JP2010274010A - Rotary brush, suction tool for cleaner, and vacuum cleaner - Google Patents

Rotary brush, suction tool for cleaner, and vacuum cleaner Download PDFInfo

- Publication number

- JP2010274010A JP2010274010A JP2009131648A JP2009131648A JP2010274010A JP 2010274010 A JP2010274010 A JP 2010274010A JP 2009131648 A JP2009131648 A JP 2009131648A JP 2009131648 A JP2009131648 A JP 2009131648A JP 2010274010 A JP2010274010 A JP 2010274010A

- Authority

- JP

- Japan

- Prior art keywords

- brush

- vacuum cleaner

- wing

- suction tool

- rotor

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Pending

Links

Images

Landscapes

- Nozzles For Electric Vacuum Cleaners (AREA)

Abstract

Description

本発明は、掃除機用吸込具などに回転自在に設けられた清掃用の回転ブラシ、その回転ブラシを用いた掃除機用吸込具及び電気掃除機に関するものである。 The present invention relates to a cleaning rotary brush provided on a vacuum cleaner suction tool and the like, a vacuum cleaner suction tool using the rotary brush, and an electric vacuum cleaner.

従来の、この種の回転ブラシとして、図13に示されるようなものがあった(例えば、特許文献1参照)。 As a conventional rotating brush of this type, there is one as shown in FIG. 13 (see, for example, Patent Document 1).

図13は、従来の回転ブラシの断面図である。図13において、従来の回転ブラシ1は、アルミニューム等の金属材料からなり略棒状の回転ロータ2と、回転ロータ2の外周に取り付けられた清掃ブラシ体3から構成されている。回転ロータ2は、軸体2aと、軸体2aの外周部から放射状に延在し、かつ円弧状に形成された複数のブレード2bと、各ブレード2bの先端部に設けられ清掃ブラシ体3の下端を保持する保持部2cから構成されている。

FIG. 13 is a cross-sectional view of a conventional rotating brush. In FIG. 13, a conventional

また、従来の回転ブラシの他の例として、図14に示されるようなものもある(例えば、特許文献2参照)。 Another example of a conventional rotating brush is shown in FIG. 14 (see, for example, Patent Document 2).

図14は、従来の回転ブラシの部分断面図である。図14において、従来の回転ブラシ4は、アルミニューム等の金属材料からなり略棒状の回転ロータ5と、回転ロータ5の外周に取り付けられた清掃ブラシ体6から構成されている。回転ロータ5は、軸体5aと、軸体5aの外周部から放射状でかつ直線状に延在した複数のブレード5bからなり、各ブレード5bの先端部に、清掃ブラシ体6の下端を保持する保持部5cが形成されている。

FIG. 14 is a partial cross-sectional view of a conventional rotating brush. In FIG. 14, the conventional

しかしながら、上記特許文献1及び2に記載された従来の回転ブラシ1、4のいずれにおいても、ブレード2b、5bを構成する外側面2d、5dと内側面2e、5eの両方に保持部2c、5cが延設されているので、外側面2d、5dと内側面2e、5eの両方に屈曲部2f、5fが形成される。この為、回転ブラシ1、4を、電動機(図示せず)で、或いは掃除機用吸込具(図示せず)の底部の開口部から流入する吸引風をブレード2b、5bに当てて回転させたときに、ブレード2b、5bそれぞれの外側面2d、5d側の屈曲部2f、5fにより、空気流が遮断され、ブレード2b、5bに接触する空気をスムーズに整流して、外周方向に流出させることができず、空気抵抗が増大して回転ブラシ1、4の回転力が阻害されてしまい、安定した回転力が得られない、という課題があった。

However, in any of the conventional

また、図14に示すように、軸体5aの半径距離rより、ブレード5bの距離Lの方が大きいので、吸引風で回転ブラシ4を回転させる場合、風受面は大きくなり、その回転力は向上するが、ブレード5bの外側面5dと内側面5eが同形状で、しかも、外側面5dにも保持部5cがあるために空気流が阻害される。この為、回転力にブレーキがかかってしまい、回転ブラシ4の回転数の向上が期待できず、回転ブラシ4の除塵効率の向上につながらない、という課題があった。

Further, as shown in FIG. 14, since the distance L of the

本発明は、上記従来の課題を解決するもので、吸引風を効率よく受けて高トルクで回転することができると共に、空気抵抗が少なく、効率よく回転させることができる回転ブラシ及び、清掃性に優れた掃除機用吸込具及び電気掃除機を提供することを目的とする。 SUMMARY OF THE INVENTION The present invention solves the above-mentioned conventional problems, and can efficiently receive suction air and rotate at a high torque, has a low air resistance, can be rotated efficiently, and is cleanable. It aims at providing the suction tool for vacuum cleaners and the vacuum cleaner which were excellent.

上記従来の課題を解決するために、本発明の回転ブラシは、機器に回転自在に取着されるロータと、前記ロータの外周部に配されると共に被清掃面に当接して除塵する清掃ブラシ体からなる回転ブラシにおいて、前記ロータは、軸体と、前記軸体の外周面から外方に向かって延設され内側面と外側面をそれぞれ有する複数の翼状体と、前記翼状体の前記内側面側の先端部のみに設けられ前記清掃ブラシ体を保持する保持部とを備え、前記内側面側を風受面としたもので、翼状体の内側面の先端部に、清掃ブラシ体を取り付ける保持部を設けることによりその部分に屈曲部が形成されるので、翼状体の内側面を空気流の上流側に配して、空気流を風受面で受けるようにすると、屈曲部により、空気流はスムーズに流れず、翼状体を積極的に押す力が作用し、回転ブラシに強い回転力が生じると共に、翼状体の外側面側には保持部が形成されていないので、回転ブラシの回転時の空気抵抗が小さくなるので、回転ブラシを効率よくかつ高トルクで回転させることができ、清掃性能を向上させることができる。 In order to solve the above-described conventional problems, a rotating brush according to the present invention includes a rotor that is rotatably attached to a device, a cleaning brush that is disposed on an outer peripheral portion of the rotor and that abuts against a surface to be cleaned and removes dust. In the rotary brush composed of a body, the rotor includes a shaft body, a plurality of wings extending outward from the outer peripheral surface of the shaft body, and each having an inner surface and an outer surface, and the inner surface of the wing member. A holding portion that holds the cleaning brush body provided only on the side surface side tip portion, and has the inner side surface as a wind receiving surface, and attaches the cleaning brush body to the tip portion on the inner side surface of the wing-like body Since the bent portion is formed at the portion by providing the holding portion, when the inner surface of the wing-like body is arranged on the upstream side of the air flow and the air flow is received by the wind receiving surface, the bent portion The flow does not flow smoothly and positively pushes the wings Acts, and a strong rotational force is generated in the rotating brush, and since no holding portion is formed on the outer surface side of the wing-like body, the air resistance during rotation of the rotating brush is reduced. It can be rotated with high torque, and the cleaning performance can be improved.

また、本発明の掃除機用吸込具は、請求項1又は2に記載の回転ブラシを回転自在に備えたもので、回転ブラシを、少ないエネルギーで効率よく回転させることができるので、その分、小型軽量で、操作性、清掃性能に優れた掃除機用吸込具を提供することができる。 Further, the vacuum cleaner suction tool of the present invention is provided with the rotary brush according to claim 1 or 2 in a freely rotatable manner, and the rotary brush can be efficiently rotated with less energy. It is possible to provide a vacuum cleaner suction tool that is compact and lightweight and has excellent operability and cleaning performance.

また、本発明の電気掃除機は、請求項3に記載の掃除機用吸込具を備えたもので、軽量で、操作性、清掃性能に優れた掃除機用吸込具を使用することにより、清掃性能、操作性の良い電気掃除機を提供することができる。 Moreover, the vacuum cleaner of this invention is equipped with the suction tool for vacuum cleaners of Claim 3, and is cleaning by using the suction tool for vacuum cleaners which was lightweight, and was excellent in operativity and cleaning performance. A vacuum cleaner with good performance and operability can be provided.

本発明の回転ブラシは、空気流を効率よく受けて高トルクで回転することができると共に回転時の空気抵抗が少ないので効率よく回転させることができるもので、また、本発明の掃除機用吸込具及び電気掃除機は、清掃性に優れたものである。 The rotating brush of the present invention can receive air flow efficiently and rotate at high torque, and can be rotated efficiently because of low air resistance during rotation. Also, the vacuum cleaner suction of the present invention Tools and vacuum cleaners are excellent in cleanability.

第1の発明は、機器に回転自在に取着されるロータと、前記ロータの外周部に配されると共に被清掃面に当接して除塵する清掃ブラシ体からなる回転ブラシにおいて、前記ロータは、軸体と、前記軸体の外周面から外方に向かって延設され内側面と外側面をそれぞれ有する複数の翼状体と、前記翼状体の前記内側面側の先端部のみに設けられ前記清掃ブラシ体を保持する保持部とを備え、前記内側面側を風受面としたもので、翼状体の内側面の先端部に、清掃ブラシ体を取り付ける保持部を設けることによりその部分に屈曲部が形成されるので、翼状体の内側面を空気流の上流側に配して、空気流を風受面で受けるようにすると、屈曲部により、空気流はスムーズに流れず、翼状体を積極的に押す力が作用し、回転ブラシに強い回転力が生じると共に、翼状体の外側面側には保持部が形成されていないので、回転ブラシの回転時の空気抵抗が小さくなるので、回転ブラシを効率よくかつ高トルクで回転させることができ、清掃性能を向上させることができる。 1st invention is a rotary brush which consists of a rotor attached rotatably to equipment, and a cleaning brush body which is arranged on the outer peripheral part of the rotor and abuts against a surface to be cleaned and removes dust. The shaft body, the plurality of wing-like bodies extending outward from the outer peripheral surface of the shaft body, each having an inner side surface and an outer side surface, and the cleaning provided on only the tip of the wing-like body on the inner side surface side A holding portion that holds the brush body, and the inner side surface is a wind-receiving surface, and a bent portion is provided at the tip portion of the inner side surface of the wing-like body by attaching a holding portion to which the cleaning brush body is attached. Therefore, if the inner surface of the wing is placed upstream of the air flow and the air flow is received by the wind receiving surface, the air flow does not flow smoothly due to the bent portion, and the wing is positively Pressing force acts on the rotating brush, resulting in a strong rotating force. At the same time, since the holding portion is not formed on the outer surface side of the wing-like body, the air resistance during rotation of the rotating brush is reduced, so that the rotating brush can be rotated efficiently and with high torque, and the cleaning performance is improved. Can be improved.

第2の発明は、特に、第1の発明の翼状体のそれぞれの軸体の外周面から外方に向かって湾曲させて、外側面を円滑な曲面形状に形成すると共に、保持部に、前記翼状体の内側面側から延設した風受壁を一体的に形成したもので、外側面が円滑な曲面形状で回転方向側に湾曲しているので、湾曲していない形態に比べて回転ブラシの回転時の空気抵抗がより低減され、回転ブラシを効率よく、かつ省電力を図りながらスムーズに回転させることができる。また、内側面側に風受壁を延設することで、内側面側で外気を受けるときに、風受け面積が広くなり、高トルクで回転ブラシを回転させることができる。 In the second invention, in particular, the outer surface of each of the shafts of the wing-like body of the first invention is curved outward to form an outer surface in a smooth curved shape, and the holding portion includes The wind-insulating wall that extends from the inner side of the wing-like body is integrally formed, and the outer side is curved in the direction of rotation with a smooth curved surface. The air resistance during rotation is further reduced, and the rotating brush can be rotated smoothly while efficiently and saving power. In addition, by extending the wind receiving wall on the inner side, when the outside air is received on the inner side, the wind receiving area is increased and the rotating brush can be rotated with high torque.

第3の発明における掃除機用吸込具は、請求項1又は2に記載の回転ブラシを回転自在に備えたもので、回転ブラシを、少ないエネルギーで効率よく回転させることができるので、その分、小型軽量で、操作性、清掃性能に優れた掃除機用吸込具を提供することができる。 The vacuum cleaner suction tool according to the third aspect of the present invention comprises the rotary brush according to claim 1 or 2 so as to be rotatable, and the rotary brush can be efficiently rotated with less energy. It is possible to provide a vacuum cleaner suction tool that is compact and lightweight and has excellent operability and cleaning performance.

第4の発明における電気掃除機は、請求項3に記載の掃除機用吸込具を備えたもので、軽量で、操作性、清掃性能に優れた掃除機用吸込具を使用することにより、清掃性能、操作性の良い電気掃除機を提供することができる。 According to a fourth aspect of the present invention, there is provided a vacuum cleaner comprising the vacuum cleaner suction tool according to claim 3, which is light by using a vacuum cleaner suction tool excellent in operability and cleaning performance. A vacuum cleaner with good performance and operability can be provided.

以下、本発明の実施例について、図面を参照しながら説明する。尚、この実施例によって本発明が限定されるものではない。 Embodiments of the present invention will be described below with reference to the drawings. In addition, this invention is not limited by this Example.

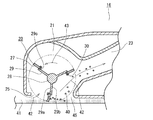

図1は、本発明の第1の実施例における回転ブラシを搭載した掃除機用吸込具が連結された電気掃除機の全体図、図2は、同掃除機用吸込具の内部構成を示す断面図、図3は、同回転ブラシの平面図、図4は、同掃除機用吸込具の要部断面図、図5は、同回転ブラシの拡大断面図、図6は、同回転ブラシの清掃ブラシ体の斜視図、図7は、同回転ブラシの軸受体の斜視図である。 FIG. 1 is an overall view of a vacuum cleaner to which a vacuum cleaner suction tool mounted with a rotating brush according to a first embodiment of the present invention is connected, and FIG. 2 is a cross-sectional view showing an internal configuration of the vacuum cleaner suction tool. 3 is a plan view of the rotary brush, FIG. 4 is a cross-sectional view of an essential part of the suction tool for the vacuum cleaner, FIG. 5 is an enlarged cross-sectional view of the rotary brush, and FIG. 6 is a cleaning of the rotary brush. FIG. 7 is a perspective view of a bearing body of the rotating brush.

図1において、本実施例における回転ブラシを搭載した掃除機用吸込具が連結された電気掃除機は、後方に電動送風機10を内蔵し、前部に塵埃を捕集する集塵袋11を収納する集塵室12を有する掃除機本体13と、一端が集塵室12と連通するように掃除機本体13に接続され、他端が延長管14に接続されるホース15と、延長管14のホース15側と反対側の端部に連結されると共に、床面の塵埃を吸引する掃除機用吸込具16を備えている。ホース15の延長管14側端部には、掃除機用吸込具16を床面上で操作するためハンドル17が設けられている。

In FIG. 1, the vacuum cleaner to which the suction tool for the vacuum cleaner mounted with the rotating brush in the present embodiment is connected has an

図2〜7において、掃除機用吸込具16は、一対の軸受24を介して本実施例における回転ブラシ20を回転自在に収納する回転ブラシ収納室21と、回動自在で、かつ延長管14に着脱自在に接続される接続パイプ22とを備え、回転ブラシ収納室21と接続パイプ22は、吸込風路23で連通している。又、掃除機用吸込具16の底面45には、下方に開口し、回転ブラシ収納室21と連通する吸塵口25が形成されている。

2 to 7, the vacuum

回転ブラシ20は、機器の一つである掃除機用吸込具16に回転自在に取着されるロータ26と、ロータ26の外周部に配されると共に被清掃面である床面に当接して除塵する清掃ブラシ体27と、軸受体A31と、軸受体B61から構成され、そのロータ26は、両端が軸受体A31と軸受体B61で支持された軸体28と、前記軸体28の外周面から外方に向かって略直線状に延設され、内側面29aと外側面29bをそれぞれ有する複数の翼状体29と、前記翼状体29の内側面29a側の先端部のみに設けられると共に清掃ブラシ体27を保持する保持部30を備えている。保持部30は、断面が略凸状の凸溝部30aを備え、また、保持部30の底部30bは、軸体28の中心軸に対し略平行に形成されている。

The rotating

本実施例では、3本の翼状体29が、軸体28の外周面の周方向に等間隔に配されている。各翼状体29の外側面29bは、根元部から先端側に向かって凹凸がなく直線状の整流面となっているが、反対側の内面側29aの先端に保持部30が設けられているため、その部分に屈曲部29cが形成され、掃除機用吸込具16の底面45に設けた吸塵口25から流入する空気流42を受ける際に、効率よく風を受けられるので、その内側面29aを風受面としている。

In the present embodiment, the three wing-

また、本実施例では、軸体28と、3本の翼状体29と、それぞれの保持部30は、アルミニューム等の軽金属材料で一体で押し出し成型で形成されている。また、翼状体29の全高さLは、軸体28の半径rより長く形成されている。

In the present embodiment, the

又、清掃ブラシ体27は、略帯状で、図6に示すように、保持部30の凸溝部30aの側方から挿入される基部27aと、下端が基部27aに固着され、多数の細径の樹脂繊維や毛、或いは軟質材のシートなどから形成されたブラシ部材27bから構成されている。本実施例では、上記のように、凸溝部30の断面形状が、略凸状になっているので、回転ブラシ20が高速で回転しても、清掃ブラシ体27の基部27aが、保持部30から外れることはない。

Further, the cleaning

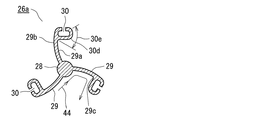

軸受体A31は、図7に示すように、中央部に略円形で、軸体28の端部をその内部に保持する中央支持部31aと、翼状体29の端部が挿入され支持して回り止めするための支持溝31bと、中央支持部31aから放射状に外方に延在し、3列の翼状体29と同形状のブレードA31eと、ブレードA31eの先端に形成され清掃ブラシ体27の保持部30からの脱落を防止するブラシ押さえ31cと、掃除機用吸込具16に形成されている軸受24に回転自在に支持される軸体B31dより構成されている。

As shown in FIG. 7, the bearing body A31 has a substantially circular shape at the center, a

以上のように構成された本実施例における回転ブラシ20、掃除機用吸込具16及び電気掃除機の動作、作用は、以下の通りである。

The operations and effects of the

図1に示すように、掃除機本体13に、ホース15、延長管14、掃除機用吸込具16を順に接続し、ハンドル17に設けた操作部(図示せず)を操作して、掃除機本体13の運転を開始すると、電動送風機10に通電されて、空気流42が発生し、床面41上の塵埃が空気流42と共に、掃除機用吸込具16の底面に設けた吸塵口25から流入する。

As shown in FIG. 1, a

このとき、吸塵口25から勢い良く流入した空気流42が、図4に示すように、回転ブラシ20の翼状体29の内側面29a、すなわち風受面に当たり、回転ブラシ20を反時計方向(回転方向43)に回転させる。これにより、床面41上のこびりついたような塵埃40が、清掃ブラシ体27で効率よく掻き取られ、塵埃40を含む空気流42は、掃除機用吸込具16内の吸込風路23、延長管14、ホース15を順に通って、掃除機本体13の集塵室12内の集塵袋11に流入し、そこで、塵埃40が捕集され、きれいになった空気が、電動送風機10を通って、掃除機本体13の背面に設けた排気口(図示せず)から、外部に排気される。

At this time, as shown in FIG. 4, the

以上のように、本実施例における回転ブラシ20は、翼状体29の内側面29aの先端部に、清掃ブラシ体27を取り付ける保持部30を設けているので、その部分に屈曲部29cが形成され、それにより、内側面29aに、掃除機用吸込具16の底面に設けた吸塵口25から流入した空気流42が当たると、屈曲部29cにより空気流42がスムーズに流れず、翼状体29を積極的に押す力、すなわち回転ブラシ20を強く回転させる力が作用し、清掃性能を大幅に向上させることができる。

As described above, the rotating

又、翼状体29の外側面29bには、凹凸が無く滑らかになっているので、空気はスムーズに翼状体29外に流出されるので、回転時の空気抵抗が少なくなり回転ブラシ20の回転力が阻害されにくい。

Further, since the

更に本実施例では、軸受体A31にもブレードA31eが形成されているため、より翼状体29の受風面積が大きくなりなり、その回転力を強めることができる。また、被掃除面が毛足の長い絨毯等の場合は、絨毯と清掃ブラシ体27との間に大きな抵抗が生じ、回転が弱まり、除塵効果が低下するが、本実施例では、軸体28の半径rを小さく、翼状体29の全長Lを大きく設定しているので、外気の受圧面積が大きくなって、その回転トルクも強力となり、回転数の低下を防ぎ、除塵効率の低下を継続的に防止することができる。

Furthermore, in this embodiment, since the blade A31e is also formed in the bearing body A31, the wind receiving area of the wing-

なお、本実施例では、回転ブラシ20の全幅に渡って、各翼状体29を所定角度で捩じって3列配したが、3列に限定することはなく、2列、4列或いはそれ以上でもよく、また、捻る代わりに直線状に配置しても良い。

In the present embodiment, each wing-

また、ブラシ部材27bを、多数の細径糸より構成された起毛布体(図示せず)で構成してもよく、4列に構成された凸溝部30aに、ブラシ状のものと、起毛布体からなるものとを交互に挿入するようにすれば、床面にこびりついた塵埃は、ブラシ状のブラシ部材27bで、床面に付着した極細塵は、起毛布体からなるブラシ部材27bで拭き、それぞれの除塵が可能となるようにしても良い。

Further, the

また、保持部30の底部30bは、軸体28の長方向の中心軸芯に対し略平行に形成しているので、風受面である内側面29aに屈曲部29cが形成され、空気流は阻害されて逆流となり、受風面は強い力で押圧されて、回転力が向上するので、例えば、毛足の長い絨毯等の被掃除面を除塵する場合でも、毛足の抵抗に負けて回転が停止するのを防止できる。また、保持部30に取り付ける清掃ブラシ体27も、軸芯に対し略垂直に形成されることになるので、被掃除面に対しても、常に垂直に当接させることができ、清掃ブラシ体27の除塵効果を最大限引き出すことができる。

Further, since the

また、回転ブラシ20の大きさには、所定の大きさ制限のある中で、軸体28の外周部から外方に向けて延在する翼状体29の根元から先端までの距離Lと、軸体28の半径rとの関係をL>>rとして、空気の流れに直接関係のない軸体28の太さをできるだけ小さく、空気の流れに直接関係のある翼状体29の表面積を大きくし、風受面である内側面29aを空気流42の上流側に配置すれば、より強い回転力が得られ、被清掃面に凹凸があり、抵抗が強くても、確実に回転ブラシ20を継続して回転させられるので、除塵効率の安定化が図れる。

In addition, the size of the rotating

なお、上記実施例では、保持部30の清掃ブラシ体27の取付け部の断面形状を凸溝状としたが、図8に示すように、一般的な凹溝状の凹溝部30cとしても良い。ただし、この場合は、回転ブラシ20の回転時に、清掃ブラシ体27が外れないように、清掃ブラシ体27の基部27aを凹溝部30cに溶着や接着などの方法で確実に固定する必要があることは言うまでも無い。

In the above embodiment, the cross-sectional shape of the attachment portion of the cleaning

(実施例2) (Example 2)

図9は、本発明の第2の実施例における回転ブラシのロータの断面図である。尚上記第1の実施例における回転ブラシと同一部分には、同一符号を付してその説明を省略する。

上記第1の実施例では、翼状体29の内側面29a、外側面29bのそれぞれを直線状に形成したのに対し、本実施例における回転ブラシ20のロータ26aは、図9に示すように、翼状体29のそれぞれを軸体28の外周面から外方に向かって湾曲、すなわち、内側面29a、外側面29bのそれぞれを、風受面である内側面29aの反対側に湾曲させて、外側面29bを円滑な曲面形状に形成すると共に、保持部30に、前記翼状体29の内側面29a側から延設した風受壁30d(図9内で、範囲30eで示された部分)を一体的に形成したもので、他の構成は、上記第1の実施例と同一である。

FIG. 9 is a cross-sectional view of the rotor of the rotating brush in the second embodiment of the present invention. In addition, the same code | symbol is attached | subjected to the same part as the rotary brush in the said 1st Example, and the description is abbreviate | omitted.

In the first embodiment, each of the

以上のように構成された本実施例の回転ブラシ20の動作は以下の通りである。

The operation of the rotating

掃除機用吸込具16の下面に設けた吸塵口25から流入した空気流42が回転ブラシ20のロータ26aの内側面29aに当たると、その内側面29aに沿って空気流44が発生すると共に、ロータ26aに回転力が加わり、回転ブラシ20が回転する。

When the

本実施例における回転ブラシ20のロータ26aは、以上のように、翼状体29の外側面29bが円滑な曲面形状で、風受面である内側面29aの反対側に湾曲、すなわち回転方向側に湾曲しているので、回転ブラシ20の回転時の空気抵抗が低減され、回転ブラシ20を効率よく、スムーズに回転させることができる。また、内側面29a側に風受壁30dを延設することで、内側面29a側で外気を受けるときに、風受け面積が広くなり、高トルクで回転ブラシ20を回転させることができる。

As described above, the

図10(a)は、3本の翼状体を設けたロータ26aの断面図、図10(b)は、2本の翼状体29を設けたロータ26bの断面図であるが、同図で二点鎖線で示されるように、軸体28と、隣り合う翼状体29と、前記翼状体29の先端部に形成された保持部30、あるいは軸体28と、対面する翼状体29と、翼状体29の先端部に形成された保持部30が略Z字状になるように形成すれば、回転ブラシ20の回転時に、Z字状の断面でより確実に風を受けることができ、その結果、回転ブラシ20をより強力に回転させることもできる。

10A is a cross-sectional view of a

(実施例3) (Example 3)

図11は、本発明の第3の実施例における掃除機用吸込具の一部切欠き平面図、図12は、同掃除機用吸込具の要部拡大断面図である。尚、上記第1及び第2の実施例における回転ブラシと同一部分には、同一符合を付してその説明を省略する。 FIG. 11 is a partially cutaway plan view of a vacuum cleaner suction tool according to a third embodiment of the present invention, and FIG. 12 is an enlarged cross-sectional view of a main part of the vacuum cleaner suction tool. The same parts as those of the rotating brush in the first and second embodiments are designated by the same reference numerals and the description thereof is omitted.

上記第1及び第2の実施例では、吸塵口25から流入する空気流42を回転ブラシ20の内側面29aに当てて回転ブラシ20を回転させるようにしたが、本実施例における掃除機用吸込具35は、図11及び図12に示すように、回転ブラシ20を一方向(本実施例では、回転方向47)に回転させるためのモーター36と、モーター36に取り付けられたギアA37と、回転ブラシ20の軸体28に設けられたギアB38と、ギアA37とギアB38に張架されたベルト60を備え、ベルト60を介してモーター36で回転ブラシ20を回転させるようにしたものである。

In the first and second embodiments, the

また、本実施例においても、図12に示すように、翼状体29の凹凸などの無い整流面である外側面29bが、吸引気流の下流側に面するように配置している。

Also in this embodiment, as shown in FIG. 12, the

以上のように、本実施の形態では、回転ブラシ20を、図4に示すように、空気流42で回転させるのではなく、図11及び図12に示すようにモーター36等の外部駆動源により強制回転させると共に、空気流の上流側に翼状体29の内側面29aを配置させることで、掃除機用吸込具35の底面に設けた吸塵口25から塵埃と共に吸引された外気は、空気流46となってスムーズに掃除機本体13側に吸引されていく。又、空気流46が内側面29aを押す事により、モーター36の回転力を補うことができ、モーター36の小型化や省エネに役立つ。

As described above, in the present embodiment, the rotating

また、表面に凹凸の無い外側面29bが回転方向47側になっているので、外側面29bで押される空気は、整流面である外側面29bに沿ってスムーズに流れるため、その空気抵抗は少なく、回転力が低下しにくく、モーター36に対する負担が軽減され、モーター36の小型化や省エネに役立つ。

Further, since the

また、掃除機用吸込具16に、上記実施例における回転ブラシ20を用いることにより、回転ブラシを、少ないエネルギーで効率よく回転させることができるので、その分、小型軽量で、操作性、清掃性能に優れた掃除機用吸込具を提供することができる。

Moreover, since the

また、上記掃除機用吸込具16を電気掃除機の掃除機本体13に、ホース15、延長管14を介して接続し、清掃作業を行うようにすれば、清掃性能、操作性の良い電気掃除機を提供することができる。

Further, if the vacuum

以上のように、本発明に係る回転ブラシは、吸引風を効率よく受けて高トルクで回転することができると共に、回転時の空気抵抗が少ないので効率よく回転させることができ、また、本発明の掃除機用吸込具及び電気掃除機は、清掃性に優れたもので、電気掃除機に限らず、回転ブラシを用いた各種洗浄機器、清掃機器に応用できる。 As described above, the rotating brush according to the present invention can efficiently receive suction air and rotate with high torque, and can be rotated efficiently because of low air resistance during rotation. The vacuum cleaner suction tool and the vacuum cleaner are excellent in cleanability and can be applied not only to the vacuum cleaner but also to various cleaning devices and cleaning devices using a rotating brush.

10 電動送風機

13 掃除機本体

16、35 掃除機用吸込具

20 回転ブラシ

26、26a、26b ロータ

27 清掃ブラシ体

28 軸体

29 翼状体

30 保持部

42、44、46 空気流

DESCRIPTION OF

Claims (4)

Priority Applications (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| JP2009131648A JP2010274010A (en) | 2009-05-30 | 2009-05-30 | Rotary brush, suction tool for cleaner, and vacuum cleaner |

Applications Claiming Priority (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| JP2009131648A JP2010274010A (en) | 2009-05-30 | 2009-05-30 | Rotary brush, suction tool for cleaner, and vacuum cleaner |

Publications (2)

| Publication Number | Publication Date |

|---|---|

| JP2010274010A true JP2010274010A (en) | 2010-12-09 |

| JP2010274010A5 JP2010274010A5 (en) | 2012-07-19 |

Family

ID=43421505

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| JP2009131648A Pending JP2010274010A (en) | 2009-05-30 | 2009-05-30 | Rotary brush, suction tool for cleaner, and vacuum cleaner |

Country Status (1)

| Country | Link |

|---|---|

| JP (1) | JP2010274010A (en) |

Cited By (3)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| JPH0370456A (en) * | 1989-08-04 | 1991-03-26 | Japan Servo Co Ltd | Rotor drive |

| JP2015058049A (en) * | 2013-09-17 | 2015-03-30 | 株式会社コーワ | Rotary cleaning body, suction tool for cleaner, and vacuum cleaner |

| JP2016013241A (en) * | 2014-07-01 | 2016-01-28 | 株式会社コーワ | Rotation cleaning body, suction tool of vacuum cleaner, and vacuum cleaner |

Citations (4)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| JPH1156711A (en) * | 1998-05-27 | 1999-03-02 | Hitachi Ltd | Vacuum cleaner and its suction aperture assembly |

| JP2007202673A (en) * | 2006-01-31 | 2007-08-16 | Kowa Co Ltd | Spinning rotor, suction device for cleaner, and vacuum cleaner |

| JP2007282866A (en) * | 2006-04-17 | 2007-11-01 | Kowa Co Ltd | Rotating rotor, floor suction tool for vacuum cleaner, and vacuum cleaner |

| JP4066183B2 (en) * | 2003-09-09 | 2008-03-26 | 三菱電機株式会社 | Rotating brush body for floor suction tool |

-

2009

- 2009-05-30 JP JP2009131648A patent/JP2010274010A/en active Pending

Patent Citations (4)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| JPH1156711A (en) * | 1998-05-27 | 1999-03-02 | Hitachi Ltd | Vacuum cleaner and its suction aperture assembly |

| JP4066183B2 (en) * | 2003-09-09 | 2008-03-26 | 三菱電機株式会社 | Rotating brush body for floor suction tool |

| JP2007202673A (en) * | 2006-01-31 | 2007-08-16 | Kowa Co Ltd | Spinning rotor, suction device for cleaner, and vacuum cleaner |

| JP2007282866A (en) * | 2006-04-17 | 2007-11-01 | Kowa Co Ltd | Rotating rotor, floor suction tool for vacuum cleaner, and vacuum cleaner |

Cited By (3)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| JPH0370456A (en) * | 1989-08-04 | 1991-03-26 | Japan Servo Co Ltd | Rotor drive |

| JP2015058049A (en) * | 2013-09-17 | 2015-03-30 | 株式会社コーワ | Rotary cleaning body, suction tool for cleaner, and vacuum cleaner |

| JP2016013241A (en) * | 2014-07-01 | 2016-01-28 | 株式会社コーワ | Rotation cleaning body, suction tool of vacuum cleaner, and vacuum cleaner |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| JP4758155B2 (en) | Floor nozzle for vacuum cleaner and electric vacuum cleaner | |

| JP2006071121A (en) | Air-conditioner | |

| JP4975981B2 (en) | Rotating rotor of floor nozzle for vacuum cleaner and electric vacuum cleaner | |

| JP6267515B2 (en) | Side brush for vacuum cleaner and self-propelled vacuum cleaner | |

| JP2008018104A (en) | Rotating rotor, floor suction tool for cleaner, vacuum cleaner and air conditioner | |

| JP2010063624A (en) | Suction implement for vacuum cleaner | |

| JP2007330652A (en) | Rotating rotor, floor suction tool for vacuum cleaner, vacuum cleaner, and air-conditioner | |

| JP2008178661A (en) | Suction brush assembly | |

| JP2010274010A (en) | Rotary brush, suction tool for cleaner, and vacuum cleaner | |

| EP2599420A1 (en) | A vacuum celaner rotary brush having a plurality of radial channels being rotated by an air fan | |

| JP2013031508A (en) | Suction tool for vacuum cleaner | |

| JP5295682B2 (en) | Electric blower and vacuum cleaner | |

| JP2008061785A (en) | Rotor, floor suction tool for vacuum cleaner, vacuum cleaner and air conditioner | |

| JP4815213B2 (en) | Rotating rotor, vacuum cleaner floor suction tool and vacuum cleaner | |

| JP4399198B2 (en) | Suction body of vacuum cleaner and vacuum cleaner provided with the same | |

| CN213155659U (en) | Dust collector floor brush and dust collector | |

| JP4738960B2 (en) | Vacuum cleaner floor nozzle and vacuum cleaner | |

| JP2000157462A (en) | Sucking tool for vacuum cleaner and vacuum cleaner using the same | |

| JP2009066031A (en) | Rotary cleaning body, suction nozzle for cleaner and air conditioner | |

| JP4874786B2 (en) | Electric blower and vacuum cleaner | |

| JP2005288148A (en) | Brush assembly and vacuum cleaner including brush assembly | |

| CN219070073U (en) | Cleaning apparatus | |

| JP2007202673A (en) | Spinning rotor, suction device for cleaner, and vacuum cleaner | |

| CN112515535A (en) | Cleaning head and dust collector | |

| JP4504163B2 (en) | Suction port and vacuum cleaner |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| A621 | Written request for application examination |

Free format text: JAPANESE INTERMEDIATE CODE: A621 Effective date: 20120528 |

|

| RD02 | Notification of acceptance of power of attorney |

Free format text: JAPANESE INTERMEDIATE CODE: A7422 Effective date: 20120528 |

|

| A521 | Written amendment |

Free format text: JAPANESE INTERMEDIATE CODE: A523 Effective date: 20120531 |

|

| A977 | Report on retrieval |

Free format text: JAPANESE INTERMEDIATE CODE: A971007 Effective date: 20130501 |

|

| A131 | Notification of reasons for refusal |

Free format text: JAPANESE INTERMEDIATE CODE: A131 Effective date: 20130515 |

|

| A521 | Written amendment |

Free format text: JAPANESE INTERMEDIATE CODE: A523 Effective date: 20130714 |

|

| A02 | Decision of refusal |

Free format text: JAPANESE INTERMEDIATE CODE: A02 Effective date: 20130919 |

|

| A521 | Written amendment |

Free format text: JAPANESE INTERMEDIATE CODE: A523 Effective date: 20131217 |

|

| A911 | Transfer of reconsideration by examiner before appeal (zenchi) |

Free format text: JAPANESE INTERMEDIATE CODE: A911 Effective date: 20131225 |

|

| A912 | Removal of reconsideration by examiner before appeal (zenchi) |

Free format text: JAPANESE INTERMEDIATE CODE: A912 Effective date: 20140131 |