、前記第1の円は、第1の直径と第1の中心軸とを有し、前記第2の円は、前記第1の直径に等しい第2の直径と、前記第1の中心軸からずれた第2の中心軸とを有し、前記第1の基板支持パッドは、第1の高さを形成し、前記第2の基板支持パッドは、前記第1の高さよりも小さい第2の高さを形成し、前記第3の基板支持パッドは、前記第2の高さよりも大きい第3の高さを形成し、前記第4の基板支持パッドは、前記第3の高さよりも小さい第4の高さを形成し、前記第5の基板支持パッドは、前記第4の高さよりも大きい第5の高さを形成し、前記第6の基板支持パッドは、前記第4の高さよりも大きい第6の高さを形成し、前記第7の基板支持パッドは、前記第6の高さよりも小さい第7の高さを形成する、エンドエフェクタ。 - 請求項17に記載のエンドエフェクタであって、

前記第1の中心軸と前記第2の中心軸とは、一定の角度を形成する、エンドエフェクタ。 - 請求項17に記載のエンドエフェクタであって、

前記エンドエフェクタは、本体の部分と、前記本体の部分から伸びる第1の及び第2の枝の部分とを含み、前記第4の、第5の、第6の、及び第7の基板支持パッドのそれぞれは、前記第1の枝の部分上及び前記第2の枝の部分上のいずれかに配置される、エンドエフェクタ。 - 請求項19に記載のエンドエフェクタであって、

前記本体の部分は、第1の及び第2の枝の部分と一体成形される、エンドエフェクタ。

Applications Claiming Priority (2)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| US14/687,506 US9779977B2 (en) | 2015-04-15 | 2015-04-15 | End effector assembly for clean/dirty substrate handling |

| US14/687,506 | 2015-04-15 |

Publications (2)

| Publication Number | Publication Date |

|---|---|

| JP2016208018A true JP2016208018A (ja) | 2016-12-08 |

| JP2016208018A5 JP2016208018A5 (ja) | 2019-05-16 |

Family

ID=57128876

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| JP2016077712A Pending JP2016208018A (ja) | 2015-04-15 | 2016-04-08 | 清浄な/汚れた基板のハンドリングのためのエンドエフェクタアセンブリ |

Country Status (4)

| Country | Link |

|---|---|

| US (2) | US9779977B2 (ja) |

| JP (1) | JP2016208018A (ja) |

| KR (2) | KR20160123248A (ja) |

| TW (1) | TWI693989B (ja) |

Families Citing this family (7)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| JP6630591B2 (ja) * | 2016-02-26 | 2020-01-15 | 川崎重工業株式会社 | 基板把持ハンド及び基板搬送装置 |

| KR102397110B1 (ko) | 2016-06-13 | 2022-05-12 | 도쿄엘렉트론가부시키가이샤 | 기판 반송 장치 및 기판 반송 방법 |

| US10943805B2 (en) | 2018-05-18 | 2021-03-09 | Applied Materials, Inc. | Multi-blade robot apparatus, electronic device manufacturing apparatus, and methods adapted to transport multiple substrates in electronic device manufacturing |

| TW202211357A (zh) * | 2020-08-17 | 2022-03-16 | 日商東京威力科創股份有限公司 | 搬運裝置、搬運系統、及末端執行器 |

| TWI744078B (zh) * | 2020-11-06 | 2021-10-21 | 三和技研股份有限公司 | 控制複數承接件間距之機械手臂 |

| US11970403B2 (en) * | 2022-06-27 | 2024-04-30 | Saudi Arabian Oil Company | Method of zeolite synthesis including pH-modified water-soluble oxidized disulfide oil composition |

| US11958751B2 (en) * | 2022-06-27 | 2024-04-16 | Saudi Arabian Oil Company | Method of synthesizing materials integrating supernatant recycle |

Citations (2)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| JPH0687531A (ja) * | 1992-09-09 | 1994-03-29 | Hitachi Ltd | 受け渡し治具および装置 |

| JP2002299405A (ja) * | 2001-03-29 | 2002-10-11 | Dainippon Screen Mfg Co Ltd | 基板搬送装置 |

Family Cites Families (13)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| JP3143770B2 (ja) | 1994-10-07 | 2001-03-07 | 東京エレクトロン株式会社 | 基板搬送装置 |

| US5700046A (en) | 1995-09-13 | 1997-12-23 | Silicon Valley Group, Inc. | Wafer gripper |

| WO2000014772A1 (de) * | 1998-09-02 | 2000-03-16 | Tec-Sem Ag | Vorrichtung und verfahren zum handhaben von einzelnen wafern |

| US7048316B1 (en) * | 2002-07-12 | 2006-05-23 | Novellus Systems, Inc. | Compound angled pad end-effector |

| US20090101067A1 (en) | 2005-07-08 | 2009-04-23 | Bonora Anthony C | Method and apparatus for wafer support |

| JP4976811B2 (ja) * | 2006-10-30 | 2012-07-18 | 東京エレクトロン株式会社 | 基板処理システム、基板搬送装置、基板搬送方法、および記録媒体 |

| US9437469B2 (en) | 2007-04-27 | 2016-09-06 | Brooks Automation, Inc. | Inertial wafer centering end effector and transport apparatus |

| KR101534357B1 (ko) * | 2009-03-31 | 2015-07-06 | 도쿄엘렉트론가부시키가이샤 | 기판 지지 장치 및 기판 지지 방법 |

| JP5141707B2 (ja) * | 2010-03-24 | 2013-02-13 | 株式会社安川電機 | 被処理体の支持機構、支持方法およびそれを備えた搬送システム |

| JP5490741B2 (ja) * | 2011-03-02 | 2014-05-14 | 東京エレクトロン株式会社 | 基板搬送装置の位置調整方法、及び基板処理装置 |

| JPWO2012141067A1 (ja) * | 2011-04-15 | 2014-07-28 | タツモ株式会社 | ウエハ交換装置およびウエハ支持用ハンド |

| US8864202B1 (en) * | 2013-04-12 | 2014-10-21 | Varian Semiconductor Equipment Associates, Inc. | Spring retained end effector contact pad |

| US20160155658A1 (en) * | 2014-12-02 | 2016-06-02 | Macronix International Co., Ltd. | Semiconductor wafer holder and wafer carrying tool using the same |

-

2015

- 2015-04-15 US US14/687,506 patent/US9779977B2/en active Active

-

2016

- 2016-04-08 JP JP2016077712A patent/JP2016208018A/ja active Pending

- 2016-04-11 TW TW105111170A patent/TWI693989B/zh active

- 2016-04-14 KR KR1020160045620A patent/KR20160123248A/ko not_active IP Right Cessation

-

2017

- 2017-08-29 US US15/689,330 patent/US10707113B2/en active Active

-

2023

- 2023-10-05 KR KR1020230132163A patent/KR20230145013A/ko not_active Application Discontinuation

Patent Citations (2)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| JPH0687531A (ja) * | 1992-09-09 | 1994-03-29 | Hitachi Ltd | 受け渡し治具および装置 |

| JP2002299405A (ja) * | 2001-03-29 | 2002-10-11 | Dainippon Screen Mfg Co Ltd | 基板搬送装置 |

Also Published As

| Publication number | Publication date |

|---|---|

| TWI693989B (zh) | 2020-05-21 |

| US20180005865A1 (en) | 2018-01-04 |

| TW201707897A (zh) | 2017-03-01 |

| US20160303742A1 (en) | 2016-10-20 |

| US9779977B2 (en) | 2017-10-03 |

| KR20160123248A (ko) | 2016-10-25 |

| US10707113B2 (en) | 2020-07-07 |

| KR20230145013A (ko) | 2023-10-17 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| US10699937B2 (en) | Wafer positioning pedestal for semiconductor processing | |

| KR20230145013A (ko) | 깨끗한/더러운 기판 핸들링을 위한 엔드 이펙터 어셈블리 | |

| US10741365B2 (en) | Low volume showerhead with porous baffle | |

| KR102458699B1 (ko) | 개선된 프로세스 균일도를 갖는 기판 지지부 | |

| KR102654243B1 (ko) | 고밀도 플라즈마 cvd 시스템들에서 제 1 웨이퍼 금속 오염 효과 제거 | |

| WO2018075750A1 (en) | Pin lifter assembly with small gap | |

| US20200227304A1 (en) | Planar substrate edge contact with open volume equalization pathways and side containment | |

| KR20190112167A (ko) | 아킹 (arcing) 을 감소시키기 위한 헬륨 플러그 설계 | |

| US10460977B2 (en) | Lift pin holder with spring retention for substrate processing systems | |

| US12087573B2 (en) | Modulation of oxidation profile for substrate processing | |

| TWI849145B (zh) | 基板處理系統用的縮小直徑承載環硬件 | |

| WO2023069924A1 (en) | Valve manifold for semiconductor processing |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| A521 | Request for written amendment filed |

Free format text: JAPANESE INTERMEDIATE CODE: A523 Effective date: 20160930 |

|

| A521 | Request for written amendment filed |

Free format text: JAPANESE INTERMEDIATE CODE: A523 Effective date: 20190401 |

|

| A621 | Written request for application examination |

Free format text: JAPANESE INTERMEDIATE CODE: A621 Effective date: 20190401 |

|

| A977 | Report on retrieval |

Free format text: JAPANESE INTERMEDIATE CODE: A971007 Effective date: 20200529 |

|

| A131 | Notification of reasons for refusal |

Free format text: JAPANESE INTERMEDIATE CODE: A131 Effective date: 20200623 |

|

| A02 | Decision of refusal |

Free format text: JAPANESE INTERMEDIATE CODE: A02 Effective date: 20210202 |