JP2010027704A - Production method of light-emitting device using phosphor ceramic board - Google Patents

Production method of light-emitting device using phosphor ceramic board Download PDFInfo

- Publication number

- JP2010027704A JP2010027704A JP2008184564A JP2008184564A JP2010027704A JP 2010027704 A JP2010027704 A JP 2010027704A JP 2008184564 A JP2008184564 A JP 2008184564A JP 2008184564 A JP2008184564 A JP 2008184564A JP 2010027704 A JP2010027704 A JP 2010027704A

- Authority

- JP

- Japan

- Prior art keywords

- light

- emitting device

- phosphor ceramic

- light emitting

- phosphor

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Pending

Links

Images

Landscapes

- Luminescent Compositions (AREA)

- Led Device Packages (AREA)

Abstract

Description

本発明は、半導体発光素子と蛍光体セラミック板を組み合わせた発光装置の製造方法に関し、特に均一な色度で発光する発光装置を再現性よく製造する方法に関する。 The present invention relates to a method for manufacturing a light emitting device combining a semiconductor light emitting element and a phosphor ceramic plate, and more particularly to a method for manufacturing a light emitting device that emits light with uniform chromaticity with good reproducibility.

発光装置として、GaN等の青色発光ダイオードと波長変換材料とを組み合わせた白色LEDが広く使われている。波長変換材料としては蛍光体粒子が一般的であり、蛍光体粒子を樹脂に分散させたものが用いられてきたが、近年、波長変換材料としての用途に多結晶蛍光体のセラミックが開発され、提案されている(特許文献1、特許文献2)。しかし一般的な蛍光体セラミックは、焼結体内に気孔や異相等の散乱体を含んでいるため、直線透過性が低い、また散乱体は通常不均質に分布するため、散乱光は不均質なものとなり、色ばらつきを生じやすいなど問題点がある。

As a light emitting device, a white LED combining a blue light emitting diode such as GaN and a wavelength conversion material is widely used. Phosphor particles are generally used as wavelength conversion materials, and those in which phosphor particles are dispersed in a resin have been used, but in recent years, ceramics for polycrystalline phosphors have been developed for use as wavelength conversion materials, It has been proposed (

また発光装置の発光色度は、蛍光体セラミック板の厚みに依存するため、個々の白色LED毎に均一な色管理を行なうことは容易ではない。 Further, since the emission chromaticity of the light emitting device depends on the thickness of the phosphor ceramic plate, it is not easy to perform uniform color management for each individual white LED.

これに対し、特許文献2には、波長変換材料として光変換セラミックを使用した発光デバイスを所望のスペクトル(色度)に調整する方法が開示されている。この方法では、光変換セラミックをLEDダイに接合またはダイ上に配置し、デバイスとして実際に発光させる。この状態で所望の発光スペクトルになっているかを確認し、厚みが厚い場合はレーザアブレーションやエッチンングにより厚みを減少させて所望の波長スペクトルを生成するようにする。

上述した色管理方法では、レーザアブレーション等の高価な設備を必要とし、またデバイスを個別に調整するため非常に手間とコストがかかるという問題がある。従って、蛍光体セラミックを発光装置に組み込む前に、蛍光体セラミックを調整して所望の色度を実現できるようにすることが望ましいが、発光装置の色度は、LED素子と蛍光体セラミックを組み合わせたときの色度を問題にするため、蛍光体セラミック単独での色管理はできない。一方、上述した技術のレーザアブレーションによるセラミックの削り量を予め計測しておき、個々の発光素子毎に蛍光体セラミックの削り量を予め決めた一定量にすることにより、蛍光体セラミックによって実現される色度を一定にすることが考えられる。 The above-described color management method requires expensive equipment such as laser ablation, and there is a problem that it takes a lot of labor and cost to adjust devices individually. Therefore, it is desirable to adjust the phosphor ceramic to achieve the desired chromaticity before incorporating the phosphor ceramic into the light emitting device. However, the chromaticity of the light emitting device is a combination of the LED element and the phosphor ceramic. Therefore, it is impossible to manage the color of the phosphor ceramic alone. On the other hand, the amount of ceramic cut by laser ablation of the above-described technique is measured in advance, and the amount of shaving of the phosphor ceramic is set to a predetermined fixed amount for each light emitting element, thereby realizing the phosphor ceramic. It is possible to make the chromaticity constant.

しかし、蛍光体セラミックを発光装置に組み込む際のハンドリング、例えば所定の大きさにカットし、それをLED素子上に載置するなどの処理の際に、割れたり欠けたりすることがないようにするために、蛍光体セラミックの厚みには、おのずと薄さの制限があり、蛍光体セラミックの削り量のみで色管理することには限界がある。また蛍光体セラミックは原料の仕込み量が同じであっても、原料の純度や製造条件により組成を一定に保つことは困難である。特に発光色を決めるドーパント濃度は微量であるために一定に保つことが困難であり、発光色を変動させる要因となる。 However, handling when incorporating the phosphor ceramic into the light emitting device, for example, cutting to a predetermined size and placing it on the LED element, prevents cracking or chipping. For this reason, the thickness of the phosphor ceramic is naturally limited by the thickness, and there is a limit to color management only by the amount of shaving of the phosphor ceramic. Moreover, even if the amount of the raw material of the phosphor ceramic is the same, it is difficult to keep the composition constant depending on the purity of the raw material and the manufacturing conditions. In particular, since the dopant concentration that determines the luminescent color is very small, it is difficult to keep it constant, which causes the luminescent color to fluctuate.

本発明は、発光素子に組み込む前の段階で、色管理を行なうことができ、簡便且つ少ない製造工程で発光色度が均一な発光装置を製造することが可能な製造方法を提供することを目的とする。 An object of the present invention is to provide a manufacturing method capable of performing color management at a stage before being incorporated into a light emitting element, and capable of manufacturing a light emitting device having uniform emission chromaticity with simple and few manufacturing processes. And

上記課題を解決するため本発明者らは、半導体発光素子と組み合わせたときに蛍光体セラミック板が発する光の色度は、ドーパント濃度とセラミック板の厚みの積と良好な相関があること、またこの相関を利用することにより、セラミック板の厚みに制限がある条件で、所望の色度を再現性よく実現できることを見出し、本発明に至った。 In order to solve the above problems, the present inventors have found that the chromaticity of light emitted from the phosphor ceramic plate when combined with a semiconductor light emitting element has a good correlation with the product of the dopant concentration and the thickness of the ceramic plate, By utilizing this correlation, it has been found that desired chromaticity can be realized with good reproducibility under conditions where the thickness of the ceramic plate is limited, and the present invention has been achieved.

即ち本発明の発光装置の製造方法は、励起光を発光する半導体発光素子と、蛍光体の多結晶材料から成り、半導体発光素子が発光する励起光と異なる波長の光を発する蛍光体セラミック板とを備え、前記励起光と前記蛍光体セラミック板が発光する光とを合成した光を発する発光装置の製造方法であって、前記蛍光体に含まれるドーパントの原子濃度と前記蛍光体セラミック板の厚みとの積と、前記発光装置が発光する光の色度との関係とを用いて、前記発光装置に用いる蛍光体セラミックを調整する工程を含むことを特徴とする。 That is, the method for manufacturing a light emitting device of the present invention includes a semiconductor light emitting element that emits excitation light, a phosphor ceramic plate that is made of a phosphor polycrystalline material, and emits light having a wavelength different from that of the excitation light emitted from the semiconductor light emitting element. A light emitting device that emits light obtained by synthesizing the excitation light and the light emitted from the phosphor ceramic plate, the atomic concentration of the dopant contained in the phosphor and the thickness of the phosphor ceramic plate And a step of adjusting a phosphor ceramic used in the light emitting device using a relationship between the product of the above and the chromaticity of light emitted from the light emitting device.

本発明によれば、予め求めたドーパント濃度とセラミック板の厚みの積と、発光色度との関係を用いることにより、高価な装置や複雑な工程を経ることなく、色バラツキのない発光装置を再現性よく製造することができる。 According to the present invention, by using the relationship between the product of the dopant concentration determined in advance and the thickness of the ceramic plate and the emission chromaticity, an expensive device and a light emitting device free from color variations can be obtained without going through complicated processes. It can be manufactured with good reproducibility.

以下、本発明の発光装置の製造方法の実施の形態を説明する。

本発明が対象とする発光装置は、発光素子と蛍光体セラミックを組み合わせたものであり、LED素子が発する光と蛍光体セラミックが発する光を合成した光が、発光装置の色度を決定する。

Embodiments of a method for manufacturing a light emitting device according to the present invention will be described below.

The light-emitting device targeted by the present invention is a combination of a light-emitting element and a phosphor ceramic, and light synthesized from light emitted from the LED element and light emitted from the phosphor ceramic determines the chromaticity of the light-emitting device.

発光素子としては、波長440〜460nmの光を発生する半導体発光素子(LED素子)が用いられる。具体的には、例えば、窒化ガリウム系化合物半導体発光素子、酸化亜鉛系化合物半導体発光素子、セレン化亜鉛系化合物半導体発光素子など青〜紫外の光を発生する半導体発光素子が挙げられる。 As the light emitting element, a semiconductor light emitting element (LED element) that generates light having a wavelength of 440 to 460 nm is used. Specific examples include semiconductor light emitting devices that emit blue to ultraviolet light, such as gallium nitride compound semiconductor light emitting devices, zinc oxide compound semiconductor light emitting devices, and zinc selenide compound semiconductor light emitting devices.

蛍光体セラミック板は、LED素子が発する光を吸収し、それより長波長の光を発生する。このような蛍光体セラミックには、種々のものが提案されており、そのいずれも採用することができるが、例えば、波長440〜460nmの光を発するLED素子と組み合わせて白色光を得る発光装置を得るためには、CeをドーパントとするYAG蛍光体、(Ba,Sr,Ca)2SiO4:Eu、Cax(Si,Al)12(O,N)16:Eu等が用いられる。 The phosphor ceramic plate absorbs light emitted from the LED element and generates light having a longer wavelength. Various phosphor ceramics have been proposed and any of them can be employed. For example, a light emitting device that obtains white light in combination with an LED element that emits light having a wavelength of 440 to 460 nm is used. In order to obtain, a YAG phosphor having Ce as a dopant, (Ba, Sr, Ca) 2 SiO 4 : Eu, Ca x (Si, Al) 12 (O, N) 16 : Eu, or the like is used.

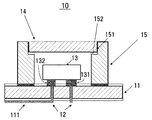

発光装置の形態は特に限定されないが、一例として、Siウェハをフォトリソグラフィーとエッチンング技術にて加工したパッケージからなる発光装置(ドットマトリクス光源)を図1および図2に示す。図1(a)、(b)は、発光装置の平面図および側面図である。図2は、発光装置を構成する一つのドット(発光要素)の側面図である。 Although the form of the light-emitting device is not particularly limited, as an example, FIGS. 1 and 2 show a light-emitting device (dot matrix light source) including a package obtained by processing a Si wafer by photolithography and etching technology. 1A and 1B are a plan view and a side view of the light emitting device. FIG. 2 is a side view of one dot (light emitting element) constituting the light emitting device.

この発光装置10は、多数のスルーホール12が形成された基板11と、各スルーホール12に対応する位置に接合された半導体発光素子(以下、LED素子という)13と、各LED素子の上に載置される蛍光体セラミック板14とを備え、個々のLED素子13とその上に載置された蛍光体セラミック板14とで発光要素が形成される。各発光要素は、基板11上に固定された型枠15によって隔てられている。図示する例では、2次元方向に配列した多数の発光素子からなるドットマトリクス光源を示しているが、1次元方向に配列したものでもよいし、あるいは単独の発光要素からなるものであってもよい。

The

発光装置を構成する各発光要素は、その一例を図2に示すように、LED素子13に設けられたp電極131とn電極132とが銅等の導電性金属からなるスルーホール12を介して基板11裏面に設けられたリード(Cu配線)111に接続されている。これら電極間に電圧を与えることにより、LED素子13が所定の波長の光を発光する。型枠15は、例えば円筒状の形状を有し、LED素子13を囲むように基板11に接合されている。型枠15の内面は、LED素子13が発する光を反射するための反射部材で構成されており、反射リングを兼ねている。また型枠15の上端の内周には、蛍光体セラミック板14を固定するための段差151が形成されており、この段差151に固定材(例えば低融点ガラス等の接着剤)152を介して蛍光体セラミック板14が載置される。

As shown in FIG. 2 for example, each light emitting element constituting the light emitting device has

LED素子13の構造には、透明な電極を用いて電極側から発光させるようにしたものや、透明基板側から発光させるようにした所謂フリップチップタイプのものなどがあり、いずれでもよいが、光の外部取り出し効果に優れたフリップチップタイプのものが特に好ましい。

The

蛍光体セラミック板14は、上述したように、CeをドーパントとするYAG蛍光体、(Ba,Sr,Ca)2SiO4:Eu、Cax(Si,Al)12(O,N)16:Eu等の多結晶からなるセラミックである。このような蛍光体セラミック板は、粒界での屈折率差が小さいため、粒界での光散乱が実質的になく、透明性が高い。従ってLED素子13及び蛍光体が発する光を効率よく、発光装置の外に取り出すことができる。

As described above, the phosphor

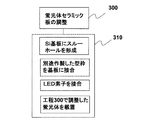

次に、このような構造の発光装置の製造方法を説明する。図3は、製造工程の概略を示す図である。本発明の発光装置の製造方法は、大きく分けて、目的とする色度を実現する蛍光体セラミック板を調整する工程300と、工程300で調整された蛍光体セラミック板を用いて発光装置を組み立てる工程310とからなり、工程300を備える点が特徴である。

Next, a method for manufacturing the light emitting device having such a structure will be described. FIG. 3 is a diagram showing an outline of the manufacturing process. The method for manufacturing a light emitting device of the present invention is roughly divided into a

蛍光体セラミック板を調整する工程300を説明する前に、まず、工程310を簡単に説明する。ここでは、図1に示す発光装置を例にして工程310を説明するが、工程310は発光装置の種類によって異なり、発光装置の種類に応じて公知の製造方法が採用される。

Before describing the

まずCu配線の埋め込み技術を用いて、Si基板11にスルーホール12を形成し、裏面となる側にCu配線111を回す。これとは別にSi板を微細加工技術でエッチングしてドット(発光素子)毎の型枠を作成し、この型枠15をスルーホール12が形成されたSi基板11に接合する。両者の接合は例えば加熱により行なうことができる。ドットの形成にフォトリソグラフィー技術を用いることにより、ドットの間隔は100μm程度に高密度化することができ、また型枠により隣接するドット間のクロストークを確実になくすことができる。

First, using a Cu wiring embedding technique, the through

次に、片面にp電極とn電極が形成された、例えばフリップチップLED素子13をAuバンドで接合する。一方、工程300において、LED素子13と組み合わせたときに色度が適切な範囲となるように調整された蛍光体セラミック板を、型枠15の大きさに合わせてダイシングした後、LED素子13の上面に載置し固定する。

Next, for example, a flip-

蛍光体セラミック板を調整する工程300を説明する。工程300の詳細を図4に示す。ここでは一例として達成すべき発光装置のスペクトルが白色である場合を例に説明する。本実施の形態では、目的とする白色は、図5に示すCIE1931色度図において、4点(0.24、0.30)、(0.31、0.26)、(0.40、0.44)、(0.34、0.48)で囲まれる領域(図中、四角で囲った領域)とする。参考として、一般に光源としてJIS Z8110に白色と定義されている範囲を点線で囲った領域で示す。

The

まず蛍光体セラミックの厚みとドーパント濃度との積([厚み×濃度])と、色度との検量線40を作成しておく。検量線は、厚み及びドーパント濃度の異なる種々の蛍光体セラミックを用意し、これら蛍光体セラミックを所定のLED素子の上に置き、LED素子を発光させたときに色度を測定することにより得る。検量線は、異なるドーパント濃度毎に、厚みと色度の検量線を得るようにしてもよい。

First, a

図6に、Ceを発光ドーパントとするYAGを用いた場合の検量線の例を示す。図6の検量線は、イットリウムに対するセリウム原子濃度(ドーパント濃度)を内率で0.05at%〜0.5at%の範囲で異ならせた場合であり、[厚み(mm)×濃度(at%)]に対し、CIE色度のx値をプロットしたものである。x値が0.30〜0.39の範囲でほぼ白色となり、数値が大きいほど黄味が強く、小さいほど青味が強くなる。このように、ドーパント濃度が比較的低いときには、[厚み×濃度]の増加に伴い、x値も増加し、[厚み×濃度]とx値との間に相関があることがわかる。 FIG. 6 shows an example of a calibration curve when YAG using Ce as a light emitting dopant is used. The calibration curve in FIG. 6 is the case where the cerium atom concentration (dopant concentration) with respect to yttrium is varied in the range of 0.05 at% to 0.5 at%, and [thickness (mm) × concentration (at%)]. On the other hand, the x value of CIE chromaticity is plotted. When the x value is in the range of 0.30 to 0.39, the color is almost white. The larger the numerical value, the stronger the yellowness, and the smaller the value, the stronger the blueness. Thus, when the dopant concentration is relatively low, the x value increases with an increase in [thickness × concentration], and it can be seen that there is a correlation between [thickness × concentration] and the x value.

ただし、ドーパント濃度がある程度以上高くなると、厚みに依存せずにx値はほぼ一定となる。これは、ドーパント濃度が高くなるとLED素子が発する光を全て吸収するため、蛍光体セラミック板が発する光の波長が支配的になるためである。図7に、Ceドーパント濃度が3.0at%における[厚み×濃度]とx値との関係を示す。図7からもわかるように、ドーパント濃度が高い場合には、[厚み×濃度]を変えても色度はほぼ一定である。この場合には、厚みを蛍光体セラミックのハンドリング上の下限値まで減らしても、色度を白色の範囲(x値を0.40以下)とすることはできない。 However, when the dopant concentration is higher than a certain level, the x value becomes substantially constant without depending on the thickness. This is because the wavelength of light emitted from the phosphor ceramic plate becomes dominant because all light emitted from the LED element is absorbed when the dopant concentration is increased. FIG. 7 shows the relationship between [thickness × concentration] and x value when the Ce dopant concentration is 3.0 at%. As can be seen from FIG. 7, when the dopant concentration is high, the chromaticity is substantially constant even if [thickness × concentration] is changed. In this case, the chromaticity cannot be in the white range (x value is 0.40 or less) even if the thickness is reduced to the lower limit for handling the phosphor ceramic.

そこで蛍光体セラミック板を調整する工程300の最初のステップでは、蛍光体材料としてドーパント濃度が所定の範囲のものを用意する(ステップ41)。例えば、Ceを発光ドーパントとするYAGを用いた発光装置であって、白色発光を目的とする場合、Ce濃度が1at%以下のものを用意する。Ce濃度が1at%以下とすることにより、ハンドリングに支障のない厚みの範囲内で白色を実現することができる。

なお蛍光体セラミックのドーパント濃度は、蛍光体セラミックを製造する際の原料の比率(仕込み量)で決める。

Therefore, in the first step of the

The dopant concentration of the phosphor ceramic is determined by the ratio of raw materials (preparation amount) when the phosphor ceramic is manufactured.

次に蛍光体セラミックの厚みを測定する(ステップ42)。測定した厚みとその蛍光体セラミックの濃度との積を求め、検量線を用いて、この値が所望の色度を達成する値の範囲であるかどうかを判断する(ステップ43)。図6に示す検量線の場合、[厚み(mm)×濃度(at%)]が0.02以上、0.06以下の範囲であれば、色度(CIE座標のx値)は0.31〜0.39の範囲となり、目的とする白色発光が実現できる。 Next, the thickness of the phosphor ceramic is measured (step 42). A product of the measured thickness and the concentration of the phosphor ceramic is obtained, and using a calibration curve, it is determined whether or not this value is within a range of values that achieve a desired chromaticity (step 43). In the case of the calibration curve shown in FIG. 6, if [thickness (mm) × concentration (at%)] is in the range of 0.02 or more and 0.06 or less, the chromaticity (x value of CIE coordinates) is in the range of 0.31 to 0.39. The target white light emission can be realized.

ステップ23で求めた値が、目的とする色度を実現できる範囲であれば、そのままデバイスに使用する(ステップ44)。ステップ43で求めた値が、目的とする色度を実現できる範囲外である場合には、ステップ42で測定した厚みが、下限値以上であるかを判断し(ステップ45)、下限値以上であれば、所定の厚みに研磨する(ステップ46)。研磨方法は、公知の研磨技術により行い、[厚み(mm)×濃度(at%)]が検量線から求められる範囲内になるまで研磨を行なう。

If the value obtained in step 23 is within a range where the target chromaticity can be realized, it is used for the device as it is (step 44). If the value obtained in

一方、ステップ42で測定した厚みが、下限値より薄い場合には、ハンドリング上、それ以下に薄くすることは好ましくないので、目的とする色度の発光装置への使用から除外し、別の色の発光装置用に用いる(ステップ47)。ステップ47に振り分けられた蛍光体についても、必要に応じて白色発光装置の場合と同様に、ステップ41〜46に相当する処理を行い、目的とする発光装置に合わせた蛍光体セラミックの調整を行なう。

On the other hand, if the thickness measured in

以上のステップ41〜46により、発光装置に用いる蛍光体セラミック板が選択されたならば、目的の発光装置に合わせた形状に切り出し、その後、上述した工程310により、LED素子と組み合わせて目的の発光装置を得る。

If the phosphor ceramic plate to be used for the light emitting device is selected in the

このように本実施の形態により製造した発光装置は、蛍光体セラミック板14がLED素子と組み合わせたときに発光色が目的のスペクトル範囲となるように調整されているので、色バラツキの極めて少ないドットマトリクス光源が実現できる。また通常の研磨技術で厚みを調整するだけでよいので、高価な設備等を必要とすることなく簡単な工程で発光装置を製造することができる。

As described above, the light emitting device manufactured according to the present embodiment is adjusted so that the emission color is in the target spectral range when the phosphor

なお、以上の説明では、目的とする発光色度が白色である場合を説明したが、白色以外の場合であっても、同様に蛍光体セラミックを調整することができ、これにより所望の色度で色バラツキの極めて少ない発光装置を実現できる。例えば、目的の色度が黄色(図5に示すCIE色度図において、(0.45,0.55)、(0.40,0.50)、(0.42,0.40)、(0.55,0.45)で囲まれる領域)の場合には、Ce濃度が1.5〜3at%の範囲の蛍光体セラミック板を用意し、ドーパント濃度と厚みとの積を0.2から2.0の範囲となるように調整することにより、目的とする黄色を実現することができる。

また図7に示すような[厚み×濃度]とx値との関係から、Ceドーパント濃度を3.0at%以上にすることによって、厚みが変化しても色度変化がなく、非常に均一な黄色発光の発光装置を実現できる。

In the above description, the case where the target light emission chromaticity is white has been described. However, even in cases other than white, the phosphor ceramic can be adjusted in the same manner, so that the desired chromaticity can be adjusted. Thus, a light emitting device with extremely little color variation can be realized. For example, when the target chromaticity is yellow (in the CIE chromaticity diagram shown in FIG. 5, the region surrounded by (0.45,0.55), (0.40,0.50), (0.42,0.40), (0.55,0.45)). Provides a phosphor ceramic plate with a Ce concentration in the range of 1.5 to 3 at% and adjusts the product of the dopant concentration and thickness to be in the range of 0.2 to 2.0 to achieve the desired yellow color. can do.

Further, from the relationship between [thickness × concentration] and x value as shown in FIG. 7, by setting the Ce dopant concentration to 3.0 at% or more, there is no chromaticity change even if the thickness changes, and a very uniform yellow A light emitting device can be realized.

以下、本発明の実施例を説明する。 Examples of the present invention will be described below.

<実施例1>

1.蛍光体セラミック板の作製

酸化セリウム粉末、酸化イットリウム粉末及び酸化アルミニウム粉末を、所定比秤量し、これにエタノール、アクリル系バインダを添加し、ナイロンボールを用いたボールミルによって20時間の混合を行なった。得られたスラリからスプレードライヤを用いて平均粒径70μmの造粒粉を作製した。造粒粉は20MPaで一軸金型成形した後、150MPa冷間静水圧成形(CIP)を行なって成形体とし、大気中1000℃で脱脂処理を行なった。脱脂体を真空雰囲気(1×10-2Pa以下)、1700℃で3時間焼成し、焼結体を得た。焼結体を所定厚みに両面研磨晶へと加工し、厚み0.1〜1.0mmの蛍光体セラミックを得た。原料粉末の秤量比を、セリウム濃度が0.05、0.1、0.15、0.5at%となるように変えて、4種類の蛍光体セラミックを作製した。

<Example 1>

1. Preparation of phosphor ceramic plate A predetermined ratio of cerium oxide powder, yttrium oxide powder and aluminum oxide powder was weighed, ethanol and an acrylic binder were added thereto, and mixing was performed for 20 hours by a ball mill using nylon balls. A granulated powder having an average particle size of 70 μm was prepared from the obtained slurry using a spray dryer. The granulated powder was uniaxially molded at 20 MPa, and then subjected to 150 MPa cold isostatic pressing (CIP) to obtain a compact, which was degreased at 1000 ° C. in the atmosphere. The degreased body was fired at 1700 ° C. for 3 hours in a vacuum atmosphere (1 × 10 −2 Pa or less) to obtain a sintered body. The sintered body was processed into a double-side polished crystal with a predetermined thickness to obtain a phosphor ceramic having a thickness of 0.1 to 1.0 mm. Four types of phosphor ceramics were produced by changing the weighing ratio of the raw material powders so that the cerium concentrations were 0.05, 0.1, 0.15, and 0.5 at%.

2.検量線の作成

上記のように作製した蛍光体セラミックを、GaNチップを使用した青色LEDを備えた発光デバイス(図2に示す構造)に組み込み、電流(350mA)を流して発光させた。このときの全光束を積分球で取り込み、その色度を測定した。測定した色度(CIE座標のx値)を、用いた蛍光体セラミックの厚み(mm)とセリウム濃度(at%)との積([濃度×厚み])に対しプロットし、図6に示すような検量線を得た。

2. Preparation of calibration curve The phosphor ceramic produced as described above was incorporated into a light-emitting device (structure shown in FIG. 2) equipped with a blue LED using a GaN chip, and light was emitted by passing an electric current (350 mA). The total luminous flux at this time was taken in with an integrating sphere, and its chromaticity was measured. The measured chromaticity (x value of CIE coordinates) is plotted against the product ([concentration × thickness]) of the thickness (mm) and cerium concentration (at%) of the phosphor ceramic used, as shown in FIG. A good calibration curve was obtained.

図6からわかるように、セリウム濃度が0.05at%〜0.5at%の範囲では、[濃度×厚み]とCIE座標のx値との間に相関が認められた。

従って、作製した蛍光体セラミック板のセリウム濃度に応じて、所望のx値が得られるように板の厚みを調整することにより、目的とする色度の発光装置を製造することができる。

As can be seen from FIG. 6, in the range where the cerium concentration is 0.05 at% to 0.5 at%, a correlation was observed between [concentration × thickness] and the x value of the CIE coordinates.

Therefore, by adjusting the thickness of the plate so as to obtain a desired x value in accordance with the cerium concentration of the produced phosphor ceramic plate, a light emitting device having a desired chromaticity can be manufactured.

3.発光装置の作製

セリウム濃度が0.05at%、厚み0.54mmの蛍光体セラミック板を用いて、図2に示す構造の白色LED光源を作製した。青色LEDとしては、ピーク波長が452nmのGaN系のフリップチップタイプのLED素子を用いた。

作製したLED光源の色度を測定した。結果を図8に示す。図8において横軸はLED光源の中心からの距離、縦軸はCIEのx値及びy値である。この結果からもわかるように、光源の面内でほぼ均一なx値(=0.33)およびy値(=0.38)を達成することができた。

3. Production of Light-Emitting Device A white LED light source having the structure shown in FIG. 2 was produced using a phosphor ceramic plate having a cerium concentration of 0.05 at% and a thickness of 0.54 mm. As the blue LED, a GaN-based flip chip type LED element having a peak wavelength of 452 nm was used.

The chromaticity of the produced LED light source was measured. The results are shown in FIG. In FIG. 8, the horizontal axis represents the distance from the center of the LED light source, and the vertical axis represents the CIE x and y values. As can be seen from this result, almost uniform x value (= 0.33) and y value (= 0.38) can be achieved in the plane of the light source.

<実施例2>

1.蛍光体セラミック板の作製

原料粉末の秤量比を、セリウム濃度が3.0at%とし、その他は実施例1と同様にして、厚みの異なる複数の蛍光体セラミックを作製した(厚み(mm)=0.1、0.2、0.3、0.35、0.5、0.7)。

<Example 2>

1. Production of Phosphor Ceramic Plate A plurality of phosphor ceramics having different thicknesses were produced in the same manner as in Example 1 except that the weighing ratio of the raw material powder was cerium concentration of 3.0 at% (thickness (mm) = 0.1, 0.2, 0.3, 0.35, 0.5, 0.7).

2.検量線の作成

上記のように作製した蛍光体セラミックを、GaNチップを使用した青色LEDを備えた発光デバイス(図2に示す構造)に組み込み、電流(350mA)を流して発光させた。このときの全光束を積分球で取り込み、その色度を測定した。測定した色度(CIE座標のx値)を、用いた蛍光体セラミックの厚み(mm)とセリウム濃度(3.0at%)との積([濃度×厚み])に対しプロットし、図7に示すような検量線を得た。

図7からわかるように、セリウム濃度が3.0at%では、[濃度×厚み]の値が0.5を超えると(すなわち厚みが約170μm以上)では厚みに依存せず一定の色度が得られた。

2. Preparation of calibration curve The phosphor ceramic produced as described above was incorporated into a light-emitting device (structure shown in FIG. 2) equipped with a blue LED using a GaN chip, and light was emitted by passing an electric current (350 mA). The total luminous flux at this time was taken in with an integrating sphere, and its chromaticity was measured. The measured chromaticity (x value of CIE coordinates) is plotted against the product ([concentration × thickness]) of the thickness (mm) and cerium concentration (3.0 at%) of the phosphor ceramic used, and is shown in FIG. A calibration curve like this was obtained.

As can be seen from FIG. 7, when the cerium concentration is 3.0 at%, when the value of [concentration × thickness] exceeds 0.5 (that is, the thickness is about 170 μm or more), constant chromaticity is obtained regardless of the thickness.

3.発光装置の作製

セリウム濃度が3.0at%、厚み0.2mmの蛍光体セラミック板を用いて、図2に示す構造の黄橙色LED光源を作製した。青色LEDとしては、ピーク波長が452nmのGaN系のフリップチップタイプのLED素子を用いた。

作製したLED光源の色度を測定した。結果を図9に示す。図9において横軸はLED光源の中心からの距離、縦軸はCIEのx値及びy値である。この結果からもわかるように、光源の面内でほぼ均一なx値(=0.47)およびy値(=0.5)を達成することができた。

3. Production of Light-Emitting Device A yellow-orange LED light source having the structure shown in FIG. 2 was produced using a phosphor ceramic plate having a cerium concentration of 3.0 at% and a thickness of 0.2 mm. As the blue LED, a GaN-based flip chip type LED element having a peak wavelength of 452 nm was used.

The chromaticity of the produced LED light source was measured. The results are shown in FIG. In FIG. 9, the horizontal axis represents the distance from the center of the LED light source, and the vertical axis represents the CIE x and y values. As can be seen from this result, almost uniform x value (= 0.47) and y value (= 0.5) could be achieved in the plane of the light source.

本発明の製造方法により発光装置は、極めて色の均一性、再現性に優れ、また多結晶蛍光体を用いているため発光効率に優れている。この発光装置は、車両照明装置、液晶ディスプレイ照明装置、室内照明装置、屋外照明装置等の種々の照明装置用の光源として用いることができる。 With the manufacturing method of the present invention, the light emitting device is extremely excellent in color uniformity and reproducibility, and has excellent luminous efficiency because it uses a polycrystalline phosphor. This light emitting device can be used as a light source for various lighting devices such as a vehicle lighting device, a liquid crystal display lighting device, an indoor lighting device, and an outdoor lighting device.

11・・・基板、13・・・LED素子、14・・・蛍光体セラミック板、15・・・型枠(反射リング)

DESCRIPTION OF

Claims (5)

前記蛍光体に含まれるドーパントの原子濃度と前記蛍光体セラミック板の厚みとの積と、前記発光装置が発光する光の色度との関係とを用いて、前記発光装置に用いる蛍光体セラミックを調整する工程を含むことを特徴とする発光装置の製造方法。 A semiconductor light-emitting element that emits excitation light; and a phosphor ceramic plate that is made of a phosphor polycrystalline material and emits light having a wavelength different from that of the excitation light emitted from the semiconductor light-emitting element, the excitation light and the phosphor ceramic A method of manufacturing a light emitting device that emits light, which is obtained by combining light emitted by a plate,

Using the relationship between the product of the atomic concentration of the dopant contained in the phosphor and the thickness of the phosphor ceramic plate, and the chromaticity of the light emitted from the light emitting device, the phosphor ceramic used in the light emitting device is The manufacturing method of the light-emitting device characterized by including the process to adjust.

前記蛍光体セラミックを調整する工程は、

前記ドーパントの原子濃度が予め定めた範囲である蛍光体セラミック板を選択するステップと、

前記選択された蛍光体セラミック板について、前記ドーパントの原子濃度と前記蛍光体セラミック板の厚みとの積が、前記色度との関係から、所望の色度に対応する範囲となるように、前記蛍光体セラミック板の厚みを調整するステップと、を含むことを特徴とする発光装置の製造方法。 A method of manufacturing a light emitting device according to claim 1,

The step of adjusting the phosphor ceramic comprises:

Selecting a phosphor ceramic plate having an atomic concentration of the dopant in a predetermined range;

About the selected phosphor ceramic plate, the product of the atomic concentration of the dopant and the thickness of the phosphor ceramic plate is in a range corresponding to a desired chromaticity from the relationship with the chromaticity. Adjusting the thickness of the phosphor ceramic plate.

前記発光装置が発光する光の色度は、CIE色度座標のx値及びy値で規定されることを特徴とする発光装置の製造方法。 A method of manufacturing a light emitting device according to claim 1 or 2,

A method for manufacturing a light emitting device, wherein the chromaticity of light emitted from the light emitting device is defined by an x value and a y value of CIE chromaticity coordinates.

前記蛍光体セラミック板は、CeをドーパントとするYAG系蛍光体からなり、前記所望の色度が白色(CIE色度座標のx値及びy値が(0.24、0.30)、(0.31、0.26)、(0.40、0.44)、(0.34、0.48)で囲まれる領域)であることを特徴とする発光装置の製造方法。 A method of manufacturing a light emitting device according to any one of claims 1 to 3,

The phosphor ceramic plate is made of a YAG phosphor having Ce as a dopant, and the desired chromaticity is white (x and y values of CIE chromaticity coordinates are (0.24, 0.30), (0.31, 0.26), (A region surrounded by (0.40, 0.44) and (0.34, 0.48)).

Priority Applications (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| JP2008184564A JP2010027704A (en) | 2008-07-16 | 2008-07-16 | Production method of light-emitting device using phosphor ceramic board |

Applications Claiming Priority (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| JP2008184564A JP2010027704A (en) | 2008-07-16 | 2008-07-16 | Production method of light-emitting device using phosphor ceramic board |

Publications (2)

| Publication Number | Publication Date |

|---|---|

| JP2010027704A true JP2010027704A (en) | 2010-02-04 |

| JP2010027704A5 JP2010027704A5 (en) | 2011-08-04 |

Family

ID=41733277

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| JP2008184564A Pending JP2010027704A (en) | 2008-07-16 | 2008-07-16 | Production method of light-emitting device using phosphor ceramic board |

Country Status (1)

| Country | Link |

|---|---|

| JP (1) | JP2010027704A (en) |

Cited By (8)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US20120039064A1 (en) * | 2010-08-11 | 2012-02-16 | Nitto Denko Corporation | Light-emitting device |

| WO2012037733A1 (en) * | 2010-09-26 | 2012-03-29 | 海洋王照明科技股份有限公司 | Field emission anode plate, filed emission light source and manufacturing method for light source |

| JP2012234966A (en) * | 2011-04-28 | 2012-11-29 | Toshiba Corp | Substrate processing system and substrate processing program |

| US8664678B2 (en) | 2010-06-30 | 2014-03-04 | Nitto Denko Corporation | Phosphor ceramic and light-emitting device |

| WO2014061748A1 (en) | 2012-10-17 | 2014-04-24 | 宇部興産株式会社 | Wavelength conversion member and light-emitting device employing same |

| JP2014095077A (en) * | 2012-11-07 | 2014-05-22 | Rolex Sa | Persistent phosphorescent composite material |

| WO2018012273A1 (en) * | 2016-07-14 | 2018-01-18 | 日本電気硝子株式会社 | Method for manufacturing wavelength conversion member and wavelength conversion member group |

| WO2023229022A1 (en) * | 2022-05-27 | 2023-11-30 | パナソニックIpマネジメント株式会社 | Fluorescent body device and light source module |

Citations (4)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| JP2000208815A (en) * | 1996-07-29 | 2000-07-28 | Nichia Chem Ind Ltd | Light-emitting diode |

| JP2003168711A (en) * | 2001-11-30 | 2003-06-13 | Shin Etsu Handotai Co Ltd | Method of measuring carrier concentration and method of manufacturing iii-v compound semiconductor wafer |

| WO2006001316A1 (en) * | 2004-06-24 | 2006-01-05 | Ube Industries, Ltd. | White light emitting diode device |

| JP2008515184A (en) * | 2004-09-28 | 2008-05-08 | コーニンクレッカ フィリップス エレクトロニクス エヌ ヴィ | Light emitting device with improved conversion layer |

-

2008

- 2008-07-16 JP JP2008184564A patent/JP2010027704A/en active Pending

Patent Citations (5)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| JP2000208815A (en) * | 1996-07-29 | 2000-07-28 | Nichia Chem Ind Ltd | Light-emitting diode |

| JP2005317985A (en) * | 1996-07-29 | 2005-11-10 | Nichia Chem Ind Ltd | Light-emitting device and indicating device |

| JP2003168711A (en) * | 2001-11-30 | 2003-06-13 | Shin Etsu Handotai Co Ltd | Method of measuring carrier concentration and method of manufacturing iii-v compound semiconductor wafer |

| WO2006001316A1 (en) * | 2004-06-24 | 2006-01-05 | Ube Industries, Ltd. | White light emitting diode device |

| JP2008515184A (en) * | 2004-09-28 | 2008-05-08 | コーニンクレッカ フィリップス エレクトロニクス エヌ ヴィ | Light emitting device with improved conversion layer |

Cited By (11)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US8664678B2 (en) | 2010-06-30 | 2014-03-04 | Nitto Denko Corporation | Phosphor ceramic and light-emitting device |

| US20120039064A1 (en) * | 2010-08-11 | 2012-02-16 | Nitto Denko Corporation | Light-emitting device |

| CN102376851A (en) * | 2010-08-11 | 2012-03-14 | 日东电工株式会社 | Light-emitting device |

| WO2012037733A1 (en) * | 2010-09-26 | 2012-03-29 | 海洋王照明科技股份有限公司 | Field emission anode plate, filed emission light source and manufacturing method for light source |

| JP2012234966A (en) * | 2011-04-28 | 2012-11-29 | Toshiba Corp | Substrate processing system and substrate processing program |

| US9303976B2 (en) | 2011-04-28 | 2016-04-05 | Kabushiki Kaisha Toshiba | Substrate processing system and substrate processing program |

| WO2014061748A1 (en) | 2012-10-17 | 2014-04-24 | 宇部興産株式会社 | Wavelength conversion member and light-emitting device employing same |

| US9708533B2 (en) | 2012-10-17 | 2017-07-18 | Ube Industries, Ltd. | Wavelength conversion member and light-emitting device employing same |

| JP2014095077A (en) * | 2012-11-07 | 2014-05-22 | Rolex Sa | Persistent phosphorescent composite material |

| WO2018012273A1 (en) * | 2016-07-14 | 2018-01-18 | 日本電気硝子株式会社 | Method for manufacturing wavelength conversion member and wavelength conversion member group |

| WO2023229022A1 (en) * | 2022-05-27 | 2023-11-30 | パナソニックIpマネジメント株式会社 | Fluorescent body device and light source module |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| JP3065263B2 (en) | Light emitting device and LED display using the same | |

| EP2113949B1 (en) | Encapsulation for phosphor-converted white light emitting diode | |

| US7810956B2 (en) | Light source including reflective wavelength-converting layer | |

| US8008673B2 (en) | Light-emitting device | |

| JP4374913B2 (en) | Light emitting device | |

| KR102144151B1 (en) | Single crystal phosphor | |

| US8748902B2 (en) | Light-emitting diode device generating light of multi-wavelengths | |

| JP2010024278A (en) | Phosphor ceramic plate and light-emitting element using it | |

| US20160254418A1 (en) | Luminescent ceramic for a light emitting device | |

| JP2010027704A (en) | Production method of light-emitting device using phosphor ceramic board | |

| US20080191609A1 (en) | Illumination System Comprising a Red-Emitting Ceramic Luminescence Converter | |

| JP2010510650A (en) | Light emitting device including luminescent ceramic and light scattering material | |

| JP6850265B2 (en) | Fluorescent ceramic | |

| JPH1146019A (en) | Light-emitting diode and method for forming led indicator | |

| JP3729001B2 (en) | Light emitting device, bullet-type light emitting diode, chip type LED | |

| JP2008159791A (en) | Luminescent device and manufacturing method therefor | |

| WO2012120433A1 (en) | Phosphor composition for leds | |

| JP2000315826A (en) | Light emitting device, formation thereof, gun type light emitting diode, chip type led | |

| JP3604298B2 (en) | Method of forming light emitting diode | |

| JP3087828B2 (en) | LED display | |

| JP3775268B2 (en) | Method for forming light emitting device | |

| JP2004080058A (en) | Light emitting diode | |

| JP7147138B2 (en) | Light-emitting device, lighting device, image display device, and vehicle indicator light | |

| JPH11233832A (en) | Light emitting device forming method | |

| US11807791B2 (en) | Phosphor plate and light emitting device using the same |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| A521 | Written amendment |

Free format text: JAPANESE INTERMEDIATE CODE: A523 Effective date: 20110620 |

|

| A621 | Written request for application examination |

Free format text: JAPANESE INTERMEDIATE CODE: A621 Effective date: 20110620 |

|

| A977 | Report on retrieval |

Free format text: JAPANESE INTERMEDIATE CODE: A971007 Effective date: 20120711 |

|

| A131 | Notification of reasons for refusal |

Free format text: JAPANESE INTERMEDIATE CODE: A131 Effective date: 20120717 |

|

| A02 | Decision of refusal |

Free format text: JAPANESE INTERMEDIATE CODE: A02 Effective date: 20121113 |