JP2015229041A5 - - Google Patents

Download PDFInfo

- Publication number

- JP2015229041A5 JP2015229041A5 JP2014117379A JP2014117379A JP2015229041A5 JP 2015229041 A5 JP2015229041 A5 JP 2015229041A5 JP 2014117379 A JP2014117379 A JP 2014117379A JP 2014117379 A JP2014117379 A JP 2014117379A JP 2015229041 A5 JP2015229041 A5 JP 2015229041A5

- Authority

- JP

- Japan

- Prior art keywords

- fiber

- cleaning sheet

- scraping layer

- cleaning

- diameter

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Granted

Links

- 238000004140 cleaning Methods 0.000 claims description 38

- 238000007790 scraping Methods 0.000 claims description 24

- XLYOFNOQVPJJNP-UHFFFAOYSA-N water Substances O XLYOFNOQVPJJNP-UHFFFAOYSA-N 0.000 claims description 8

- 238000005296 abrasive Methods 0.000 claims description 7

- 239000002245 particle Substances 0.000 claims description 7

- 238000010521 absorption reaction Methods 0.000 claims description 3

- 238000000034 method Methods 0.000 claims description 3

- 239000000835 fiber Substances 0.000 claims 27

- 239000005022 packaging material Substances 0.000 claims 7

- 239000011248 coating agent Substances 0.000 claims 3

- 238000000576 coating method Methods 0.000 claims 3

- 238000004519 manufacturing process Methods 0.000 claims 3

- 238000004806 packaging method and process Methods 0.000 claims 3

- 230000002093 peripheral Effects 0.000 claims 2

- 239000002002 slurry Substances 0.000 claims 2

- 238000001035 drying Methods 0.000 claims 1

- 239000004745 nonwoven fabric Substances 0.000 claims 1

- 230000035699 permeability Effects 0.000 description 4

- 238000004049 embossing Methods 0.000 description 3

- 239000002689 soil Substances 0.000 description 1

Images

Description

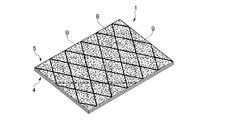

清掃用シート1には、掻き取り層5の表面に凹凸を形成してもよい。例えば図1に示すとおり、掻き取り層5の表面に、菱形格子状のヒートエンボス加工を施すことで、菱形格子状の凹部8を形成してもよい。この菱形格子状の凹部8によって取り込まれた領域は、凸部9からなる非エンボス領域となっている。凹部8は、ヒートエンボス加工による熱及び圧力の適用によって、凸部9からなる非エンボス領域よりも圧密化している。このヒートエンボス加工は、掻き取り層5の表面に凹凸を形成することに加えて、掻き取り層5と吸水層4とを接合するためにも用いることができる。

In the cleaning sheet 1, irregularities may be formed on the surface of the

凹部8のパターン形状は菱形格子状に限定されず、線状、点状、特定模様の任意の形状が採用され得る。凹部8の総面積は、清掃用シート1の清掃面の面積に対して5%以上、特に10%以上であることが好ましい。また、50%以下、特に40%以下であることが好ましい。具体的には、凹部8の総面積は、清掃用シート1の清掃面の面積に対して5%以上50%以下であることが好ましく、10%以上40%以下であることが更に好ましい(以下この値を凹部8の面積率という)。凹部8の面積率をこの範囲内に設定することで、清掃時の表面強度と清掃性とを首尾よく両立させることができる。

The pattern shape of the

<22>

吸水層の坪量は、好ましくは30g/m 2 以上、更に好ましくは40g/m 2 以上であり、好ましくは100g/m 2 以下、更に好ましくは80g/m2以下である前記<1>ないし<21>のいずれか1に記載の清掃用シート。

<23>

掻き取り層と吸水層からなる清掃用シートの総坪量は、好ましくは50g/m 2 以上300g/m2以下である前記<1>ないし<22>のいずれか1に記載の清掃用シート。<24>

面内方向の通気度TMDよりも垂直厚み方向の通気度TVDの方が小さく、掻き取り層の垂直厚み方向の通気度TVDよりも吸水層の垂直厚み方向の通気度TVDの方が小さい前記<1>ないし<23>のいずれか1に記載の清掃用シート。

<25>

清掃用シートの厚み方向において研磨粒子は掻き取り層の裏面側(吸水層)寄りの位置に相対的に多く存在し、表面側(清掃面側)に相対的に少ないか、又は存在しない前記<1>ないし<24>のいずれか1に記載の清掃用シート。

<26>

前記<1>ないし<25>のいずれか1に記載の清掃用シートを、使用前の状態では乾式タイプものとなし、使用に際しては、乾式のまま、あるいは湿潤させて使用し、

湿潤させて使用する場合、清掃対象面を水で湿潤させておき、湿潤状態の清掃対象表面を掻き取り層で清掃し、次いで湿潤状態の該清掃対象表面の水分を含む汚れを含んだ汚液を吸水層で拭き取る、清掃方法。

<22>

The basis weight of the water absorption layer is preferably 30 g / m 2 or more, more preferably 40 g / m 2 or more, preferably 100 g / m 2 or less, more preferably 80 g / m 2 or less <1> to <21> The cleaning sheet according to any one of 21>.

<23>

The cleaning sheet according to any one of <1> to <22>, wherein the total basis weight of the cleaning sheet composed of the scraping layer and the water absorbing layer is preferably 50 g / m 2 or more and 300 g / m 2 or less. <24>

Smaller towards the air permeability T VD in the vertical thickness direction than the air permeability T MD in the direction of the plane, towards the vertical thickness direction of the air permeability T VD scraping layer water-absorbing layer than the air permeability T VD in the vertical thickness direction <1> thru | or <23> in any one of said <1> thru | or <23> which is small.

<25>

In the thickness direction of the cleaning sheet, the abrasive particles are present in a relatively large amount at a position near the back surface side (water absorbing layer) of the scraping layer, and are relatively small or not present on the front surface side (cleaning surface side). The cleaning sheet according to any one of 1> to <24>.

<26>

The cleaning sheet according to any one of the above <1> to <25> is used as a dry type in a state before use, and is used in a dry state or wetted before use.

When wetted, the surface to be cleaned is moistened with water, the wet surface to be cleaned is cleaned with a scraping layer, and then the soiled water-containing soil containing dirt is contained. Wipe with a water-absorbing layer, cleaning method.

Claims (12)

前記掻き取り層は、太径繊維及び該太径繊維よりも繊度の小さい熱融着性繊維からなる 細径繊維を含み、

前記掻き取り層は、太径繊維の繊維交点が接合されており、かつ複数の該太径繊維が起立して、その先端部が該掻き取り層の表面に存在しているエアレイド不織布からなり、

前記太径繊維は、その繊度が10dtex以上150dtex以下であり、かつ前記掻き取り層中に10質量%以上含まれており、

前記掻き取り層は、前記太径繊維どうしの間に空間を有し、該空間に研磨粒子が脱離可能に存在しており、

前記太径繊維のうち、前記掻き取り層の表面に先端部が存在している太径繊維は、該先端部を含む先端域に、前記研磨粒子が実質的に付着していない、清掃用シート。A cleaning sheet in which a scraping layer and a water absorption layer containing pulp fibers are laminated,

The scraping layer includes a fine fiber made of a thick fiber and a heat-fusible fiber having a fineness smaller than that of the thick fiber ,

The scraping layer is made of an airlaid nonwoven fabric in which fiber intersections of large-diameter fibers are joined, and a plurality of the large-diameter fibers are erected, and the tip portion thereof is present on the surface of the scraping layer,

The fine fiber has a fineness of 10 dtex or more and 150 dtex or less, and is contained in the scraping layer by 10% by mass or more,

The scraping layer has a space between the large diameter fibers, and abrasive particles are present in the space so as to be removable.

Wherein among the large diameter fiber, large diameter fiber tip surface of the scraping layer that not exist, the tip region including a tip portion, wherein the abrasive particles are not substantially adhered, the cleaning sheet .

前記包装材は、前記清掃用シートを取り出すための開口部と、該開口部を閉鎖するリシ ール可能な閉鎖部材とを備えており、

前記清掃用シートは、その吸水層の側が前記開口部の側を向くように前記包装材内に積層されている、清掃用シート包装体。A plurality of cleaning sheets according to any one of claims 1 to 7, wherein a plurality of cleaning sheets are laminated and stored in a packaging material,

The packaging material is provided with an opening for taking out the cleaning sheet, and a Rishi Lumpur possible closure member for closing the opening,

The cleaning sheet packaging body, wherein the cleaning sheet is laminated in the packaging material such that the water absorption layer side faces the opening.

前記包装材の周縁部に開孔又はフックが設けられており、該開孔又は該フックによって吊り下げが可能になっている清掃用シート包装体。A cleaning sheet package according to any one of claims 1 to 7 , wherein the cleaning sheet package is housed in a packaging material and individually wrapped.

A cleaning sheet packaging body in which an opening or a hook is provided in a peripheral edge portion of the packaging material and can be suspended by the opening or the hook.

研磨粒子が付与される前の清掃用シートにおける掻き取り層に、研磨粒子を含むスラリーを塗工して塗膜を形成し、

前記塗膜が湿潤状態のうちに、前記掻き取り層に、表面が平滑な部材を押し当てて、該掻き取り層の表面域からスラリーを除去する工程を有する、清掃用シートの製造方法。A method for producing a cleaning sheet according to any one of claims 1 to 7 ,

To the scraping layer in the cleaning sheet before the abrasive particles are applied, a slurry containing abrasive particles is applied to form a coating film,

The manufacturing method of the sheet | seat for cleaning which has a process which presses a member with a smooth surface against the said scraping layer, and removes a slurry from the surface area of this scraping layer in the wet state of the said coating film.

The manufacturing method of the sheet | seat for cleaning of Claim 11 which further has the process of wiping off the surface area of a scraping layer with the wiping member which consists of fibers, after drying the said coating film.

Priority Applications (6)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| JP2014117379A JP6118290B2 (en) | 2014-06-06 | 2014-06-06 | Manufacturing method of cleaning sheet |

| CN201580023432.7A CN106455893B (en) | 2014-06-06 | 2015-05-29 | Cleaning sheet and the cleaning method for using it |

| PCT/JP2015/065546 WO2015186622A1 (en) | 2014-06-06 | 2015-05-29 | Cleaning sheet and cleaning method in which same is used |

| MYPI2016704424A MY174231A (en) | 2014-06-06 | 2015-05-29 | Cleaning sheet and cleaning method in which same is used |

| SG11201609175RA SG11201609175RA (en) | 2014-06-06 | 2015-05-29 | Cleaning sheet and cleaning method in which same is used |

| TW104118001A TW201602436A (en) | 2014-06-06 | 2015-06-03 | Cleaning sheet and cleaning method in which same is used |

Applications Claiming Priority (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| JP2014117379A JP6118290B2 (en) | 2014-06-06 | 2014-06-06 | Manufacturing method of cleaning sheet |

Related Child Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| JP2017043712A Division JP2017131676A (en) | 2017-03-08 | 2017-03-08 | Cleaning sheet |

Publications (3)

| Publication Number | Publication Date |

|---|---|

| JP2015229041A JP2015229041A (en) | 2015-12-21 |

| JP2015229041A5 true JP2015229041A5 (en) | 2016-04-07 |

| JP6118290B2 JP6118290B2 (en) | 2017-04-19 |

Family

ID=54766695

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| JP2014117379A Active JP6118290B2 (en) | 2014-06-06 | 2014-06-06 | Manufacturing method of cleaning sheet |

Country Status (6)

| Country | Link |

|---|---|

| JP (1) | JP6118290B2 (en) |

| CN (1) | CN106455893B (en) |

| MY (1) | MY174231A (en) |

| SG (1) | SG11201609175RA (en) |

| TW (1) | TW201602436A (en) |

| WO (1) | WO2015186622A1 (en) |

Families Citing this family (3)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| JP6928446B2 (en) * | 2016-12-22 | 2021-09-01 | 王子ホールディングス株式会社 | Cleaning sheet |

| JP2019137419A (en) * | 2018-02-08 | 2019-08-22 | 花王株式会社 | Storage container |

| CN108442033A (en) * | 2018-04-16 | 2018-08-24 | 许大鹏 | Functional Nonwoven Fabrics and preparation method thereof |

Family Cites Families (10)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| JPS5877655U (en) * | 1981-11-20 | 1983-05-25 | 岩田 秋雄 | Special finishing cloth |

| JPH04372440A (en) * | 1991-06-19 | 1992-12-25 | Ishihara Chem Co Ltd | Cleaning sheet for vehicle |

| JPH10245756A (en) * | 1997-03-03 | 1998-09-14 | Lion Corp | Cleaning material and cleaning product using the material |

| TWI264309B (en) * | 1999-07-08 | 2006-10-21 | Kao Corp | Personal cleansing sheet |

| US20020106478A1 (en) * | 2000-12-01 | 2002-08-08 | Taeko Hayase | Cleaning sheet |

| JP2005185429A (en) * | 2003-12-25 | 2005-07-14 | Kao Corp | Nonwoven fabric for cleaning |

| JP2005312711A (en) * | 2004-04-30 | 2005-11-10 | Kao Corp | Cleaning article for artificial marble |

| JP4406584B2 (en) * | 2004-07-02 | 2010-01-27 | 高志 秋廣 | Lip device |

| JP4688442B2 (en) * | 2004-07-02 | 2011-05-25 | 花王株式会社 | Cleaning sheet |

| WO2009084500A1 (en) * | 2007-12-27 | 2009-07-09 | Kao Corporation | Cleaning sheet |

-

2014

- 2014-06-06 JP JP2014117379A patent/JP6118290B2/en active Active

-

2015

- 2015-05-29 SG SG11201609175RA patent/SG11201609175RA/en unknown

- 2015-05-29 MY MYPI2016704424A patent/MY174231A/en unknown

- 2015-05-29 WO PCT/JP2015/065546 patent/WO2015186622A1/en active Application Filing

- 2015-05-29 CN CN201580023432.7A patent/CN106455893B/en active Active

- 2015-06-03 TW TW104118001A patent/TW201602436A/en unknown

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| CA2685904C (en) | Cleaning article with non-planar element in place of strips | |

| CN105960189B (en) | Cleaning sheet and laminate thereof | |

| RU2017106639A (en) | Non-woven material with discrete three-dimensional deforming elements containing areas of varying opacity | |

| TW201813574A (en) | Textured cleansing article | |

| JP2007531567A5 (en) | ||

| JP2006305327A5 (en) | ||

| RU2015148026A (en) | Double core absorbent article | |

| JP2015229041A5 (en) | ||

| TWI705786B (en) | Cleaning equipment | |

| JP2016514627A5 (en) | ||

| JP2015525681A5 (en) | ||

| TWI564450B (en) | Manufacture of nonwovens and nonwovens | |

| TW201623722A (en) | Cleaning sheet | |

| JP2017520420A (en) | Nonwoven articles containing abrasive particles | |

| GB201215158D0 (en) | Hand and surface cleaning wet wipe and method of manufacturing | |

| JP6118290B2 (en) | Manufacturing method of cleaning sheet | |

| JP5866257B2 (en) | Manufacturing method of concrete wet curing sheet | |

| CN205434098U (en) | Manufacture equipment of health supplies absorbent core body | |

| JP2022008129A (en) | Cleaning sheet | |

| TWM493301U (en) | Cosmetic cotton | |

| ES2781874T3 (en) | Procedure for manufacturing printing cylinder cleaning cloths | |

| JP6814603B2 (en) | Wet cleaning sheet | |

| US20170087598A1 (en) | Two-sided cleaning implement | |

| JP2013029825A5 (en) | ||

| KR20180001590U (en) | Textile material for manufacturing beauty mask pack |