JP2016013812A - Component for mounting vehicular component - Google Patents

Component for mounting vehicular component Download PDFInfo

- Publication number

- JP2016013812A JP2016013812A JP2014137867A JP2014137867A JP2016013812A JP 2016013812 A JP2016013812 A JP 2016013812A JP 2014137867 A JP2014137867 A JP 2014137867A JP 2014137867 A JP2014137867 A JP 2014137867A JP 2016013812 A JP2016013812 A JP 2016013812A

- Authority

- JP

- Japan

- Prior art keywords

- sticking

- release paper

- mounting

- adhesive material

- retainer

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Pending

Links

- 239000000853 adhesive Substances 0.000 claims abstract description 29

- 230000001070 adhesive effect Effects 0.000 claims abstract description 29

- 239000000463 material Substances 0.000 claims abstract description 19

- 230000015572 biosynthetic process Effects 0.000 claims description 11

- 230000002093 peripheral effect Effects 0.000 claims description 3

- 238000000926 separation method Methods 0.000 abstract 1

- 238000005452 bending Methods 0.000 description 3

- 239000000919 ceramic Substances 0.000 description 3

- 229920001707 polybutylene terephthalate Polymers 0.000 description 3

- 230000005540 biological transmission Effects 0.000 description 2

- 230000000694 effects Effects 0.000 description 1

- 238000000034 method Methods 0.000 description 1

- 238000012986 modification Methods 0.000 description 1

- 230000004048 modification Effects 0.000 description 1

- -1 polybutylene terephthalate Polymers 0.000 description 1

- 239000011347 resin Substances 0.000 description 1

- 229920005989 resin Polymers 0.000 description 1

- 230000009466 transformation Effects 0.000 description 1

Images

Classifications

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B60—VEHICLES IN GENERAL

- B60R—VEHICLES, VEHICLE FITTINGS, OR VEHICLE PARTS, NOT OTHERWISE PROVIDED FOR

- B60R19/00—Wheel guards; Radiator guards, e.g. grilles; Obstruction removers; Fittings damping bouncing force in collisions

- B60R19/02—Bumpers, i.e. impact receiving or absorbing members for protecting vehicles or fending off blows from other vehicles or objects

- B60R19/48—Bumpers, i.e. impact receiving or absorbing members for protecting vehicles or fending off blows from other vehicles or objects combined with, or convertible into, other devices or objects, e.g. bumpers combined with road brushes, bumpers convertible into beds

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F16—ENGINEERING ELEMENTS AND UNITS; GENERAL MEASURES FOR PRODUCING AND MAINTAINING EFFECTIVE FUNCTIONING OF MACHINES OR INSTALLATIONS; THERMAL INSULATION IN GENERAL

- F16B—DEVICES FOR FASTENING OR SECURING CONSTRUCTIONAL ELEMENTS OR MACHINE PARTS TOGETHER, e.g. NAILS, BOLTS, CIRCLIPS, CLAMPS, CLIPS OR WEDGES; JOINTS OR JOINTING

- F16B47/00—Suction cups for attaching purposes; Equivalent means using adhesives

-

- G—PHYSICS

- G01—MEASURING; TESTING

- G01S—RADIO DIRECTION-FINDING; RADIO NAVIGATION; DETERMINING DISTANCE OR VELOCITY BY USE OF RADIO WAVES; LOCATING OR PRESENCE-DETECTING BY USE OF THE REFLECTION OR RERADIATION OF RADIO WAVES; ANALOGOUS ARRANGEMENTS USING OTHER WAVES

- G01S7/00—Details of systems according to groups G01S13/00, G01S15/00, G01S17/00

- G01S7/52—Details of systems according to groups G01S13/00, G01S15/00, G01S17/00 of systems according to group G01S15/00

- G01S7/521—Constructional features

Landscapes

- Engineering & Computer Science (AREA)

- General Engineering & Computer Science (AREA)

- Mechanical Engineering (AREA)

- Computer Networks & Wireless Communication (AREA)

- Physics & Mathematics (AREA)

- General Physics & Mathematics (AREA)

- Radar, Positioning & Navigation (AREA)

- Remote Sensing (AREA)

- Hooks, Suction Cups, And Attachment By Adhesive Means (AREA)

- Measurement Of Velocity Or Position Using Acoustic Or Ultrasonic Waves (AREA)

Abstract

Description

本発明は、超音波センサなどの車両用部品を車両に取り付けるための取付用部品に関する。 The present invention relates to a mounting component for mounting a vehicle component such as an ultrasonic sensor to a vehicle.

例えば、特許文献1に、車両用部品としての超音波センサを、車両のバンパに取り付けるための取付用部品としての固定用リテーナが開示されている。この固定用リテーナは、センサを支持するセンサ支持部と、断面が略六角形状であるセンサ支持部の対向する2組の各辺から斜め下方に向かって突出する二対(合計4本)の支柱部と、各支柱部の先端部と連結する固定部と、を有している。固定部の底面部には、接着部材としての両面テープが取り付けられていて、この両面テープにより、固定部がバンパの裏面に接着されることで、固定用リテーナがバンパに固定される。 For example, Patent Document 1 discloses a fixing retainer as an attachment part for attaching an ultrasonic sensor as a vehicle part to a bumper of a vehicle. This fixing retainer has two pairs (four in total) of struts projecting obliquely downward from each of two opposing sides of the sensor support part for supporting the sensor and the sensor support part having a substantially hexagonal cross section. Part and a fixing part connected to the tip part of each support part. A double-sided tape as an adhesive member is attached to the bottom surface of the fixed part, and the fixed retainer is fixed to the bumper by bonding the fixed part to the back surface of the bumper with the double-sided tape.

特許文献1に記載のように、バンパなどの被接着面に、接着部材を用いて取付用部品を固定する場合、その固定前においては、接着部材の接着性を保持するため、取付用部品の取り扱いを容易にするため等の理由から、接着部材を剥離紙で覆っておくことが一般的に行われる。 As described in Patent Document 1, in the case where an attachment component is fixed to an adherend surface such as a bumper using an adhesive member, in order to maintain the adhesiveness of the adhesive member before the fixing, For reasons such as easy handling, the adhesive member is generally covered with release paper.

しかしながら、車両用部品を車両に取り付けるための取付用部品の場合、車両が走行する際の振動を受けても、自動車用部品を確実に固定しておく必要がある。そのため、接着部材として、接着力の相当強いものを用いる必要がある。その結果、剥離紙を接着部材から剥離する際に、接着部材にはかなりの応力が作用することになる。 However, in the case of an attachment part for attaching the vehicle part to the vehicle, it is necessary to securely fix the automobile part even if it receives vibrations when the vehicle travels. Therefore, it is necessary to use an adhesive member having a considerably strong adhesive force. As a result, considerable stress acts on the adhesive member when the release paper is peeled from the adhesive member.

その一方で、接着部材が設けられる固定部としては、バンパなどの被接着面の形状に合わせて柔軟に変形することが求められるので、固定部の形成材料としては、変形し易い柔軟な材料が用いられる。そのため、作業者が、例えば、センサ支持部を保持しつつ、支柱部とは反対側の固定部の先端側の剥離紙の端部を摘んで、剥離紙を接着部材から引き剥がそうとした場合、固定部が、剥離紙の引き剥がし方向に強く折り曲げられてしまう。その結果、固定部(もしくは支柱部)に折り曲げ方向にくせがついてしまい(塑性変形)、非接着面へ取り付ける際の作業性を悪化させたり、場合によっては、固定部(もしくは支柱部)が損傷して、十分な取り付け強度を確保できなかったり、といった不具合が生じる虞がある。 On the other hand, since the fixing portion provided with the adhesive member is required to be flexibly deformed in accordance with the shape of the surface to be bonded such as a bumper, the forming material of the fixing portion is a flexible material that is easily deformable. Used. Therefore, for example, when an operator tries to peel off the release paper from the adhesive member by holding the sensor support part and picking the end of the release paper on the tip side of the fixed part opposite to the support part. The fixing portion is strongly bent in the peeling direction of the release paper. As a result, the fixing part (or support part) is distorted in the bending direction (plastic deformation), and the workability when attaching to the non-adhesive surface is deteriorated, or in some cases, the fixing part (or support part) is damaged. As a result, there may be a problem that sufficient attachment strength cannot be secured.

本発明は、上述した点に鑑みてなされたものであり、接着用材料が形成された貼付部から剥離紙を剥離するときに、貼付部の変形や損傷を防止することが可能な取付用部品を提供する事を目的とする。 The present invention has been made in view of the above-described points, and is an attachment component capable of preventing deformation and damage of the sticking portion when the release paper is peeled from the sticking portion on which the adhesive material is formed. The purpose is to provide.

上記目的を達成するために、本発明による取付用部品は、部品を車両に取り付けるためのものであって、

部品を保持する保持部(21)と、

保持部の周囲から延び、表面に接着用材料が形成された貼付面(26a)を有し、当該貼付面が、部品を取り付けるべき車両の被貼付面に貼り付けられる複数の貼付部(26)と、を備え、

貼付部が車両に貼り付けられる前は、貼付面の接着用材料の形成領域を覆う剥離紙(30)が、貼付面に貼り付けられており、

剥離紙を剥離する際に、貼付部を保持できるように、保持部から遠い側の貼付部の先端に、接着用材料が形成されない把持部(29)が設けられていることを特徴とする。

In order to achieve the above object, the mounting component according to the present invention is for mounting the component on a vehicle,

A holding part (21) for holding parts;

A plurality of affixing parts (26) having an affixing surface (26a) extending from the periphery of the holding part and having an adhesive material formed on the surface thereof, and affixing the affixing surface to the affixed surface of the vehicle to which the parts are to be attached. And comprising

Before the affixing part is affixed to the vehicle, a release paper (30) that covers the formation area of the adhesive material on the affixing surface is affixed to the affixing surface,

A grip part (29) where no adhesive material is formed is provided at the tip of the sticking part far from the holding part so that the sticking part can be held when peeling the release paper.

このように、本発明では、貼付部の先端に、接着用材料が形成されない把持部が設けられている。このため、作業者は、この把持部を把持しつつ、剥離紙を接着用材料から剥離することができる。その結果、剥離紙の剥離時に、貼付部に応力が作用しても、貼付部が大きく変形することを抑制することができる。そのため、貼付部の変形や損傷を防止することができる。 Thus, in this invention, the holding part in which the adhesive material is not formed is provided in the front-end | tip of the sticking part. For this reason, the operator can peel the release paper from the adhesive material while gripping the grip portion. As a result, when the release paper is peeled off, it is possible to prevent the sticking portion from being greatly deformed even if stress is applied to the sticking portion. Therefore, deformation and damage of the sticking part can be prevented.

上記構成において、剥離紙は、複数の貼付部の貼付面における接着用材料の形成領域を、1枚で全て覆うことが可能なものであり、把持部は、複数の貼付部の中の少なくとも1つの貼付部に設けられても良い。1枚の剥離紙で、複数の貼付部の貼付面における接着用材料の形成領域を全て覆うようにすると、それぞれの接着用材料の形成領域を個別の剥離紙によって覆うようにした場合に比較し、剥離紙の剥離作業を効率的に行うことができる。さらに、剥離紙を剥離する際、その剥離開始時に、貼付部において剥離紙を引きはがす方向に大きな応力が作用する。従って、剥離開始時に作用する応力による変形を防止すれば十分であるため、把持部は、複数の貼付部の中の少なくとも1つの貼付部に設けるだけで済む。 In the above-described configuration, the release paper can cover all the formation region of the adhesive material on the application surfaces of the plurality of application parts with one sheet, and the gripping part is at least one of the plurality of application parts. It may be provided in one sticking part. Covering all of the adhesive material formation areas on the application surfaces of a plurality of application parts with a single release paper, compared to the case where each adhesive material formation area is covered with an individual release paper. The release paper can be efficiently peeled off. Further, when the release paper is peeled off, a large stress acts in the direction of peeling the release paper at the sticking portion at the start of the peeling. Therefore, since it is sufficient to prevent deformation due to stress acting at the start of peeling, the gripping portion only needs to be provided on at least one pasting portion among the plurality of pasting portions.

上記括弧内の参照番号は、本発明の理解を容易にすべく、後述する実施形態における具体的な構成との対応関係の一例を示すものにすぎず、なんら本発明の範囲を制限することを意図したものではない。 The reference numerals in the parentheses merely show an example of a correspondence relationship with a specific configuration in an embodiment described later in order to facilitate understanding of the present invention, and are intended to limit the scope of the present invention. Not intended.

また、上述した特徴以外の、特許請求の範囲の各請求項に記載した技術的特徴に関しては、後述する実施形態の説明及び添付図面から明らかになる。 Further, the technical features described in the claims of the claims other than the features described above will become apparent from the description of embodiments and the accompanying drawings described later.

以下、本発明に係る取付用部品の実施形態について図面を用いて説明する。なお、本実施形態では、車両周囲の障害物を検出するための超音波センサを車両用部品とし、当該超音波センサを車両のバンパの裏面に取り付けるための取付用部品であるリテーナについて説明する。 Hereinafter, embodiments of a mounting part according to the present invention will be described with reference to the drawings. In the present embodiment, an ultrasonic sensor for detecting obstacles around the vehicle is used as a vehicle component, and a retainer that is a mounting component for mounting the ultrasonic sensor on the back surface of a bumper of the vehicle will be described.

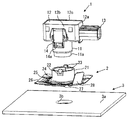

まず、超音波センサ1について、図1を参照しつつ説明する。超音波センサ1は、例えば、圧電効果により圧電セラミック振動子を振動させて超音波を発射し、また圧電セラミック振動子に入射した超音波の振動を電気信号に変換する送受信兼用型のものである。この超音波センサ1は、図1に示されるように、センサ本体11、筐体部12などから構成される。

First, the ultrasonic sensor 1 will be described with reference to FIG. The ultrasonic sensor 1 is, for example, a transmission / reception type that oscillates a piezoelectric ceramic vibrator by a piezoelectric effect to emit ultrasonic waves, and converts ultrasonic vibrations incident on the piezoelectric ceramic vibrator into electric signals. . As shown in FIG. 1, the ultrasonic sensor 1 includes a sensor

センサ本体11は、その先端部11a(下端部)が最小径とされた段付き円筒状に形成されている。センサ本体11の先端部11aには、圧電セラミック振動子を内蔵したマイクロホンが組み込まれている。

The

筐体部12は、センサ本体11に連結されており、平面視にてセンサ本体11を包含する大きさに形成されている。筐体部12には、マイクロホンから超音波を発射させたり、マイクロホンに超音波が入射されたときに、その超音波による電気信号を処理して、超音波を受信したことを検出したりする処理を行う制御基板が収容されている。そして、筐体部12の一側面12aには、図示しない外部装置との接続のためのケーブルの一端が接続される接続端子部13が設けられている。そのケーブルを介して、超音波センサ1から外部装置に、超音波の送受信結果が送信される。

The

また、筐体部12の、接続端子部13が設けられた側面12aの両隣の側面12b、12cには、それぞれ、下方に向かって伸びる腕部14が設けられている。腕部14には、係合用貫通孔14aが形成されている。この係合用貫通孔14aは、超音波センサ1がリテーナ2に取り付けられるとき、リテーナ2のテーパ状突起22と係合し、超音波センサ1がリテーナ2から抜け落ちることを防止する。なお、リテーナ2に係合用貫通孔を設け、超音波センサ1に、その係合用貫通孔と係合するテーパ状突起を設けても良い。

Moreover, the

さらに、腕部14の内部には、リテーナ2の上端面から突出する突起23と嵌合する溝が形成されている。リテーナ2のテーパ状突起22が、腕部14の係合用貫通孔14aに係合したとき、同時に、腕部14の内部の溝に突起23が嵌合されることで、超音波センサ1が、中心軸線周りに回転することを防止することができる。

Further, a groove is formed in the

なお、超音波センサ1が、リテーナ2に取り付けられる際には、リテーナ2のリテーナ本体21の上端面が、筐体部12の下端面に当接して、超音波センサ1の筐体部12を支持する。

When the ultrasonic sensor 1 is attached to the

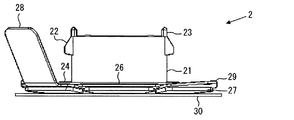

次に、リテーナ2について、図1〜図5を参照して、詳しく説明する。なお、図2はリテーナ2の平面図、図3は図2の矢印A方向からみたリテーナ2の側面図、図4は図2の矢印B方向からみたリテーナ2の側面図、及び図5はリテーナ2の下面図である。ここで、図2〜図4においては、剥離紙30が貼り付けられた状態のリテーナ2を示している。一方、図5においては、リテーナ2の下面の様子を示すために、剥離紙30の図示を省略している。

Next, the

リテーナ2は、必要な寸法精度や強度が得られる、また柔軟性も有しているなどの観点から、例えばポリブチレンテレフタレート(PBT)や、ポリカーボネート−ポリブチレンテレフタレート(PCPBT)等の樹脂材料で形成される。このリテーナ2は、センサ本体11が挿入されるとともに、テーパ状突起22や突起23及びその上端面により、超音波センサ1を支持固定する円筒状のリテーナ本体21を有する。リテーナ本体21の下端部には、リテーナ本体21よりも大径に形成されたリング状の基部24が設けられている。

The

そして、基部24の側面には、複数の連結部25を介して、複数の貼付部26が接続されている(図1に示す例では、貼付部26の数は8)。連結部25は、貼付部26がバンパ3の形状に追従して変形しやすいように、貼付部26の横幅よりも細くなっている。そして、連結部25は、貼付部26の横幅の中央位置において、貼付部26に連なっている。

And the some sticking

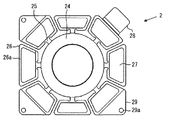

各貼付部26は、下面がバンパ3に貼り付けられる貼付面26aとなっている。その貼付面26aと反対側の上面には、複数の溝部26bが形成されている。図2に示すように、テーパ状突起22の直下から連結部25が伸びる一対の貼付部26を除く貼付部26においては、横幅方向に沿って2本の溝部26bが形成されている。また、テーパ状突起22の直下から連結部25が伸びる一対の貼付部26においては、貼付部26の横幅方向の中央付近にて、略台形状の貼付部26の平行に伸びる2辺に対して直交する方向に、一本の溝部26b1が形成され、その一本の溝部26b1の両側において、それぞれ、横幅方向に伸びる2本の溝部26b2が形成されている。

Each sticking

溝部26b、26b1、26b2が形成された部位は、溝部26b、26b1、26b2が形成されていない貼付部26の他の部位に比べて薄肉となっている。このため、貼付部26は、溝部26b、26b1、26b2を曲げ中心として図示紙面の表裏方向に曲がりやすくなっている。これにより、貼付部26のバンパ3の形状への追従性を向上することができる。なお、溝部26b、26b1、26b2の形成位置は、図2に示す例に限られず、貼付部26のバンパ3の形状への追従性を向上できるものであれば、採用することができる。

The site | part in which

図5に示すように、複数の貼付部26の各貼付面26aは、すべて略台形状となっている。これにより、隣接する貼付部26との隙間を小さくすることができ、貼付面26aの面積を十分に確保しやすくなる。

As shown in FIG. 5, each of the pasting surfaces 26 a of the plurality of

複数の貼付面26aには、それぞれ、両面テープ27が貼り付けられている。この両面テープ27は、図5に示すように、各貼付面26aの形状と相似する台形状をなしている。このため、各貼付面26aの大部分の領域をカバーするように、両面テープ27を設けることができ、十分な貼付面積を得ることが可能になる。また、両面テープ27は、車両が走行する際の振動を受けても、バンパ3から脱落しないよう、十分に強い接着強度を有するものが用いられる。

Double-

そして、複数の貼付部26の貼付面26aにおける両面テープ27をバンパ3の内側面(裏面)3aの所定位置に貼り付けることにより、リテーナ2をバンパ3の内側面3aに固定する。この際、貼付部26は、十分な柔軟性を有しているため、バンパ3の内側面3aが曲面状に形成されていても、その形状に追従するように変形することができる。

Then, the

なお、バンパ3には、当該バンパ3を貫通するとともに、センサ本体11の先端部11aが挿入されるバンパ孔3bが形成されている。リテーナ2は、リテーナ本体21が、そのバンパ孔3bを取り囲むように、バンパ3の内側面3aに固定される。これにより、リテーナ2に超音波センサ1を固定したとき、センサ本体11の先端部11aが、バンパ3の表面側に露出される。

The

ここで、複数の貼付面26aに両面テープ27を貼り付けて、貼付部26をバンパ3の内側面3aに貼り付ける場合、その貼付直前まで、両面テープ27の接着性を劣化させないため、また、リテーナ2の取り扱いを容易にするため等の理由から、両面テープ27を剥離紙30で覆っておく。

Here, in the case where the double-

この剥離紙30は、図2〜図4に示すように、複数の貼付部26の貼付面26aにおける両面テープ27の形成領域を、1枚で全て覆うことが可能なものである。1枚の剥離紙30で、複数の貼付部26の貼付面26aにおける両面テープ27の形成領域を全て覆うようにすると、それぞれの両面テープ27の形成領域を個別の剥離紙によって覆うようにした場合に比較し、剥離紙30の剥離作業を効率的に行うことができる。

As shown in FIGS. 2 to 4, the

さらに言えば、剥離紙30は、複数の貼付部26の貼付面26aにおける両面テープ27の形成領域の全部を1枚で覆ったときに、剥離紙30の周縁部が、貼付部26の先端よりも外側にはみ出る大きさを有する。これにより、作業者が、剥離紙30を剥離する作業を行う際に、剥離紙30の周縁部を摘みやすくなり、作業性を向上することができる。

Furthermore, when the

しかしながら、上述したように、複数の連結部25及び貼付部26は、バンパ3の内側面3aの形状に追従できるように容易に変形可能に形成されている。そのため、作業者が、例えば、リテーナ本体21を保持しつつ、貼付部26の先端側からはみ出た剥離紙30の端部を摘んで、剥離紙30を両面テープ27から引き剥がそうとした場合、貼付部26が、剥離紙30の引き剥がし方向に強く力を受ける。その結果、連結部25や貼付部26に折り曲げ方向にくせがついてしまい、非接着面へ取り付ける際の作業性を悪化させたり、場合によっては、連結部25や貼付部26が損傷して、十分な取り付け強度を確保できなかったり、といった不具合が生じる虞がある。

However, as described above, the plurality of connecting

そこで、本実施形態では、各図に示すように、複数の貼付部26の内の1つの貼付部26において、当該貼付部26の先端に、両面テープ27が形成されない把持部28を設けた。つまり、把持部28は、貼付部26の先端に連なって設けられており、作業者が把持するために十分な面積を有している。従って、作業者が剥離紙30の剥離作業を行うときに、剥離紙30によって貼付部26を折り曲げようとする力が作用しても、作業者が把持部28を把持することにより、貼付部26が大きく変形することを抑制することができる。そのため、貼付部26及び連結部25の変形や損傷を防止することができる。

Therefore, in the present embodiment, as shown in each drawing, in one affixing

さらに、把持部28は、剥離紙30から離間するように、貼付部26の貼付面26aに対して折曲して設けられている。これにより、把持部28と剥離紙30との間には、十分な間隔が開くので、作業者は、容易に、剥離紙30の端部を摘んだり、把持部28を把持したりすることができる。その結果、作業者は、剥離紙30の剥離作業を効率的に行うことが可能となる。

Further, the

本実施形態では、上述したように、複数の貼付部26の貼付面26aにおける両面テープ27の形成領域を、1枚で全て覆うことが可能な剥離紙30を用いている。この場合、剥離紙30を剥離する際の初期段階において、貼付部26において剥離紙を引きはがす方向に最も大きな応力が作用する。従って、剥離開始時に作用する応力による変形を防止すれば、連結部25及び貼付部26の変形や損傷の防止には十分であるため、把持部28は、複数の貼付部26の中の1つの貼付部26に設けるだけで良い。

In the present embodiment, as described above, the

なお、本実施形態では、図2や図5に示すように、把持部28が設けられた貼付部26以外に、剥離紙30の四隅に位置する残り3つの貼付部26においても、貼付部26の先端側に、略三角形状の延長部29が設けられている。図5に示すように、この延長部29の下面には、両面テープ27が形成されていない。この延長部29の主たる役割は、リテーナ2に外観状の特徴を持たせることである。つまり、車両の種類に応じてバンパ3の形状が異なるので、そのバンパ3の形状に合わせて、貼付部26の形状や、溝部26bの形成位置を異ならせる場合がある。そのような場合に、いずれの種類の車両用のリテーナ2であるかを一見して判断できるように、外観状の特徴を持たせるのである。そのため、あるリテーナ2は、全く延長部29を有さない場合もあれば、一つの延長部29しか有さない場合、あるいは、2つの延長部29、もしくは3つの延長部29を有する場合もある。さらに、外観上の特徴として、延長部29に形成する貫通穴29aも利用できる。

In this embodiment, as shown in FIG. 2 and FIG. 5, in addition to the

ただし、上述した延長部29も、下面に両面テープ27が形成されないので、剥離紙30を剥離する際に、貼付部26を保持するための把持部として利用することが可能である。

However, since the double-

以上、本発明の好ましい実施形態について説明したが、本発明は、上述した実施形態になんら制限されるものではなく、本発明の主旨を逸脱しない範囲において、種々変形して実施することが可能なものである。 The preferred embodiments of the present invention have been described above. However, the present invention is not limited to the above-described embodiments, and various modifications can be made without departing from the spirit of the present invention. Is.

例えば、上述した実施形態では、連結部25の幅を、貼付部26の横幅よりも細くした例について説明した。しかしながら、連結部25の幅は、貼付部26の連結部25側の横幅と同じであっても良い。また、台形状の貼付部26のハの字型に狭まる二辺を、そのまま基部24まで延長しても良い。

For example, in the above-described embodiment, the example in which the width of the connecting

上述した実施形態では、貼付部26を8個設けたが、貼付部26の数は、8個に限られない。また、貼付部26の形状も、台形形状以外の形状としても良い。

In the embodiment described above, eight

また、上述した実施形態では、超音波センサ1を車両のバンパ3に取り付けるためのリテーナ2について説明したが、他の車両部品を、車両の他の部位に固定するために、本発明を利用しても良い。

In the embodiment described above, the

1 超音波センサ

2 リテーナ

3 バンパ

21 リテーナ本体

22 テーパ状突起

23 突起

24 基部

25 連結部

26 貼付部

27 両面テープ

28 把持部

29 延長部

DESCRIPTION OF SYMBOLS 1

Claims (6)

前記部品を保持する保持部(21)と、

前記保持部の周囲から延び、表面に接着用材料が形成された貼付面(26a)を有し、当該貼付面が、前記部品を取り付けるべき前記車両の被貼付面(3a)に貼り付けられる複数の貼付部(26)と、を備え、

前記貼付部が、前記車両に貼り付けられる前は、前記貼付面の接着用材料の形成領域を覆う剥離紙(30)が、前記貼付面に貼り付けられており、

前記剥離紙を剥離する際に、前記貼付部を保持できるように、前記保持部から遠い側の前記貼付部の先端に、前記接着用材料が形成されない把持部(28)が設けられていることを特徴とする取付用部品。 A mounting part for mounting a part on a vehicle,

A holding portion (21) for holding the component;

A plurality of sticking surfaces (26a) extending from the periphery of the holding portion and having an adhesive material formed on the surface thereof, the sticking surfaces being attached to the to-be-attached surface (3a) of the vehicle to which the parts are to be attached. And a sticking part (26).

Before the affixing portion is affixed to the vehicle, a release paper (30) that covers the adhesive material forming region of the affixing surface is affixed to the affixing surface,

A gripping part (28) where the adhesive material is not formed is provided at the tip of the sticking part far from the holding part so that the sticking part can be held when the release paper is peeled off. Mounting parts characterized by

前記把持部は、前記複数の貼付部の中の少なくとも1つの貼付部に設けられることを特徴とする請求項1に記載の取付用部品。 The release paper is capable of covering all the formation region of the adhesive material on the application surface of the plurality of application parts with one sheet,

The mounting part according to claim 1, wherein the grip portion is provided in at least one pasting portion of the plurality of pasting portions.

前記取付用部品は、前記超音波センサを、前記車両のバンパ(3)の裏面を前記被貼付面として、前記バンパの裏面側に取り付けるためのものであることを特徴とする請求項1乃至5のいずれか1項に記載の取付用部品。 The component is an ultrasonic sensor (1),

The mounting part is for mounting the ultrasonic sensor on the back side of the bumper with the back surface of the bumper (3) of the vehicle as the pasted surface. The mounting part according to any one of the above.

Priority Applications (3)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| JP2014137867A JP2016013812A (en) | 2014-07-03 | 2014-07-03 | Component for mounting vehicular component |

| PCT/JP2015/002057 WO2016002117A1 (en) | 2014-07-03 | 2015-04-13 | Fitting component |

| CN201580009826.7A CN106030334A (en) | 2014-07-03 | 2015-04-13 | Fitting component |

Applications Claiming Priority (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| JP2014137867A JP2016013812A (en) | 2014-07-03 | 2014-07-03 | Component for mounting vehicular component |

Publications (2)

| Publication Number | Publication Date |

|---|---|

| JP2016013812A true JP2016013812A (en) | 2016-01-28 |

| JP2016013812A5 JP2016013812A5 (en) | 2016-06-16 |

Family

ID=55018701

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| JP2014137867A Pending JP2016013812A (en) | 2014-07-03 | 2014-07-03 | Component for mounting vehicular component |

Country Status (3)

| Country | Link |

|---|---|

| JP (1) | JP2016013812A (en) |

| CN (1) | CN106030334A (en) |

| WO (1) | WO2016002117A1 (en) |

Cited By (2)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| JP2017144913A (en) * | 2016-02-18 | 2017-08-24 | 株式会社デンソー | Retainer for sensor |

| US10696237B2 (en) | 2016-10-04 | 2020-06-30 | Honda Access Corp. | Attachment component |

Families Citing this family (3)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| FR3057239B1 (en) * | 2016-10-07 | 2021-02-19 | Renault Sas | SUPPORT FOR FIXING A FUNCTIONAL BODY WITH A CARRIER STRUCTURE, FOR EXAMPLE A SHIELD OF A MOTOR VEHICLE |

| CN107284383A (en) * | 2017-06-26 | 2017-10-24 | 重庆长安汽车股份有限公司 | A kind of charge port box mounting structure for being arranged in rear bumper |

| TWI653165B (en) * | 2017-10-19 | 2019-03-11 | 為升電裝工業股份有限公司 | Mounting mechanism of vehicle sensor |

Citations (2)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| JPS53260U (en) * | 1976-06-22 | 1978-01-05 | ||

| JP2013221880A (en) * | 2012-04-18 | 2013-10-28 | Denso Corp | Retainer for mounting sensor |

Family Cites Families (11)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| JPH0827839A (en) * | 1994-07-15 | 1996-01-30 | Yutani Heavy Ind Ltd | Control device of construction machinery |

| EP0923677B1 (en) * | 1997-07-11 | 2001-12-05 | Robert Bosch Gmbh | Element for securing a body into a wall |

| CN2430315Y (en) * | 2000-07-13 | 2001-05-16 | 钱建华 | Fixing board for mounting automobile instrument |

| DE10314862A1 (en) * | 2003-04-02 | 2004-10-14 | Bayerische Motoren Werke Ag | Parking aid sensor arrangement |

| CN2887678Y (en) * | 2006-03-10 | 2007-04-11 | 深圳市豪恩实业有限公司 | Backing display device |

| JP2008118256A (en) * | 2006-11-01 | 2008-05-22 | Mitsukuni Ito | Cognitive psycho-patient protective system |

| FR2950943A1 (en) * | 2009-10-06 | 2011-04-08 | Faurecia Bloc Avant | Fixation element for fixing functional unit i.e. ultrasonic sensor, at rear of bumper skin of motor vehicle, has rectangular connection plate provided with fixation units, where connection plate is conformed to geometry of receiving zone |

| JP5459508B2 (en) * | 2010-10-15 | 2014-04-02 | 株式会社デンソー | Retainer for fixing the sensor to the bumper |

| FR2978400B1 (en) * | 2011-07-25 | 2014-04-18 | Renault Sa | DEVICE FOR FASTENING A FUNCTIONAL ORGAN FOR A PROTECTIVE ELEMENT OF A MOTOR VEHICLE |

| JP2013124981A (en) * | 2011-12-15 | 2013-06-24 | Panasonic Corp | Obstacle detector for vehicle |

| DE112012005811B4 (en) * | 2012-02-03 | 2016-07-28 | Mitsubishi Electric Corporation | Mounting structure for an ultrasonic sensor module |

-

2014

- 2014-07-03 JP JP2014137867A patent/JP2016013812A/en active Pending

-

2015

- 2015-04-13 CN CN201580009826.7A patent/CN106030334A/en active Pending

- 2015-04-13 WO PCT/JP2015/002057 patent/WO2016002117A1/en active Application Filing

Patent Citations (2)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| JPS53260U (en) * | 1976-06-22 | 1978-01-05 | ||

| JP2013221880A (en) * | 2012-04-18 | 2013-10-28 | Denso Corp | Retainer for mounting sensor |

Cited By (2)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| JP2017144913A (en) * | 2016-02-18 | 2017-08-24 | 株式会社デンソー | Retainer for sensor |

| US10696237B2 (en) | 2016-10-04 | 2020-06-30 | Honda Access Corp. | Attachment component |

Also Published As

| Publication number | Publication date |

|---|---|

| CN106030334A (en) | 2016-10-12 |

| WO2016002117A1 (en) | 2016-01-07 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| WO2016002117A1 (en) | Fitting component | |

| JP5971551B2 (en) | Retainer for sensor mounting | |

| JP6350020B2 (en) | Retainer for sensor mounting | |

| JP6365968B2 (en) | FIXING MEMBER AND ULTRASONIC SENSOR DEVICE USING THE FIXING MEMBER | |

| JP2016013812A5 (en) | ||

| JP5696894B2 (en) | Retainer for sensor mounting | |

| KR102396349B1 (en) | Electronic device including detachable adhesive member | |

| JP5575857B2 (en) | Battery fixing device and electronic device using the same | |

| JP6058022B2 (en) | Sensor module | |

| JP2008026458A (en) | Optical fiber sheet with connector and its manufacturing method | |

| JP7222905B2 (en) | Stick-on biosensor | |

| JP2007139437A (en) | Mounting method of ultrasonic sensor, and ultrasonic sensor mounting holder | |

| KR20120005260U (en) | .Adhesive system accessories for mobile information devices | |

| JP2005351653A (en) | Pressure sensor | |

| CN216214755U (en) | Assembling device special for M12 connector | |

| JP2021077599A5 (en) | ||

| JP2009125882A (en) | Robot hand | |

| JP6125264B2 (en) | Electronic device with flexible lead board | |

| JP2019140356A (en) | Flexible circuit board | |

| JP2013149182A (en) | Input device | |

| JP3736783B2 (en) | Method of attaching buffer member for liquid crystal display device | |

| JP2006292003A (en) | Release paper removal mechanism | |

| JP6562714B2 (en) | Electronics | |

| JP6649606B2 (en) | Speaker | |

| JP4353831B2 (en) | Horn for ultrasonic bonding machine |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| A521 | Request for written amendment filed |

Free format text: JAPANESE INTERMEDIATE CODE: A523 Effective date: 20160421 |

|

| A621 | Written request for application examination |

Free format text: JAPANESE INTERMEDIATE CODE: A621 Effective date: 20170228 |

|

| A131 | Notification of reasons for refusal |

Free format text: JAPANESE INTERMEDIATE CODE: A131 Effective date: 20171003 |

|

| A521 | Request for written amendment filed |

Free format text: JAPANESE INTERMEDIATE CODE: A523 Effective date: 20171110 |

|

| A02 | Decision of refusal |

Free format text: JAPANESE INTERMEDIATE CODE: A02 Effective date: 20180109 |