JP2008184676A - Brush roll and cleaning device - Google Patents

Brush roll and cleaning device Download PDFInfo

- Publication number

- JP2008184676A JP2008184676A JP2007021207A JP2007021207A JP2008184676A JP 2008184676 A JP2008184676 A JP 2008184676A JP 2007021207 A JP2007021207 A JP 2007021207A JP 2007021207 A JP2007021207 A JP 2007021207A JP 2008184676 A JP2008184676 A JP 2008184676A

- Authority

- JP

- Japan

- Prior art keywords

- brush

- shaft

- brush roll

- roll

- cleaning

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Pending

Links

- 238000004140 cleaning Methods 0.000 title claims abstract description 71

- 239000007788 liquid Substances 0.000 claims abstract description 31

- 239000000463 material Substances 0.000 claims description 34

- 239000007921 spray Substances 0.000 claims description 2

- 238000004804 winding Methods 0.000 abstract description 5

- 239000000835 fiber Substances 0.000 description 24

- 229910000831 Steel Inorganic materials 0.000 description 8

- 239000010959 steel Substances 0.000 description 8

- 210000004209 hair Anatomy 0.000 description 6

- 239000000428 dust Substances 0.000 description 5

- 238000000034 method Methods 0.000 description 5

- 230000002093 peripheral effect Effects 0.000 description 5

- 239000002131 composite material Substances 0.000 description 4

- 238000012545 processing Methods 0.000 description 4

- 239000000126 substance Substances 0.000 description 4

- 229920002994 synthetic fiber Polymers 0.000 description 4

- 239000012209 synthetic fiber Substances 0.000 description 4

- 230000000694 effects Effects 0.000 description 3

- 239000002184 metal Substances 0.000 description 3

- 229910052751 metal Inorganic materials 0.000 description 3

- 241000196324 Embryophyta Species 0.000 description 2

- CWYNVVGOOAEACU-UHFFFAOYSA-N Fe2+ Chemical compound [Fe+2] CWYNVVGOOAEACU-UHFFFAOYSA-N 0.000 description 2

- 241001465754 Metazoa Species 0.000 description 2

- VYPSYNLAJGMNEJ-UHFFFAOYSA-N Silicium dioxide Chemical compound O=[Si]=O VYPSYNLAJGMNEJ-UHFFFAOYSA-N 0.000 description 2

- 210000000720 eyelash Anatomy 0.000 description 2

- 239000012784 inorganic fiber Substances 0.000 description 2

- 229910052500 inorganic mineral Inorganic materials 0.000 description 2

- 238000004519 manufacturing process Methods 0.000 description 2

- 239000011707 mineral Substances 0.000 description 2

- 238000005498 polishing Methods 0.000 description 2

- -1 polypropylene Polymers 0.000 description 2

- 238000005507 spraying Methods 0.000 description 2

- 238000004381 surface treatment Methods 0.000 description 2

- 238000005406 washing Methods 0.000 description 2

- 244000198134 Agave sisalana Species 0.000 description 1

- 241000430525 Aurinia saxatilis Species 0.000 description 1

- 229910001369 Brass Inorganic materials 0.000 description 1

- 229910000906 Bronze Inorganic materials 0.000 description 1

- 241000283707 Capra Species 0.000 description 1

- 229920000049 Carbon (fiber) Polymers 0.000 description 1

- 229920000742 Cotton Polymers 0.000 description 1

- YCKRFDGAMUMZLT-UHFFFAOYSA-N Fluorine atom Chemical compound [F] YCKRFDGAMUMZLT-UHFFFAOYSA-N 0.000 description 1

- 239000004677 Nylon Substances 0.000 description 1

- OAICVXFJPJFONN-UHFFFAOYSA-N Phosphorus Chemical compound [P] OAICVXFJPJFONN-UHFFFAOYSA-N 0.000 description 1

- 239000004698 Polyethylene Substances 0.000 description 1

- 241000985694 Polypodiopsida Species 0.000 description 1

- 239000004743 Polypropylene Substances 0.000 description 1

- BQCADISMDOOEFD-UHFFFAOYSA-N Silver Chemical compound [Ag] BQCADISMDOOEFD-UHFFFAOYSA-N 0.000 description 1

- 239000003082 abrasive agent Substances 0.000 description 1

- PNEYBMLMFCGWSK-UHFFFAOYSA-N aluminium oxide Inorganic materials [O-2].[O-2].[O-2].[Al+3].[Al+3] PNEYBMLMFCGWSK-UHFFFAOYSA-N 0.000 description 1

- 239000004760 aramid Substances 0.000 description 1

- 229920003235 aromatic polyamide Polymers 0.000 description 1

- 239000010425 asbestos Substances 0.000 description 1

- 239000010951 brass Substances 0.000 description 1

- 239000010974 bronze Substances 0.000 description 1

- 239000004917 carbon fiber Substances 0.000 description 1

- 239000000919 ceramic Substances 0.000 description 1

- 238000012993 chemical processing Methods 0.000 description 1

- 239000003245 coal Substances 0.000 description 1

- 150000001875 compounds Chemical class 0.000 description 1

- KUNSUQLRTQLHQQ-UHFFFAOYSA-N copper tin Chemical compound [Cu].[Sn] KUNSUQLRTQLHQQ-UHFFFAOYSA-N 0.000 description 1

- OMZSGWSJDCOLKM-UHFFFAOYSA-N copper(II) sulfide Chemical compound [S-2].[Cu+2] OMZSGWSJDCOLKM-UHFFFAOYSA-N 0.000 description 1

- 229910003460 diamond Inorganic materials 0.000 description 1

- 239000010432 diamond Substances 0.000 description 1

- 238000007599 discharging Methods 0.000 description 1

- 235000013399 edible fruits Nutrition 0.000 description 1

- 238000001914 filtration Methods 0.000 description 1

- 239000011737 fluorine Substances 0.000 description 1

- 229910052731 fluorine Inorganic materials 0.000 description 1

- 239000011521 glass Substances 0.000 description 1

- 238000000227 grinding Methods 0.000 description 1

- 150000002484 inorganic compounds Chemical class 0.000 description 1

- 229910010272 inorganic material Inorganic materials 0.000 description 1

- 229920001778 nylon Polymers 0.000 description 1

- 239000003921 oil Substances 0.000 description 1

- 238000012856 packing Methods 0.000 description 1

- 239000003208 petroleum Substances 0.000 description 1

- 229920002647 polyamide Polymers 0.000 description 1

- 229920000573 polyethylene Polymers 0.000 description 1

- 229920001155 polypropylene Polymers 0.000 description 1

- 229920000915 polyvinyl chloride Polymers 0.000 description 1

- 239000004800 polyvinyl chloride Substances 0.000 description 1

- 239000000843 powder Substances 0.000 description 1

- 239000011347 resin Substances 0.000 description 1

- 229920005989 resin Polymers 0.000 description 1

- 239000011342 resin composition Substances 0.000 description 1

- 229910052895 riebeckite Inorganic materials 0.000 description 1

- HBMJWWWQQXIZIP-UHFFFAOYSA-N silicon carbide Chemical compound [Si+]#[C-] HBMJWWWQQXIZIP-UHFFFAOYSA-N 0.000 description 1

- 229910010271 silicon carbide Inorganic materials 0.000 description 1

- 239000000377 silicon dioxide Substances 0.000 description 1

- 229910052709 silver Inorganic materials 0.000 description 1

- 239000004332 silver Substances 0.000 description 1

- 229910001220 stainless steel Inorganic materials 0.000 description 1

- 238000003786 synthesis reaction Methods 0.000 description 1

- 229920001059 synthetic polymer Polymers 0.000 description 1

- 239000002699 waste material Substances 0.000 description 1

- 210000002268 wool Anatomy 0.000 description 1

Images

Landscapes

- Cleaning In General (AREA)

- Cleaning And De-Greasing Of Metallic Materials By Chemical Methods (AREA)

Abstract

【課題】洗浄性能、異物等の対象物の除去性能に優れたブラシロールを提供する。

【解決手段】略棒状又は円筒状のシャフト2と、シャフト2の外周に螺旋状に巻き付けられたブラシ部A4a、ブラシ部B4bからなり、ブラシ部A4a、ブラシ部B4bを、シャフト2の長手方向の一部に設定した対称軸3を中心に、巻き付け時の傾斜角が対称になるようにすると共に、ブラシ部A4aとブラシ部B4bを並列に配したもので、複数本のブラシ部A4a、ブラシ部B4bにより、洗浄性能が向上すると共に、巻き付け時の傾斜角を大きくして、ブラシ部A4a、ブラシ部B4bをシャフト2の長手方向に広げられるので、ダム効果により、洗浄液を効果的に堰き止めながら、被洗浄面上の異物等の対象物を、洗浄液と共に外側に洗い流すことができる。さらに、ブラシ部A4a、ブラシ部B4bの傾斜角が大きくなることにより、被洗浄面にブラシマークが付き難くくなる。

【選択図】図1A brush roll having excellent cleaning performance and performance for removing objects such as foreign matters is provided.

SOLUTION: A substantially rod-like or cylindrical shaft 2 and a brush part A4a and a brush part B4b wound spirally around the outer periphery of the shaft 2, the brush part A4a and the brush part B4b are arranged in the longitudinal direction of the shaft 2. Centering on the symmetrical axis 3 set in part, the inclination angle at the time of winding is symmetrical, and the brush part A4a and the brush part B4b are arranged in parallel, and a plurality of brush parts A4a, brush parts With B4b, the cleaning performance is improved, and the angle of inclination at the time of winding is increased, so that the brush part A4a and the brush part B4b can be expanded in the longitudinal direction of the shaft 2. The object such as the foreign matter on the surface to be cleaned can be washed out together with the cleaning liquid. Furthermore, brush marks are less likely to be attached to the surface to be cleaned by increasing the inclination angles of the brush portions A4a and B4b.

[Selection] Figure 1

Description

本発明は、鋼板、非鉄金属板、樹脂板、ガラス板 あるいはフィルム状樹脂組成物等を洗浄、清掃、研磨、表面処理などを行うブラシロール及び洗浄装置に関するものである。 The present invention relates to a brush roll and a cleaning device that perform cleaning, cleaning, polishing, surface treatment, and the like on a steel plate, a non-ferrous metal plate, a resin plate, a glass plate, or a film-like resin composition.

従来のこの種のブラシロールとして、ロール本体の外周面に、中央の対称軸に対して対称にブラシを螺旋状に巻き付けて形成し、それを鋼板などのブランク材上で回転させて、ブランク材に付着した塵埃などを除去するようにしたものがある(例えば、特許文献1参照)。 As a conventional brush roll of this kind, a brush is formed on the outer peripheral surface of a roll body by spirally wrapping a brush symmetrically with respect to the central axis of symmetry and rotating it on a blank material such as a steel plate. There is one that removes dust or the like adhering to the surface (for example, see Patent Document 1).

図7は、上記特許文献1に記載された従来のブラシロールの平面図、図8は、同ブラシロールでブランク材を洗浄する様子を示す斜視図である。 FIG. 7 is a plan view of a conventional brush roll described in Patent Document 1, and FIG. 8 is a perspective view showing a state in which a blank material is washed with the brush roll.

図7において、従来のブラシロール40は、ロール本体41と、ロール本体41の外周に螺旋状に巻き付け固定されたブラシ42から構成されている。ブラシ42は、ロール本体41の中央に設定された対称軸43に対して対称に、且つ、対称軸43からロール本体41のそれぞれの端部に向かって1本づつ螺旋状に設けられている。Sは、ブラシ42をロール本体41に巻き付ける際の開始端である。

In FIG. 7, a

次に、図8を用いて、上記ブラシロール40によるブランク材の洗浄について説明する。45は、加工前の鋼板など洗浄を必要とするブランク材で、このブランク材45の表面にブラシ42の先端が摺接するようにブラシロール40の位置を設定する。

Next, the cleaning of the blank material by the

そして、ブランク材45を白抜き矢印方向に図示しない移動手段で送りながら、駆動手段46で、ブラシロール40を実線矢印で示すように反時計方向に、かつ、ブラシ42の先端の周速度がブランク材45の移動速度より大きくなるような回転数で回転させ、同時に洗浄ノズル47より洗浄液をブラシロール40の回転入口側に吹き付けるようにする。

Then, while feeding the blank 45 in the direction of the white arrow by the moving means (not shown), the driving means 46 causes the

このようにすることにより、ブランク材45の表面に付着した塵埃や金屑などの対象物48が洗浄液と共に、ブラシロール40の長手方向の略中央部から端部に向かって移動し、除去される。

By doing in this way, the

しかしながら、上記従来のブラシロール40の構成では、図7及び図8の如く、ブラシ42がロール本体41の中央の対称軸43より、左右の端部に向けてそれぞれ1本のみ螺旋状に配されているため、ブラシ42の傾き角度αが大きく、そのため、隣り合うブラシ42間の隙間Gが大きくなって、洗浄性能が悪いという問題があった。

However, in the configuration of the

この問題を解決するために、ブラシ42の傾き角度αを小さくして、隣り合うブラシ42間の隙間Gを小さくする、すなわちブラシ42を、ロール本体41に密に巻き付ける方法も考えられるが、そうすると、ブラシ42による、対象物48を中央から左右端部に移動させるための力が減少し、ブランク材45の表面に対象物48が残ってしまい、ブランク材45の加工に支障をきたすという課題がある。また、ブラシ42の傾き角度αが小さくなって、ブランク材45の移動方向とブラシ42の回転方向が略同一方向になってくると、ブランク材45の表面にブラシ42が接触した軌跡がブラシマークとして残るという課題もある。

In order to solve this problem, a method of reducing the inclination angle α of the

本発明は、前記従来の課題を解決するもので、表面にブラシマークを残すことがなく、洗浄性能、異物等の対象物の除去性能に優れたブラシロール及び洗浄装置を提供する事を目的とする。 An object of the present invention is to solve the above-mentioned conventional problems, and to provide a brush roll and a cleaning device that do not leave a brush mark on the surface and are excellent in cleaning performance and removal performance of objects such as foreign matters. To do.

前記従来の課題を解決するために、本発明のブラシロールは、略棒状又は円筒状のシャフトと、前記シャフトの外周に螺旋状に巻き付けられたブラシ部からなり、前記ブラシ部を、前記シャフトの長手方向の一部に設定した対称軸を中心に、巻き付け時の傾斜角αが対称になるようにすると共に、左右それぞれに複数本並列に設けたもので、左右それぞれの複数本のブラシ部により、洗浄性能が向上すると共に、左右それぞれにブラシ部を一本のみ設けた場合と比較し、ブラシ部の傾斜角αを大きくしてブラシ部をシャフトの長手方向に広げられるので、ダム効果により、洗浄液を効果的に堰き止めながら、ブランク材などの被洗浄面上の異物等の対象物を、洗浄液と共に外側に洗い流すことができる。さらに、ブラシ部の傾斜角αが大きくなることにより、被洗浄面にブラシマークが付き難くくなる。 In order to solve the conventional problems, a brush roll according to the present invention includes a substantially rod-shaped or cylindrical shaft and a brush portion spirally wound around the outer periphery of the shaft. Centering on the symmetry axis set in a part of the longitudinal direction, the inclination angle α at the time of winding is symmetric, and a plurality of them are provided in parallel on each of the left and right sides. In addition to improving the cleaning performance, compared to the case where only one brush part is provided on each of the left and right, the brush part can be expanded in the longitudinal direction of the shaft by increasing the inclination angle α of the brush part. An object such as a foreign substance on the surface to be cleaned such as a blank material can be washed out together with the cleaning liquid while effectively damming the cleaning liquid. Furthermore, the brush mark is less likely to be attached to the surface to be cleaned by increasing the inclination angle α of the brush portion.

また、本発明の洗浄装置は、請求項1〜4のいずれか1項に記載されたブラシロールと、前記ブラシロールを回転駆動する駆動手段と、前記ブラシロールに洗浄液などの液体を吹き付ける複数のノズルを有するもので、洗浄性能に優れ、しかも被洗浄面にブラシマークがつきにくいものである。 Moreover, the cleaning apparatus of the present invention includes a brush roll according to any one of claims 1 to 4, a driving unit that rotationally drives the brush roll, and a plurality of spraying liquids such as cleaning liquid on the brush roll. It has a nozzle, is excellent in cleaning performance, and has a brush mark not easily attached to the surface to be cleaned.

本発明のブラシロール及び洗浄装置は、表面にブラシマークを残すことがなく、洗浄性能、異物等の対象物の除去性能に優れたものである。 The brush roll and the cleaning apparatus of the present invention do not leave a brush mark on the surface, and are excellent in cleaning performance and removal performance of objects such as foreign matters.

第1の発明は、略棒状又は円筒状のシャフトと、前記シャフトの外周に螺旋状に巻き付けられたブラシ部からなり、前記ブラシ部を、前記シャフトの長手方向の一部に設定した対称軸を中心に、巻き付け時の傾斜角αが対称になるようにすると共に、左右それぞれに複数本並列に設けたもので、左右それぞれの複数本のブラシ部により、洗浄性能が向上すると共に、左右それぞれにブラシ部を一本のみ設けた場合と比較し、ブラシ部の傾斜角αを大きくしてブラシ部をシャフトの長手方向に広げられるので、ダム効果により、洗浄液を効果的に堰き止めながら、ブランク材などの被洗浄面上の異物等の対象物を、洗浄液と共に外側に洗い流すことができる。さらに、ブラシ部の傾斜角が大きくなることにより、被洗浄面にブラシマークが付き難くくなる。 1st invention consists of a substantially rod-shaped or cylindrical shaft, and a brush part spirally wound around the outer periphery of the shaft, and a symmetrical axis in which the brush part is set as a part in the longitudinal direction of the shaft. In the center, the inclination angle α when wrapping is made symmetrical, and a plurality of right and left brushes are provided in parallel. Compared to the case where only one brush part is provided, the brush part can be widened in the longitudinal direction of the shaft by increasing the inclination angle α of the brush part. An object such as a foreign substance on the surface to be cleaned such as can be washed out together with the cleaning liquid. Furthermore, since the inclination angle of the brush portion is increased, it becomes difficult to attach a brush mark to the surface to be cleaned.

第2の発明は、特に、第1の発明の対称軸をシャフトの長手方向の略中央に設定したもので、左右それぞれのブラシで、中央から端部に向けて掻き寄せられる対象物の移動距離が等しくなるので、洗浄効果にむらが生じることが無い。 In the second invention, in particular, the axis of symmetry of the first invention is set at the approximate center in the longitudinal direction of the shaft, and the movement distance of the object that is scraped from the center toward the end by the left and right brushes. Therefore, the cleaning effect is not uneven.

第3の発明は、特に、第1又は第2の発明の左右いずれか一方のブラシ部の対称軸側の端部と、他方のブラシ部の対称軸側の端部とを、シャフトの長手方向でオーバーラップさせたもので、被洗浄面の対称軸の真下部分の対象物も確実に除去されるので、洗浄、除去漏れが発生することが無い。 In the third aspect of the invention, in particular, the end portion on the symmetrical axis side of either the left or right brush portion of the first or second aspect and the end portion on the symmetrical axis side of the other brush portion are arranged in the longitudinal direction of the shaft. Since the object directly below the symmetry axis of the surface to be cleaned is also reliably removed, no cleaning or removal leakage occurs.

第4の発明は、特に、第1〜3のいずれか一つの発明のブラシ部を、断面略U字状の帯状体と、前記帯状体で芯線と共に挟持されるブラシ毛材とで構成したもので、ブラシ部の製造及び、ブラシ部のシャフトへの取り付けが容易になり、ブラシロールを安価に提供することができる。 In the fourth invention, in particular, the brush portion according to any one of the first to third inventions is configured by a belt-like body having a substantially U-shaped cross section and a brush bristle material sandwiched with the core wire by the belt-like body. Thus, the manufacture of the brush part and the attachment of the brush part to the shaft are facilitated, and the brush roll can be provided at low cost.

第5の発明は、請求項1〜4のいずれか1項に記載されたブラシロールと、前記ブラシロールを回転駆動する駆動手段と、前記ブラシロールに洗浄液などの液体を吹き付ける複数のノズルを有するもので、洗浄性能に優れ、しかも被洗浄面にブラシマークがつきにくい洗浄装置を提供することができる。 5th invention has the brush roll described in any one of Claims 1-4, the drive means which rotationally drives the said brush roll, and the some nozzle which sprays liquids, such as a washing | cleaning liquid, to the said brush roll. Therefore, it is possible to provide a cleaning apparatus that is excellent in cleaning performance and that does not easily have a brush mark on the surface to be cleaned.

以下、本発明の実施例について、図面を参照しながら説明する。なお、この実施例によって本発明が限定されるものではない。 Embodiments of the present invention will be described below with reference to the drawings. In addition, this invention is not limited by this Example.

(実施例1)

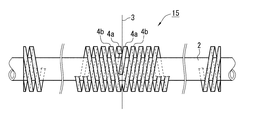

図1は、本発明の第1の実施例におけるブラシロールの平面図、図2は、同ブラシロールのブラシ部の斜視図、図3は、同ブラシロールの組み立て方法を示す図である。

(Example 1)

FIG. 1 is a plan view of a brush roll in a first embodiment of the present invention, FIG. 2 is a perspective view of a brush portion of the brush roll, and FIG. 3 is a view showing a method for assembling the brush roll.

図1〜3において、本実施例におけるブラシロール1は、棒状又は円筒状のシャフト2と、シャフト2の長手方向の略中央に設定した対称軸3を中心に、シャフト2の外周面に、左右それぞれの端部に向かって、巻き付け時の傾斜角αが対称になるように、螺旋状に巻き付けられたブラシ部A4a、ブラシ部B4bから構成されている。本実施例ではブラシ部A4aとブラシ部B4bは平行に設けられている。

1 to 3, the brush roll 1 according to the present embodiment has a rod-like or

S1は、左右それぞれのブラシ部A4aをシャフト2に巻き付ける際の開始端で、S2は、左右それぞれのブラシ部B4bをシャフト2に巻き付ける際の開始端である。

S1 is a start end when the left and right brush portions A4a are wound around the

ブラシ部A4a、ブラシ部B4bのそれぞれは、図2に示すように、シャフト2の外周面に螺旋状に巻き付けられる断面略U字状の帯状体5と、前記帯状体5で芯線6と共に挟持されるブラシ毛材7とで構成されている。ブラシ毛材7は、天然繊維、あるいは化学繊維を、使用目的に応じて、適時、設定して使用する事ができる。なお、天然繊維とは、植物、動物、鉱物を原料とする繊維であり、植物繊維には、例えば、シダ、シュロ等の靭皮繊維、パッキン、サイザル等の葉脈繊維、パーム等の果実繊維、綿、麻、石綿等がある。動物繊維には、例えば、硬毛として、豚毛、馬毛、猪毛があり、軟毛として、山羊毛、人毛、狸毛があり、他にも羊毛、絹等がある。また、化学繊維とは、石油、石炭などから化学的な合成や加工により作られる繊維であり、合成繊維、研削材入り繊維、通電性複合繊維、無機繊維、再生繊維、半合成繊維がある。合成繊維とは、合成高分子化合物から紡糸した繊維であり、フッ素系、ポリアミド系、ポリ塩化ビニール系、ポリプロピレン系、ポリエチレン系、アラミド系等の各合成繊維がある。研削材入り繊維とは、例えば、炭化珪素、アルミナ、ダイヤモンド等の各種鉱物、シリカ、セラミック等の研削性能を有する材質を、ナイロン、PBT等の基材の繊維にたいして付着、練込み、あるいは混入させて形成した繊維である。通電性複合繊維とは、電流を流す事ができる性能を有する繊維であり、各種炭素繊維、硫化銅複合繊維、銀複合繊維がある。無機繊維とは、無機化合物からなる繊維であり、例えば、ピアノ線、硬鋼線、ステンレス鋼線、オイルテンパー線等の各種鋼線、真鍮線、りん青銅線等の非鉄金属線等がある。

As shown in FIG. 2, each of the brush portion A4a and the brush portion B4b is sandwiched between the belt-

ブラシ部A4a、ブラシ部B4bのシャフト2への取り付けは、図3(a)に示すように、シャフト2の外周部へ、ブラシ部A4a、ブラシ部B4bそれぞれの帯状体5を複数の溶接部50で溶接して固定する。また、図3(b)に示すように、シャフト2に予め設けた複数のネジ穴10に、ブラシ部A4a、ブラシ部B4bのそれぞれをシャフト2に押さえつけるように止め部材11を、ネジ12でネジ止めして行なうこともできる。

As shown in FIG. 3A, attachment of the brush part A4a and the brush part B4b to the

以上のように構成された本実施例におけるブラシロール1を、移動する鋼板などのブランク材(図示せず)の表面(被洗浄面)に接触させて、図1中の矢印方向に図示しない駆動手段で回転させながら、同時にブラシロール1あるいは、ブランク材のブラシ部A4a、ブラシ部B4bで擦られる部分に洗浄液を吹き付けると、ブランク材上の塵埃などの対象物(図示せず)が、ブラシ部A4a、ブラシ部B4bで掻き取られると共に、ブラシ部A4a、ブラシ部B4bが対称軸3を中心に対称の傾斜角αで左右のそれぞれの端部に向かって螺旋状に巻き付けられているので、連続的に、ブラシロール1の中心(対称軸3)の真下部から左右の端部に向かって送られ、ブランク材の側部から外方に送り出される。 The brush roll 1 in the present embodiment configured as described above is brought into contact with the surface (surface to be cleaned) of a blank material (not shown) such as a moving steel plate, and is not shown in the direction of the arrow in FIG. When the cleaning liquid is sprayed onto the brush roll 1 or a portion of the blank material that is rubbed with the brush portion A4a and the brush portion B4b at the same time while being rotated by the means, the object (not shown) such as dust on the blank material becomes the brush portion. A4a and brush part B4b are scraped off, and the brush part A4a and brush part B4b are wound spirally toward the respective left and right ends with a symmetrical inclination angle α around the symmetry axis 3, Specifically, the brush roll 1 is fed from right below the center (symmetric axis 3) toward the left and right ends, and fed out from the side of the blank.

以上のように、本実施例によれば、シャフト2の左右それぞれに、ブラシ部A4a、ブラシ部B4bの2本を設けることにより、洗浄性能が向上すると共に、左右それぞれにブラシ部を一本のみ(例えば、ブラシ部A4aのみ)を設けた場合と比較し、ブラシ部A4a、ブラシ部B4bの傾斜角を大きくして、ブラシ部A4a、ブラシ部B4bを、シャフト2の長手方向に広げられるので、ダム効果により、洗浄液を効果的に堰き止めながら、ブランク材などの被洗浄面上の対象物を、洗浄液と共に外側に洗い流すことができる。さらに、ブラシ部A4a、ブラシ部B4bのそれぞれの傾斜角αが大きくなることにより、被洗浄面にブラシマークが付き難くくなる。

As described above, according to this embodiment, by providing two brush portions A4a and B4b on the left and right sides of the

尚、本実施例では、シャフト2の左右それぞれに、ブラシ部A4a、ブラシ部B4bの2本を設けたが、勿論3本あるいはそれ以上でもよい。

In the present embodiment, two brush portions A4a and B4b are provided on the left and right sides of the

また、本実施例では、対称軸3をシャフト2の長手方向の略中央に設定しているので、左右それぞれのブラシ部A4a、ブラシ部B4bで中央から端部に向けて掻き寄せられる対象物の移動距離が等しくなり、洗浄効果にむらが生じることが無い。

Further, in this embodiment, since the symmetry axis 3 is set at the approximate center in the longitudinal direction of the

また、ブラシ部A4a、ブラシ部B4bのそれぞれを、断面略U字状の帯状体5と、前記帯状体5で芯線6と共に挟持されるブラシ毛材7とで構成したので、ブラシ部A4a、ブラシ部B4bの、製造及び、シャフト2への取り付けが容易になり、安価なブラシロール1を提供することができる。

Further, each of the brush part A4a and the brush part B4b is constituted by the belt-

(実施例2)

図4は、本発明の第2の実施例におけるブラシロールの平面図である。なお、上記第1の実施例におけるブラシロールと同一部分については、同一符号を付してその説明を省略する。

(Example 2)

FIG. 4 is a plan view of a brush roll in the second embodiment of the present invention. In addition, about the same part as the brush roll in the said 1st Example, the same code | symbol is attached | subjected and the description is abbreviate | omitted.

本実施例におけるブラシロール15は、図4に示すように、左右いずれか一方のブラシ部A4aの対称軸3側の端部と、他方のブラシ部A4aの対称軸3側の端部とを、シャフト2の長手方向でオーバーラップさせたもので、他の構成は、上記第1の実施例におけるブラシロール1と同じである。

As shown in FIG. 4, the

本実施例では、図示していないが、一方のブラシ部B4bの対称軸3側の端部と、他方のブラシ部B4bの対称軸3側の端部とを、同様にシャフト2の長手方向でオーバーラップさせている。

In the present embodiment, although not shown, the end of the one brush part B4b on the side of the symmetry axis 3 and the end of the other brush part B4b on the side of the symmetry axis 3 are similarly arranged in the longitudinal direction of the

本実施例におけるブラシロール15は、以上のように構成されているので、被洗浄面の、対称軸3の真下部分の対象物も確実に除去されるので、洗浄、除去漏れが発生することが無い。

Since the

(実施例3)

図5は、本発明の第3の実施例における洗浄装置の斜視図、図6は、同洗浄装置の部分断面図(図5のA−A断面)である。なお、上記実施例におけるブラシロールと同一部分については、同一符号を付してその説明を省略する。また、構成の説明を容易にするために、各部品の軸受け部や、支持部品の図示、説明は省略することとする。

(Example 3)

FIG. 5 is a perspective view of a cleaning device according to a third embodiment of the present invention, and FIG. 6 is a partial sectional view of the cleaning device (cross section AA in FIG. 5). In addition, about the same part as the brush roll in the said Example, the same code | symbol is attached | subjected and the description is abbreviate | omitted. In addition, in order to facilitate the description of the configuration, illustration and description of bearing parts of each component and support components are omitted.

本実施例における洗浄装置20は、プレス加工ラインなどに設置され、プレス機等の加工機器(図示せず)に供給される鋼板などのブランク材を洗浄するもので、ロール状に巻かれた鋼板などのブランク材21を引っ張り送り出す送り部22と、送り部22から送り出されるブランク材21の両面を洗浄する洗浄部23から構成されている。

The cleaning device 20 in the present embodiment is installed in a press processing line or the like, and cleans a blank material such as a steel plate supplied to a processing device (not shown) such as a press machine, and is a steel plate wound in a roll shape. And the like, and a

送り部22は、ブランク材21を上下から挟持するように圧接される上ロール24、下ロール25と、上・下ロール24、25のそれぞれを所定の回転数で回転駆動するための第1駆動手段26から構成されている。

The

洗浄部23は、ブランク材21を上下から挟持するように配置された1対の上ブラシロール27、下ブラシロール28と、上・下ブラシロール27、28のそれぞれを所定の回転数で回転駆動するための第2駆動手段29と、上・下ブラシロール27、28のそれぞれに洗浄液を吹き付けるための複数の洗浄ノズル30と、各洗浄ノズル30に洗浄液を供給する配管31と、上・下ブラシロール27、28でブランク材21から除去された塵埃等の対象物(図示せず)及び洗浄後の洗浄液を受ける液受け32から構成されている。液受け32の下端には、対象物と共に汚れた洗浄液を排出するための排出配管33が設けられている。

The

本実施例では、上・下ブラシロール27、28として、上記第1、第2実施例におけるブラシロール1又は15を用いている。

In this embodiment, as the upper and lower brush rolls 27 and 28, the

以上のように構成された本実施例における洗浄装置20の動作、作用は以下の通りである。 The operation and action of the cleaning apparatus 20 in the present embodiment configured as described above are as follows.

第1駆動手段26、第2駆動手段29の運転を開始し、各洗浄ノズル30に配管31を通して洗浄液を供給しながら、ブランク材21の端部を、回転している上ロール24と、下ロール25との間に差し込むと、ブランク材21は、自動的に連続的に洗浄部23に送られ、上ブラシロール27でブランク材21の表面が、下ブラシロール28でブランク材21の裏面がそれぞれ清掃される。

The operation of the first driving means 26 and the second driving means 29 is started, and the cleaning liquid is supplied to the

ブランク材21の表面では、上ブラシロール27で擦りとられた塵埃や金属粉などの対象物が、洗浄液と共に上ブラシロール27の長手方向における中央部からそれぞれの端部へ向かって送り出され、液受け32に落下していく。また、ブランク材21の裏面では、下ブラシロール28で擦るとられた対象物の一部は、洗浄液と共に、直ちに液受け32に落下すると共に、洗浄液の粘着性や表面張力により、ブランク材21の裏面に残った対象物は、下ブラシロール28の螺旋状のブラシ部A4a、ブラシ部B4bにより、下ブラシロール28の略中央部からそれぞれの端部へ向かって送り出され、その間に液受け32に落下していく。

On the surface of the blank 21, objects such as dust and metal powder rubbed by the

液受け32で回収された対象物は、汚れた洗浄液と共に排出配管33を通って、図示しない濾過装置や、廃液処理装置に送られていく。

The object collected by the

以上のように、本実施例によれば、洗浄性能に優れ、しかもブランク材21の表面に上ブラシロール27、下ブラシロール28のブラシ部A4a、ブラシ部B4bによるブラシマークがつきにくい洗浄装置を提供することができる。

As described above, according to the present embodiment, a cleaning device that has excellent cleaning performance and that is not easily attached to the surface of the blank 21 by the brush portions A4a and B4b of the

以上のように、本発明にかかるブラシロール及び洗浄装置は、洗浄性能、異物等の対象物の除去性能に優れたもので、各種洗浄装置、清掃装置、研磨装置、表面処理装置などに適用できる。 As described above, the brush roll and the cleaning device according to the present invention are excellent in cleaning performance and removal performance of objects such as foreign matters, and can be applied to various cleaning devices, cleaning devices, polishing devices, surface treatment devices, and the like. .

1、15 ブラシロール

2 シャフト

3、43 対称軸

4a ブラシ部A(ブラシ部)

4b ブラシ部B(ブラシ部)

5 帯状体

6 芯線

7 ブラシ毛材

10 ネジ穴

11 止め部材

12 ネジ

20 洗浄装置

21、45 ブランク材

22 送り部

23 洗浄部

26 第1駆動手段

24、27 上ブラシロール(ブラシロール)

25、28 下ブラシロール(ブラシロール)

29 第2駆動手段(駆動手段)

30 洗浄ノズル(ノズル)

31 配管

32 液受け

33 排出配管

40 従来のブラシロール

41 従来のロール本体

42 ブラシ

46 駆動手段

47 洗浄ノズル

48 対象物

50 溶接部

1, 15

4b Brush part B (Brush part)

DESCRIPTION OF

25, 28 Lower brush roll (brush roll)

29 Second drive means (drive means)

30 Cleaning nozzle (nozzle)

31 piping 32

50 welds

Claims (5)

Priority Applications (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| JP2007021207A JP2008184676A (en) | 2007-01-31 | 2007-01-31 | Brush roll and cleaning device |

Applications Claiming Priority (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| JP2007021207A JP2008184676A (en) | 2007-01-31 | 2007-01-31 | Brush roll and cleaning device |

Publications (2)

| Publication Number | Publication Date |

|---|---|

| JP2008184676A true JP2008184676A (en) | 2008-08-14 |

| JP2008184676A5 JP2008184676A5 (en) | 2010-03-18 |

Family

ID=39727914

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| JP2007021207A Pending JP2008184676A (en) | 2007-01-31 | 2007-01-31 | Brush roll and cleaning device |

Country Status (1)

| Country | Link |

|---|---|

| JP (1) | JP2008184676A (en) |

Cited By (3)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| JP2020116560A (en) * | 2019-01-28 | 2020-08-06 | 富士キネティックス株式会社 | Corrugated board sheet foreign matter removing device |

| CN112011801A (en) * | 2020-09-03 | 2020-12-01 | 浙江明铖金属科技有限公司 | Steel acid pickling device and process based on Fenton oxidation reaction |

| JP7557207B2 (en) | 2021-05-27 | 2024-09-27 | ジョイボンド株式会社 | Adhesive roll for removing dust |

Citations (7)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| JP2000129478A (en) * | 1998-10-28 | 2000-05-09 | Sumitomo Metal Ind Ltd | Brush roll for steel strip cleaning |

| JP2002096038A (en) * | 2000-09-25 | 2002-04-02 | Shibaura Mechatronics Corp | Device for treating substrate |

| JP2003145060A (en) * | 2001-11-15 | 2003-05-20 | Shibaura Mechatronics Corp | Cleaning brush and cleaning device |

| JP2003275026A (en) * | 2002-03-25 | 2003-09-30 | Yuichiro Niizaki | Waved channel brush material and method for manufacturing the same |

| JP2004137573A (en) * | 2002-10-18 | 2004-05-13 | Honda Motor Co Ltd | Cleaning method of steel sheet, and brush roll of cleaning machine for steel sheet |

| JP2006080187A (en) * | 2004-09-08 | 2006-03-23 | Dainippon Screen Mfg Co Ltd | Roll brush, substrate washing device |

| JP2007007501A (en) * | 2005-06-28 | 2007-01-18 | Shimada Phys & Chem Ind Co Ltd | Substrate washing brush |

-

2007

- 2007-01-31 JP JP2007021207A patent/JP2008184676A/en active Pending

Patent Citations (7)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| JP2000129478A (en) * | 1998-10-28 | 2000-05-09 | Sumitomo Metal Ind Ltd | Brush roll for steel strip cleaning |

| JP2002096038A (en) * | 2000-09-25 | 2002-04-02 | Shibaura Mechatronics Corp | Device for treating substrate |

| JP2003145060A (en) * | 2001-11-15 | 2003-05-20 | Shibaura Mechatronics Corp | Cleaning brush and cleaning device |

| JP2003275026A (en) * | 2002-03-25 | 2003-09-30 | Yuichiro Niizaki | Waved channel brush material and method for manufacturing the same |

| JP2004137573A (en) * | 2002-10-18 | 2004-05-13 | Honda Motor Co Ltd | Cleaning method of steel sheet, and brush roll of cleaning machine for steel sheet |

| JP2006080187A (en) * | 2004-09-08 | 2006-03-23 | Dainippon Screen Mfg Co Ltd | Roll brush, substrate washing device |

| JP2007007501A (en) * | 2005-06-28 | 2007-01-18 | Shimada Phys & Chem Ind Co Ltd | Substrate washing brush |

Cited By (3)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| JP2020116560A (en) * | 2019-01-28 | 2020-08-06 | 富士キネティックス株式会社 | Corrugated board sheet foreign matter removing device |

| CN112011801A (en) * | 2020-09-03 | 2020-12-01 | 浙江明铖金属科技有限公司 | Steel acid pickling device and process based on Fenton oxidation reaction |

| JP7557207B2 (en) | 2021-05-27 | 2024-09-27 | ジョイボンド株式会社 | Adhesive roll for removing dust |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| JP2010099579A (en) | Brush roller, and cleaner | |

| CN106663620B (en) | Cleaning device and roller cleaning component | |

| TWI443732B (en) | Post-cmp wafer cleaning apparatus | |

| JP2008184676A (en) | Brush roll and cleaning device | |

| JP2009148474A (en) | Brush roll and cleaning device | |

| KR102211328B1 (en) | Apparatus for cleaning a polishing surface, polishing apparatus, and method of manufacturing an apparatus for cleaning a polishing surface | |

| KR100825575B1 (en) | Foreign material removal device on the back of the conveyor belt | |

| JP2004137573A (en) | Cleaning method of steel sheet, and brush roll of cleaning machine for steel sheet | |

| WO2021002031A1 (en) | Wiping device and wiping method | |

| US20240066664A1 (en) | Pad surface cleaning device around pad conditioner to enable insitu pad conditioning | |

| KR100746111B1 (en) | Ultrasonic sprinkler | |

| JP3071107B2 (en) | Wire cleaning equipment for wire saws | |

| JPH1034091A (en) | Roller for washing | |

| JP6703202B1 (en) | Wiping device and wiping method | |

| JP2010005504A (en) | Brush roll and cleaning apparatus | |

| JP2007189208A (en) | Bevel processing method and apparatus | |

| KR20150046104A (en) | Strip casting installation and method for operating the same | |

| JP2008184676A5 (en) | ||

| CN118698963B (en) | Wire surface cleaning device | |

| JP2006187272A (en) | Spherical body wiping-off device | |

| CN206218828U (en) | The Handling device of glass sheet | |

| CN219233235U (en) | Rolling brush assembly for cleaning wafer | |

| JP5446208B2 (en) | Scrub member purification method, scrub member purification device, scrub cleaning device, disk material, and magnetic disk | |

| KR20030019914A (en) | Scraper for rotary brush and blanket drum cleaning device | |

| JP2025003347A (en) | Abrasive brush |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| A521 | Request for written amendment filed |

Free format text: JAPANESE INTERMEDIATE CODE: A523 Effective date: 20100129 |

|

| A621 | Written request for application examination |

Free format text: JAPANESE INTERMEDIATE CODE: A621 Effective date: 20100129 |

|

| RD02 | Notification of acceptance of power of attorney |

Free format text: JAPANESE INTERMEDIATE CODE: A7422 Effective date: 20100129 |

|

| A977 | Report on retrieval |

Free format text: JAPANESE INTERMEDIATE CODE: A971007 Effective date: 20100414 |

|

| A131 | Notification of reasons for refusal |

Free format text: JAPANESE INTERMEDIATE CODE: A131 Effective date: 20120216 |

|

| A521 | Request for written amendment filed |

Free format text: JAPANESE INTERMEDIATE CODE: A523 Effective date: 20120415 |

|

| A02 | Decision of refusal |

Free format text: JAPANESE INTERMEDIATE CODE: A02 Effective date: 20120521 |

|

| A521 | Request for written amendment filed |

Free format text: JAPANESE INTERMEDIATE CODE: A523 Effective date: 20120810 |

|

| A911 | Transfer to examiner for re-examination before appeal (zenchi) |

Free format text: JAPANESE INTERMEDIATE CODE: A911 Effective date: 20120820 |

|

| A912 | Re-examination (zenchi) completed and case transferred to appeal board |

Free format text: JAPANESE INTERMEDIATE CODE: A912 Effective date: 20120831 |